High-purity steel and production process

A technology of production process and purity, applied in the field of high-purity steel and production process, can solve the problems of adverse effects of molten steel quality, increased consumption of aluminum strips, difficult to remove alumina inclusions, etc., so as to achieve fewer nozzle nodules and reduce impurities. The content and the effect of adding high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

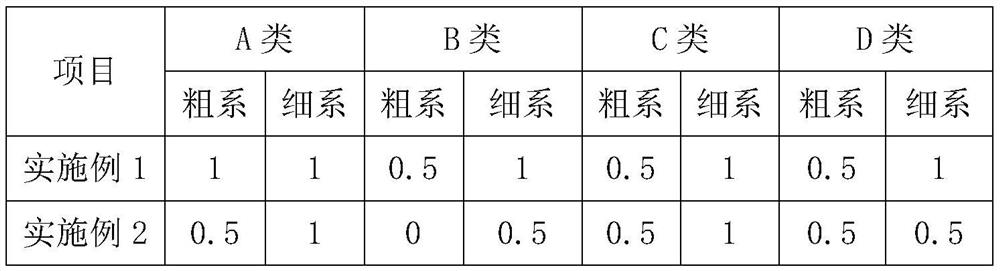

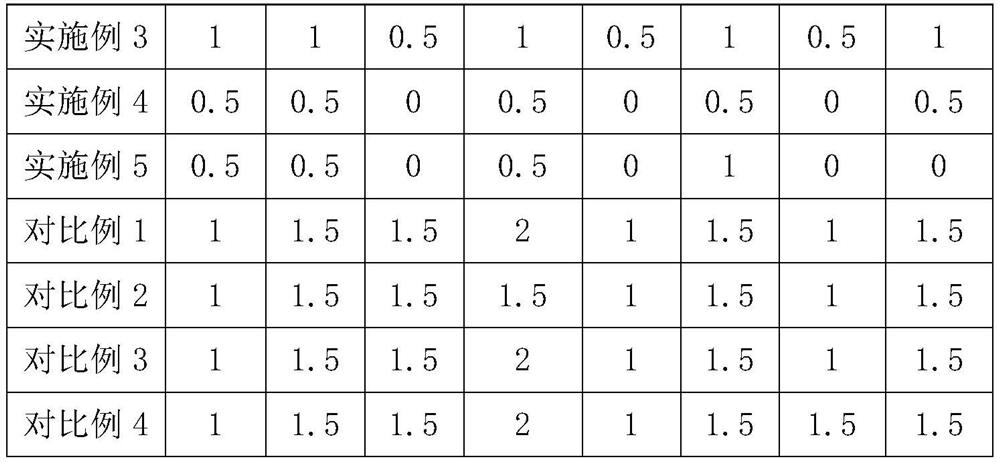

Examples

Embodiment 1

[0041] A high-purity steel prepared by the following process, comprising the following steps:

[0042] (1) Primary smelting of converter

[0043] (11) First add molten iron to the converter, and the temperature of the molten iron entering the furnace is controlled at ≥ 1250 ° C. In terms of mass percentage, P in the molten iron is ≤ 0.120%, and the slag content is ≤ 0.5%; then, scrap steel is added to the molten iron, and the molten iron The total amount of scrap steel and steel scrap added is 110t, of which scrap steel is 32t; after that, top-blown oxygen and bottom-blown argon are used to stir and compound blow for 12-min, the pressure of top-blown oxygen is 1.0MPa, nitrogen is blown 2 minutes before bottom blowing, and then switched to Bottom blowing argon; adding lime 32kg / t steel and dolomite 9kg / t steel to make slag during the blowing process, slag is melted throughout the process, and the slag alkalinity is controlled at 3.8; at the end of blowing, molten steel C≥0.08%;...

Embodiment 2

[0057] A high-purity steel prepared by the following process, comprising the following steps:

[0058] (1) Primary smelting of converter

[0059] (11) First add molten iron to the converter, and the temperature of the molten iron entering the furnace is controlled at ≥ 1250 ° C. In terms of mass percentage, P in the molten iron is ≤ 0.120%, and the slag content is ≤ 0.5%; then, scrap steel is added to the molten iron, and the molten iron The total amount of steel scrap added is 112t, of which scrap steel is 30t; after that, top-blown oxygen and bottom-blown argon are used to stir and composite blow for 13 minutes, the pressure of top-blown oxygen is 0.9MPa, nitrogen is blown 3 minutes before bottom blowing, and then switched to bottom blowing Argon gas; add lime 35kg / t steel and dolomite 8kg / t steel to make slag during the blowing process, and control the slag alkalinity at 3.5 during the whole process; at the end of blowing, C≥0.08% in molten steel; P≤0.015% ; Tapping temper...

Embodiment 3

[0073] A high-purity steel prepared by the following process, comprising the following steps:

[0074] (1) Primary smelting of converter

[0075] (11) First add molten iron to the converter, and the temperature of the molten iron entering the furnace is controlled at ≥ 1250 ° C. In terms of mass percentage, P in the molten iron is ≤ 0.120%, and the slag content is ≤ 0.5%; then, scrap steel is added to the molten iron, and the molten iron The total amount of steel scrap added is 115t, of which scrap steel is 25t; after that, top-blown oxygen and bottom-blown argon are used to stir and composite blow for 15min, the pressure of top-blown oxygen is 0.8MPa, nitrogen is blown 4min before bottom blowing, and then switched to bottom blowing Argon gas; add lime 37kg / t steel and dolomite 7kg / t steel to make slag during the blowing process, and control the slag alkalinity at 3 during the whole process; at the end of blowing, C≥0.08% in molten steel; P≤0.015% ; Tapping temperature: 1630°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com