DC arc induction furnace

A DC arc and induction furnace technology, applied in the field of induction furnaces, can solve the problems of increased production costs, reduced furnace life, and longer smelting time, and achieve the effects of preventing bridge formation of scrap steel, ensuring the quality of molten steel, and shortening the smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

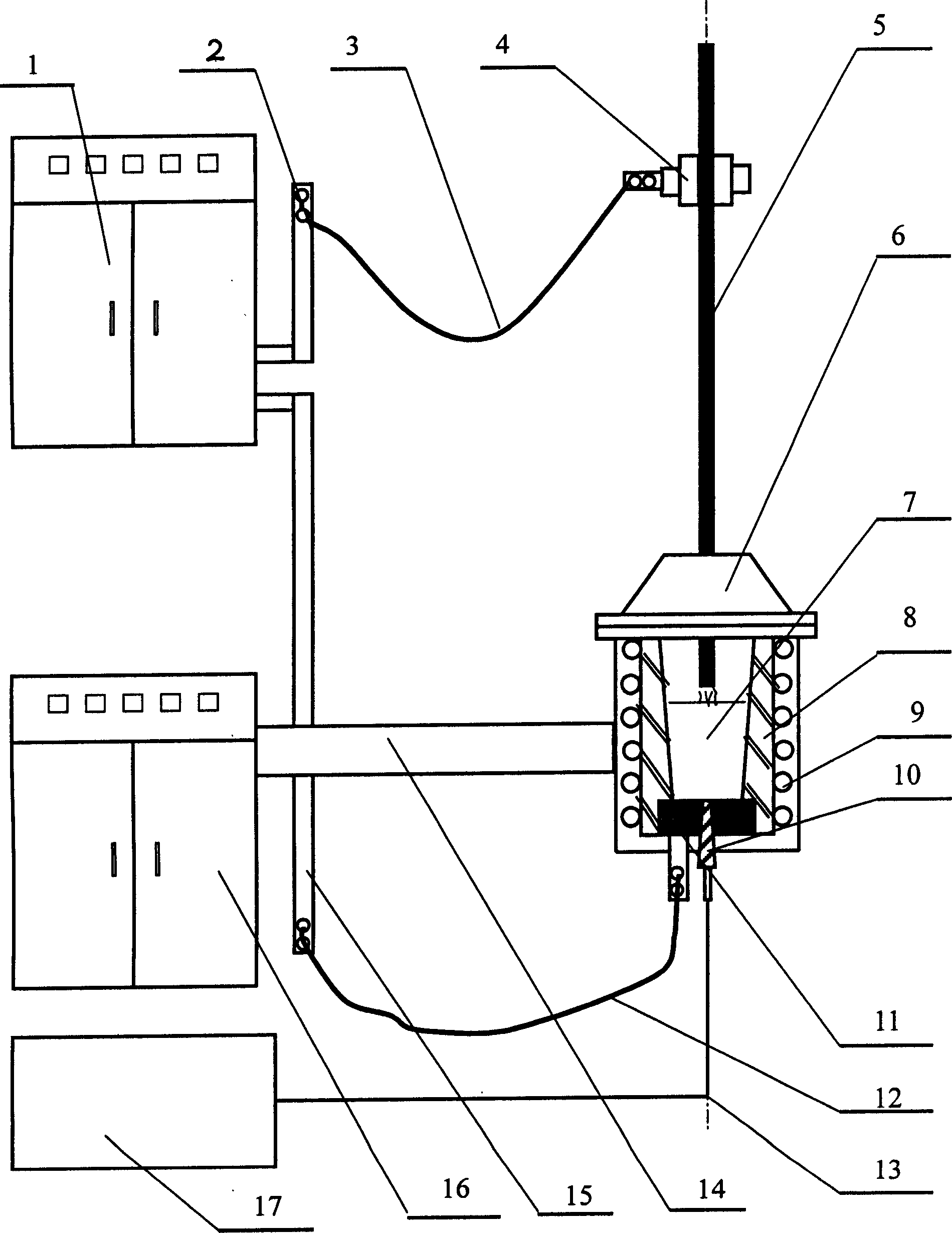

[0009] As shown in the drawings, the DC arc induction furnace of the present invention includes a rectifier cabinet 1, a top cathode copper bar 2, a top cathode water-cooled cable 3, a holder 4, a top cathode 5, a furnace cap 6, a crucible 8, an induction coil 9, Bottom anode conductive brick 10, bottom blowing vent plug 11, bottom gas pipe 12, intermediate frequency conductive copper bar and water-cooled cable 13, bottom anode water-cooled cable 14, bottom anode copper bar 15, intermediate frequency power supply cabinet 16. An induction coil 9 is set on the outer wall of the crucible 8 of the DC arc induction furnace, and the induction coil 9 is connected to the power supply of the intermediate frequency power supply cabinet 16 through an intermediate frequency conductive copper bar and a water-cooled cable 13, and can inductively heat the charge in the crucible during smelting; at the bottom of the furnace Install furnace bottom conductive brick and large current bottom anode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com