Patents

Literature

47results about How to "Reduce unqualified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

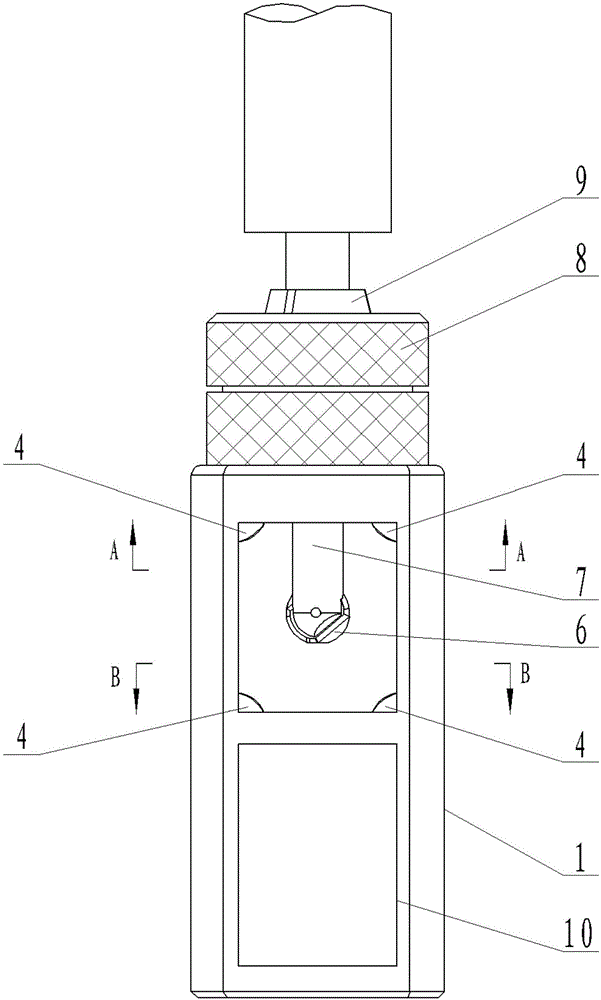

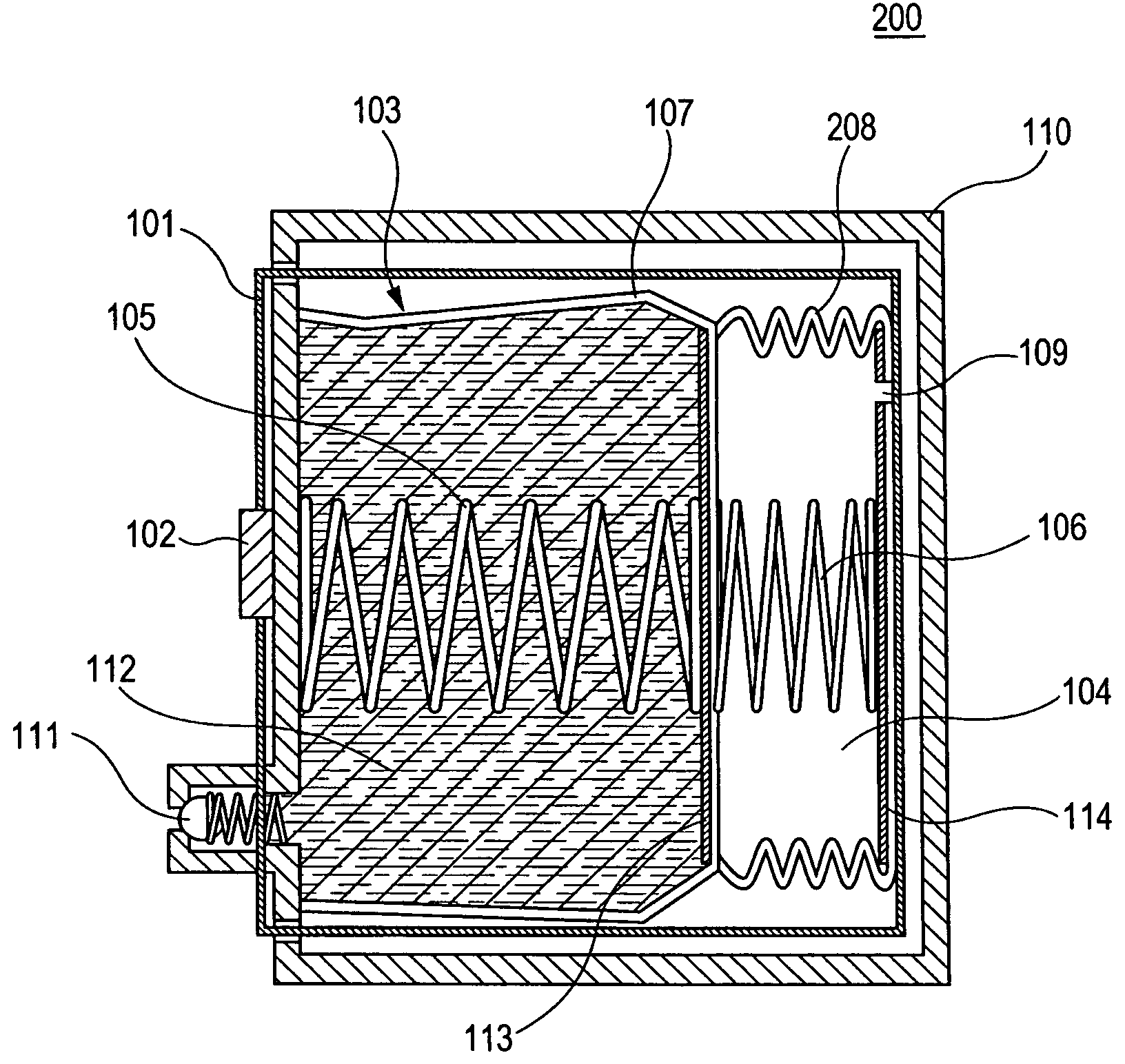

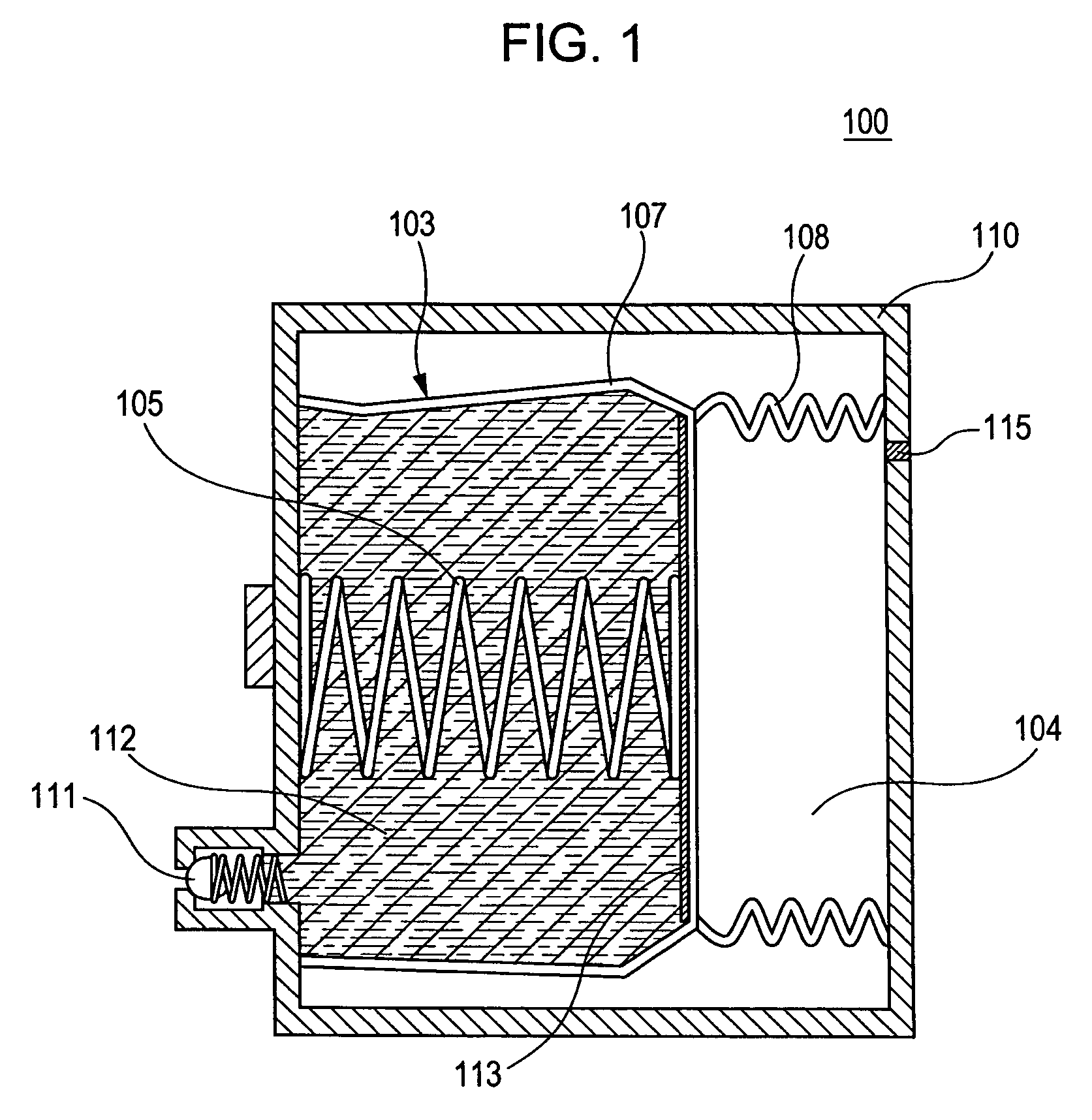

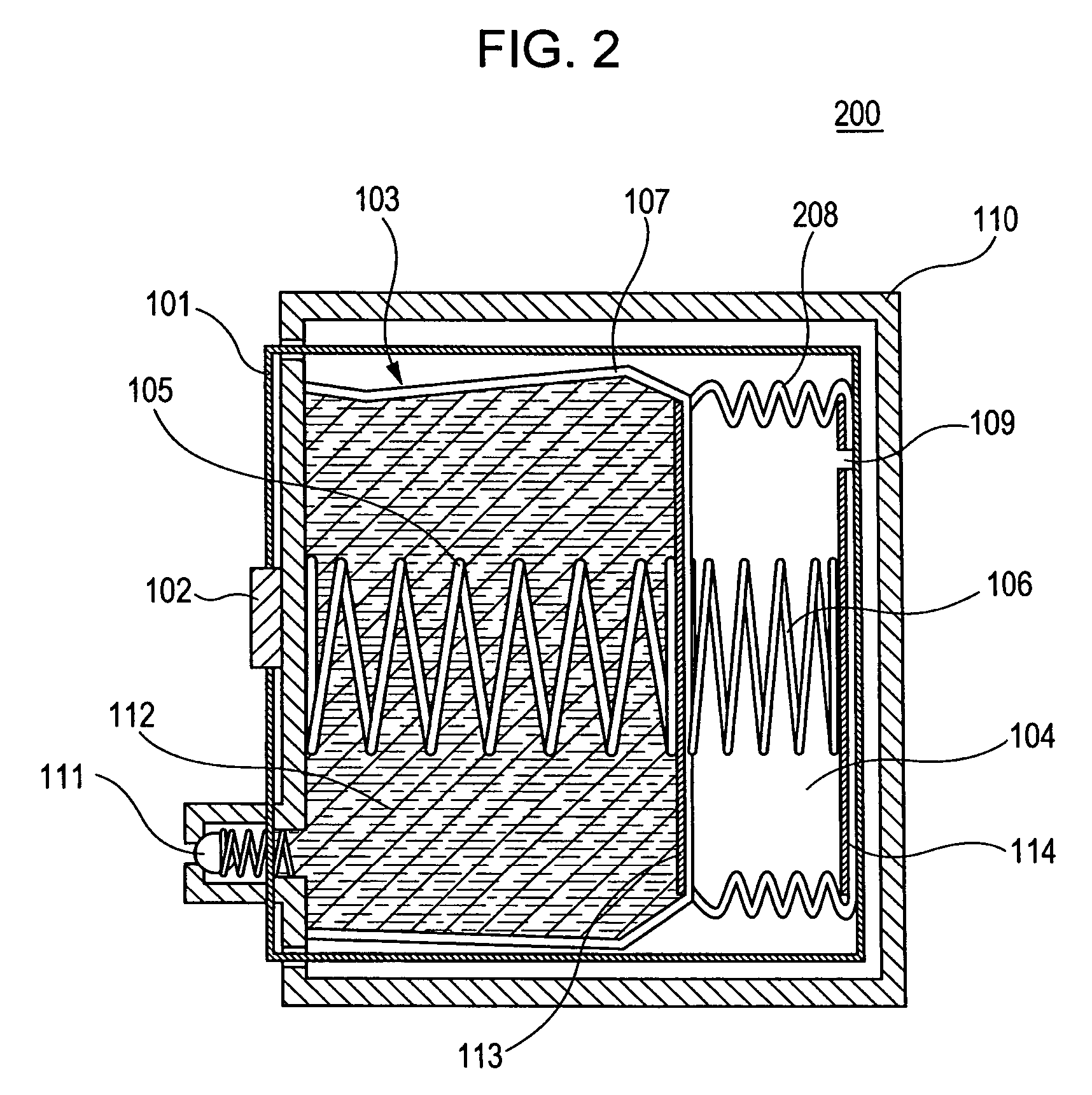

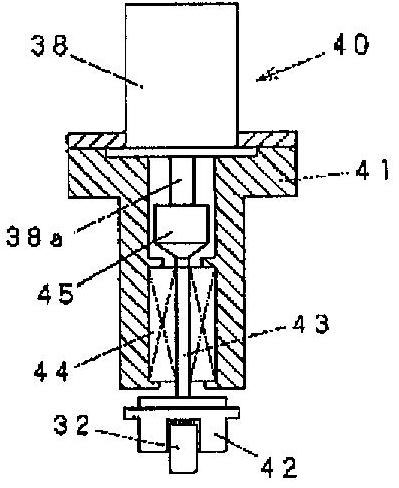

Liquid storage container and liquid ejection recording apparatus having the container mounted thereon

InactiveUS20060221153A1Prevent printing nonconformityAlleviating rapid external impactPrintingNozzleLiquid storage

