Patents

Literature

35results about How to "Effective deoxygenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

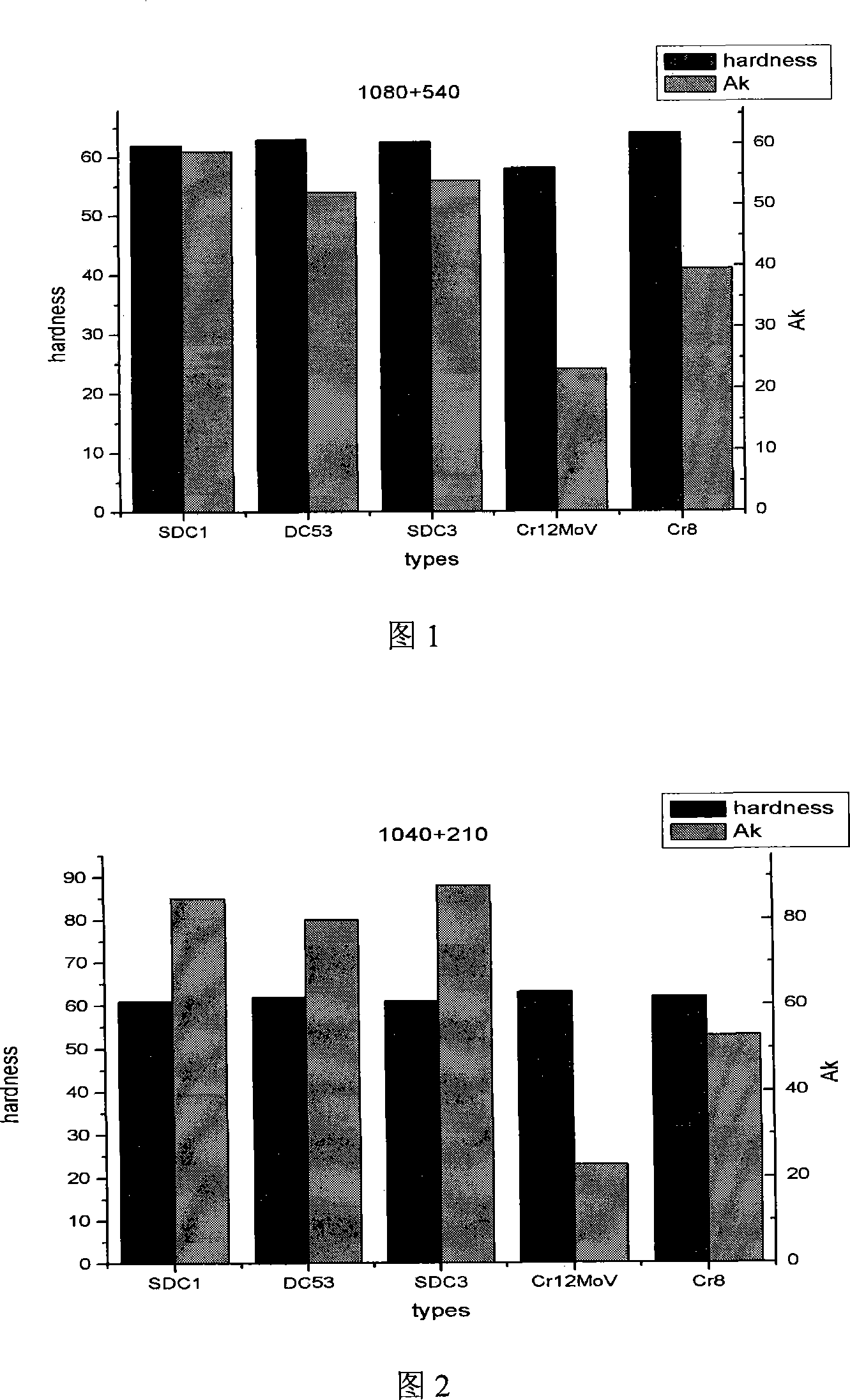

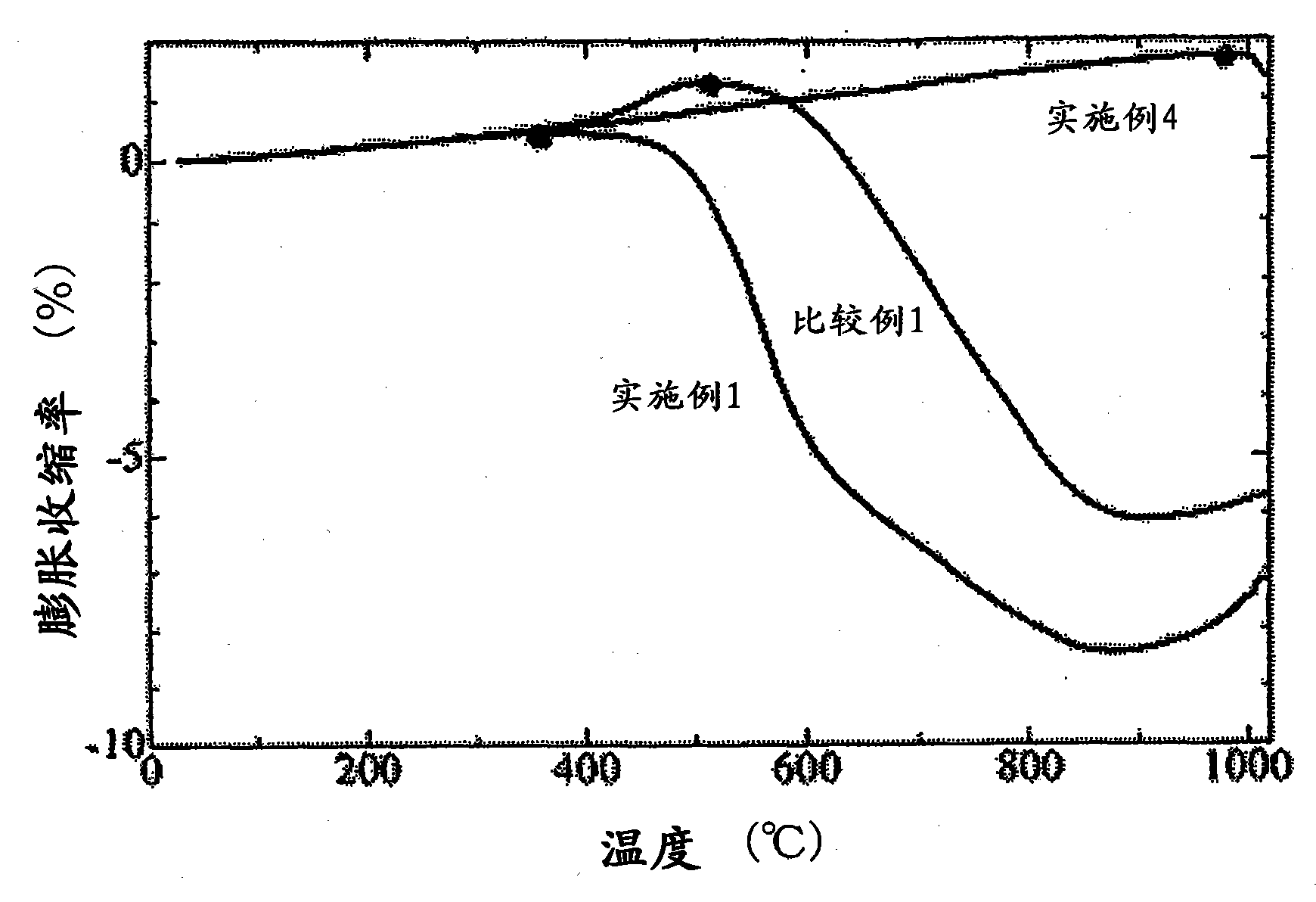

High-strength toughness cold working die steel and method of producing the same

The invention relates to a high-strength toughness cold-working die steel and a manufacturing method thereof, belonging to the technical field of alloy steel manufacturing technology. The chemical composition and weight percentage of the alloy steel of the present invention: C 0.9~1.0%, Cr 9~10%, Mo 2.0%, V 0.8~1.0%, Si 1.0%, P<0.02%, S<0.02%, Fe surplus quantity. The preparation process and steps of the cold work die steel of the present invention are as follows: (1) smelting, (2) electroslag remelting, (3) annealing, (4) rough forging, (5) re-annealing, (6) spheroidizing annealing , (7) Quenching and tempering. The hardness of the alloy steel prepared by the method of the invention can reach 61-63HRC, and the impact energy AK can reach 61-85J, which is more than three times higher than that of the original Cr12MoV steel.

Owner:上大鑫仑材料科技(上海)有限公司

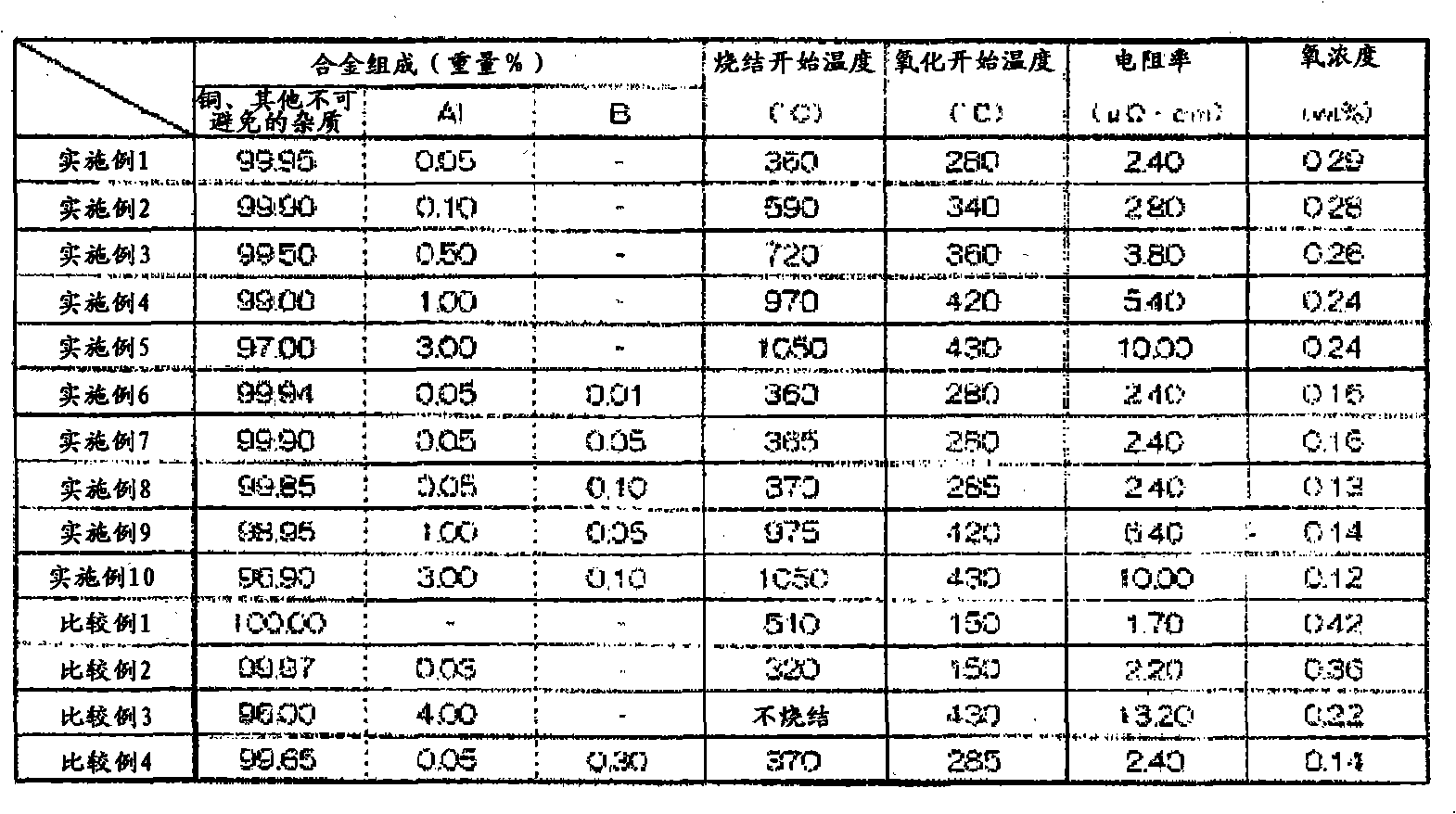

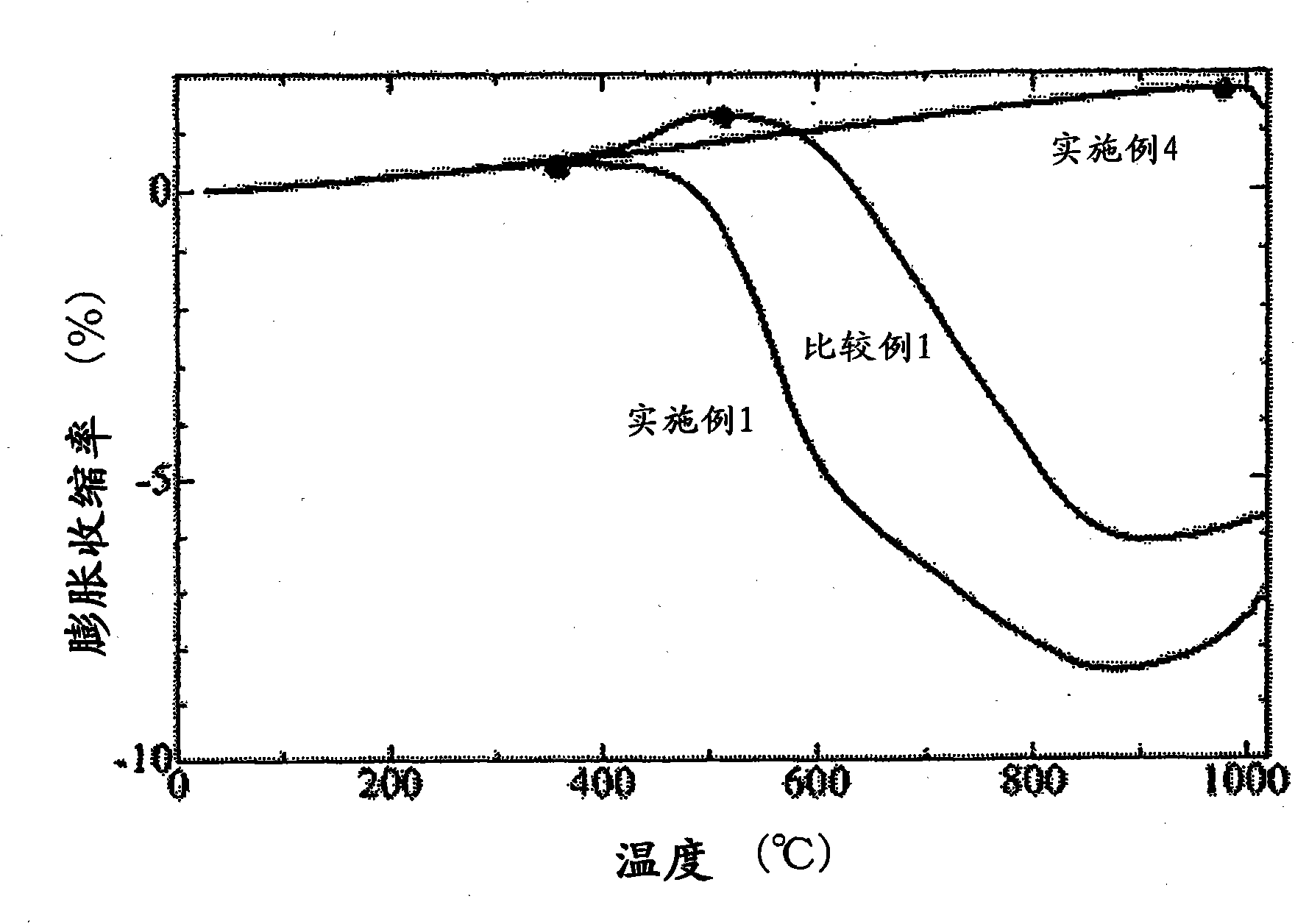

Copper alloy powder and method for producing the same

InactiveCN101815799ALow resistivityImprove oxidation resistanceConductive materialMetal/alloy conductorsBoronImpurity

Disclosed is a copper alloy powder having excellent oxidizability and electrical conductivity, whose sintering starting temperature can be set discretionally. This copper alloy powder enables low production cost, that is composed of the costs for raw materials and production facilities. Specifically disclosed is a copper alloy powder composed of 0.05-3.00% by mass of aluminum, and the balance of copper and unavoidable impurities, while additionally containing 0.01-0.10% by mass of boron, if necessary. This copper alloy powder is granulated by a water atomization process.

