Patents

Literature

38results about How to "Rapid deoxygenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid production method of flavored pickled vegetables

ActiveCN103892225AImprove permeabilityReduce processing timeClimate change adaptationFood ultrasonic treatmentBiotechnologyNutrition

The invention discloses a rapid production method of flavored pickled vegetables. The rapid production method comprises the following steps: selecting raw materials, carrying out ultrasonic salting, carrying out lactobacillus fermentation, blending with flavor condiments, enabling the vegetables to be tasty by ultrasonic waves, and weighing and packaging the product. The rapid production method is simple in production process, easy to control and suitable for industrial production; the pickled vegetable product is delicious, tender and crispy, has a moderate salty and sour taste and has a nourishing nutrition; the used ultrasonic treatment not only accelerates the speed of salting and enabling the product to be tasty and shortens the needed time for processing, but also can also prevent nitrite from being generated, so that the content of nitrite is reduced and the safety of the flavored pickled vegetables is improved.

Owner:江苏新天地食品股份有限公司

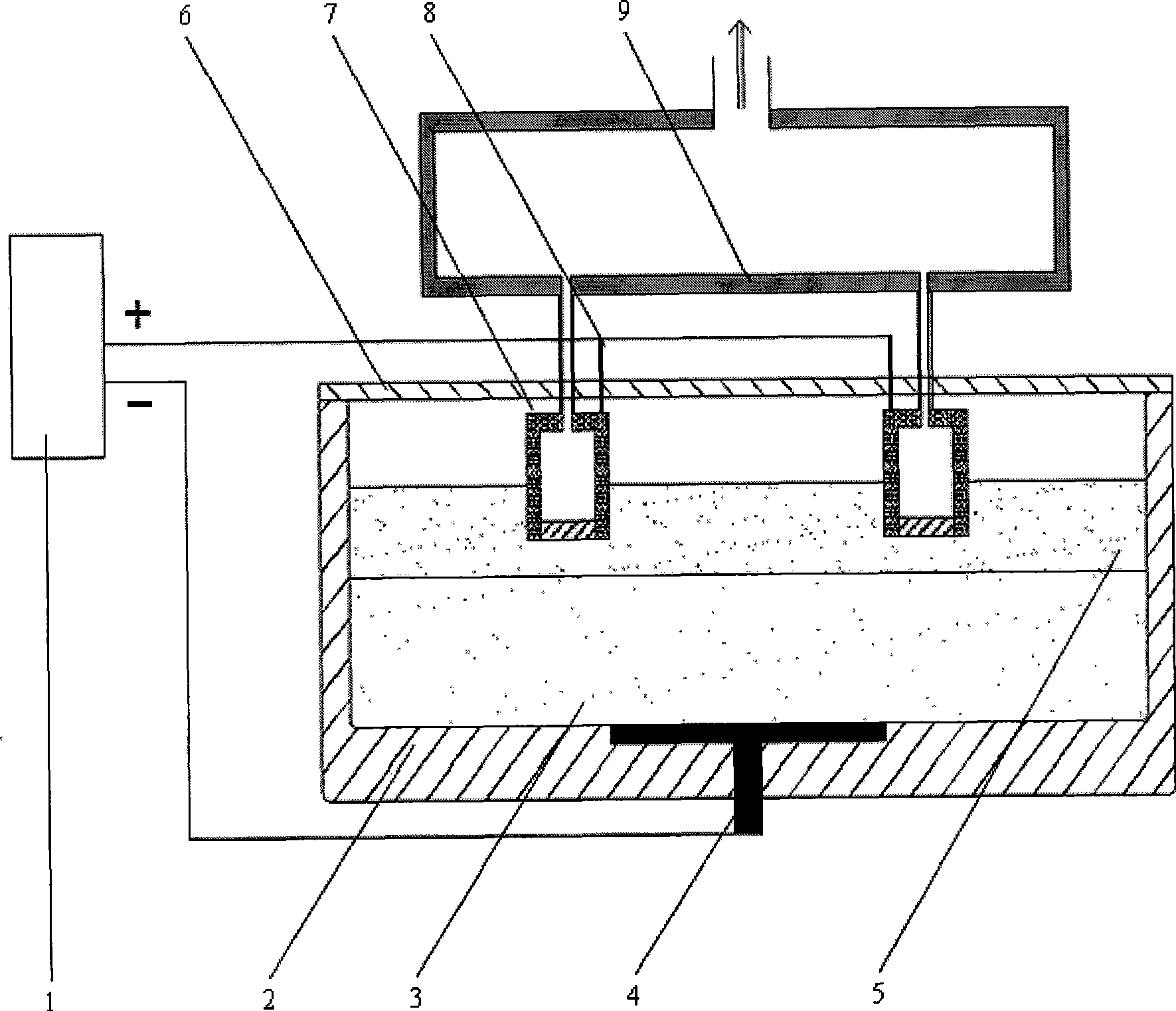

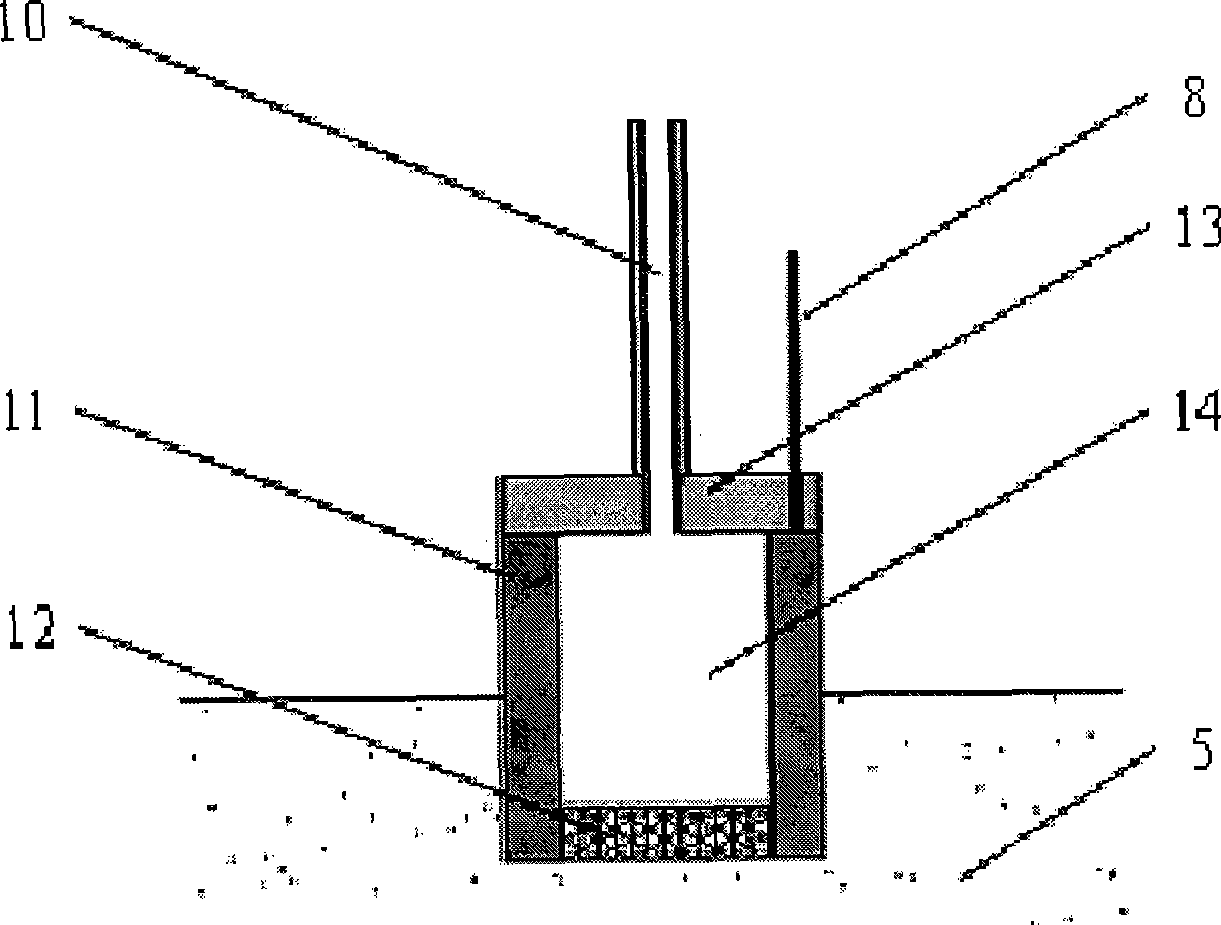

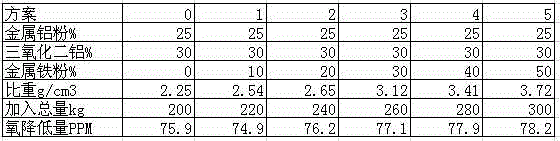

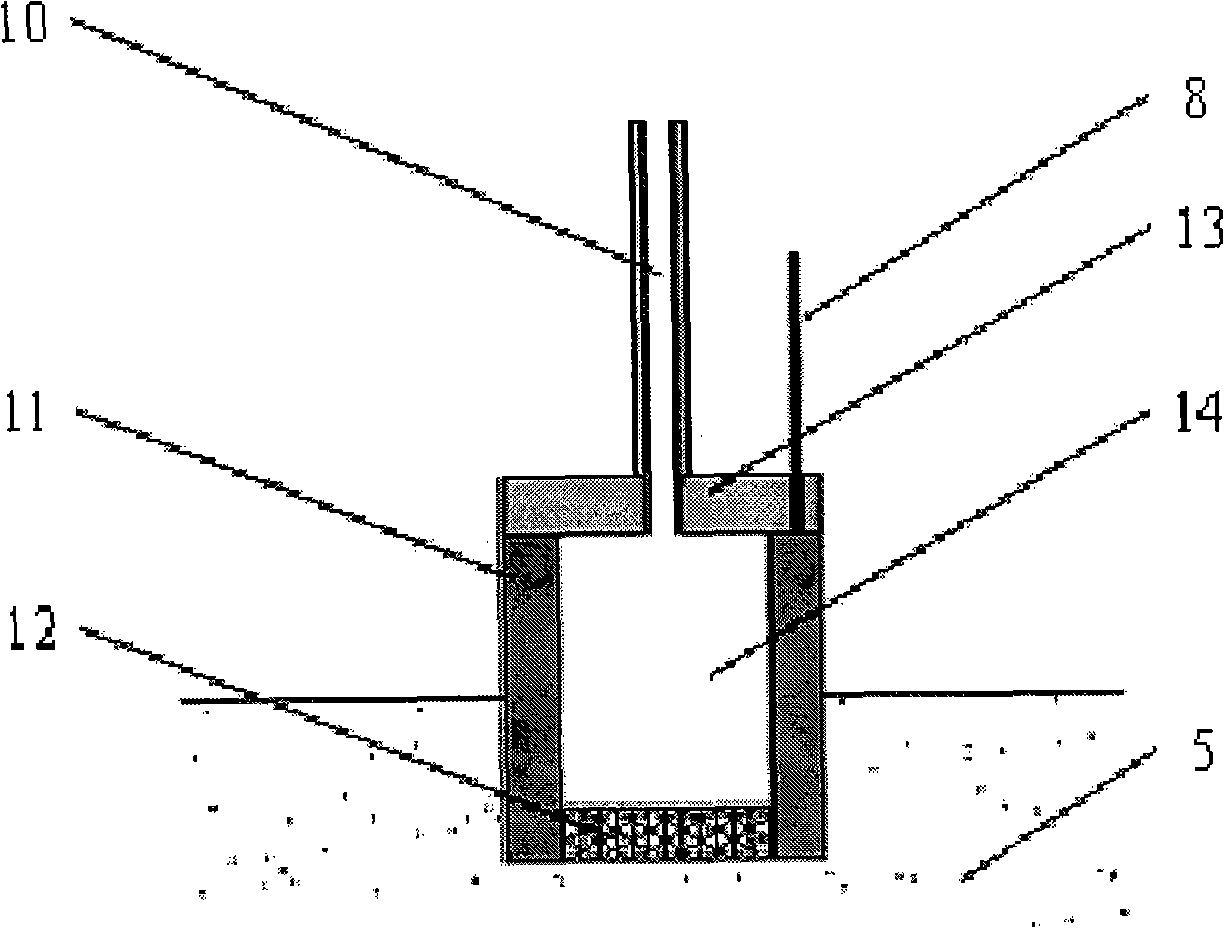

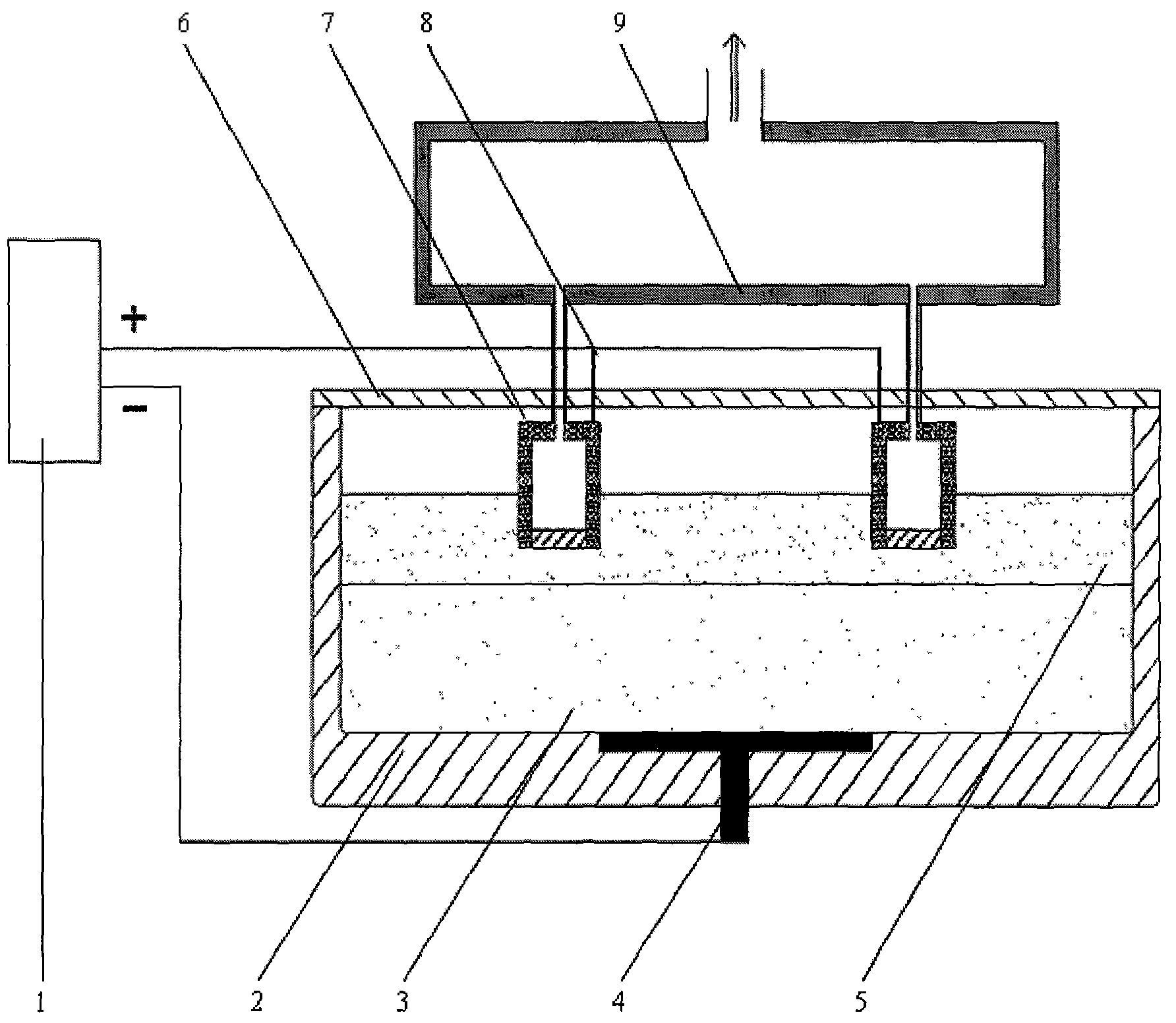