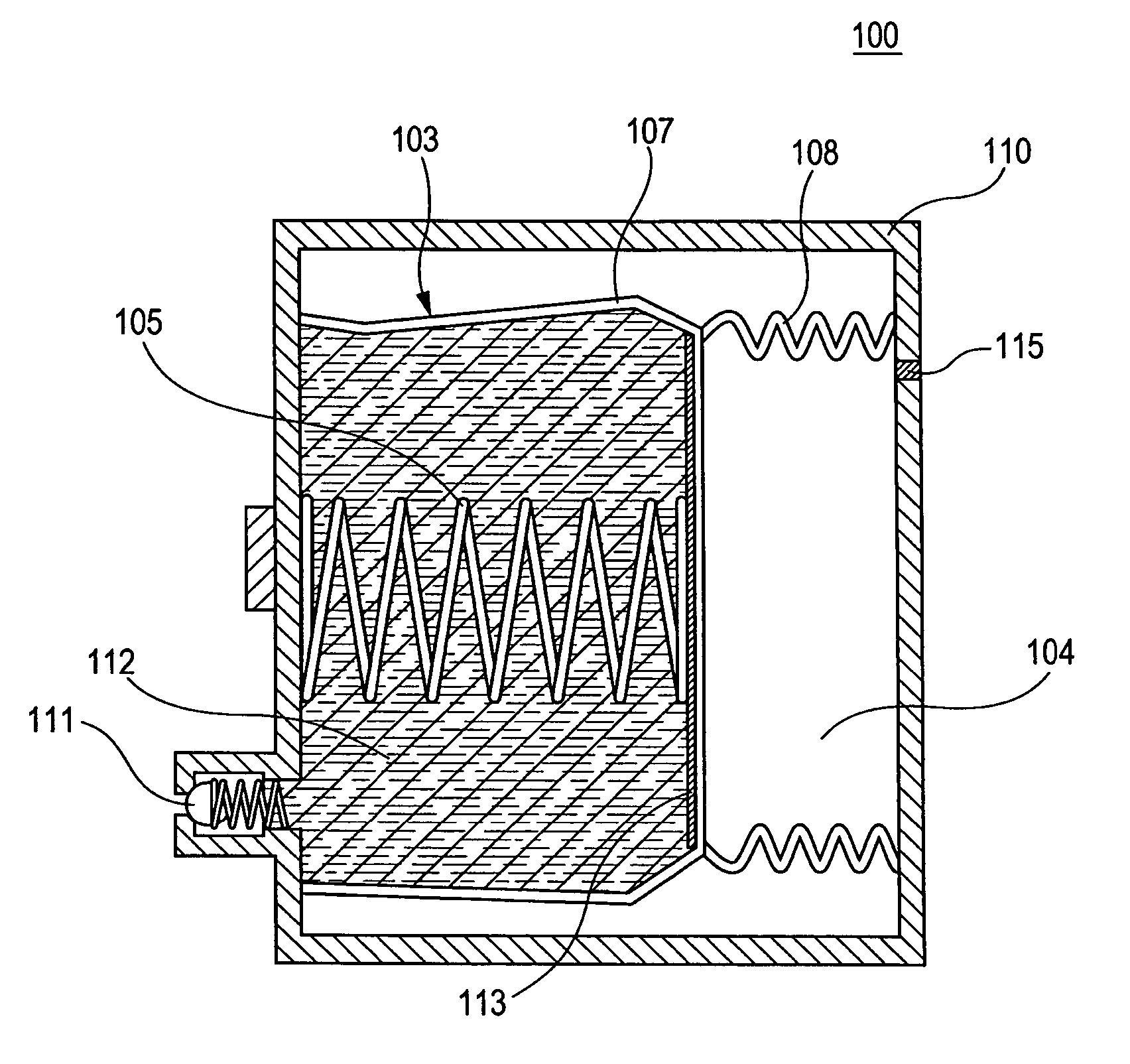

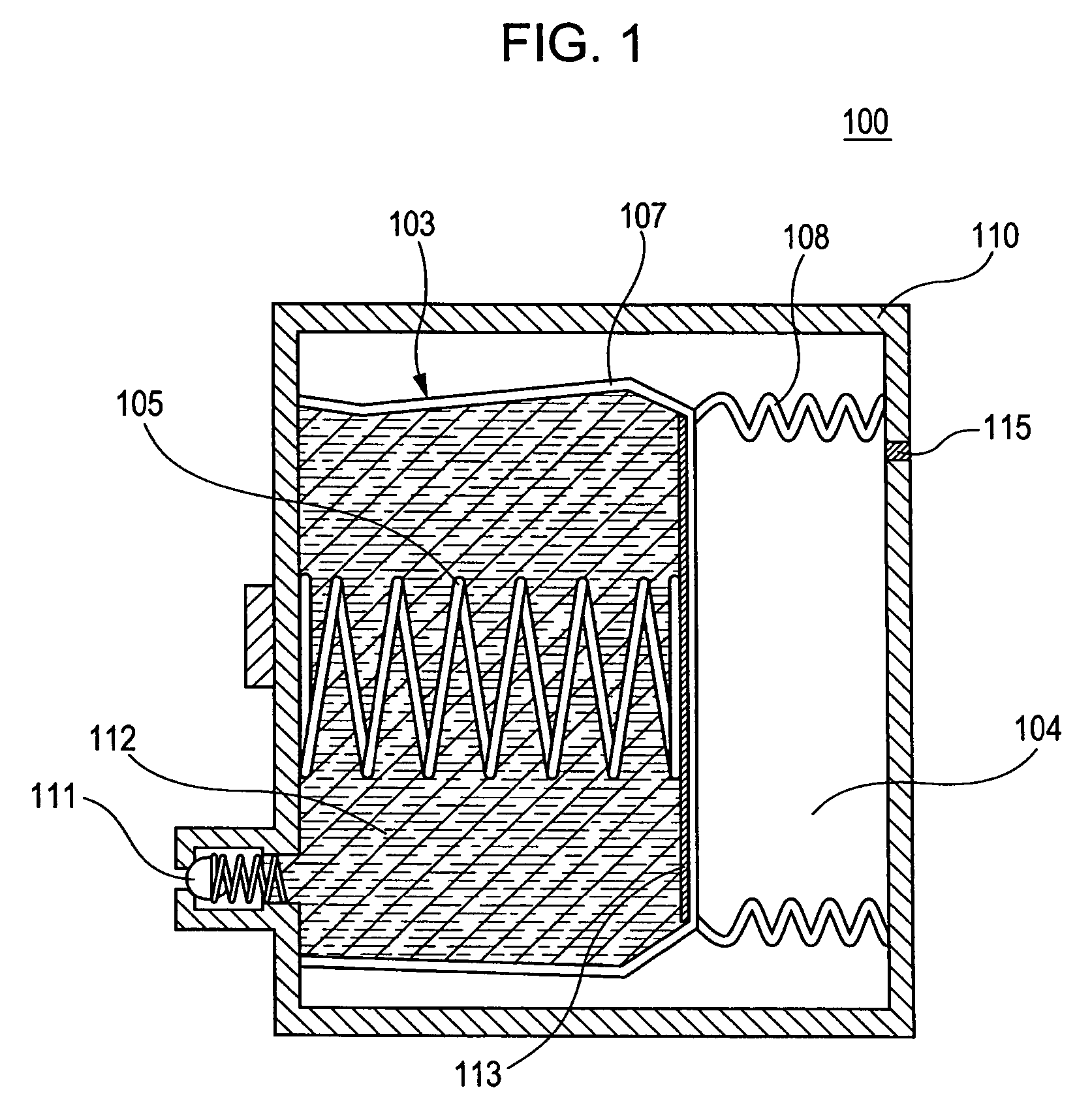

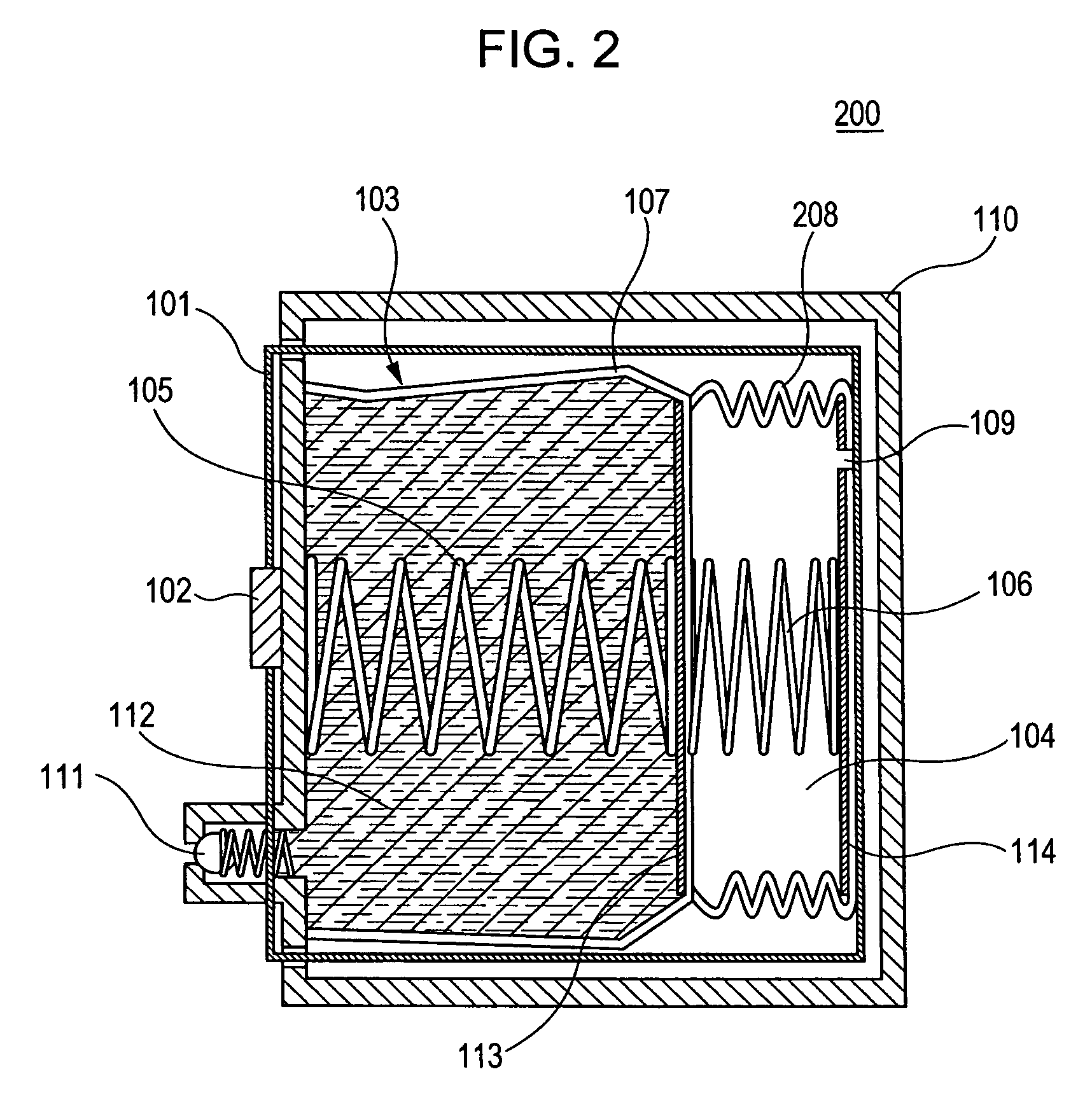

A reliable ink cartridge that reduce printing nonconformity even during high speed inkjet-recording with multiple nozzles by alleviating rapid external impact applied from the outside of the ink cartridge. Within a casing of an ink cartridge, a flexible bag forming an ink reservoir is accommodated. Between the surface of the flexible bag where a sheet member is bonded and a wall surface of the casing, a stress damping chamber is provided. The stress damping chamber communicates with the atmosphere outside the ink cartridge via an orifice formed on a wall surface of the casing.

Owner:CANON KK

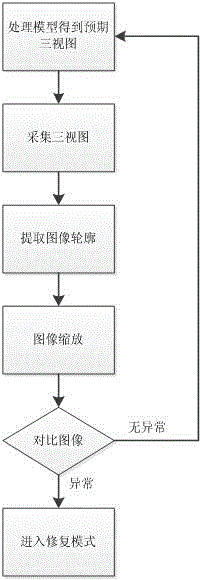

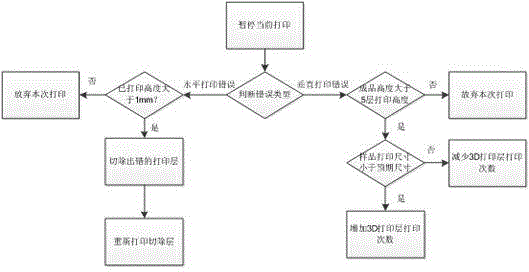

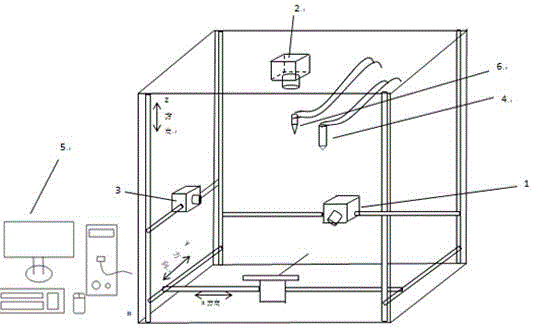

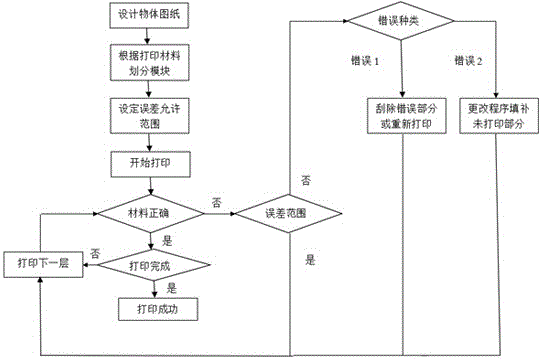

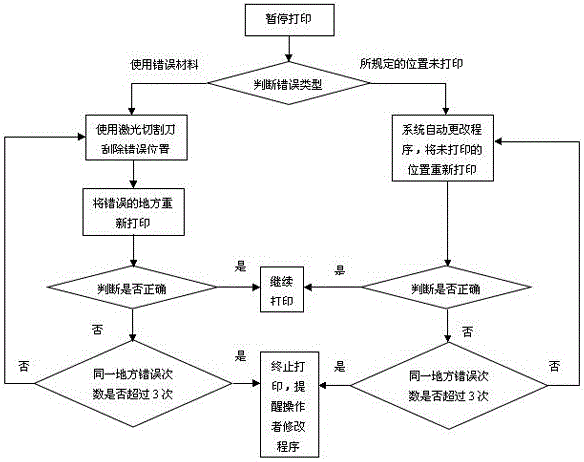

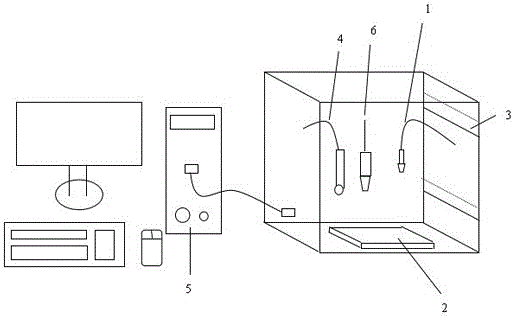

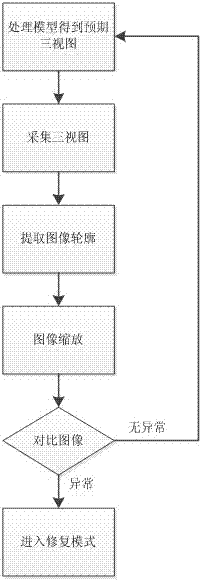

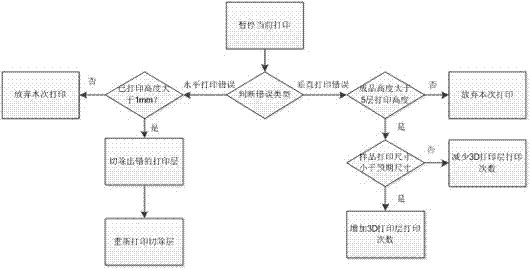

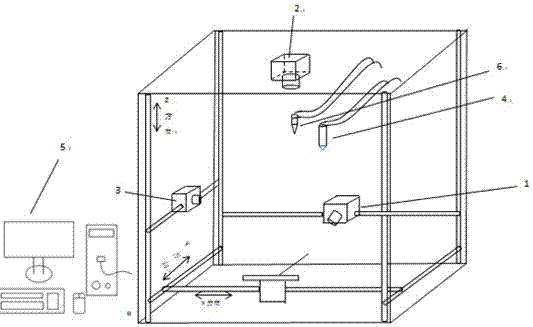

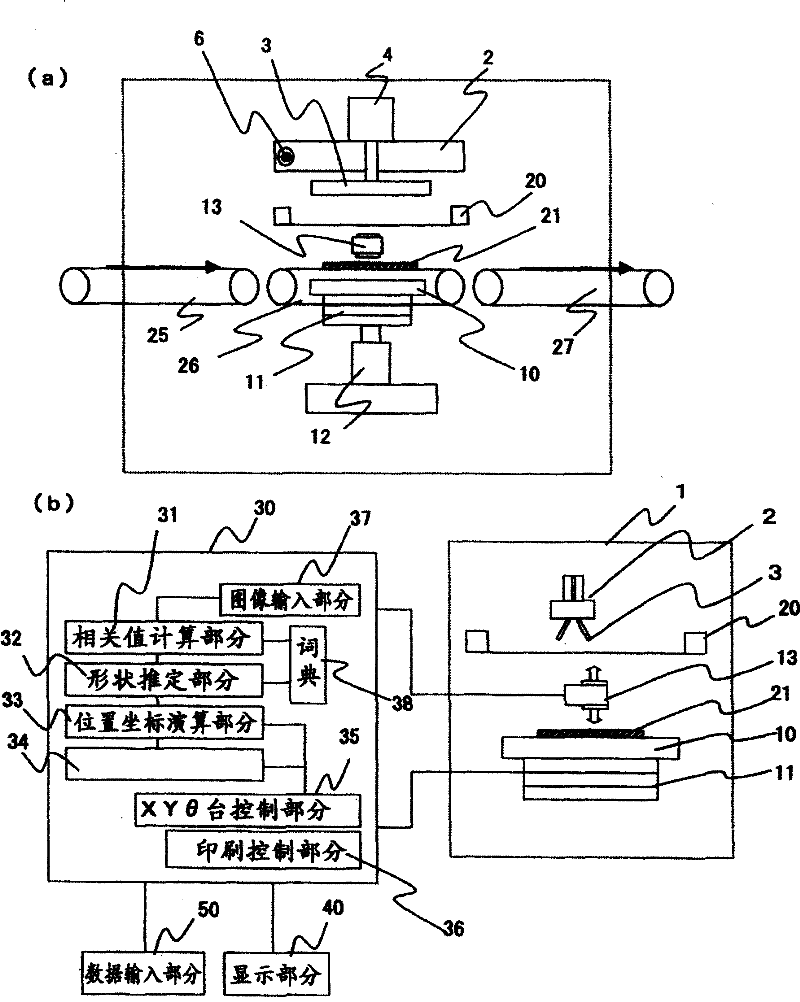

3D printing monitoring error correction method based on three views

ActiveCN104407823AReduce unqualifiedSimple compositionHardware monitoringCharacter and pattern recognitionImaging processing3d printer

The invention provides a 3D printer monitoring error correction method. The method is used for monitoring whether errors occur in the printing process of a 3D printer and making timely and proper correction, and is characterized in that a system comprises three cameras and monitoring and error correcting software, wherein the three cameras are used for three-view monitoring and correspond to three view angles; the monitoring and error correcting software uses an image processing method for comparing the expected three views in each step in the printing process; whether the errors occur in the printing process or not is monitored and judged; repairable small errors are corrected in time; and errors which cannot be corrected are left uncorrected, so that the printing time is saved. The system has the advantages that the printing correctness is improved, and the average time for printing qualified products is reduced.