Owner:SINTOKOGIO LTD

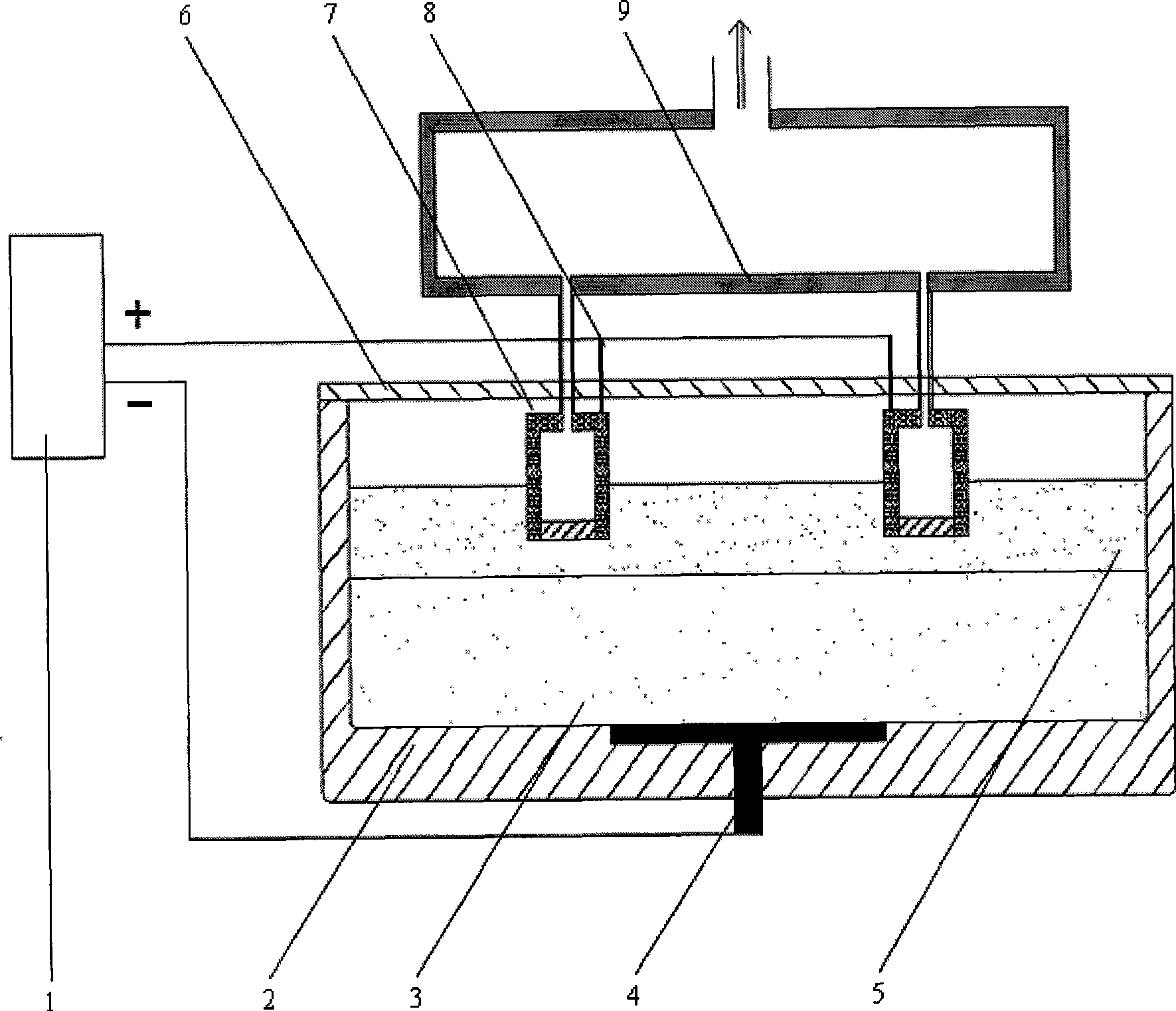

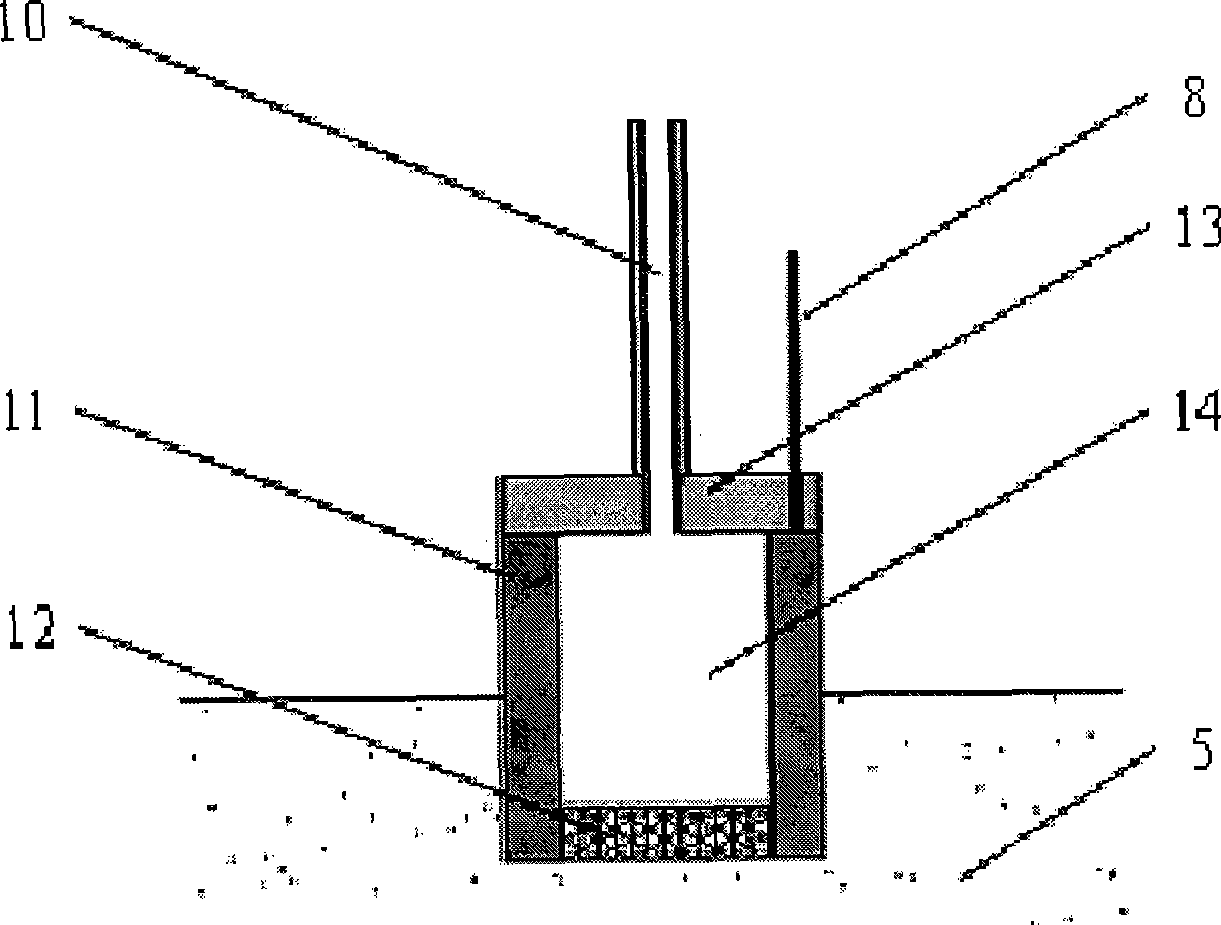

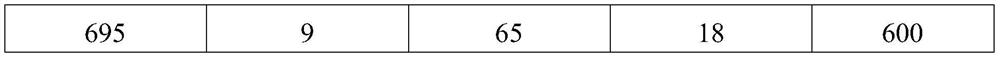

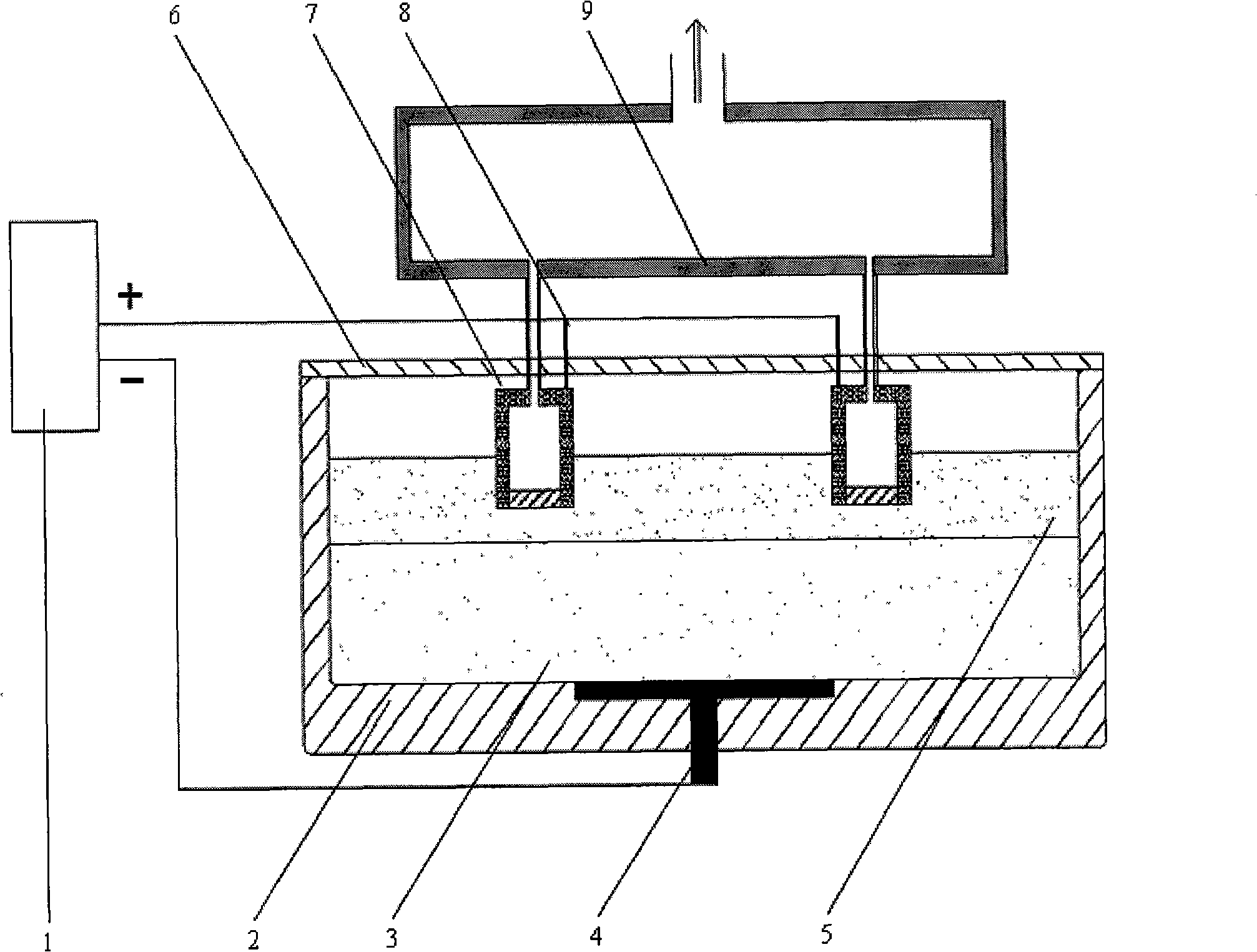

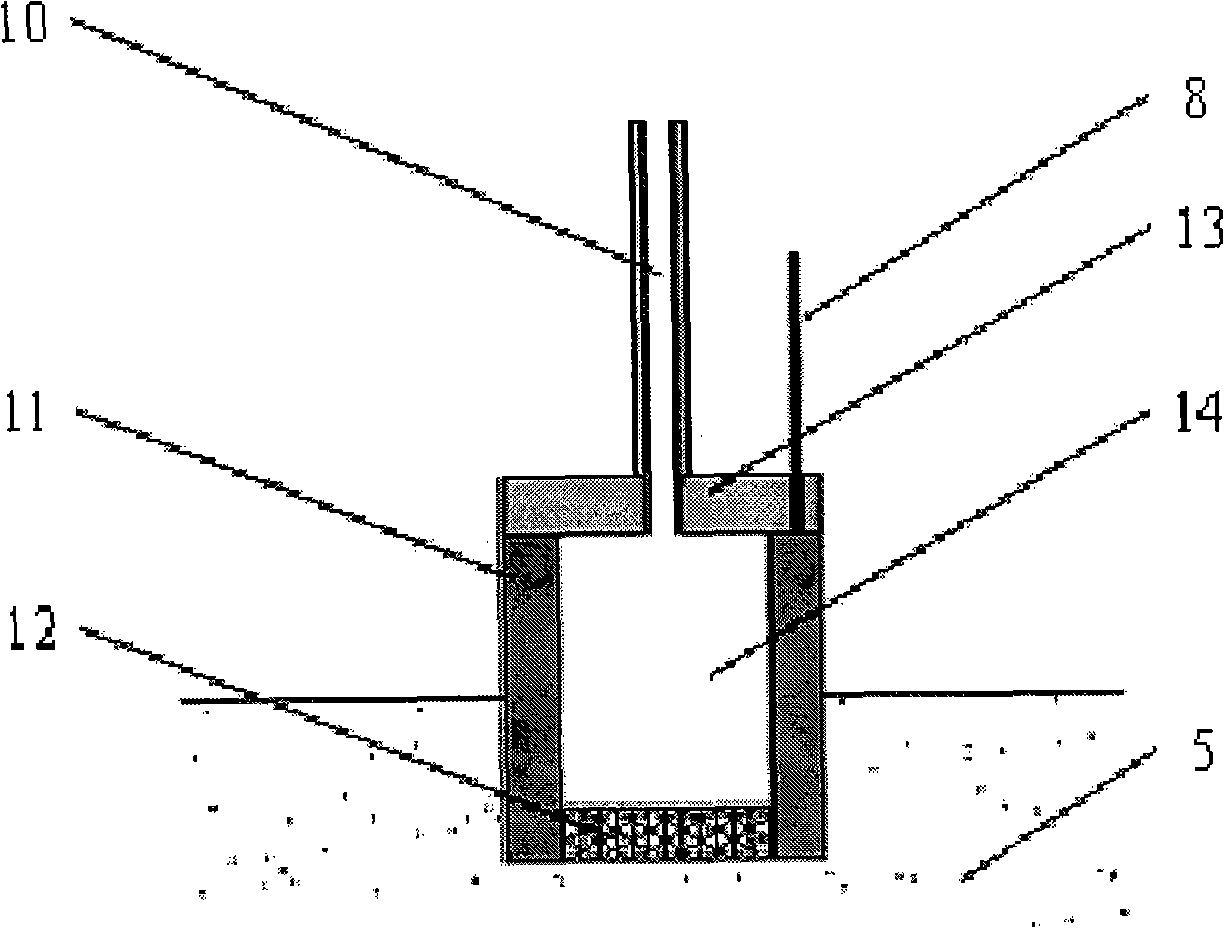

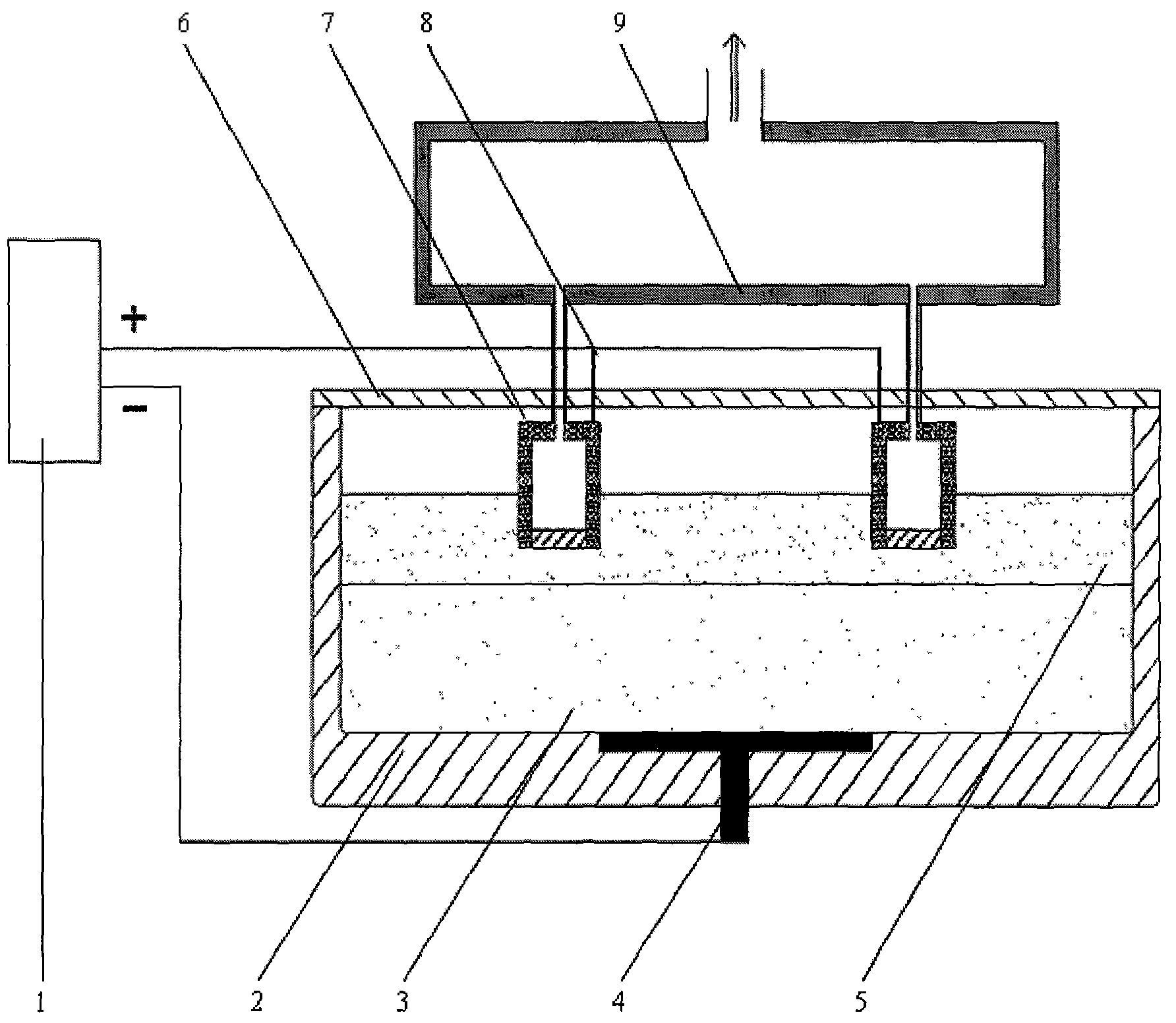

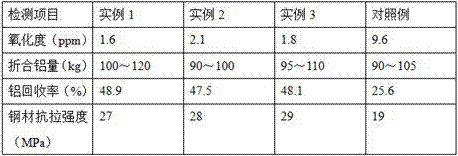

Slag nonpollution deoxygenation method capable of regulating anode oxygen partial pressure and device thereof

InactiveCN101457276AImprove pollutionAccelerated exclusionGas emission reductionOxygen ionsVacuum chamber

The invention relates to a pollution-free molten slag deoxidization method capable of adjusting anode oxygen partial pressure and a device thereof, and belongs to the technical field of metallurgical refining process. In the method, molten steel or molten metal is deoxidized and purified by the special device. In the method, the molten slag is taken as electrolyte, a deaeration cavity electrode inserted into the molten slag is taken as an anode, and the molten steel or the molten metal is taken as a cathode; the deaeration electrode is provided with an electrode cavity and is communicated with a vacuum chamber by a conduit; an applied DC power supply exerts direct current impulse voltage so that an electric field is formed between the molten steel or the molten metal and an oxygen electrode of the molten slag, and the conduction of oxygen ions in a molten slag system and mass transfer of dissolved oxygen in the molten steel are controlled by controlling a current value and a voltage value of the DC power supply as well as components of the molten slag. The oxygen is diffused from the molten slag to the electrode cavity and discharged by an air exhaust system by controlling the oxygen partial pressure of the electrode cavity.