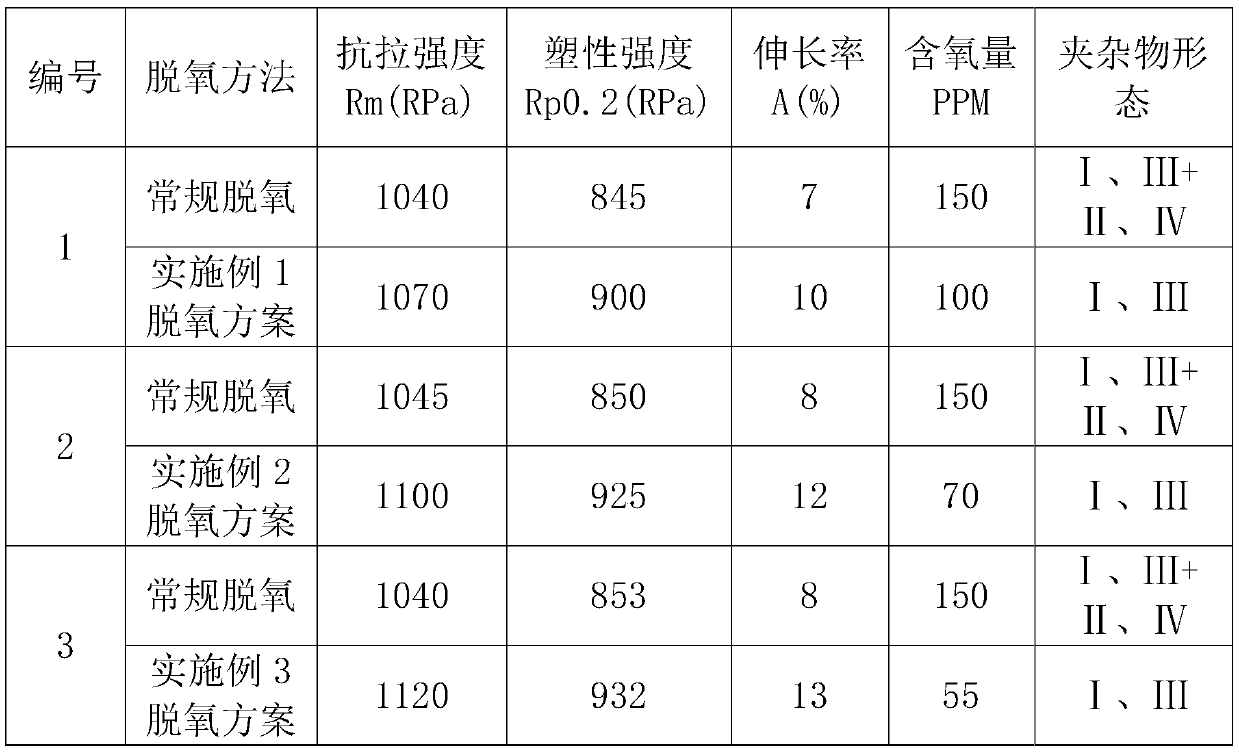

Slag nonpollution deoxygenation method capable of regulating anode oxygen partial pressure and device thereof

InactiveCN101457276AImprove pollutionAccelerated exclusionGas emission reductionOxygen ionsVacuum chamber

The invention relates to a pollution-free molten slag deoxidization method capable of adjusting anode oxygen partial pressure and a device thereof, and belongs to the technical field of metallurgical refining process. In the method, molten steel or molten metal is deoxidized and purified by the special device. In the method, the molten slag is taken as electrolyte, a deaeration cavity electrode inserted into the molten slag is taken as an anode, and the molten steel or the molten metal is taken as a cathode; the deaeration electrode is provided with an electrode cavity and is communicated with a vacuum chamber by a conduit; an applied DC power supply exerts direct current impulse voltage so that an electric field is formed between the molten steel or the molten metal and an oxygen electrode of the molten slag, and the conduction of oxygen ions in a molten slag system and mass transfer of dissolved oxygen in the molten steel are controlled by controlling a current value and a voltage value of the DC power supply as well as components of the molten slag. The oxygen is diffused from the molten slag to the electrode cavity and discharged by an air exhaust system by controlling the oxygen partial pressure of the electrode cavity.