Owner:FUZHOU UNIV

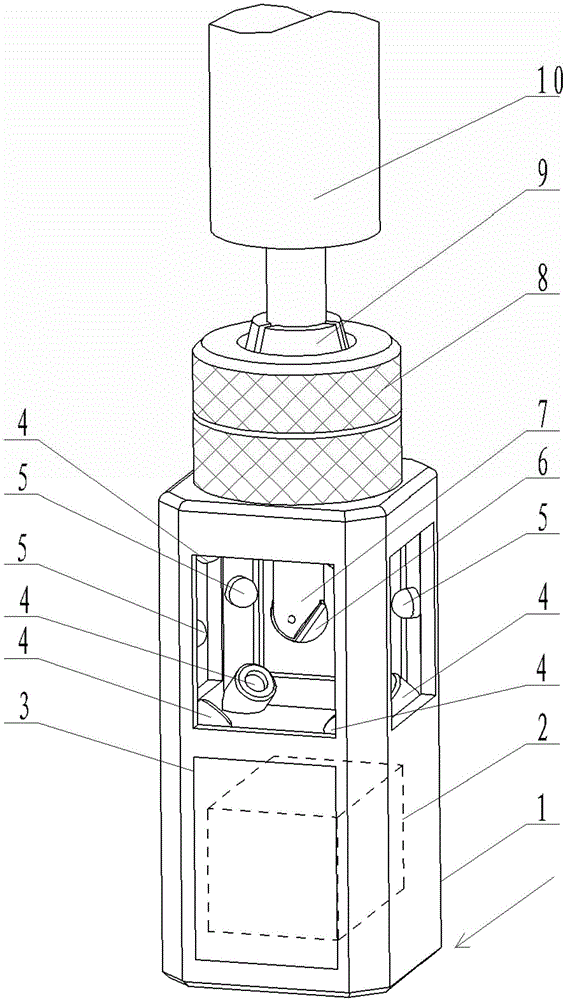

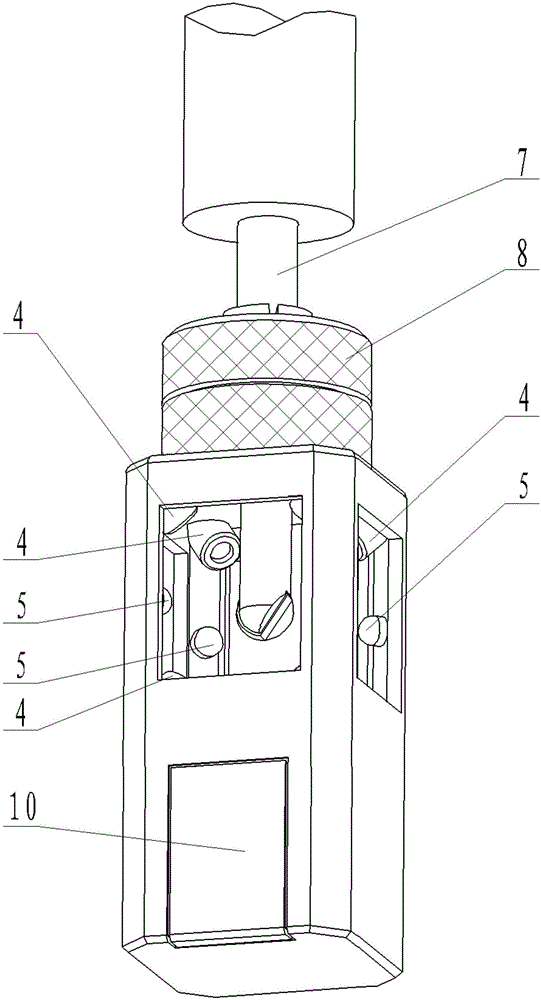

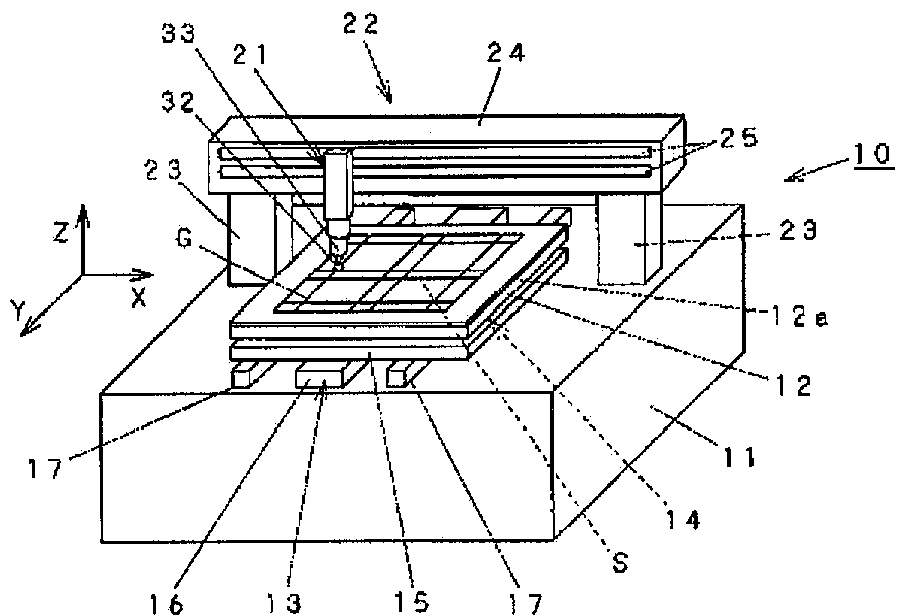

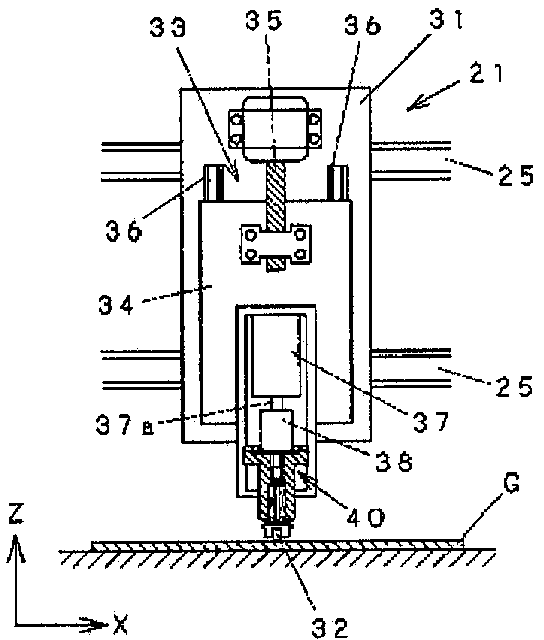

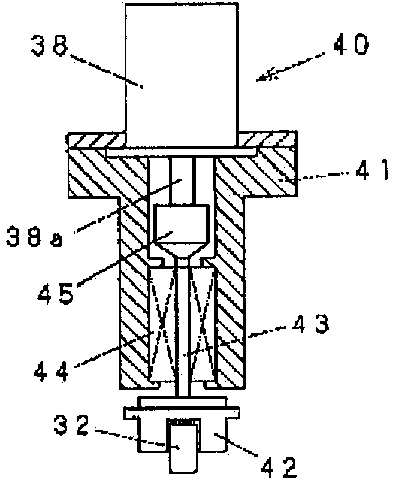

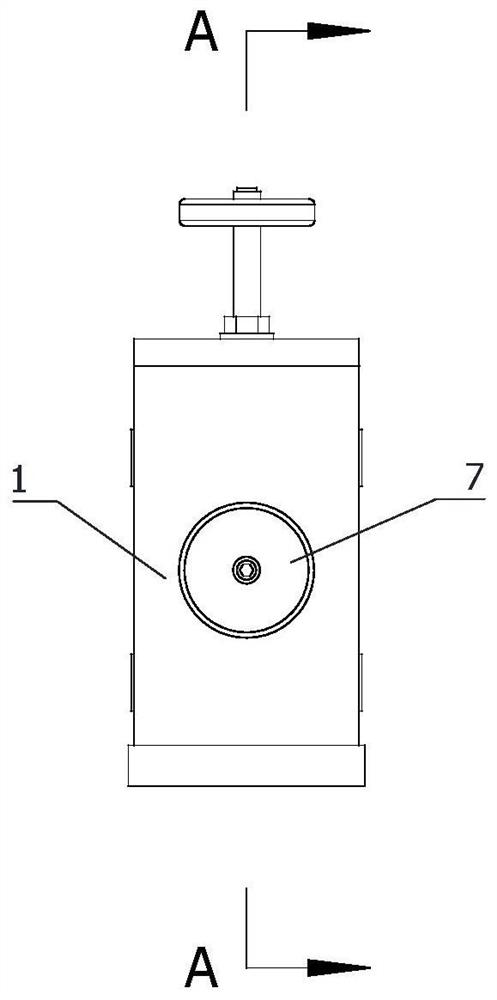

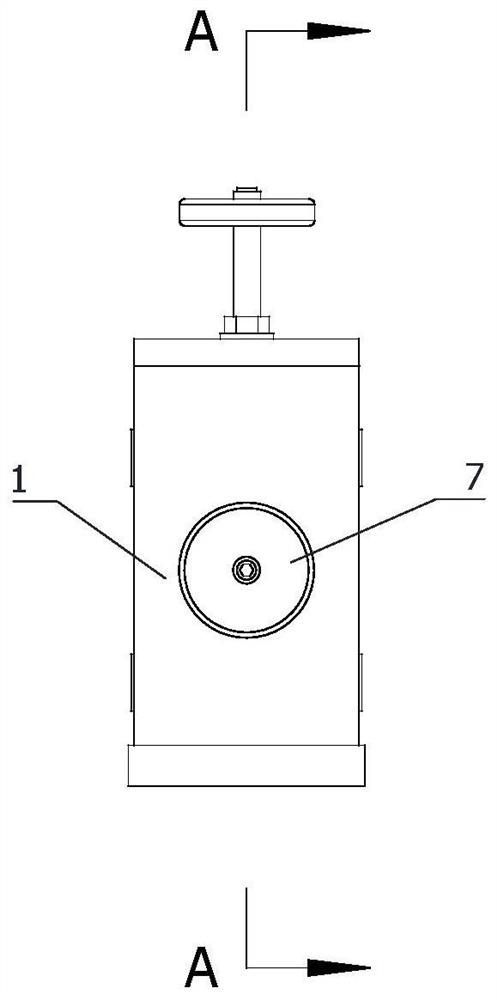

Portable tool wear measuring instrument and method for predicting remaining service life of tool through measuring instrument

InactiveCN105014481AAvoid secondary clamping errorsSimple structureMeasurement/indication equipmentsMeasuring instrumentMechanical engineering

The invention provides a portable tool wear measuring instrument and a method for predicting the remaining service life of a tool through the measuring instrument and relates to the technology of tool wear measurement. The problems that software / hardware systems of an existing tool wear measuring device is huge, installation and debugging are complex, the service life of a tool is mainly judged by human experience, and judgment is inaccurate are solved. An opening is formed in a shell and used for making the tool extend into the measuring instrument. Cameras and light source lamps are arranged on the periphery of the tool. The brand-new tool is used for cutting a workpiece multiple times according to specific cutting parameters till the tool face abrasion amount reaches the bluntness standard, and cutting time of each time and the tool face abrasion amount are recorded; and the cutting time of each time and the tool face abrasion amount are fitted into a curve through a data processing circuit, and the curve is a service life curve. The abrasion amount of the used tool is measured and compared with the service life curve, so that the service life of the tool is acquired. The portable tool wear measuring instrument is simple in structure, convenient to install and accurate in service life prediction.