Owner:SHANGHAI UNIV

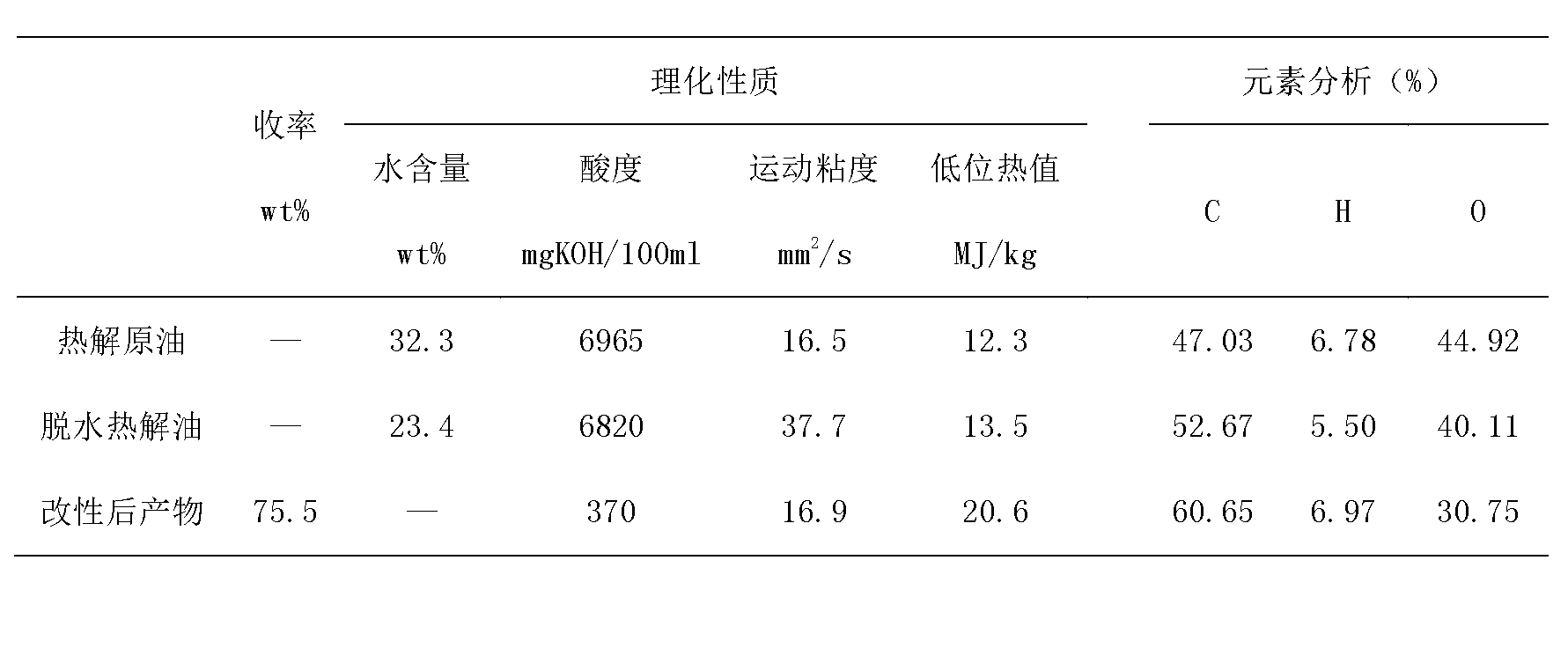

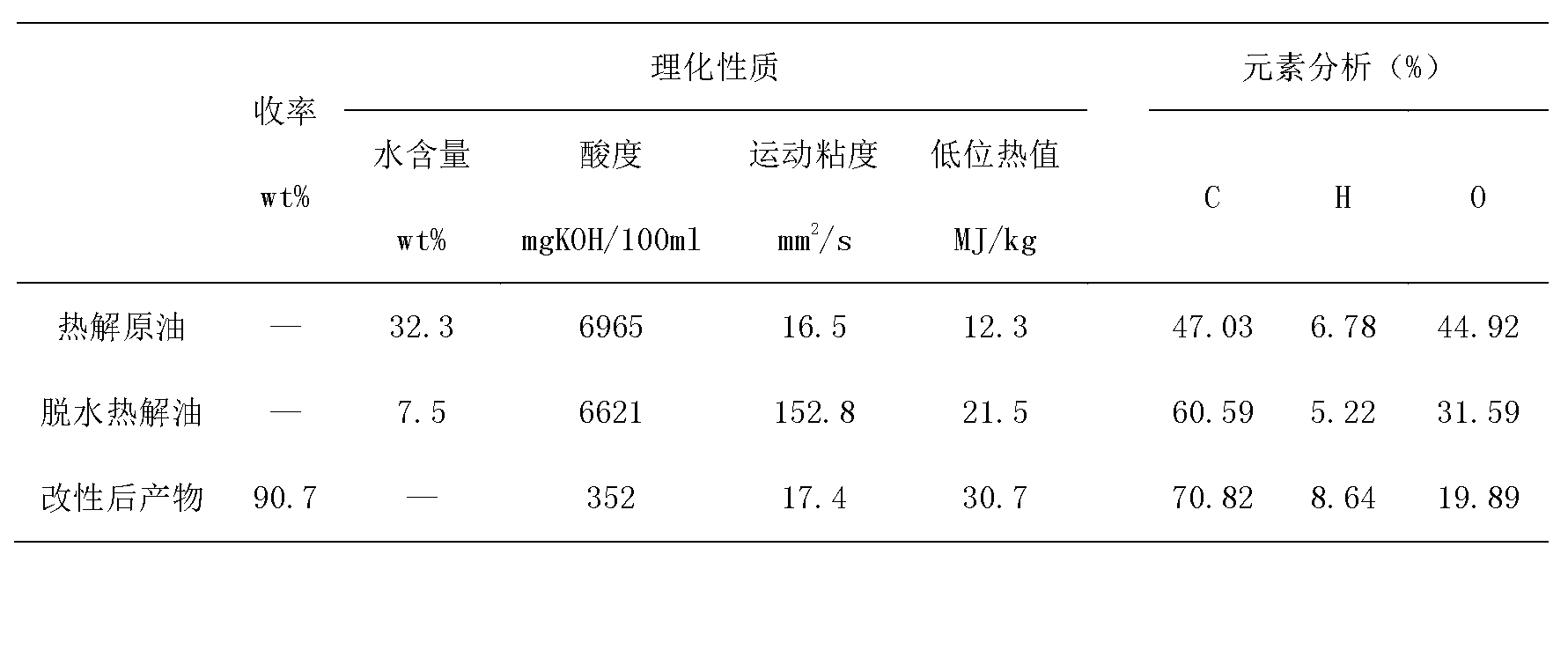

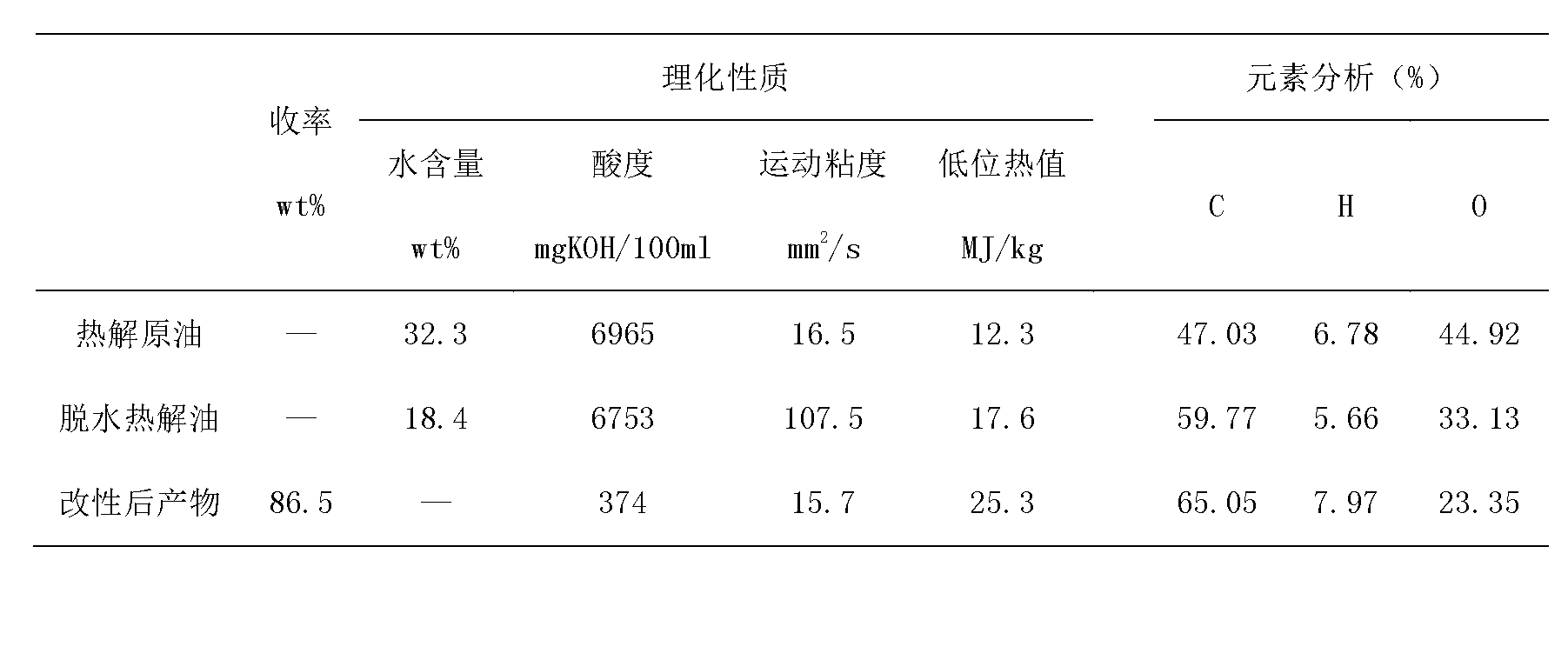

Modification method of biomass pyrolysis oil

ActiveCN103215068AEasy to separateAchieve the effect of pyrolysis oil and water removalDewatering/demulsification with chemical meansCatalytic crackingInorganic saltsDemulsifier

The invention provides a modification method of biomass pyrolysis oil. The modification method of the biomass pyrolysis oil specifically comprises the following steps of: I, demulsification layering dehydration: adding an inorganic salt iron and an organic demulsifier into the biomass pyrolysis oil, wherein the mass ratio of the inorganic salt to the biomass pyrolysis oil is (1:2000)-(1:800), the mass ratio of the organic demulsifier to the biomass pyrolysis oil is (1:4000)-(1:1000), mixing completely, standing and taking an upper-layer biomass pyrolysis oil; II, carrying out catalytic cracking modification on the biomass pyrolysis oil: using a modified catalyst: (1) modified catalyst: carrying out ageing treatment on a zeolite molecular sieve load carclazyte catalyst for 2-8 hours with 100% water vapor at 500-800 DEG C; placing the aged catalyst in a reactor, injecting the biomass pyrolysis oil in a reactor with the catalyst, wherein the agent-oil ratio is 1:(3-16), and carrying out biomass pyrolysis oil catalytic cracking modification at the mass airspeed of 6-15h<1>, the reaction temperature of 380-700 DEG C and the reaction pressure of 0.1Mpa-0.8Mpa.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