Owner:SHANGHAI UNIV

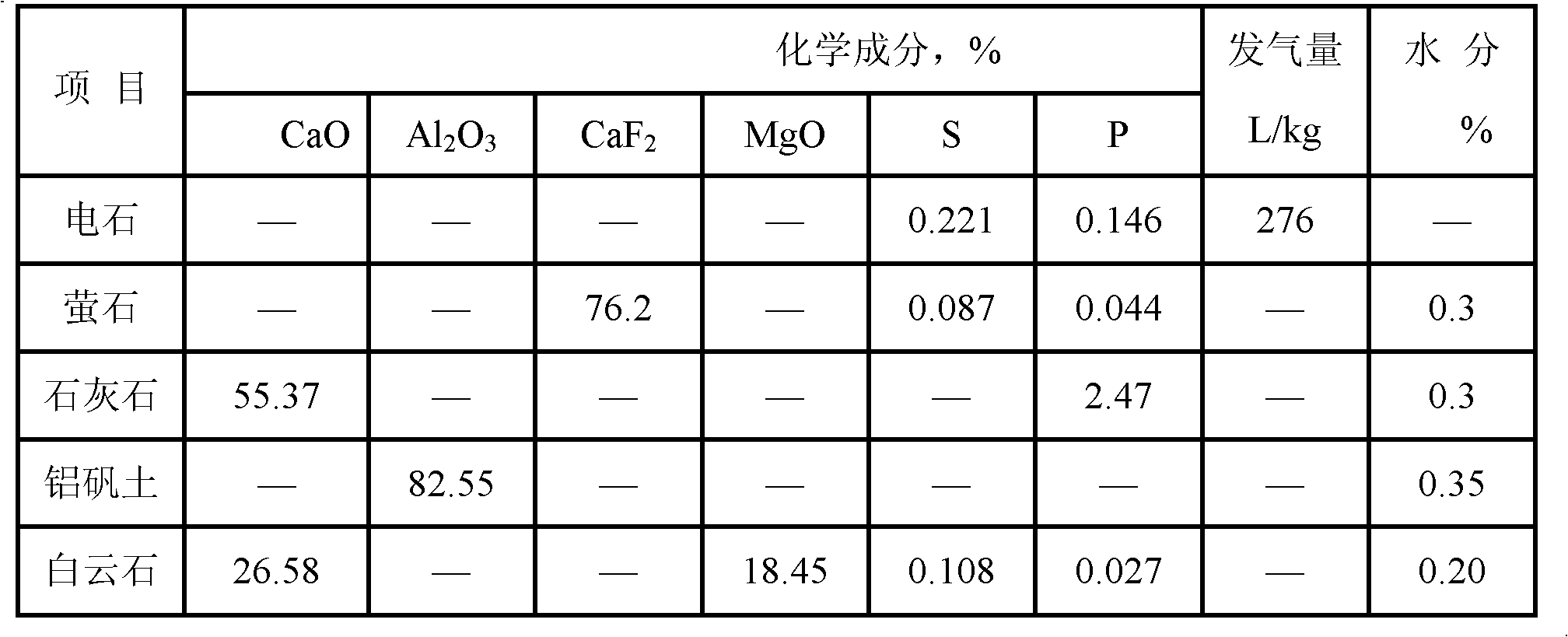

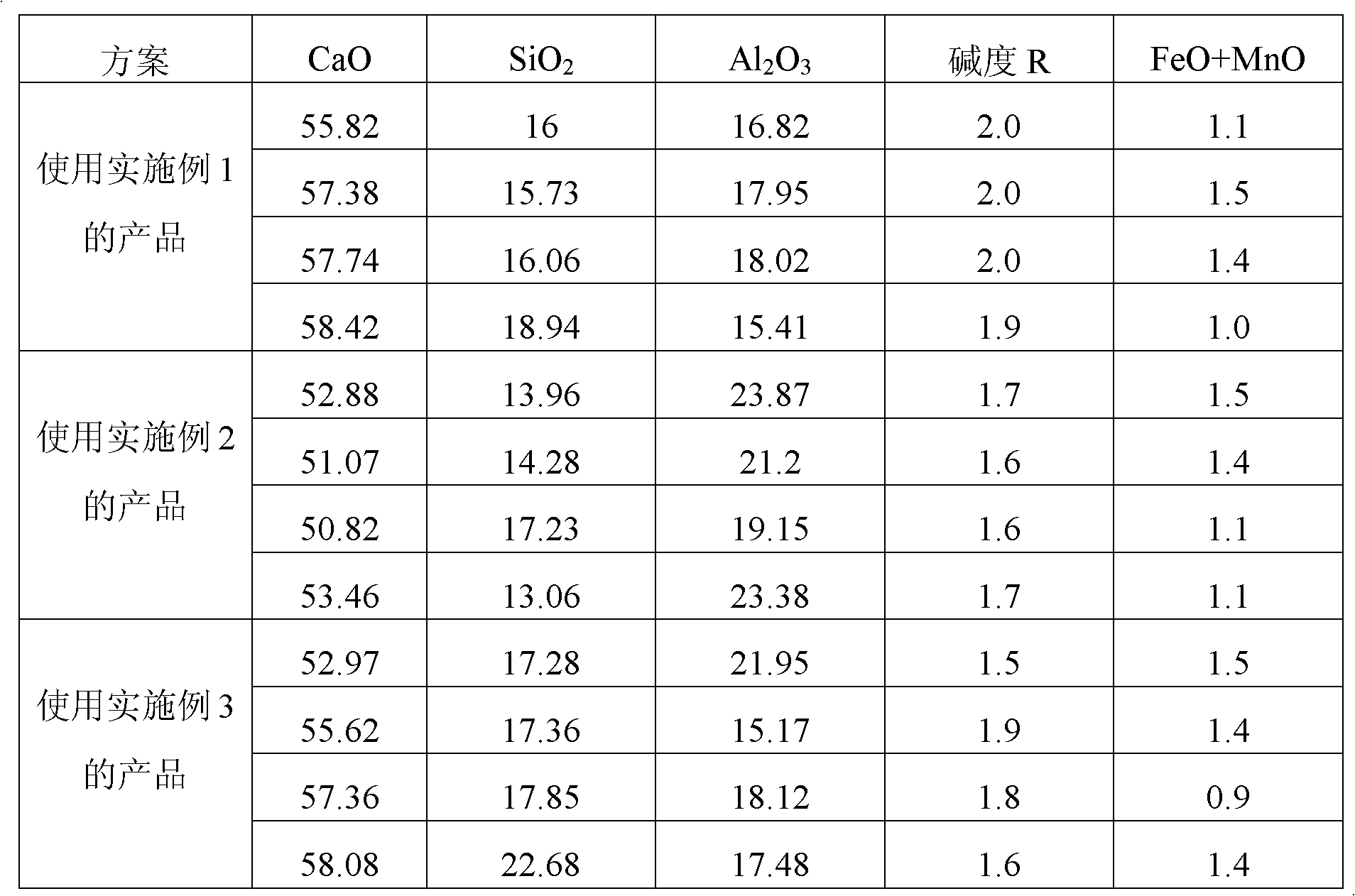

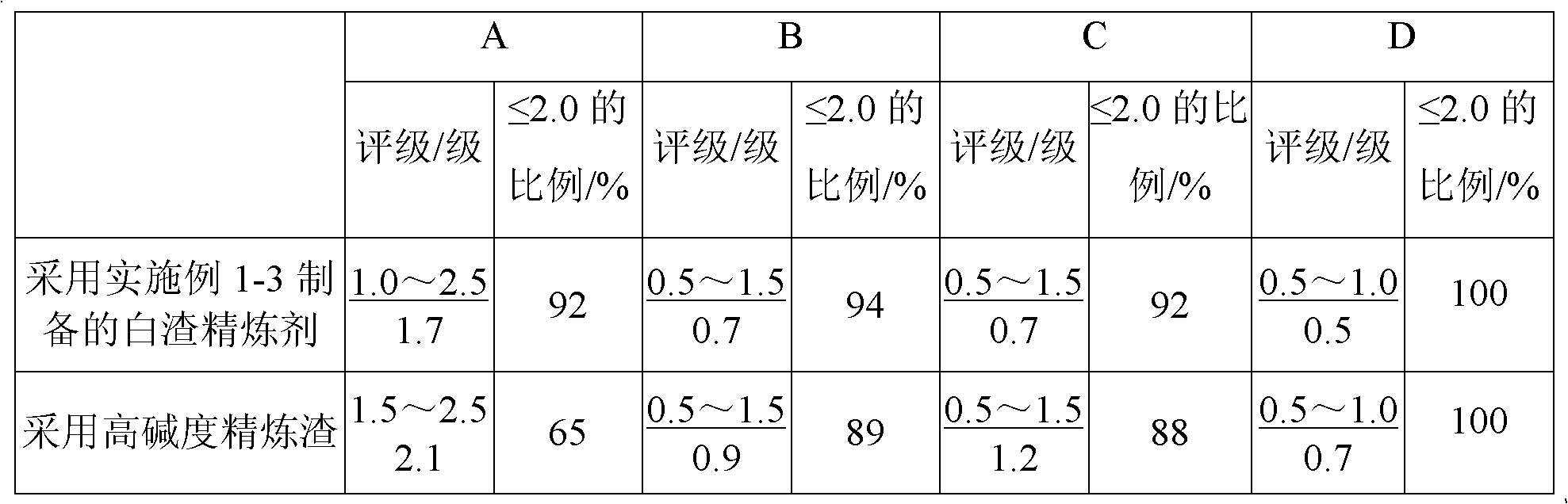

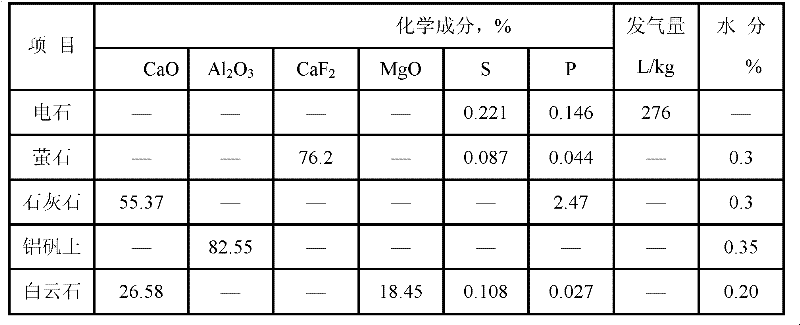

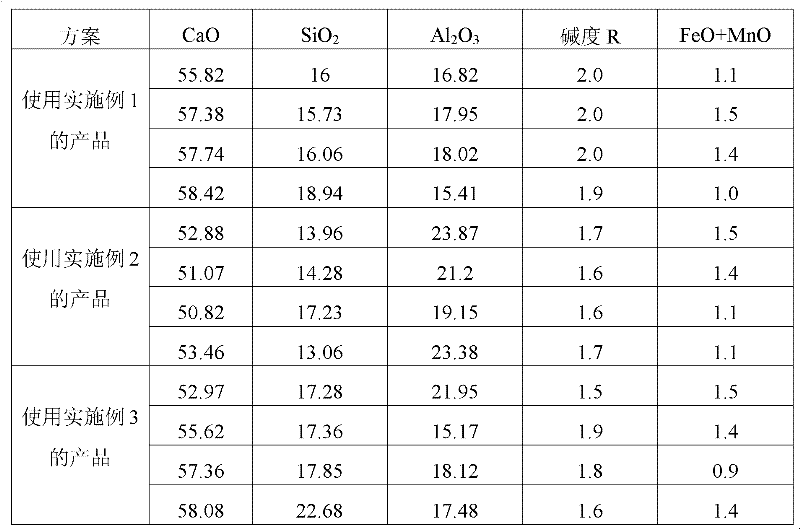

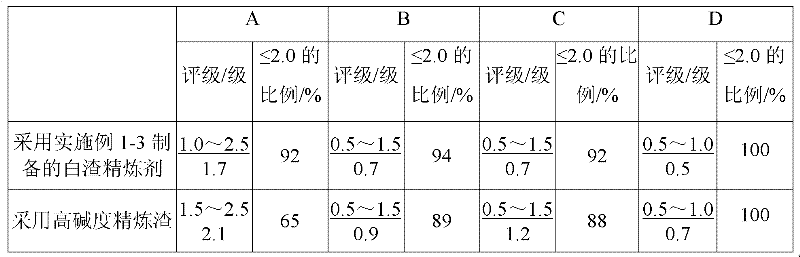

White slag refining agent for LF (Ladle Furnace) refining furnace and preparation method thereof

The invention relates to a white slag refining agent for an LF (Ladle Furnace) refining furnace, belonging to the technical field of steel making, in particular to the technical field of ladle slag modification treatment of the LF refining furnace. The invention aims to provide the white slag refining agent which has the advantages of low cost and strong inclusion adsorption capacity. The white slag refining agent for the LF refining furnace is characterized by comprising the following components in percentage by weight: 40-50 percent of calcium carbide, 8-14 percent of fluorite, 24-30 percent of limestone, 4-6 percent of bauxite and 4-12 percent of dolomite. The white slag refining agent has the advantages of low cost and wider application range and is suitable for a non Al deoxidized steel (a kind of steel, strictly controlling the aluminum content), for example. After being added into the LF refining furnace, the white slag refining agent can fulfill the functions of rapid deoxidation and white slag production and can enable the content of FeO and MnO in ladle slag to be no more than 1.5 percent to satisfy the smelting needs of high-grade steels.

