Patents

Literature

58 results about "Heat capacity rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The heat capacity rate is heat transfer terminology used in thermodynamics and different forms of engineering denoting the quantity of heat a flowing fluid of a certain mass flow rate is able to absorb or release per unit temperature change per unit time. It is typically denoted as C, listed from empirical data experimentally determined in various reference works, and is typically stated as a comparison between a hot and a cold fluid, Cₕ and Cc either graphically, or as a linearized equation. It is an important quantity in heat exchanger technology common to either heating or cooling systems and needs, and the solution of many real world problems such as the design of disparate items as different as a microprocessor and an internal combustion engine.

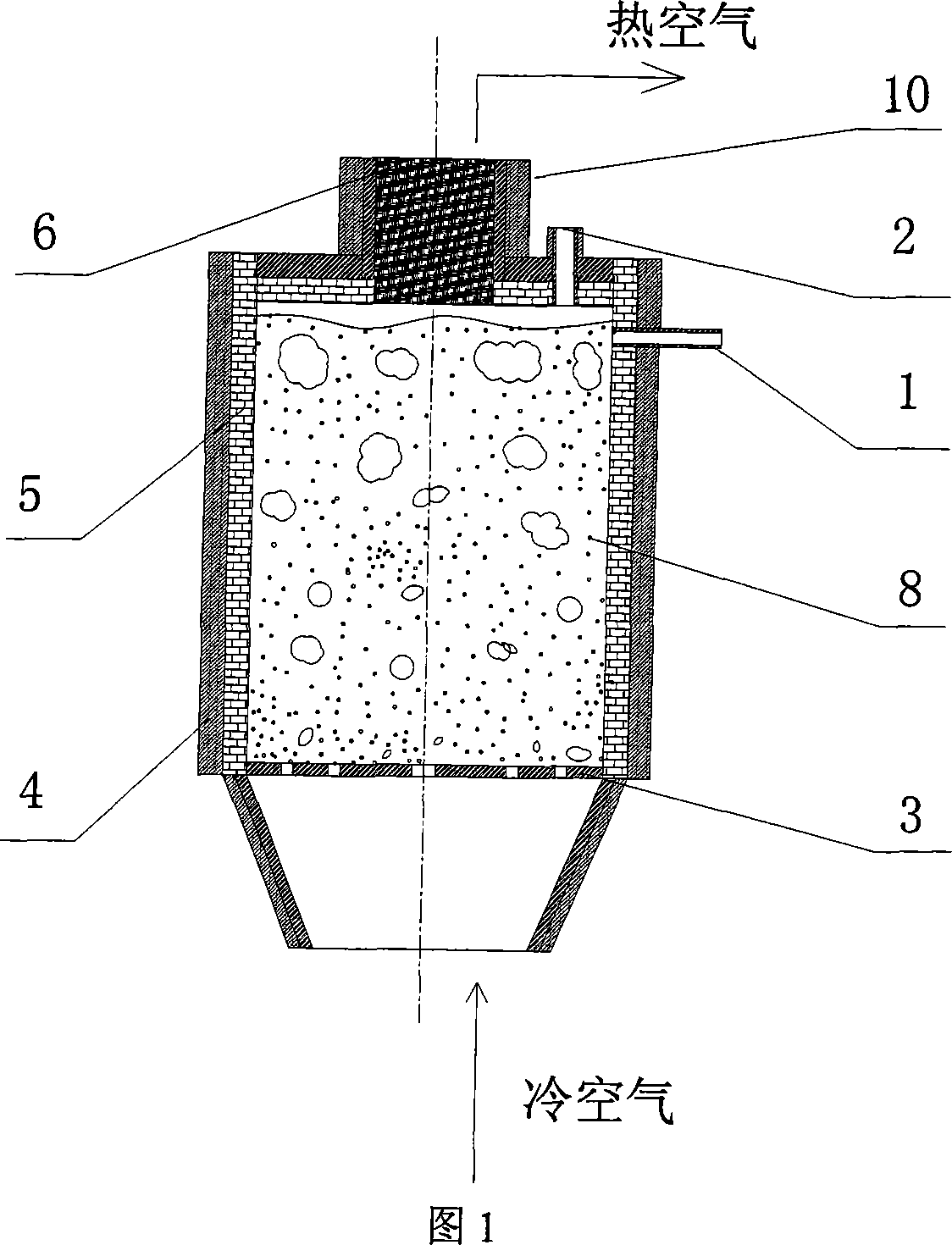

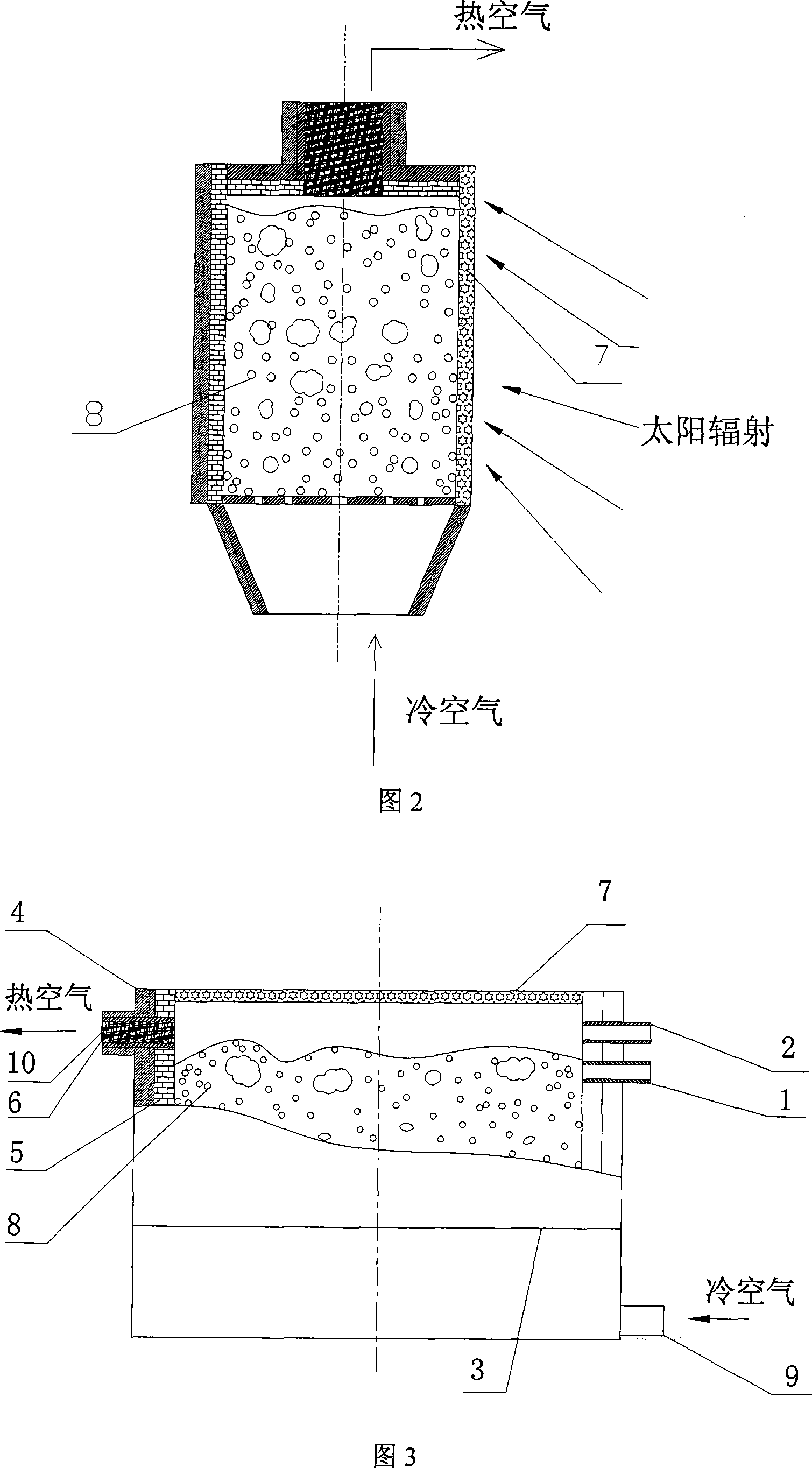

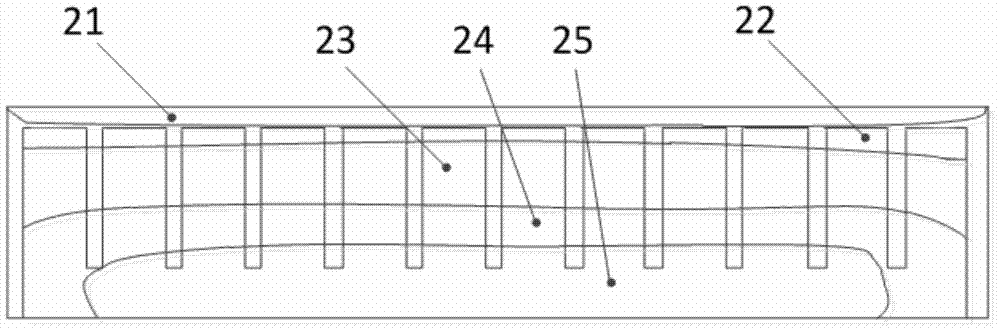

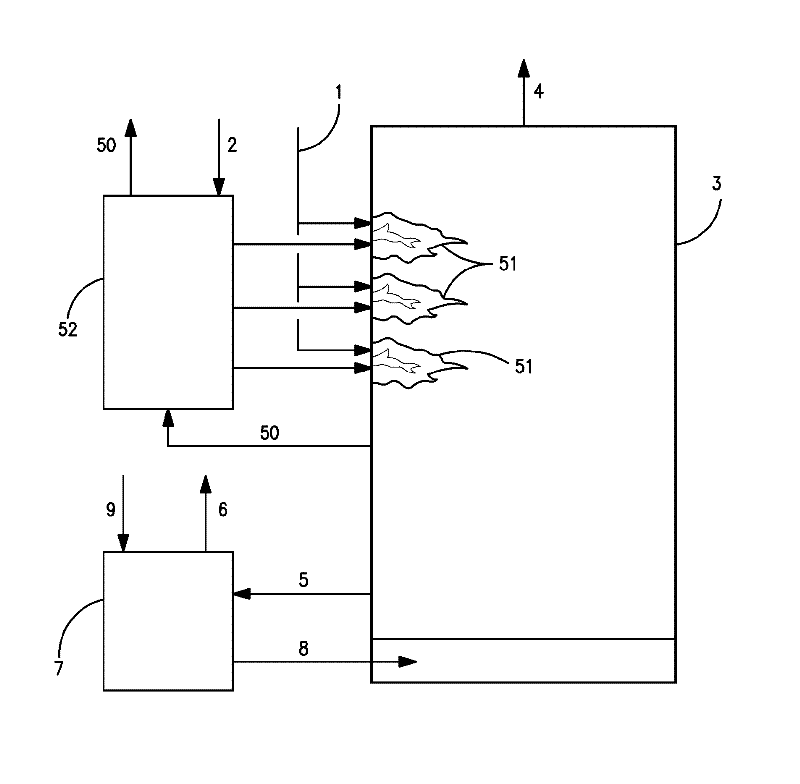

Fluid bed high temperature heat absorber for solar energy tower type thermal generation and its heat absorbing-heat storage double fluid bed system

InactiveCN101122422AOvercoming heat-absorbing surface ablationOvercome stressSolar heating energySolar heat devicesFluidized bedEngineering

A fluidized bed high temperature endothermic device used for solar tower thermal power generation and heat absorbing-accumulating double fluidized bed system is provided. The double fluidized bed system consists of a fluidized bed heat absorber (15) and a fluidized bed heat accumulator (14). A regenerative ball (8) flows between the fluidized bed heat absorber (15) and the fluidized bed heat accumulator (14). The regenerative ball is both a heat absorbing media and a heat accumulating media, which makes heat absorbing-accumulating integration realized. The invention can adjust the absorbed heat and the accumulated heat according to the conditions of sunlight. The fluidized bed heat absorber (15) makes full use of the flow characteristics of the fluidized bed to overcome the heat exchange problem caused by the uneven distributed radiation after the aggregation of the sunlight. With the heat capacity of the regenerative ball (8), thermal shock influences on the heat absorber under the conditions such as cloudy can be eliminated. The invention has the advantages of safety, reliability and low cost.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

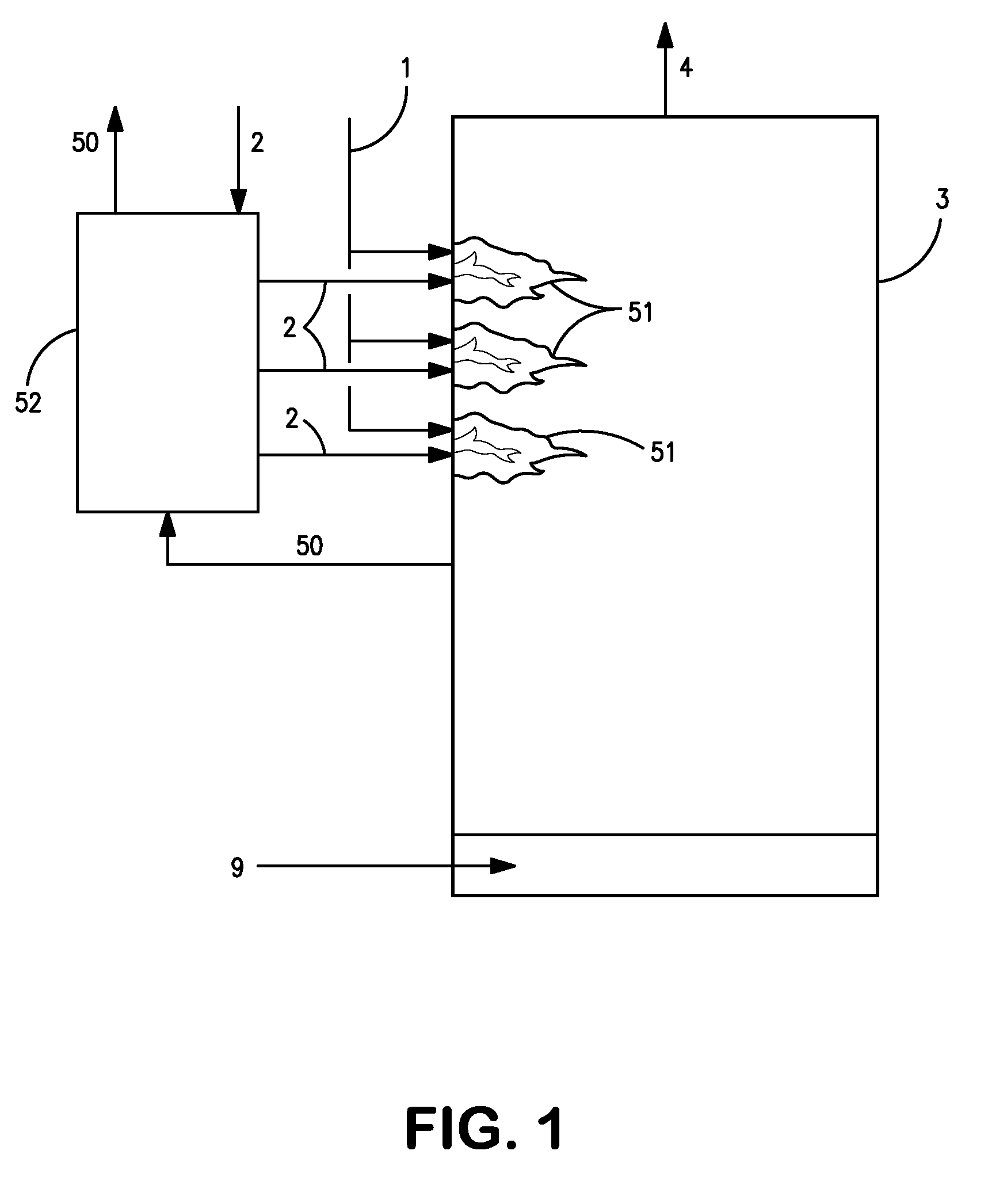

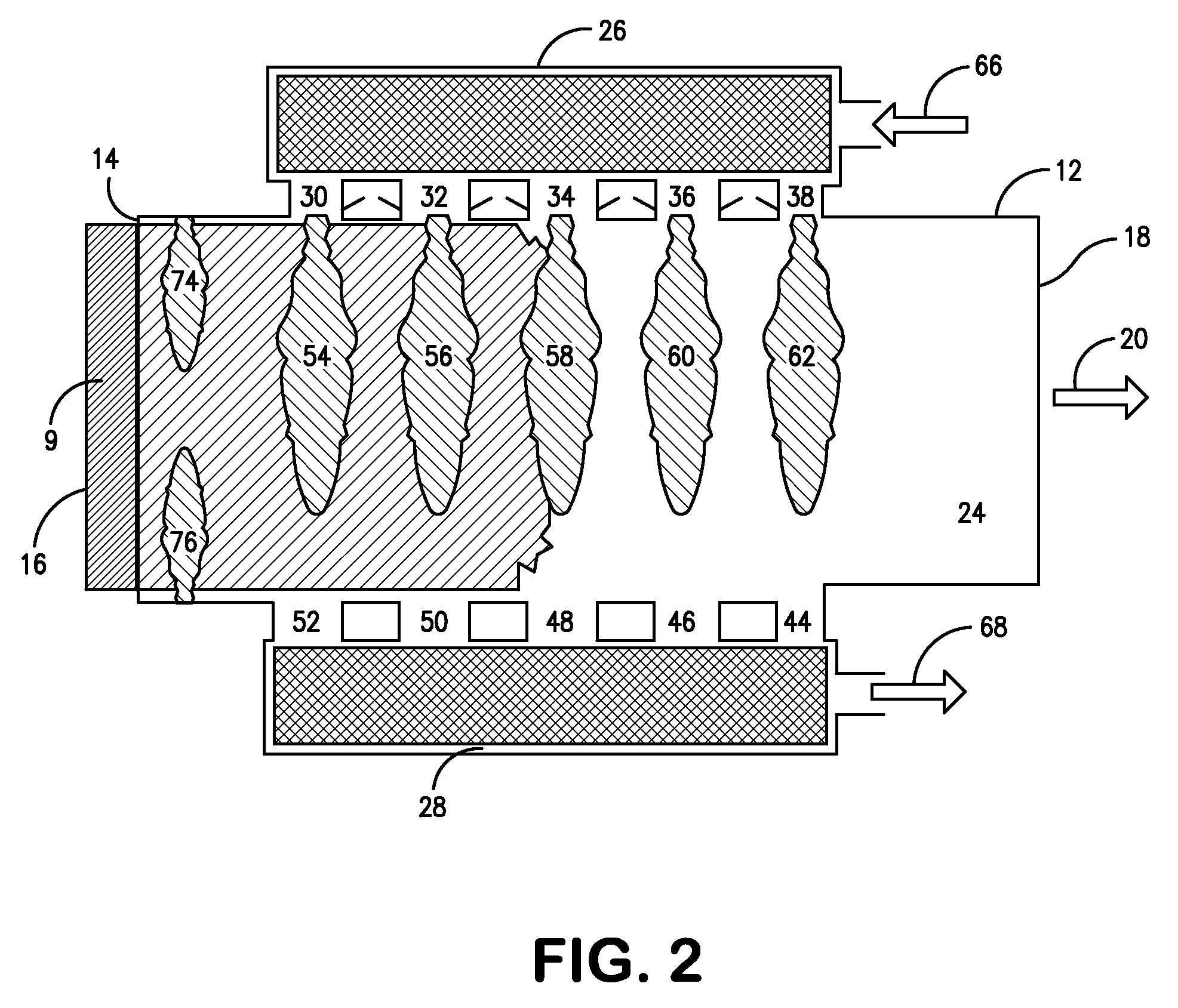

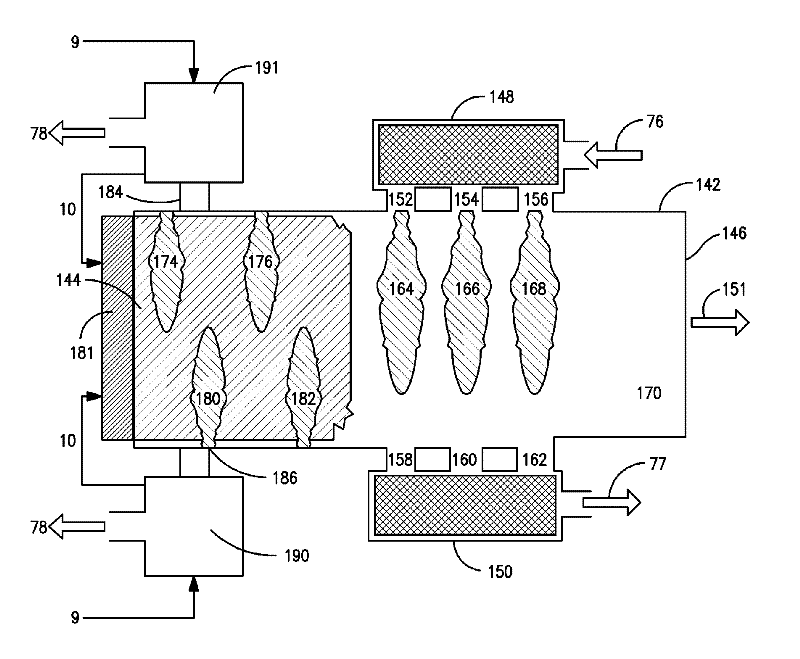

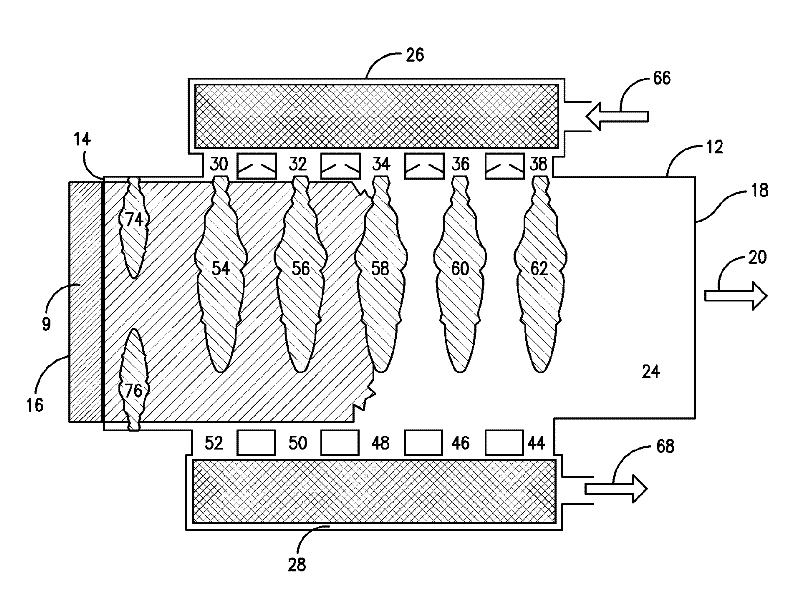

Furnace with multiple heat recovery systems

InactiveUS20100081103A1Glass drawing apparatusGlass forming apparatusProcess engineeringHeat capacity rate

In a furnace such as a glassmelting furnace, a portion of the combustion products formed by combustion of fuel with gaseous oxidant within the furnace are passed through a recuperative or regenerative heat exchanger system to heat a portion of the incoming gaseous oxidant, and a portion of the combustion products are passed instead through a secondary heat exchanger system, wherein the hot combustion products and oxidant which are passed through said first heat exchanger are passed at a heat capacity rate ratio of combustion products to oxidant of less than 1.3.

