A continuous process for the production of a superabsorbent polymer

A polymer, mixture technology, used in absorbent pads, medical science, bandages, etc., can solve problems such as inertization of monomer mixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

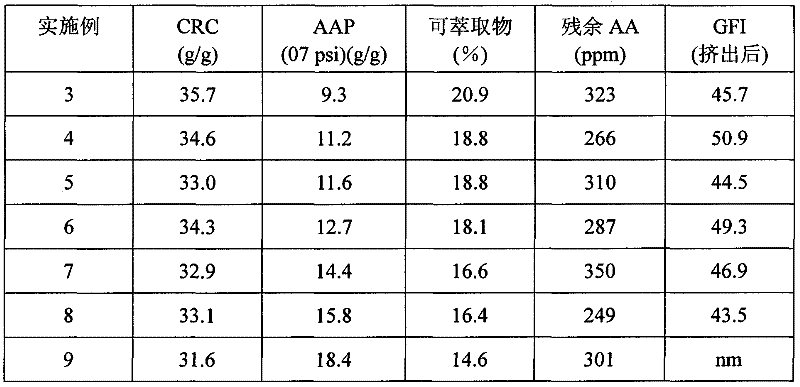

Examples

preparation example Construction

[0068] It is preferred for smooth production conditions to have a buffer vessel of polymer gel downstream in the process between the reactor and the next unit. In addition to holding the desired amount of buffer material, the container also acts as a storage tank to further allow for a conversion of the polymer gel of greater than 99%, more preferably greater than 99.5%. Furthermore, additional locations are provided where additives can be introduced into the polymer and mixed in. The design of the vessel is not critical as long as means are provided for adequate agitation and maintaining the desired gel temperature. The vessel is preferably insulated to maintain the gel at the desired temperature, permits substantial plug flow, and is designed so that the polymer gel can be continuously and reliably charged and discharged. The containers may be horizontally or vertically arranged containers, single or multi-screw conveyors or moving belts. The container can supply multiple ...

Embodiment 1

[0160]Example 1 (deoxygenation in 250 ml glass reactor; reference example)

[0161] By mixing 86.67 grams of 99.8% active ingredient acrylic acid, 60.55 grams of 50% active ingredient NaOH, 77.7 grams of water, 0.23 grams of highly ethoxylated trimethylolpropane triacrylate having an average of 15 EO units in the molecule (HE-TMPTA) and 0.87 grams of PEG 600 to prepare a monomer solution. Particles are not dispersed therein. The monomer solution was charged to a 250 ml glass reactor equipped with a magnetic stir bar and a lid with 3 openings. One opening bears a membrane-covered electrochemical sensor inserted into the monomer solution for oxygen measurement. One opening is equipped with a gas check valve and is used to vent gas. The final degree of neutralization was brought to a level of 70% by adding 22.9 grams of 20% aqueous sodium carbonate solution through a third valve with gentle stirring of the monomer solution. After adding carbonate solution (Na 2 CO 3 ) begin...

Embodiment 2

[0164] Embodiment 2 (reference embodiment)

[0165] Example 1 was repeated except that 86.67 grams of 99.8% active acrylic acid and 68.79 grams of 49% active NaOH were used, and 34.67 grams of scrubbing water were added instead of the carbonate solution. Due to the presence of carbonates in the scrubbing water, its contact with the prepared monomer solution showed the same release of CO as in the previous examples. 2 Reaction. The oxygen concentration in the mixture drops, as shown in Table 2. As in Example 1, add 0.05 g of 35% active ingredient H 2 o 2 solution, 1.3 g of 10% active ingredient Na 2 S 2 o 8 and 0.34 g of a 1% active ingredient in ascorbic acid solution immediately initiated the polymerization process and heated the reaction mass to a peak temperature of 115° C. within 3 minutes.

[0166] Table 2

[0167] Time after adding scrubbing water (min)

[0168] Reference Examples 1 and 2 relate to a batch process and are therefore not examples accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com