Package structure of optical fiber grating temperature sensor

A technology of temperature sensor and optical fiber grating, which is applied in the packaging field of fiber Bragg grating temperature sensor, can solve the problems of unbearable pressure, unsatisfactory stress shielding, acid and alkali resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

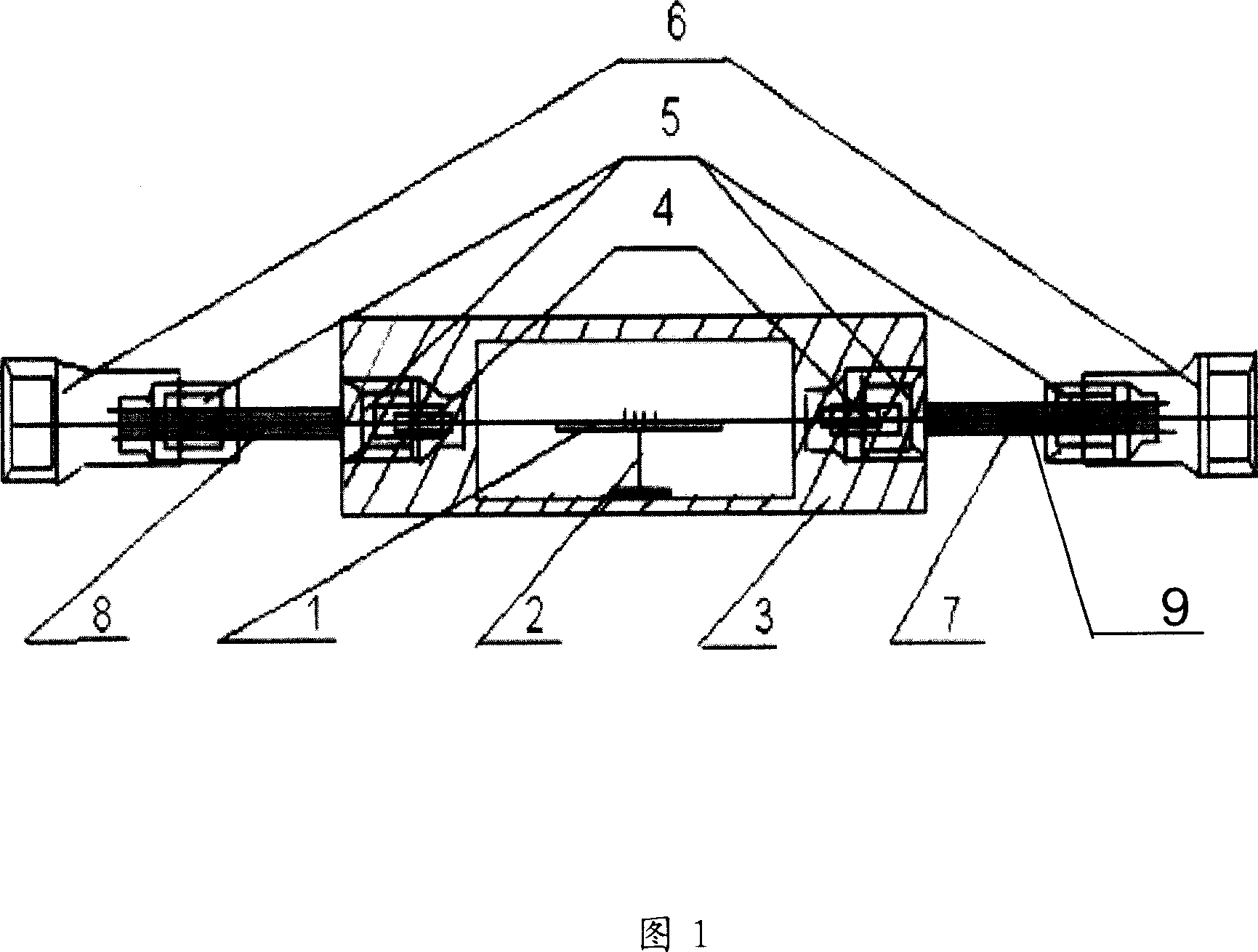

[0027] Fig. 1 is the packaging structure of the fiber grating temperature sensor of the present invention, especially the packaging structure suitable for the downhole fiber grating temperature sensor of oil and gas, which includes: a bare fiber grating 1, a protection tube 3, a bare fiber grating that is not subjected to stress in the protection tube 3 Optical fiber grating support frame 2, hollow tube 7, tube valve part 5, protective tube plug 4 with a small hole, optical fiber ointment 9, optical fiber connector 6. The bare fiber grating 1 is pasted or welded on the upper part of the bare fiber grating support frame 2, and the bare fiber grating support frame 2 is pasted or welded on the inner wall of the protection tube 3 through its base, and the bare fiber grating support frame 2 is removed from the base and the protection tube. The inner wall of the tube 3 is in contact with the outside, and the rest is not in contact with the protection tube 3 . The transmission optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com