Owner:PRAXAIR TECH INC

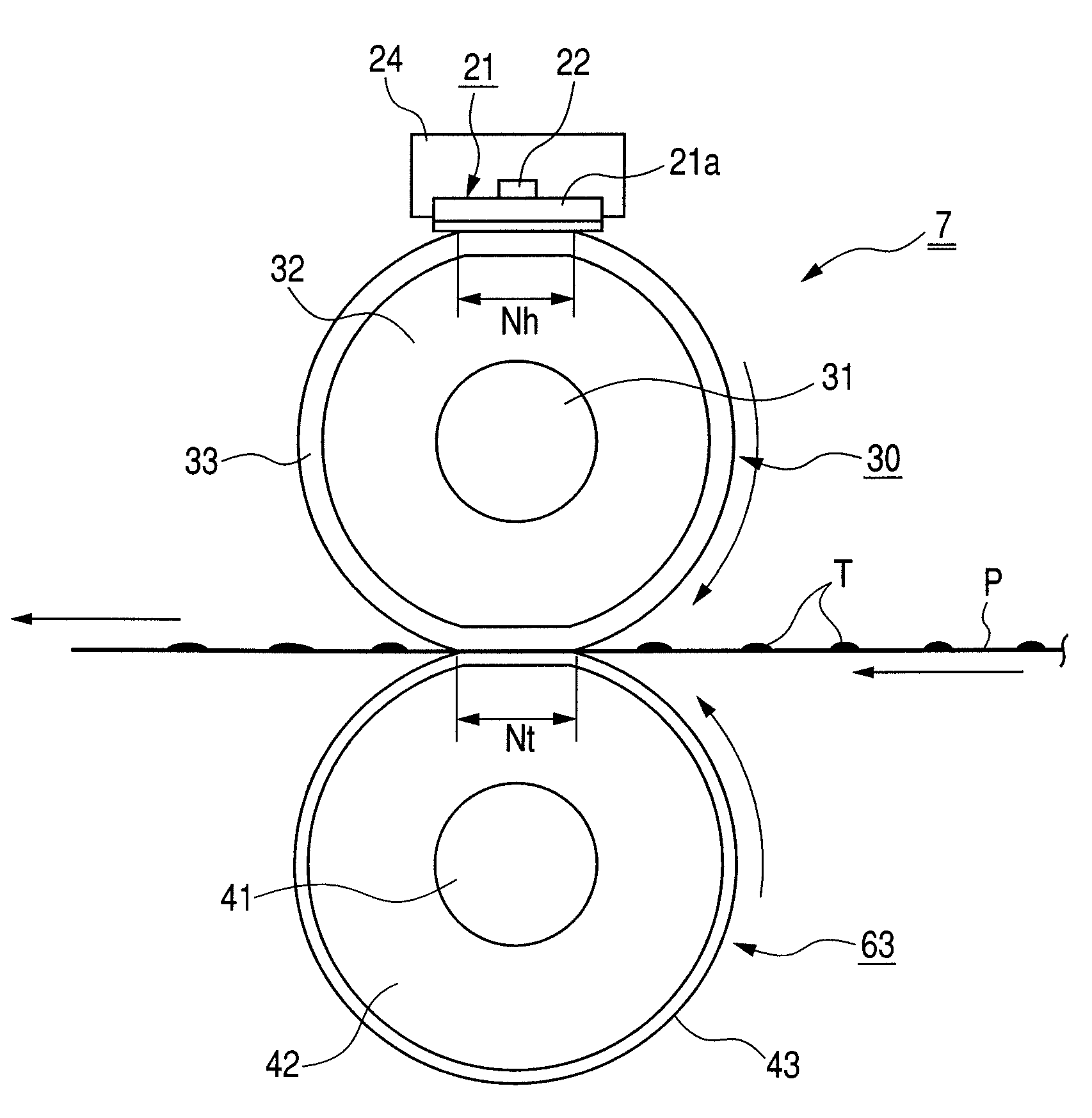

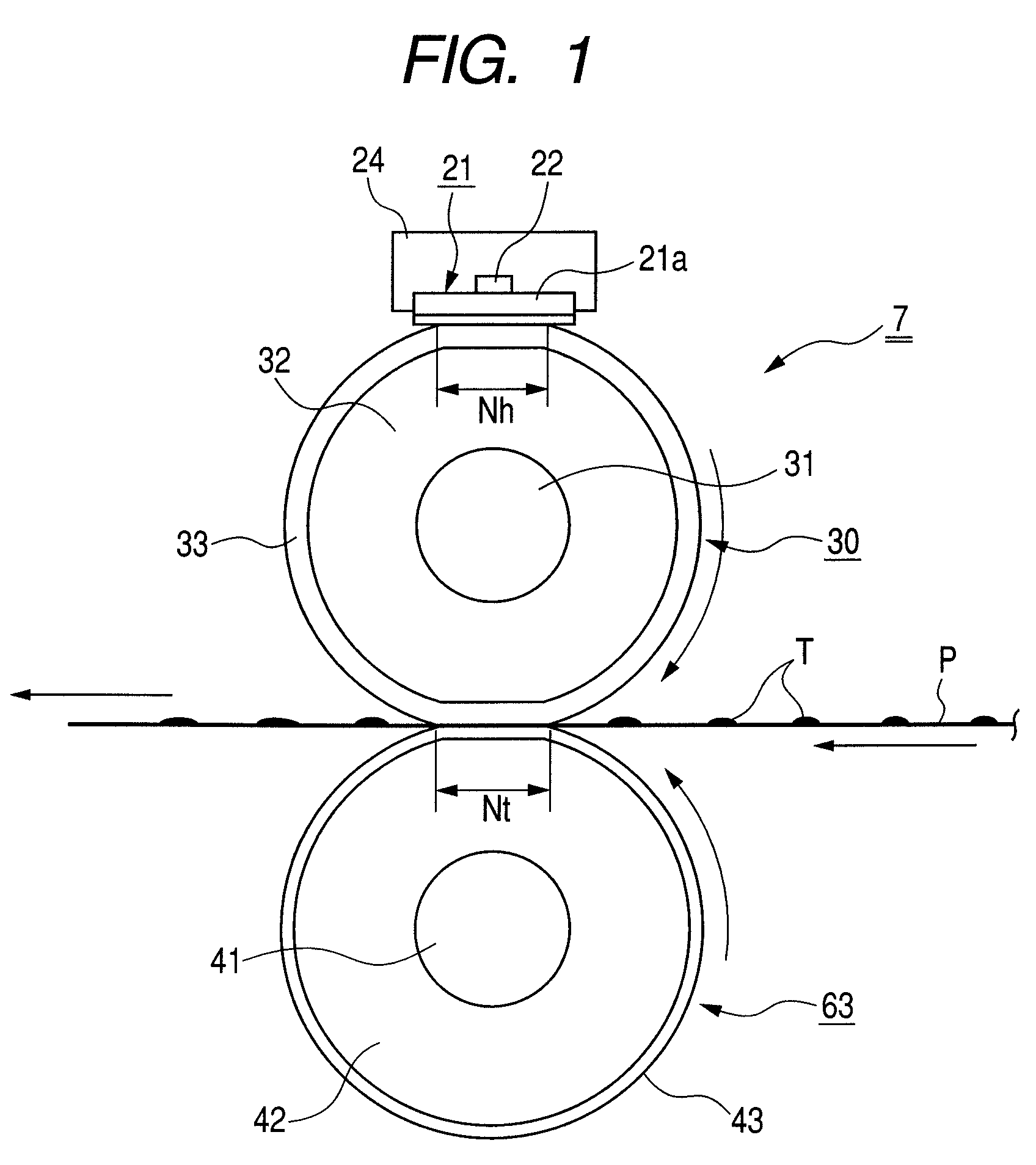

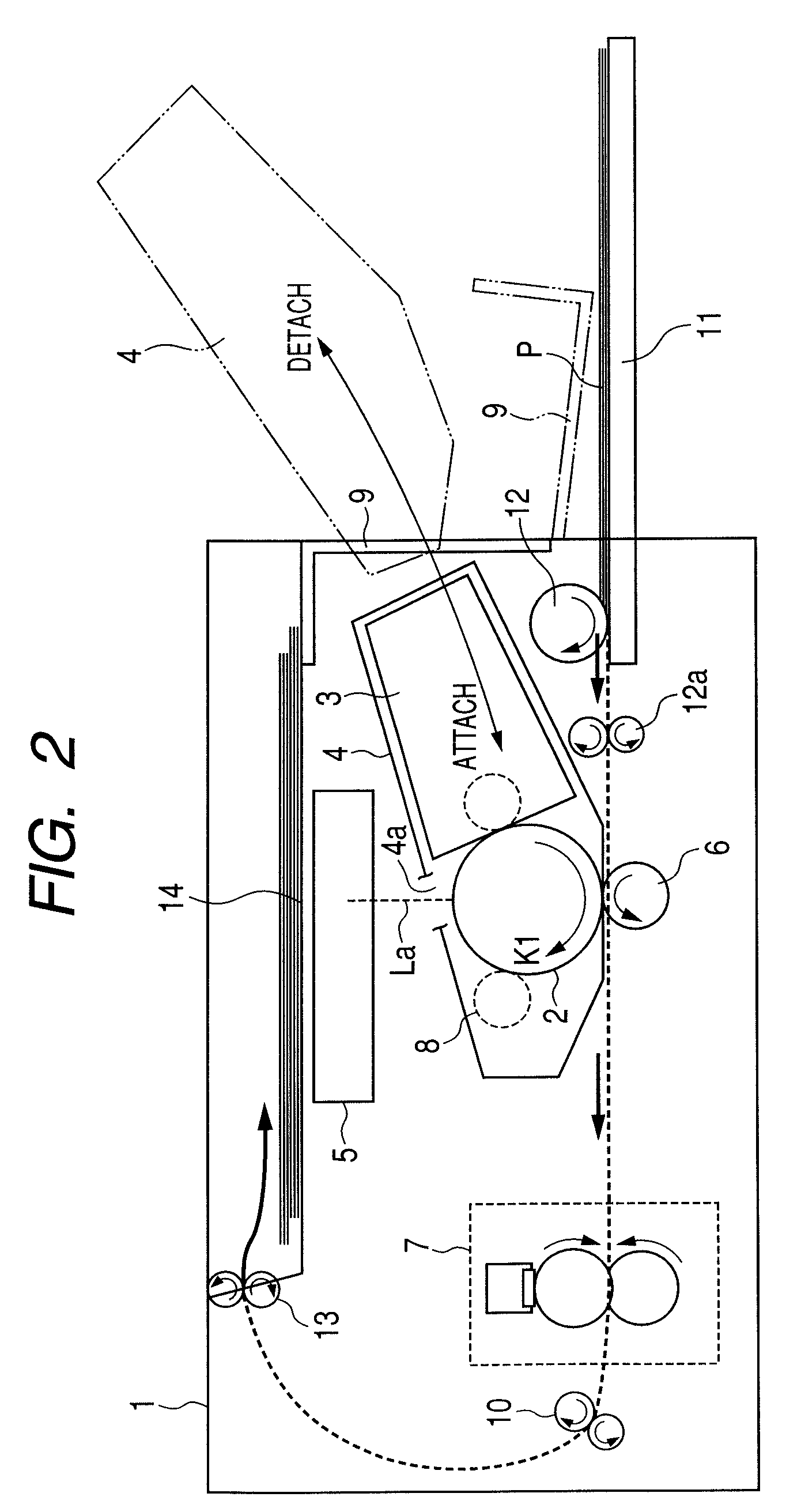

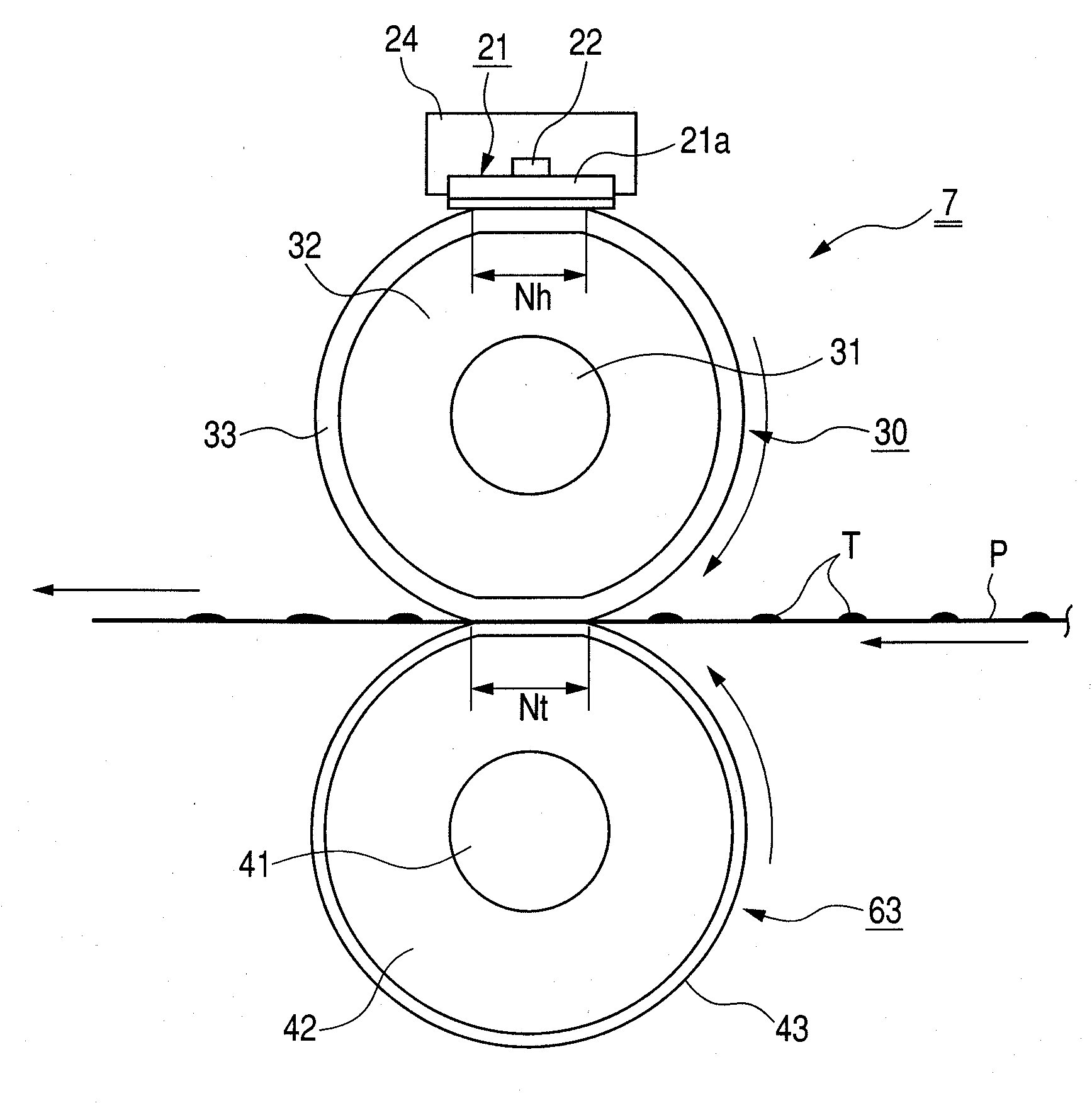

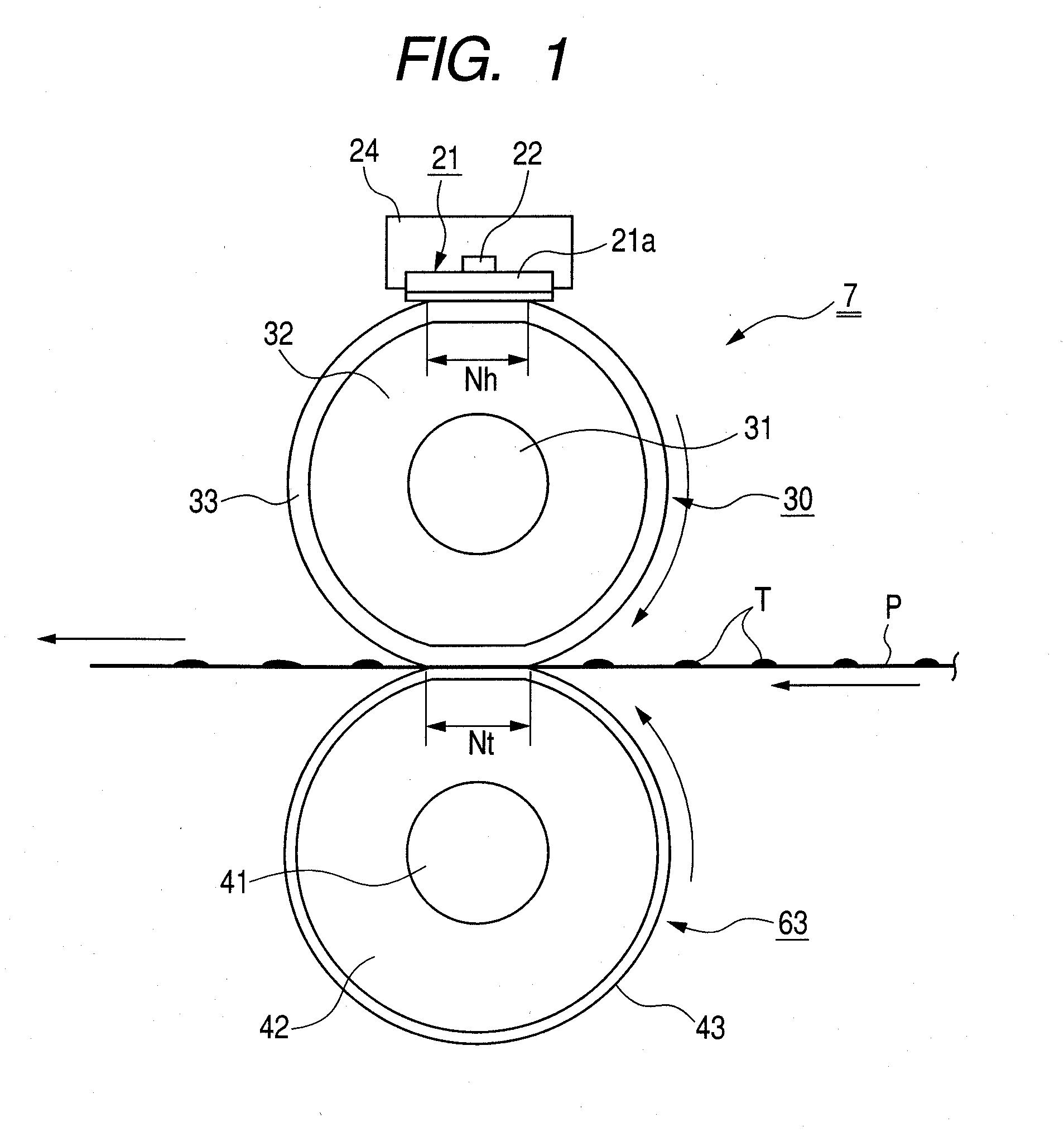

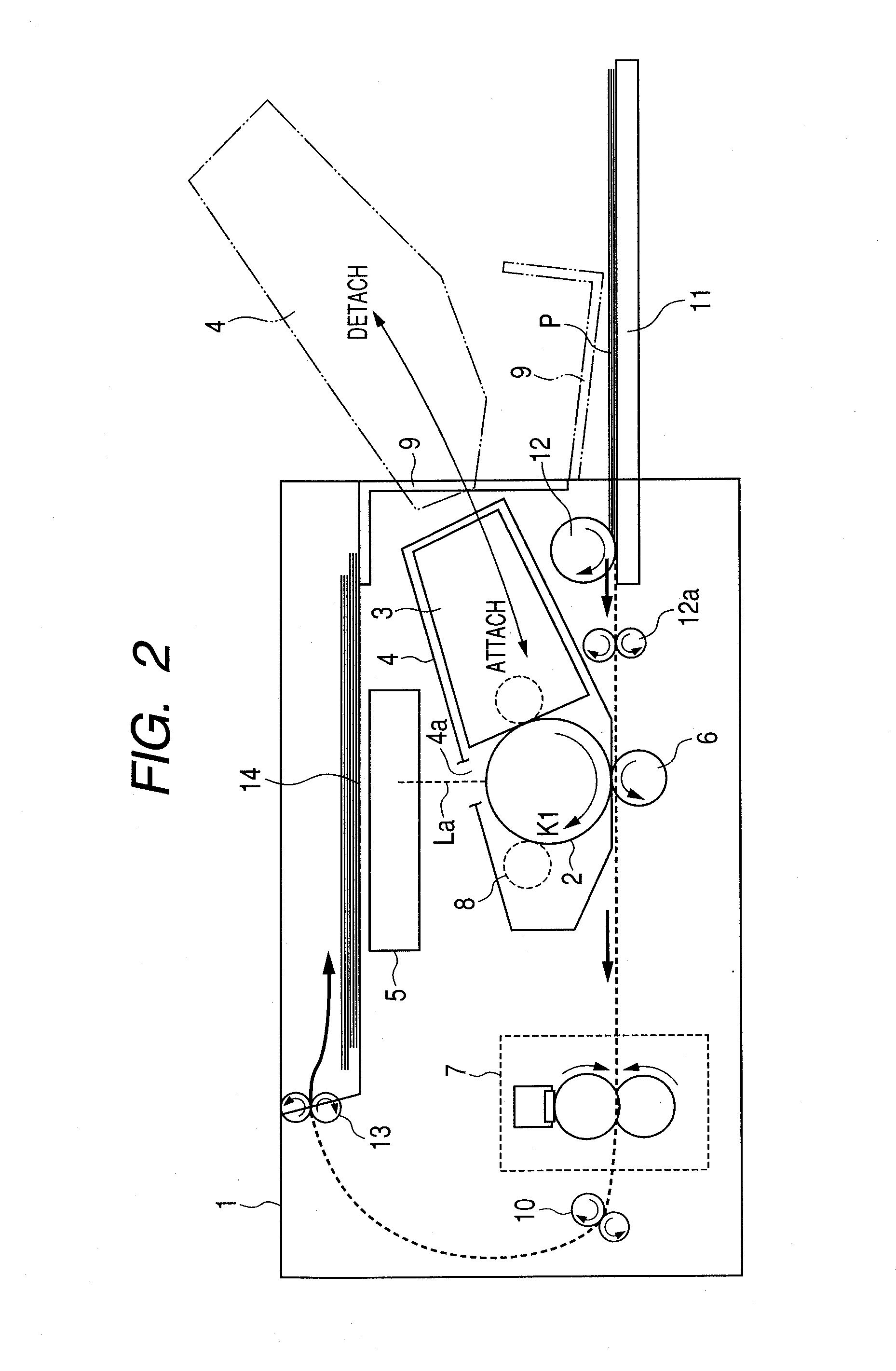

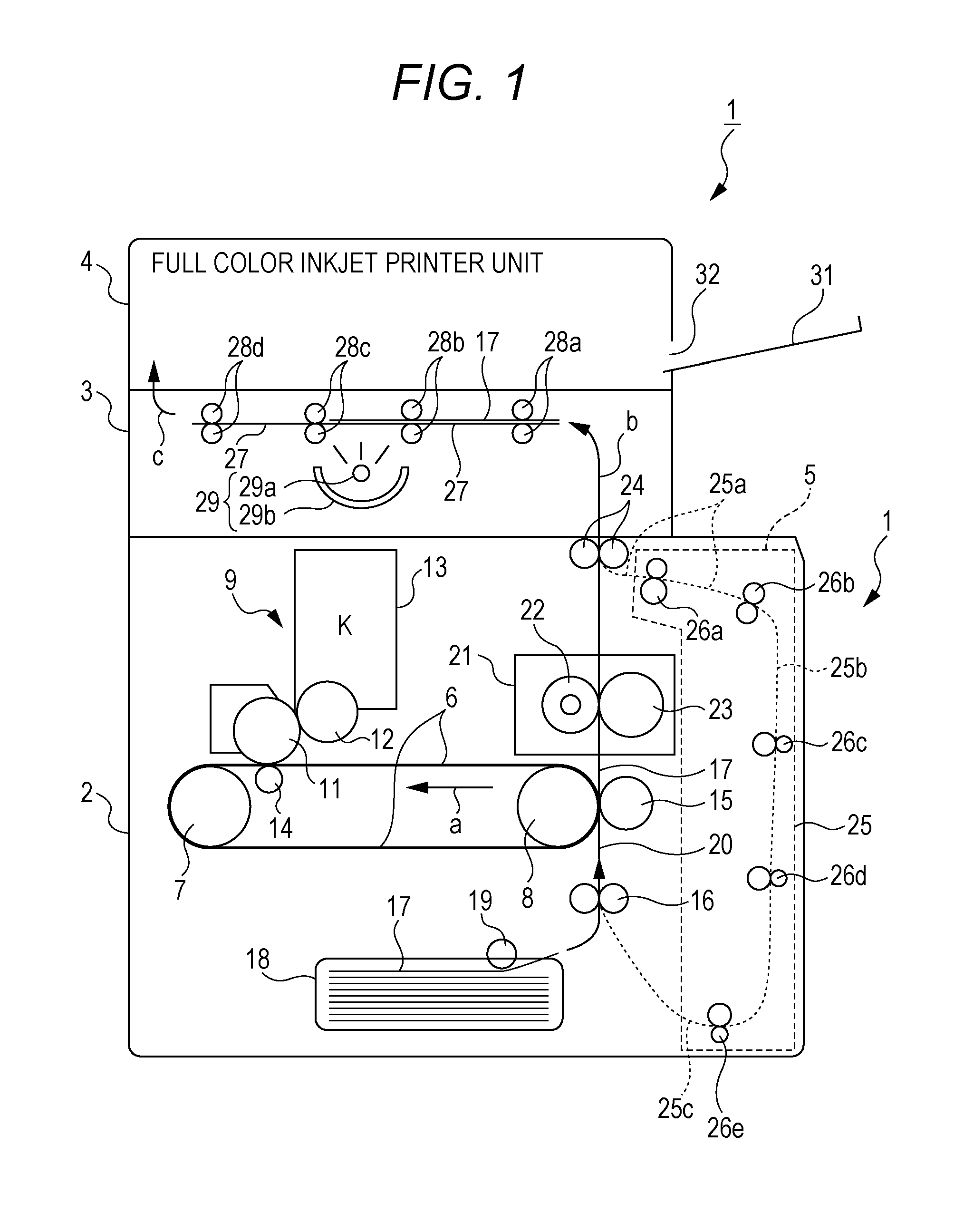

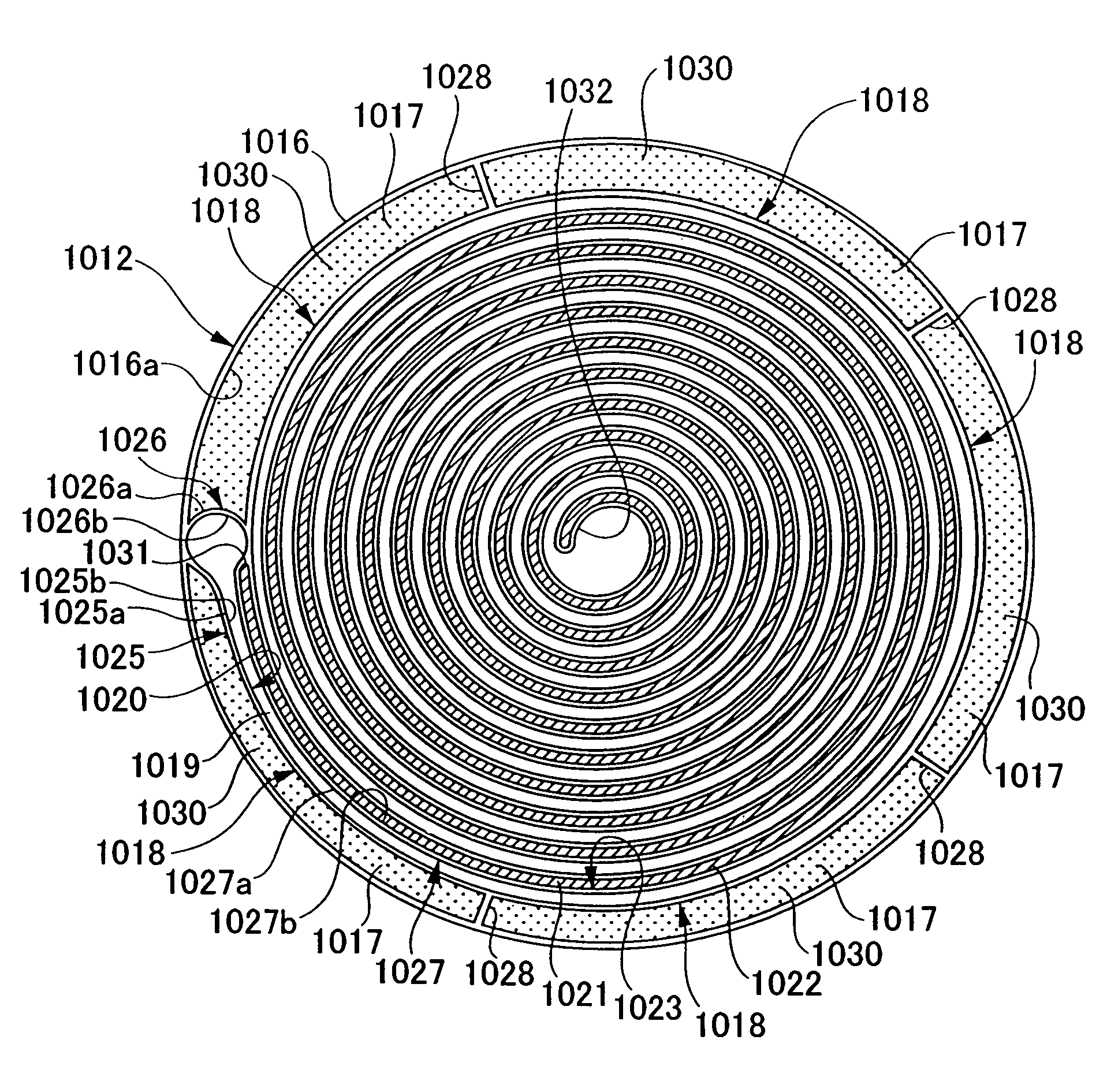

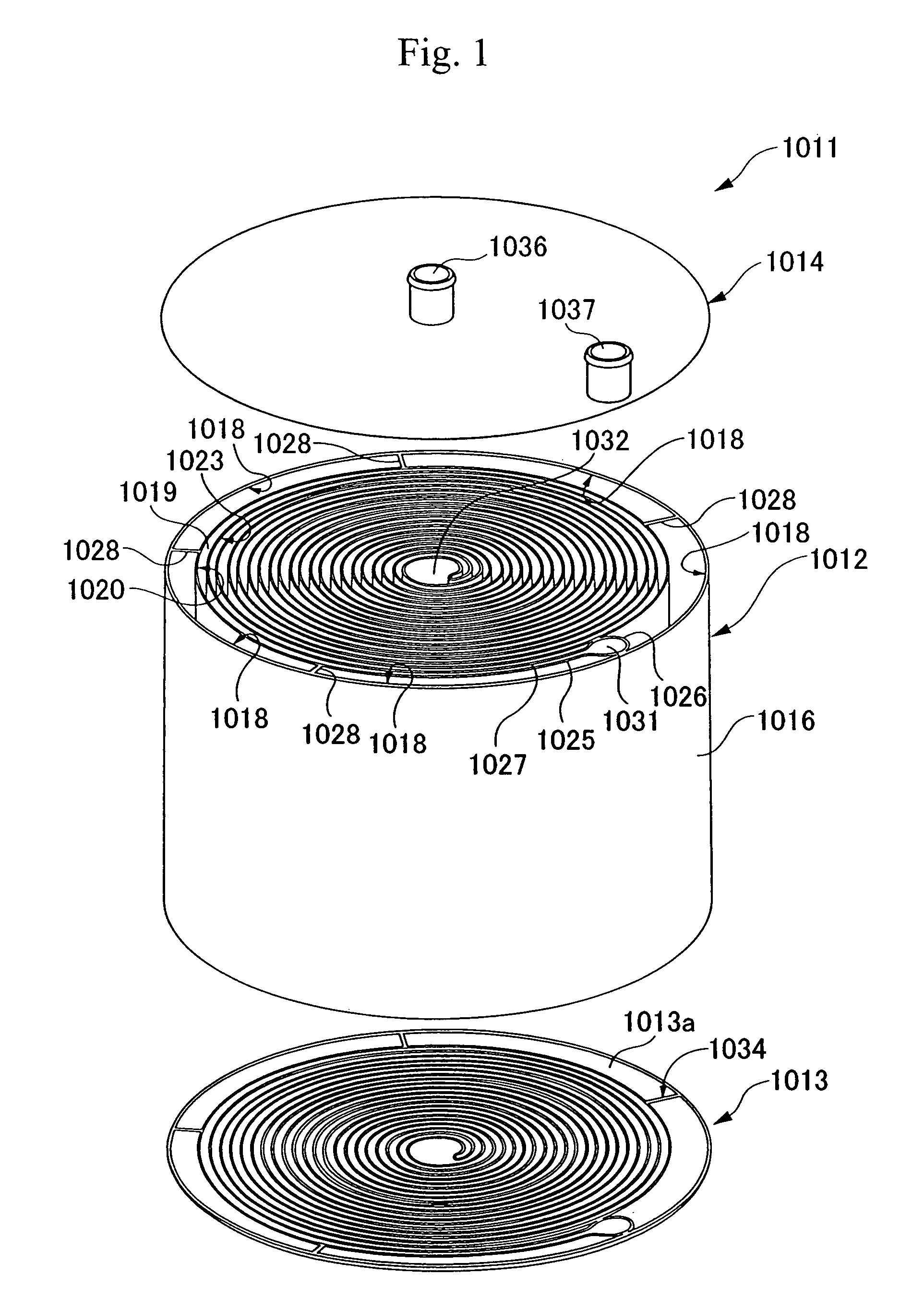

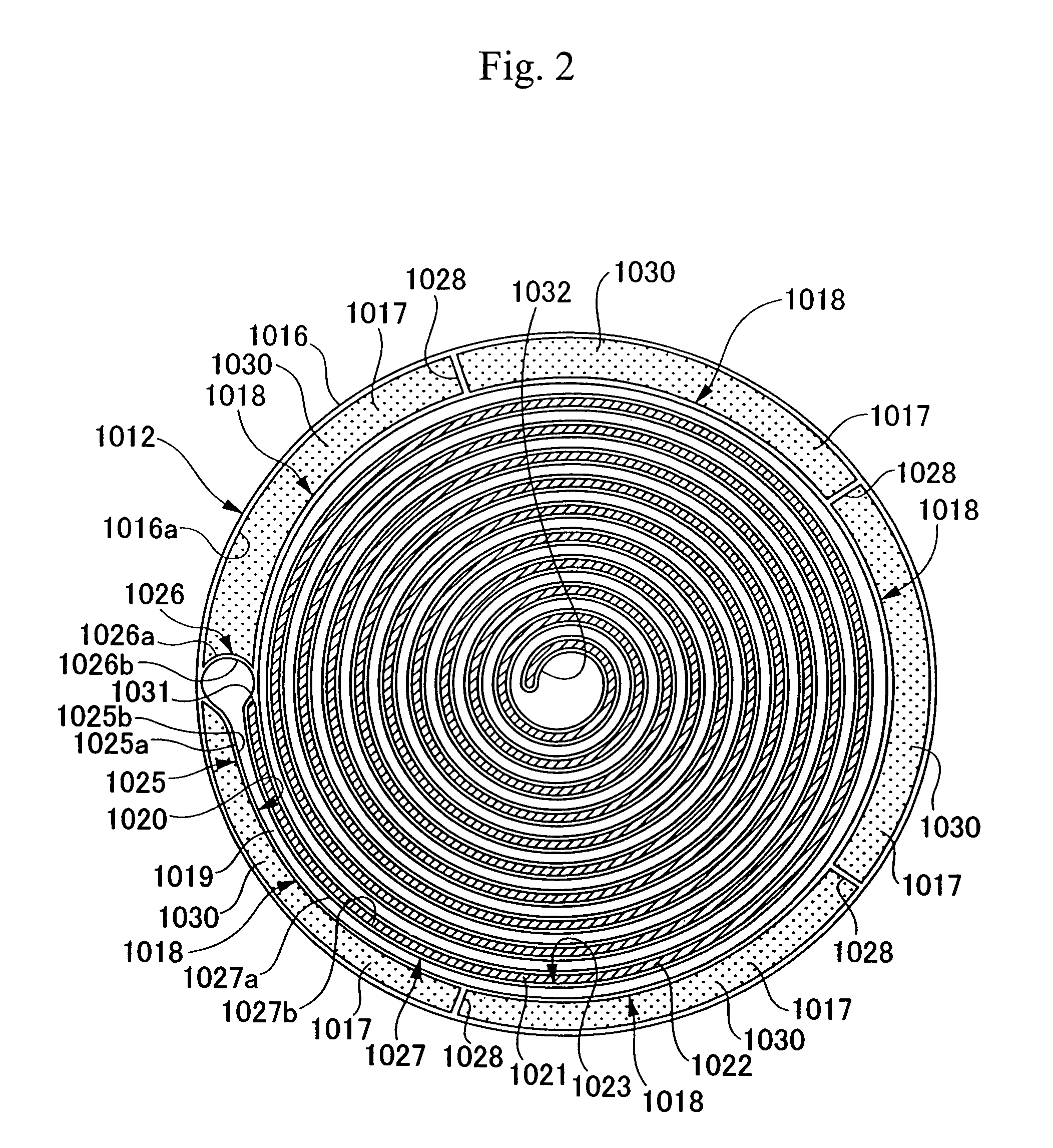

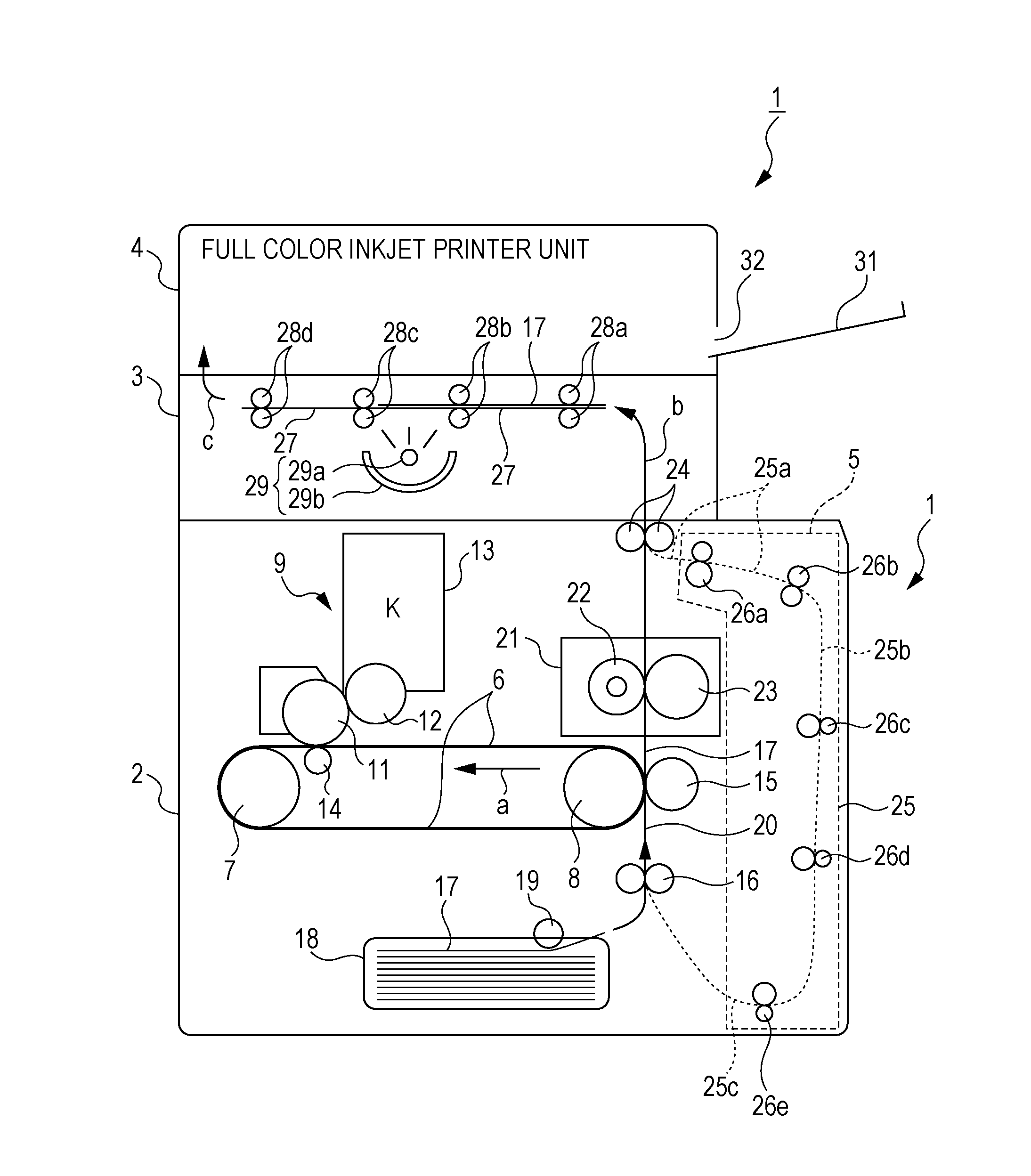

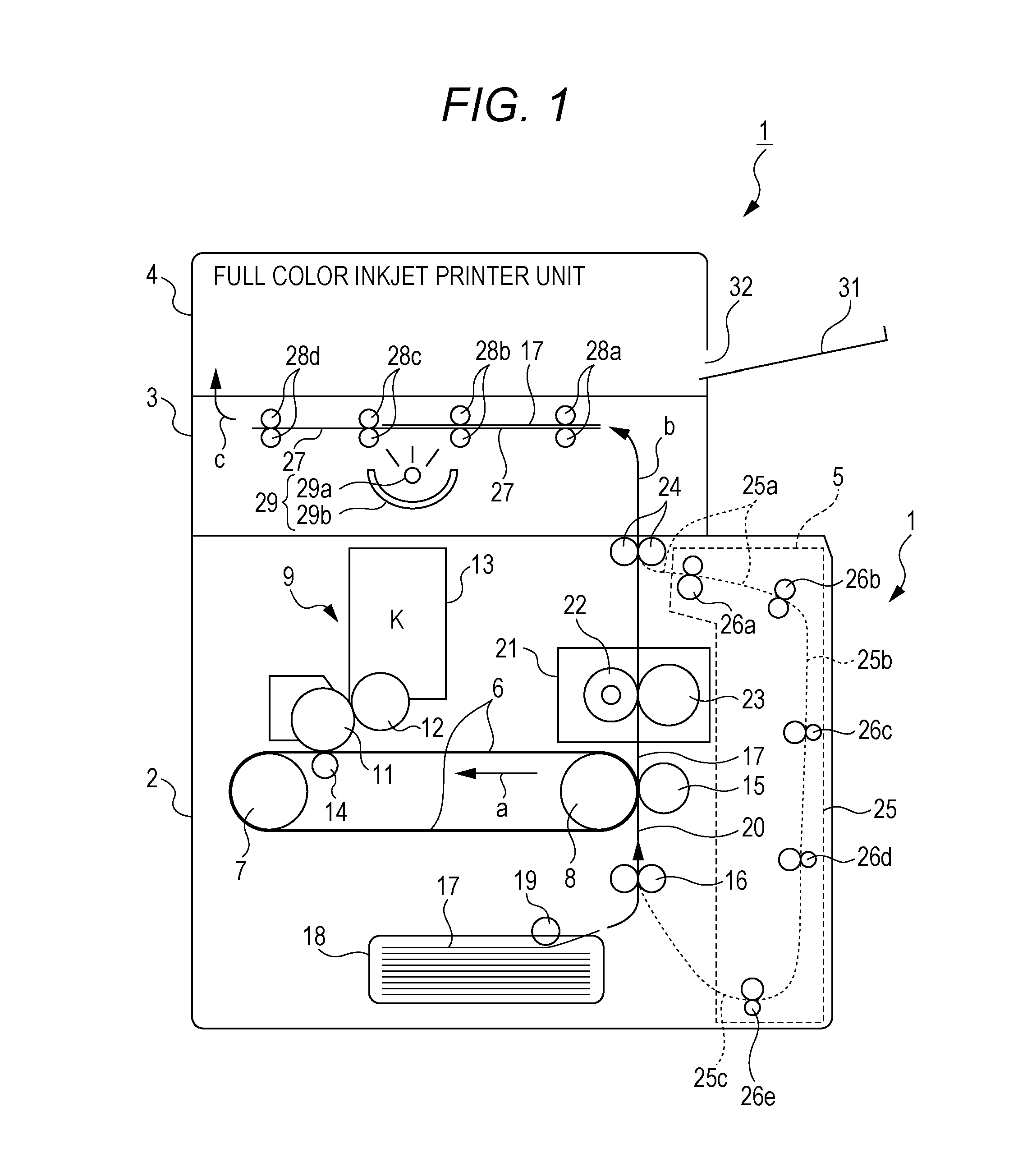

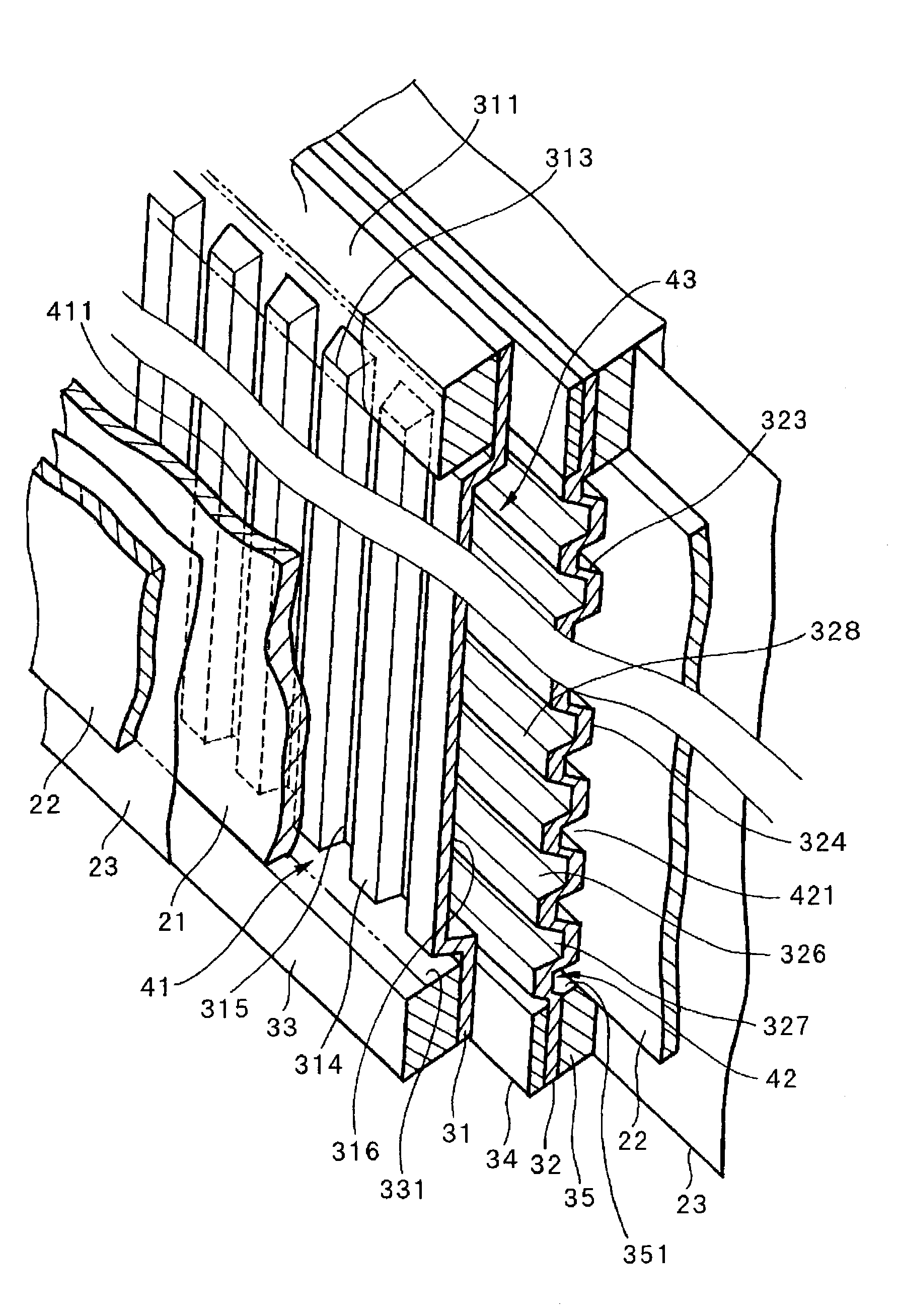

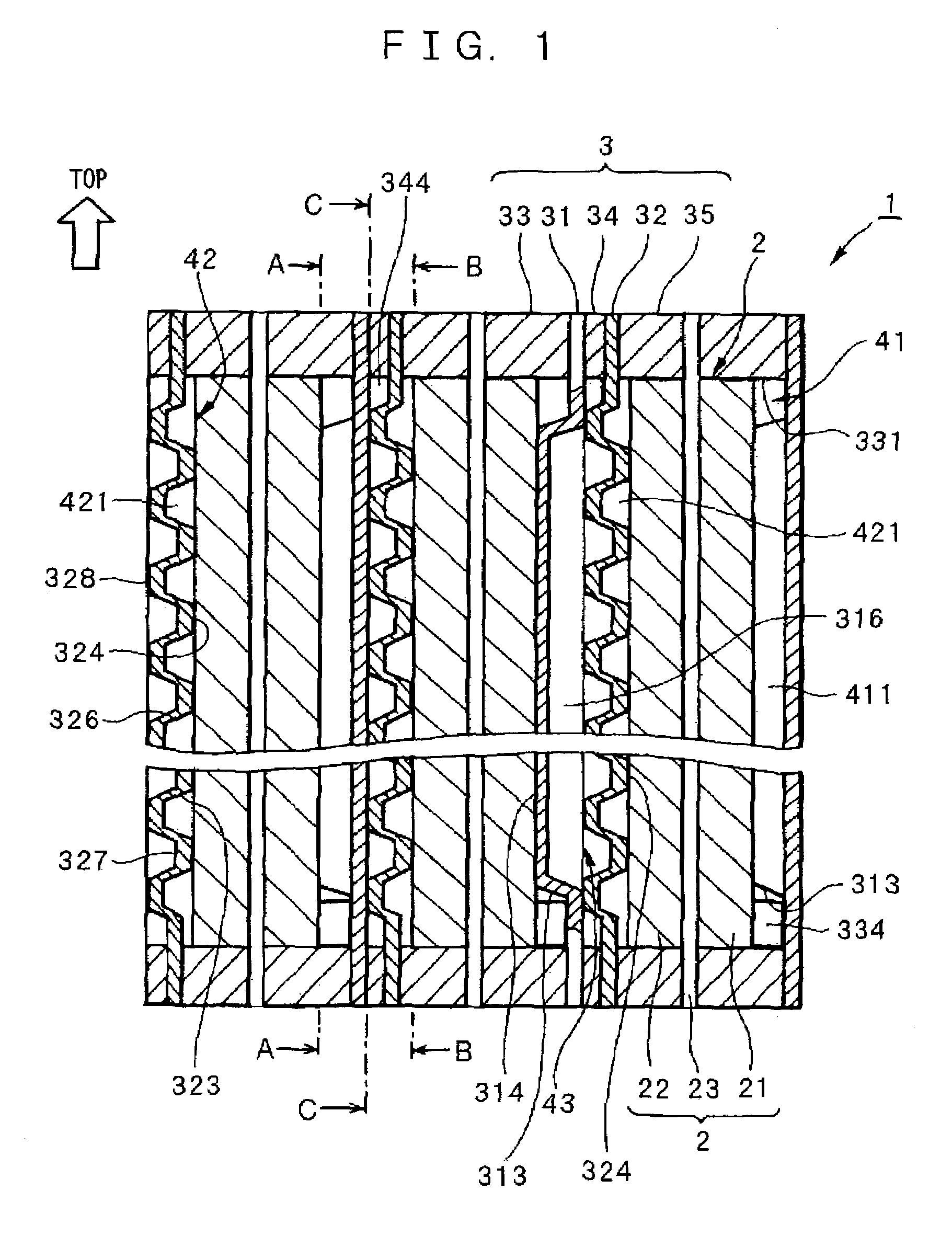

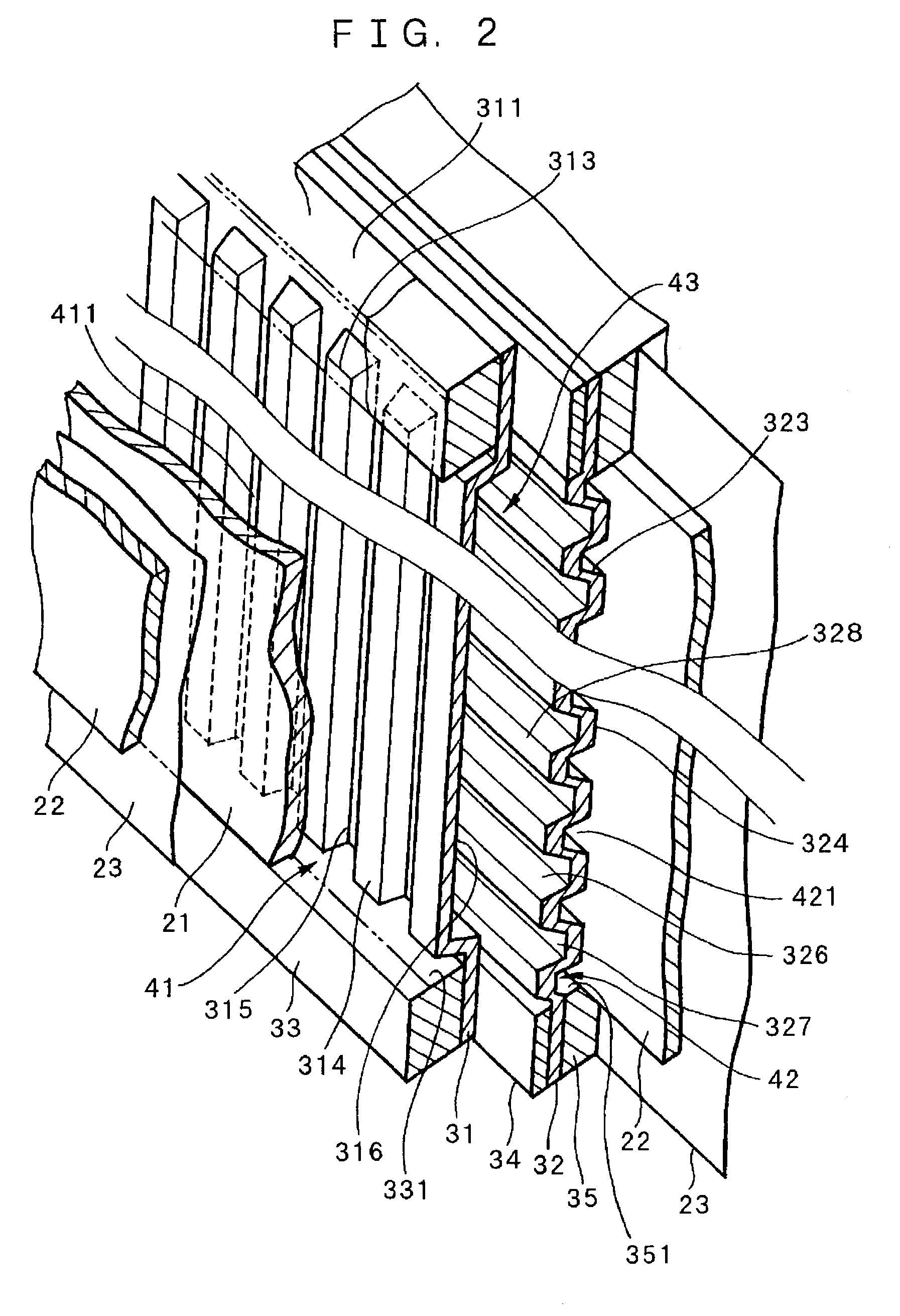

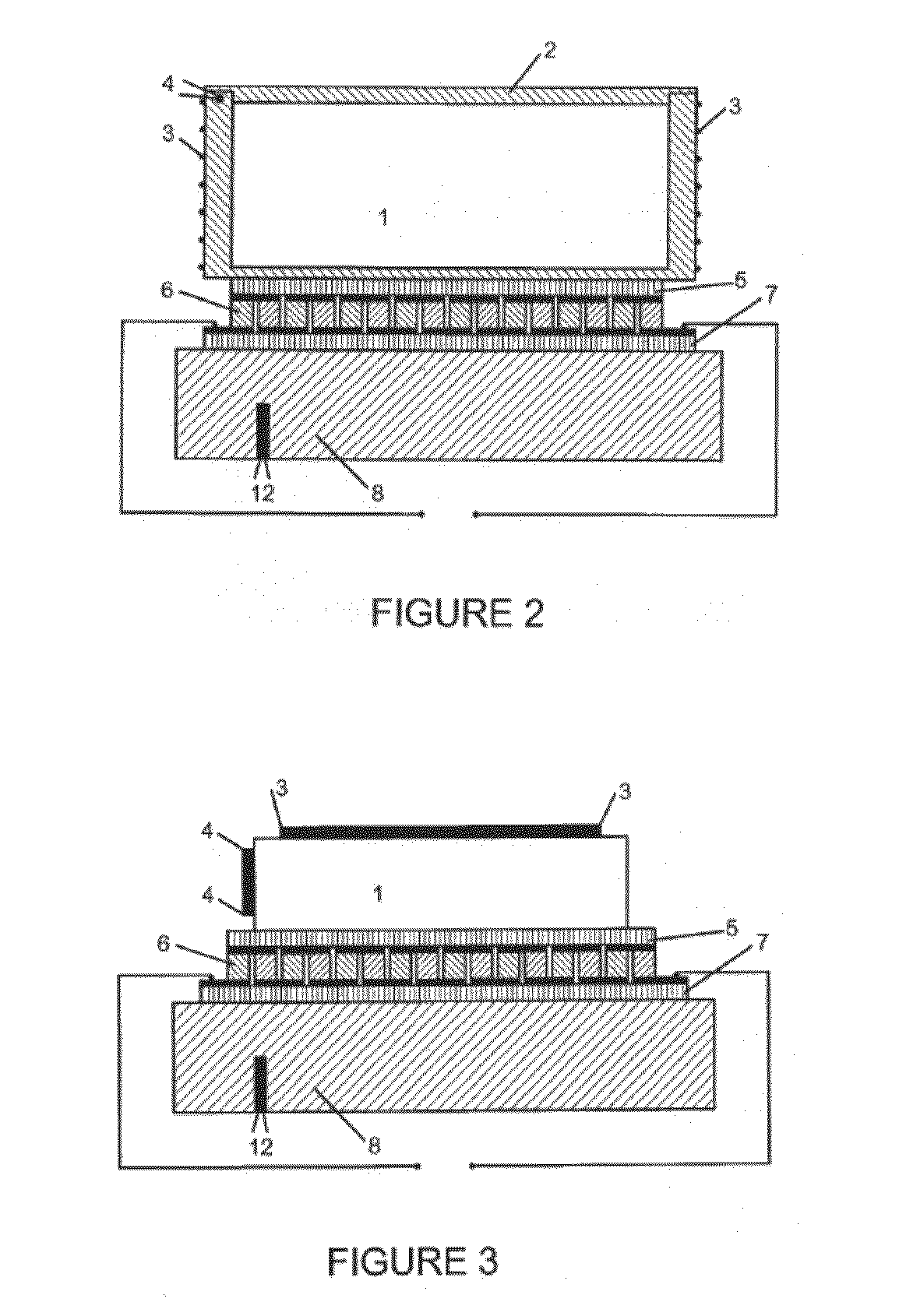

Image heating apparatus and rotatable heating member used for the same

ActiveUS7734241B2Electrographic process apparatusElectrographic processes using charge patternImaging qualityHeat capacity rate

Disclosed is an image heating apparatus. The image heating apparatus includes a rotatable heating member for heating an image on a recording material in a nip portion, and a heating unit for heating the heating member from the outside thereof. With this structure, a warm-up time period or a first print-out time period can be reduced, and low power consumption can be accomplished. Further, satisfactory image quality can be realized with no heating (fixing) irregularity. The heating member has a low thermal conductive elastic layer, and a heat storage layer outside the low thermal conductive elastic layer to have a volume heat capacity larger than the low thermal conductive elastic layer. A heat capacity of the heat storage layer per unit surface area of a fixing member is in a range of 100 J / m2K to 600 J / m2K.

Owner:CANON KK

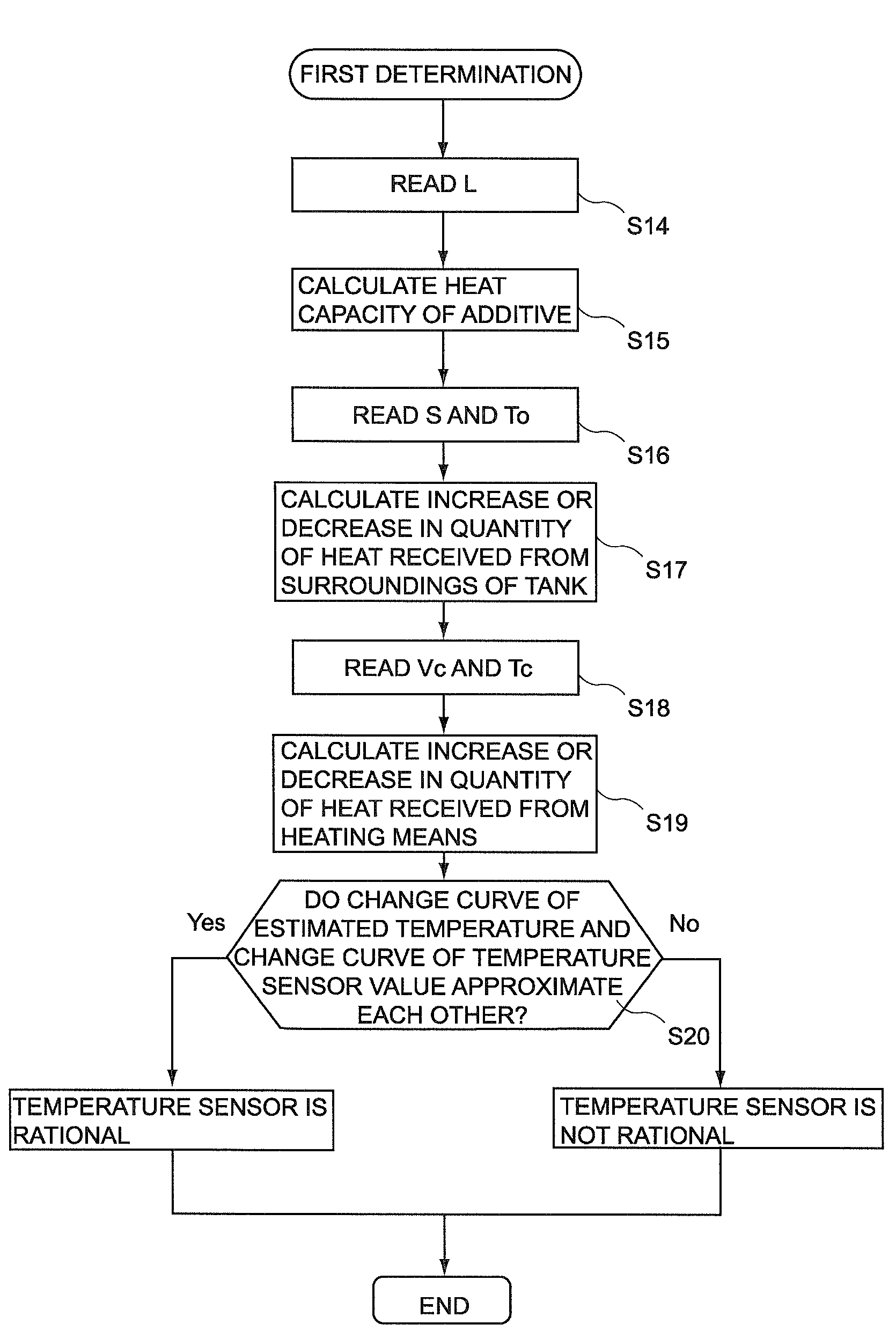

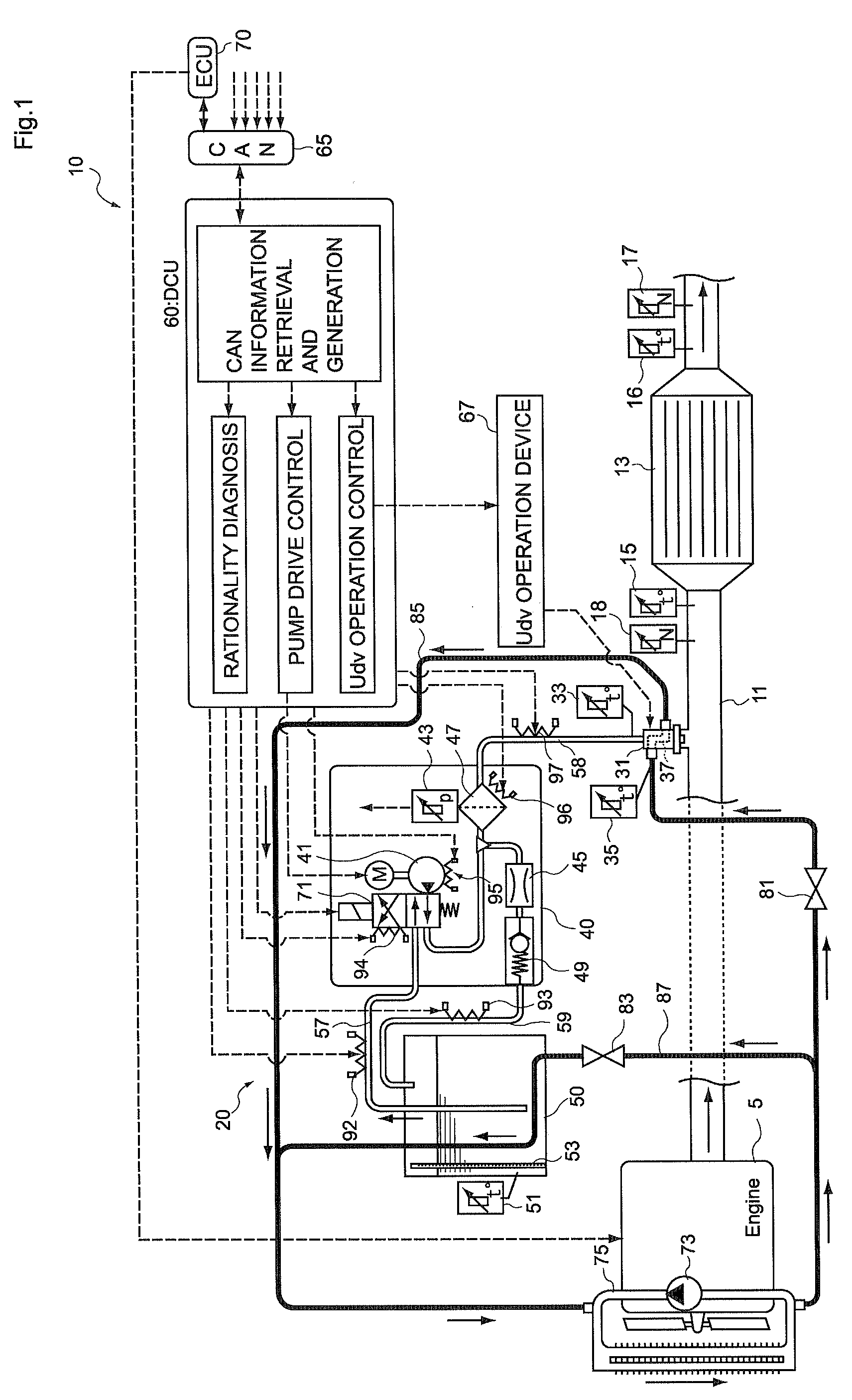

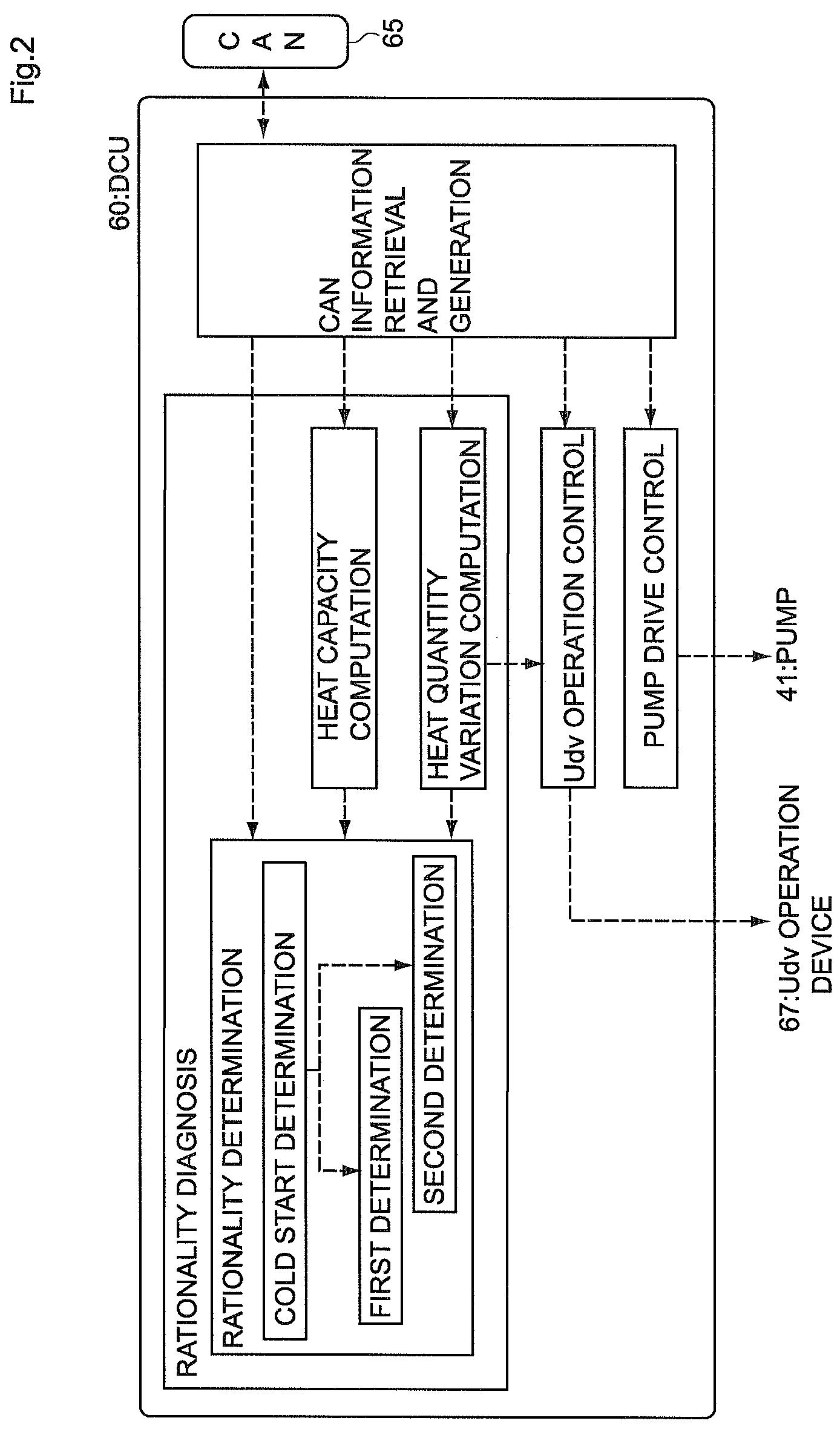

Temperature sensor plausibility diagnosis unit and plausibility diagnosis method and internal combustion engine exhaust purification apparatus

ActiveUS8303174B2Accurately determinedReliability of plausibilityVehicle testingThermometer detailsDiagnosis methodsProcess engineering

A temperature sensor plausibility diagnosis unit performs plausibility diagnosis of a temperature sensor disposed inside a storage tank in an exhaust purification apparatus of an internal combustion engine that delivers an additive inside the storage tank to an exhaust pipe upstream of a reduction catalyst and selectively reduces and purifies NOx in the exhaust. The temperature sensor plausibility diagnosis unit includes an additive heat