Owner:PANZHIHUA GANGCHENG GROUP

Kalzium metal for deoxidization during steel making

The invention discloses a kalzium metal for deoxidization during steel making, comprising the following components by weigh percent: 40% of metallic aluminium grains, 15% of silicon carbide, 10% of limestone and 35% of silicate slag, wherein the deoxidized product of the kalzium metal is calcium aluminate with low melting point, which is easy to remove by aggregation and upward flotation. Therefore, the kalzium metal has the capabilities of removing dissolved oxygen from smelting steel and removing mixed oxygen by adsorption simultaneously, and has the capability of rapid white slag formationand strong desulfuration. The kalzium metal utilizes strong deoxidizing elements aluminum and calcium to deoxidize, thus promoting limestone to melt rapidly to form white slag to realize high-efficiency desulfuration, meanwhile, the deoxidized product of calcium aluminate with low melting point can well mild the desulfurized product CaS, thus being conducive to adsorbing the desulfurized product to discharge molten steel, so as to reach high desulfuration efficiency. The invention has stable metallurgical effect and strong operability.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

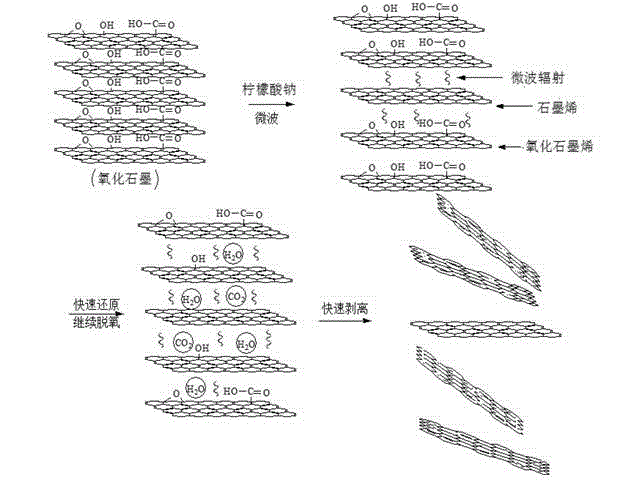

Microwave-assisted method for preparing graphene through reduction of sodium citrate

InactiveCN102976315AUniform size distributionGood electrical propertiesGrapheneReaction temperatureRoom temperature

The invention relates to a microwave-assisted method for preparing graphene through reduction of sodium citrate. The microwave-assisted method comprises the following steps in sequence: dispersing 0.05 to 0.3g of graphite oxide prepared by an improved Hummers method into 200ml of deionized water; ultrasonically dispersing for 40 to 80 minutes at the power of 210 to 300W; adding 1 to 30g of sodium citrate; uniformly stirring; transferring the mixture into a microwave reactor with rated output power of 1000W; setting the reaction temperature to 70 to 95 DEG C to react for 60 to 300 seconds at the stirring speed of 600rpm / min; cooling to reach room temperature; centrifugally cleaning more than three times under centrifugal speed more than 13000rpm / min; and refreezing and drying the black solid at the lower layer, thus obtaining the graphene. The microwave-assisted method has the fast, environment-friendly and energy-saving characteristics, can be carried out to prepare the graphene which is uniform in size distribution and excellent in electrical properties, and can provide technical guarantee to the application of the graphene.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

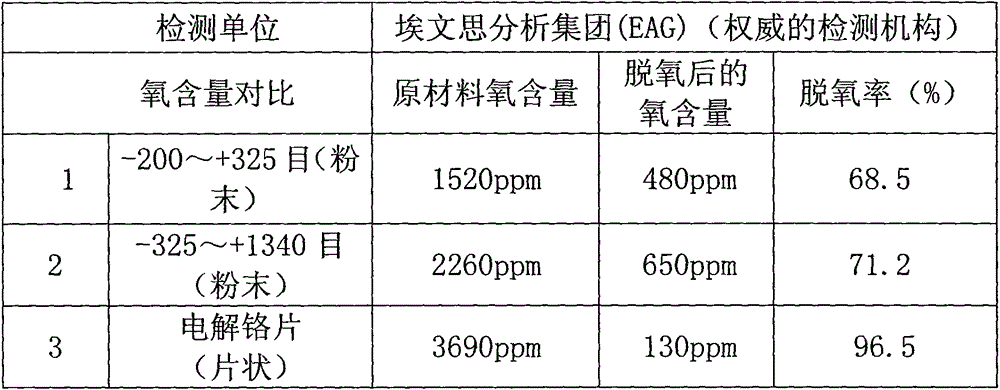

Hydrogen plasma deoxidation method for chromium powder

The invention discloses a hydrogen plasma deoxidation method for chromium powder. The hydrogen plasma deoxidation method is characterized by comprising the following steps: selecting a metal chromium block and crushing the metal chromium block into chromium powder of -325 to -1340 mesh; carrying out hydrogen plasma deoxidation on the chromium powder, wherein the deoxidation is carried out in a stainless steel container with radio-frequency hydrogen plasma equipment, the radio-frequency hydrogen plasma equipment takes hydrogen gas as a working gas, and a slotted water-cooling copper furnace is arranged in the stainless steel container; firstly, manufacturing the chromium powder subjected to ball grinding into a plurality of chromium powder rod bodies, each of which having a diameter of 15-20mm and a length of 20-3mm, preparing a plurality of chromium powder rod bodies from chromium powder subjected to ball grinding by arc melting in the presence of argon gas at 0.02-0.05Mpa, and then connecting every two chromium powder rod bodies end to end and placing on the slotted water-cooling copper furnace; feeding gas through the radio-frequency hydrogen plasma equipment; manufacturing chromium rods in an once forming manner through a zone-melting method so as to finish deoxidation. The hydrogen plasma deoxidation method is used for carrying out chromium powder deoxidation by using the radio-frequency plasma equipment and is simple in process and low in cost, and the oxygen content of the product can accord with using requirements.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

