Slide with thin bottom sample slot

A technology for sample tanks and glass slides, applied in microscopes, optics, instruments, etc., can solve the problems of not being able to change the volume of sample tanks, increase experimental costs, and delay time, and achieve the effects of simple fixing methods, saving time, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

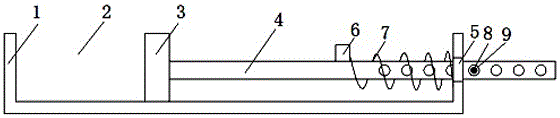

[0013] refer to figure 1 , a slide glass with a thin-bottom sample tank, comprising a slide body 1, a sample tank 2 is provided in the slide body 1, a baffle 3 is provided in the sample tank 2, and one side of the baffle 3 is provided There is a pull rod 4, and the pull rod 4 extends to the outside of the slide body 1, a notch 5 is provided on one side of the slide body 1, and the pull rod 4 is movably installed in the notch 5, and a fixed block is provided on one side of the pull rod 4 6. A spring 7 is sleeved on the pull rod between the fixed block 6 away from the baffle 3, the side of the spring 7 close to the baffle 3 is installed on the fixed block 6, and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com