capacity calculating portion that calculates the heat capacity of the additive, a heat quantity variation calculating portion that calculates an increase or decrease in the quantity of heat that the additive receives, and a plausibility diagnosing portion that determines the plausibility of the temperature sensor by comparing an estimated temperature course of the additive estimated from the heat capacity of the additive and the increase or decrease in the quantity of heat with a sensor temperature course of the additive detected by the temperature sensor.

Owner:BOSCH CORP

Image heating apparatus and rotatable heating member used for the same

ActiveUS20080273904A1Electrographic process apparatusElectrographic processes using charge patternImaging qualityEngineering

Disclosed is an image heating apparatus. The image heating apparatus includes a rotatable heating member for heating an image on a recording material in a nip portion, and a heating unit for heating the heating member from the outside thereof. With this structure, a warm-up time period or a first print-out time period can be reduced, and low power consumption can be accomplished. Further, satisfactory image quality can be realized with no heating (fixing) irregularity. The heating member has a low thermal conductive elastic layer, and a heat storage layer outside the low thermal conductive elastic layer to have a volume heat capacity larger than the low thermal conductive elastic layer. A heat capacity of the heat storage layer per unit surface area of a fixing member is in a range of 100 J / m2K to 600 J / m2K.

Owner:CANON KK

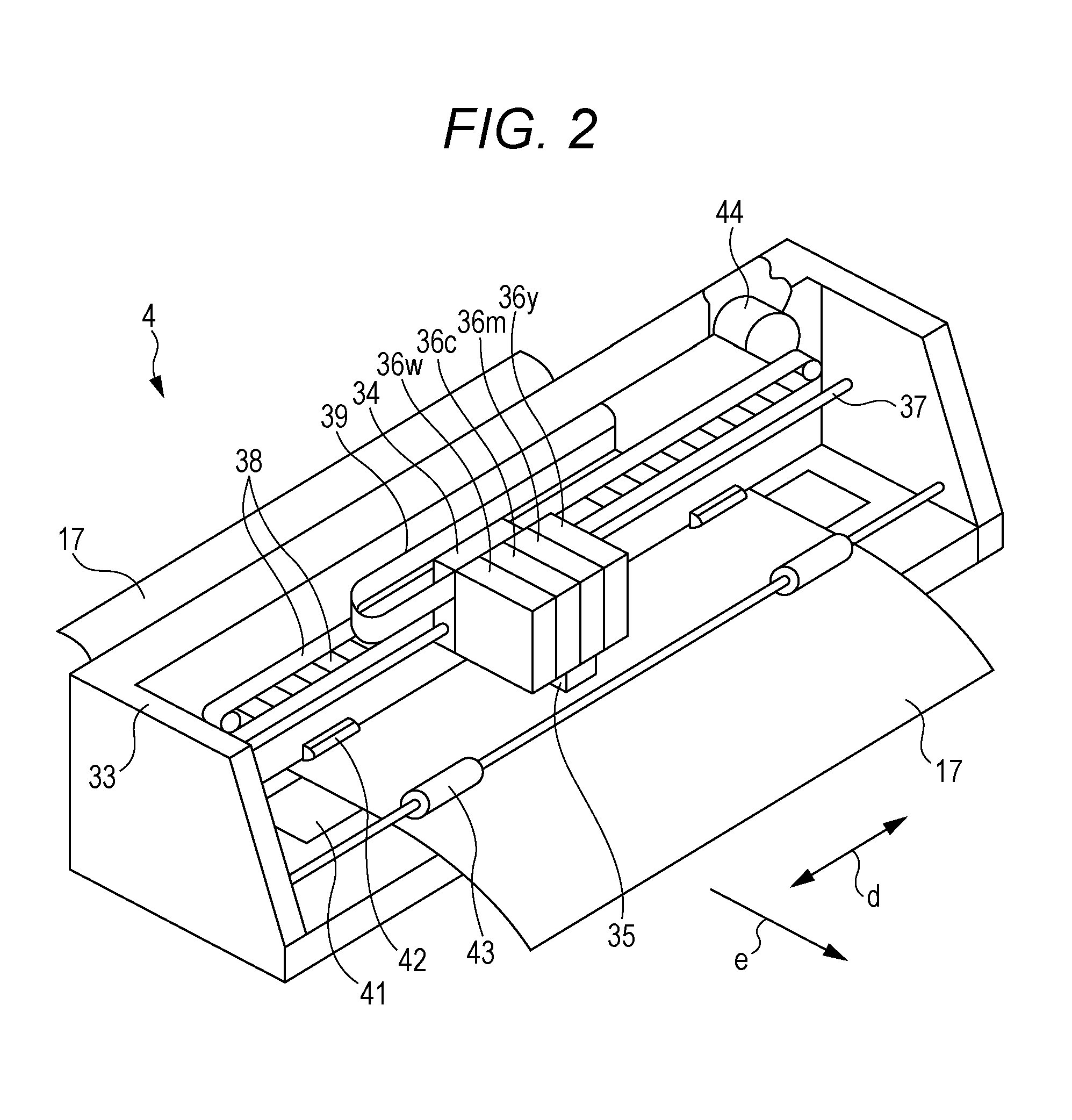

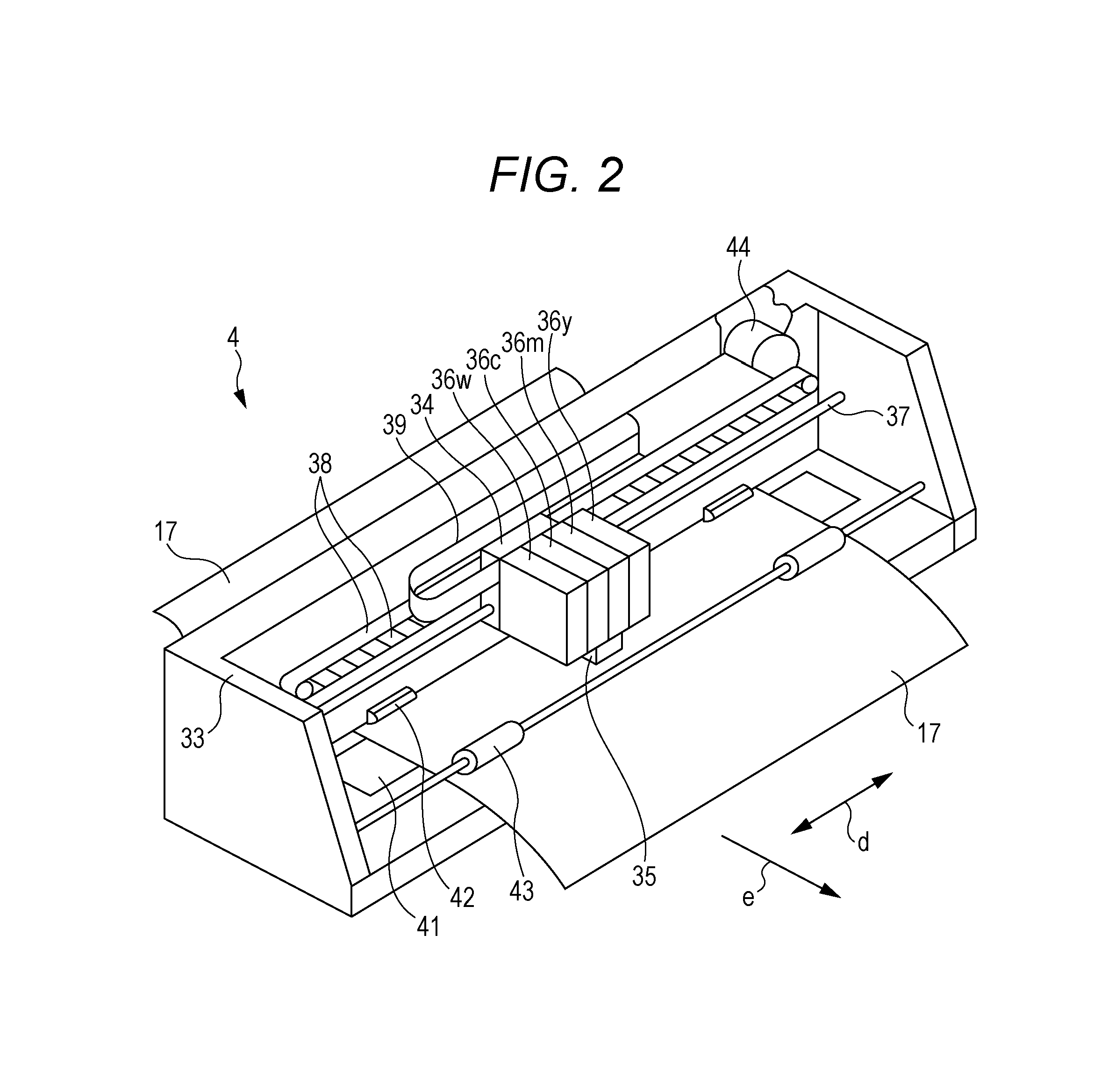

Three-dimensional printer, three-dimensional image forming method, and three-dimensional image

When a heat capacity of a recording medium having a base material coated with a foamable resin layer is larger than a normal heat capacity, to form a raised amount equal to that with the normal case with a normal heating quantity, a turned mirror image of the image is generated. The image is transferred onto the front face of the recording medium and fixed. The recording medium is reversed, and conveyed again to the transfer part. The turned mirror image is transferred onto the rear face of the recording medium and fixed. The recording medium is heated with the heat quantity equal to that in the normal case, and combination of heat absorbed by the turned minor image and heat absorbed by the image is transmitted to the foamable resin layer to expand the foamable resin layer.