Owner:HARBIN UNIV OF SCI & TECH

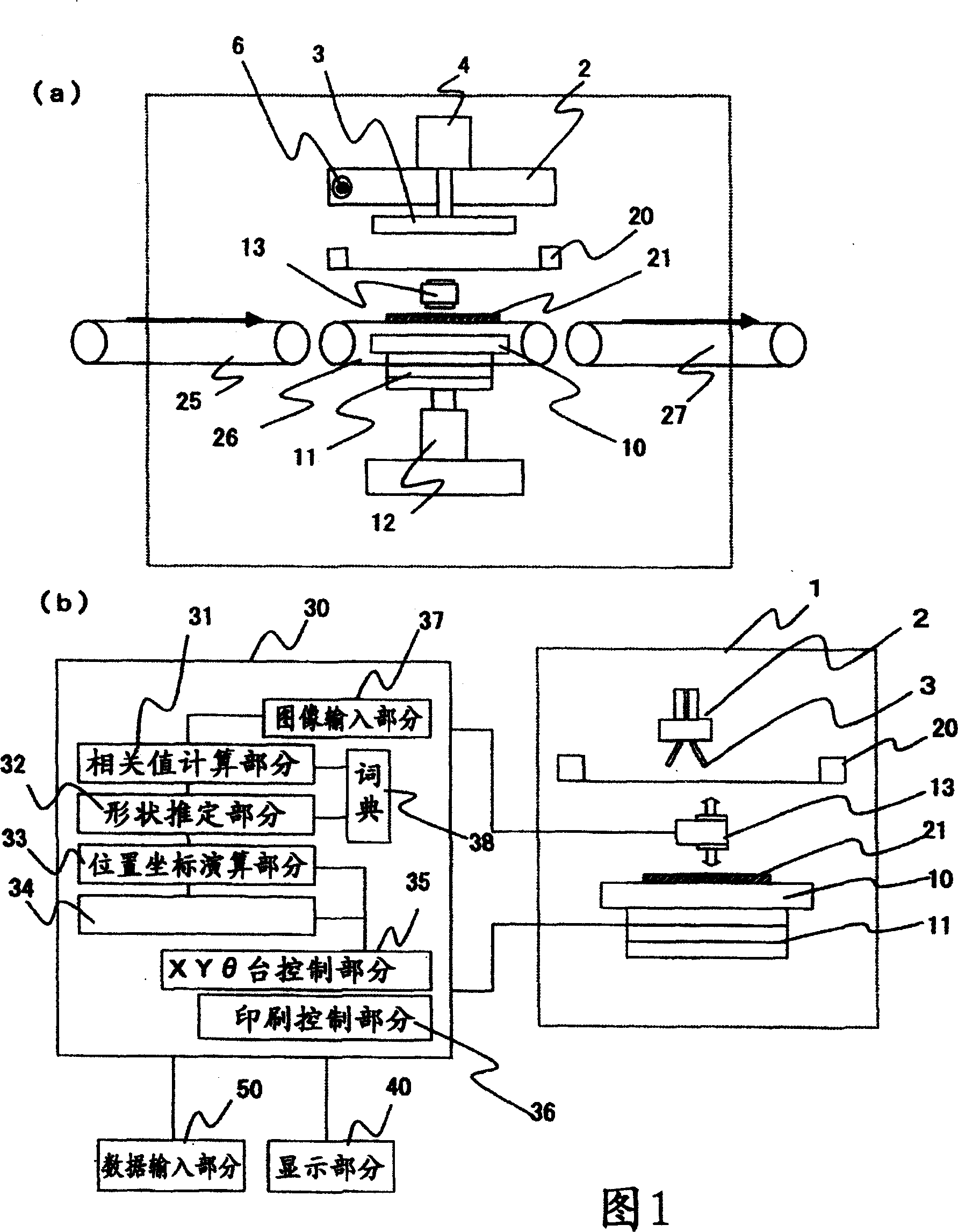

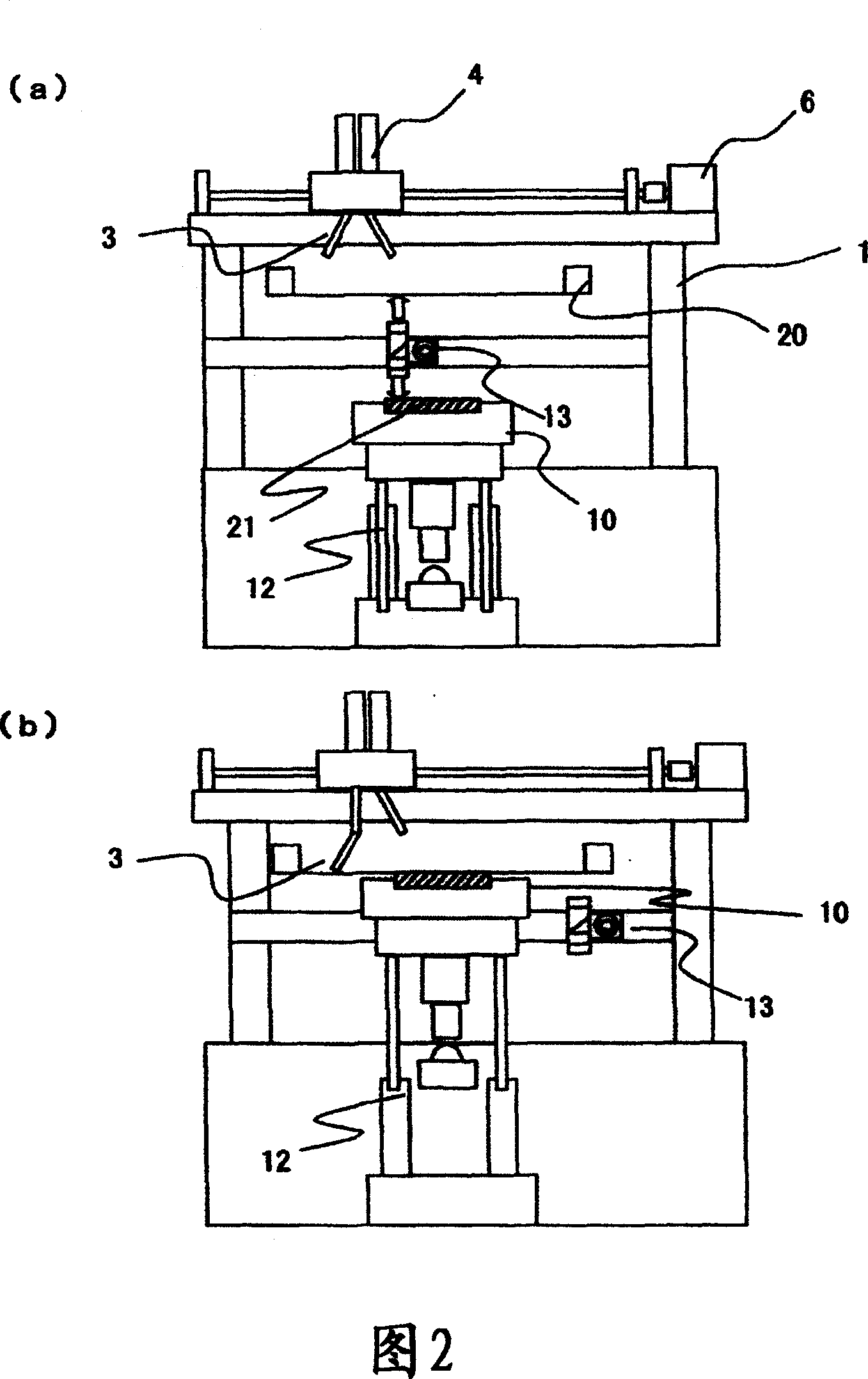

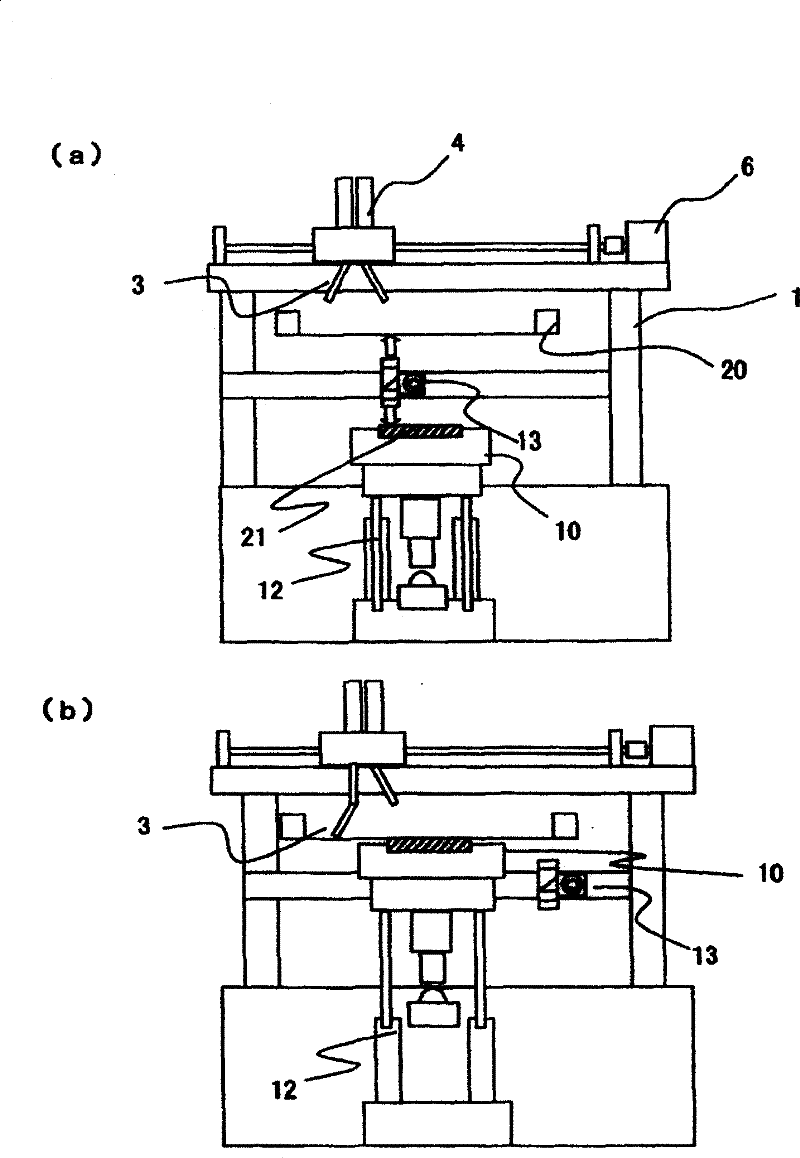

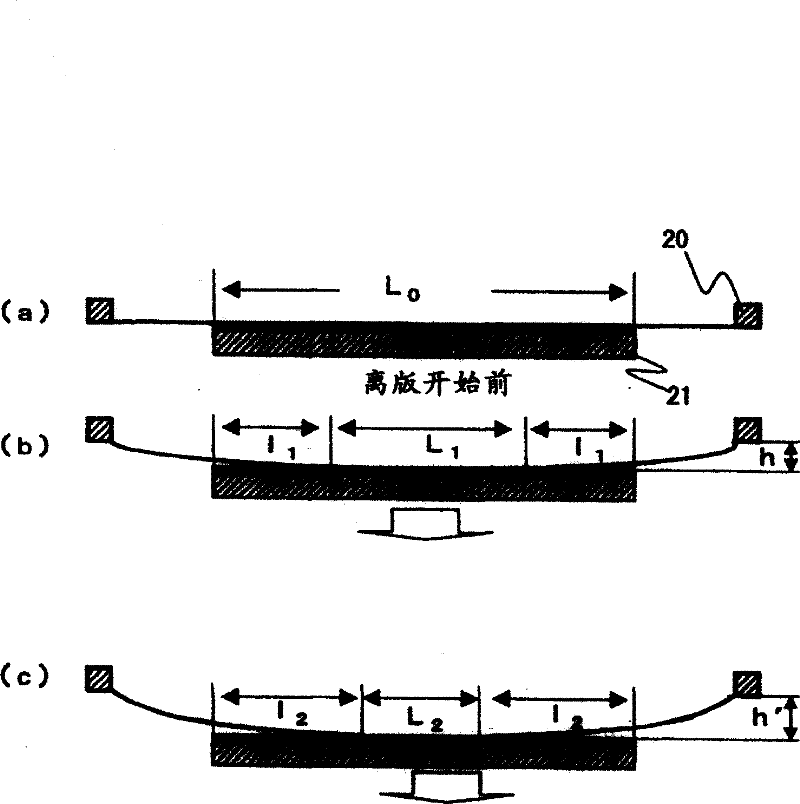

Silk-screen printing device

InactiveCN101045360AImprove yieldImprove printing qualityPrinted circuit assemblingScreen printersScreen printingBaseboard

Provided is a screen printing apparatus. In the forming of the protrude electrode using the screen printing method, resulting the adhesive force of the solder paste which is transferred by many opening-part groups and the metal mask, the departing of the printing board starts from the perimeter part, finally the middle part of the metal mask departs from the printing board, the occurring of this phenomenon is the main reason for the defective printing which concludes the thickness error of the printing film ,the printing deficiency and so on. Using the different thickness of the mentioned mask component sheet, or the different material, or the different elastic coefficient, connect every mask component sheet which is set on the accessory pattern of the printing baseboard or at all the patterns formed in the scheduled area, and the adjusting equipment which accords to the mentioned connection status and can reproduce random curve is also provided.

Owner:HITACHI LTD

Liquid storage container and liquid ejection recording apparatus having the container mounted thereon

InactiveUS7470012B2Alleviating rapid external impact appliedReduce unqualifiedPrintingLiquid jetEngineering

A reliable ink cartridge that reduce printing nonconformity even during high speed inkjet-recording with multiple nozzles by alleviating rapid external impact applied from the outside of the ink cartridge. Within a casing of an ink cartridge, a flexible bag forming an ink reservoir is accommodated. Between the surface of the flexible bag where a sheet member is bonded and a wall surface of the casing, a stress damping chamber is provided. The stress damping chamber communicates with the atmosphere outside the ink cartridge via an orifice formed on a wall surface of the casing.

Owner:CANON KK

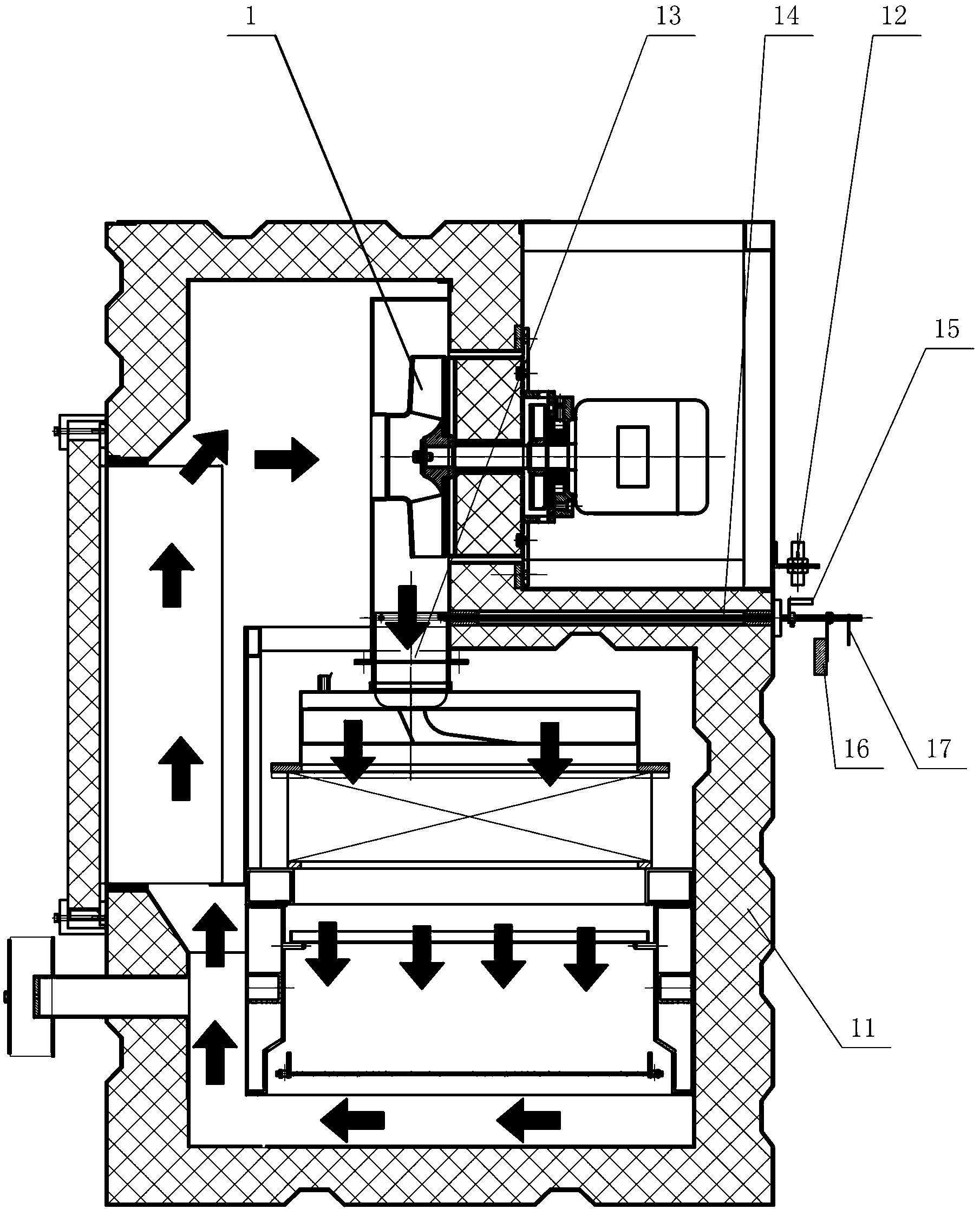

Method for quick deoxidization in smelting process of ladle furnace (LF)

InactiveCN107653358AReduce unqualifiedReduce the chance of nodulationSmelting processThermal efficiency

The invention discloses a method for quick deoxidization in the smelting process of a ladle furnace (LF). The method comprises the following steps: (1) adding aluminum iron containing 40% of aluminumat a time after molten steel enters the ladle furnace (LF), so that the aluminum content in the molten steel reaches 0.04%-0.05%, and adding 150 kg of low aluminum slag balls, and 2-2.5 kg of active lime per ton of steel; (2) powering on and slagging, powering on for 3-5 times, adding 0.2 kg of molten steel deoxidizing agents per ton of steel, powering on for 5 min, melting top slag, and then powering off; (3) adjusting argon gas flow such that the diameter of the slag face blown by argon gas is 450-500 mm, adding 1-1.5 kg of the low aluminum slag balls per ton of steel, and 0.4 kg of the molten steel deoxidizing agents per ton of steel, stirring the mixtures for 15-20s, and then adding 1-1.5 kg of the low aluminum slag balls per ton of steel and 0.4 kg of the molten steel deoxidizing agents per ton of steel if the deoxidization effect is poor; stirring the mixtures for 15-20s, till the section of the top slag is yellowish white, namely that the deoxidization is finished; and adjustingthe argon gas flow to 100-150 L / min in time, and performing subsequent operation. According to the method disclosed by the invention, not only the quick deoxidization of molten steel in the smeltingprocess is achieved, the output of inclusions in the smelting process is reduced, and the quality of steel billets is improved, but also the thermal efficiency in the power-on heating process is improved, and the power consumption and slag consumption are reduced.

