Cr-Ni austenitic heat-resistant steel with endogenous precipitated reinforcing phase and preparation method thereof

A technology of austenitic heat-resistant steel and reinforcing phase, which is applied in the field of metallurgy and can solve the problems of high price of Ni resources and increased cost of Cr-Ni austenitic heat-resistant steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

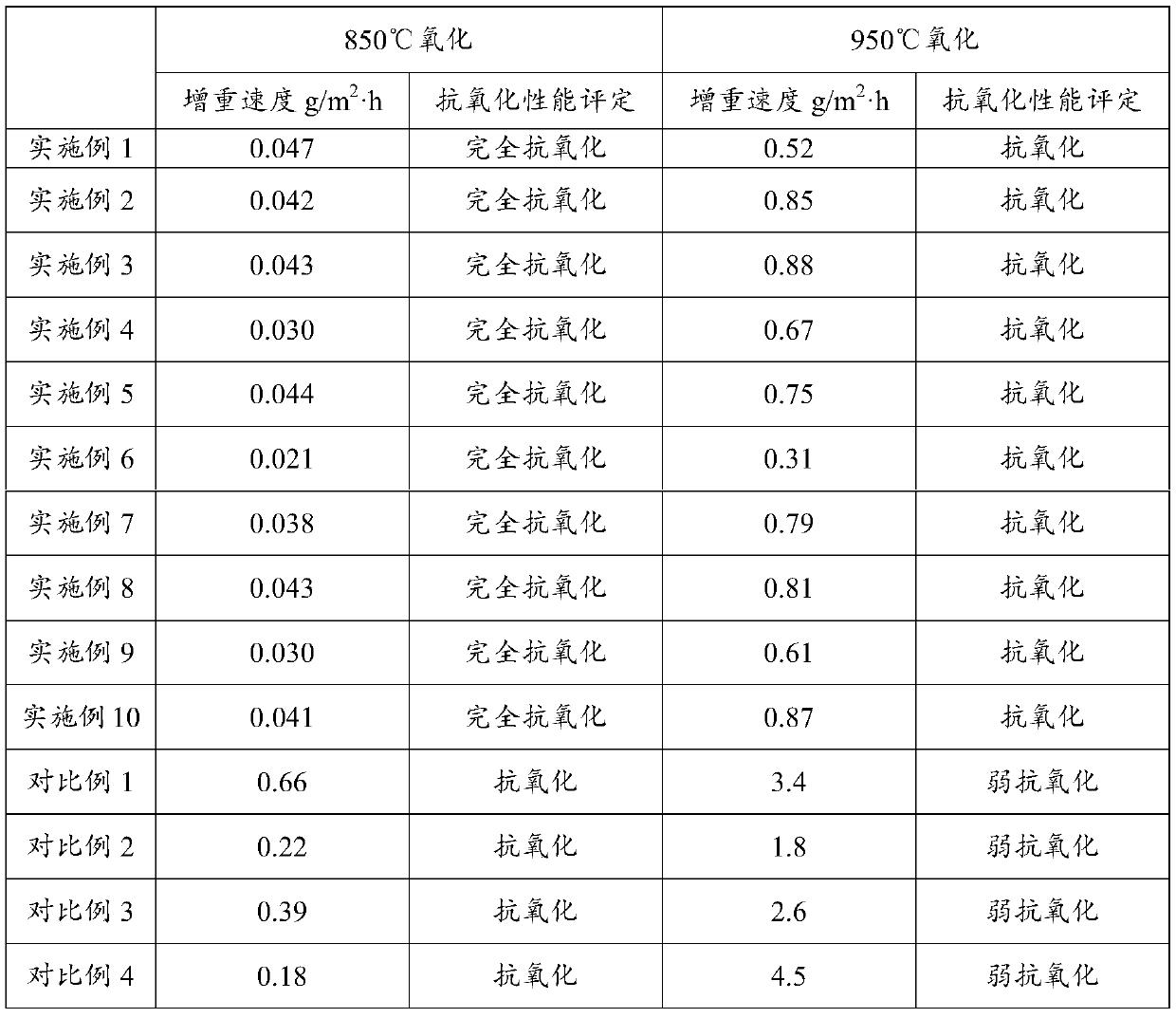

Embodiment 1

[0062] This embodiment provides a Cr-Ni austenitic heat-resistant steel with endogenous precipitation of reinforcing phases, the chemical composition of which includes C: 0.3%, B: 0.4%, Ti: 1.8%, Cr: 15% by weight. %, Ni: 10%, Mo: 0.2%, Si: 0.2%, S≤0.03%, P≤0.03%, and the rest are Fe and unavoidable impurity elements.

[0063] The Cr-Ni austenitic heat-resistant steel with endogenous precipitation of strengthening phase simultaneously generates TiB 2 Reinforcement particles and TiC reinforcement particles, TiB 2 The volume fractions of reinforcement particles and TiC reinforcement particles are 2.1% and 3.0%, respectively. TiB 2 The particle sizes of the particles and TiC particles were 5.8 and 4.7 microns, respectively.

[0064] The Cr-Ni system austenitic heat-resistant steel with endogenous precipitation reinforcement phase is obtained in this way:

[0065] Set the ratio of the total mass of steel, ferrosilicon, pig iron, nickel, and ferrochrome to the total mass of rei...

Embodiment 2

[0076] This embodiment provides a Cr-Ni austenitic heat-resistant steel with endogenous precipitation of reinforcing phases, the chemical composition of which includes C: 0.9%, B: 1.3%, Ti: 6.1%, Cr: 25% by weight. %, Ni: 20%, Mo: 2%, Si: 1.0%, S≤0.03%, P≤0.03%, and the rest are Fe and unavoidable impurity elements.

[0077] The Cr-Ni austenitic heat-resistant steel with endogenous precipitation of strengthening phase simultaneously generates TiB 2 Reinforcement particles and TiC reinforcement particles, TiB 2 The volume fractions of reinforcement particles and TiC reinforcement particles are 8.5% and 7.4%, respectively. TiB 2 The particle sizes of the particles and TiC particles were 8.8 and 10.7 microns, respectively.

[0078] The preparation steps of the heat-resistant steel are the same as those in Example 1, except that the ratio of the total mass of steel, ferrosilicon, pig iron, ferronickel, and ferrochrome to the total mass of reinforcement raw materials is 100:8.2....

Embodiment 3

[0080] This embodiment provides a Cr-Ni austenitic heat-resistant steel with endogenous precipitation of reinforcing phases, the chemical composition of which includes C: 0.2%, B: 0.5%, Ti: 2.0%, Cr: 17% by weight. %, Ni: 11%, Mo: 0.2%, Si: 0.4%, S≤0.03%, P≤0.03%, and the rest are Fe and unavoidable impurity elements.

[0081] The Cr-Ni austenitic heat-resistant steel with endogenous precipitation of strengthening phase simultaneously generates TiB 2 Reinforcement particles and TiC reinforcement particles, TiB 2 The volume fractions of reinforcement particles and TiC reinforcement particles are 2.1% and 1.7%, respectively. TiB 2 The particle sizes of the particles and TiC particles were 4.5 and 5.1 microns, respectively.

[0082] The preparation steps of the heat-resistant steel are the same as those in Example 1, except that the ratio of the total mass of steel, ferrosilicon, pig iron, ferronickel, and ferrochrome to the total mass of the reinforcement material is 100:2.0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com