Owner:CASIO COMPUTER CO LTD

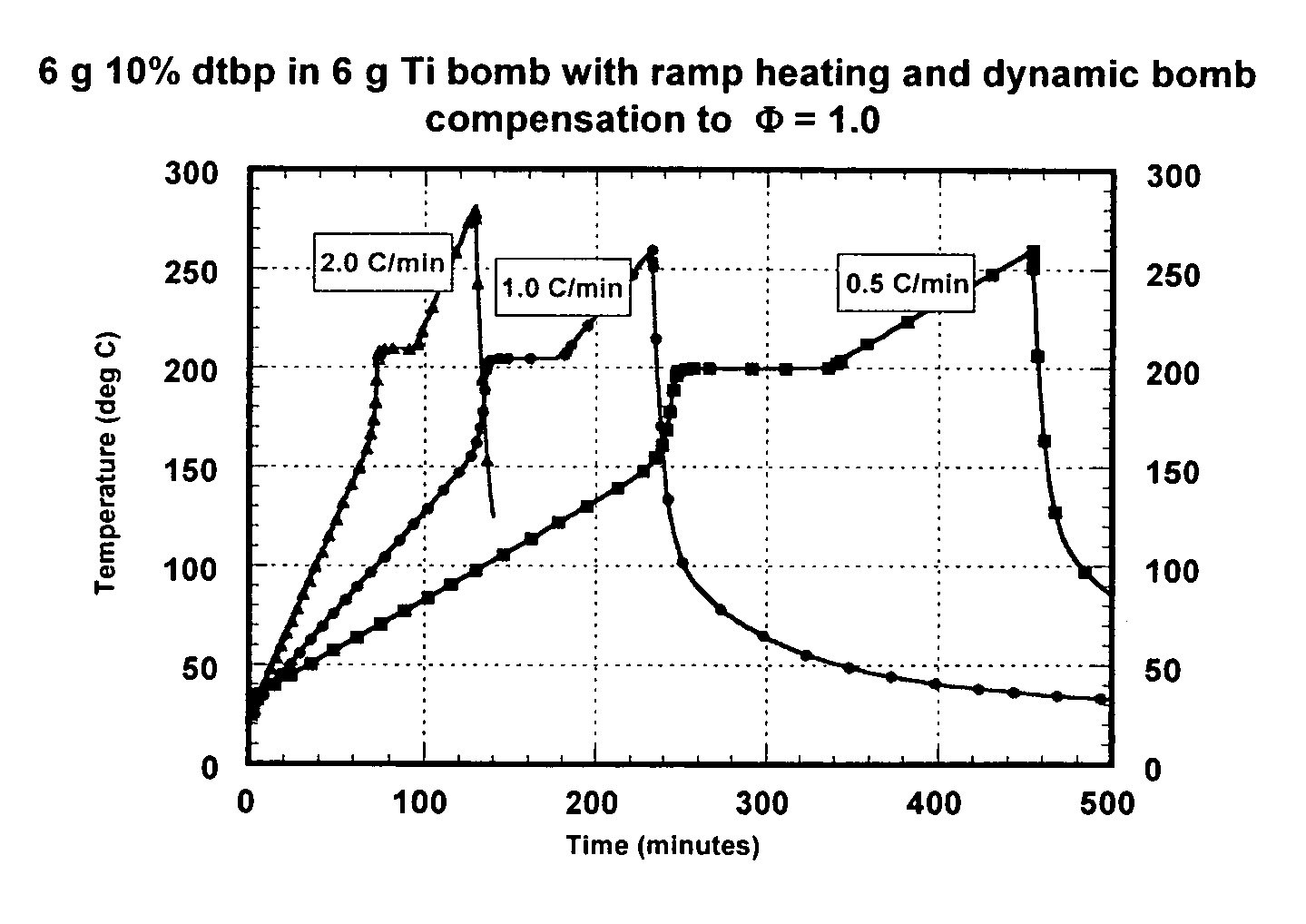

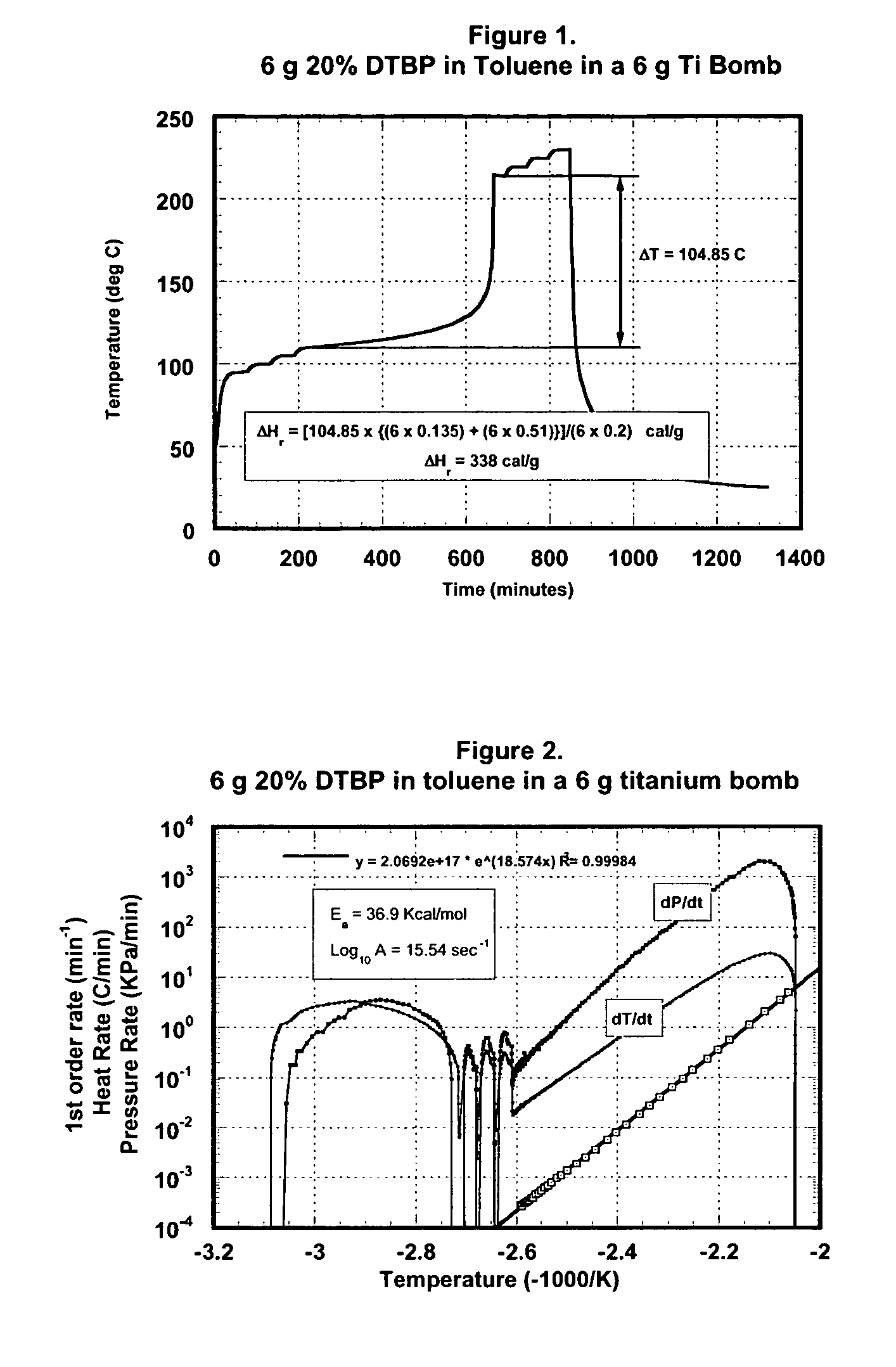

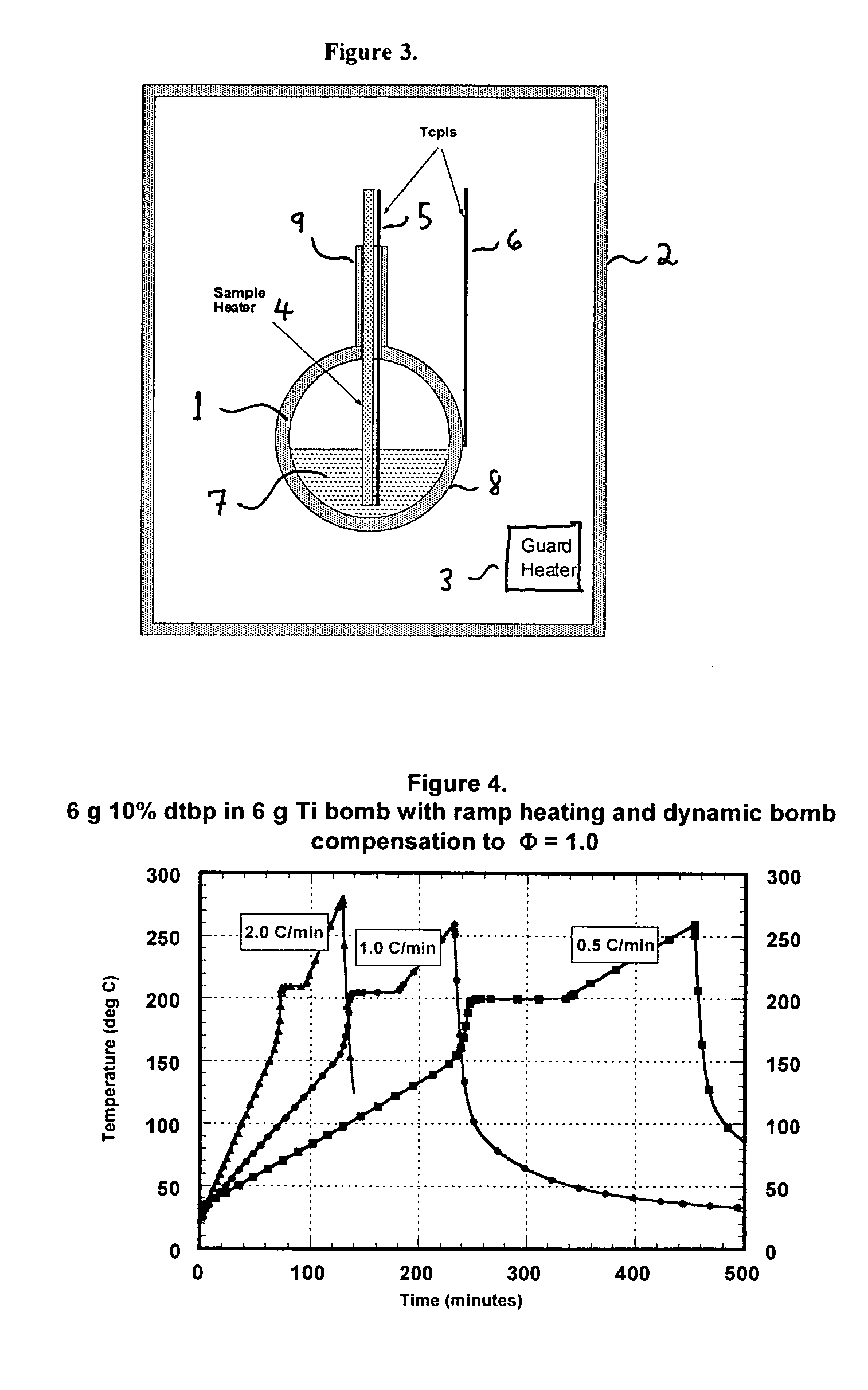

Low thermal inertia scanning adiabatic calorimeter

ActiveUS7021820B2Prevent heat lossReduce heat outputMaterial heat developmentThermometers using electric/magnetic elementsProduction rateHigh pressure

A new adiabatic scanning calorimeter allows the thermal mass of a high-pressure reaction vessel to be dynamically compensated during a test. This allows the effective Φ factor for the experiment to be reduced to 1.0 without the use of complex pressure balancing equipment. Endothermic events can be quantified and sample specific heats can be measured. The time required for test completion is much shorter than for conventional adiabatic calorimeters, thus considerably improving apparatus productivity. The sensitivity to exotherm detection is at least as good as existing adiabatic calorimeters employing the Heat-Wait-Search strategy, but does depend on the temperature-scanning rate. In addition, the heat of reaction is obtained without reference to the heat capacity of the sample, pressure is measured continuously, reactants may be injected into the test vessel and the sample can be mixed during the test.

Owner:NETZSCH GERATEBAU GMBH

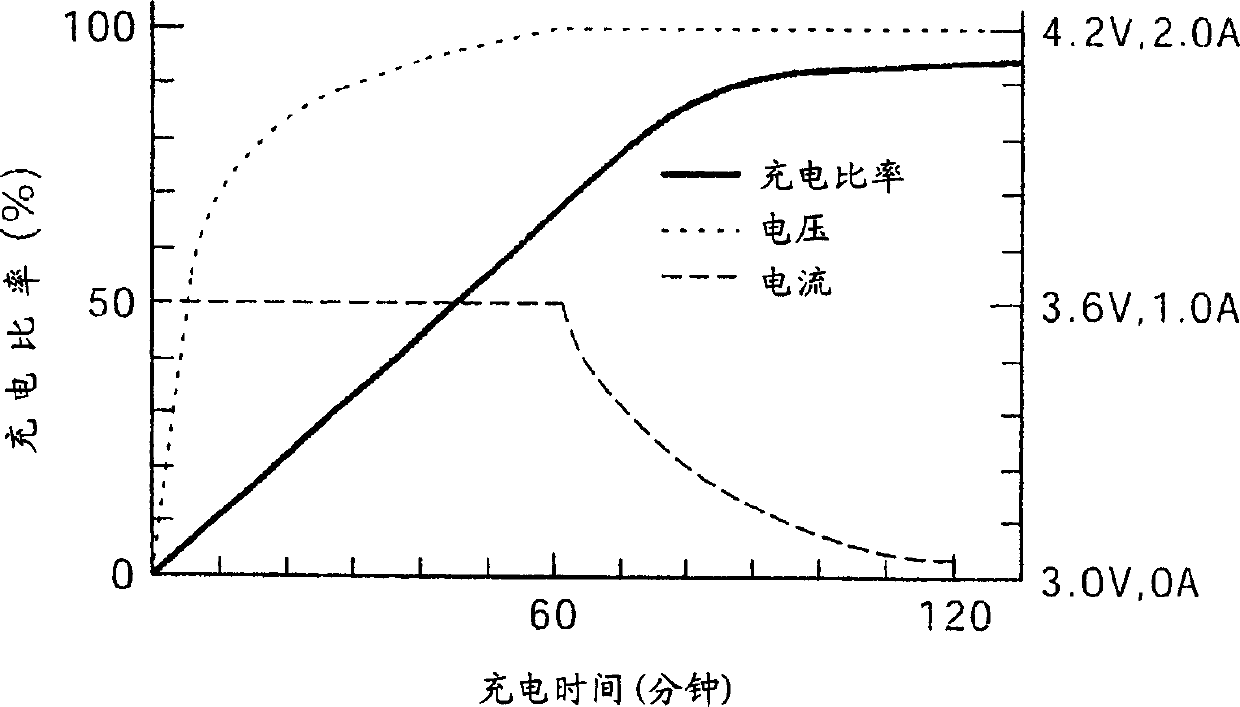

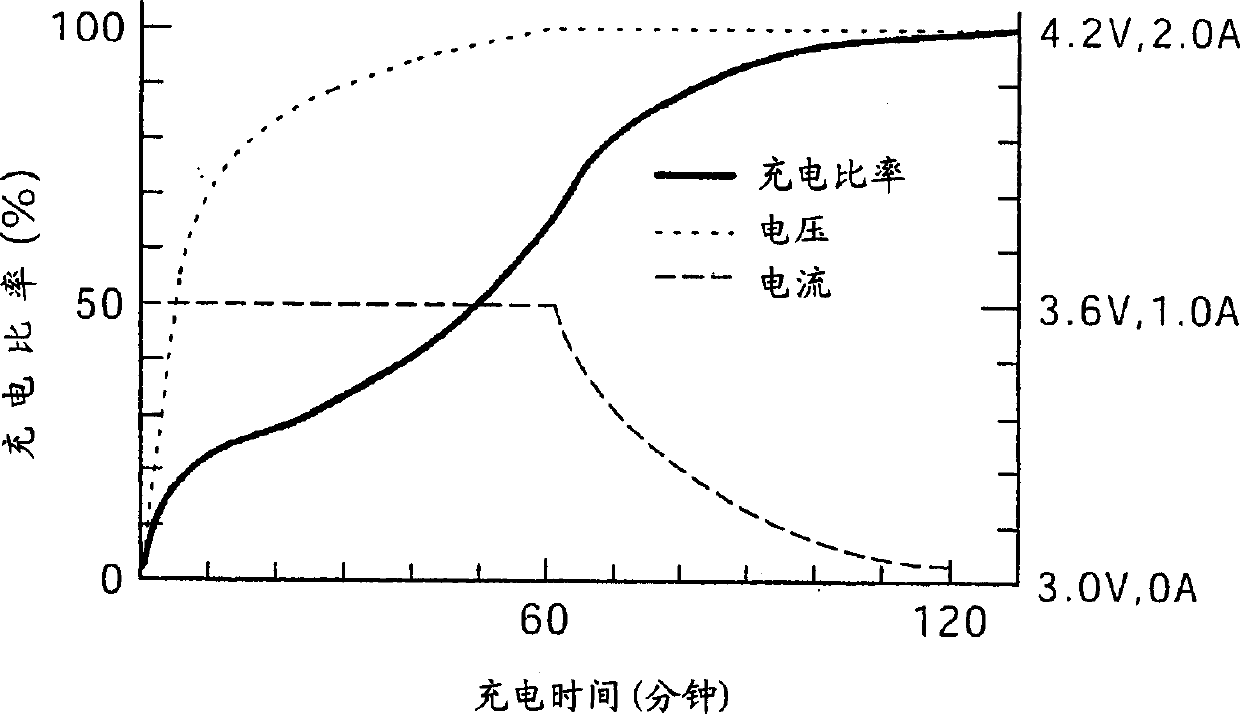

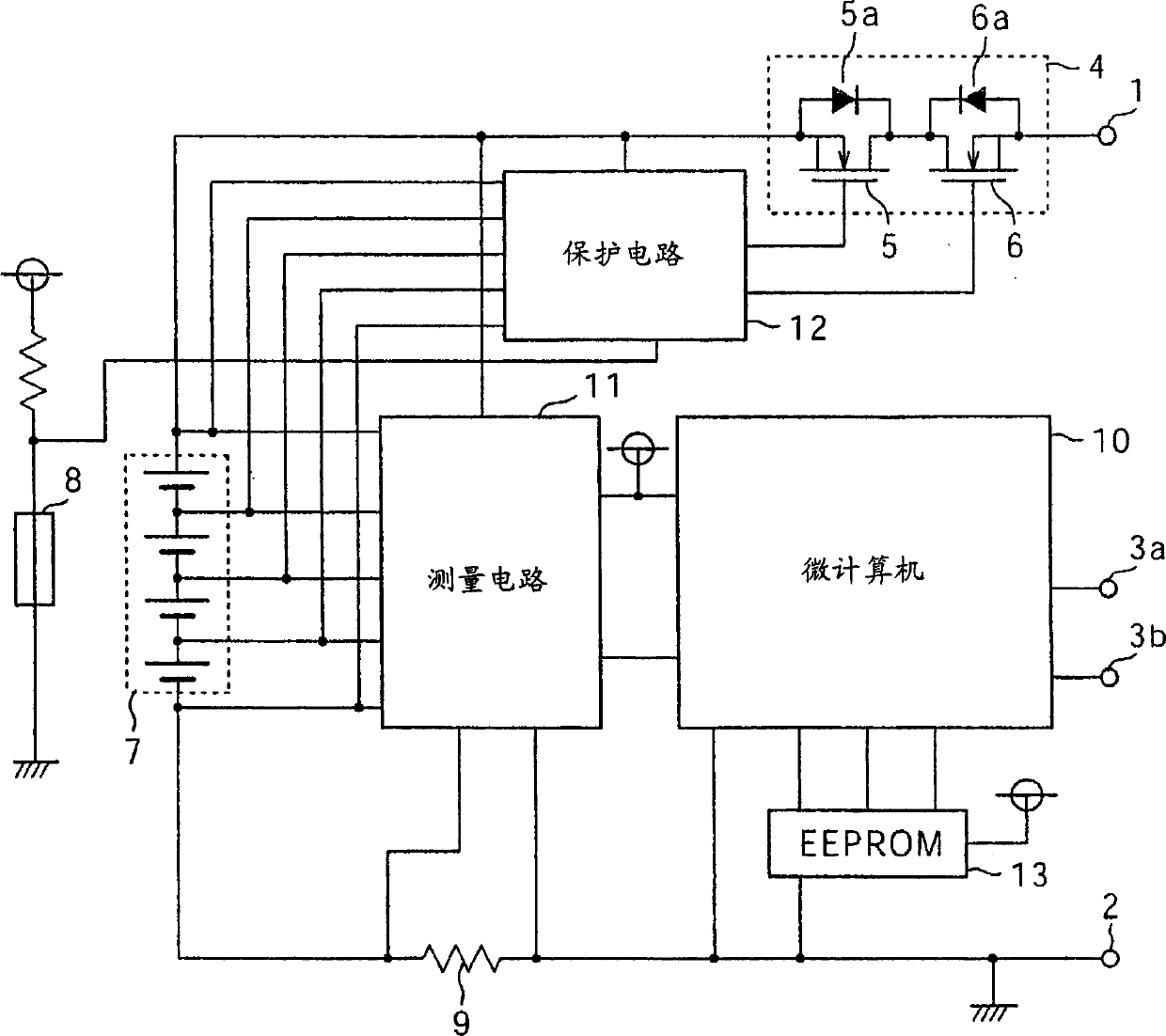

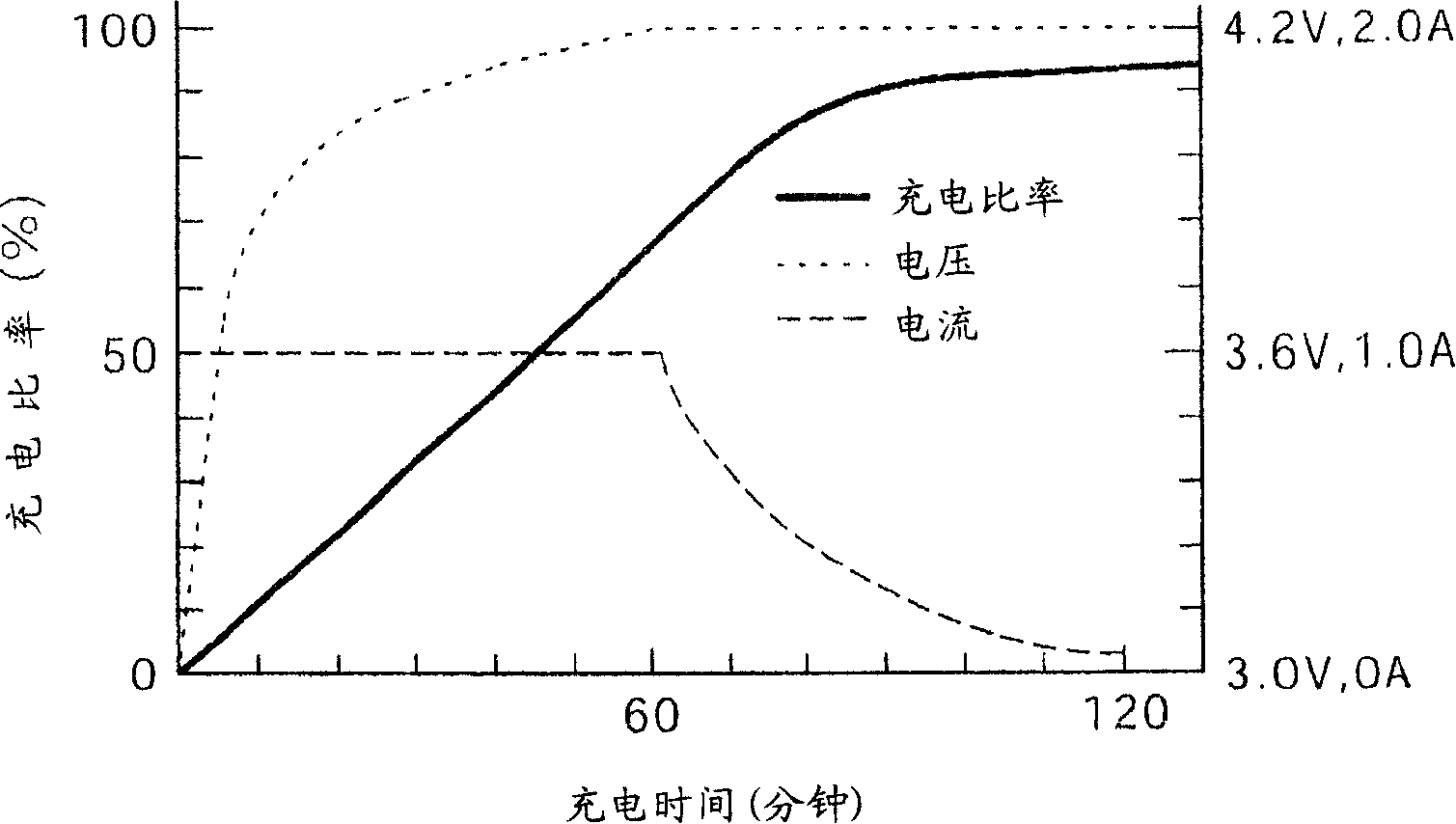

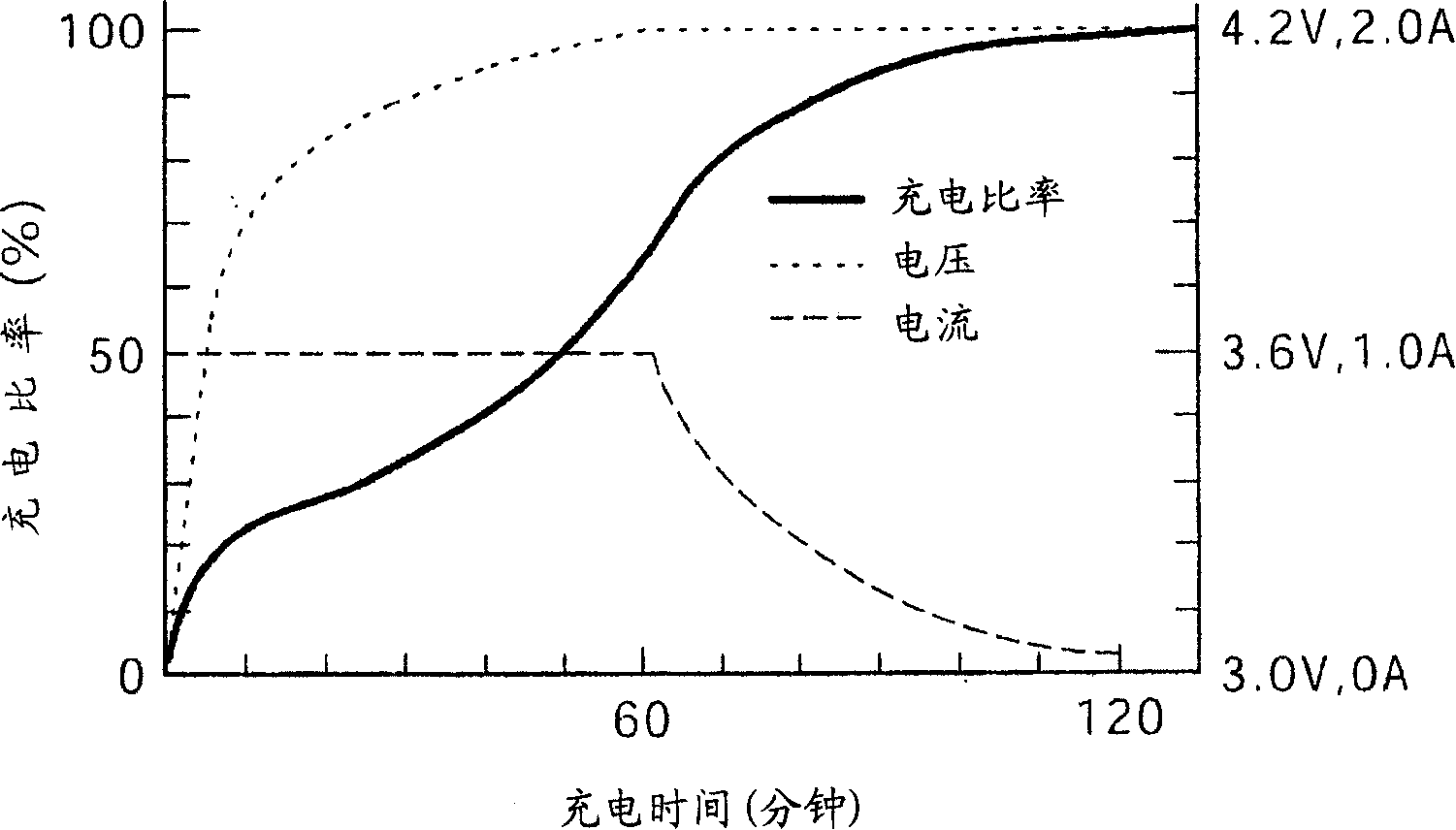

Method of charging secondary battery, method of calculating remaining capacity rate of secondary battery, and battery pack

ActiveCN1691461AAccurate detectionBatteries circuit arrangementsSecondary cells charging/dischargingCharge detectionCharge rate

PROBLEM TO BE SOLVED: To correctly detect full charge by further accurately measuring a charging capacity, in a charging method for a secondary battery obtained by combining an integration method and a voltage method that have conventionally been used.SOLUTION: The charging capacity (charging rate) is calculated by the integration method (current integration or power integration) from the start of charging to the vicinity of the full charge. The charging capacity is gradually shifted to a value calculated by the voltage method by adding thereto values obtained by both the calculation methods in accordance with a proportion multiplied by a voltage-method reliability coefficient by using a coefficient being a voltage-method reliability when the charging capacity reaches the vicinity of the full charging, and the integration method calculated value can be switched to the voltage method calculated value without an uncomfortable feeling, thus performing the correct full charge detection (charging rate calculation).