Owner:XINJIANG BAYI IRON & STEEL

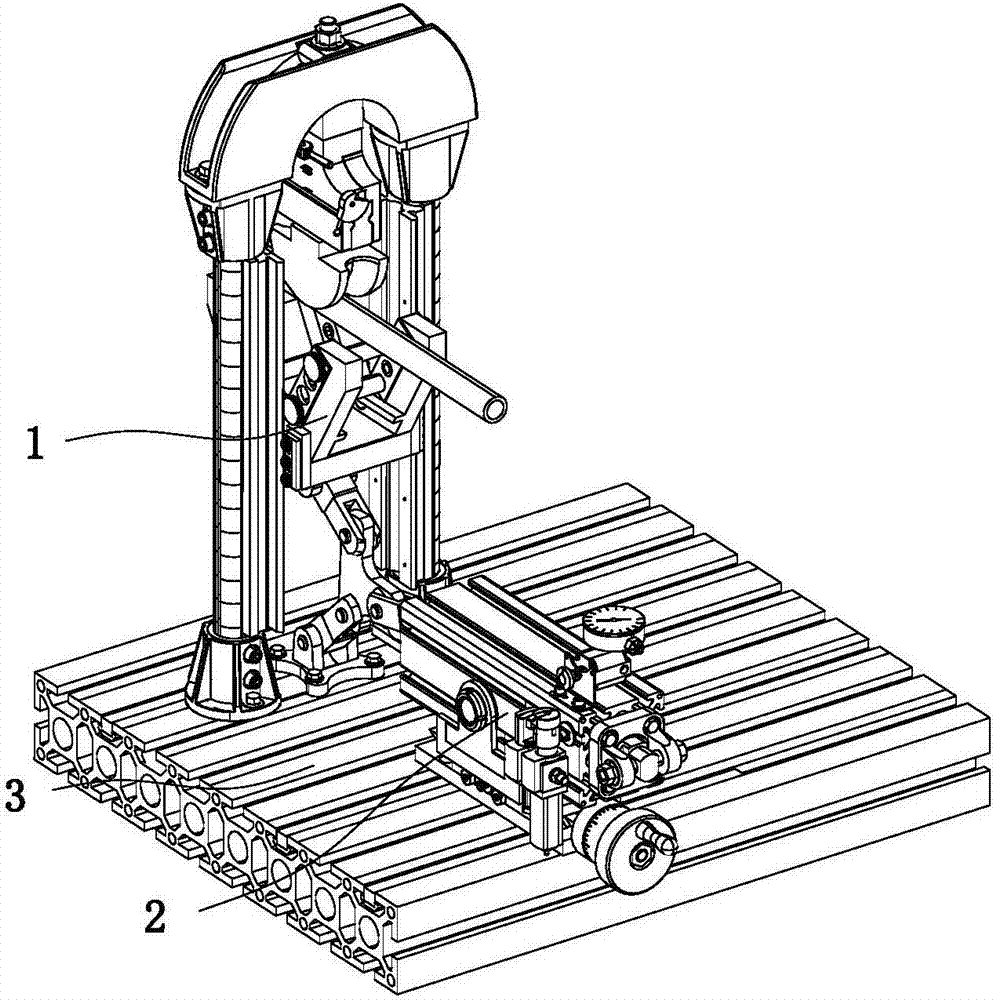

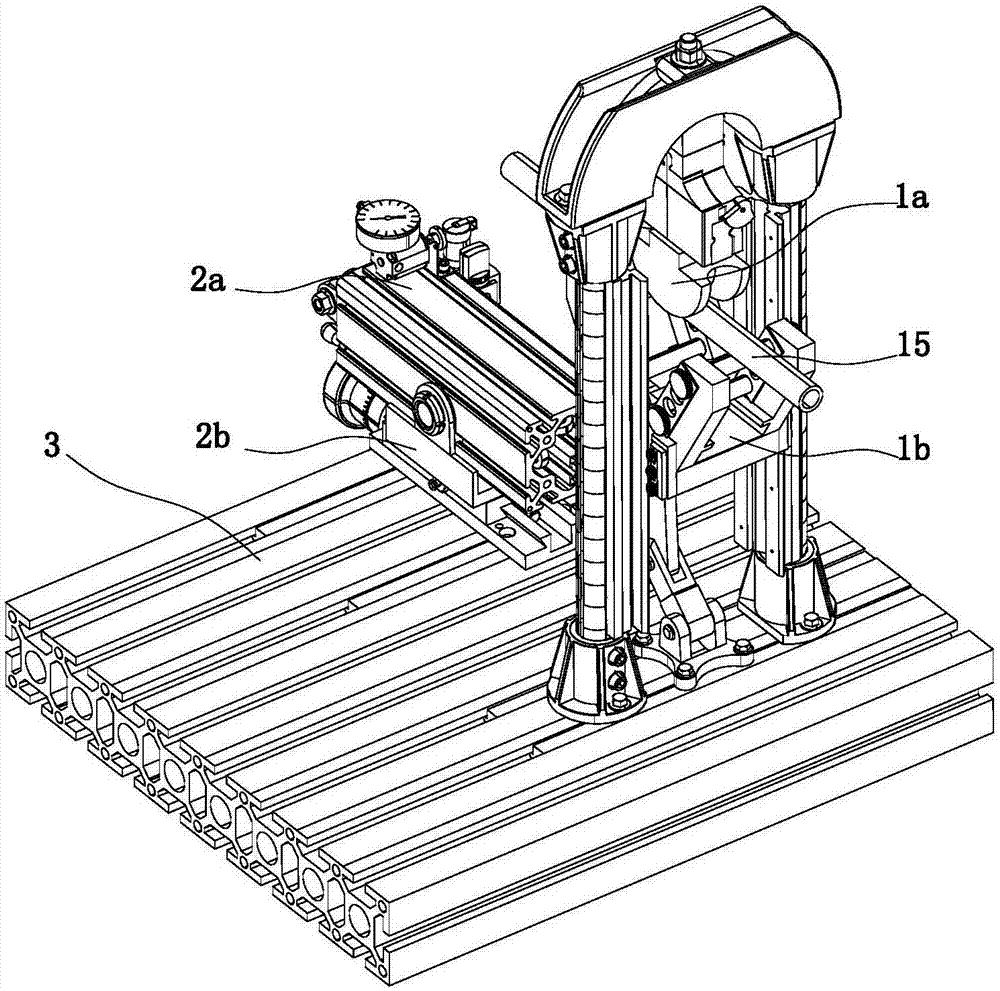

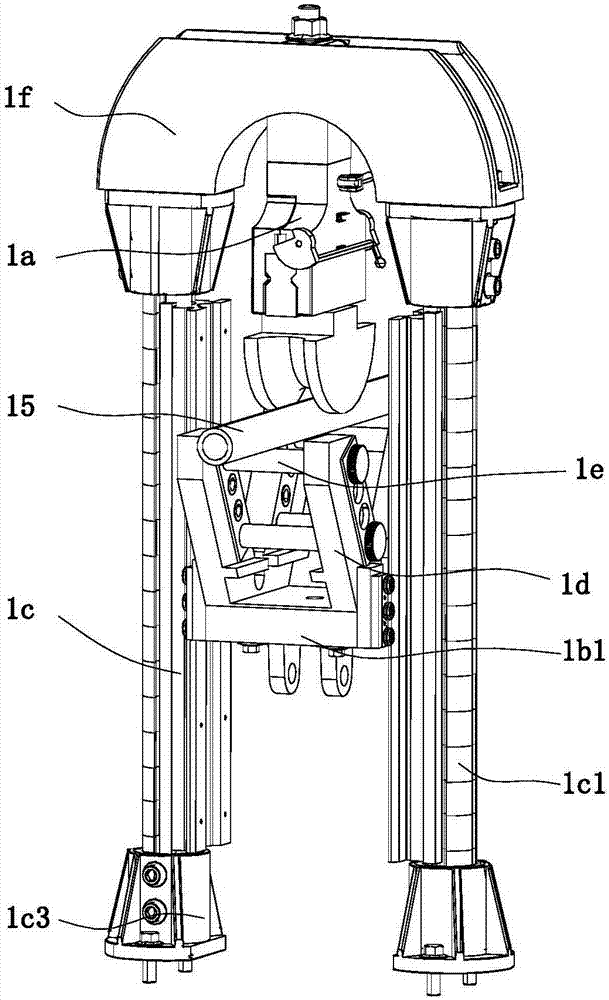

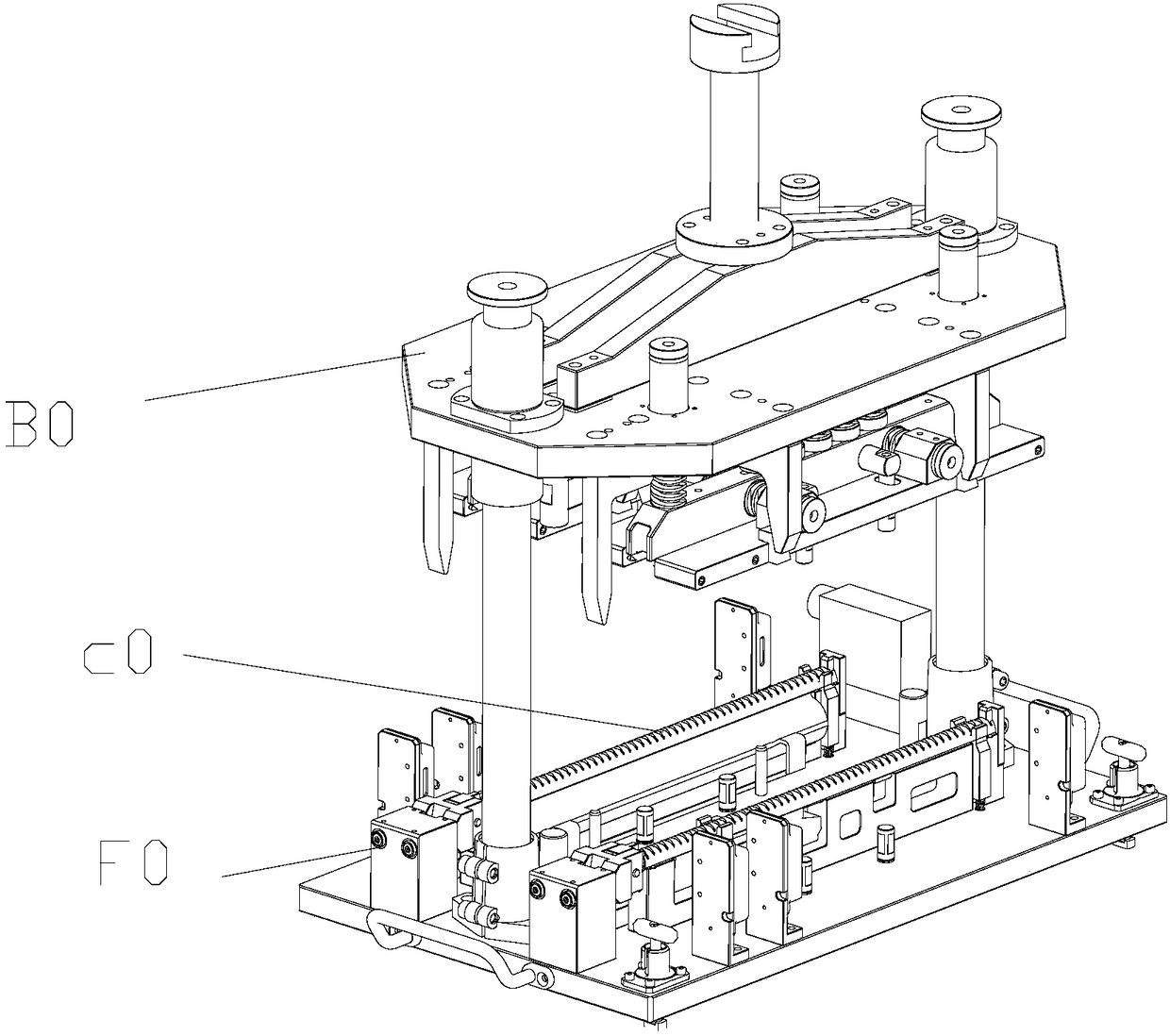

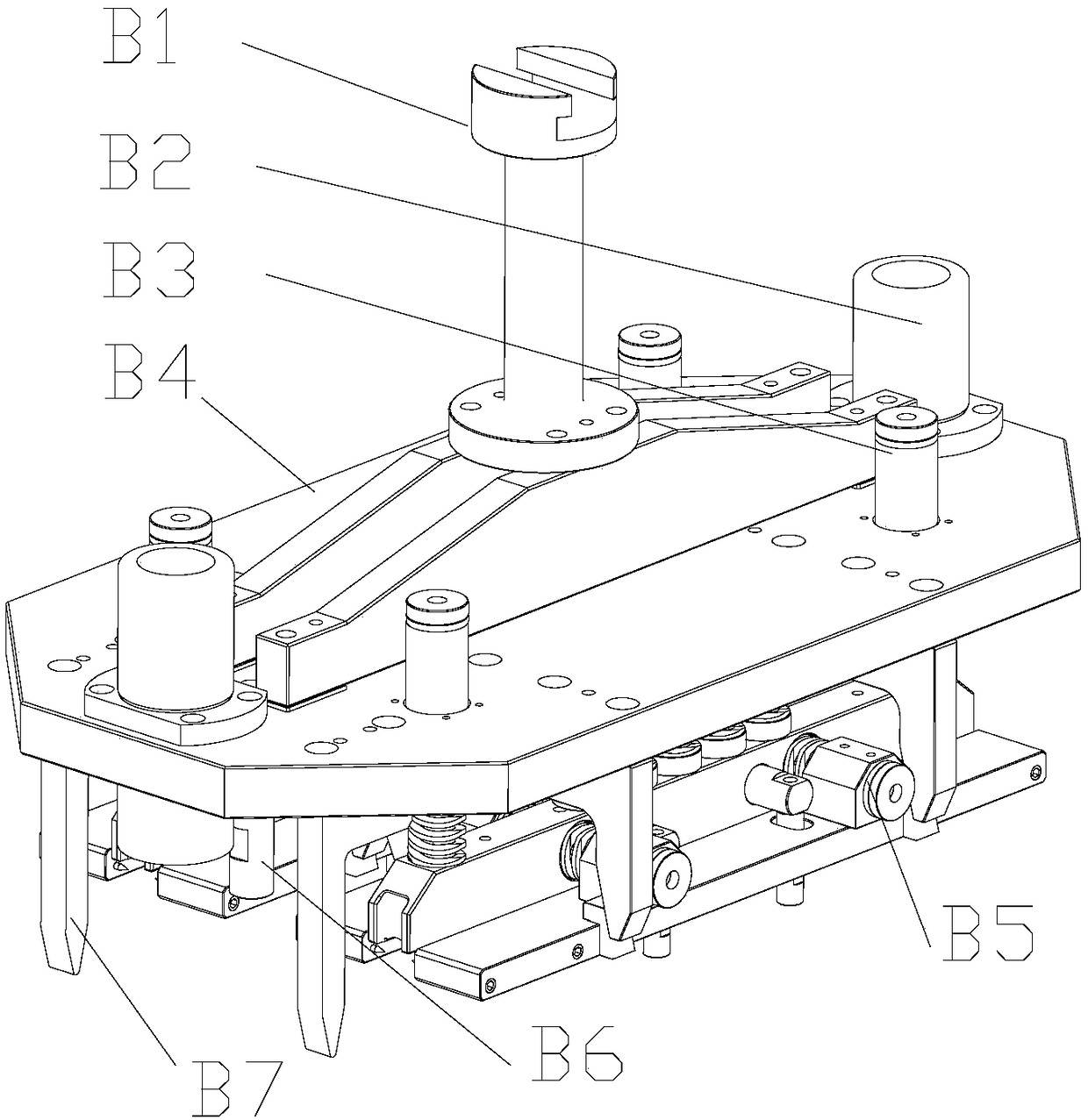

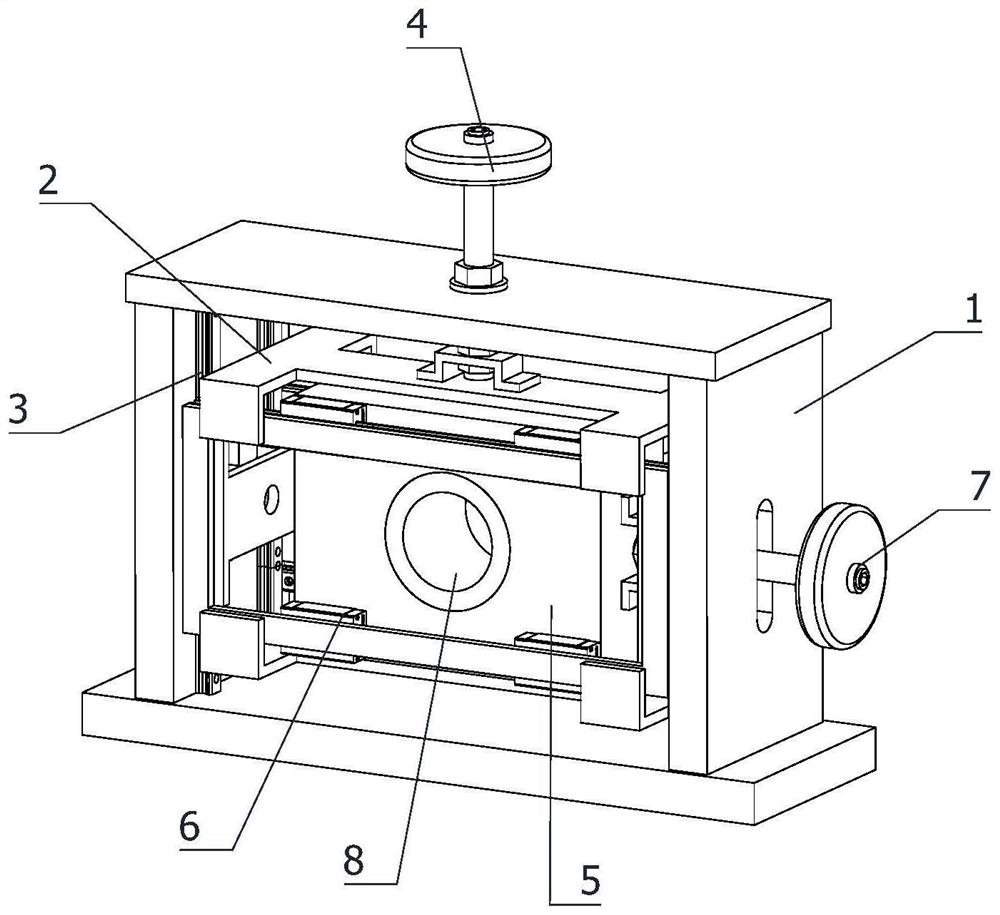

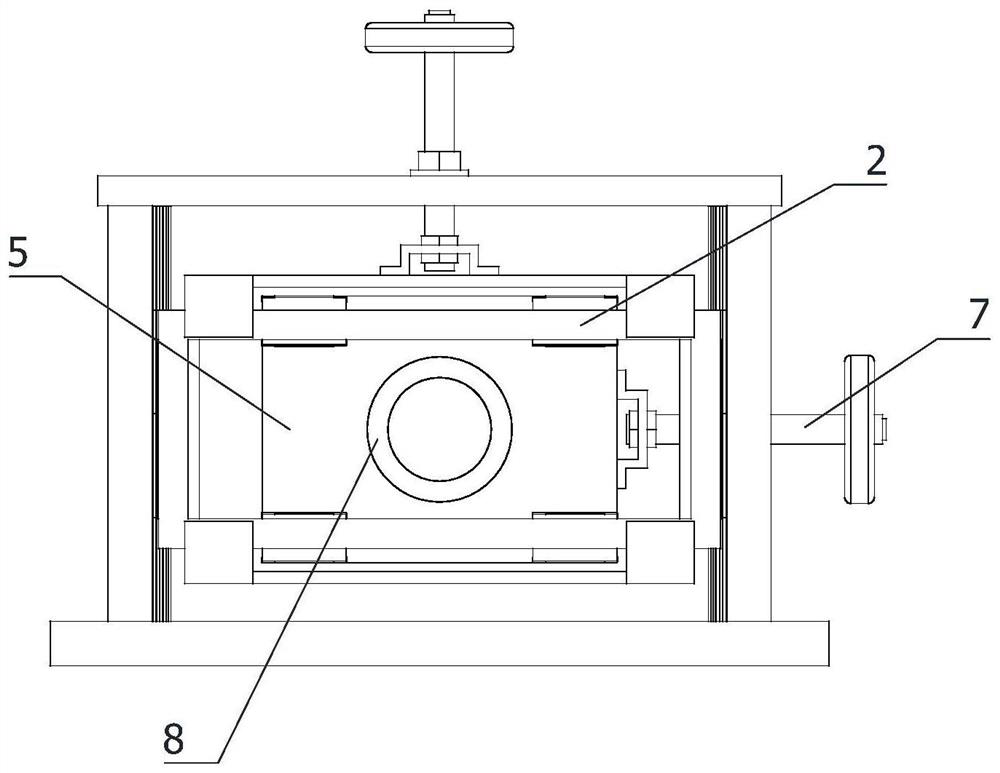

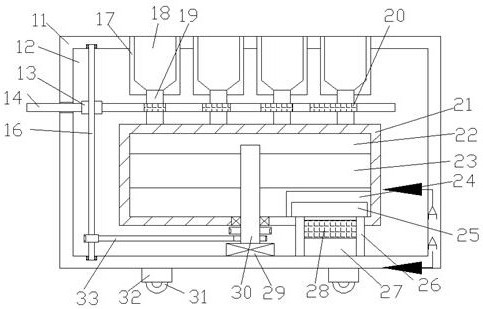

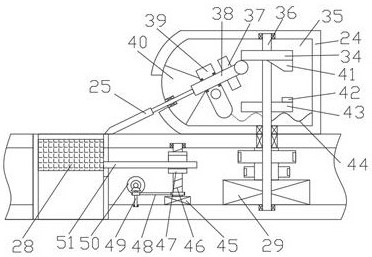

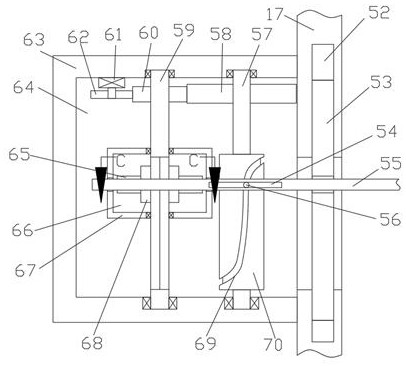

Pneumatic pipe bender

The invention relates to the field of mechanical manufacturing equipment, in particular to a pneumatic pipe bending machine, which includes a pipe bending device, a pipe bending drive device and a base for driving the pipe bending device to achieve pipe bending, and the pipe bending device includes a shaping mechanism and a top bending mechanism And two slideways for the top bending mechanism to slide, the shaping mechanism is arranged on the top of the slideway, the top bending mechanism is provided with a first roller that cooperates with the slideway on the side close to the slideway, and the top bending mechanism includes a support plate 1. The clamping arm set on the top of the support plate and the clamping rod set that runs through the clamping arm set and is arranged horizontally, the bending pipe driving device includes a guide slide channel, an adjustment mechanism and a drive mechanism arranged at the bottom of the guide slide channel, The pipe bending driving device of the present invention drives the top bending mechanism to rise, and the first rollers of the top bending mechanism arranged on both sides of the slideway slide and cooperate with the slideway to ensure that the top bending mechanism rises steadily along the slideway, and the shaping mechanism and the top bender Cooperate with the top bending of the workpiece, it can maintain stability and avoid the workpiece from shifting during the top bending.