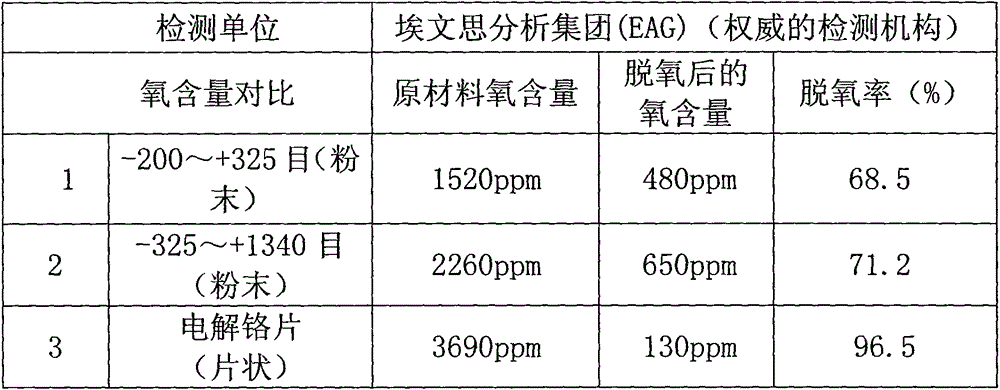

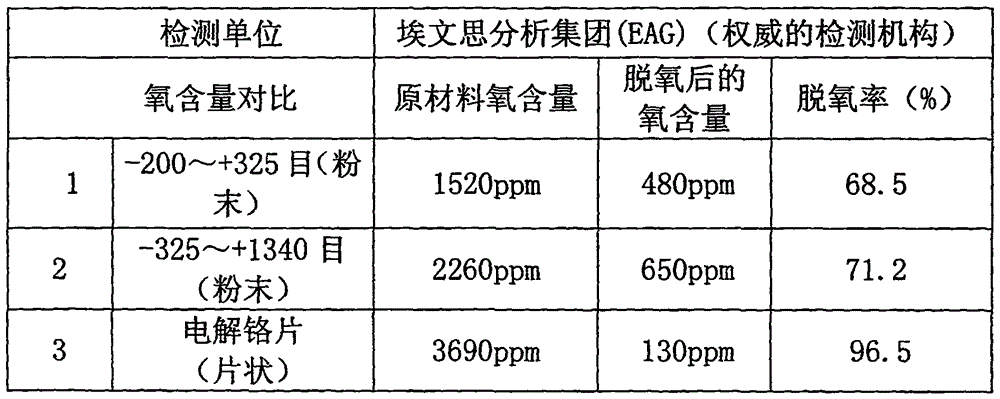

Hydrogen plasma deoxidation method for chromium powder

The invention discloses a hydrogen plasma deoxidation method for chromium powder. The hydrogen plasma deoxidation method is characterized by comprising the following steps: selecting a metal chromium block and crushing the metal chromium block into chromium powder of -325 to -1340 mesh; carrying out hydrogen plasma deoxidation on the chromium powder, wherein the deoxidation is carried out in a stainless steel container with radio-frequency hydrogen plasma equipment, the radio-frequency hydrogen plasma equipment takes hydrogen gas as a working gas, and a slotted water-cooling copper furnace is arranged in the stainless steel container; firstly, manufacturing the chromium powder subjected to ball grinding into a plurality of chromium powder rod bodies, each of which having a diameter of 15-20mm and a length of 20-3mm, preparing a plurality of chromium powder rod bodies from chromium powder subjected to ball grinding by arc melting in the presence of argon gas at 0.02-0.05Mpa, and then connecting every two chromium powder rod bodies end to end and placing on the slotted water-cooling copper furnace; feeding gas through the radio-frequency hydrogen plasma equipment; manufacturing chromium rods in an once forming manner through a zone-melting method so as to finish deoxidation. The hydrogen plasma deoxidation method is used for carrying out chromium powder deoxidation by using the radio-frequency plasma equipment and is simple in process and low in cost, and the oxygen content of the product can accord with using requirements.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

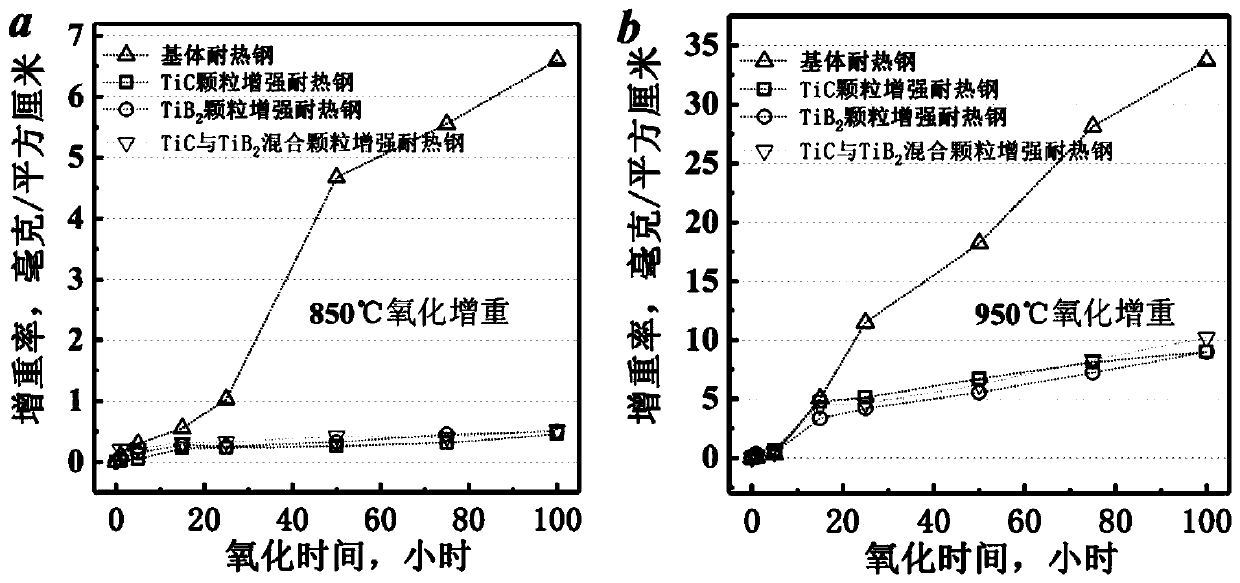

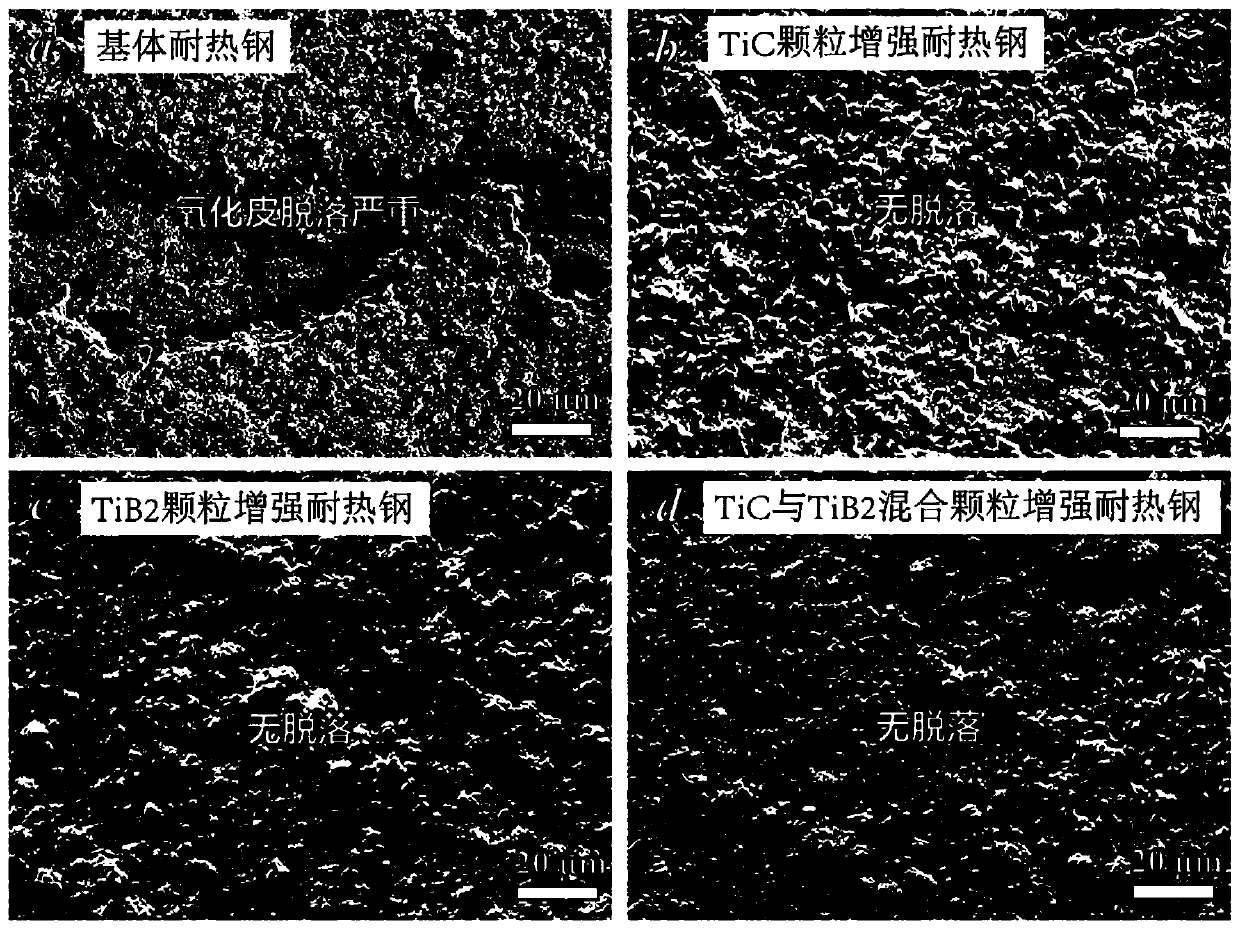

Cr-Ni austenitic heat-resistant steel with endogenous precipitated reinforcing phase and preparation method thereof

ActiveCN110952028AImprove antioxidant capacityImprove mechanical propertiesOxidation resistantAustenite

The invention relates to the technical field of metallurgy, in particular to Cr-Ni austenitic heat-resistant steel with an endogenous precipitated reinforced phase and a preparation method thereof. The Cr-Ni austenitic heat-resistant steel reinforced by TiC and / or TiB2 particles has a metal and ceramic two-phase structure, so that the mechanical property of the heat-resistant steel can be improved. Meanwhile, due to the reaction particle effect caused by TiC and / or TiB2, the high-temperature oxidation resistance of the heat-resistant steel is greatly improved. In the heat-resistant steel, thevolume fraction of the endogenous precipitated reinforcing phase is 1.2%-15.9%, uniform dispersion distribution of ceramic particles in a Cr-Ni austenitic heat-resistant steel matrix can be ensured, so that the high-temperature oxidation resistance of the Cr-Ni austenitic heat-resistant steel is greatly improved on the premise of lower Cr content.

Owner:GUANGDONG INST OF NEW MATERIALS

Magnesium-containing steel 45 and preparation process thereof

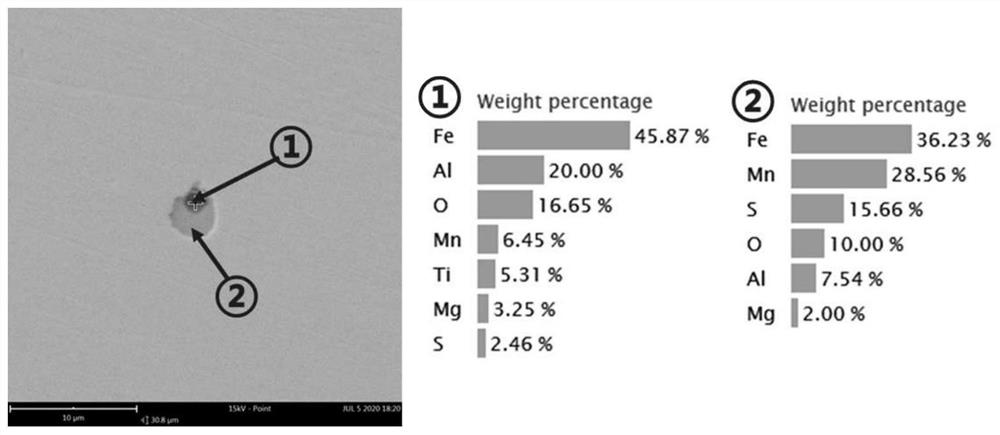

PendingCN113957338AIncreased level of controlIncrease ratingsTemperature control deviceProcess efficiency improvementOxide compositeMolten steel

The invention discloses magnesium-containing steel 45 and a preparation process thereof, and relates to the technical field of steel production. The steel 45 comprises the following chemical components of, in percentage by mass, 0.45%-0.48% of C, 0.17%-0.37% of Si, 0.65%-0.80% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.0005%-0.0020% of Mg, and the balance iron and inevitable impurities. On the basis of ensuring the safe production of the steel 45, the inclusion in the steel is modified by feeding a magnesium-silicon cored wire into molten steel at the final stage of refining, so that the inclusion in the steel is converted into the fine and dispersively distributed sulfide-oxide composite inclusion, the rating of the inclusion is optimized, and the comprehensive mechanical property of the steel 45 is improved.

Owner:NANJING IRON & STEEL CO LTD

Preparation method of fluoride-free low-titanium molten steel cleaning agent (refining material)

The invention relates to a preparation method of a fluorine-free low-titanium molten steel purifying agent (refined material), and belongs to the technical field of deep processing of non-metallic materials. The preparation method is as follows: melting at least one of natural wollastonite, quartz and calcium carbonate as a raw material to obtain a fluorine-free low-titanium molten steel purifier (refined material). The fluorine-free low-titanium molten steel purifier (refined material) prepared by the present invention can be directly used for impurity removal, refining and cleaning molten steel during steel smelting; the fluorine-free low-titanium molten steel purifier (refined material) forms slag quickly and It absorbs impurities in molten steel, increases the fluidity of molten steel, and at the same time, removes non-metallic inclusions in molten steel, effectively deoxidizes, and promotes desulfurization. It is an ideal molten steel refining material for smelting special steel and pure steel.

Owner:大连环球矿产股份有限公司

High-manganese low-carbon composite alloy and method for preparing same

The invention discloses a kind of high manganese and low carbon composition alloy and the preparation method of it, the composition alloy contain the percentage by weight component as follow: Mn 70~75, Si 11~17, Al 7~14, P<0.2, C<0.3, S<0.03,surplus is Fe. The invention of composition alloy component proportioning science and rational, specific weight controlling strict, the method can deoxidize efficient for liquid steel, remove the foreign substance in liquid steel and deoxidize rapidly, make the steel slag easily floated upward and removed to obtain high degree of purity liquid steel, the composition alloy can be used as deoxidant in smelting kinds of steel, especially suitable for smelting conduit wiring steel, bridge and canal steel and high-strength ship plate steel that need strength deoxidation capacity, the composition alloy can reach high deoxidation effect.

Owner:危松林

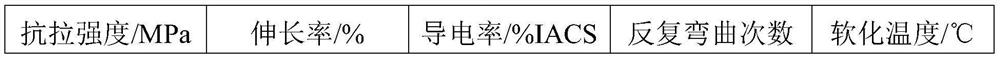

High-strength and high-conductivity copper-magnesium alloy for dropper, wire rod and preparation method of wire rod

The invention relates to a high-strength and high-conductivity copper-magnesium alloy for a dropper, a wire rod and a preparation method of the wire rod, and belongs to the technical field of alloys. The alloy comprises the following components in percentage by mass: 0.2 to 0.7 percent of Mg, 0.02 to 0.06 percent of Cr or Cr + Zr, 0 to 0.045 percent of La, 0 to 0.045 percent of Ce and the balance of Cu. The wire rod made of the alloy has a monofilament diameter of 0.5 to 0.65 mm. The preparation method of the wire rod comprises the steps of up-drawing continuous casting, continuous extrusion, primary drawing, bell jar type intermediate annealing, secondary drawing and online annealing treatment. According to the novel copper-magnesium alloy wire rod prepared through the method, the monofilament tensile strength is larger than or equal to 650 MPa, the electric conductivity is larger than or equal to 62% IACS, the elongation is larger than or equal to 6%, the repeated bending frequency is larger than or equal to 12, the softening temperature is larger than or equal to 550 DEG C, and the performance meets the standard of TB / T 3111-2017 Copper and copper alloy stranded conductors for electrified Railway.

Owner:GRIMAT ENG INST CO LTD

DC arc induction furnace

InactiveCN1712871AAvoid the technical problem of freezing to the point where refining is impossibleWon't "freeze" packetsLighting and heating apparatusBrickHeat capacity

A DC arc induction furnace for refining molten steel has the top graphite cathode connected to the cathodic copper bus of rectifier chest via the water-cooled cable and the electrically conductive bottom bricks used as bottom anode connected to the anodic copper bus of rectifier chest via the water-cooled cable. Its advantages are high volume and heat capacity, long service life and high quality of molten steel.