Owner:MURATA MFG CO LTD

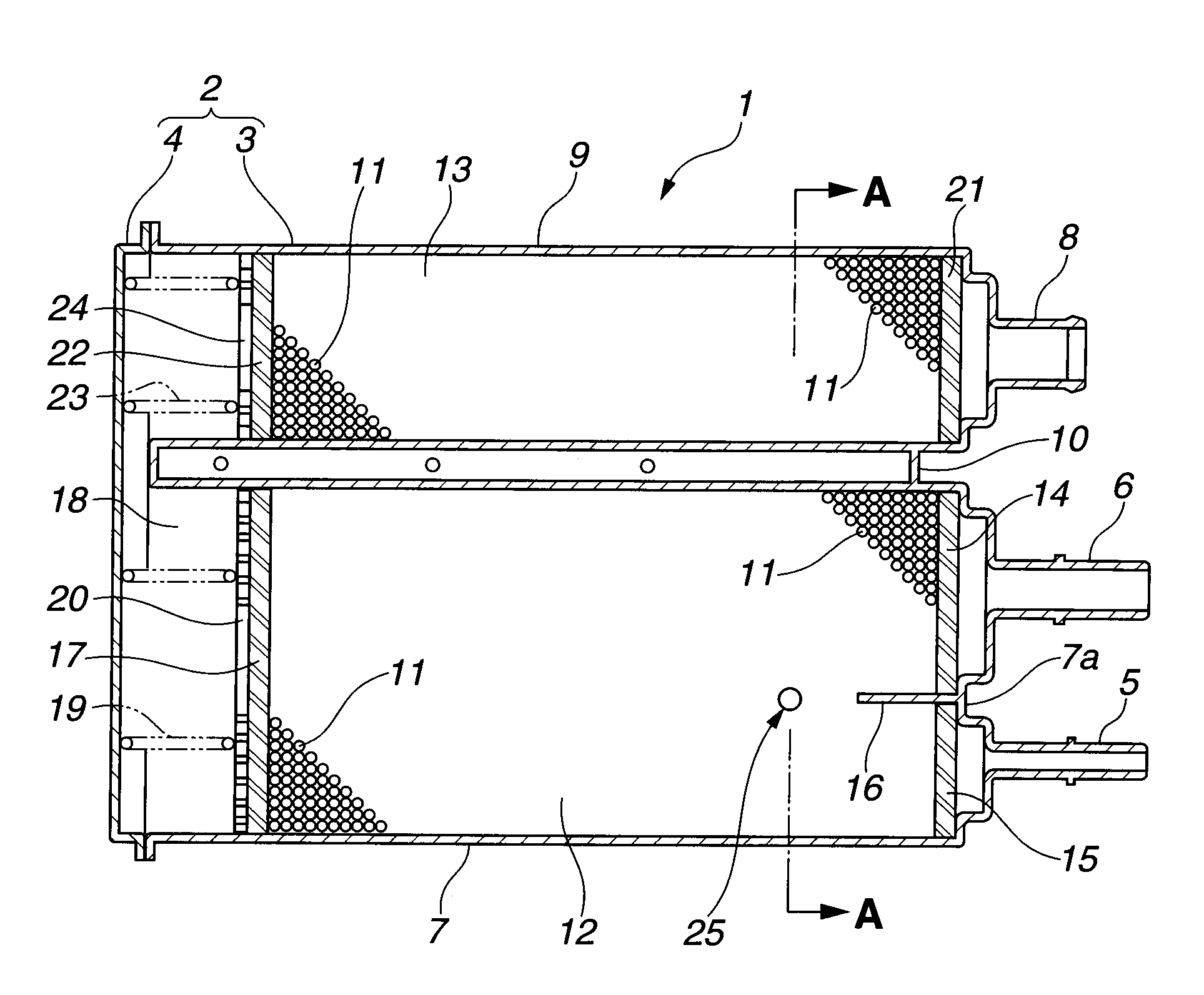

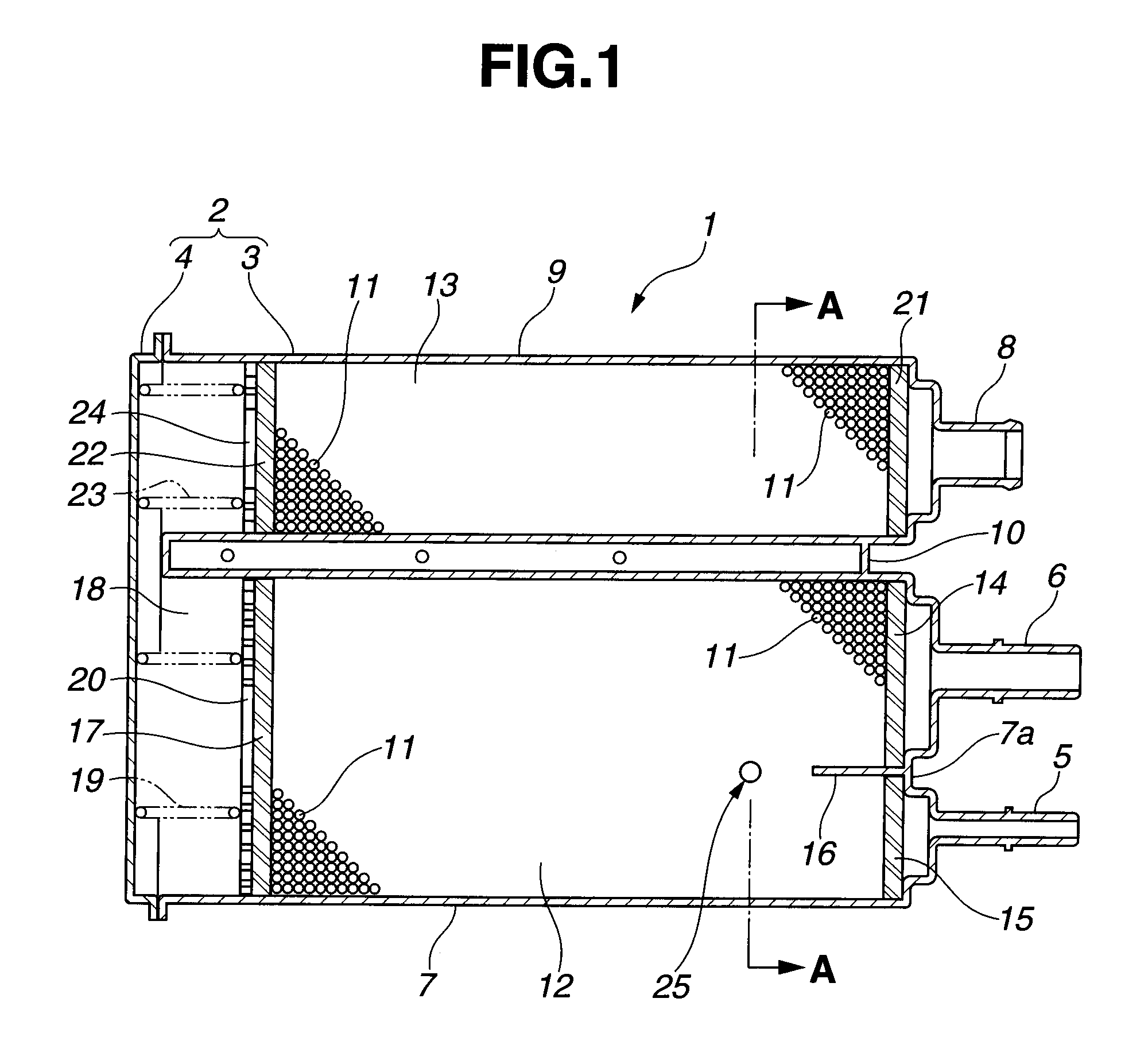

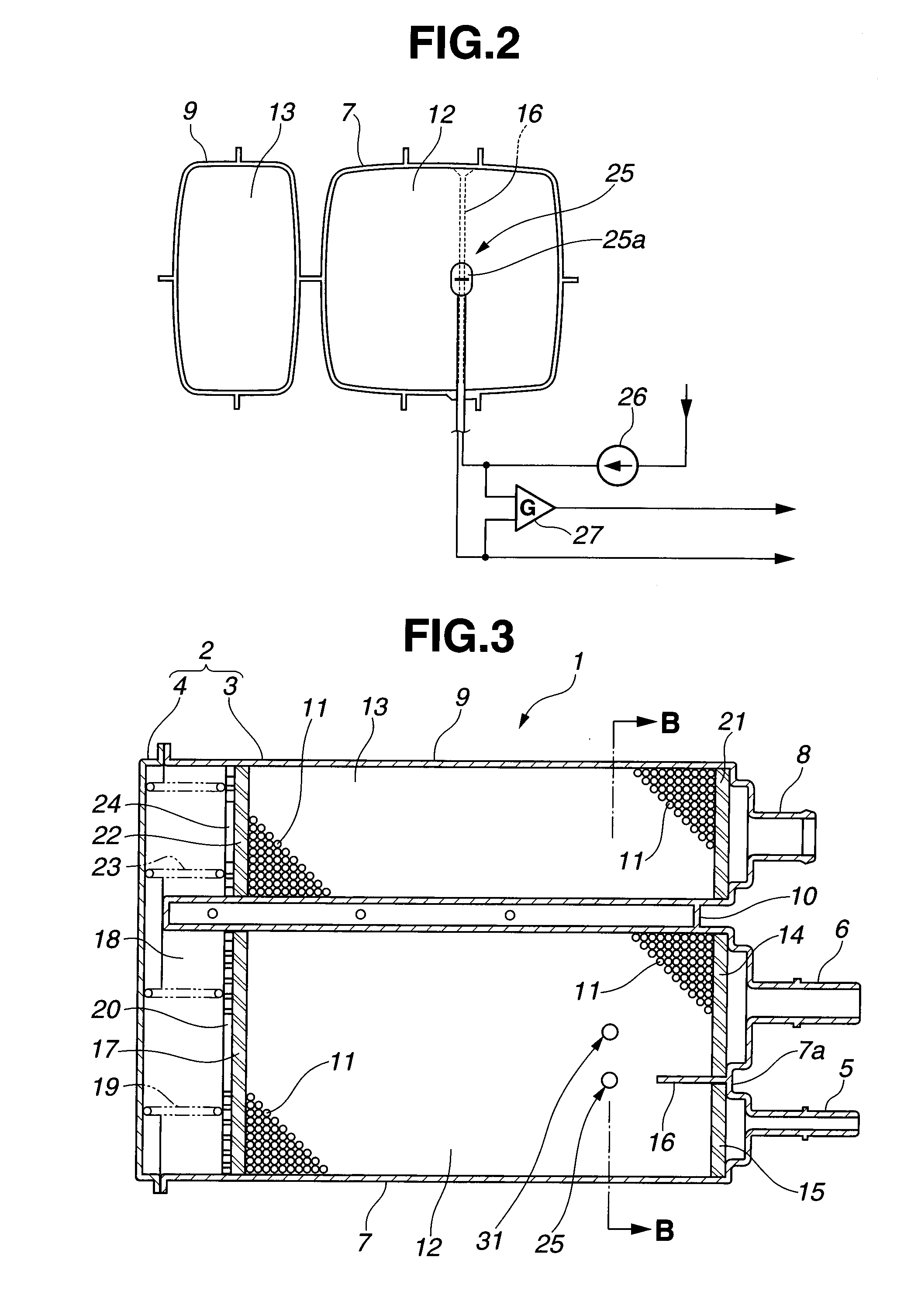

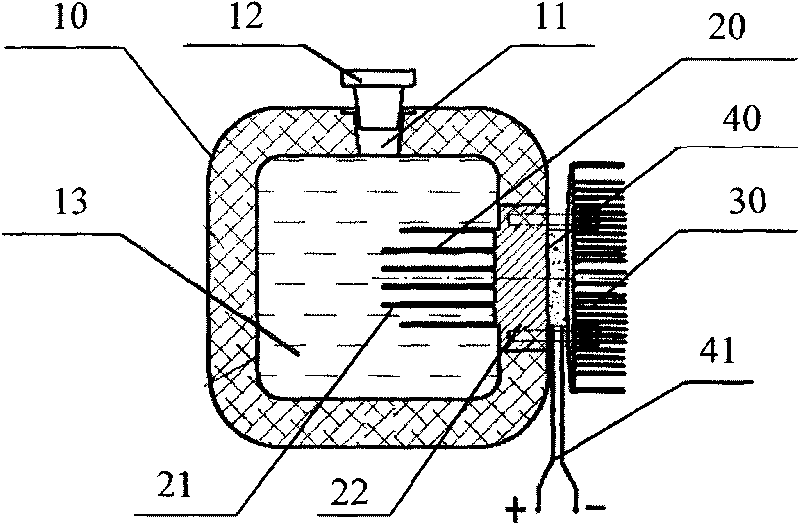

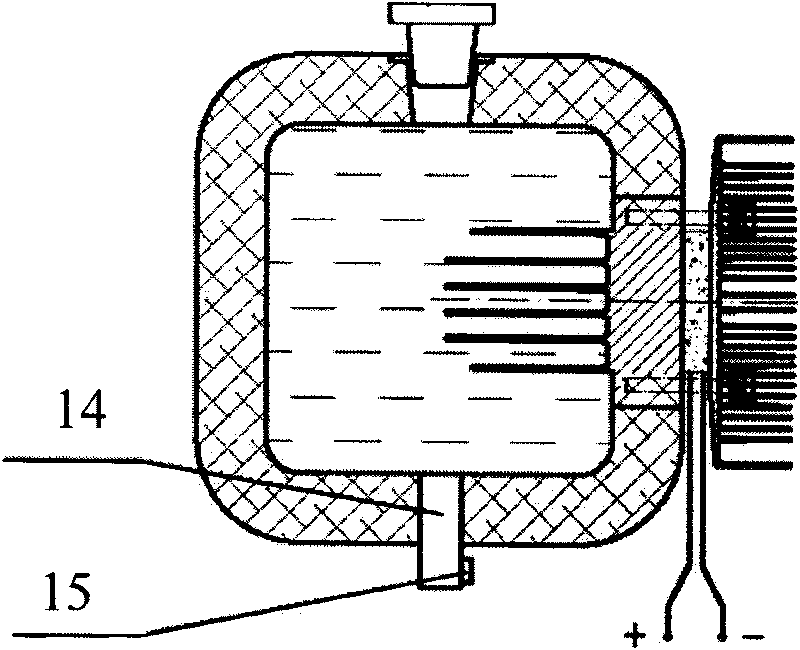

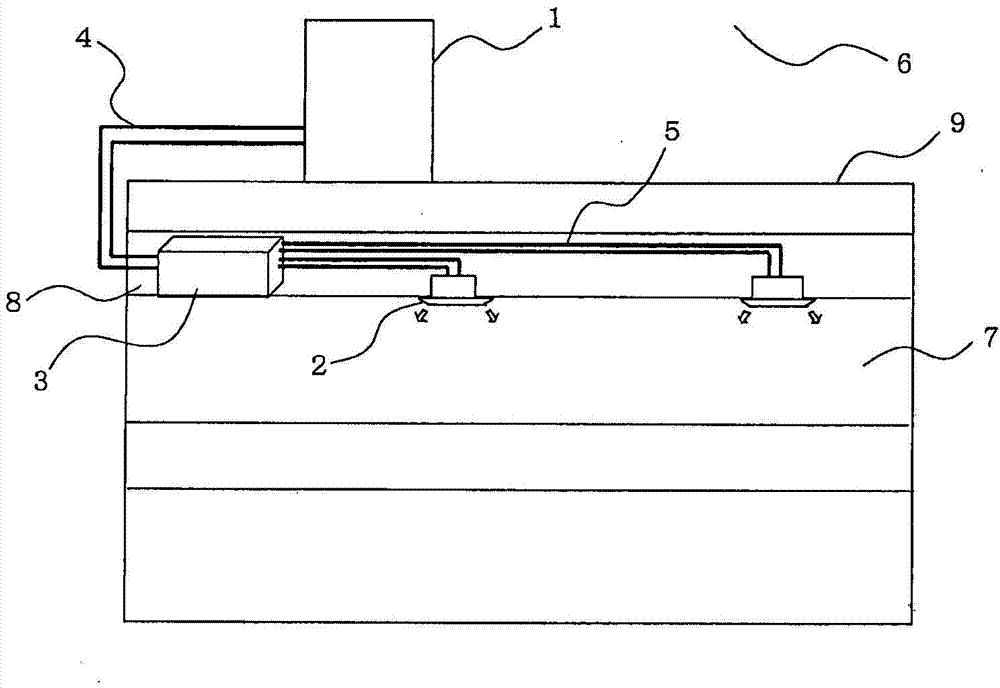

Heat storage unit and manufacturing method therefor

InactiveUS7156155B2Reduce heating capacityReduce heatHeat storage plantsRegenerative heat exchangersVolume variationHeat storage material

As a heat storage unit wherein, the volume variation of a heat storage material can be absorbed without an accompanying decrease in heat capacity, decrease in heat transfer coefficient, and oxidation and deterioration of the heat storage material due to oxygen in the air, so that the heat storage capacity can be adequately maintained and high performance can be attained, and moreover, the number of parts and the cost can be reduced, there is provided on the outside of a main member having; a fluid passage formation section which forms a fluid passage for circulating a fluid introduced from an inlet, on the inside of an outer wall section, and a heat storage material filling space formation section which forms a heat storage material filling space for filling with a heat storage material for which the volume varies corresponding to the heat storage condition, adjacent to the fluid passage, a passage switching section which selectively switches a flow-in destination of a fluid introduced from the inlet by the position of a travelling member which travels due to the volume variation of the heat storage material, to the fluid passage or to a bypass passage which bypasses the fluid passage to discharge the fluid.

Owner:HONDA MOTOR CO LTD

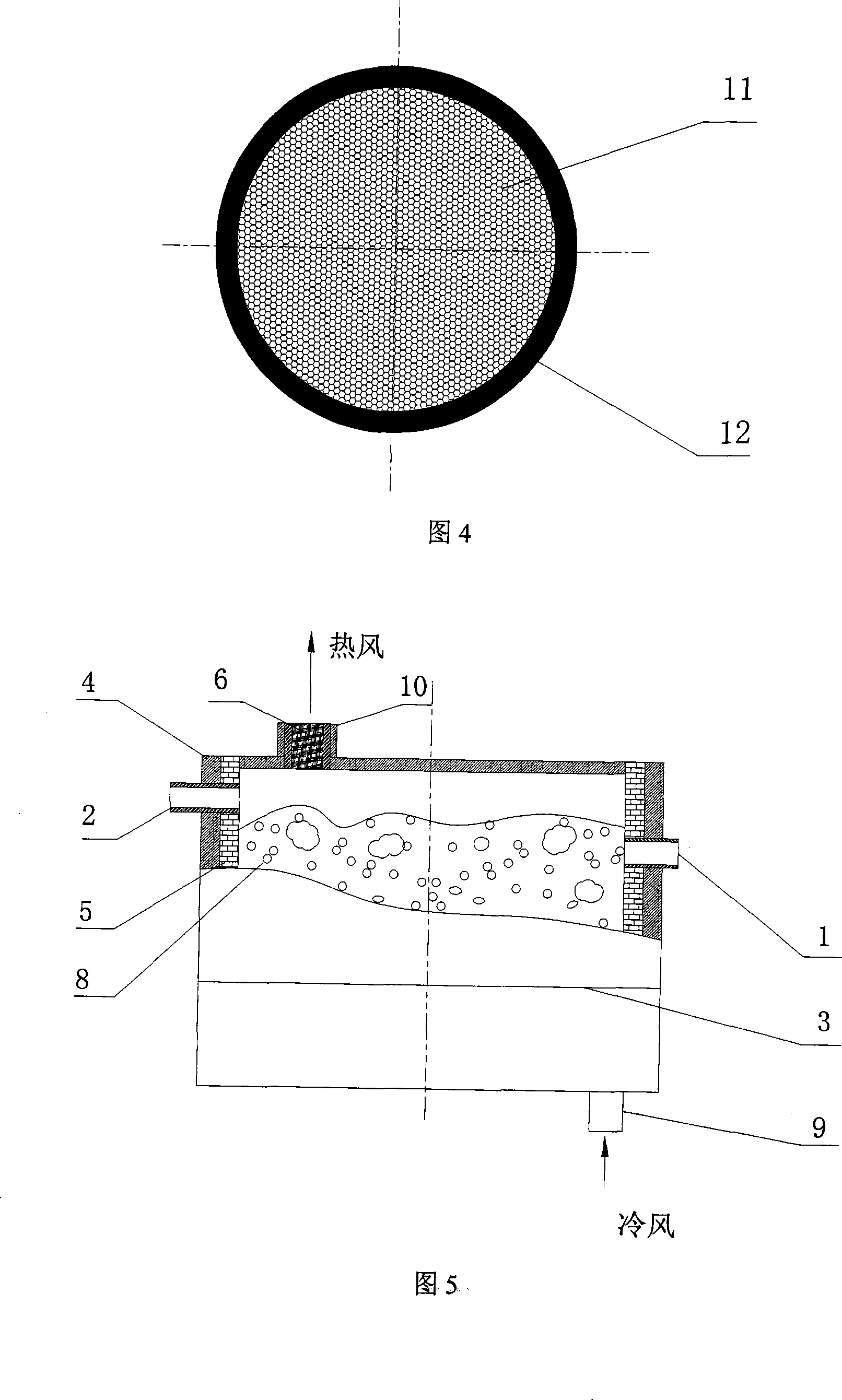

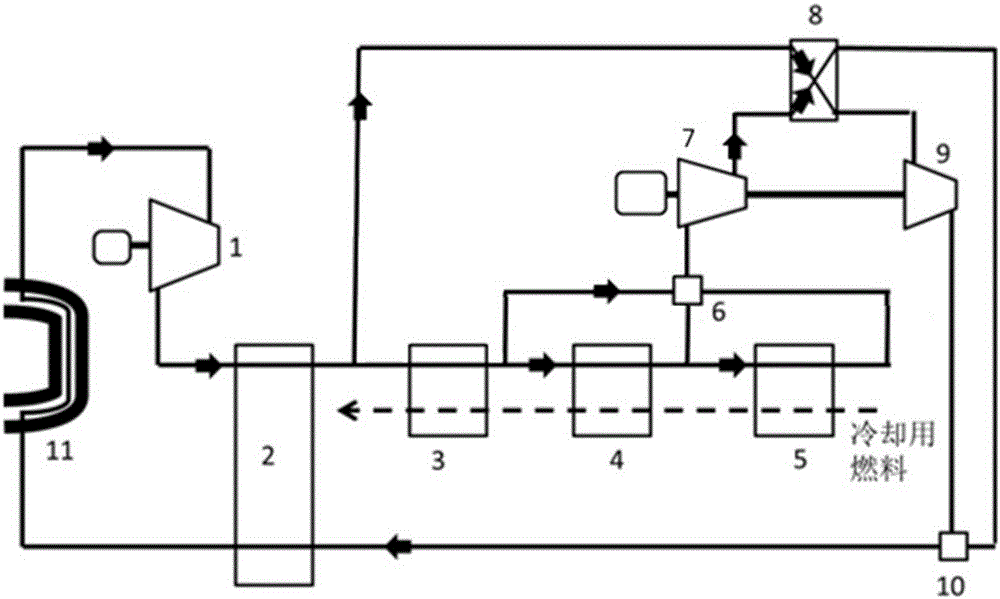

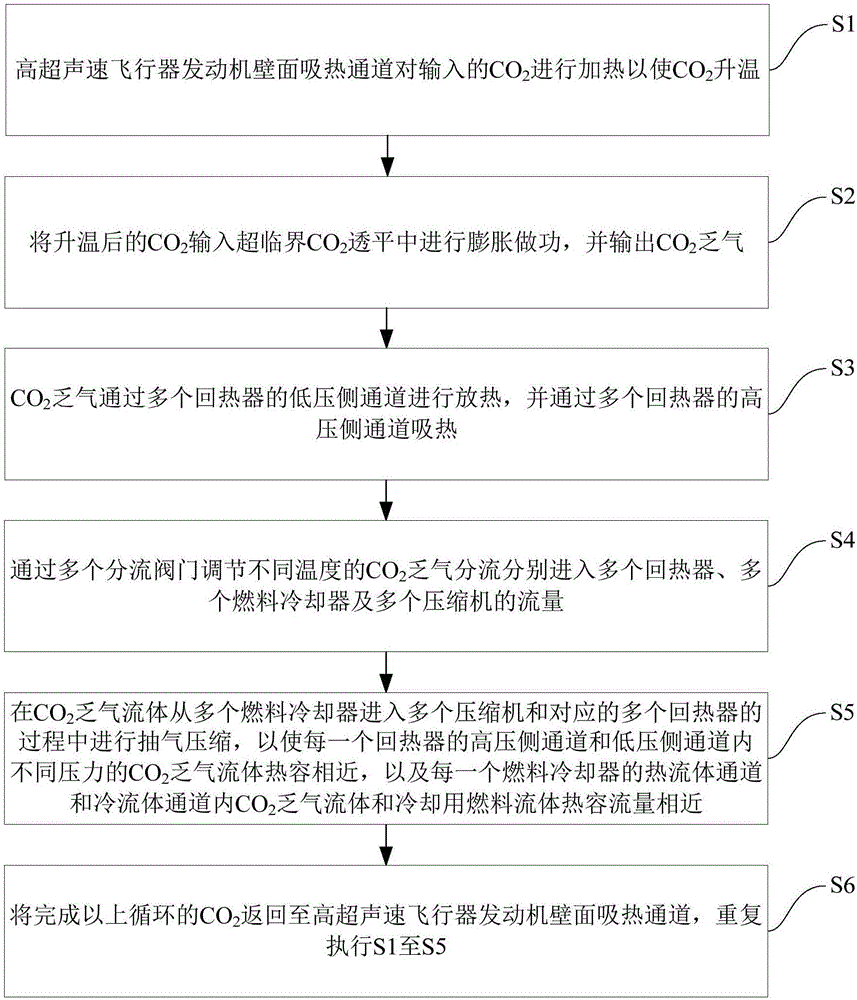

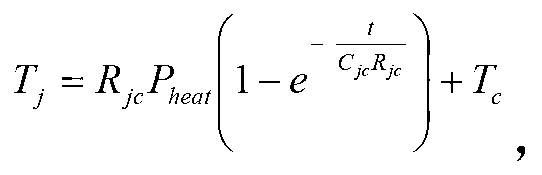

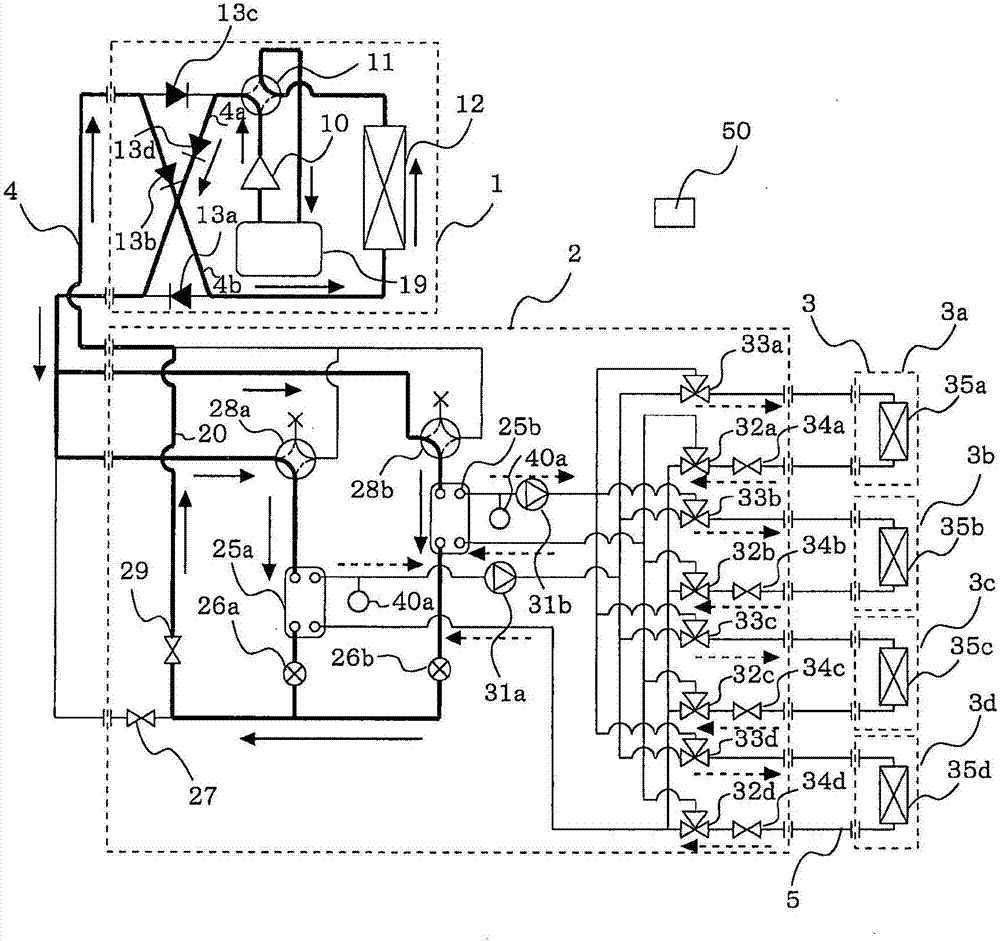

Hypersonic flight vehicle engine heat recovery power generation system and control method thereof

ActiveCN106640242AEfficient conversionFully recycleEngine fuctionsTurbine/propulsion engine coolingEngineeringHigh pressure

The invention provides a hypersonic flight vehicle engine heat recovery power generation system and a control method thereof. CO2 is heated in a hypersonic flight vehicle engine wall face heat absorption channel to enter a supercritical CO2 turbine to swell to act, output CO2 exhaust air releases heat through low-pressure side channels of multiple heat regenerators and absorbs heat through high-pressure side channels, air exhaust compression is carried out in the process that CO2 exhaust air fluid enters multiple compressors and the corresponding heat regenerators from multiple fuel coolers, the heat capacities of different-pressure CO2 exhaust air fluid in the high-pressure side channel and the low-pressure side channel of each heat regenerator are close, and the heat capacity of the CO2 exhaust air fluid in a heat fluid channel and a cold fluid channel of each fuel cooler and the heat capacity of fuel fluid for cooling are close. By means of the hypersonic flight vehicle engine heat recovery power generation system and the control method, the heat of the engine wall face can be efficiently converted into electric energy and compressor power; and meanwhile, the heat recovery rate is improved, the amount of fuel for cooling is reduced, and cost is saved.

Owner:TSINGHUA UNIV

Purge gas concentration estimation apparatus

InactiveUS8099999B2Accurate concentrationInternal-combustion engine testingNon-fuel substance addition to fuelEngineeringProduct gas

A purge gas concentration estimation apparatus has a canister having a casing that is filled with adsorbent which adsorbs and desorbs evaporated fuel and a heat capacity detection device that is disposed in the casing. The heat capacity detection device detects a heat capacity of an inside of the casing. An adsorption amount of the evaporated fuel that is adsorbed in the casing is detected from the heat capacity of the inside of the casing detected by the heat capacity detection device, and a purge gas concentration is estimated from the detected adsorption amount of the evaporated fuel.

Owner:MAHLE FILTER SYST JAPAN CORP

Three-dimensional printer, three-dimensional image forming method, and three-dimensional image

When a heat capacity of a recording medium having a base material coated with a foamable resin layer is larger than a normal heat capacity, to form a raised amount equal to that with the normal case with a normal heating quantity, a turned mirror image of the image is generated. The image is transferred onto the front face of the recording medium and fixed. The recording medium is reversed, and conveyed again to the transfer part. The turned mirror image is transferred onto the rear face of the recording medium and fixed. The recording medium is heated with the heat quantity equal to that in the normal case, and combination of heat absorbed by the turned minor image and heat absorbed by the image is transmitted to the foamable resin layer to expand the foamable resin layer.