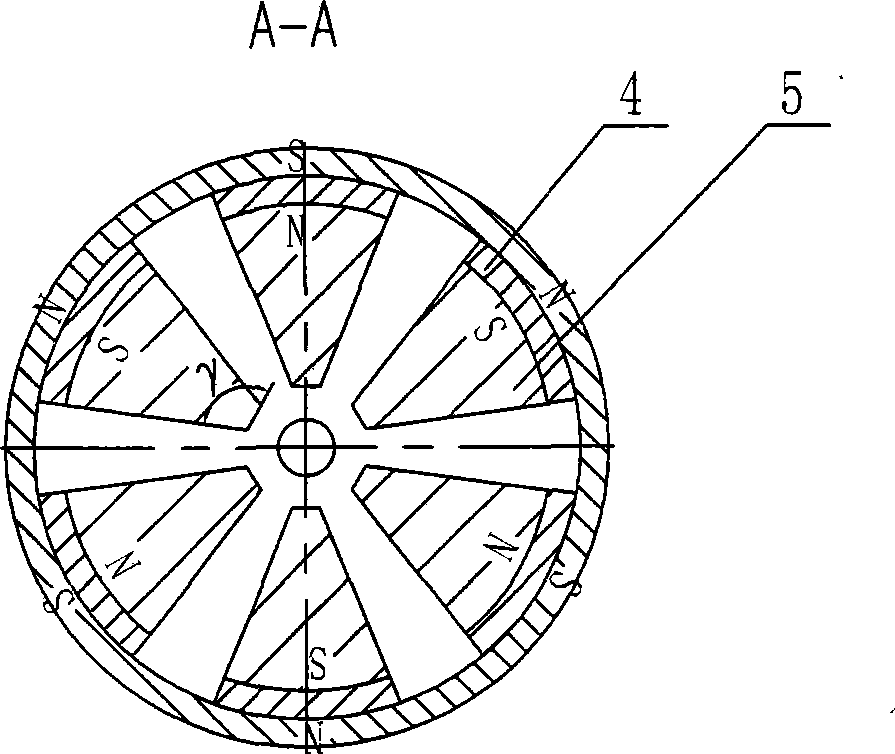

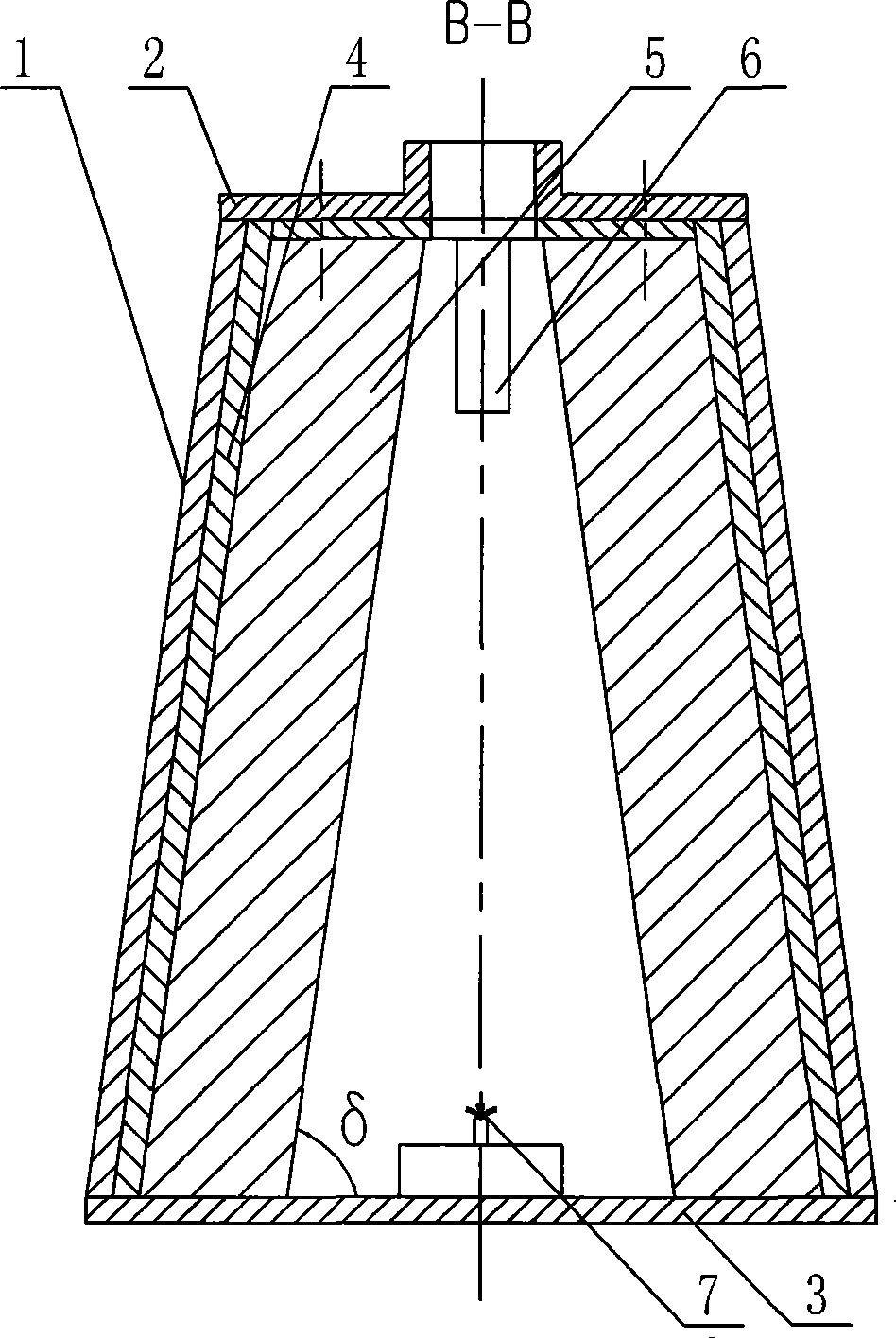

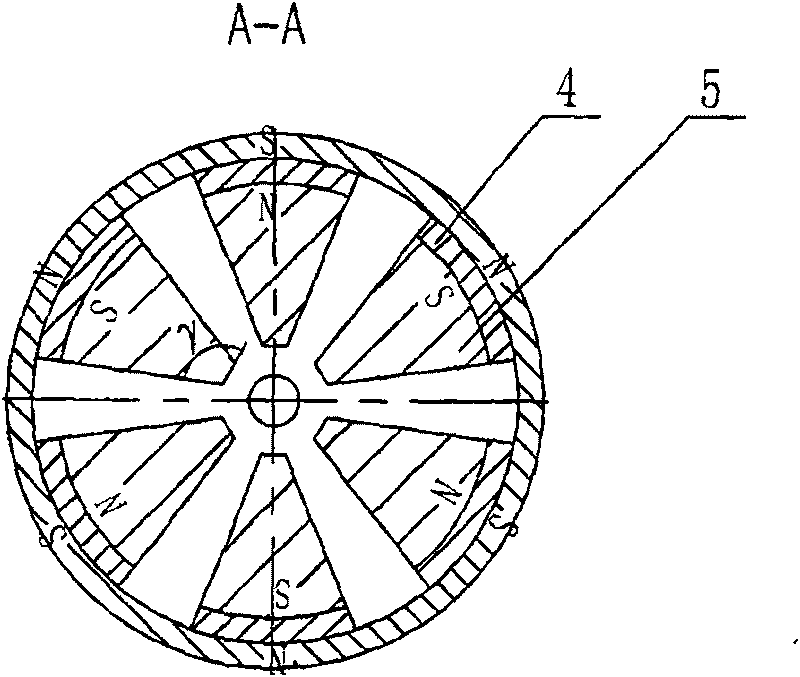

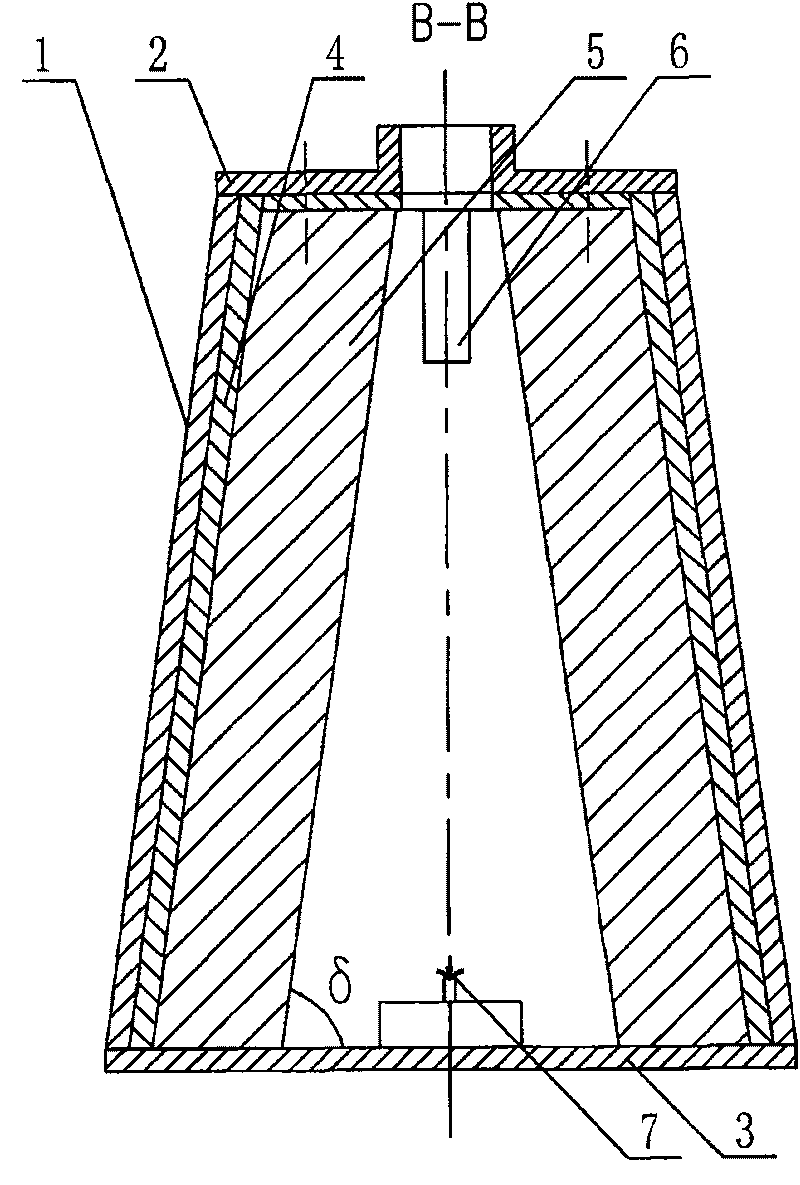

Magnetic thermal field cooperate with oxygen-enriched air generating device

The invention relates to a magneto-thermal field synergistic oxygen-enriched air generating device; a casing is a stage tubular body or a column tubular body, an upper cover with an air outlet a is arranged on upper end of the casing, a base is arranged at lower end of the casing, permanent magnets with magnetic shoes are circumferentially and evenly arranged in the casing, polarities of adjacent and opposite permanent magnets are different, an air inlet b is arrange between lower part of lateral side of the casing and the permanent magnets, clearance which is communicated with the air inlet b is retained between adjacent permanent magnets and magnetic shoes, forming a convergence type air inlet channel which is communicated with the air inlet b from the external to the internal; lateral side of radial direction of the permanent magnets is at the same plane with the laterals side of radial direction of the magnetic shoes, a convergence type air outlet channel is formed from the upper part to the lower part among the circumferentially adjacent permanent magnets, adjacent and opposite magnetic shoes in the casing, a heater is arranged at the air outlet a of the upper cover in the casing and an air negative ion generating device is arranged on the base in the casing. The oxygen-enriched air generating device has the advantages that the device can be used for indoor oxygen-enriching and ventilating and can also be used as the oxygen-enriched source of combustion as well as oxygen-charging source of water body.

Owner:SHAANXI NORMAL UNIV

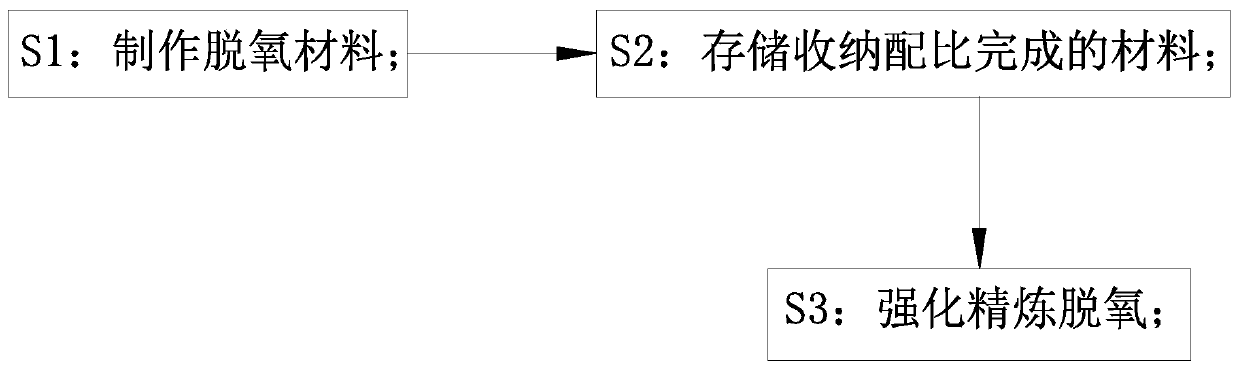

Method for quick deoxidization in smelting process of ladle furnace (LF)

InactiveCN107653358AReduce unqualifiedReduce the chance of nodulationSmelting processThermal efficiency

The invention discloses a method for quick deoxidization in the smelting process of a ladle furnace (LF). The method comprises the following steps: (1) adding aluminum iron containing 40% of aluminumat a time after molten steel enters the ladle furnace (LF), so that the aluminum content in the molten steel reaches 0.04%-0.05%, and adding 150 kg of low aluminum slag balls, and 2-2.5 kg of active lime per ton of steel; (2) powering on and slagging, powering on for 3-5 times, adding 0.2 kg of molten steel deoxidizing agents per ton of steel, powering on for 5 min, melting top slag, and then powering off; (3) adjusting argon gas flow such that the diameter of the slag face blown by argon gas is 450-500 mm, adding 1-1.5 kg of the low aluminum slag balls per ton of steel, and 0.4 kg of the molten steel deoxidizing agents per ton of steel, stirring the mixtures for 15-20s, and then adding 1-1.5 kg of the low aluminum slag balls per ton of steel and 0.4 kg of the molten steel deoxidizing agents per ton of steel if the deoxidization effect is poor; stirring the mixtures for 15-20s, till the section of the top slag is yellowish white, namely that the deoxidization is finished; and adjustingthe argon gas flow to 100-150 L / min in time, and performing subsequent operation. According to the method disclosed by the invention, not only the quick deoxidization of molten steel in the smeltingprocess is achieved, the output of inclusions in the smelting process is reduced, and the quality of steel billets is improved, but also the thermal efficiency in the power-on heating process is improved, and the power consumption and slag consumption are reduced.

Owner:XINJIANG BAYI IRON & STEEL

Refining deoxidizing method of low-carbon low-silicon welding wire steel

ActiveCN110643785ASolve the blockage and reduce the problem of air bubbles under the skin of the continuous casting slabReduce Als contentSlag (welding)Iron powder

The invention relates to a refining deoxidizing method for low-carbon low-silicon welding wire steel. The method comprises the following specific steps that (1) deoxidizing and alloying are carried out on molten steel in a converter tapping process; and (2) high-aluminum refining slag is added into an LF refining furnace to perform deoxidation on the slag surface according to the content of argonstation Als, and silicon iron powder is add for deoxidation. By optimizing the refining deoxidizing method, the problem that a continuous casting gate is blocked is solved, and skin blowholes of continuous casting blanks are reduced.

Owner:SGIS SONGSHAN CO LTD

Process of calcium carbonate carbon balls for converter or electric furnace steel tapping deoxidation

The invention discloses a process of calcium carbonate carbon balls for converter or electric furnace steel tapping deoxidation. Lime stones are grinded to powder with a particle size below 1 mm, are uniformly mixed with graphite carbons with a carbon content of 90%, and are pressed to calcium carbonate carbon balls with a diameter of 30 mm by a dry powder ball press, wherein the adding proportion of the lime stones is 93 mass% of the carbon balls; the adding proportion of the graphite carbons is 7 mass% of the carbon balls; the carbon content in the calcium carbonate carbon balls is controlled at 6 mass%; and in the steel tapping process of an electric furnace or a converter after smelting, 1.5 kg carbon balls are added in each tonnage of steel.

Owner:XINJIANG ZHONGHE DAZHENG COMMERCE & TRADE

High-purity steel and production process

ActiveCN112795728AImprove abilitiesImprove joining efficiencyProcess efficiency improvementSlagArgon flow

The invention relates to high-purity steel and a production process, and belongs to the technical field of steel production. The production process comprises the procedures of carrying out converter primary smelting, carrying out LF refining, carrying out VD vacuum treatment and carrying out continuous casting, the LF refining procedure comprises the following steps that (21) online bottom argon blowing is carried out when the steel enters a station, the argon flow is 120-140L / min, and the Ar pressure is 0.35-0.4MPa; (22) a slag former and a deoxidizing agent are added for first-time electrifying slagging, 6-level voltage is adopted, the current is 28000-30000A, the argon flow is 280-300L / min, the argon pressure is 0.35-0.4MPa, sampling is conducted after slagging is conducted for 8-12min through power transmission heating, and alloy is added to adjust components; the slag former comprises 4.5-7.2kg of calcite per ton of steel, 0.7-1.1kg of fluorite per ton of steel and 0.3-0.5kg of bauxite per ton of steel; and (23) after the components are adjusted, secondary electrifying is conducted, 4-level voltage is adopted, the current is 32000-34000 A, the argon flow is 70-90L / min, the Ar pressure is 0.3-0.35MPa and when the temperature of molten steel is greater than or equal to 1670 DEG C, a silicon-calcium wire is fed. The high-purity steel and the production process have the effects of reducing the impurity content in the molten steel and improving the purity of the molten steel.