Owner:NORTHEASTERN UNIV

High-strength composite solder

InactiveCN110076476AMaterial deviation is smallImprove matchWelding/cutting media/materialsSoldering mediaSlagManganese

The invention relates to high-strength composite solder. Deposited metal formed by the solder comprises, by mass percentage, 0.04%-0.08% of carbon, 0.30%-0.50% of silicon, 4%-8% of manganese, 10%-18%of nickel, 4%-8% of chromium, 2%-4% of titanium, 0.4%-0.8% of molybdenum, 60%-70% of iron and the balance impurities, specifically, the weight ratio of the nickel to the chromium is 2-3:1. The high-strength composite solder has the high strength and the high mechanical stretch performance, is stable in performance under the high temperature condition, low in cost and few in electric arc splash, and easily achieves slag removal.

Owner:HUANGSHI GAOCHAO IND & MINING MACHINERY

Process of producing Zn-Cu-Ni alloy strip

Owner:ANHUI XINKE NEW MATERIALS

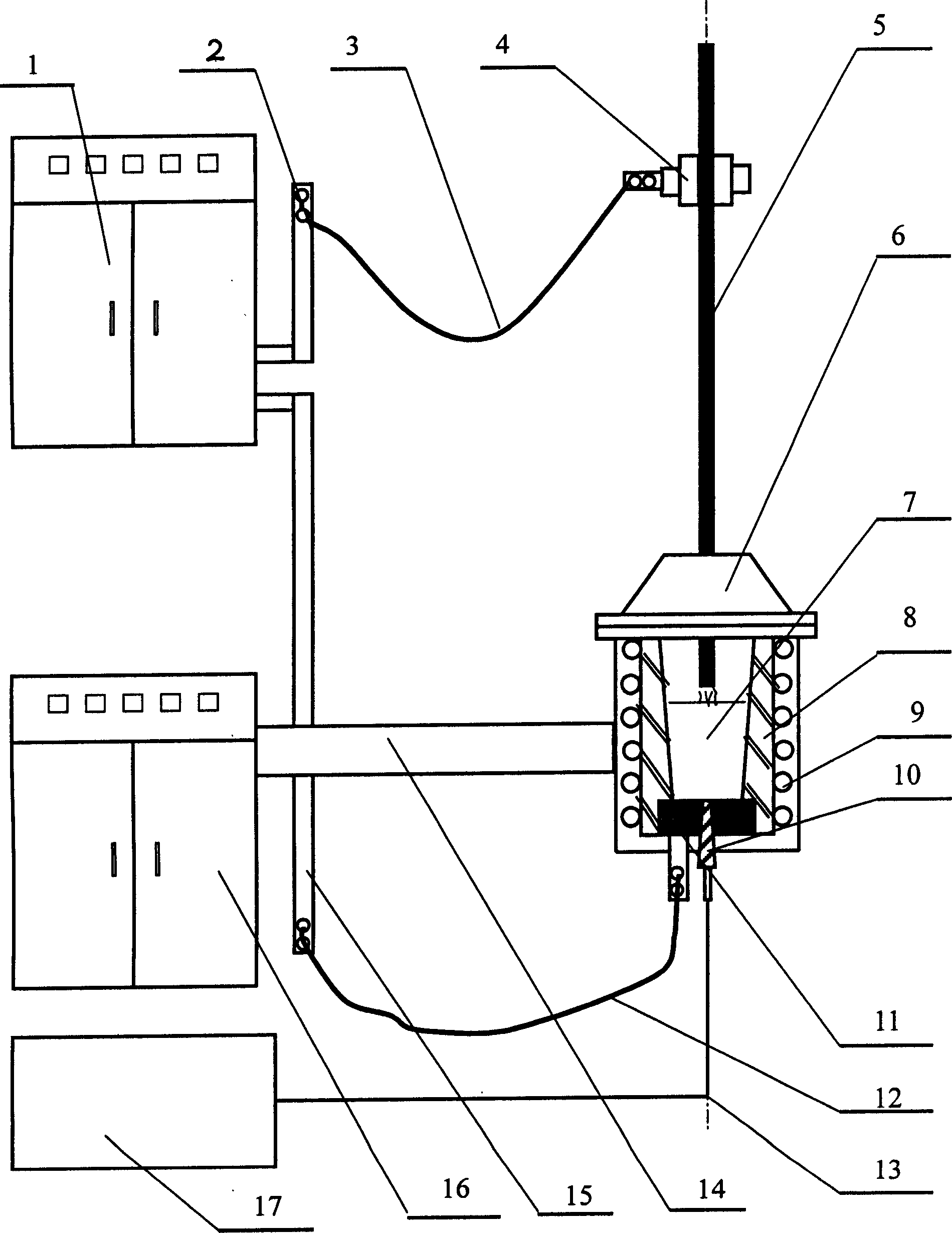

High-strength corrosion-resistant copper alloy and preparation method thereof

PendingCN114395710AImprove performanceConsistent performanceFurnace typesHeat treatment furnacesPetrochemicalMechanical property

The invention discloses a high-strength corrosion-resistant copper alloy and a preparation method thereof. The high-strength corrosion-resistant copper alloy comprises 4.0 to 10.0 wt% of Al, 1.0 to 4.0 wt% of Fe, 1.0 to 4.5 wt% of Mn, 0.8 to 3.5 wt% of Ni, 0.08 to 0.5 wt% of Cr, 0.001 to 0.05 wt% of P, less than or equal to 0.15 wt% of inevitable impurities in total, and the balance of Cu. By adjusting the contents of the Fe, Ni, Cr and P elements, optimizing the processing technology and the heat treatment technology, controlling the composition of a matrix, the grain size and the fine dispersed distribution of a strengthening phase, the effects of all alloy elements are fully exerted, the mechanical property, machinability and corrosion resistance of the alloy are remarkably improved, and the performance of the alloy can be comprehensively improved through thermomechanical treatment. The tensile strength of an annealed material is 560 MPa or above, the yield strength is 330 MPa or above, the yield ratio is 0.55 or above, the ductility is 42% or above, the total immersion uniform corrosion rate is 0.01-0.02 mm / a, and the erosion corrosion rate is 0.2 mm / a or below under the seawater condition with the flow speed being 5 m / s. The alloy can meet the requirements of ocean engineering, ships, petrochemical engineering and the like on the comprehensive performance of the aluminum bronze.

Owner:KUNMING METALLURGY INST

Slag nonpollution deoxygenation method capable of regulating anode oxygen partial pressure and device thereof

InactiveCN101457276BImprove pollutionAccelerated exclusionGas emission reductionOxygen ionsVacuum chamber

The invention relates to a pollution-free molten slag deoxidization method capable of adjusting anode oxygen partial pressure and a device thereof, and belongs to the technical field of metallurgical refining process. In the method, molten steel or molten metal is deoxidized and purified by the special device. In the method, the molten slag is taken as electrolyte, a deaeration cavity electrode inserted into the molten slag is taken as an anode, and the molten steel or the molten metal is taken as a cathode; the deaeration electrode is provided with an electrode cavity and is communicated with a vacuum chamber by a conduit; an applied DC power supply exerts direct current impulse voltage so that an electric field is formed between the molten steel or the molten metal and an oxygen electrode of the molten slag, and the conduction of oxygen ions in a molten slag system and mass transfer of dissolved oxygen in the molten steel are controlled by controlling a current value and a voltage value of the DC power supply as well as components of the molten slag. The oxygen is diffused from the molten slag to the electrode cavity and discharged by an air exhaust system by controlling the oxygen partial pressure of the electrode cavity.

Owner:SHANGHAI UNIV

Preparation method of molten steel deoxidizing agent

The invention relates to a preparation method of a molten steel deoxidizing agent and belongs to the technical field of iron and steel smelting. The preparation method comprises the steps that lanthanum oxide and boron powder are mixed, ball-milled, sieved and then pressed, and a billet is obtained; the billet is cooled to the room temperature after being calcined and then is crushed and ball-milled, and modified powder is obtained; A00 aluminum, metal manganese powder and manganese chloride are melted, and alloy melt is obtained; and the modified powder is added into the alloy melt to be stirred and mixed, the mixture is cooled to the room temperature after heating melting and segmented cooling are conducted, and the mixture is crushed, ball-milled and sieved. According to the preparation method, manganese and aluminum are compounded to prepare an alloy material, and the alloy material conforms to molten steel in density, so that the floating speed is remarkably reduced after the alloy material is thrown into the molten steel; the alloy material too late to dissolve suspends in the molten steel, the upper half portion of the alloy material is oxidized by furnace slag possibly, the lower half portion of the alloy material can still continue suspending in the molten steel for deoxygenation treatment, and the metal recovery rate is effectively increased; and meanwhile generation of intragranular acicular ferrite in steel is effectively promoted while the molten steel material is deoxidized, so that the performance of a steel material is improved.

Owner:常州市协旺纺织品有限公司

A kind of strong and tough flux-cored welding wire and its preparation method

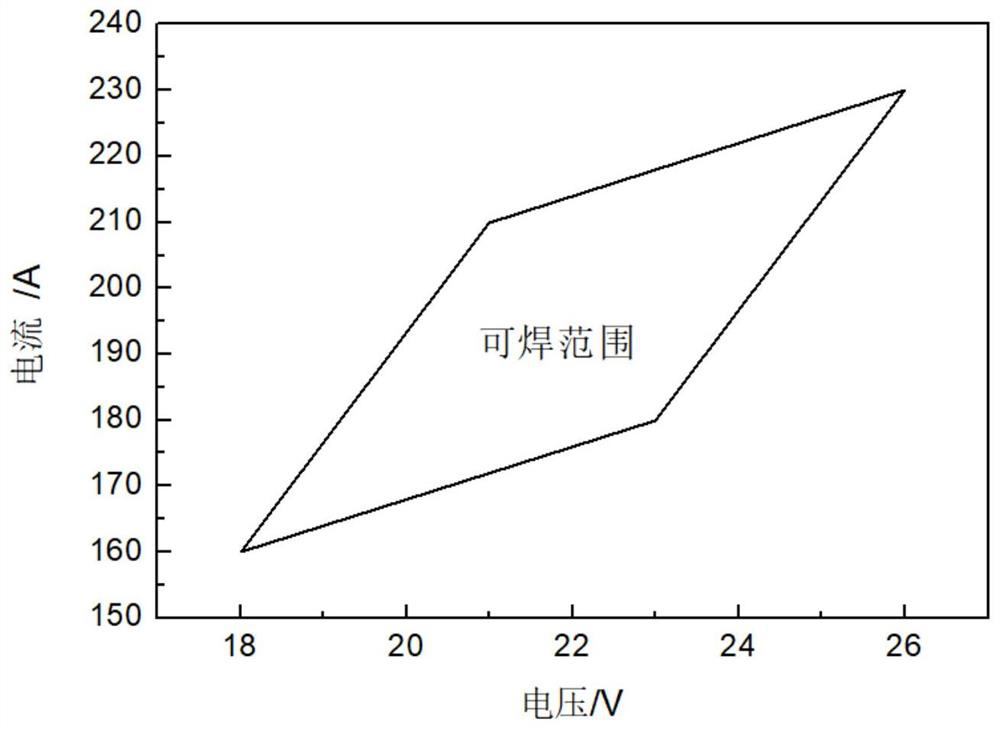

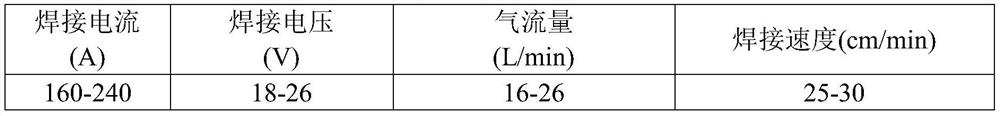

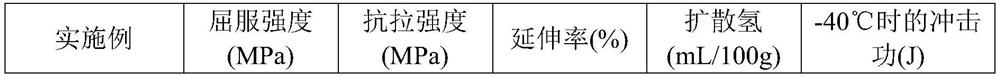

ActiveCN112975206BEffective deoxygenationSimple structureWelding/cutting media/materialsSoldering mediaFerrosiliconCarbide

Owner:江苏东南焊材有限公司

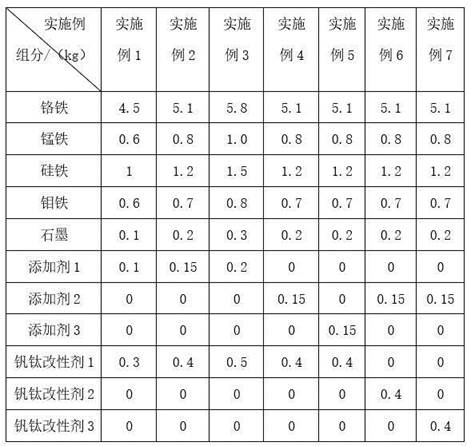

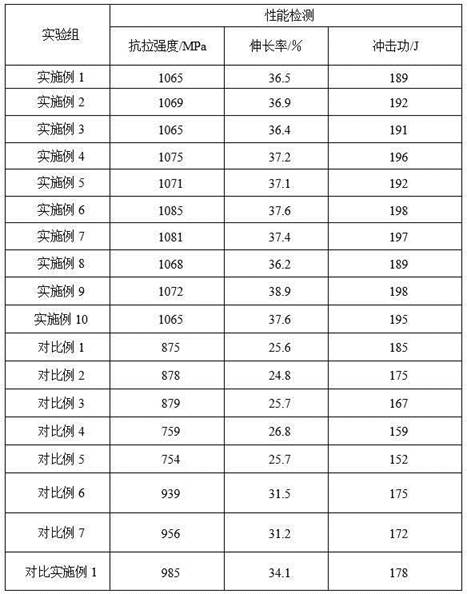

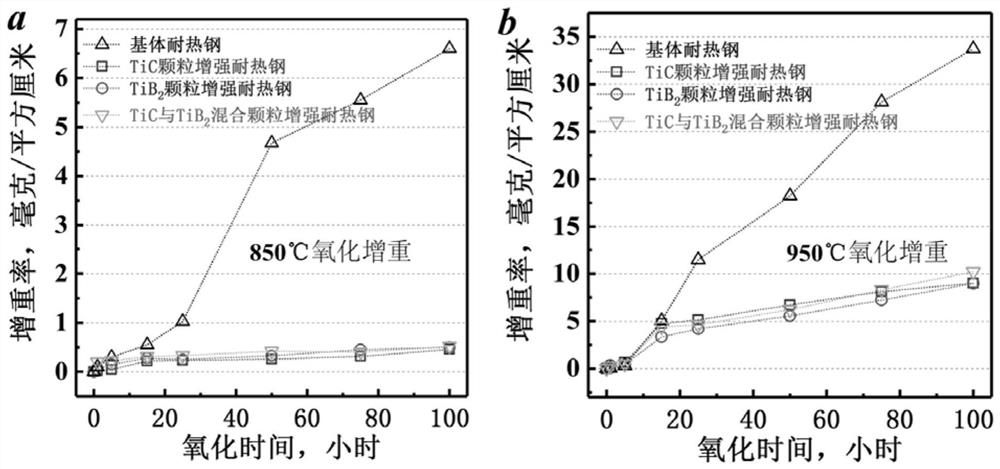

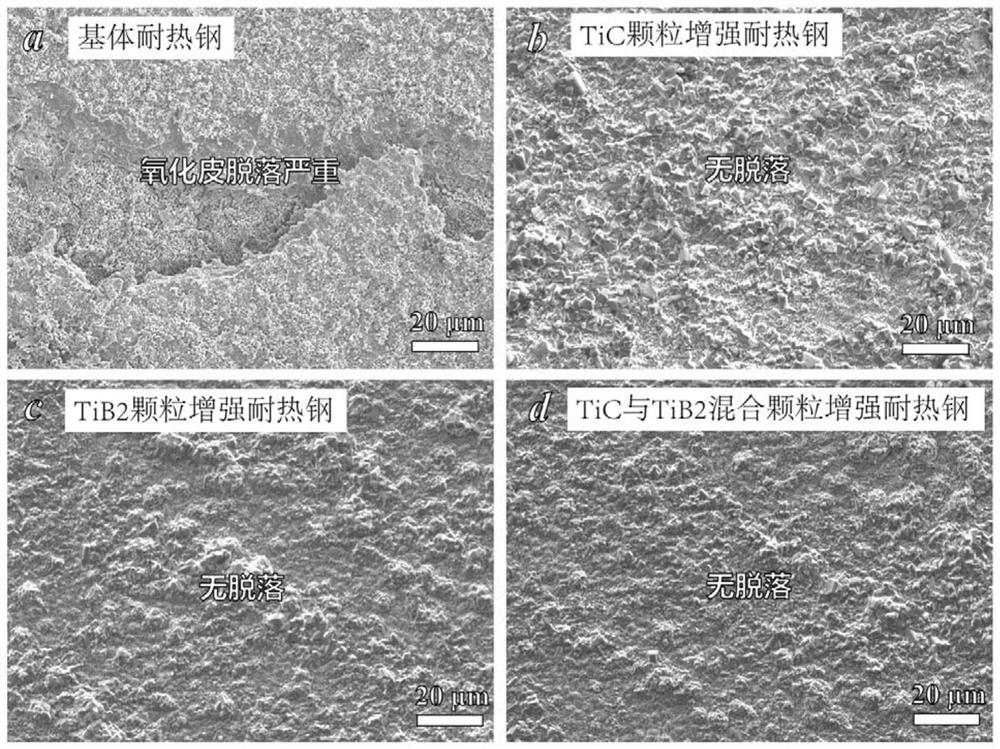

Cr-Ni system austenitic heat-resistant steel with endogenous precipitation reinforcing phase and preparation method thereof

ActiveCN110952028BImprove antioxidant capacityImprove mechanical propertiesOxidation resistantAustenite

The present application relates to the field of metallurgy technology, in particular, to a Cr-Ni austenitic heat-resistant steel with endogenously precipitated reinforcing phase and a preparation method thereof. Using TiC and / or TiB 2 The particle-reinforced Cr-Ni austenitic heat-resistant steel has a metal and ceramic two-phase structure, which can improve the mechanical properties of the heat-resistant steel. At the same time, since TiC and / or TiB 2 The "reactive particle effect" brought about greatly improves the high temperature oxidation resistance of heat-resistant steel. In the heat-resistant steel, the volume fraction of the endogenous precipitated reinforcing phase is 1.2-15.9%, which can ensure the uniform dispersion and distribution of ceramic particles in the Cr-Ni series austenitic heat-resistant steel matrix, so that at a lower Cr content Under the premise, the high temperature oxidation resistance of Cr-Ni austenitic heat-resistant steel is greatly improved.