Owner:CASIO COMPUTER CO LTD

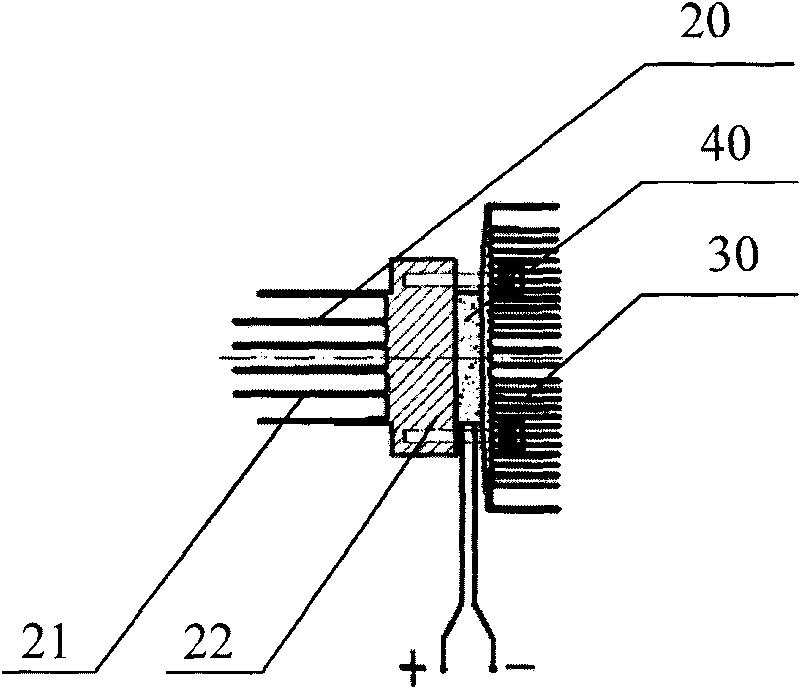

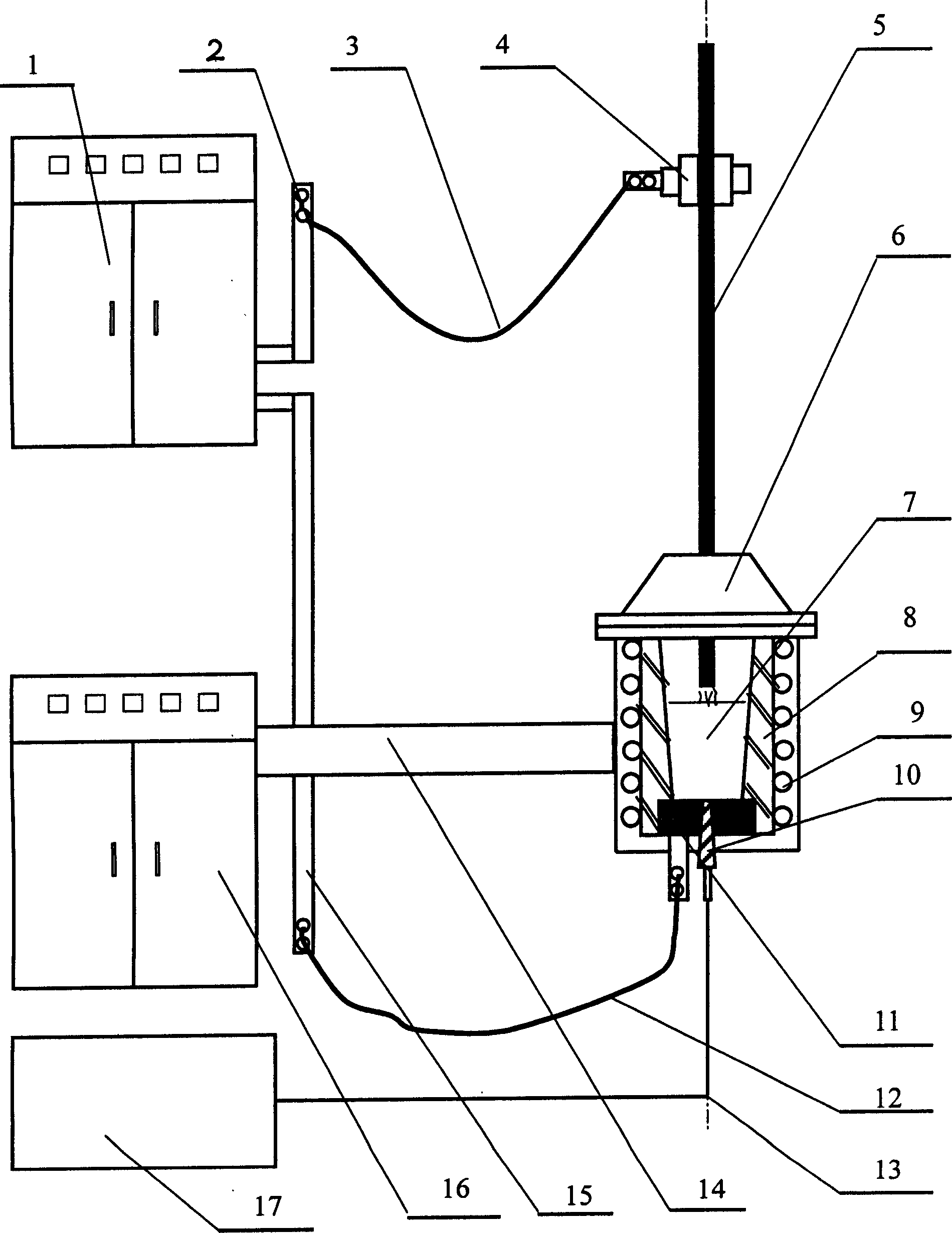

Semiconductor temperature difference power generation device

ActiveCN101728994ARealize temperature difference power generationAchieve continuous power generationGenerators/motorsEngineeringTemperature difference

The invention provides a semiconductor temperature difference power generation device which comprises a heat absorber, a heat radiator and a semiconductor power generation chip, wherein the heat absorber comprises a heat absorbing part and a heat transfer part, and the heat absorbing part is used for being in contact with a liquid heat source to absorb heat from the liquid heat source; the heat transfer part is used for conducting heat absorbed by the absorbing part; the heat radiator is positioned outside the liquid heat source and arranged on the heat transfer part of the heat absorber; thesemiconductor power generation chip is positioned between the heat transfer part of the heat absorber and the heat radiator, the heat end of the semiconductor power generation chip is connected with the heat transfer part, and the cold end of the semiconductor power generation chip is connected with the heat radiator. The device stores a plurality of energy in the liquid by adopting high-temperature liquid as the heat source through the heat capacity of the high-temperature liquid to realize temperature difference power generation, thereby realizing continuous power generation.

Owner:GUANGDONG FUXIN ELECTRONICS TECH

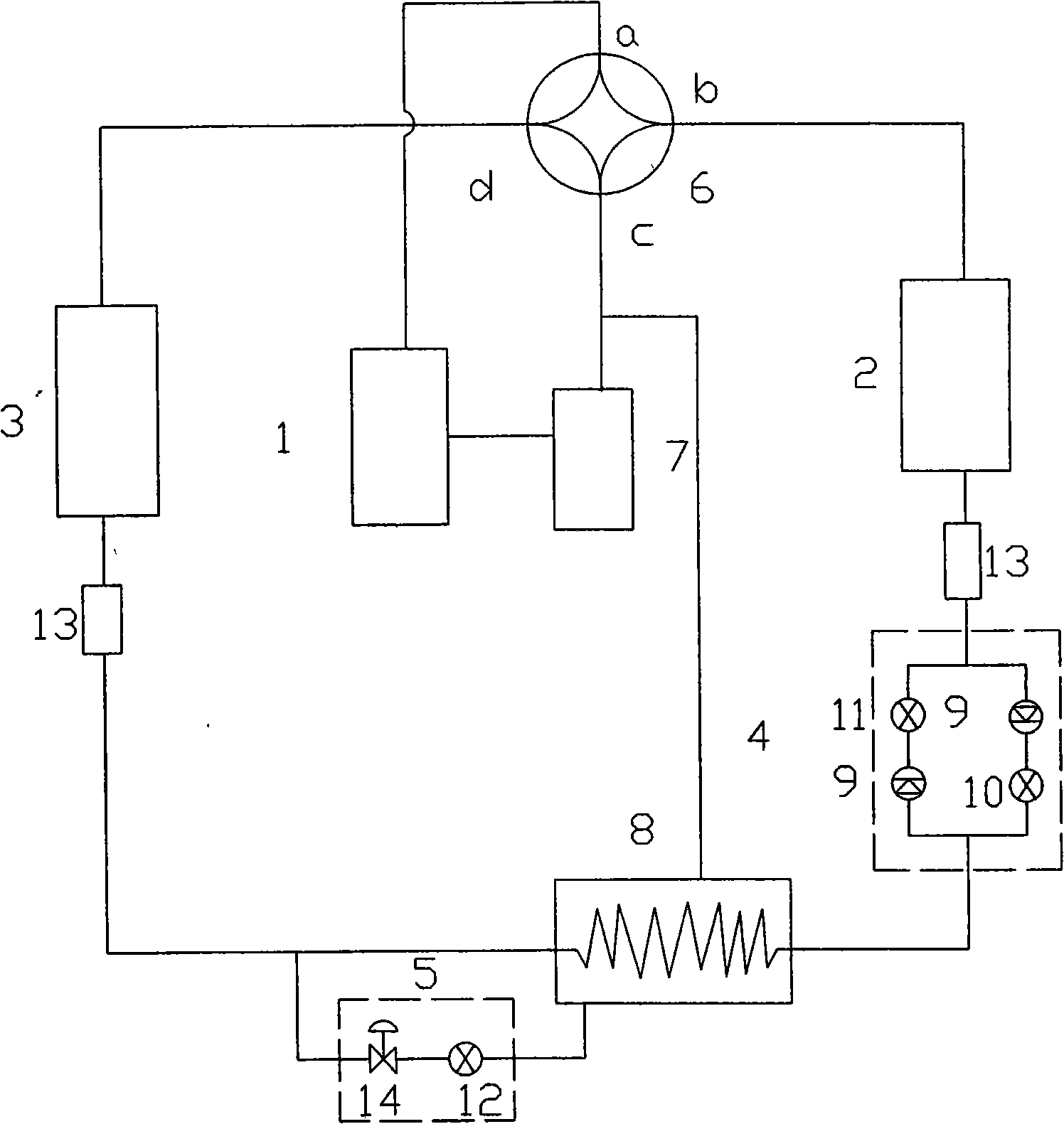

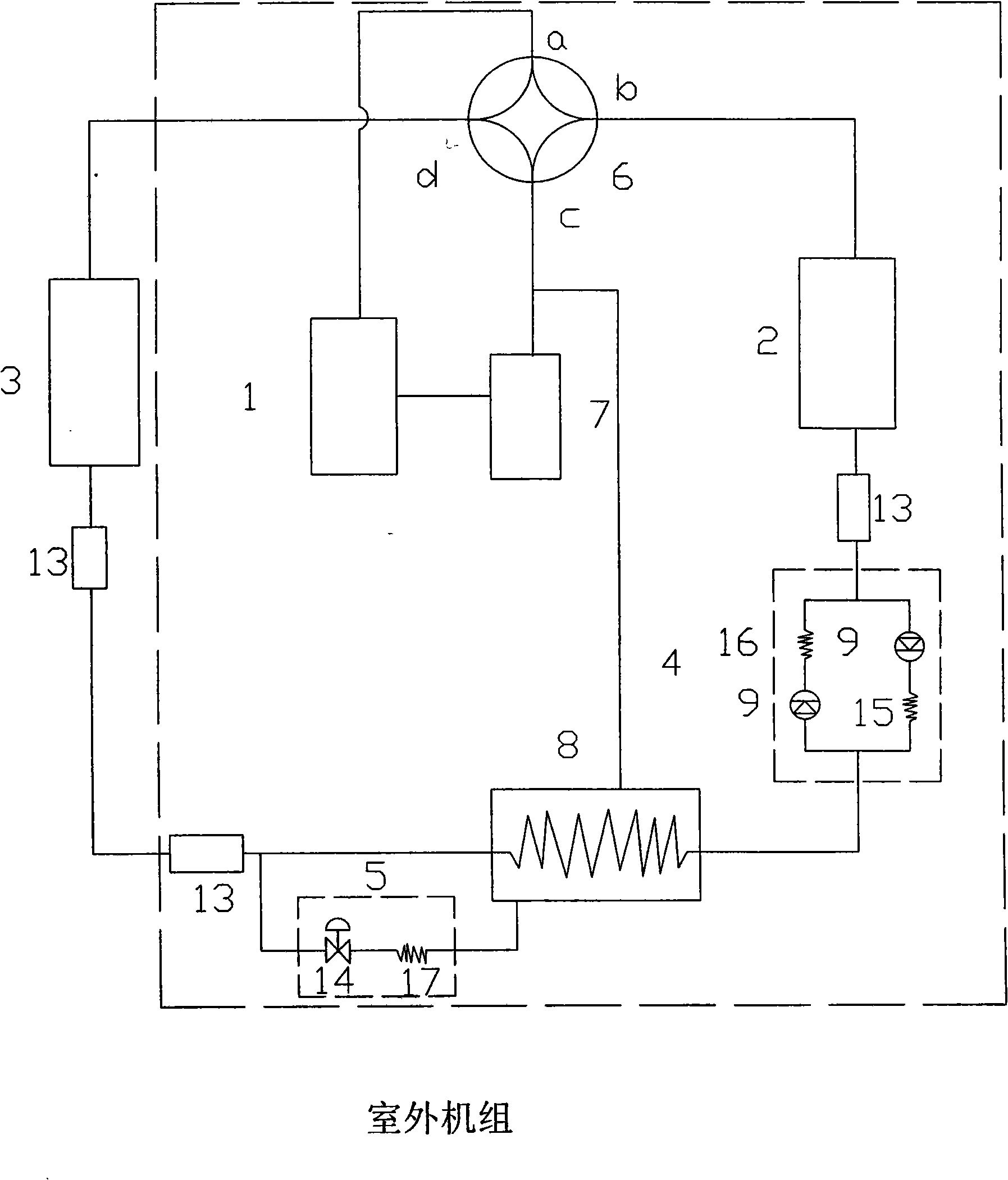

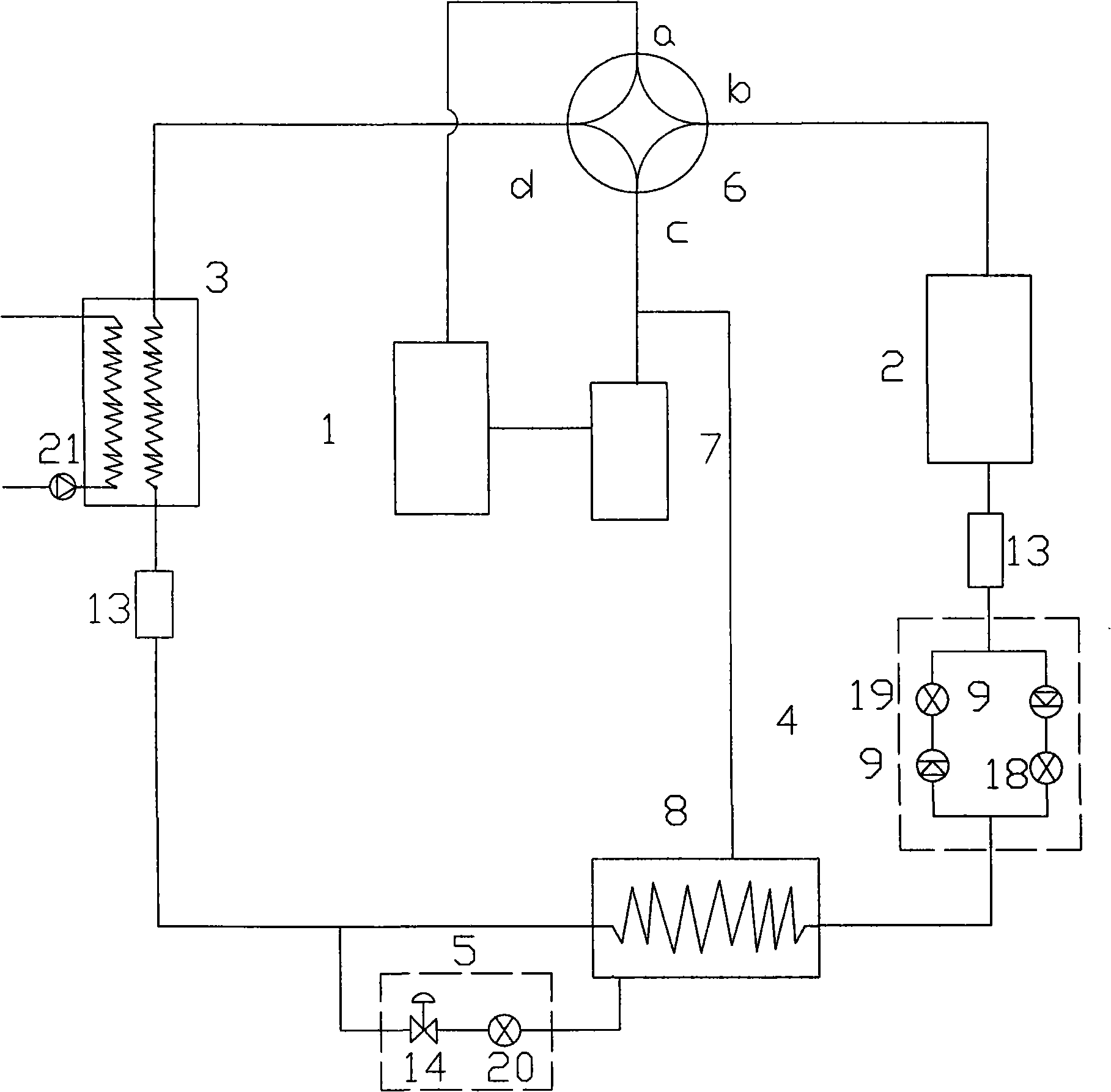

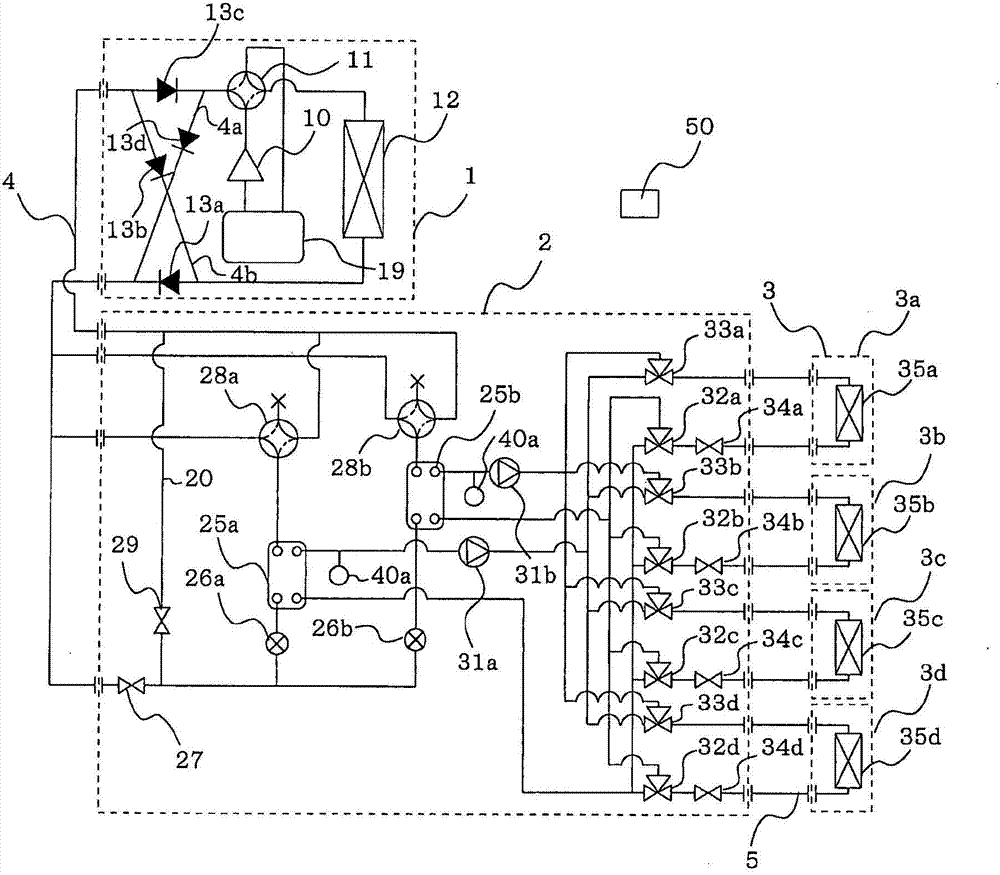

Low temperature heat pump air conditioning system

InactiveCN101493269AIncrease inspiratory capacityReduce the compression ratioFluid circulation arrangementCompression machines with reversible cycleFour-way valveIntercooler

The invention relates to a low temperature heat pump air conditioning system, consisting of a compressor, an electromagnetic four-way valve, an outdoor heat exchanger, a throttle mechanism, a super cooling intercooler, an indoor heat exchanger and a gas-liquid separator. In the invention, an air supply device for the super cooling intercooler is provided, when heating is carried out under the low temperature working condition, the super cooling intercooler is used for supplementing the compressor with medium pressured saturated refrigerant gas to increase the super cooling degree of the refrigerant in the main circulation and simultaneously increase inspiration capacity of the compressor so as to enhance the mass flux of the refrigerant in the main circulation, thus heating capacity is increased and compression ratio and gas discharge temperature are decreased. The low temperature heat pump air conditioning system has the advantages of simple structure, easy manufacturing, low manufacturing cost, high efficiency, energy-saving, stable and reliable operation, etc.

Owner:林贤华

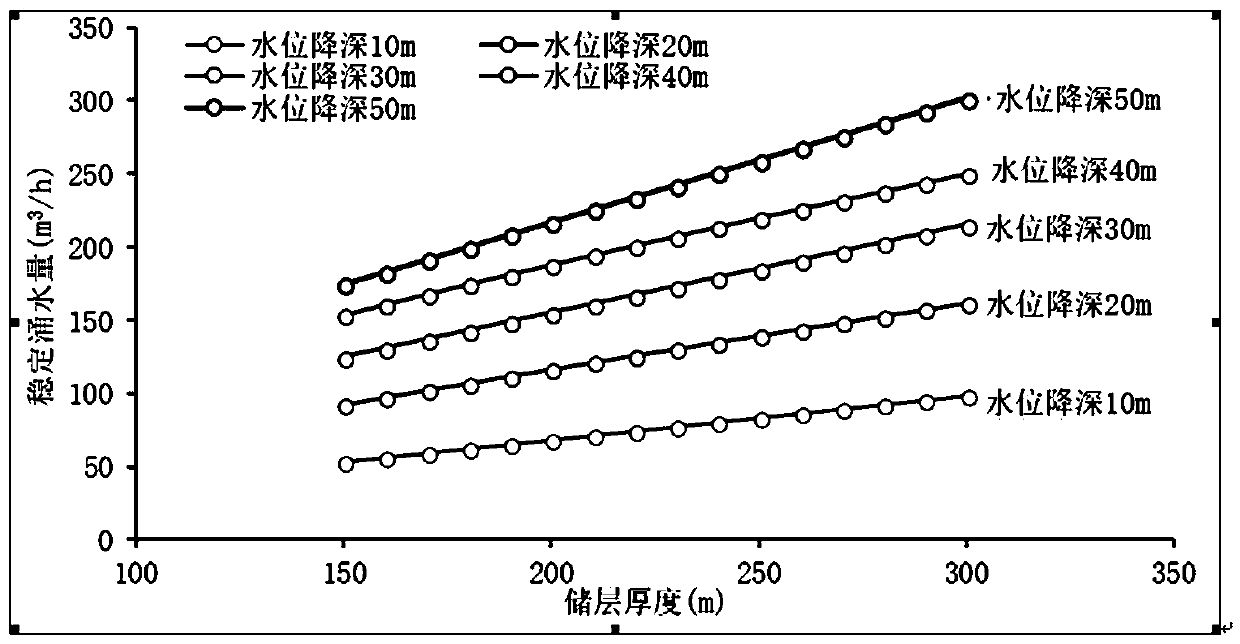

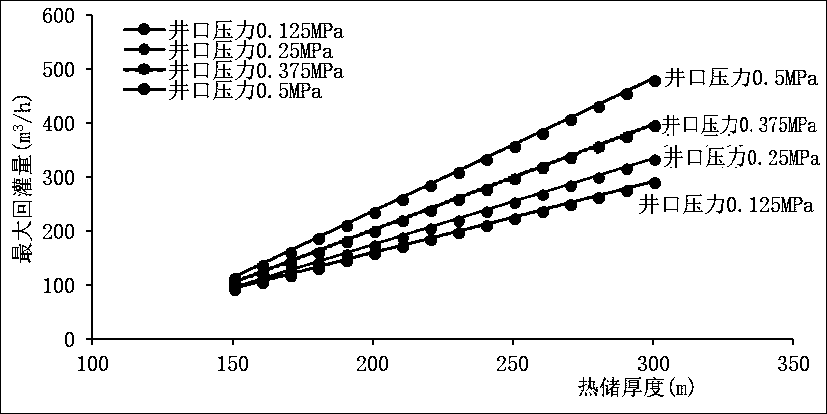

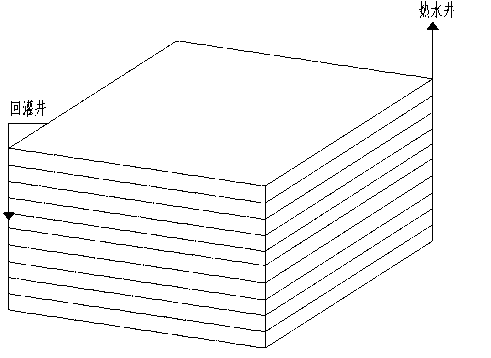

The invention discloses a tThermal storage engineering evaluation method for geothermal resources

PendingCN109614753AGuaranteed reliabilityEasy to operateDesign optimisation/simulationSpecial data processing applicationsOperabilityNumerical models

A thermal storage engineering evaluation method for geothermal resources comprises the following steps: 1) analyzing an existing geothermal well water pumping test report of a region according to water pumping test data; 2) establishing a research area terrestrial heat numerical model by utilizing the existing parameters; 3) simulating the maximum recharge quantity of the recharge well under different wellhead recharge pressure conditions by utilizing a numerical model, and determining the maximum recharge quantity of the recharge well in the region; 4) determining the optimal well distance ofthe geothermal well by utilizing the numerical model; 5) adopting a numerical simulation method to select a minimum mining and irrigation well distance; 6) flexibly selecting a well pattern form by combining the actual condition of the ground; 7) calculating the heat collection capacity per unit square kilometer according to the principle of combining the ground and the underground; T; the methodhas the advantages that the operability is high, t, the optimal mining and irrigation well distance and the optimal mining and irrigation amount are designed and optimized, parameters such as the reasonable water taking amount, t, the well distance, t, the recharge temperature and the heat capacity rate of the geothermal well are clear, and multiple methods such as a theoretical formula, an empirical formula and numerical simulation are comprehensively used.

Owner:SENUO TECH CO LTD

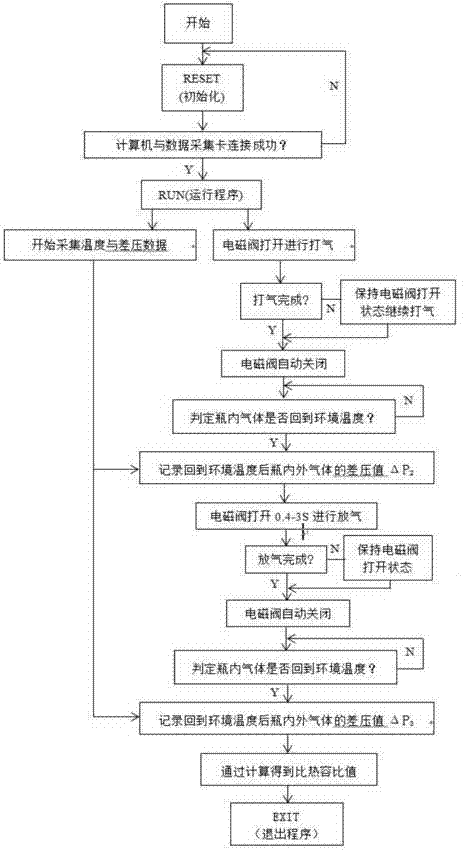

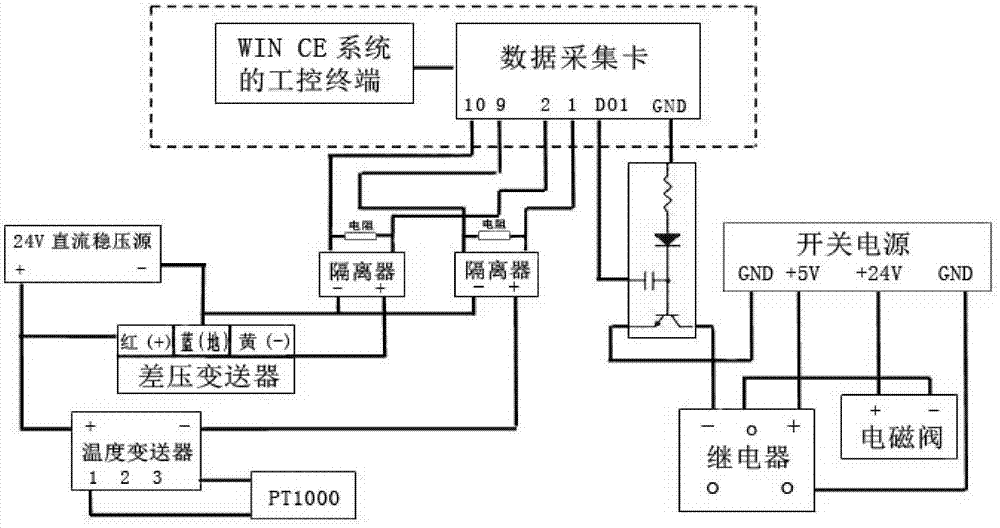

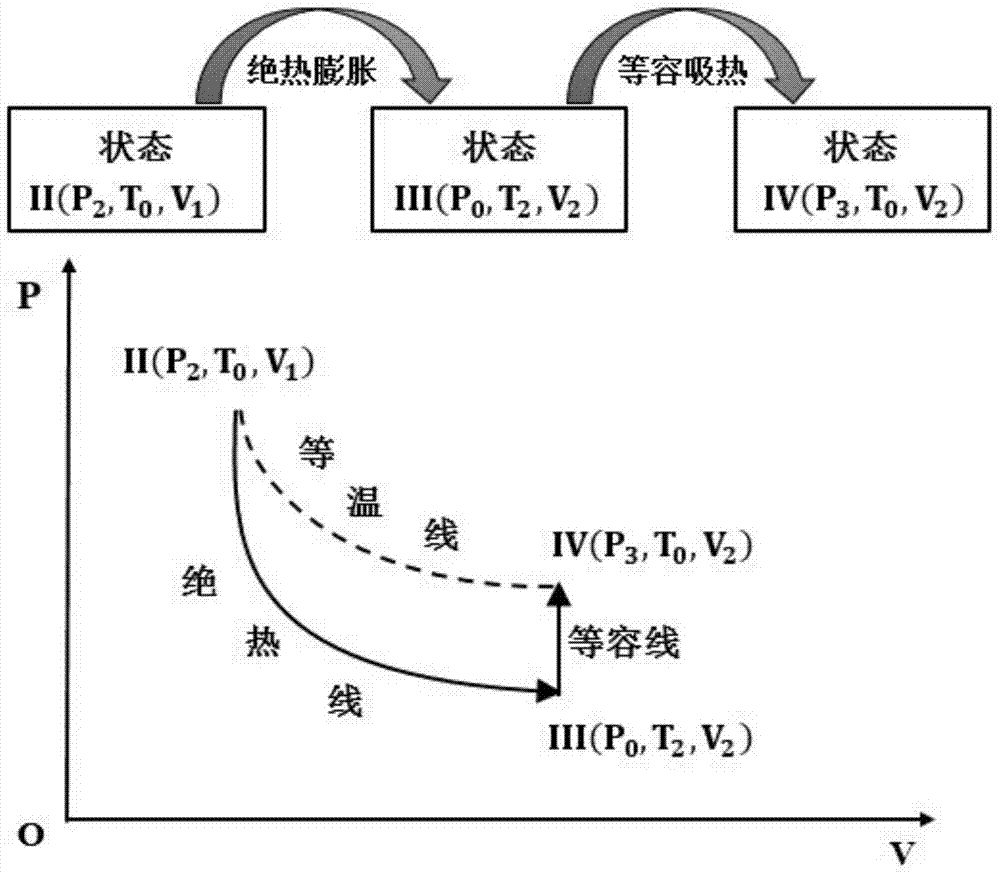

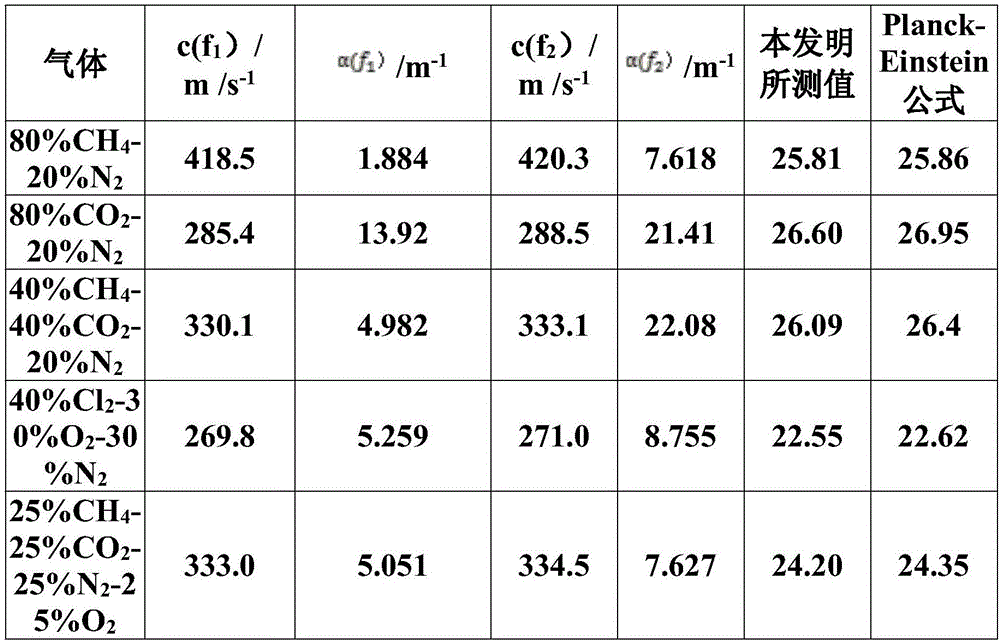

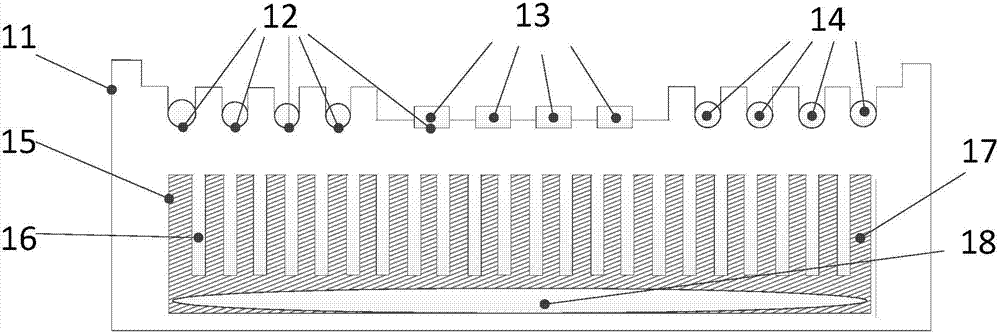

Intelligent tester and testing method for testing gas ratio and heat capacity ratio

ActiveCN104849309AIntuitive reflectionDeepen understandingMaterial heat developmentGas cylinderDifferential pressure

The invention provides an intelligent tester and a testing method for testing a gas ratio and a heat capacity ratio. The tester comprises a gas storage unit, a control unit and a gas injection unit, wherein the gas storage unit comprises a gas storage bottle, a sealing plug and a gas guide tube; the control unit comprises a differential pressure sensor, a temperature sensor, a data acquisition unit, an industrial control terminal, a touch screen, an electromagnetic valve, an electromagnetic valve control circuit and a power supply module; the sealing plug is mounted at an upper opening of the gas storage bottle; the signal acquisition ends of the differential pressure sensor and the temperature sensor are respectively inserted in the gas storage bottle and the signal output ends of the differential pressure sensor and the temperature sensor are respectively connected with the data acquisition unit; the data acquisition unit is connected with the industrial control terminal; the electromagnetic valve is arranged on the sealing plug of the gas storage bottle; the electromagnetic valve is connected with a data acquisition card by the electromagnetic valve control circuit. According to the invention, a sensor measurement technology is combined to improve a conventional adiabatic expansion method and measurement on a (reference to the specification) is carried out. An error caused by man-made judgment can be effectively avoided; data is recorded in real time, so that the thermotics process can be more visually reflected and the understanding of an experimenter is deepened.