Owner:天津荣程联合钢铁集团有限公司

High-manganese low-carbon composite alloy and method for preparing same

The invention discloses a kind of high manganese and low carbon composition alloy and the preparation method of it, the composition alloy contain the percentage by weight component as follow: Mn 70~75, Si 11~17, Al 7~14, P<0.2, C<0.3, S<0.03,surplus is Fe. The invention of composition alloy component proportioning science and rational, specific weight controlling strict, the method can deoxidize efficient for liquid steel, remove the foreign substance in liquid steel and deoxidize rapidly, make the steel slag easily floated upward and removed to obtain high degree of purity liquid steel, the composition alloy can be used as deoxidant in smelting kinds of steel, especially suitable for smelting conduit wiring steel, bridge and canal steel and high-strength ship plate steel that need strength deoxidation capacity, the composition alloy can reach high deoxidation effect.

Owner:危松林

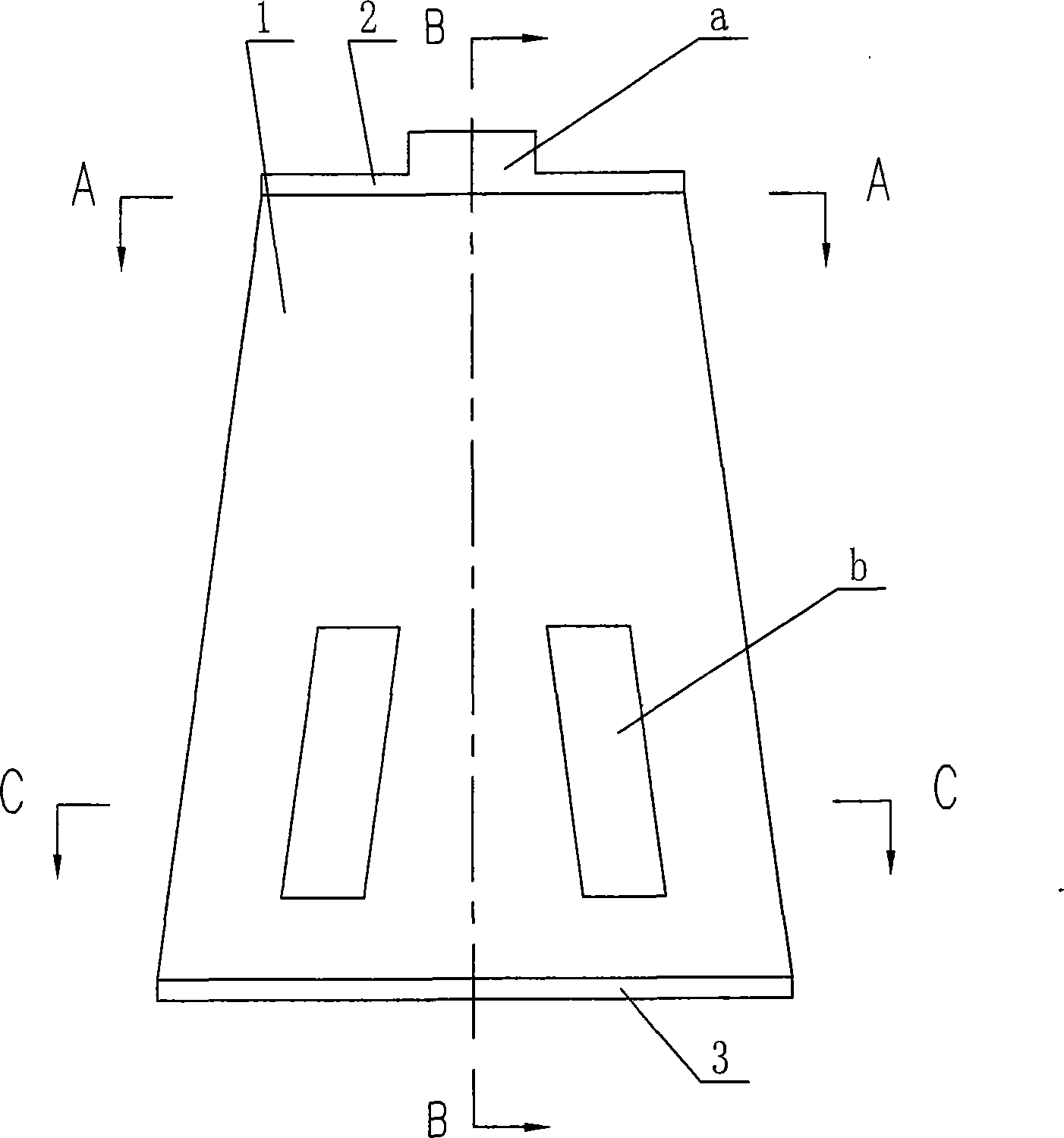

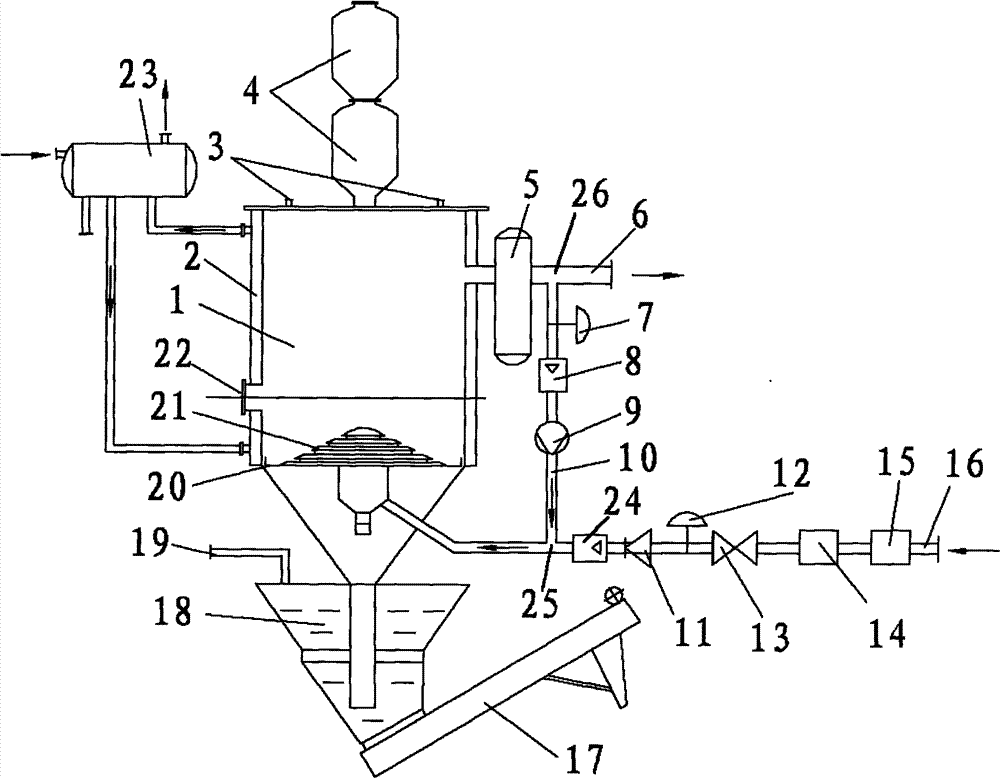

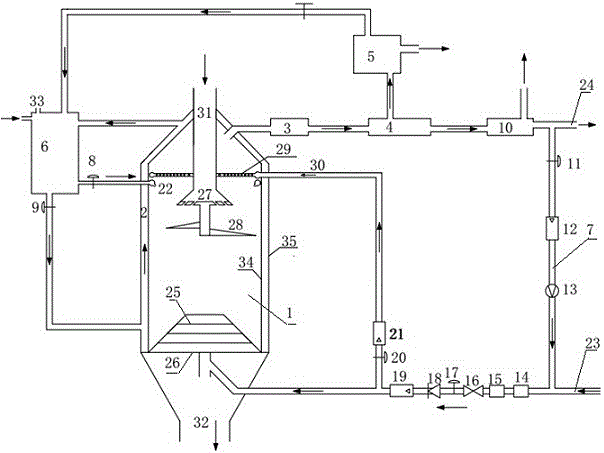

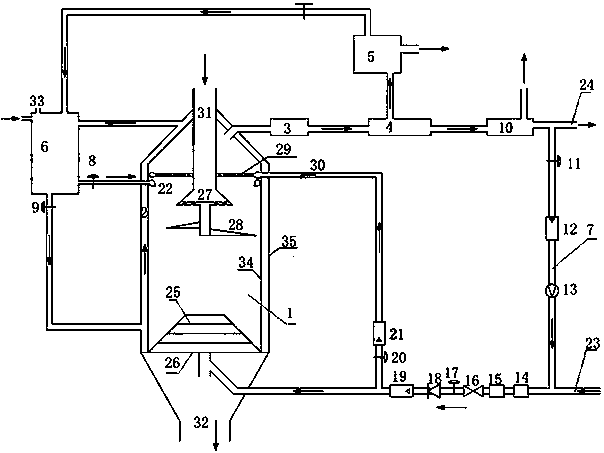

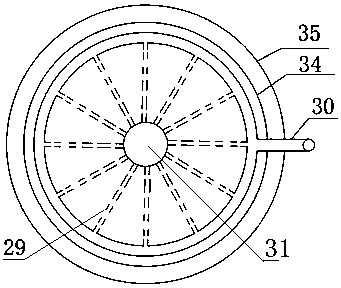

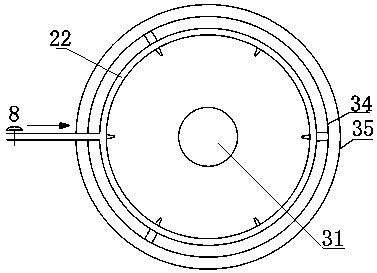

Fixed bed coal seam gas non-catalytic deoxidization method and device

ActiveCN101914402BSolving security problems in enrichmentAvoid security issuesGaseous fuelsFixed bedEngineering

The invention discloses a fixed bed coal seam gas non-catalytic deoxidization method and a fixed bed coal seam gas non-catalytic deoxidization device. The device comprises a fixed bed coal seam gas deoxidization device body including a furnace body (1), wherein the side wall of the furnace body (1) is provided with a water jacket (2) enclosing the side wall of the furnace body; the upper part of the water jacket (2) is connected with an air inlet of a steam pocket (23) through a pipeline; and a water inlet pipe on the lower part of the water jacket is connected with a water outlet of the steam pocket (23). The device deoxidizes the coal seam gas, can effectively control the deoxidization temperature and reduce the oxygen content in the coal seam gas to less than 0.5 percent, and maximallyreduces methane decomposition to make the methane loss less than 5 percent.