Owner:GUANGDONG INST OF NEW MATERIALS

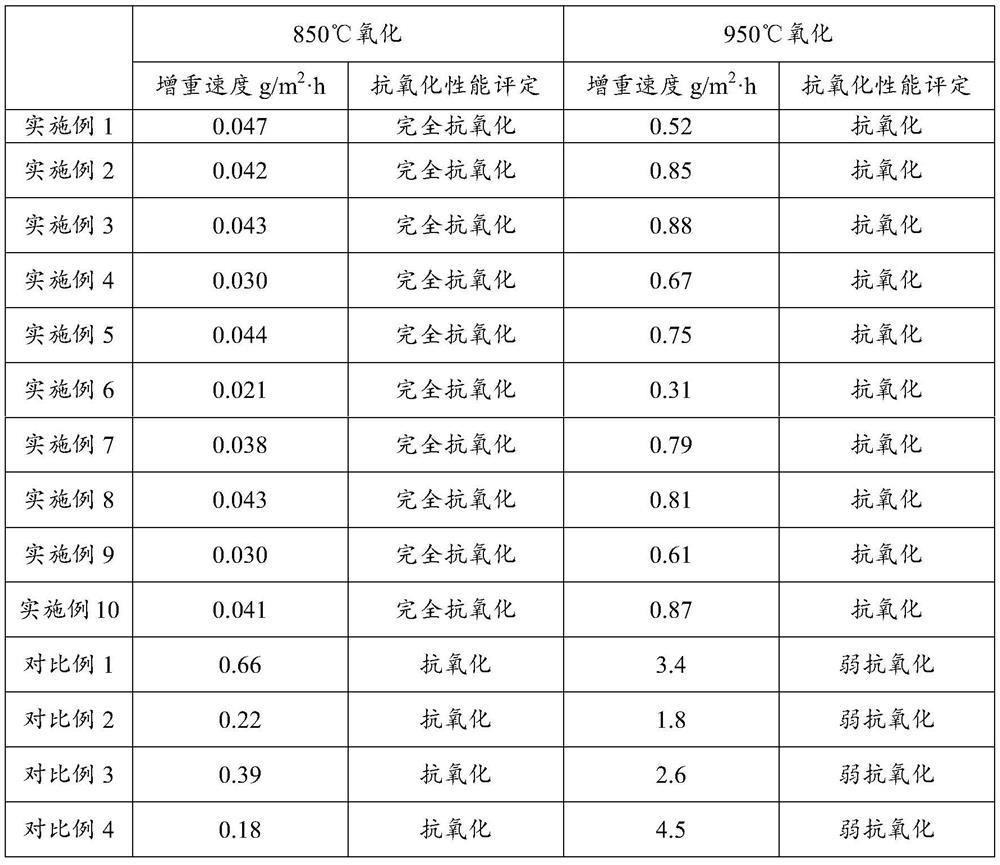

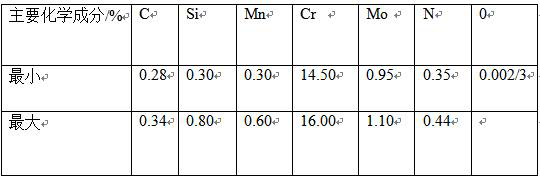

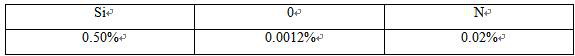

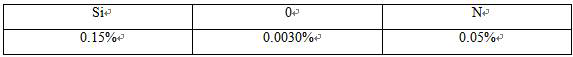

Smelting process for supersaturated high-nitrogen stainless steel electrode bar

PendingCN112481447AEffective deoxygenationReduce a large number of poor studentsProcess efficiency improvementVacuum furnaceFerrous metallurgy

The invention discloses a smelting process for a supersaturated high-nitrogen stainless steel electrode bar, and belongs to the technical field of high-nitrogen ferrous metallurgy application. The smelting process comprises the steps of manufacturing foam slag by using coke powder in the primary smelting process, and tapping in a steel and slag remaining mode; performing slagging deoxidation, desulfurization and impurity removal treatment to molten steel flowing into a ladle refining furnace to obtain furnace slag, and meanwhile adding multiple intermediate alloys into the ladle refining furnace; determining whether to add a small amount of Al blocks or not according to the situation that the molten steel deoxidation and the furnace slag deoxidation are good or not in the process; puttingthe refined molten steel into a VD vacuum furnace for vacuum treatment, and blowing argon at the vacuum degree of no higher than 67 Pa; replacing argon with nitrogen for soft blowing and stirring themolten steel when the vacuum degree is higher than 98 Pa; controlling the temperature of the obtained supersaturated high-nitrogen molten steel to be 1525-1535 DEG C, pouring the supersaturated high-nitrogen molten steel into an electrode bar grinding tool, and then cooling and conveying the supersaturated high-nitrogen molten steel; and forging and processing the molten steel to obtain the supersaturated high-nitrogen stainless steel electrode bar.

Owner:DEQING TIANMA BEARING CO LTD

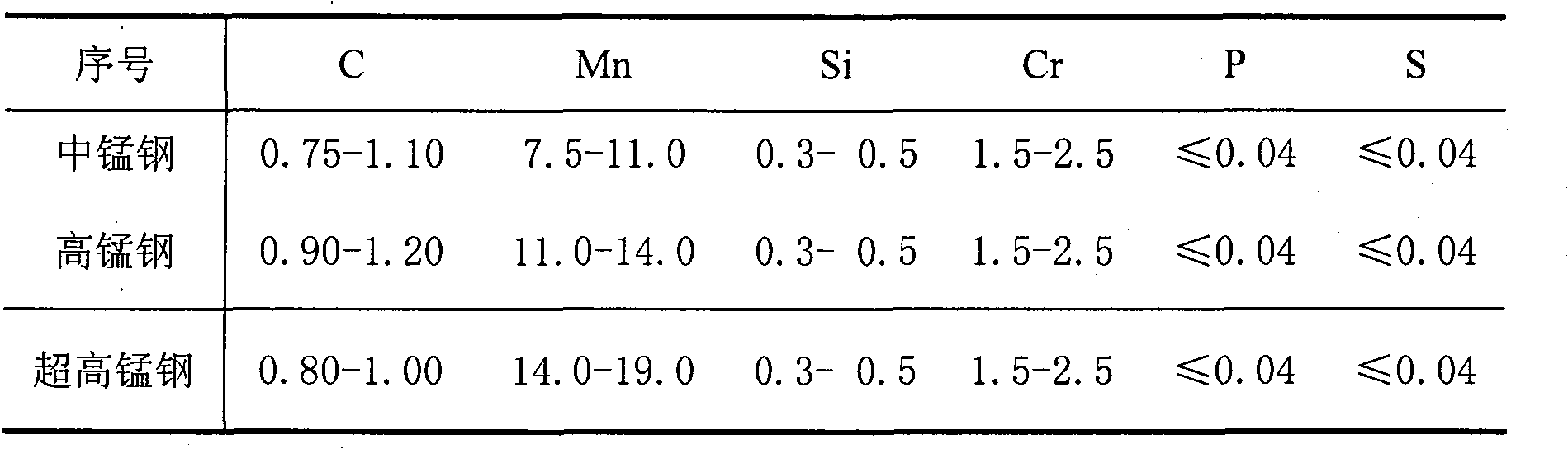

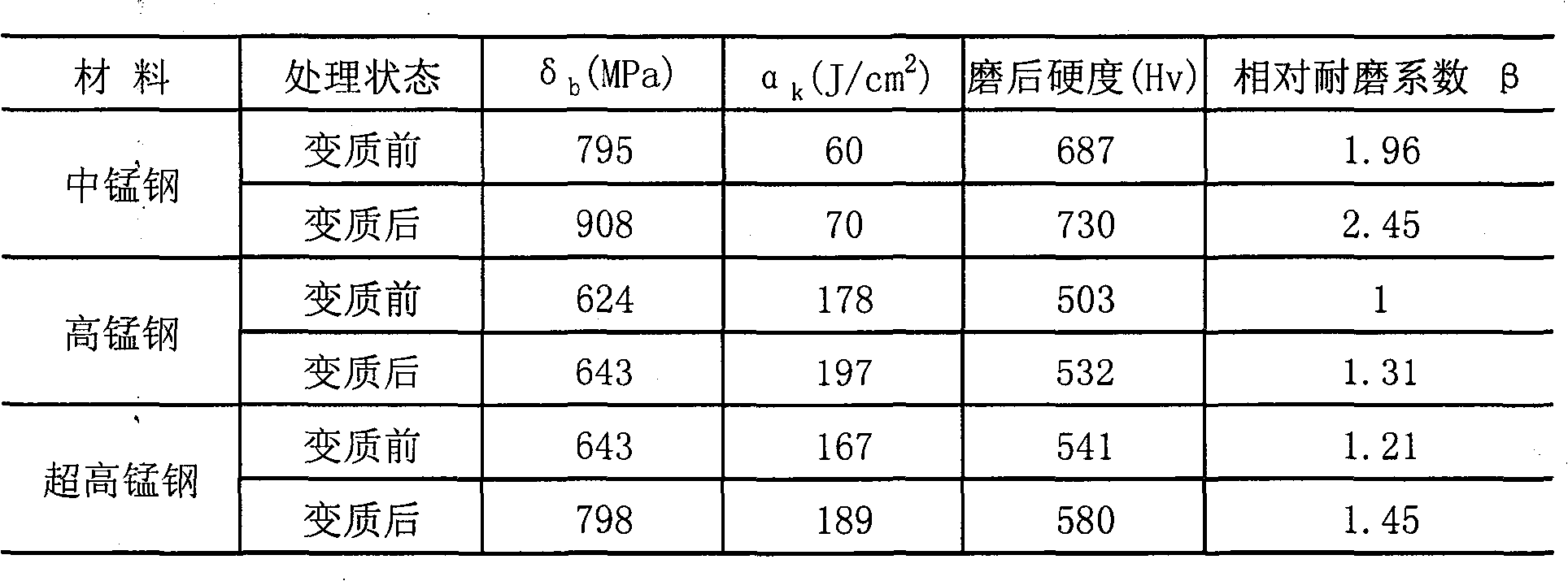

Novel composite modifier for austenitic manganese steel

InactiveCN101289723BControl crystallizationEnhance the ability to resist "recession"Melting tankRare earth

The invention discloses a novel composite modifier for austenitic manganese steel, comprising rare earth alloy, ferrotitanium, calcium silicon and aluminum, wherein the dosage of the Re-containing rare earth alloy accounts for 0.20-0.25 percent of the weight of molten steel; the dosage of the ferrotitanium accounts for 0.02-0.03 percent of the weight of the molten steel; the dosage of the calciumsilicon accounts for 0.20-0.25 percent of the weight of the molten steel; and the dosage of the aluminum accounts for 0.15-0.20 percent of the weight of the molten steel. Treatment inside a furnace is carried out in the alloying adjustment stage for the composition of the molten steel after ferromanganese is added for the fine adjustment of the manganese content of the molten steel; one third of the rare earth alloy is added to a molten pool, and the aluminum is added before the tapping of the molten steel. Treatment outside the furnace is to add the calcium silicon, two thirds of the rare earth alloy and the ferrotitanium to a steel ladle. The adoption of the Re-Ca-Ti-Al multi-element composite modifier prolongs the effective time of the modification process of the molten steel and guarantees good modification effect.