Owner:ANHUI SHENGMEI METAL TECH CO LTD

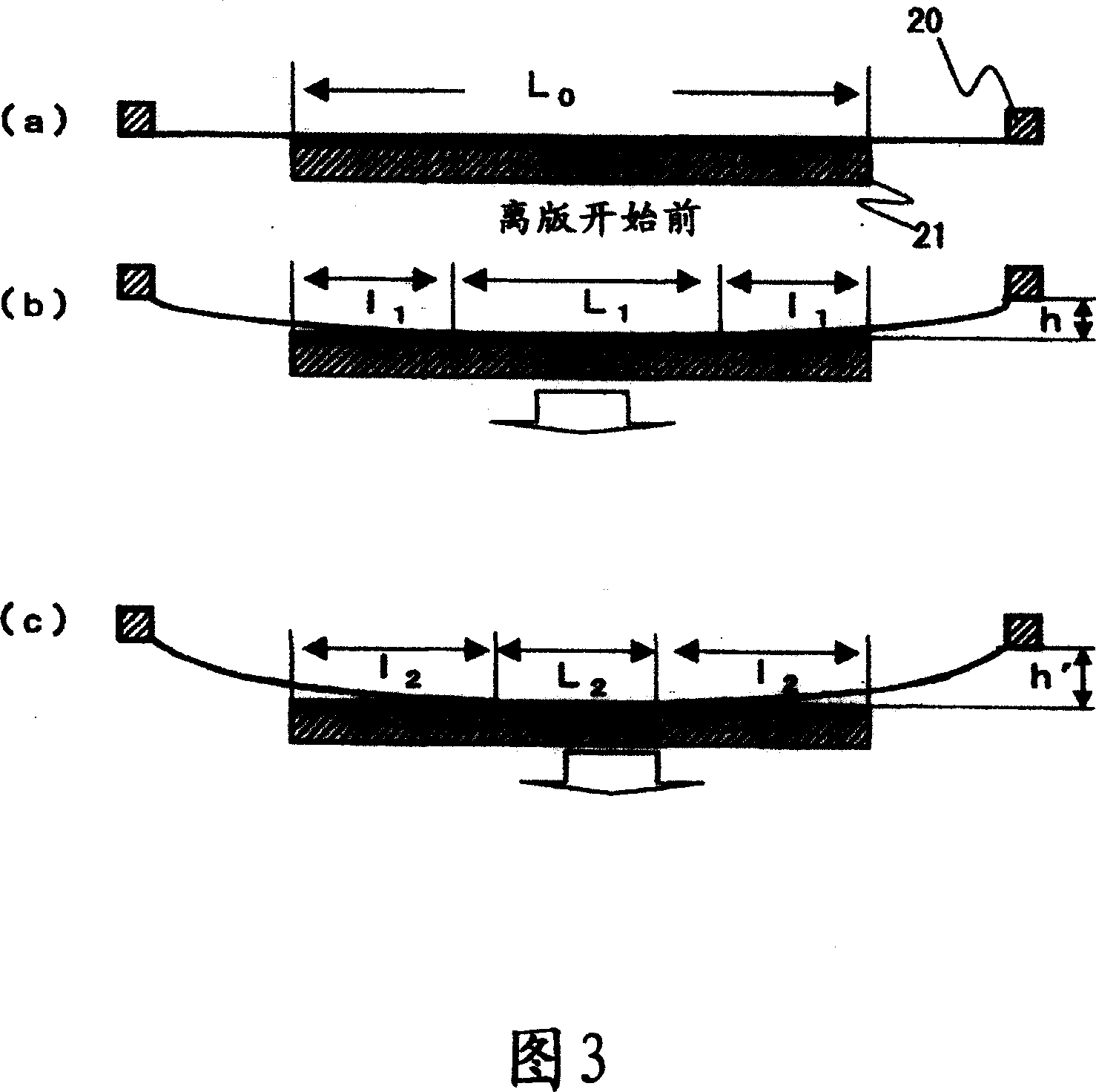

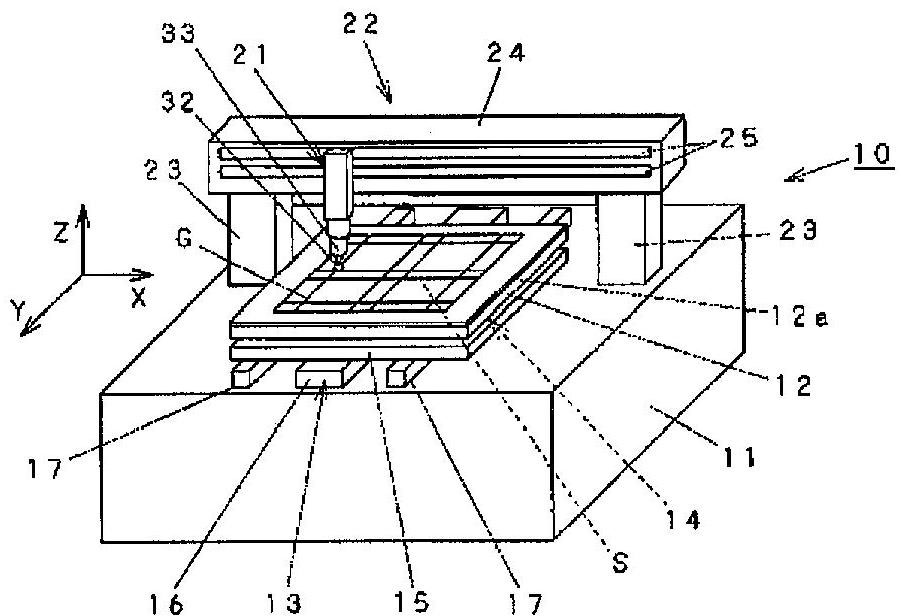

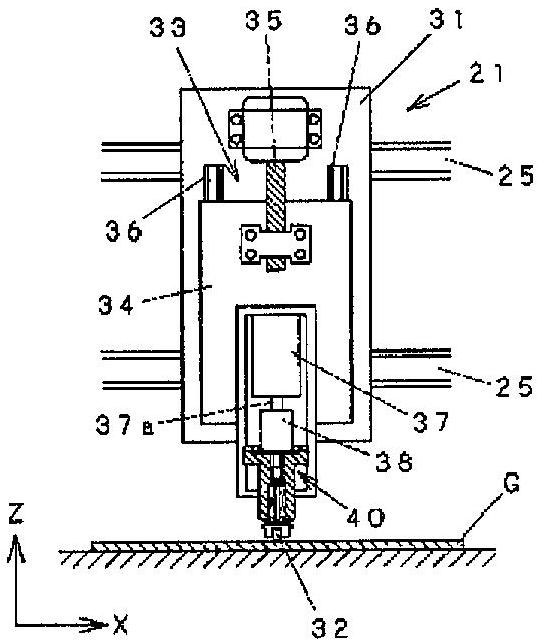

Method for breaking brittle material substrate

InactiveCN102596523AReduce vibration effectsReduce the amount of bendingFine working devicesGlass severing apparatusEngineeringUltimate tensile strength

Provided is a breaking method by which an end surface strength can be stronger. A method for breaking a brittle material substrate comprises a step for forming a scribe line on the brittle material substrate, and a breaking step for breaking along the scribe line. In the breaking step, a break roller is pressed on and applies a load to the brittle material substrate placed on a table by rolling the break roller near the scribe line along a position separate from the scribe line to one side, so as to fold at a low load and divide the substrate.

Owner:MITSUBOSHI DIAMOND IND CO LTD

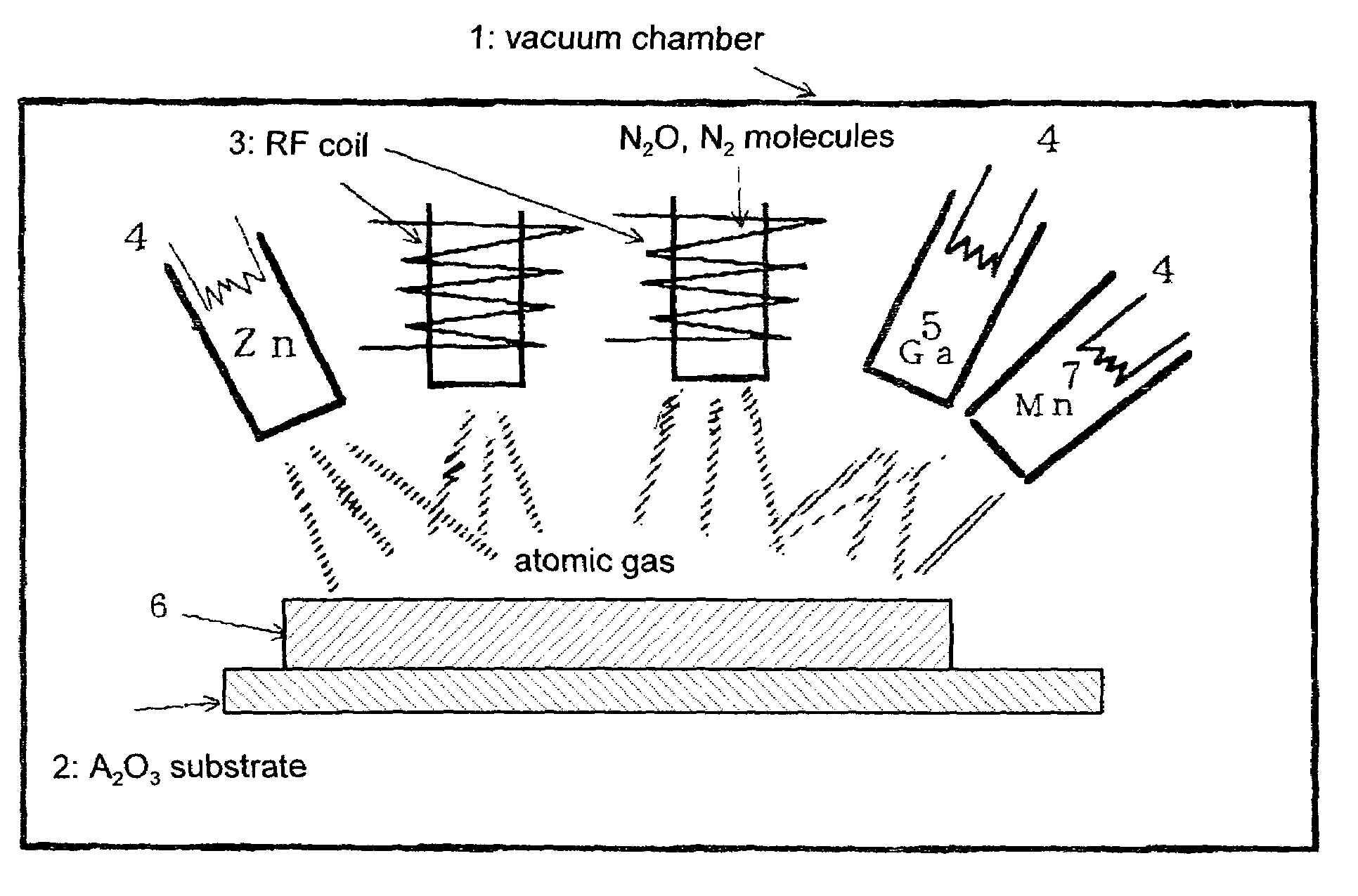

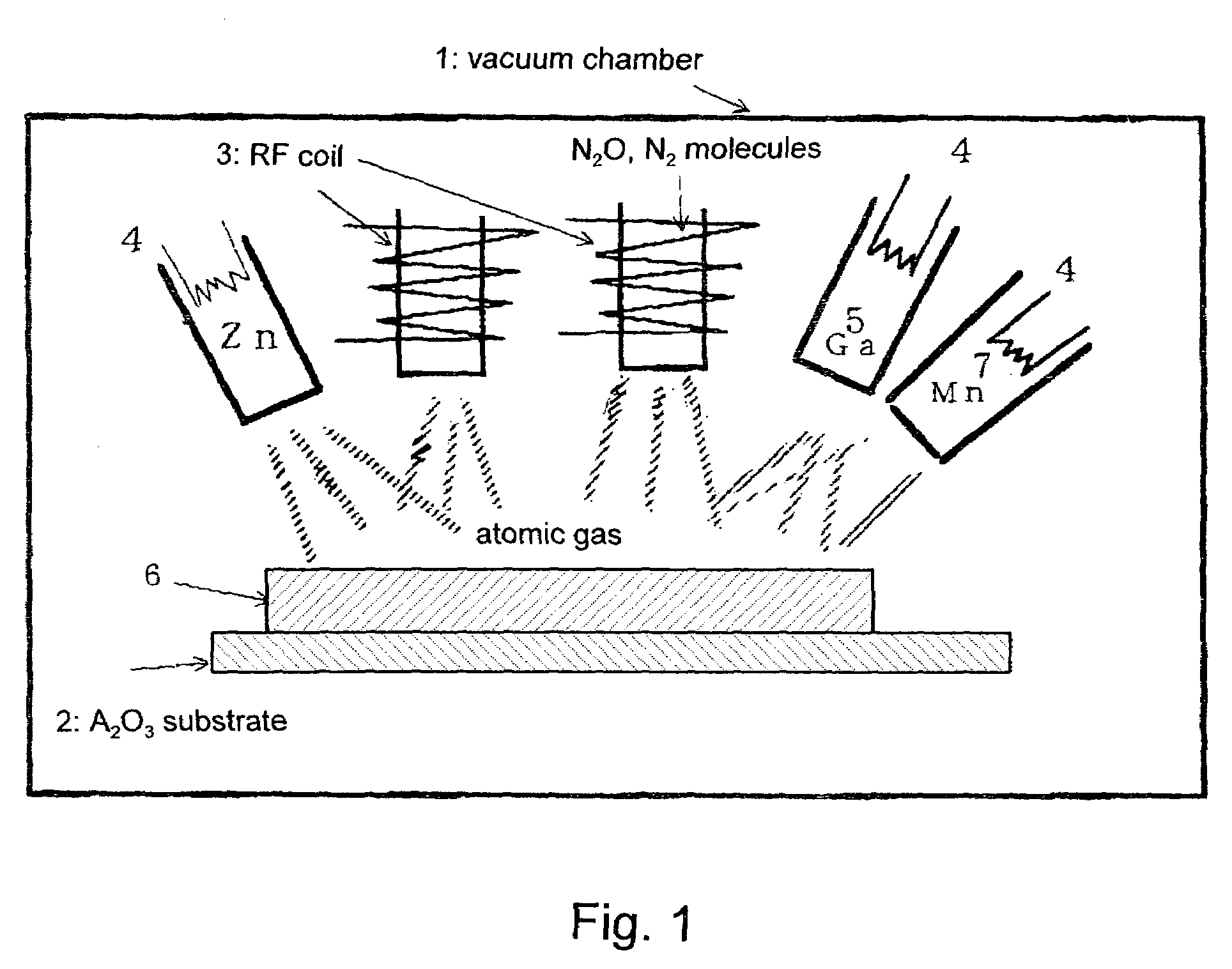

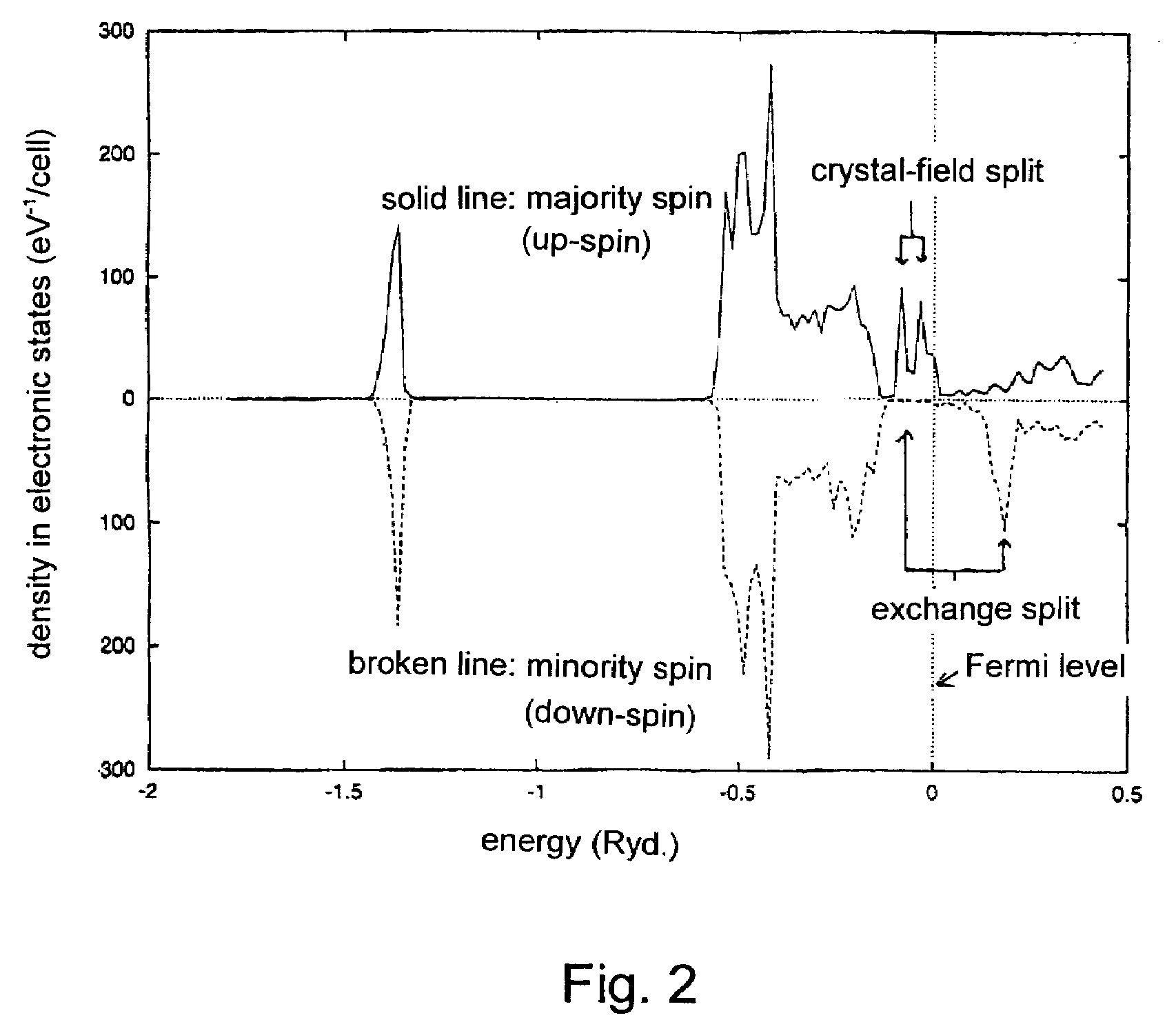

Ferromagnetic p-type single-crystal zinc oxide material and manufacturing method thereof

InactiveUS7022182B1Facilitate extensive evolutionA large amountQuantum computersPolycrystalline material growthUltraviolet lightsSingle crystal

The present invention provides a single-crystal ZnO thin film having a high ferromagnetic transition temperature. In one aspect of the present invention, the ZnO thin film comprises a ferromagnetic p-type single-crystal zinc oxide including a transition metal element consisting of Mn, and a p-type dopant. In another aspect of the present invention, the thin film comprises a ferromagnetic p-type single-crystal zinc oxide including a transition metal element consisting of Mn, a p-type dopant, and an n-type dopant. The single-crystal zinc oxide material can be applied to quantum computers and high-capacity magnetic-optical recording medium by combining with conventional n-type or p-type transparent electrode ZnO materials or optical fibers, and to powerful information-communication devices or quantum computers as a photoelectric material usable for a wide range from visible light to ultraviolet light.

Owner:JAPAN SCI & TECH CORP

Manufacturing method of pressing mould turner, turning device and turning method

The invention provides a pressing mould turner which comprises a clamp hoop, four clamp rings, two wire ropes, two T-shaped hanging blocks and a screw rod, wherein two clamp rings clamp the clamp hoop and are screwed through screws to obtain a T-shaped groove sliding block and fixed with one ends of the wire ropes; the other ends of the wire ropes are tightly locked by the T-shaped hanging blocks; and the T-shaped groove sliding block is fastened with the screw rod. The invention also provides a mould turning method which comprises the following steps of: (1) adjusting the position of the T-shaped groove sliding block; (2) locking the mould with a tightening lock on the screw rod; (3) starting a driver, and pulling the mould upwards; and (4) pushing the turning mould. The method is simple and safe to operate, and solves the problems that the conventional manual mould turning operation needs large working space, is time-consuming and labor-consuming, easily causes industrial injury and the like.

