Discontinuous foaming agent control lead-in system and method

A technology for introducing a system and a control system, applied in the field of polymer foam plastic processing, can solve the problems of increasing the complexity and production cost of the gas introduction system, increasing the processing accuracy of the supercharger, the electric control accuracy, and the local gas concentration, etc. The effect of industrialized production, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

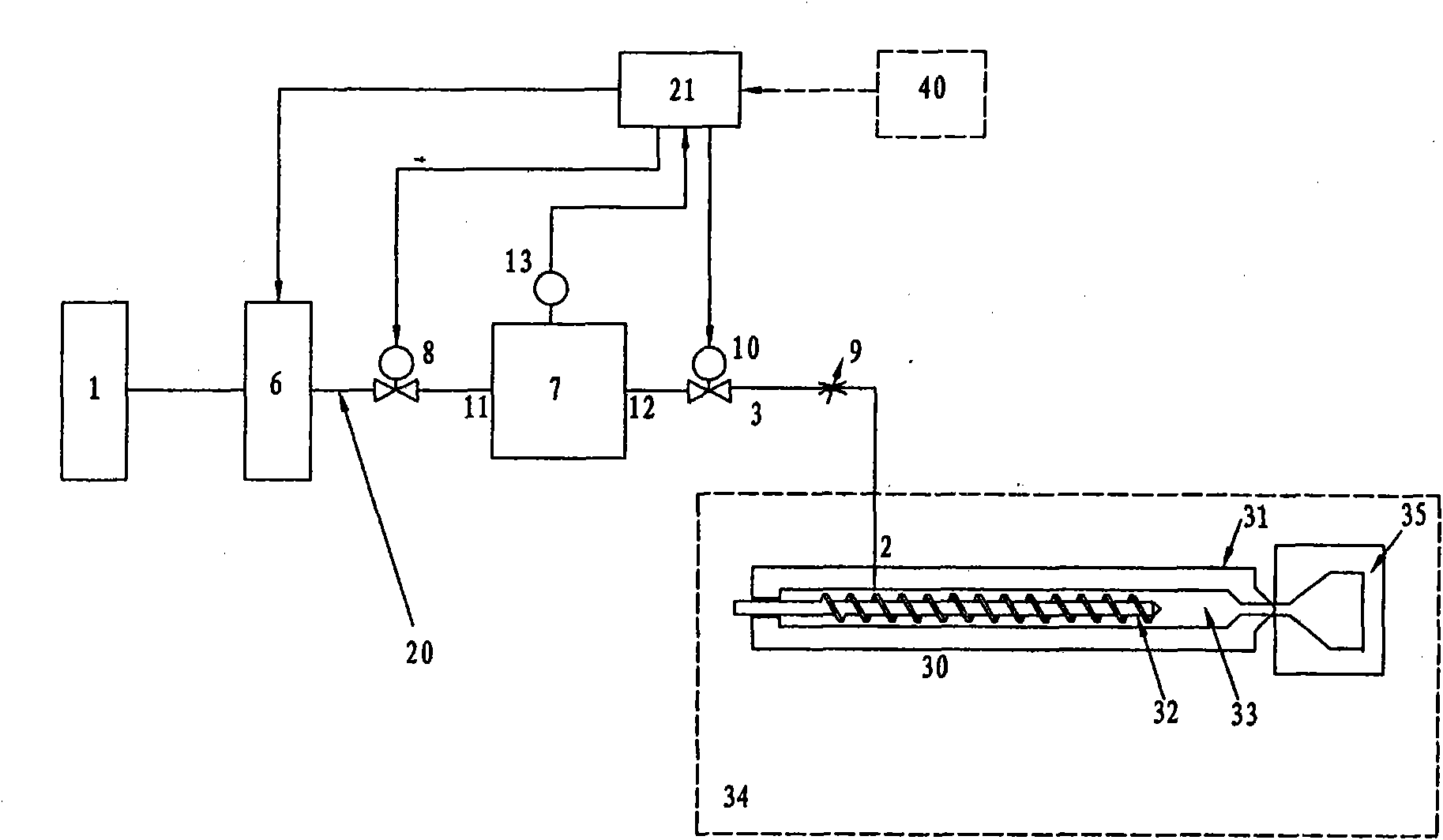

[0050] Injection molding machine T120, screw diameter 36mm, aspect ratio 23.6, a blowing agent injection port is opened on the injection molding machine barrel, the discontinuous foaming agent control introduction system is connected to the injection molding machine through a pipeline at the gas injection port, and the blowing agent The introduction system includes: N 2 Gas tank, with N 2 A pipeline system in which the gas storage tank and the blowing agent injection port are fluidly connected. A gas booster, a gas collection tank, and two channels respectively connected to the inlet and outlet of the gas collection tank are installed in the pipeline system. The volume of the airtight space enclosed between the inlet and outlet of the gas collection tank is 20ml. A pressure sensor is installed on the gas collection tank, and a Flow regulating valve, the flow regulating range of the regulating valve is 0.1~0.5kg / h. In addition, it also includes a control system, which can rec...