Owner:NANJING UNIV OF TECH

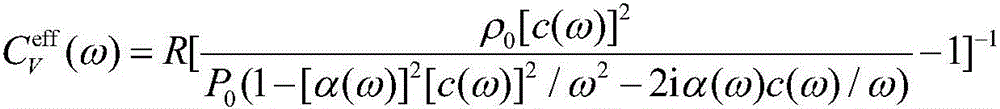

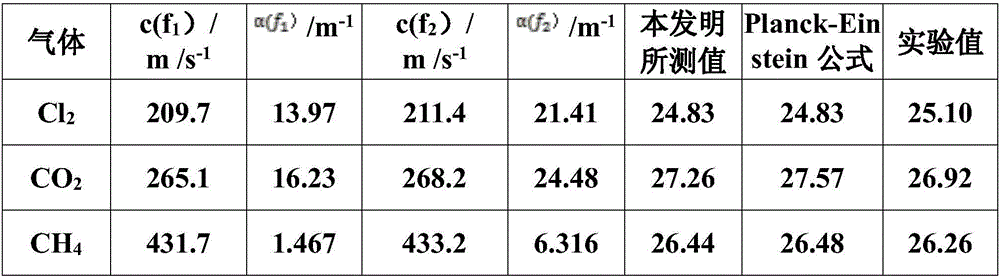

Method for two frequency point sound measurement of heat capacity of ideal gas

InactiveCN106706752AEliminate the effects ofAvoid systematic errorsMaterial analysis using sonic/ultrasonic/infrasonic wavesVelocity dispersionAcoustic wave

The invention discloses a method for two frequency point sound measurement of heat capacity of ideal gas. First two-frequency signals with sound frequencies being Omega1 and Omega2 respectively occur; the two-frequency signals are converted into mechanical sound waves respectively, transmission sound velocities c(Omega1) and c(Omega1) of the mechanical sound waves in an ideal gas medium and relaxation absorption coefficient Alpha(Omega1) and Alpha(Omega2) are respectively measured; according to the measured c(Omega1), c(Omega1), Alpha(Omega1) and Alpha(Omega2), effective heat capacities as shown in the descriptions are obtained by the formula as shown in the description, vibrational coupling molar heat capacities, as shown in the description, of the ideal gas are obtained by calculating the effective heat capacities as shown in the descriptions; and finally the heat capacity Cv of the ideal gas is obtained through a formula as shown in the description according to the vibrational coupling molar heat capacities. According to the measurement method, the influence of acoustic disturbance on gas heat capacity measurement results is effectively eliminated, and system errors generated in a conventional gas heat capacity acoustic measurement method due to sound velocity dispersion can be avoided.

Owner:GUIZHOU INST OF TECH

High-power optical fiber laser for anhydrous cooling heat capacity

ActiveCN103682964AReduce the potential threat of pollutionReduce complexityActive medium shape and constructionHeat conductingEngineering

The invention relates to a high-power fiber laser for anhydrous cooling heat capacity. Hollow structures, heat-conducting strips, filling phase-change materials and airbags are arranged inside a substrate, wherein the heat-conducting strips adopting a deep groove structure is arranged between the hollow structures, and the resilient airbags are placed under the hollow structures; the phase-change materials in the solid state and the liquid state are different in density; when the phase-change materials change from the solid state to the liquid state in the process of heat absorbing, the volume of the phase-change materials increases, and the airbag is compressed to provide an extra volume; when the phase-change materials change from the liquid state to solid state in the process of heat releasing, the volume of phase-change materials decreases, and the airbag is expanded to compensate the volume loss; in the process of the volume changing of phase-change materials, the volume is buffered to guarantee a good contact between the phase-change materials and a heat-conducting base. When the laser is in operation, the heat is transmitted to phase-change materials through the heat-conducting strips. After reaching the phase-change temperature, the materials change in phase and absorb a large amount of heat, so as to realize the temperature control of a laser cavity and a pump device.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

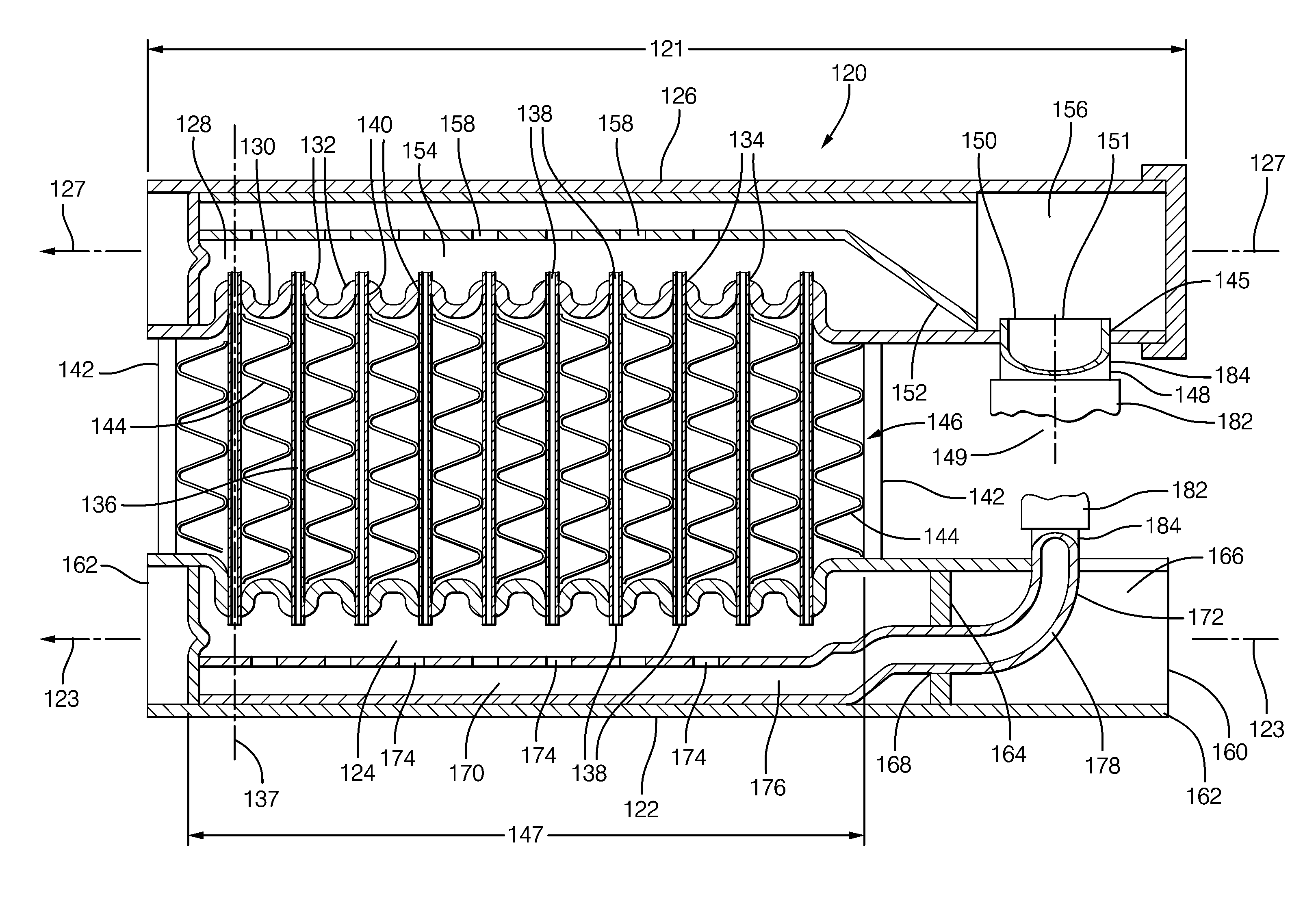

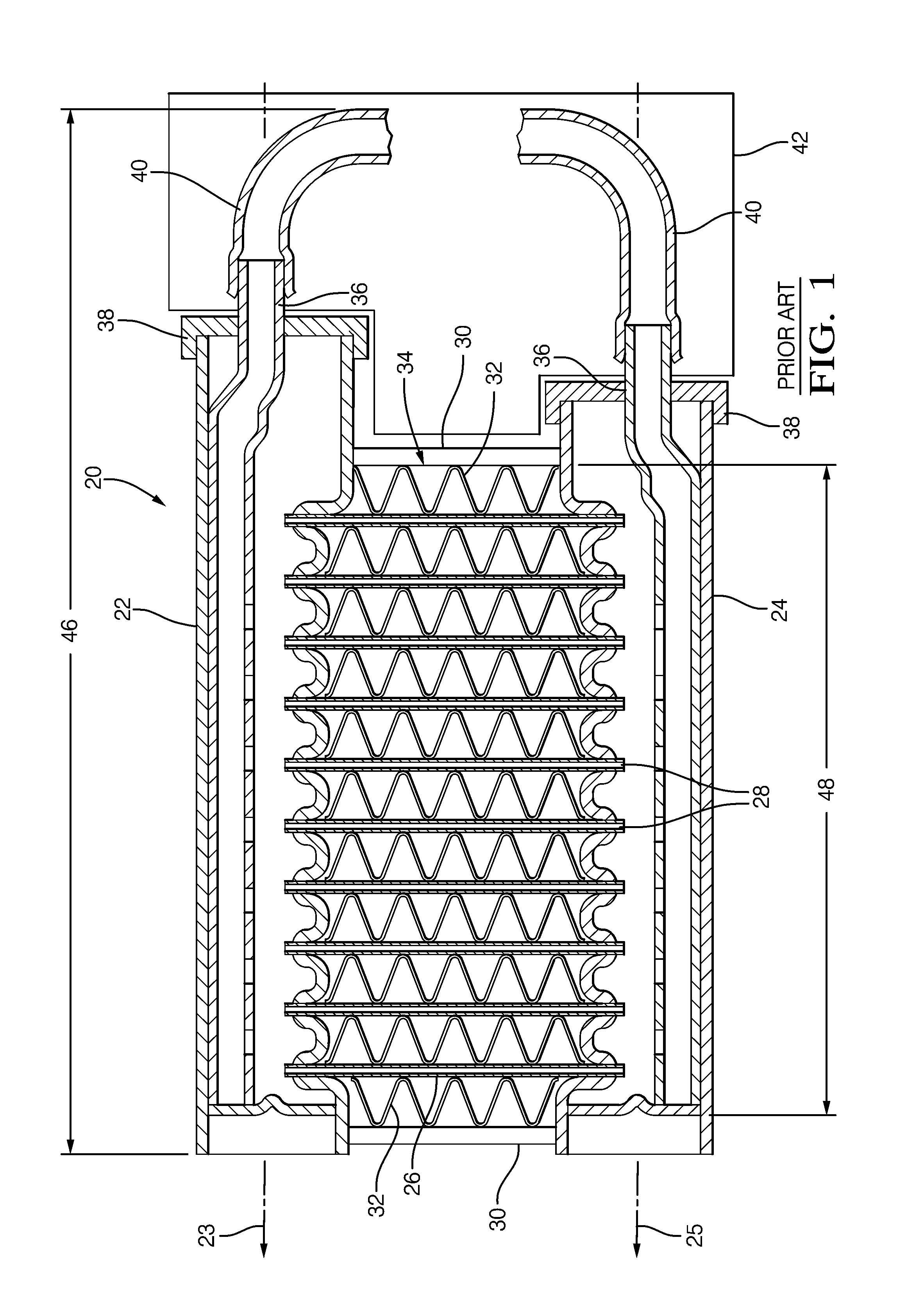

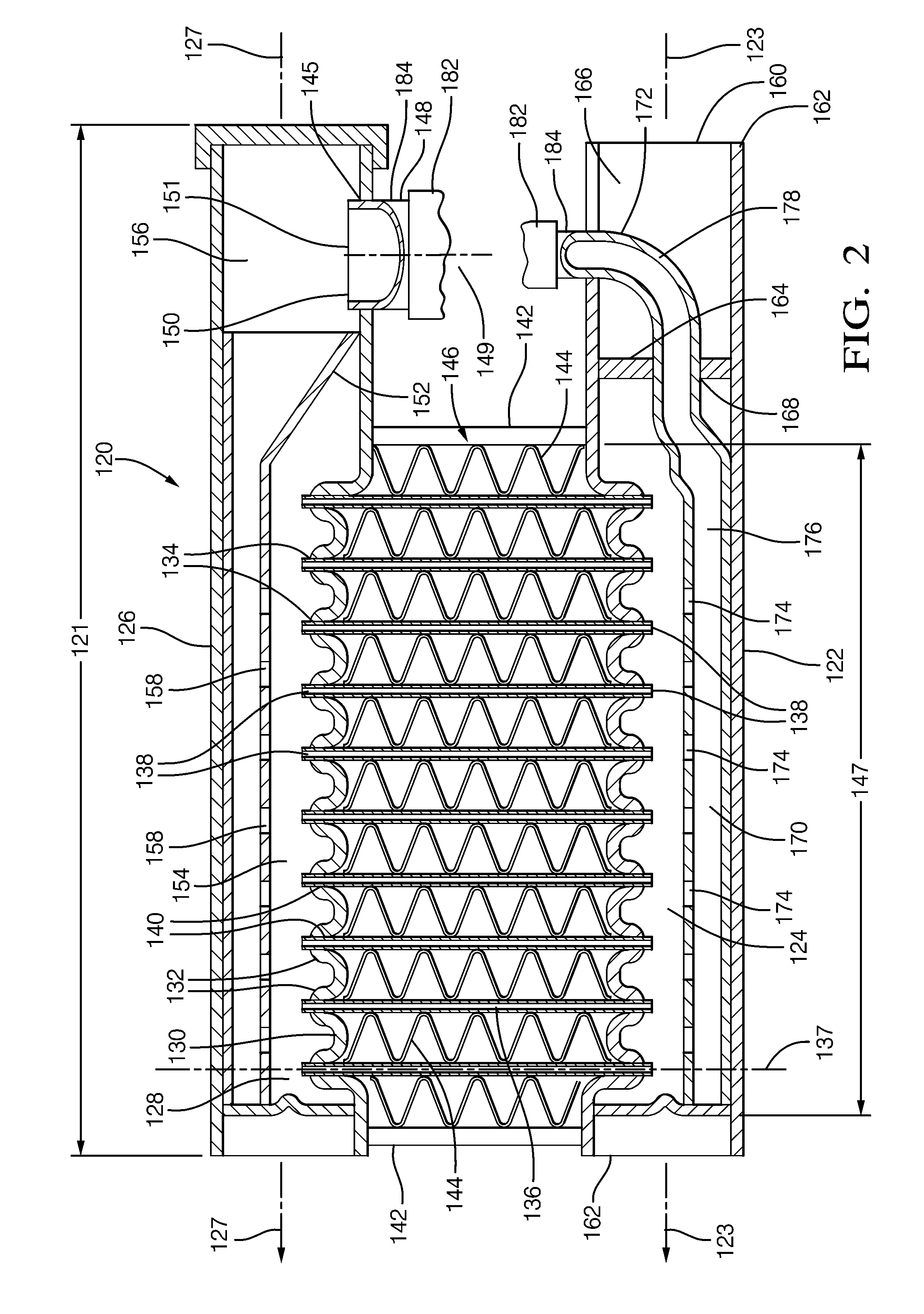

Heat exchanger assembly

InactiveUS8408284B2Stationary conduit assembliesHeat exchanger casingsRefrigerant distributionEngineering

A heat exchanger assembly that includes an outlet header / manifold defining an outlet cavity, an outlet tube in fluidic communication with the outlet cavity, and a heat exchanger core. The outlet tube and the outlet cavity cooperate to reduce a temperature value range across the heat exchanger core by equalizing refrigerant distribution between the refrigerant tubes within the heat exchanger core. The length of the heat exchanger headers / manifolds may be increased for a predetermined packaging width because the outlet tube and inlet conduit may exit the headers / manifolds perpendicularly rather than axially, allowing the heat exchanger core width to be increased. The increased heat exchanger core width allows additional refrigerant tubes to be included in the heat exchanger core, providing decreased air pressure difference for air flowing through the heat exchanger assembly and increased heat capacity of the heat exchanger assembly.

Owner:MAHLE INT GMBH

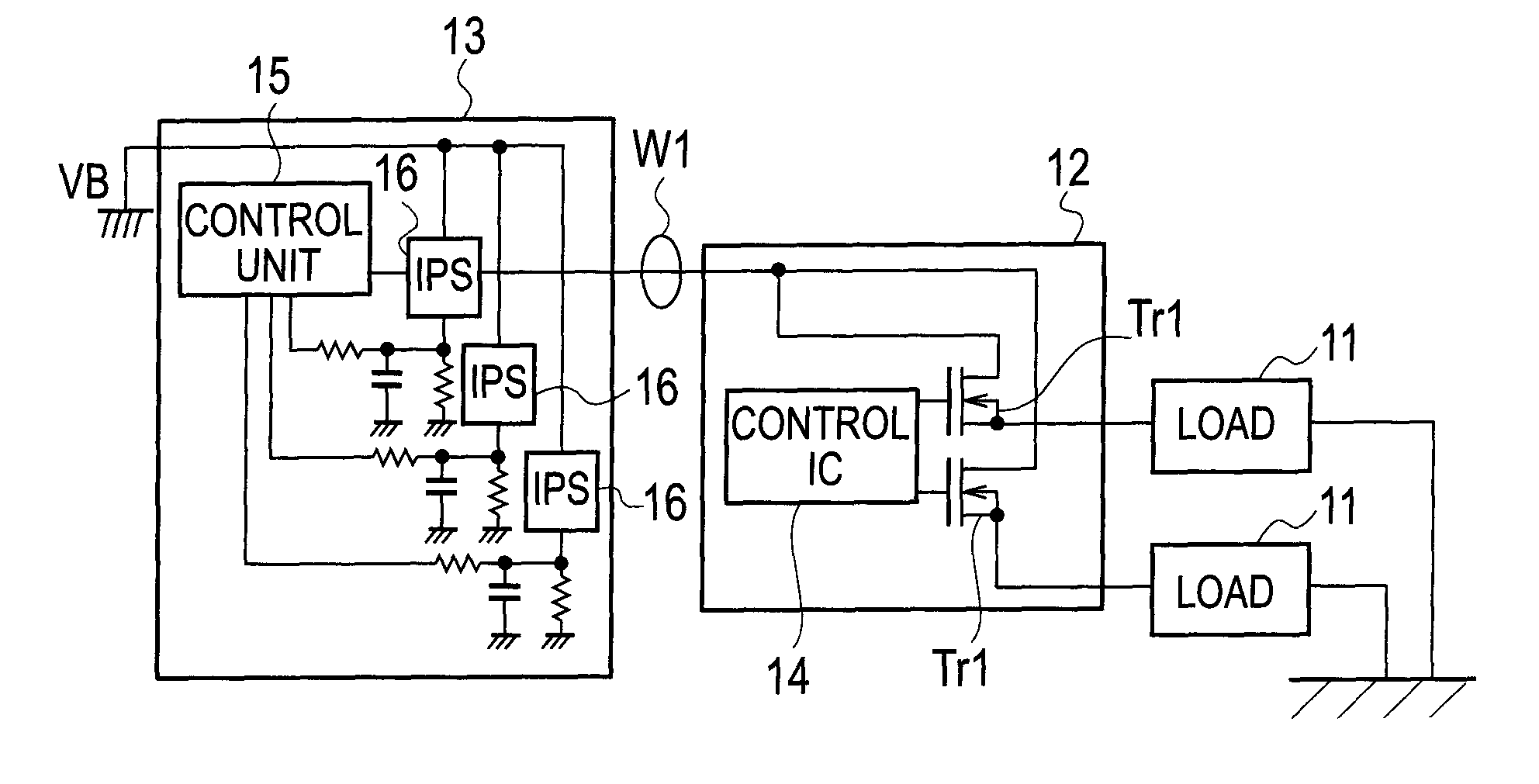

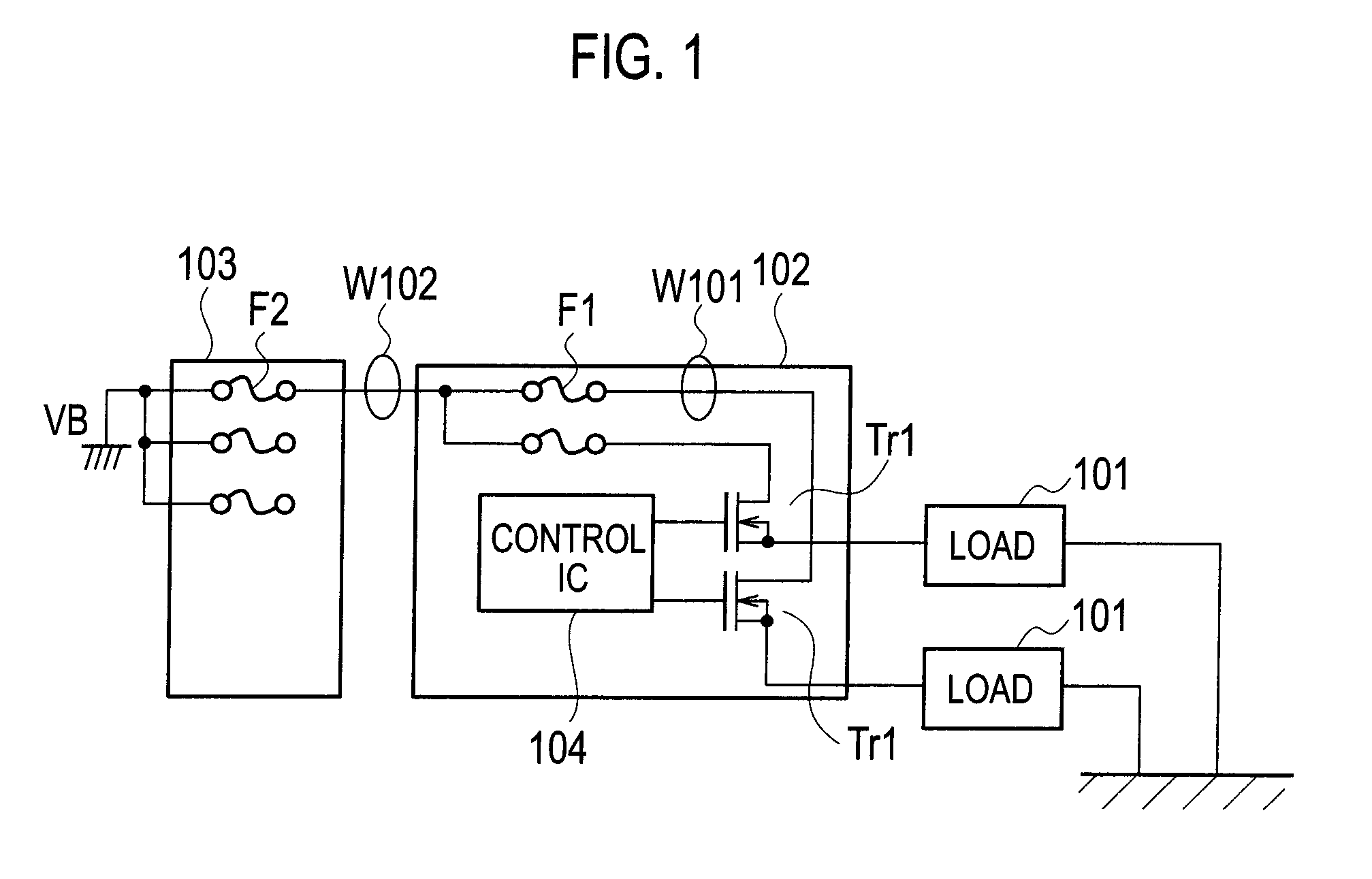

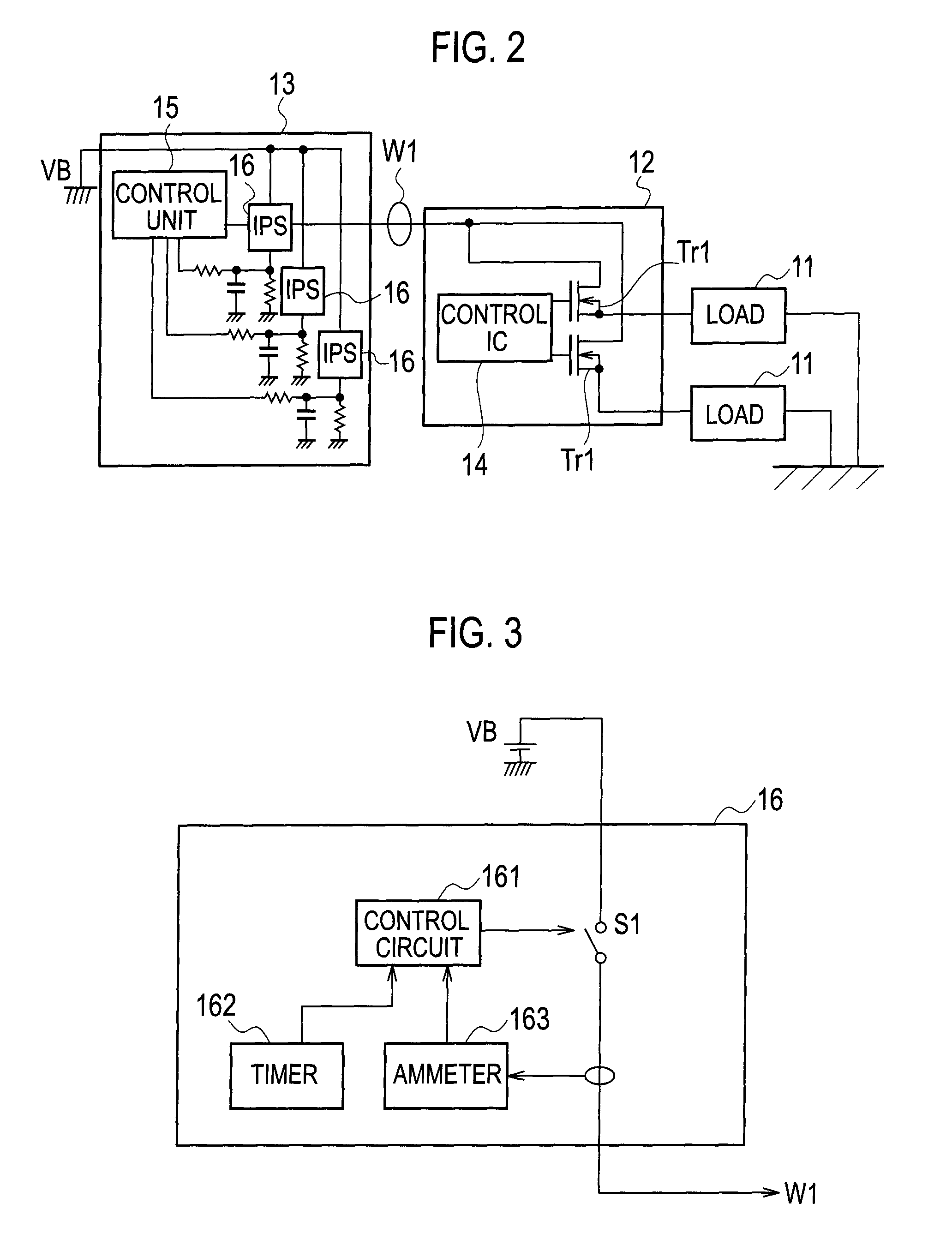

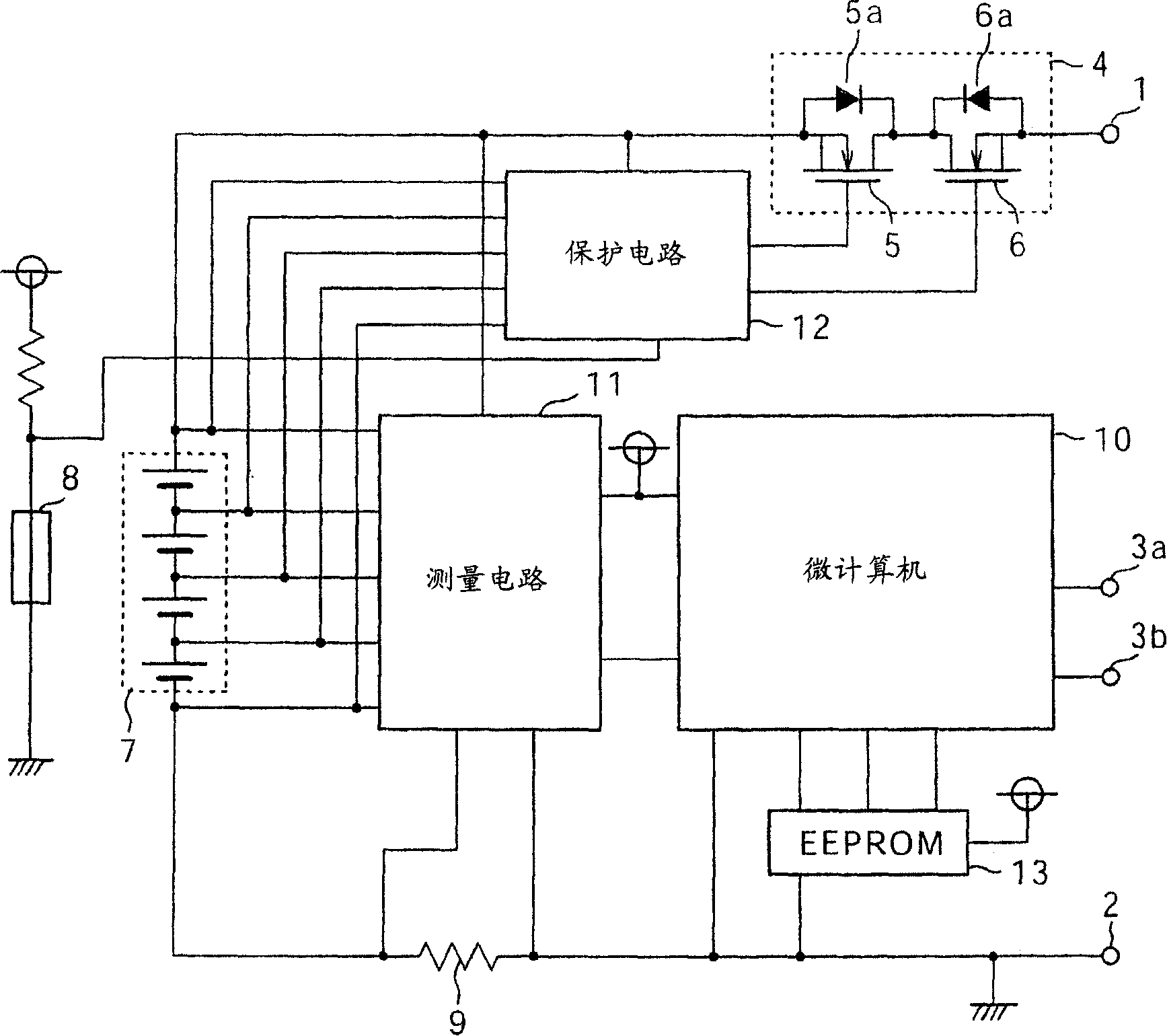

Protection apparatus of load circuit

ActiveUS8437110B2Reduce switchingIncrease fuel consumptionArrangements responsive to excess currentEmergency protective arrangements for limiting excess voltage/currentLoad circuitElectrical resistance and conductance

A protection apparatus of a load circuit, comprises: a temperature estimation unit configured to estimate a temperature of an electric wire based on a pseudo-temperature arithmetic expression; and a breaking control unit configured to break a switch portion when the temperature estimated by the temperature estimation unit has reached an allowed temperature of the electric wire. The pseudo-temperature arithmetic expression is set in such a manner that, in a temperature arithmetic expression of the electric wire, the temperature arithmetic expression using the elapsed time counted by the timer, the current detected by the current detection unit, and a heat capacity and conductor resistance of the electric wire, a pseudo-heat capacity smaller than the heat capacity of the electric wire is assigned to the heat capacity, and a pseudo-conductor resistance larger than the conductor resistance of the electric wire is assigned to the conductor resistance.

Owner:YAZAKI CORP

Method of charging secondary battery, method of calculating remaining capacity rate of secondary battery, and battery pack

ActiveCN100382408CAccurate detectionBatteries circuit arrangementsSecondary cells charging/dischargingCharge detectionCharge rate

PROBLEM TO BE SOLVED: To correctly detect full charge by further accurately measuring a charging capacity, in a charging method for a secondary battery obtained by combining an integration method and a voltage method that have conventionally been used.SOLUTION: The charging capacity (charging rate) is calculated by the integration method (current integration or power integration) from the start of charging to the vicinity of the full charge. The charging capacity is gradually shifted to a value calculated by the voltage method by adding thereto values obtained by both the calculation methods in accordance with a proportion multiplied by a voltage-method reliability coefficient by using a coefficient being a voltage-method reliability when the charging capacity reaches the vicinity of the full charging, and the integration method calculated value can be switched to the voltage method calculated value without an uncomfortable feeling, thus performing the correct full charge detection (charging rate calculation).