Owner:铜陵市大明玛钢有限责任公司

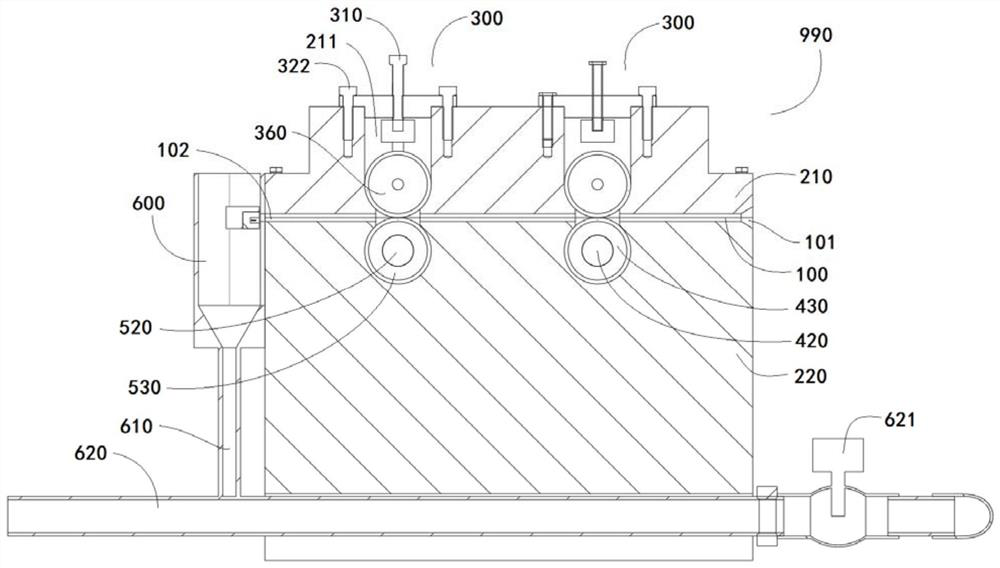

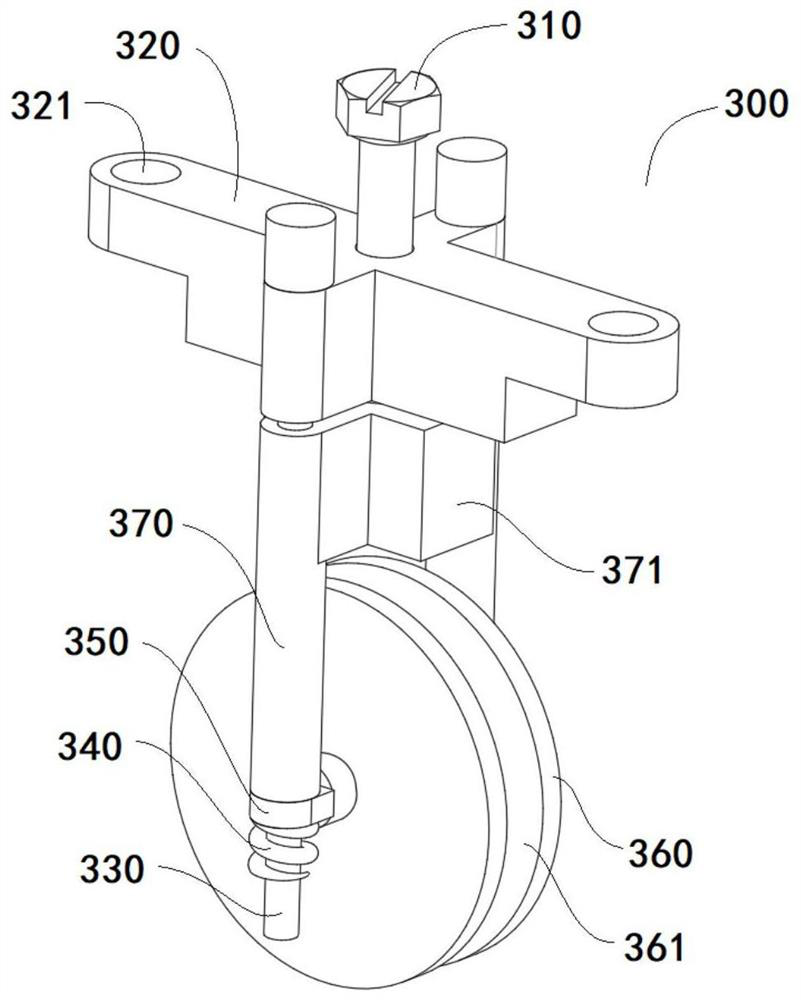

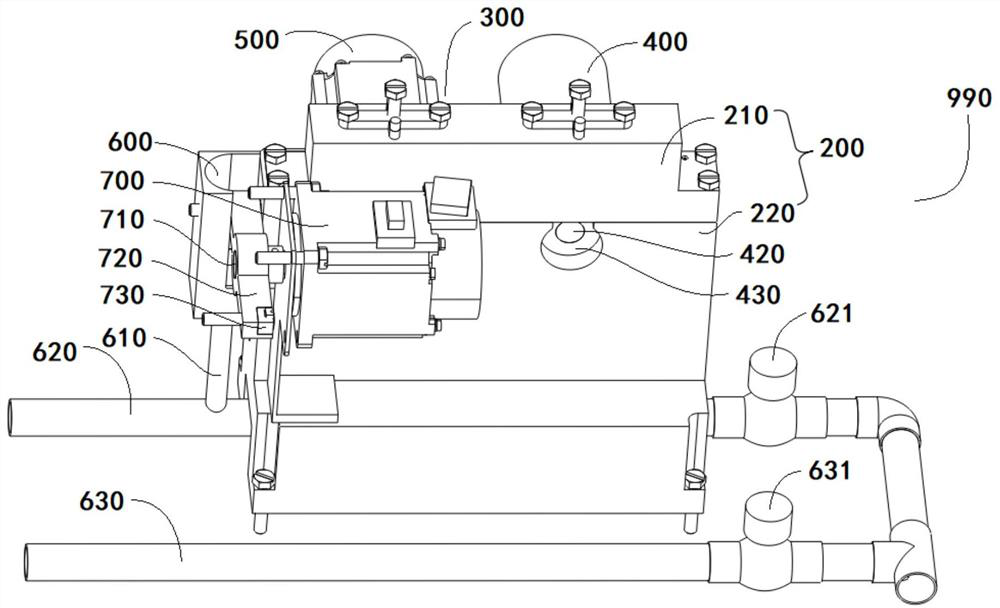

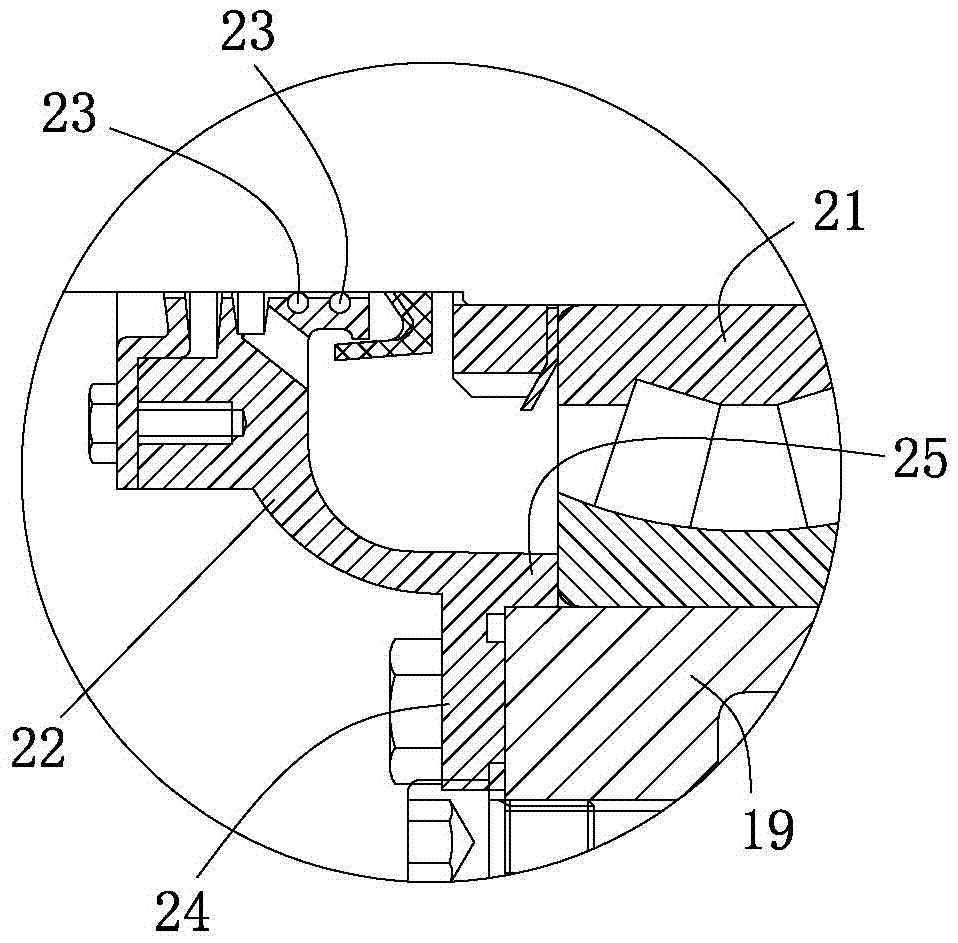

Metal wire feeding device, charging system and charging method

ActiveCN113684370AReduce burning lossStable deliveryFilament handlingIncreasing energy efficiencyDrive wheelMetallurgy

The invention discloses a metal wire feeding device, a charging system and a charging method, and belongs to the technical field of electroslag metallurgy. The metal wire feeding device comprises a feeding channel, a pressing mechanism, a driving mechanism, a driving wheel and a support; the pressing mechanism comprises a guide rod, an elastic piece, a pressing wheel and a sliding sleeve; the guide rod is vertically arranged on the support; the sliding sleeve is arranged outside the guide rod in a sliding mode and connected with the guide rod through the elastic piece, and the pressing wheel is rotationally connected with the sliding sleeve; the driving mechanism is arranged on the support, is connected with the driving wheel and is used for driving the driving wheel to rotate; the driving wheel and the pressing wheel are arranged on the two opposite side portions of the feeding channel respectively, and the rotating plane of the driving wheel and the rotating plane of the pressing wheel and the feeding channel are located in the same plane; and the driving wheel and the pressing wheel can be connected with a metal wire material in the feeding channel in a rolling manner. By means of the metal wire feeding device, stable pressing conveying can be achieved, the conveying amount of metal wire materials can be accurately controlled, the oxygen content of an electroslag remelting system is stably controlled to range from 20 ppm to 30 ppm, and the quality of electroslag ingots is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

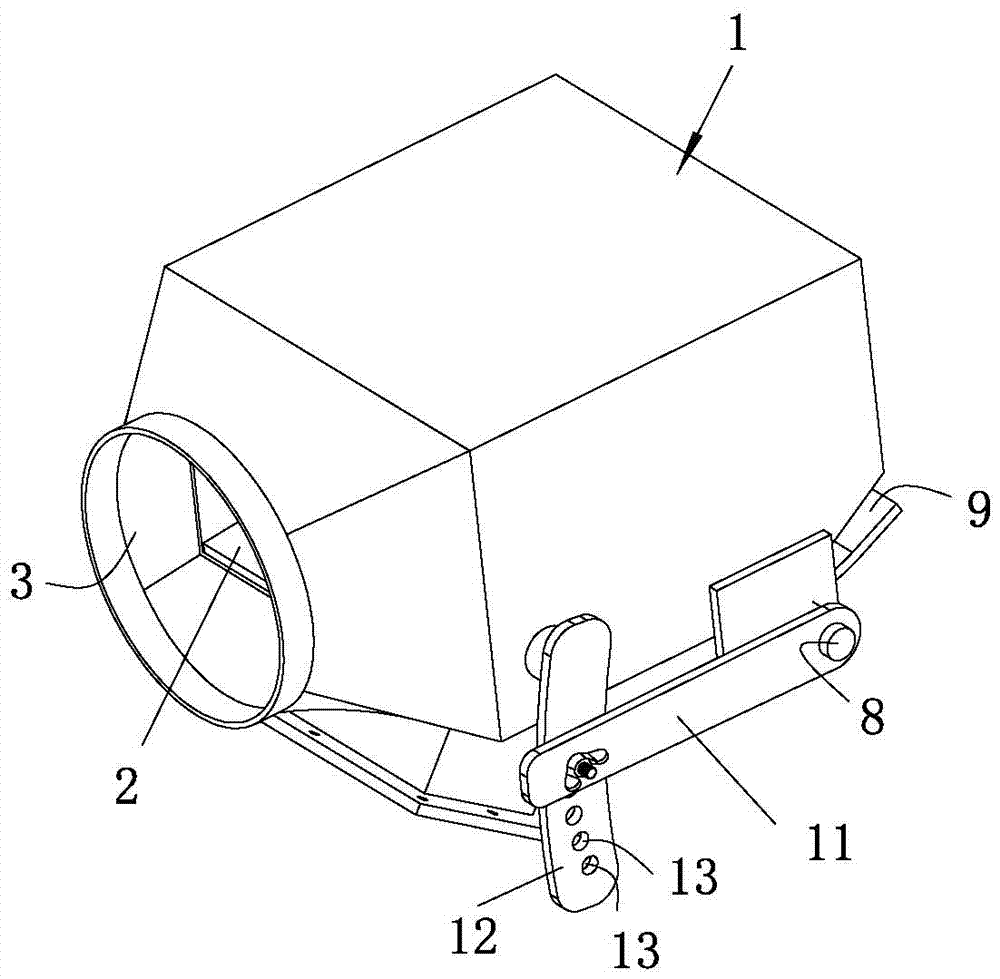

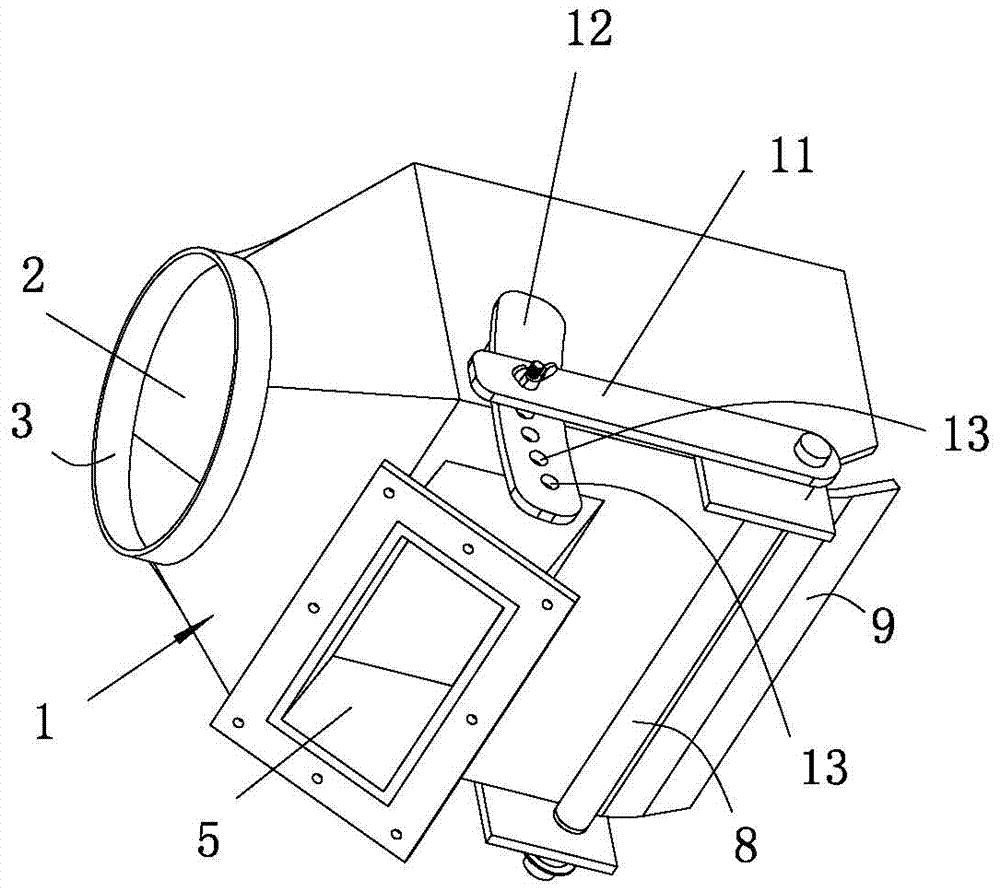

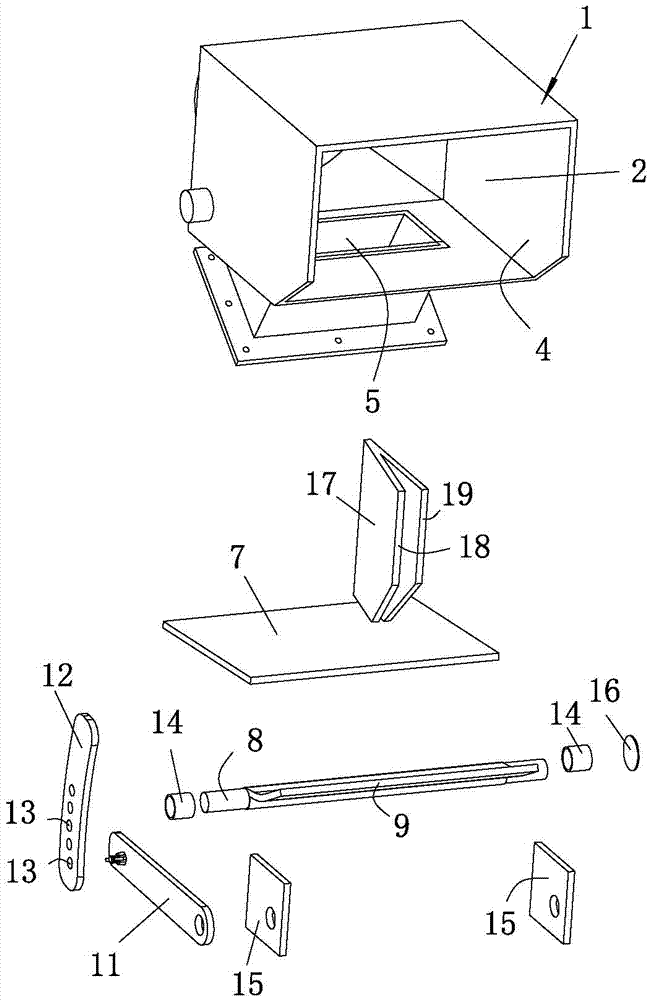

Material spraying device for combusting and feeding biomass bagasse

ActiveCN107314392AImprove high temperature resistanceAccelerated corrosionFuel feeding arrangementsLump/pulverulent fuel feeder/distributionNitrogen oxidesEnvironmental engineering

The invention relates to the technical field of material supply devices and in particular discloses a material spraying device for combusting and feeding biomass bagasse. The material spraying device comprises a shell body, wherein the shell body is internally provided with a feeding hole penetrating through the shell body; a feeding opening and a discharging opening are formed in two ends of the feeding hole respectively; the shell body is further provided with an air inlet hole communicated with the feeding hole; an air inlet is formed in one end, far away from the feeding hole, of the air inlet hole; a communication opening is formed in one end, communicated with the feeding hole, of the air inlet hole; the shell body is provided with an interlayer plate located in the feeding hole; the interlayer plate is used for separating the communication between the feeding opening and the communication opening; the air inlet hole is communicated with the discharging opening through a gap between the interlayer plate and the shell body; when the material spraying device is actually utilized, the biomass bagasse to be combusted is conveyed into the feeding hole through the feeding opening and external air enters the shell body through the air inlet hole; the biomass bagasse in the feeding hole is sprayed into a boiler so that the biomass bagasse is dispersed in the boiler and a condition that the biomass bagasse enters the boiler for combustion in a pile manner is prevented; and the combustion efficiency of the biomass bagasse is improved and the generation of low-nitrogen oxide is reduced.