Embodiment 2

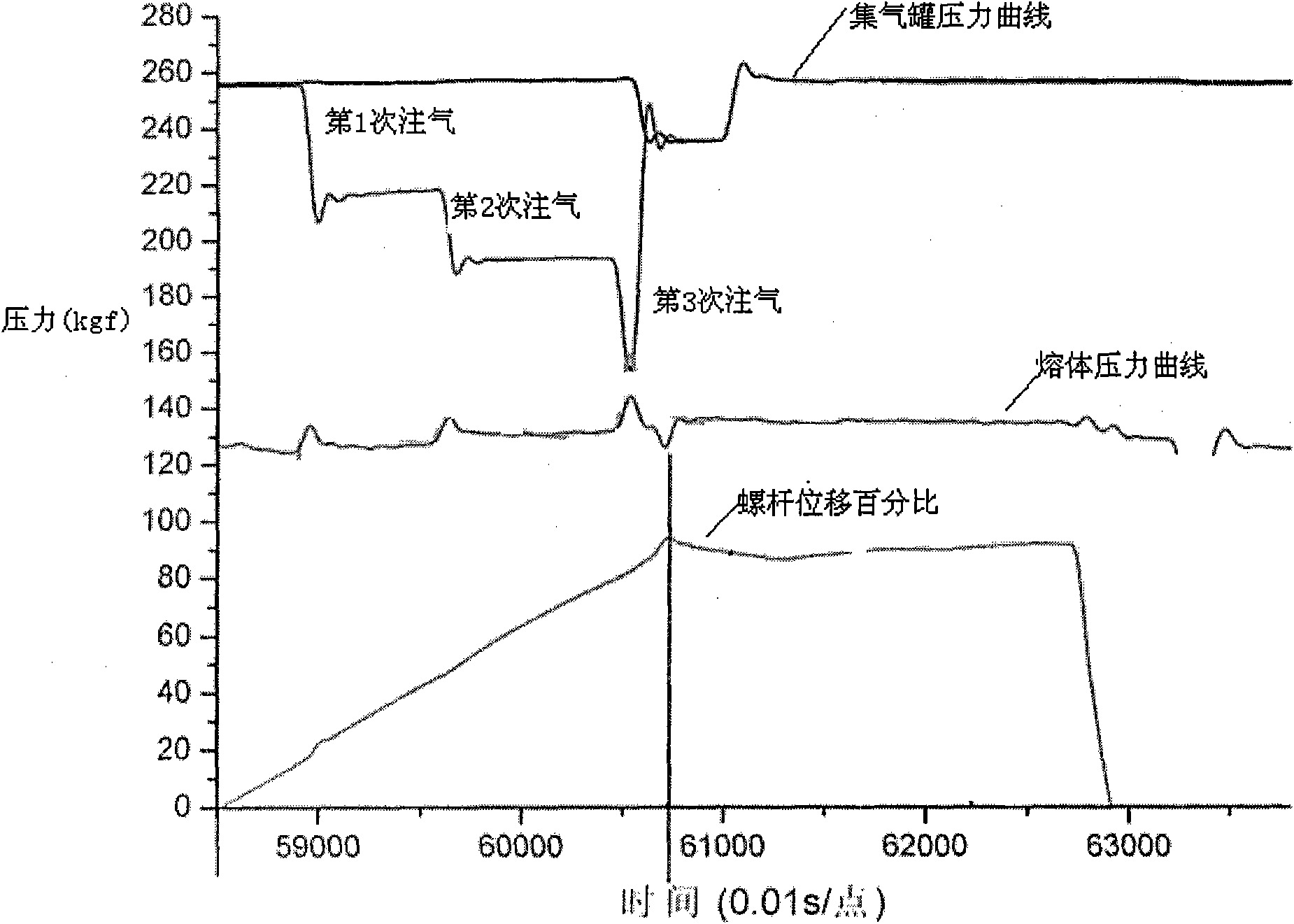

[0056] The injection molding machine used, the blowing agent control introduction system, and the polymer material used in the test are the same as in Example 1. The opening of the flow regulating valve is 20% of the full scale, the gas injection rate is 0.5%, and the pressure in the gas collecting tank is increased by controlling the supercharger. to 30MPa. In addition, the foaming agent injection method is the same as Example 1, the difference is that in a plasticizing cycle, the screw starts to rotate, and the plasticized material is transported to the storage chamber at the front end of the screw. When the pressure near the gas injection port reaches a stable level, open the shut-off valve at the outlet of the gas-collecting tank. The foaming agent in the gas-collecting tank enters the polymer material melt in the injection molding machine after passing through the flow regulating valve. After 1s, the shut-off valve Close, when the displacement of the injection molding scr...

Embodiment 3

[0059] The injection molding machine used, the blowing agent control introduction system, and the polymer material used in the test are the same as in Example 1. The opening of the flow regulating valve is 5% of the full scale, the gas injection rate is 0.8%, and the supercharger is controlled to increase the pressure in the gas collection tank. to 40MPa. In addition, the injection method of the foaming agent is the same as that of Example 1, the difference is that in a plasticizing cycle, the screw starts to rotate, and the plasticized material is transported to the storage chamber at the front end of the screw, at this time Monitor the pressure near the gas injection port. When the pressure is stable, open the cut-off valve at the outlet of the gas-collecting tank. The foaming agent in the gas-collecting tank enters the polymer material melt in the injection molding machine after passing through the flow regulating valve. It lasts for 0.3s and then stops. The valve is closed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com