A kind of strong and tough flux-cored welding wire and its preparation method

A flux-cored welding wire, strong and tough technology, which is applied in the field of strong and tough flux-cored welding wire and its preparation, can solve problems such as insufficient toughness, achieve the effects of not being easily deformed and broken, improving the welding process, and stabilizing high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

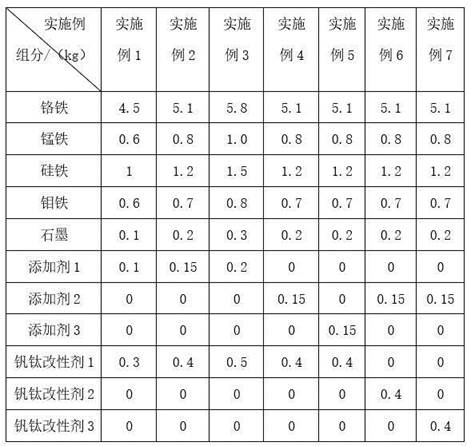

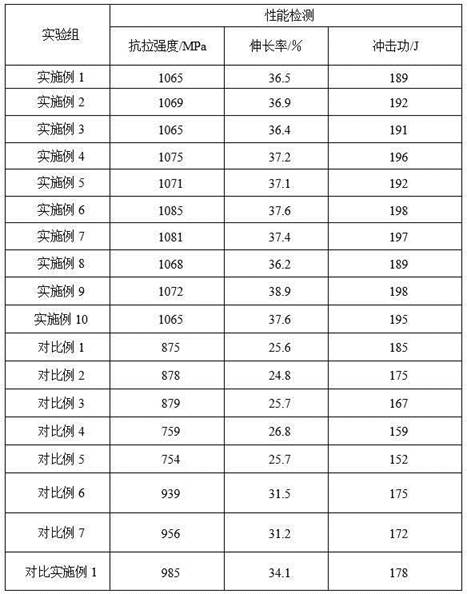

Examples

preparation example 1

[0035]Weigh 4.5kg of absolute ethanol, 0.6kg of butyl titanate, 1kg of innumerable ethanol, 0.6kg of 5% acetic acid solution by mass and 1kg of deionized water and place them in a stirring device, stir and mix and collect the mixed sol liquid. The molar ratio of element and titanium element is 3:8. Add 15% ammonium metavanadate solution by mass to 6kg mixed sol solution, stir and mix and let stand for 6h, collect and let stand the mixed solution and air dry naturally, then grind it at 125 Heat preservation treatment at ℃ for 6h, stand to cool to room temperature, grind and sieve to prepare 150 μm vanadium-titanium modifier 1.

preparation example 2

[0037] Weigh 4.7kg of absolute ethanol, 0.7kg of butyl titanate, 1.2kg of innumerable ethanol, 0.7kg of 5% acetic acid solution by mass and 1.2kg of deionized water, respectively, and place them in a stirring device, stir and mix and collect the mixed sol solution. According to the molar ratio of vanadium element and titanium element being 3:8, add 15% ammonium metavanadate solution by mass to 7kg mixed sol solution, stir and mix and let stand for 7 hours, collect and let stand the mixed solution and air dry naturally, and then grind it again. Incubate treatment at 134°C for 7 hours, stand to cool to room temperature, grind and sieve to prepare 225 μm vanadium-titanium modifier 1.

preparation example 3

[0039] Weigh 5.0kg of absolute ethanol, 0.8kg of butyl titanate, 1.5kg of innumerable ethanol, 0.8kg of 5% acetic acid solution by mass and 1.5kg of deionized water, respectively, and place them in a stirring device, stir and mix and collect the mixed sol solution. According to the molar ratio of vanadium element and titanium element being 3:8, add 15% ammonium metavanadate solution by mass to 8kg mixed sol solution, stir and mix and let stand for 8 hours, collect and let stand the mixed solution and air dry naturally, and then grind it again. Incubate treatment at 150°C for 8 hours, stand to cool to room temperature, grind and sieve to prepare 300 μm vanadium-titanium modifier 1.

[0040] Welding wire coating preparation

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com