Owner:CCTEG CHINA COAL RES INST

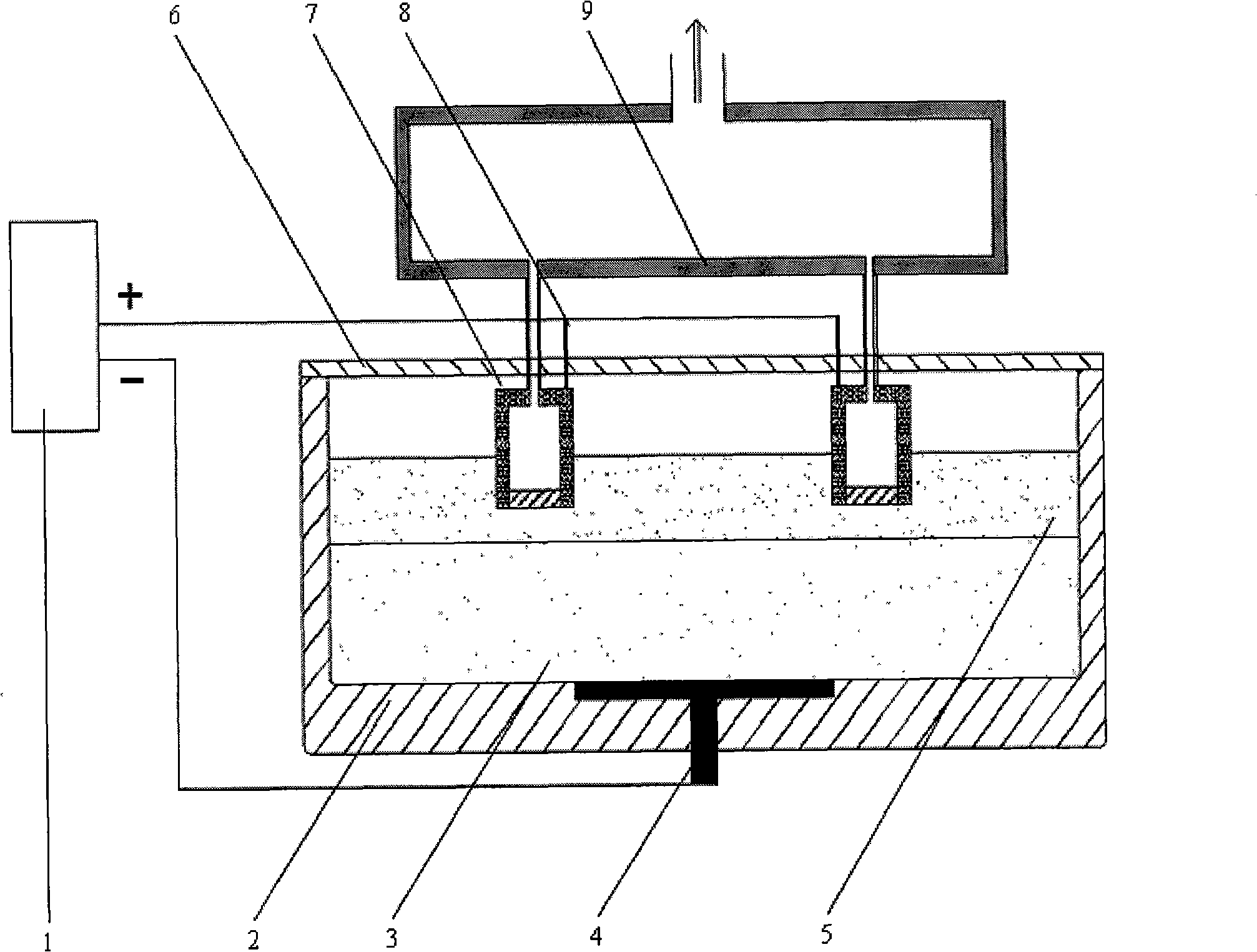

Special desoxidant for petroleum tube steel

InactiveCN104630417AMeet special requirements for steelRapid deoxygenationElectricityWater insoluble

The invention relates to a special desoxidant for petroleum tube steel. The desoxidant is characterized by being prepared from the following components in percentage by weight: 22-33 percent of Al, 28-43 percent of Al2O3, 0.1-3 percetn of SiO2, 0.1-2 percent of C, 0.1-0.3 percent of water-insoluble adhesive, 5-18 percent of an additive and the balance of Fe, wherein the granularity of Al and Al2O3 is not more than 5mm. The desoxidant can be used for achieving the effects of quickly deoxidizing, adsorbing impurities, shortening melting time, reducing electricity consumption for melting and greatly reducing melting cost, and can meet the special requirement for steels for petroleum tubes.

Owner:LAIWU LUHENG METALLURGICAL MATERIALS CO LTD

Smelting method for copper-clad steel

ActiveCN106834591ASimplify the smelting processRapid responseManufacturing convertersProcess efficiency improvementSmelting processOxygen

The invention discloses a smelting method for copper-clad steel. A smelting process comprises BOF (Basic Oxygen Furnace) smelting-LF (Ladle Furnace) refining-small square billet continuous casting working procedures in sequence, wherein the BOF smelting controls decarburization strength and tapping temperature, an end point [C] is less than or equal to 0.040%, T is equal to 1620-1680DEG C, and slags are pushed off for tapping; the LF refining controls slag ingredients and static mixing time, (FeO+MnO) is less than or equal to 1.0%, the static mixing time is longer than or equal to 10min, and slag surface deoxidization and calcium feeding processing are carried out; the square billet continuous casting controls pouring temperatures and electromagnetic stirring technologies, T is equal to 1560-1620DEG C, and liquid surface fluctuation and casting speed can be stabilized. Through the smelting method for the copper-clad steel, on the basis of the accurate control on each smelting link, a smelting working procedure of the copper-clad steel is simplified, pre-desulfurization and vacuum processing are omitted, while product quality is kept, production efficiency is improved, cost is lowered, and competitive power is improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method for producing white slag in bearing steel LF refining process

PendingCN113930586AReduce oxygen contentPrevent nitrogen increase and secondary oxidationSlagIron production

The invention discloses a method for producing white slag in a bearing steel LF (ladle furnace) refining process, and relates to the technical field of steel production. On the basis of the requirement of bearing steel on ultra-purity, the bearing steel LF deoxidation refining process is optimized in process details; and 70 minutes LF refining slagging of the bearing steel is optimized for the first 20 minutes, so that rapid deoxidation, white slag production and power supply atmosphere protection can be conveniently realized, the purpose of reducing the oxygen content of the bearing steel is achieved, nitrogen increase and secondary oxidation of molten steel are prevented, and the LF refining time of the bearing steel is shortened.

Owner:NANJING IRON & STEEL CO LTD

Slag nonpollution deoxygenation method capable of regulating anode oxygen partial pressure and device thereof

InactiveCN101457276BImprove pollutionAccelerated exclusionGas emission reductionOxygen ionsVacuum chamber

The invention relates to a pollution-free molten slag deoxidization method capable of adjusting anode oxygen partial pressure and a device thereof, and belongs to the technical field of metallurgical refining process. In the method, molten steel or molten metal is deoxidized and purified by the special device. In the method, the molten slag is taken as electrolyte, a deaeration cavity electrode inserted into the molten slag is taken as an anode, and the molten steel or the molten metal is taken as a cathode; the deaeration electrode is provided with an electrode cavity and is communicated with a vacuum chamber by a conduit; an applied DC power supply exerts direct current impulse voltage so that an electric field is formed between the molten steel or the molten metal and an oxygen electrode of the molten slag, and the conduction of oxygen ions in a molten slag system and mass transfer of dissolved oxygen in the molten steel are controlled by controlling a current value and a voltage value of the DC power supply as well as components of the molten slag. The oxygen is diffused from the molten slag to the electrode cavity and discharged by an air exhaust system by controlling the oxygen partial pressure of the electrode cavity.

Owner:SHANGHAI UNIV

Novel environment-friendly converter rapid repair material

InactiveCN111792920AImprove adhesion rateShort sintering timeManufacturing convertersProcess efficiency improvementRepair materialMineralogy

The invention relates to a novel environment-friendly converter rapid repair material, which comprises the following components in parts by mass: 95-97 parts of magnesite blocks and 3-5 parts of graphite, wherein the size of the magnesite blocks is 80-150mm, the particle size of the graphite is 80-150 meshes, and the mass percentage content of carbon in the graphite is not less than 90%. The repair material is prepared by mixing a refractory raw material (magnesite blocks) and an antioxidant (graphite), and has the characteristics of high adhesion rate, no smoke, short sintering time and longservice life.

Owner:鞍山赛诺新材料有限公司

Arc furnace steel-making method capable of effectively preventing steel part surface from cracking

InactiveCN101798616AShorten smelting timeReduce power consumptionProcess efficiency improvementElectric furnaceElectric arc furnaceSilicon alloy

The invention discloses an arc furnace steel-making method capable of effectively preventing steel part surface from cracking. The method improves smelting technology, uses carborundum as deoxidant for reduction for arc furnace steel making, combines a packet cutting-in method, and adopts yttrium base heavy rare earth ferro-silicon alloy to purify molten steel. The method comprises the steps of reducing, deoxidizing, sampling, purifying molten steel with the packet cutting-in method and pouring. The method provided by the invention can effectively reduce cast steel surface cracking phenomenon, improves the quality and the production efficiency of the cast steel, is an innovation of production technology and industrial application effect, and can make contribution for improving the comprehensive economic benefit of arc furnace steel making.

Owner:WUHAN UNIV OF TECH +1

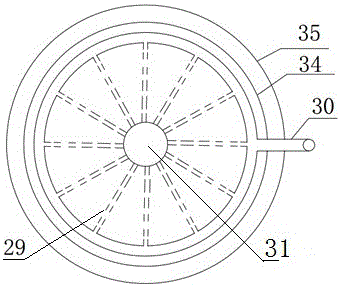

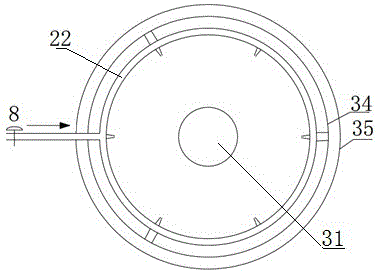

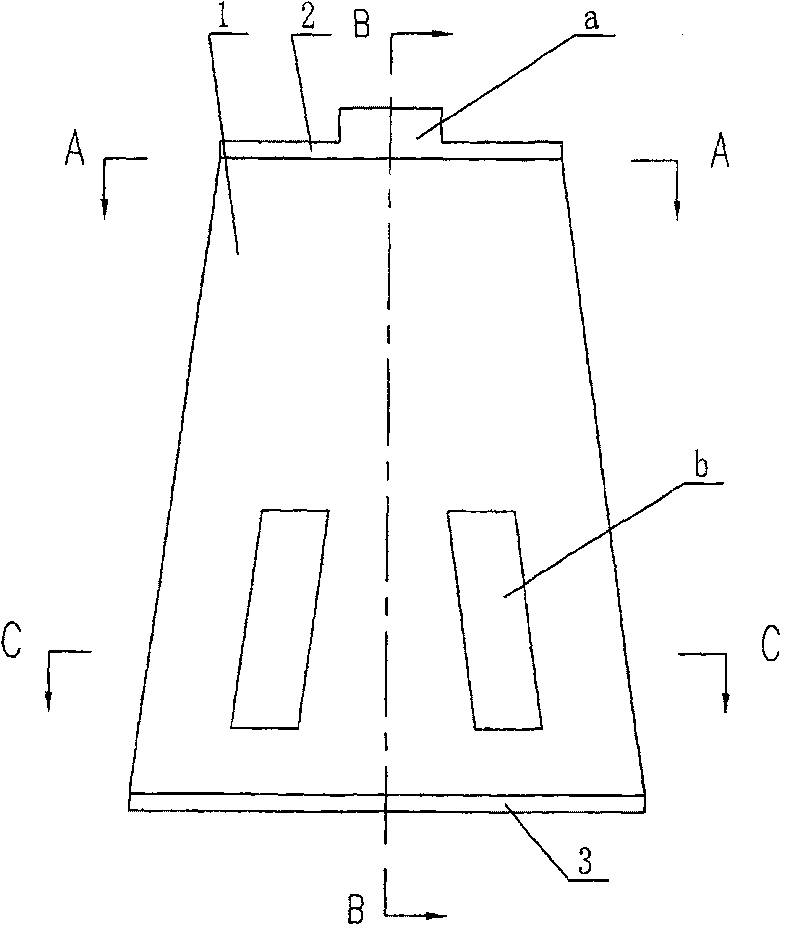

Fixed-bed coal seam gas non-catalytic deoxygenation device and method

InactiveCN105733720ALow investment consumptionSmall footprintGaseous fuelsFixed bedProcess engineering

The invention discloses a fixed-bed coal seam gas non-catalytic deoxygenation device and method.The device comprises a fixed-bed deoxygenation furnace, wherein a sidewall and conical top of a furnace body are provided with a water jacket surrounding the sidewall and the conical top; the upper portion of the water jacket at the conical top is connected with a water inlet of a steam drum, and the bottom of the water jacket is connected with a water outlet of the steam drum; a circular coal seam gas pipe and a water spray pipe are arranged in the furnace body.By using the device to deoxygenate coal seam gas, H2 produced in coal pyrolysis and water gas reaction is made full use in deoxygenation, the coal seam gas enters the furnace body through upper and lower paths, coal seam gas treatment quantity is high, deoxygenation temperature is effectively controlled, oxygen content of the coal seam gas is decreased to below 0.5%, methane splitting can be reduced maximally, and methane loss is below 5%.