Owner:广东新志密封技术有限公司

A 3D printing detection method based on infrared spectrum analysis

ActiveCN104400998BReduce unqualifiedImprove pass rateColor/spectral properties measurementsSpectroscopy3d printer

The invention discloses a 3D printing detection method used for detecting whether a current 3D-printed surface material is consistent with a design sample at real time. A 3D printer contains a 3D printer body and a movable infrared spectrometric analyzer (containing infrared total reflection accessories), and is simultaneously provided with error correction software for correcting or choosing to reprint by comparing infrared spectrum of a test point with standard spectrum of the design sample. According to the invention, accuracy of a material used for a printed object can be monitored at real time, defective rate of printing is reduced, unnecessary material wastage is minimized, and time is saved.

Owner:FUZHOU UNIV

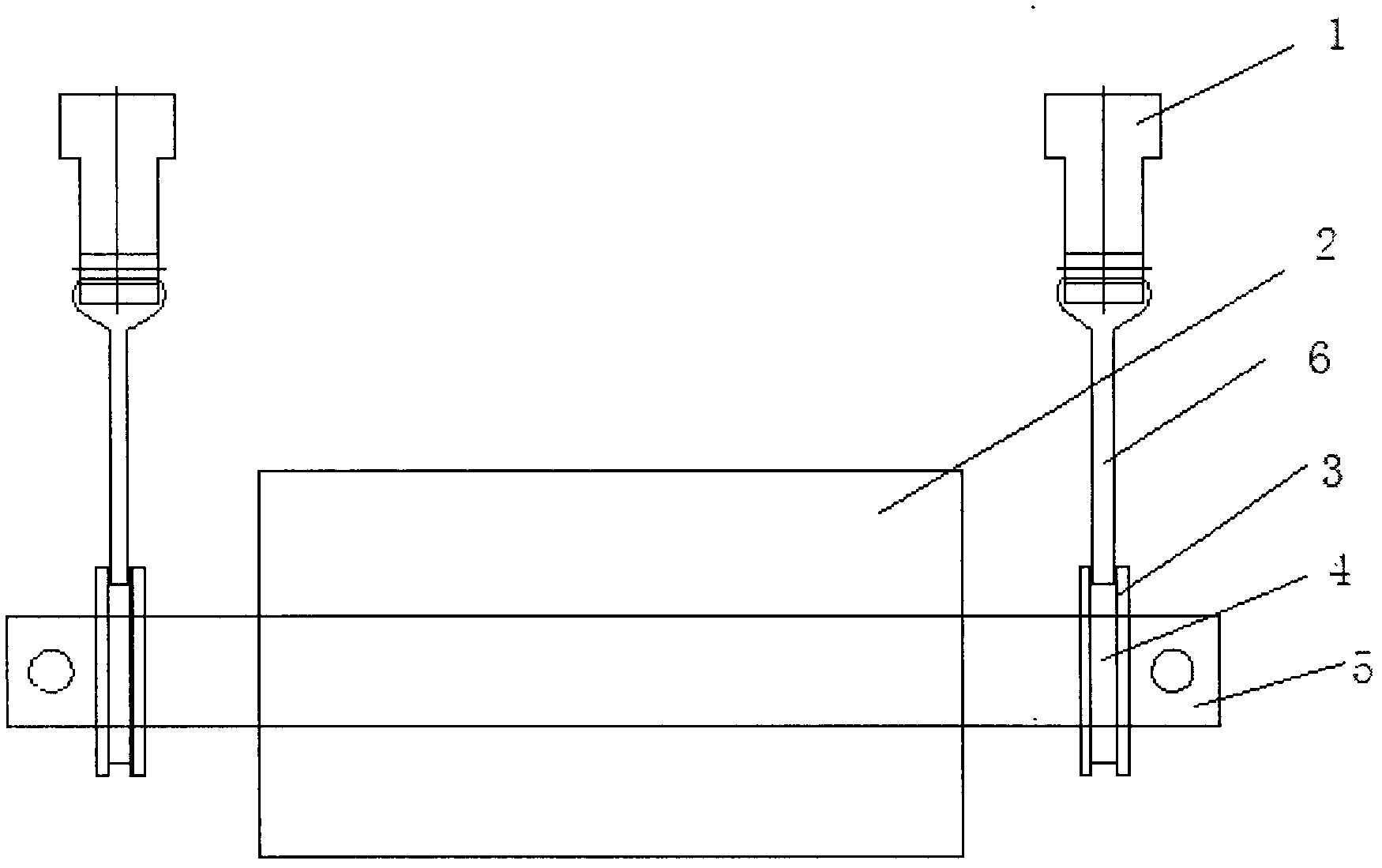

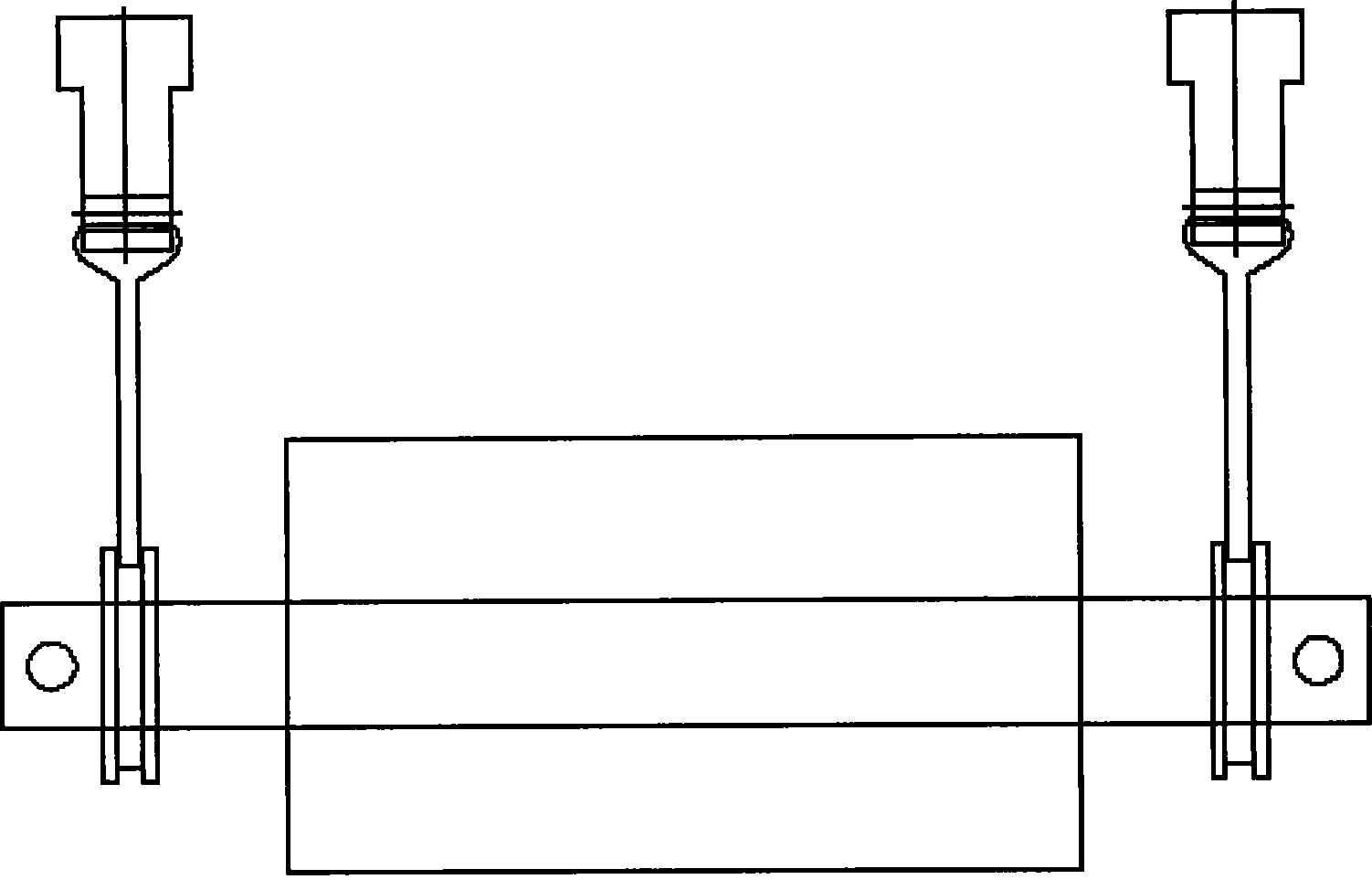

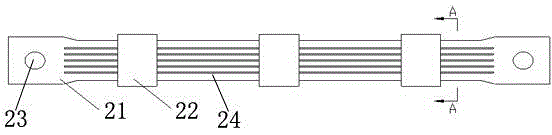

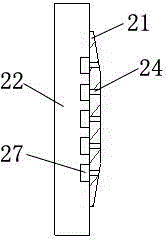

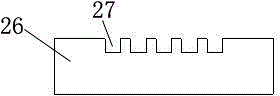

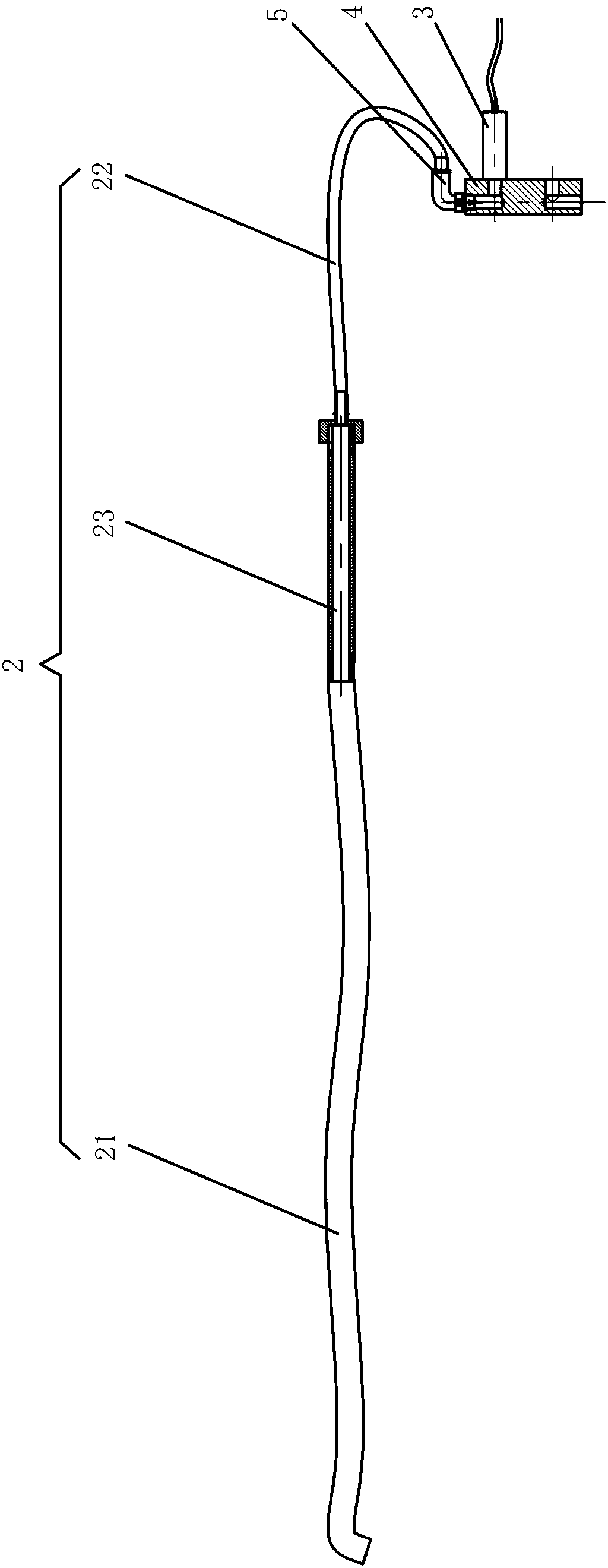

Anti-deformation processing method and special tool for magnetic isolation groove of pull plate of transformer clamp

ActiveCN103506746BAvoid deformationControl deformationWelding/cutting auxillary devicesInductances/transformers/magnets manufactureUnderwaterTransformer

The invention relates to method and special tools for anti-deformation machining of flux barriers of a clamp pulling plate of a transformer and belongs to the technical field of transformers. According to the technical scheme, the multiple special tools (22) for anti-deformation machining and the clamp pulling plate (21) are fixed together in a spot welding mode, the clamp pulling plate is placed on a working table of a plasma cutting machine and is adjusted to be located at a position suitable for machining, then the height of the water surface of the plasma cutting machine is adjusted to guarantee reliable cooling of the clamp pulling plate during cutting, then the flux barriers are cut-formed in the clamp pulling plate underwater by means of the plasma cutting machine, the deformation of the clamp pulling plate is controlled by means of the special tool for anti-deformation machining during plasma cutting, and then the machining of the flux barriers of the clamp pulling plate of the transformer is achieved. The method and special tools for anti-deformation machining of the flux barriers of the clamp pulling plate of the transformer aim at the pulling plate, of a multi-groove structure, of the transformer, the flux barriers are formed in a plasma underwater cutting mode, the special tools for anti-deformation machining are manufactured according to the distance between the flux barriers, and therefore the deformation of the multi-groove clamp pulling plate is effectively controlled during machining, the occurrence of unqualified products is reduced, and the machining efficiency of the clamp pulling plate is improved.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

Fracture method of brittle material substrate

InactiveCN102596523BReduce unqualifiedFine working devicesGlass severing apparatusLow loadOptoelectronics

The present invention provides a fracture method that can make the strength of the end surface stronger than before. The method for fracturing a brittle material substrate of the present invention includes the step of forming a scribe line on the brittle material substrate, and the fracturing step of fracturing along the scribe line, and during the fracturing step, the The substrate is rolled and crimped near the scribe line along a position separated from the scribe line on one side, and a load is applied, and the brittle material substrate is divided by bending under a low load.