Owner:GUANGDONG YUEWEI ENVIRONMENT TECH CO LTD

Accident alloy disposal method

The invention discloses an accident alloy disposal method and belongs to the field of steel smelting. The accident alloy disposal method comprises the following steps of S1, converter steelmaking; S2, converter tapping, specifically, before alloying operation is conducted, accident alloy and a deoxidizing agent are added for deoxidation, after the tapping amount is complete, at least part of the accident alloy is deoxidized into oxide and exists in steel slag, the oxide comprises manganese dioxide, a manganese source is added according to the lower limit of Mn contained in a steel grade for alloying operation, the accident alloy is added according to the condition that the Mn content in a silicon-manganese alloy contained in the accident alloy is not larger than 0.05% of the mass percent of molten steel, and the deoxidizing agent does not contain the silicon-manganese alloy; and S3, LF furnace refining. Therefore, on the premise that silicon-manganese alloy and silicon-iron alloy in the accident alloy are not sorted, the accident alloy is directly added into the molten steel, so that not only is effective deoxidation achieved, but also Mn is effectively added as an adding component, the accident that the components go out of the standard is not caused, the utilization rate of the accident alloy is effectively increased, and resource waste is prevented.

Owner:SGIS SONGSHAN CO LTD

A Flux-Cored Welding Wire Containing Compound Rare Earth Elements Suitable for Welding 1000mpa Ultra-High-Strength Steel

ActiveCN110480207BEffective deoxygenationEffective dehydrogenationWelding/cutting media/materialsSoldering mediaRare-earth elementCarbon steel

Owner:SHANGHAI UNIV OF ENG SCI

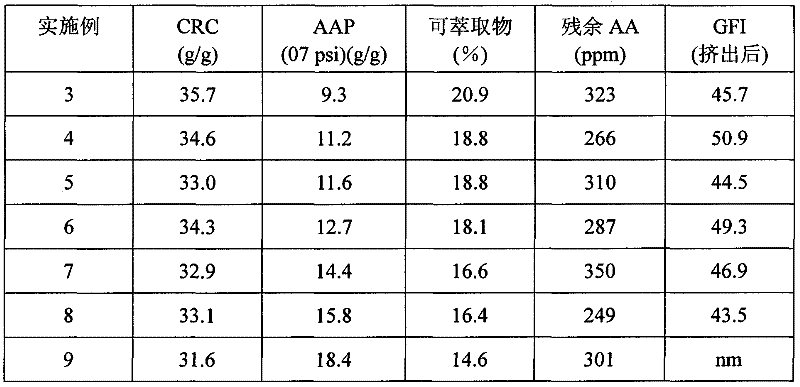

A continuous process for the production of a superabsorbent polymer

ActiveCN102176926AReduce oxygen contentEffective deoxygenationAbsorbent padsBandagesDicarbonateHydrogen

The present invention relates to a continuous process for the production of a superabsorbent polymer comprising: (a) providing an acidic liquid aqueous monomer mixture containing dissolved oxygen, whereby the monomers are selected to provide after polymerization a superabsorbent polymer, (b) continuously feeding said aqueous monomer mixture to a reactor, (c) introducing a source of carbonate or hydrogen carbonate into said aqueous monomer mixture prior to entry into the reactor thereby forming a gas phase comprising carbon dioxide and at least a part of said dissolved oxygen, said gas phase being dispersed in the liquid phase, (d) subjecting the gas / liquid mixture to at least partial phase separation immediately prior to or after entry into the reactor and at least partially removing the separated gaseous phase, (e); subjecting the liquid phase in the reactor to free-radical polymerization to obtain the superabsorbent polymer, and (f) continuously removing the superabsorbent polymer from the reactor.

Owner:EVONIK SUPERABSORBER GMBH

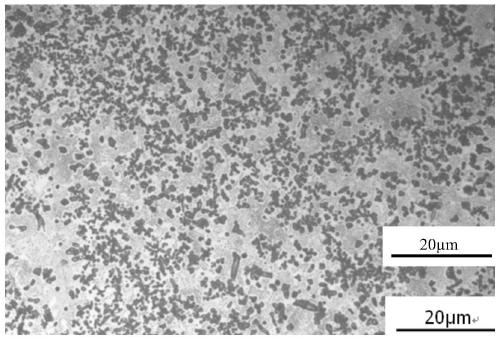

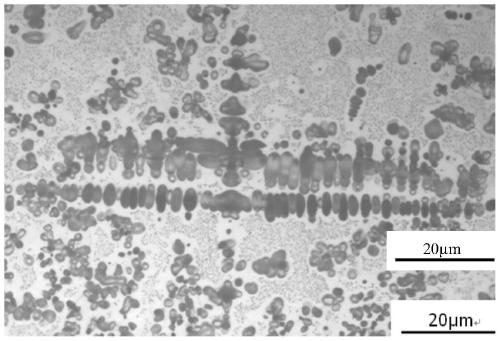

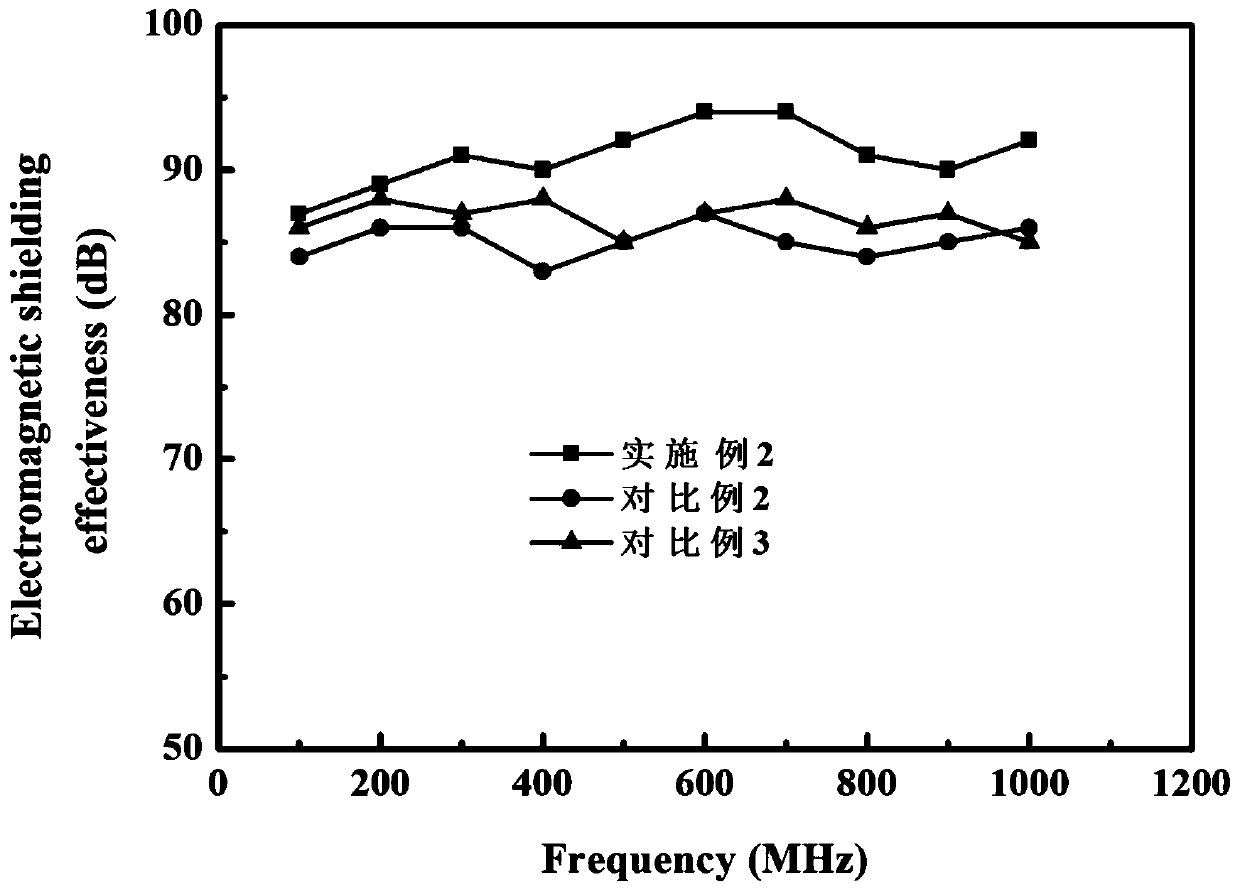

A high-strength, high-conductivity, heat-resistant cu-fe-y-mg alloy material with electromagnetic wave shielding performance and its preparation method

Owner:CENT SOUTH UNIV

Hydrogen plasma deoxidation method of chromium powder

The invention discloses a hydrogen plasma deoxidation method for chromium powder. The hydrogen plasma deoxidation method is characterized by comprising the following steps: selecting a metal chromium block and crushing the metal chromium block into chromium powder of -325 to -1340 mesh; carrying out hydrogen plasma deoxidation on the chromium powder, wherein the deoxidation is carried out in a stainless steel container with radio-frequency hydrogen plasma equipment, the radio-frequency hydrogen plasma equipment takes hydrogen gas as a working gas, and a slotted water-cooling copper furnace is arranged in the stainless steel container; firstly, manufacturing the chromium powder subjected to ball grinding into a plurality of chromium powder rod bodies, each of which having a diameter of 15-20mm and a length of 20-3mm, preparing a plurality of chromium powder rod bodies from chromium powder subjected to ball grinding by arc melting in the presence of argon gas at 0.02-0.05Mpa, and then connecting every two chromium powder rod bodies end to end and placing on the slotted water-cooling copper furnace; feeding gas through the radio-frequency hydrogen plasma equipment; manufacturing chromium rods in an once forming manner through a zone-melting method so as to finish deoxidation. The hydrogen plasma deoxidation method is used for carrying out chromium powder deoxidation by using the radio-frequency plasma equipment and is simple in process and low in cost, and the oxygen content of the product can accord with using requirements.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

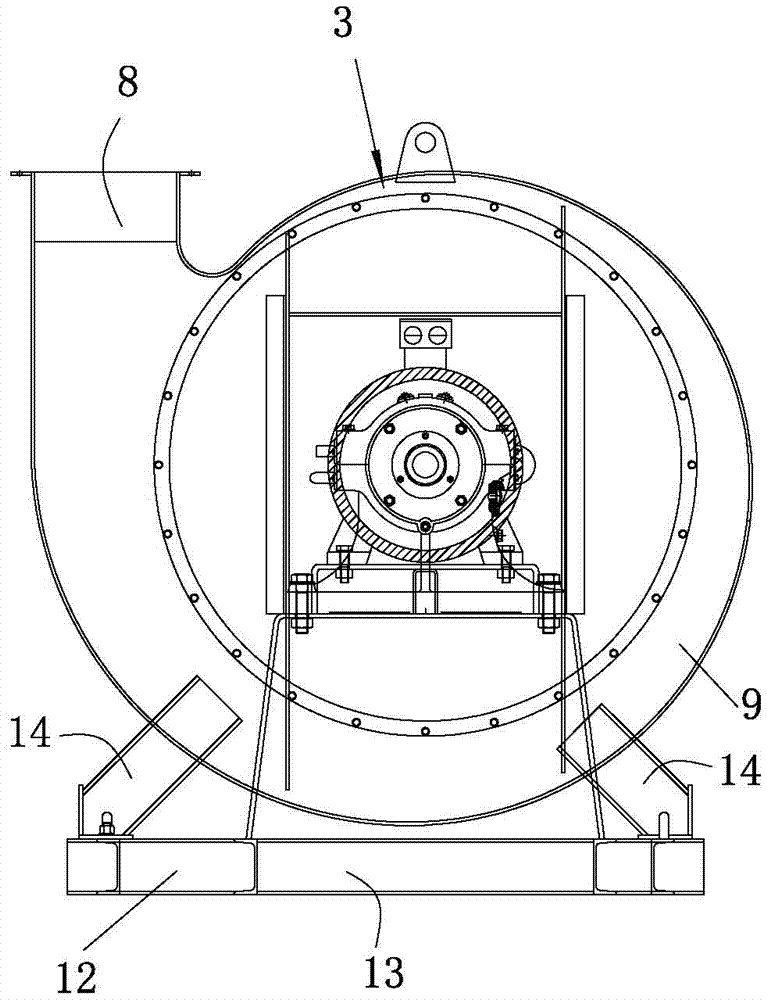

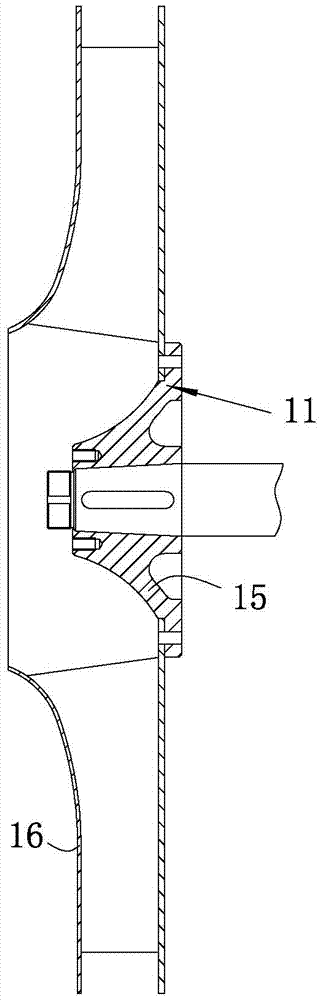

Conveying device used for conveying bagasse to boiler

PendingCN107246622AImprove feeding efficiencyExtended service lifeFuel feeding arrangementsLump/pulverulent fuel feeder/distributionPhysicsElectric machinery

The invention relates to the technical field of bagasse providing equipment, and particularly provides a conveying device used for conveying bagasse to a boiler. The conveying device comprises a bottom frame, a supporting base, an impeller, a drive motor, a tripod and a shaft body, the supporting base and the impeller are arranged on the bottom frame, the drive motor and the tripod are arranged on the supporting base, the shaft body is rotatably connected to the supporting base, the tripod is in a right triangle shape, one right-angle side of the tripod is arranged on the supporting base, the other right-angle side of the tripod is arranged on the impeller, the impeller is provided with a feeding hole and a discharging hole communicated with the feeding hole, during use, exterior bagasse to be conveyed is communicated with the feeding hole through a pipeline, the discharging hole of the impeller is communicated with the exterior boiler, the drive motor is started, the impeller extracts the exterior bagasse, the bagasse is jetted to the boiler through the discharging hole under the effect of centrifugal force effect of the impeller, the bagasse is dispersed in the boiler, the stacked bagasse is prevented from entering the boiler for combustion, the bagasse combustion efficiency is improved, and generation of nitric oxide is reduced.

Owner:GUANGDONG YUEWEI ENVIRONMENT TECH CO LTD

A method for smelting titanium-containing austenitic stainless steel plate

ActiveCN105154620BReduce generationIncrease temperatureProcess efficiency improvementElectric furnaceForeign matterSlag

The invention belongs to the technical field of metallurgy and particularly relates to a method for smelting a titaniferous austenitic stainless steel plate; and by means of the method, the defect that the surface of the titaniferous austenitic stainless steel plate has foreign matter is overcome. The technology includes the processes of electric furnace smelting, AOD furnace decarbonization, denitrifying and reduction and deoxygenation, LF furnace deoxygenation, calcium treatment, slagging off, titanium alloying, composition fine-adjustment and temperature adjusting, weak blowing and sedation and casting protection. By means of the method, carbon and nitrogen are lowered to a certain degree through AOD refining, reduction is conducted till deoxygenation is completed, and nitrogen increase and oxygen increase in the tapping process are controlled; the deoxygenation process is used when a LF furnace draws up at a station, increased oxygen in the AOD tapping process is removed effectively, and the yield of steel is increased and stabilized, generation of oxide of titan in steel is lowered as well; calcium treatment is adopted after deoxygenation, and a deoxygenation product is modified, comes up and is removed; the stirring intensity needs to be controlled in the whole LF operation process, and molten steel nitrogen increase and secondary oxidation are prevented; and meanwhile, the alkalinity of slag and the SiO2 content in the slag are controlled, the weak blowing time is prolonged, the sedation time is prolonged, rejects generated in production are lowered effectively, cost is lowered, and the product quality is improved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com