Slag nonpollution deoxygenation method capable of regulating anode oxygen partial pressure and device thereof

An adjustable oxygen partial pressure technology, applied in the direction of reducing gas emissions, can solve problems such as restricting deoxidation efficiency, hindering slag wetting, and frequent replacement, so as to improve environmental pollution, promote electrochemical reactions, and improve deoxidation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

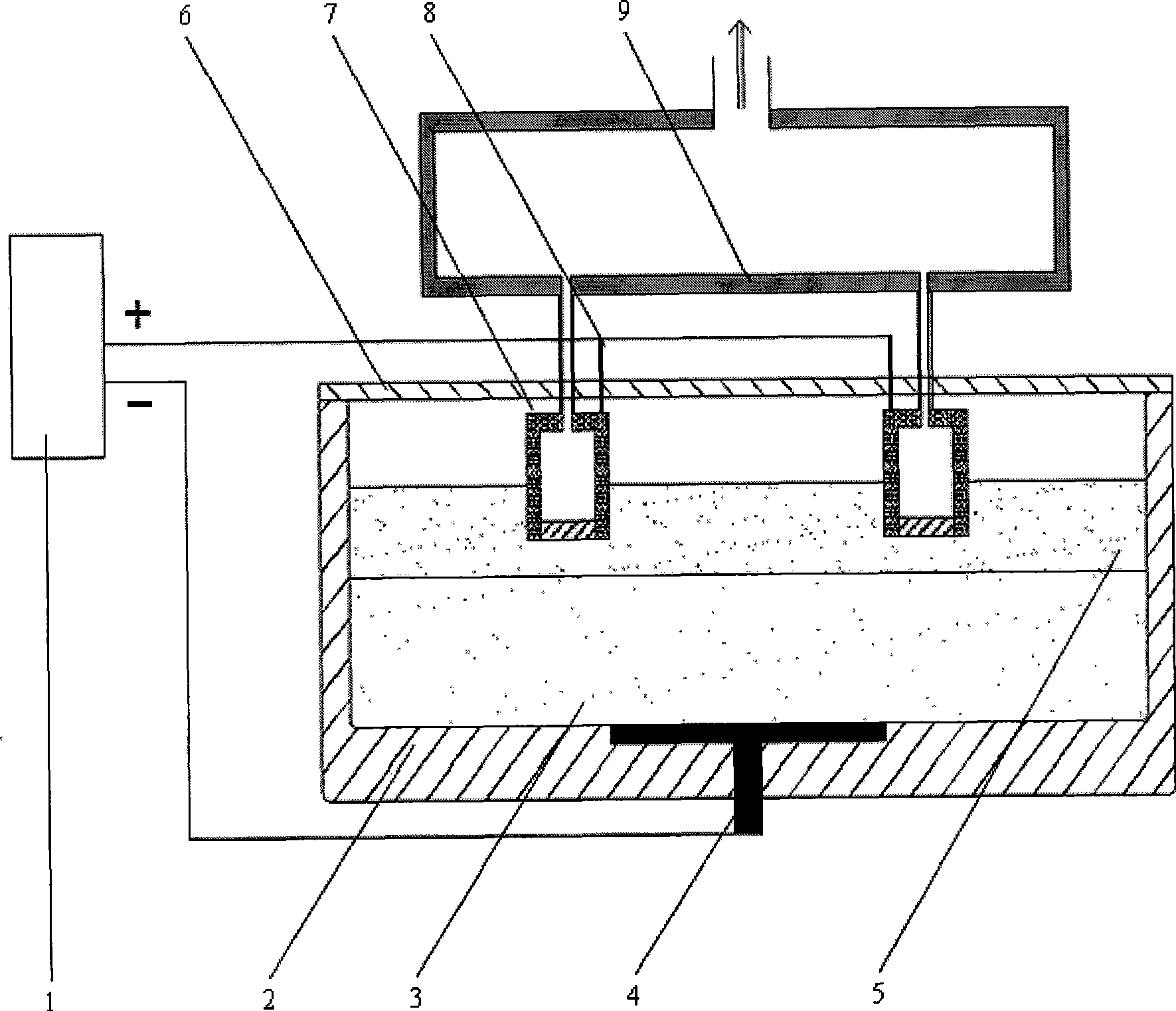

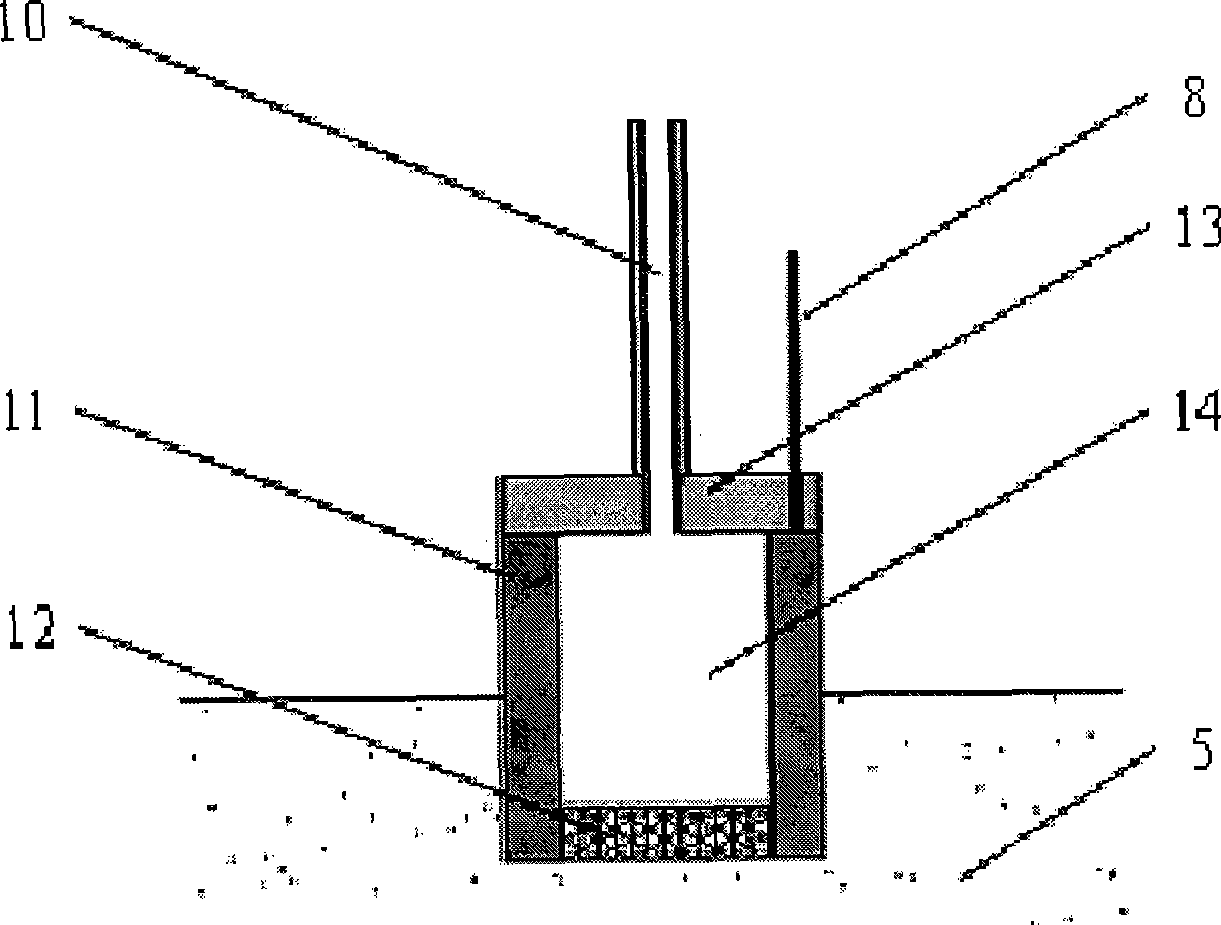

[0017] Specific embodiments of the present invention will now be described in detail below. The method of the invention mainly realizes the purpose of deoxidizing and purifying molten steel or molten metal through its special device. see figure 1 with figure 2 , the special device used in the method of the present invention comprises: DC power supply 1, electric melting furnace insulation furnace body 2, molten steel 3, bottom electrode 4, molten slag 5, heat preservation furnace cover 6, anode degassing cavity electrode 7, anode wire 8 , atmosphere control chamber 9, air duct 10, conductive ceramics 11, porous and breathable ceramics 12, sealing member 13 and cavity 14; molten steel 3 and slag 5 are placed in the insulating furnace body 2 of the electric melting furnace; molten steel is placed in the furnace The lower layer of the body, while the slag is placed on the upper layer; a plurality of anode degassing cavity electrodes 7 are arranged on the upper part of the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com