Owner:MURATA MFG CO LTD

Furnace with multiple heat recovery systems

InactiveCN102227384AVolume changeCharging furnaceCombustion processProcess engineeringHeat capacity rate

Owner:PRAXAIR TECH INC

Fuel cell stack

ActiveUS7309538B2Promote startupFuel cells groupingFuel cell auxillariesFuel cellsNuclear engineering

In starting power generation under low temperature conditions, an antifreeze liquid being coolant of a cooling system in a fuel cell stack is once recovered in a tank to reduce heat capacity of the fuel cell stack, and thereafter the power generation is started. Heat of reaction caused by the power generation restores the temperature to temperature under normal operation, and then the antifreeze liquid is again filled to drive the cooling system, so as to make it function as a cooler.

Owner:EQUOS RES

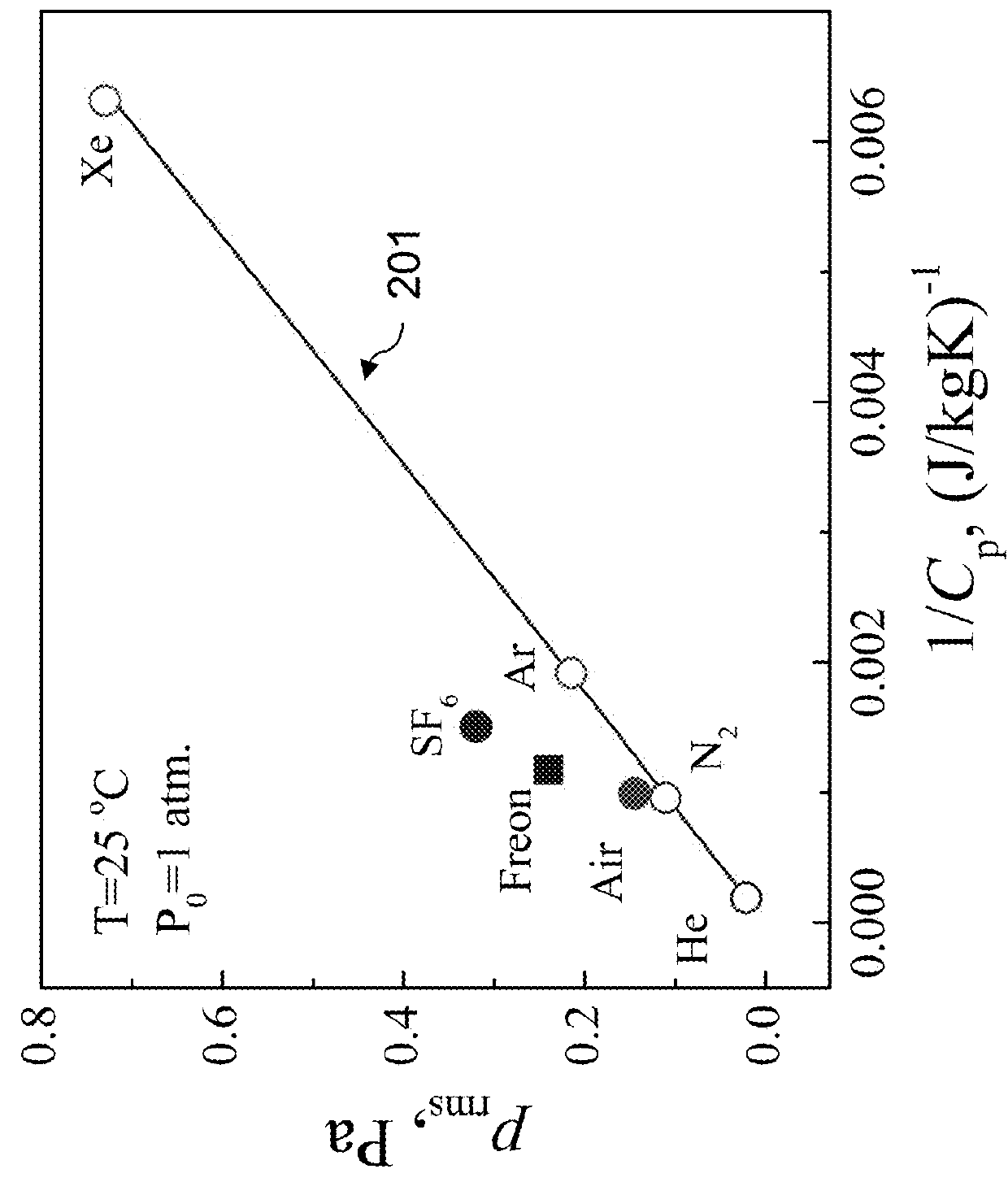

Encapsulated thermoacoustic projector based on freestanding carbon nanotube film

ActiveUS20160037267A1High vocal efficiencyReduce thermal inertiaMaterial nanotechnologyElectrothermic-effect transistorHeat capacityHeat capacity rate

A suspended nanotube film (or films) producing sound by means of the thermoacoustic (TA) effect is encapsulated between two plates, at least one of which vibrates, to enhance sound generation efficiency and protect the film. To avoid the oxidation of carbon nanotubes at elevated temperatures and reduce the thermal inertia of surrounding medium the enclosure is filled with inert gas (preferably with high heat capacity ratio, γ=Cp / Cv, and low heat capacity, Cp). To generate sound directly as the first harmonic of applied audio signal without use of an energy consuming dc biasing, an audio signal modulated carrier frequency at much higher frequency is used to provide power input. Various other inventive means are described to provide enhanced projected sound intensity, increased projector efficiency, and lengthened projector life, like the use of infrared reflecting coatings and particles on the projector plates, non-parallel sheet alignment in sheet stacks, and cooling means on one projector side.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

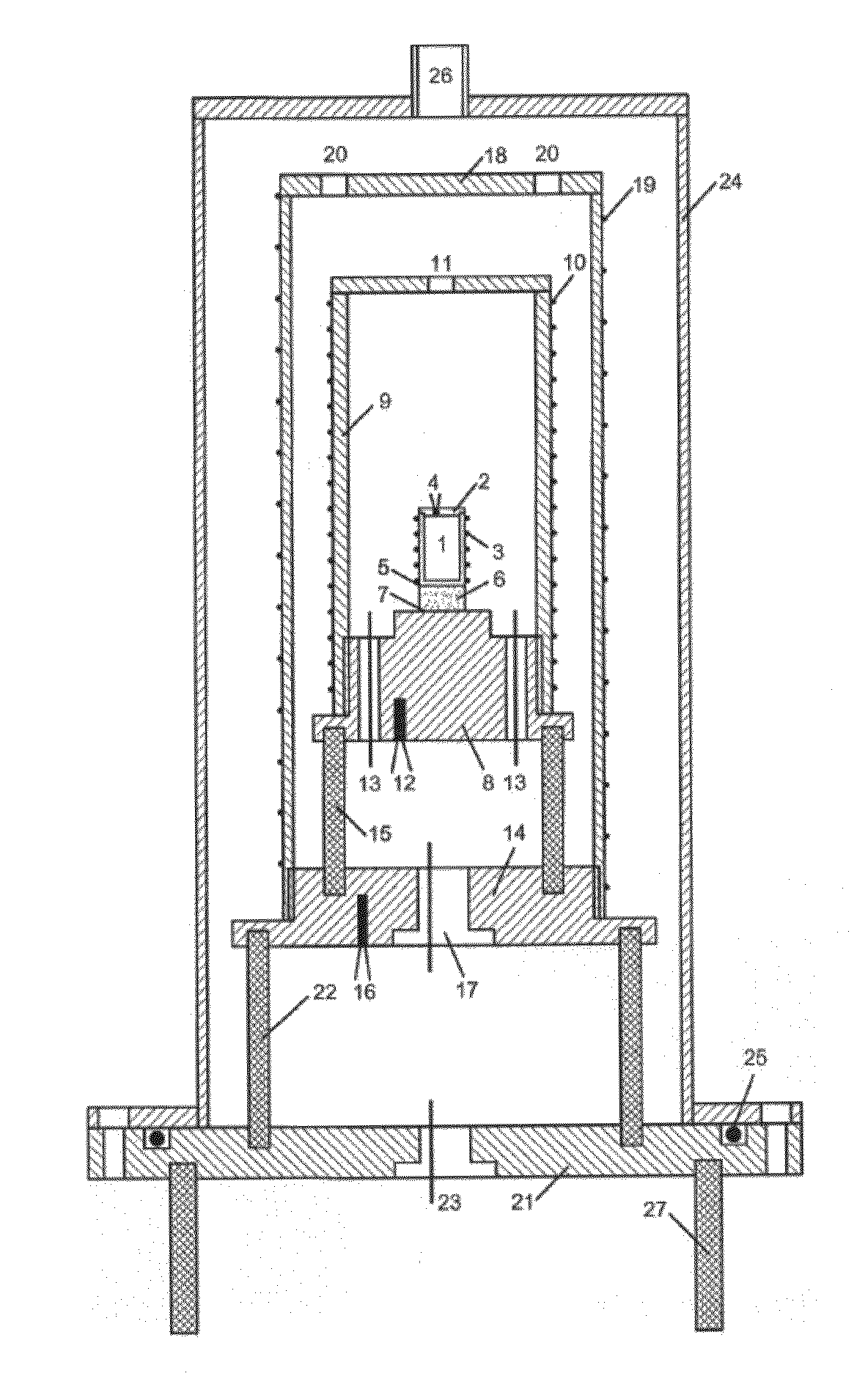

Adiabatic scanning calorimeter

ActiveUS9310263B2Accurate representationMaterial heat developmentCalorimeterHeat fluxTemperature difference

The present invention generally relates to an adiabatic scanning calorimeter for simultaneous measurements of the temperature dependence of heat capacity and enthalpy of liquids and solids and phase transitions therein. Moreover, the invention allows for an accurate separation between pretransitional enthalpy variations and true latent heats at first-order or weakly first-order phase transitions. In addition, the invention relates to calorimeters for controlling temperature differences and heat fluxes in different modes of operation.

Owner:KATHOLIEKE UNIV LEUVEN

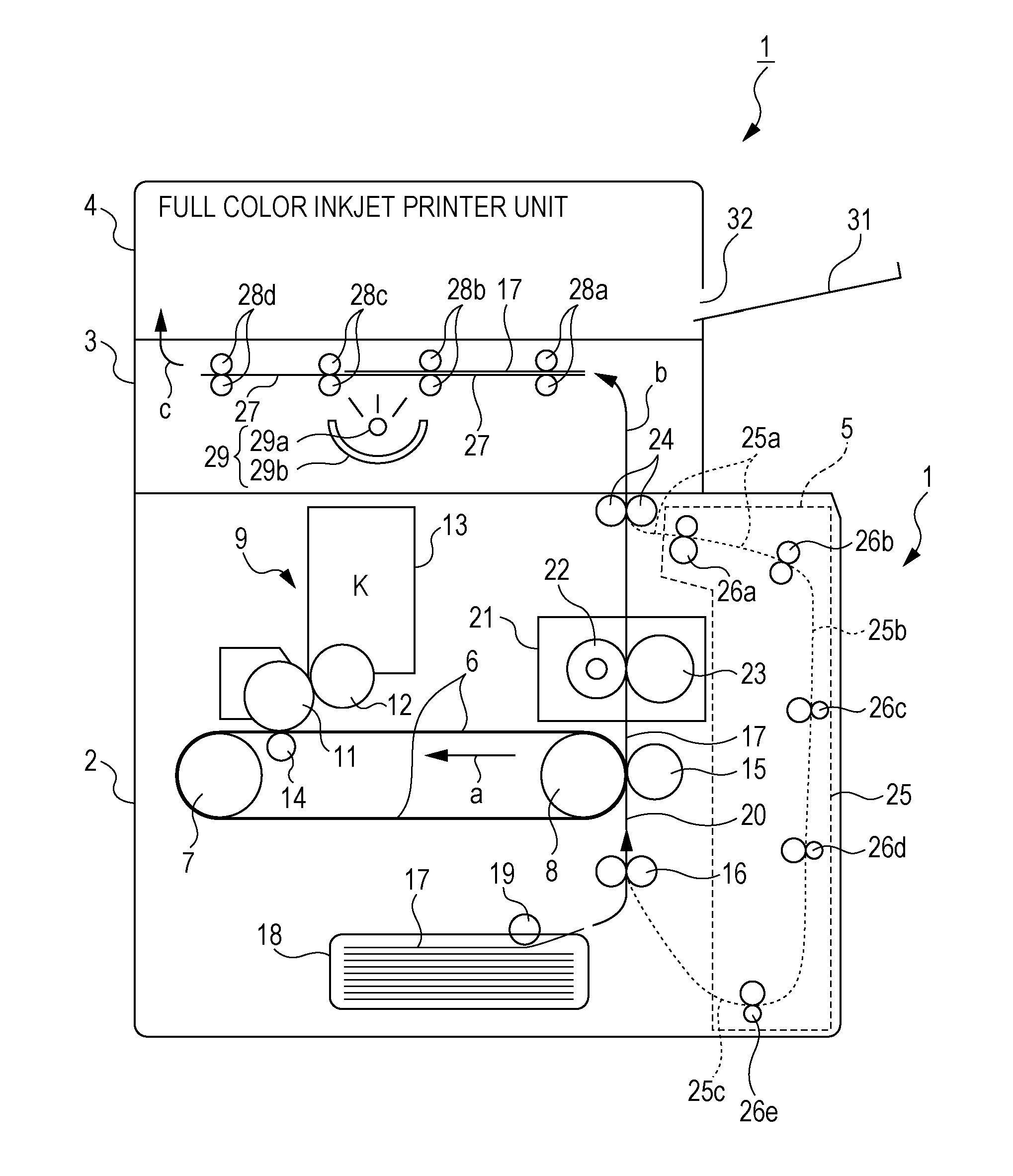

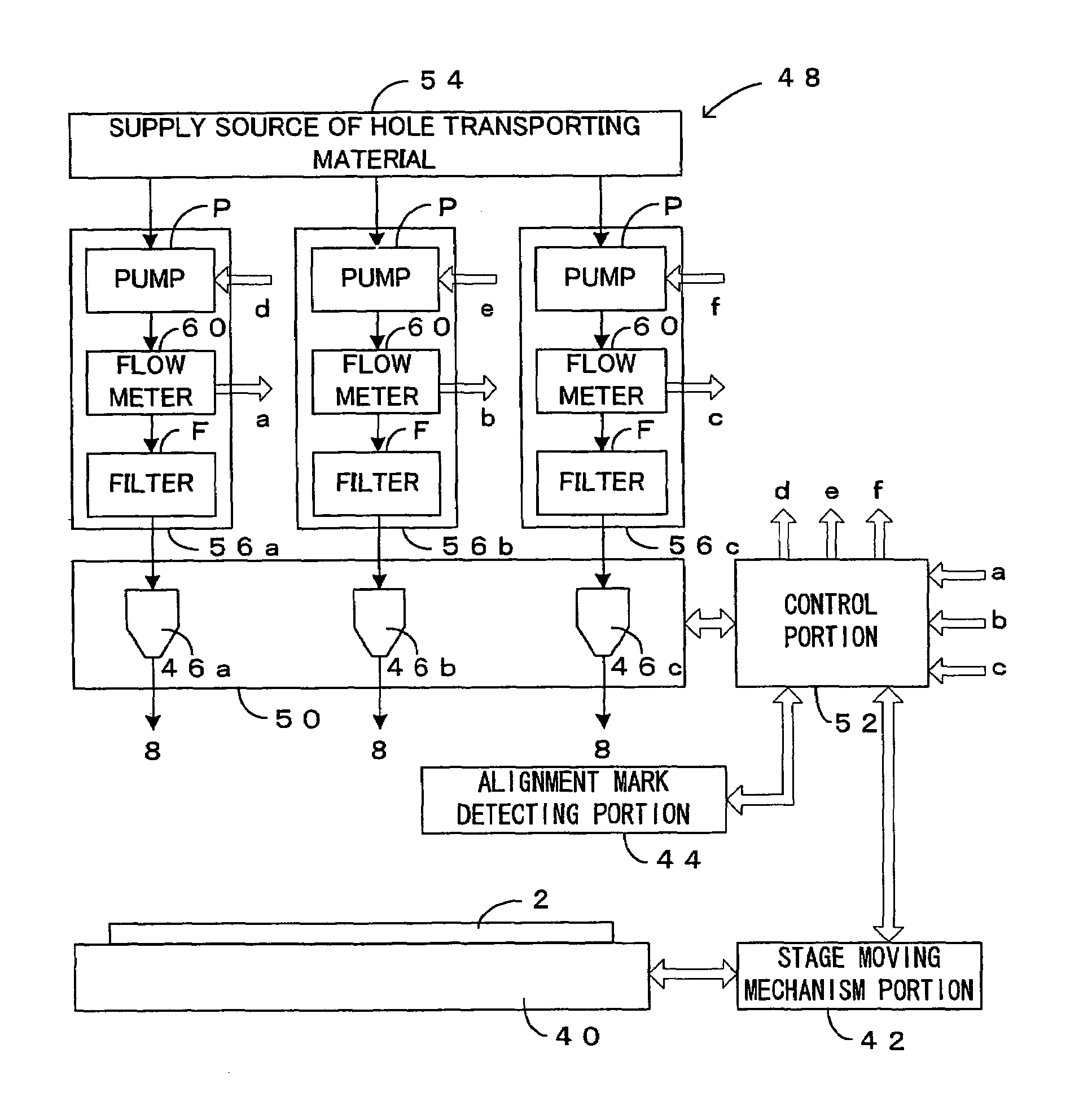

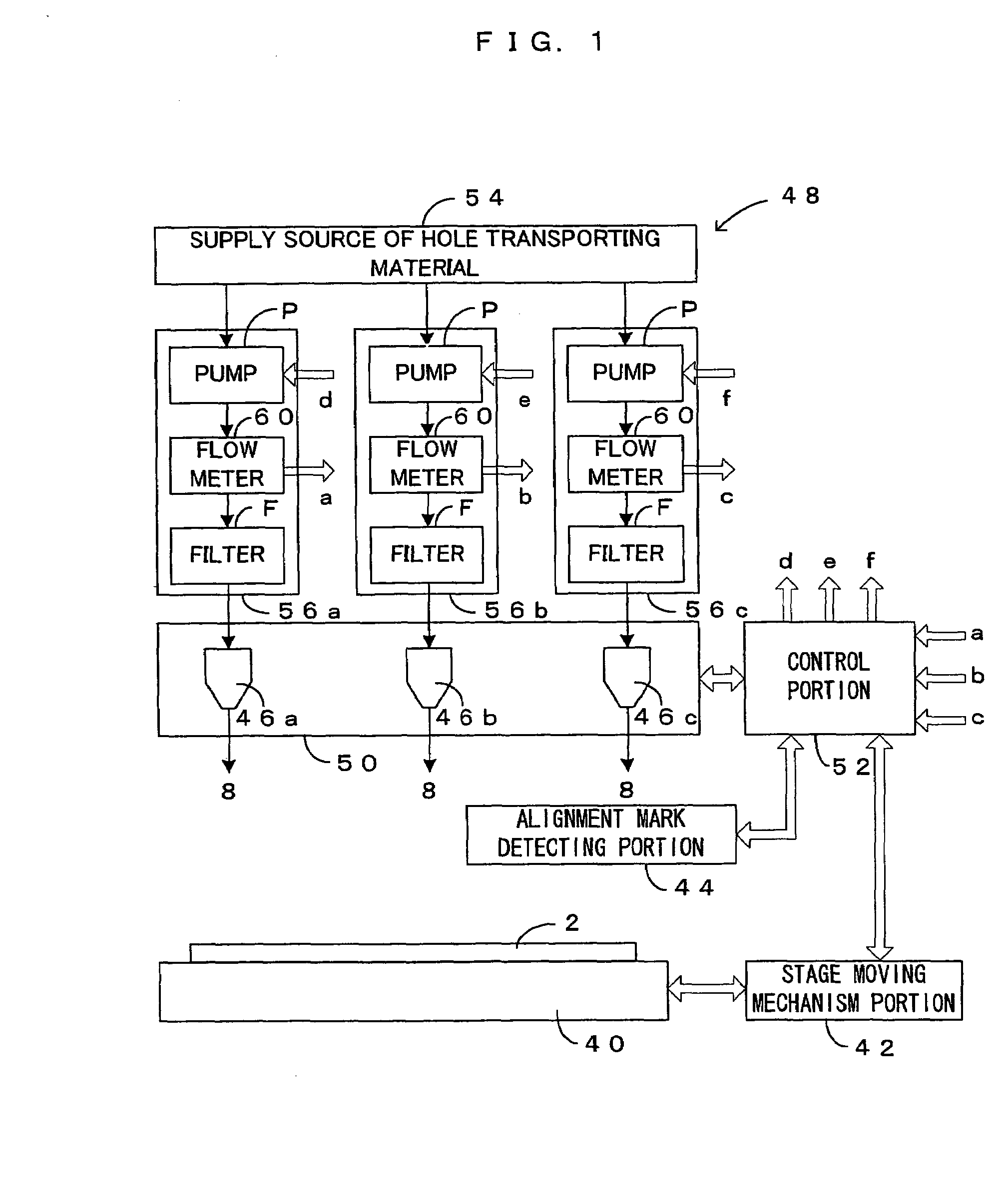

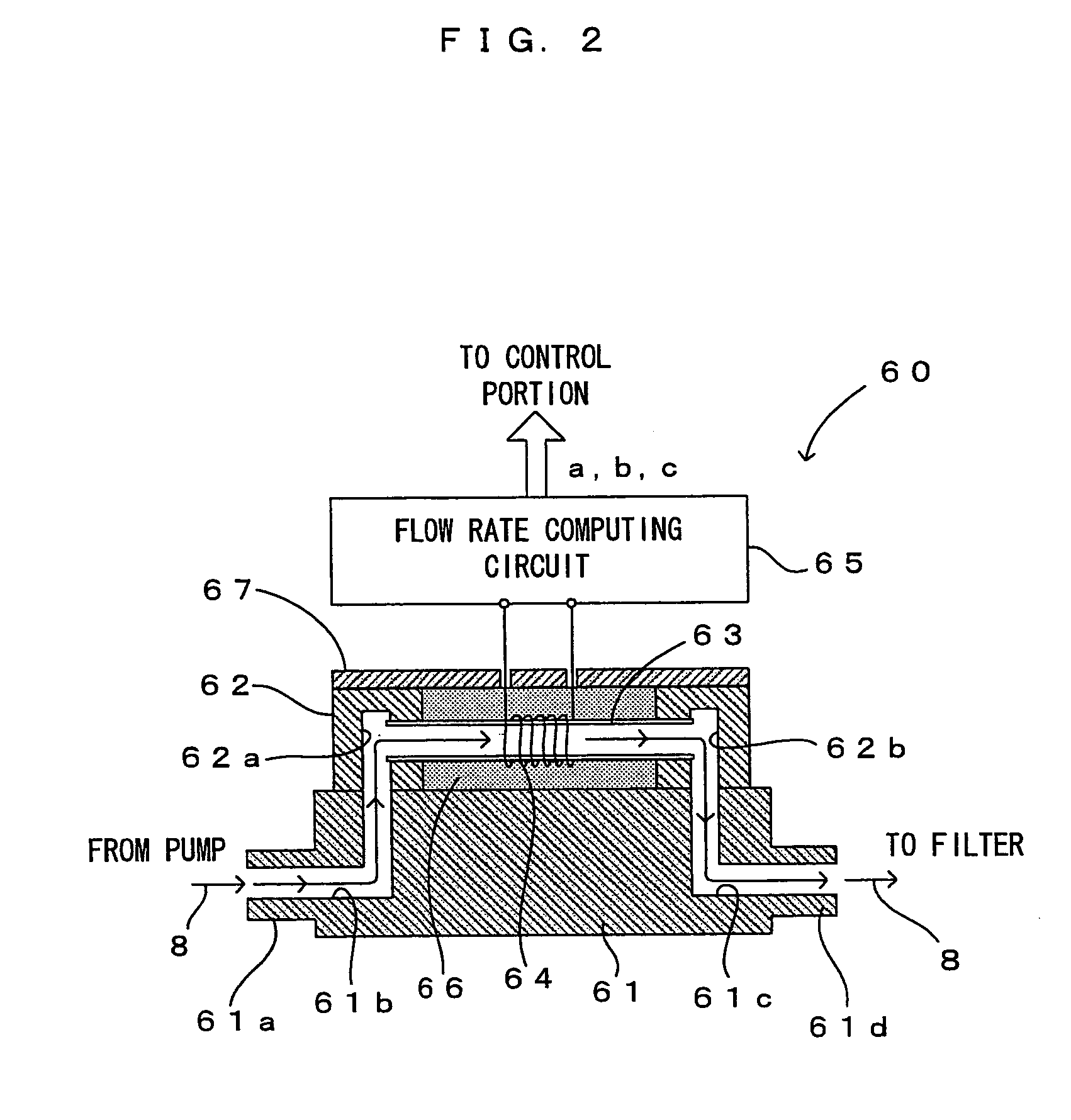

Substrate processing apparatus and thermal type flowmeter suitable to the same

InactiveUS7216534B2Accurate measurementAvoid mixingLiquid surface applicatorsVolume/mass flow by thermal effectsTemperature differenceHeat sensitive

In a thermal type flowmeter 60, a heating / heat-sensitive coil 64 which is shaped as a coil is fit close into an approximately central portion of a duct pipe 63. A flow rate computing circuit 65 supplies electric power to the heating / heat-sensitive coil 64 in accordance with an instruction received from a control portion, the heating / heat-sensitive coil 64 develops heat, and the heat developing at the heating / heat-sensitive coil 64 heats up a hole transporting material 8 which flows through the duct pipe 63. Further, the flow rate computing circuit 65 which is electrically connected with the heating / heat-sensitive coil 64 detects a difference between an upstream-side temperature and a downstream-side temperature, and calculates the flow rate (mass flow rate) of the hole transporting material 8 based on this temperature difference, the amount of heating, physical properties data such as the specific heat and the heat capacity regarding the hole transporting material 8.

Owner:DAINIPPON SCREEN MTG CO LTD

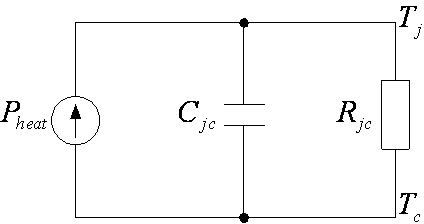

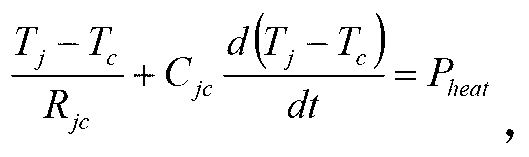

Novel method for extracting heat capacity and thermal time constant of light-emitting diode (LED) system

InactiveCN103293183AEasy extractionSimple and fast operationMaterial heat developmentSteady state temperatureRC time constant

The invention discloses a novel method and a theory for extracting heat capacity and thermal time constant of a light-emitting diode (LED) system. The method comprises the following steps: 1) measuring a temperature curve of the LED junction temperature; 2) reading the corresponding time when the temperature is raised to 63.2 percent of the highest steady state temperature in the curve, and recording the time as the thermal time constant tau jc of the LED device; 3) reading the highest junction temperature and initial junction temperature in the curve, subtracting the two temperatures, dividing the thermal power input by the LED to obtain the thermal resistance Rjc of the LED device; and 4) dividing the extracted thermal resistance by the extracted thermal time constant to obtain the heat capacity Cjc of the LED device. The invention provides a simple and convenient method and theory for extracting the overall heat capacity and the overall thermal time constant of the LED device. According to the method, the thermal resistance, heat capacity and thermal time constant of the whole device can be extracted at one time, the process for extracting the thermal resistance and heat capacity of the LED device is simplified, and the process for extracting the thermal time constant of the LED device is innovatively provided.

Owner:SUZHOU UNIV

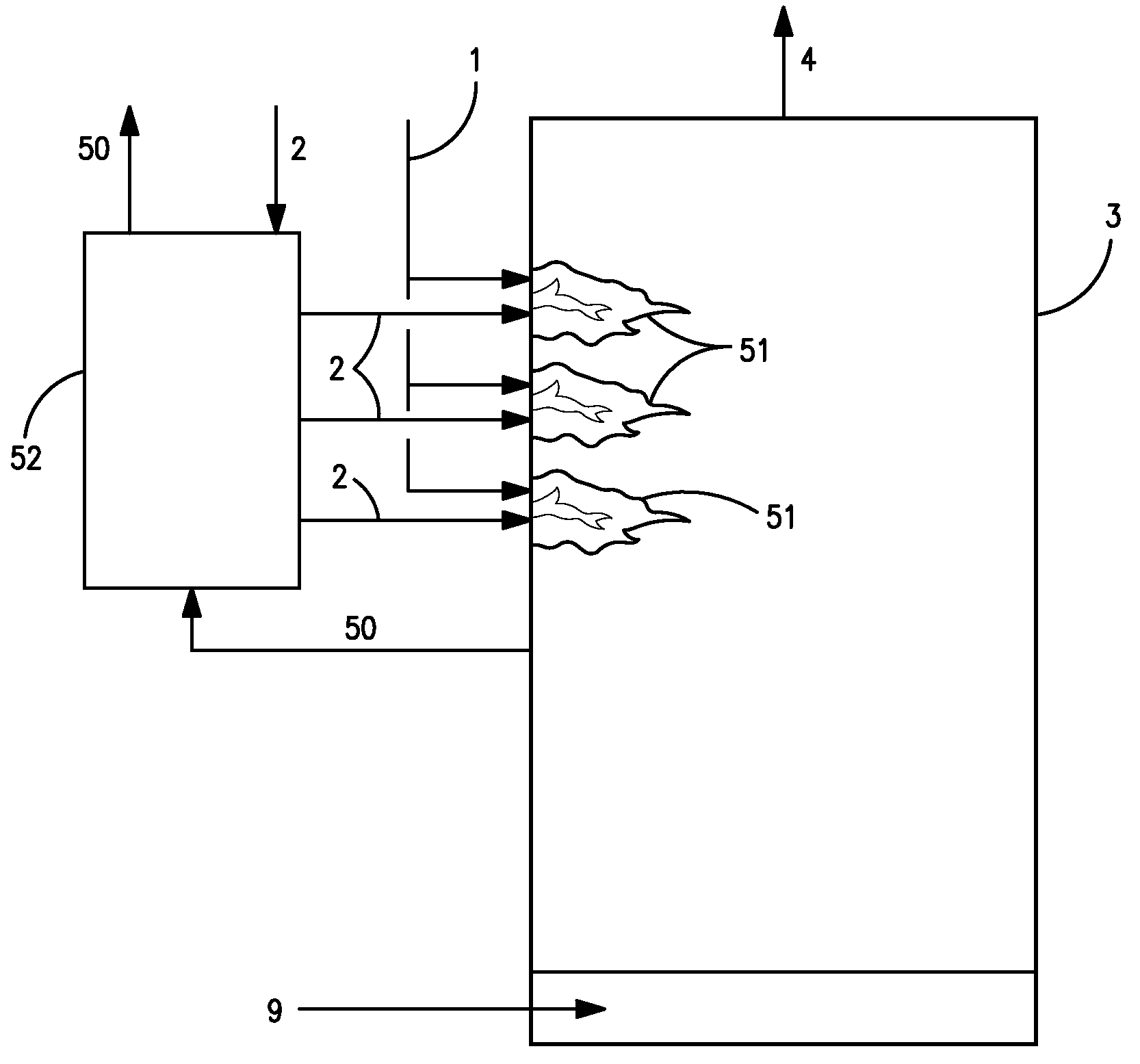

Steam power cycle thermal power generation system and steam power cycle thermal generation technology

ActiveCN105972634AAvoid Temperature Pinch LimitsReduce power consumptionFeed water supplyCombustion processAir preheaterSuperheater

The invention discloses a steam power cycle thermal power generation system and a steam power cycle thermal generation technology. A water wall is connected with a turbine through a superheater and a main steam pipeline. Multiple turbine steam extraction pipelines of the turbine are used for heat exchange with a low-pressure heater and a high-pressure heater. A draught fan draws in cold air in the atmosphere and conveys the cold air into an air pre-heater, and the cold air is heated by flue gas from a hearth and a boiler high-temperature flue gas section. The amount of the flue gas from the hearth and the boiler high-temperature flue gas section is set to be matched with the amount of the cold air so that the flue gas and the cold air can have the same heat capacity flow rate in the air pre-heater. After condensed water in a condenser is directly boosted by a high-pressure condensate pump to reach the pressure of a boiler, the condensed water enters a high-pressure condensed water heater to be heated by flue gas and then enters the water wall of the boiler. The flow of the high-pressure condensed water is adjusted to be matched with the flue gas heating the high-pressure condensed water so that the heat capacity flow rate of the high-pressure condensed water to be equal with that of the flue gas. By the adoption of the steam power cycle thermal power generation system and the steam power cycle thermal generation technology, the inherent defect that cold fluid and hot fluid are different in heat capacity flow rate is overcome, the temperature difference pinch point limit is avoided, and then the temperature of the flue gas can be lowered to be low enough.

Owner:XI AN JIAOTONG UNIV

Air conditioning device

ActiveCN104813111ASmall driving forceAvoid the risk of piping pittingSpace heating and ventilation safety systemsSpace heating and ventilation control systemsLower limitEngineering

In an air conditioning device (100), when all of a plurality of pumps (31) are operating, and a heat exchange amount of usage-side heat exchangers (35) is equal to or less than a lower limit of the heat capacity capable of being conveyed in a heating-medium circulation circuit (B), before at least one of the plurality of pumps (31) is turned off, a refrigerant-side passage of an inter-heating-medium heat exchanger (25) connected to the pump (31) to be turned off is closed, the at least one of the plurality of pumps (31) is subsequently turned off, and the remaining pump (31) is used to convey the heat capacity required for the usage-side heat exchangers (35).

Owner:MITSUBISHI ELECTRIC CORP

DC arc induction furnace

InactiveCN1712871AAvoid the technical problem of freezing to the point where refining is impossibleWon't "freeze" packetsLighting and heating apparatusBrickHeat capacity

A DC arc induction furnace for refining molten steel has the top graphite cathode connected to the cathodic copper bus of rectifier chest via the water-cooled cable and the electrically conductive bottom bricks used as bottom anode connected to the anodic copper bus of rectifier chest via the water-cooled cable. Its advantages are high volume and heat capacity, long service life and high quality of molten steel.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com