Owner:TAIYUAN UNIV OF TECH

A kind of rapid white slag production material and technology for 120tlf refining furnace

ActiveCN113502372BLow melting pointAdjust liquidityProcess efficiency improvementIron(II) oxideIron powder

The invention belongs to the technical field of steel smelting, and in particular relates to a rapid white slag making material and process for a 120tLF refining furnace, comprising the following components by weight percentage: 8-10% of aluminum powder, 50-60% of ferrosilicon powder, and carbon powder 25‑30% and calcium fluoride 5‑10%. The white slag making material and process provided by the present invention, calcium fluoride can lower the melting point of slag, adjust the fluidity of slag, the addition of aluminum powder can realize rapid deoxidation and white slag, the addition of carbon powder can promote the formation of long-arc foam slag, ferrosilicon powder can promote the stable maintenance of white slag; the degree of deoxidation of converter molten steel is deep, and the content of ferrous oxide in the slag entering the station is low; the reuse of the liquid reduction refining slag from the previous furnace can promote rapid slagging; the invention can promote rapid desulfurization and deoxidation of 120tLF furnace , Adsorption of inclusions, fast slag formation, stable white slag.

Owner:山东磐金锻造机械有限公司

A fixed-bed coalbed gas non-catalytic deoxidation device and method

InactiveCN105733720BLow investment consumptionSmall footprintGaseous fuelsFixed bedProcess engineering

The invention discloses a fixed-bed coal seam gas non-catalytic deoxygenation device and method.The device comprises a fixed-bed deoxygenation furnace, wherein a sidewall and conical top of a furnace body are provided with a water jacket surrounding the sidewall and the conical top; the upper portion of the water jacket at the conical top is connected with a water inlet of a steam drum, and the bottom of the water jacket is connected with a water outlet of the steam drum; a circular coal seam gas pipe and a water spray pipe are arranged in the furnace body.By using the device to deoxygenate coal seam gas, H2 produced in coal pyrolysis and water gas reaction is made full use in deoxygenation, the coal seam gas enters the furnace body through upper and lower paths, coal seam gas treatment quantity is high, deoxygenation temperature is effectively controlled, oxygen content of the coal seam gas is decreased to below 0.5%, methane splitting can be reduced maximally, and methane loss is below 5%.

Owner:TAIYUAN UNIV OF TECH

LF (ladle furnace) refining technology of small-flow bottom-blown ladle

PendingCN113106201AUniform molten steel composition and temperaturePromote steel slag interface reactionProcess efficiency improvementSlagProcess engineering

The invention discloses an LF (ladle furnace) refining technology of a small-flow bottom-blown ladle. The LF refining technology comprises the steps of: adding an alloy and a slag making material at 1 / 4-1 / 2 of converter tapping, and feeding an alloy wire and a pure calcium wire under the condition of small-flow bottom blowing. The method provided by the invention can reduce the refining time under the condition of small-flow bottom blowing and improve the quality of a finished product, and production accidents or quality accidents caused by unplanned interruption of a casting machine are avoided.

Owner:LIUZHOU IRON & STEEL

Magnetic thermal field cooperate with oxygen-enriched air generating device

InactiveCN101244807BIncrease oxygen contentRapid deoxygenationOxygen preparationInlet channelCombustion

The invention relates to a magneto-thermal field synergistic oxygen-enriched air generating device, which is characterized in that a casing is a stage tubular body or a column tubular body, an upper cover with an air outlet a is arranged on upper end of the casing, a base is arranged at lower end of the casing, permanent magnets with magnetic shoes are circumferentially and evenly arranged in thecasing, polarities of adjacent and opposite permanent magnets are different, an air inlet b is arranged between the lower part of lateral side of the casing and the permanent magnets, a clearance which is communicated with the air inlet b is retained between adjacent permanent magnets and magnetic shoes, forming a convergence type air inlet channel which is communicated with the air inlet b from the external to the internal; lateral side of radial direction of the permanent magnets is at the same plane with the lateral side of radial direction of the magnetic shoes, a convergence type air outlet channel is formed from the upper part to the lower part among the circumferentially adjacent permanent magnets, adjacent and opposite magnetic shoes in the casing, a heater is arranged at the air outlet a of the upper cover in the casing and an air negative ion generating device is arranged on the base in the casing. The oxygen-enriched air generating device has the advantages that the device can be used for indoor oxygen-enriching and ventilating and can also be used as the oxygen-enriched source of combustion as well as oxygen-charging source of water body.

Owner:SHAANXI NORMAL UNIV

An electric arc furnace steelmaking method capable of effectively eliminating surface cracks of steel castings

InactiveCN101798616BShorten smelting timeReduce power consumptionProcess efficiency improvementElectric furnaceElectric arc furnaceSilicon alloy

The invention discloses an arc furnace steel-making method capable of effectively preventing steel part surface from cracking. The method improves smelting technology, uses carborundum as deoxidant for reduction for arc furnace steel making, combines a packet cutting-in method, and adopts yttrium base heavy rare earth ferro-silicon alloy to purify molten steel. The method comprises the steps of reducing, deoxidizing, sampling, purifying molten steel with the packet cutting-in method and pouring. The method provided by the invention can effectively reduce cast steel surface cracking phenomenon, improves the quality and the production efficiency of the cast steel, is an innovation of production technology and industrial application effect, and can make contribution for improving the comprehensive economic benefit of arc furnace steel making.

Owner:WUHAN UNIV OF TECH +1

A kind of cast steel deoxidation alloy and its processing method and using method

The invention discloses a cast steel deoxidized alloy and a processing method and a use method of the cast steel deoxidized alloy, and belongs to the field of cast steel molten steel smelting. The deoxidized alloy comprises, by mass percent, 15-25% of Re, 8-20% of Ca, 5-15% of Ba, 5-20% of Ti, 5-20% of Zr, 5-20% of Si, 0.5-3% of Mg and the balance Fe. The deoxidized alloy is prepared by adopting afusion casting method, the fusion casting method is suitable for casting ordinary carbon steel, alloy steel, stainless steel and other cast steel, the content of oxygen in the cast steel can be effectively reduced, the harmful effects of oxygen on the content of the cast steel are reduced, and the cast steel product quality is improved.

Owner:MAANSHAN RUIHUI ENTERPRISE

A deoxidizing slag suitable for silicon killed steel

The invention belongs to the technical field of iron and steel metallurgy and discloses slag for deoxidization and applicable to silicon-killed steel. The slag for the deoxidization and applicable tothe silicon-killed steel is prepared from the following components in percentage by mass: 30 to 45 percent of CaO, 30 to 40 percent of SiO2, 10 to 30 percent of Si, 2 to 5 percent of C, less than or equal to 5 percent of Al, less than or equal to 5 percent of Al2O3, less than or equal to 0.1 percent of S and less than or equal to 0.05 percent of P; the ratio of WCaO / WSiO2 is 0.9 to 1.2, wherein WCaO is the mass percent of the CaO in the slag and WSiO2 is the mass percent of the SiO2 in the slag. The invention further provides a preparation method of the slag for the deoxidization and applicable to the silicon-killed steel. The slag for the deoxidization, provided by the invention, is a whole pre-melted material, so that the components are uniform, the melting point is low and the melting time is short. When the slag is used in a factory, rapid deoxidization and rapid slag formation are facilitated.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

White slag refining agent for LF (Ladle Furnace) refining furnace and preparation method thereof

The invention relates to a white slag refining agent for an LF (Ladle Furnace) refining furnace, belonging to the technical field of steel making, in particular to the technical field of ladle slag modification treatment of the LF refining furnace. The invention aims to provide the white slag refining agent which has the advantages of low cost and strong inclusion adsorption capacity. The white slag refining agent for the LF refining furnace is characterized by comprising the following components in percentage by weight: 40-50 percent of calcium carbide, 8-14 percent of fluorite, 24-30 percent of limestone, 4-6 percent of bauxite and 4-12 percent of dolomite. The white slag refining agent has the advantages of low cost and wider application range and is suitable for a non Al deoxidized steel (a kind of steel, strictly controlling the aluminum content), for example. After being added into the LF refining furnace, the white slag refining agent can fulfill the functions of rapid deoxidation and white slag production and can enable the content of FeO and MnO in ladle slag to be no more than 1.5 percent to satisfy the smelting needs of high-grade steels.

Owner:PANZHIHUA GANGCHENG GROUP

Deoxidizing technology for electric furnace steel ladle

InactiveCN111593169AQuick responsePromote decomposition reactionManufacturing convertersElectric furnaceSlagAluminium powder

The invention discloses a deoxidizing technology for an electric furnace steel ladle. The technology comprises the steps that limestone and aluminum are ground into powder until the particle size reaches 1 mm or smaller, the limestone ground into the powder and the aluminum ground into the powder are mixed with graphite carbon with the carbon content being 90%, and the mixture is pressed into calcium carbonate carbon aluminum balls with the diameter being 20-30 mm through a dry powder ball press machine, wherein the mass percent of the adding proportion of the limestone accounts for 37-46% ofthe mass of carbon aluminum balls, the mass percent of the adding proportion of aluminum accounts for 40-50% of the mass of the carbon aluminum balls, the mass percent of the adding proportion of graphitic carbon accounts for 4-7% of the mass of carbon balls, and the mass percent of the carbon content among the calcium carbonate carbon balls is controlled to be 5-7%. Calcium carbonate can be quickly fragmented into fine CaO particles and forms a liquid or solid deoxidation product with a deoxidation product, a high reaction speed is achieved, refractory materials and furnace slag are further oxidized through addition of aluminum powder, and oxygen and oxide are conveyed into molten steel; and besides, a residual aluminum oxide product has no influence on the usability of steel, and the deoxidizing efficiency of the molten steel and the quality of the molten steel are further improved.

Owner:山东邦巨实业有限公司

A method for refining and deoxidizing low-carbon and low-silicon welding wire steel

The invention relates to a method for refining and deoxidizing low-carbon and low-silicon welding wire steel. The specific steps are as follows: 1) deoxidizing and alloying molten steel by tapping out of a converter; For deoxidation, add ferrosilicon powder for deoxidation. By optimizing the refining deoxidation method, the clogging of the continuous casting nozzle is solved, and the problem of subcutaneous air bubbles of the continuous casting slab is reduced.

Owner:SGIS SONGSHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com