Owner:MITSUBOSHI DIAMOND IND CO LTD

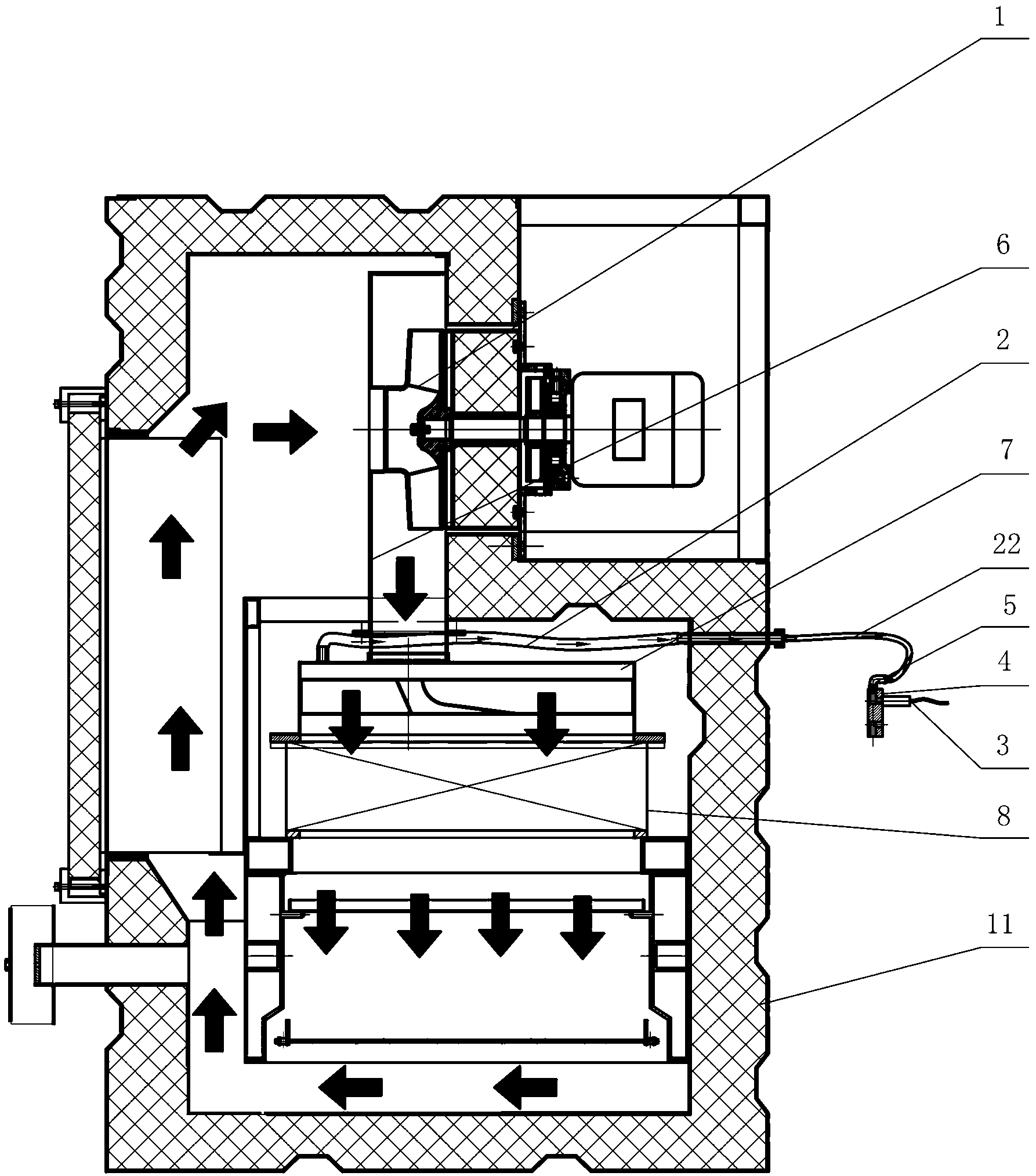

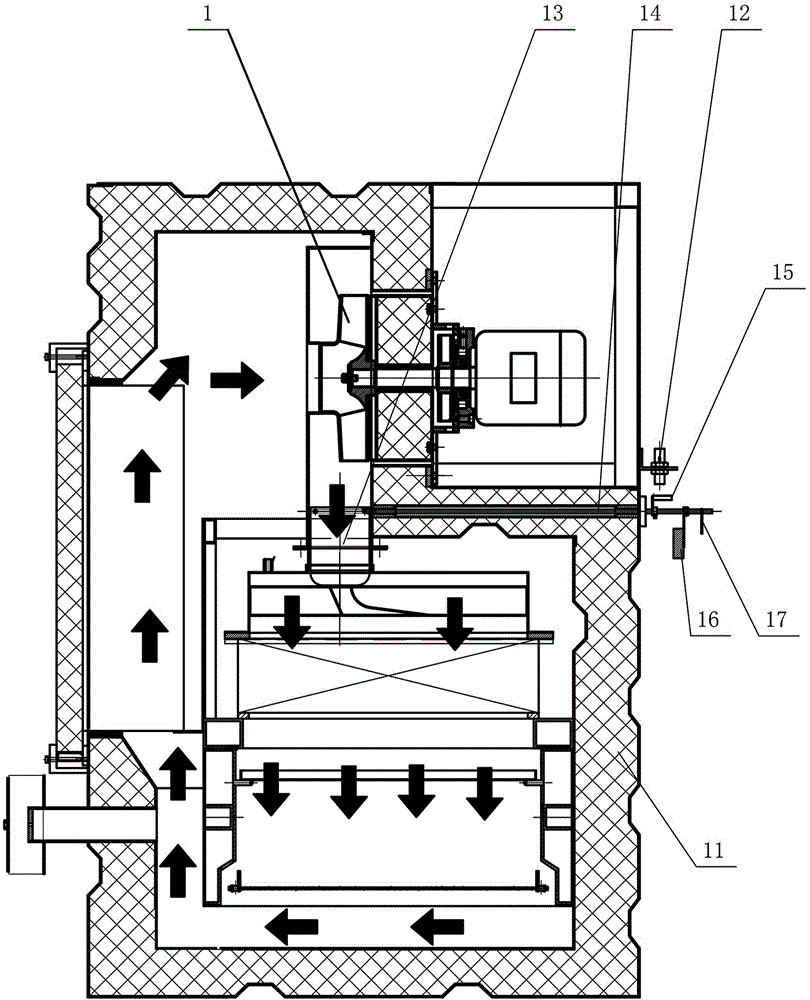

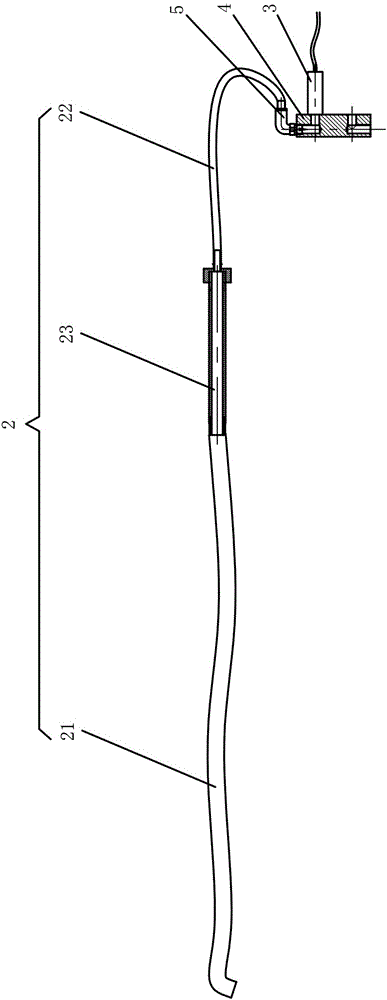

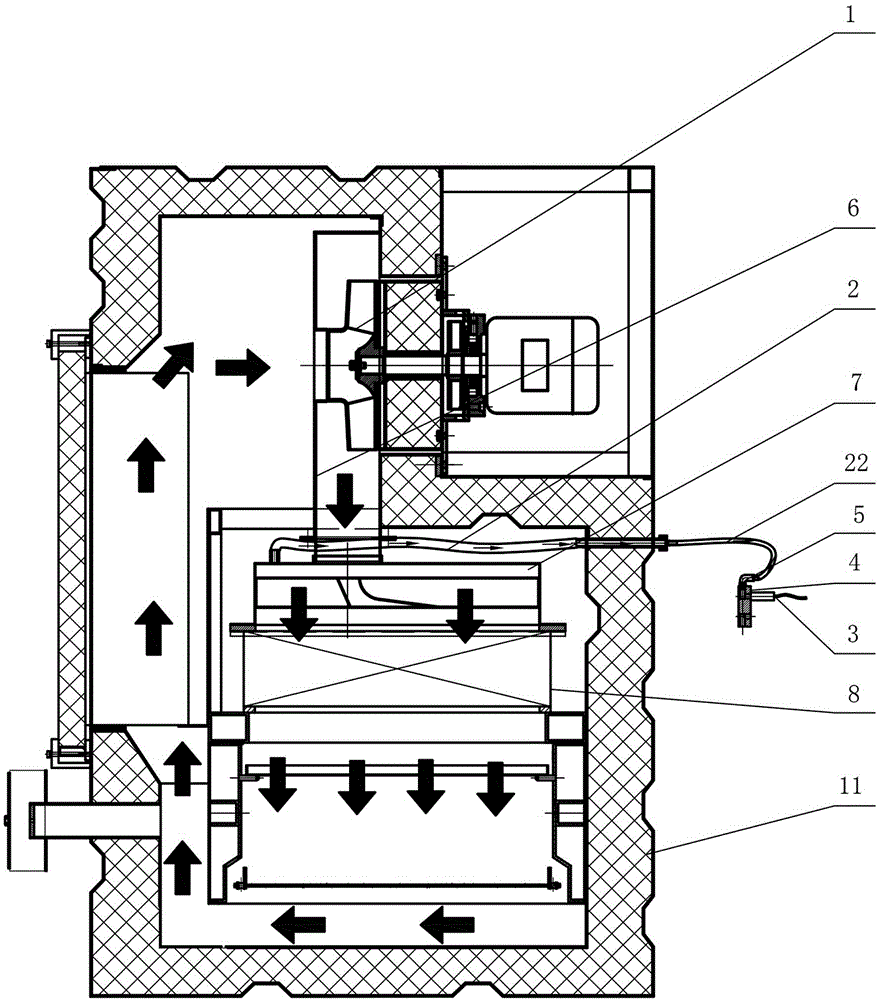

Dyer and device for detecting working state of draught fan of dryer and dryer

The invention discloses a dryer and a device for detecting a working state of a draught fan of the dryer. The device comprises a guide pipe and a pressure sensing device, wherein pressure sensing device is arranged at the outer part of a drying oven of the dryer; and one end of the guide pipe is communicated to an air outlet end of the draught fan in the drying oven while the other end of the guide pipe is connected to the pressure sensing device. The device for detecting the working state of the draught fan of the dryer has the advantages of being simple in structure, convenient to manufacture, and convenient to assemble, disassemble, debug as well as maintain. The dryer is provided with the device for detecting the working state of the draught fan of the dryer.

Owner:TRUKING TECH LTD

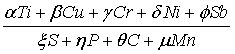

Method for measuring and calculating sulfuric acid corrosion resisting equivalent of steel material

ActiveCN102998251ATimely and effective objective evaluationProtect interestsWeather/light/corrosion resistanceSocial benefitsEconomic benefits

The invention discloses a method for measuring and calculating sulfuric acid corrosion resisting equivalent of a steel material. The corrosion resisting equivalent is measured and calculated according to the following corrosion resisting equivalent model, wherein the corrosion resisting equivalent is described in the specification, wherein Ti, Cu, Cr, Ni, Sb, S, P, C and Mn respectively represent percent contents of corresponding elements in the steel material, and alpha, beta, gamma, delta, phi, zeta, eta, theta and mu respectively represent corrosion coefficients of corresponding elements. The method has the advantages of avoiding the problem of incapability of judging whether the corrosion resisting property of the steel material reaches the standard after the steel material is produced according to the component control range formulated by all factories, being short in detection period, lowering production cost, reducing resource and energy consumption, being capable of meeting the requirement of corrosion resistance of a tobacco oven, and achieving remarkable economic benefit and social benefit.

Owner:WUKUN STEEL +1

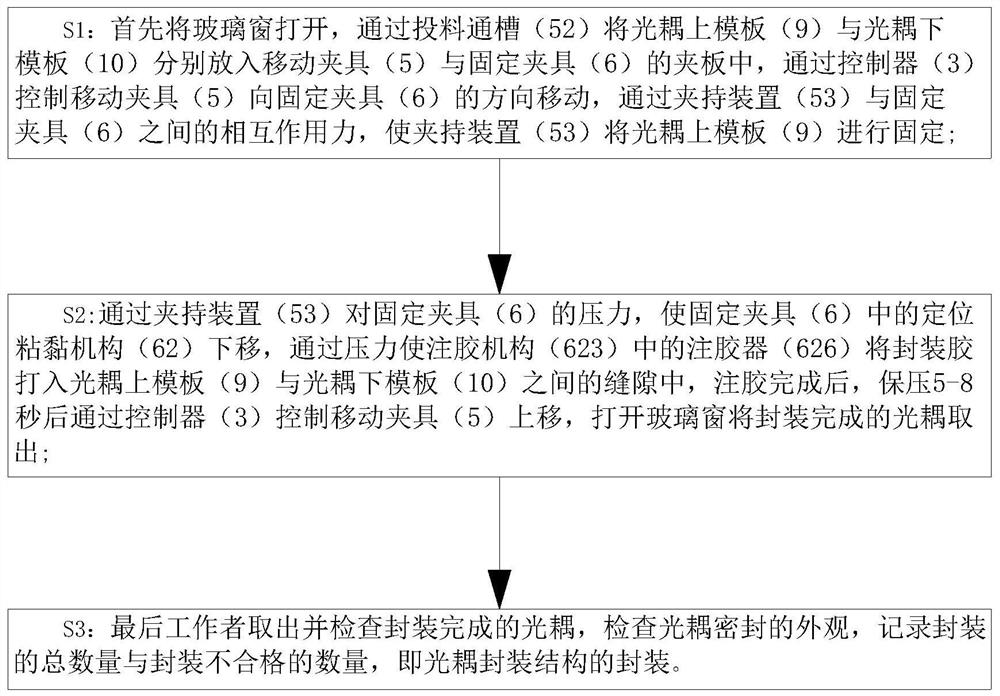

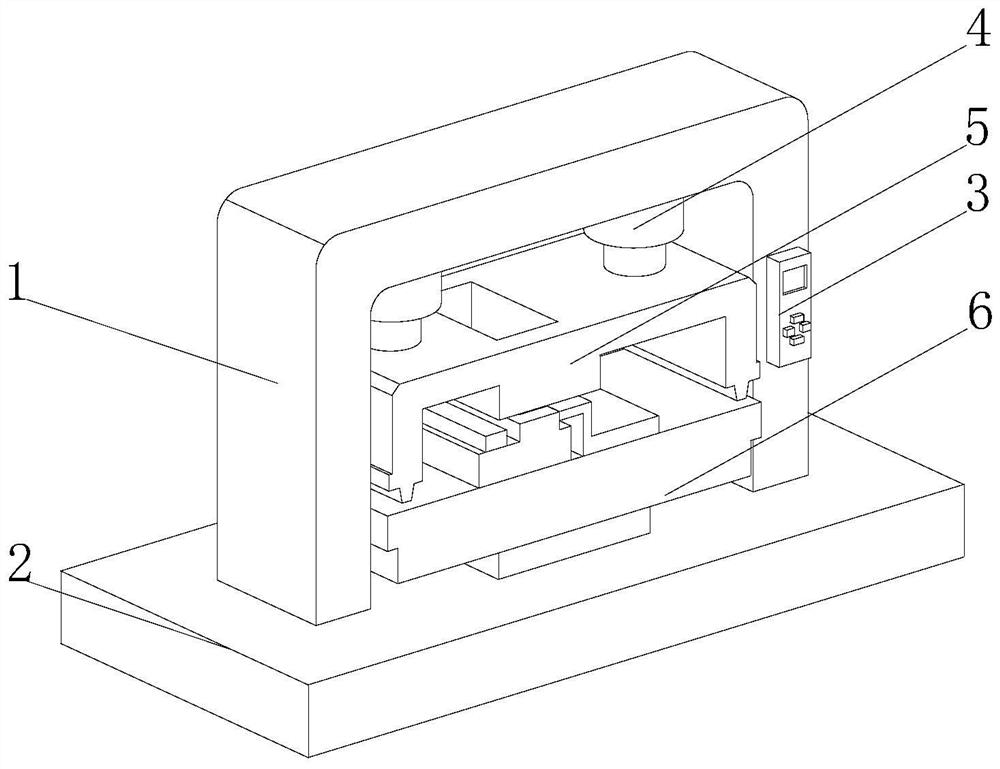

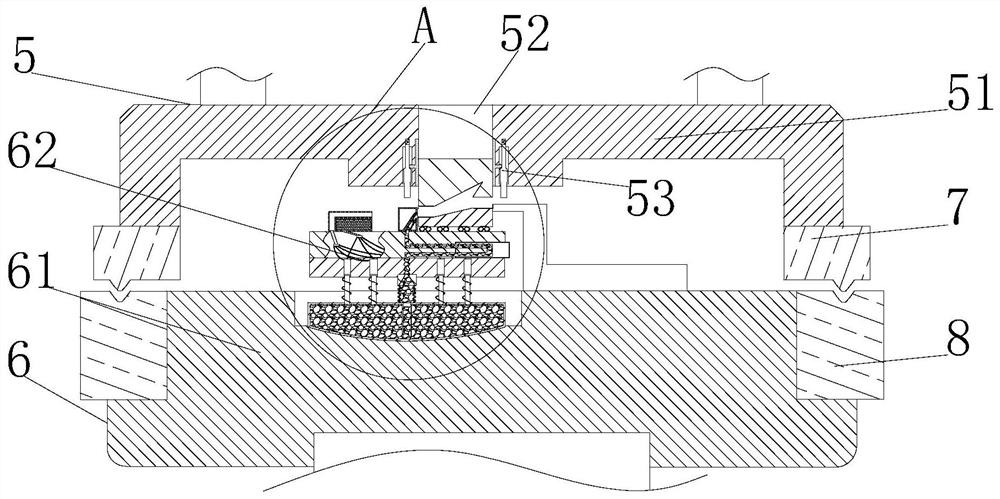

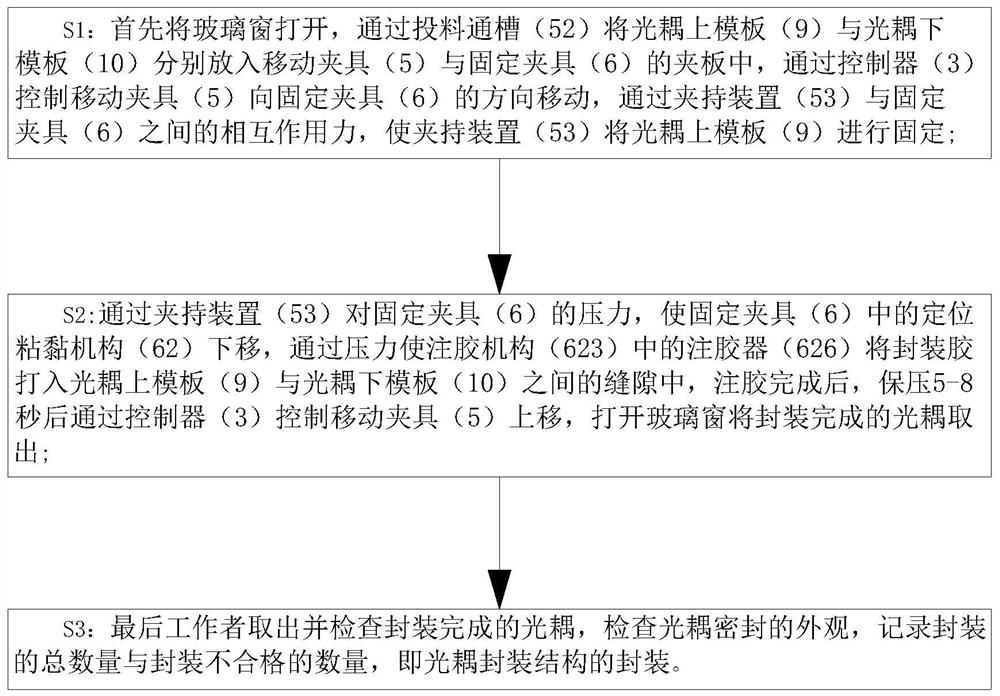

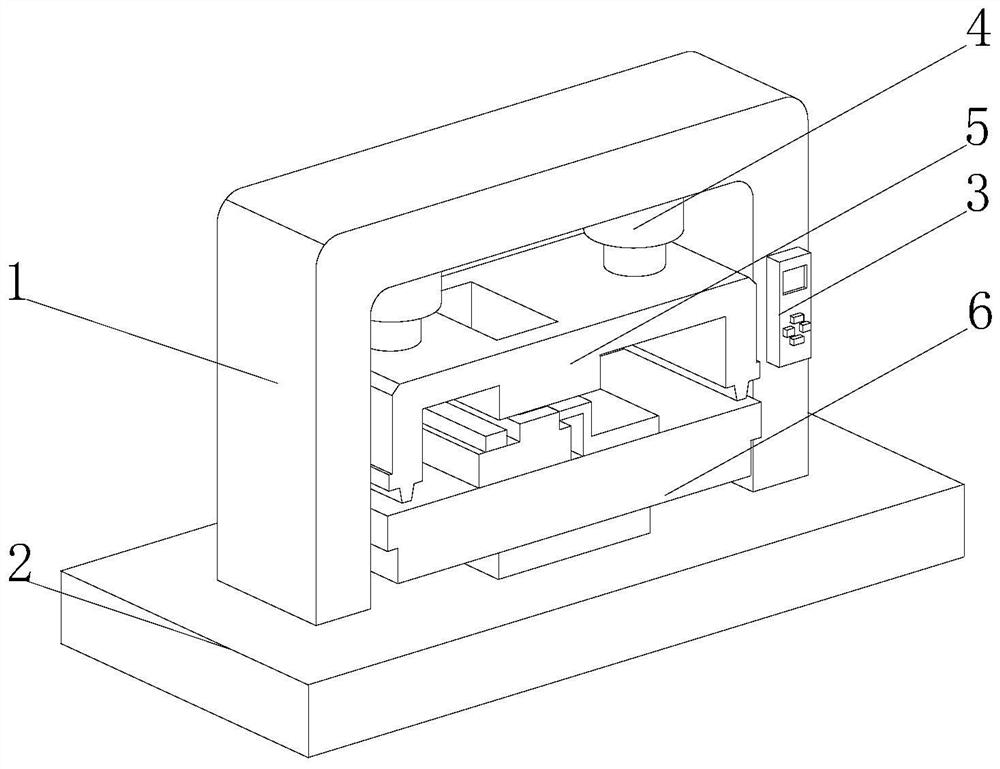

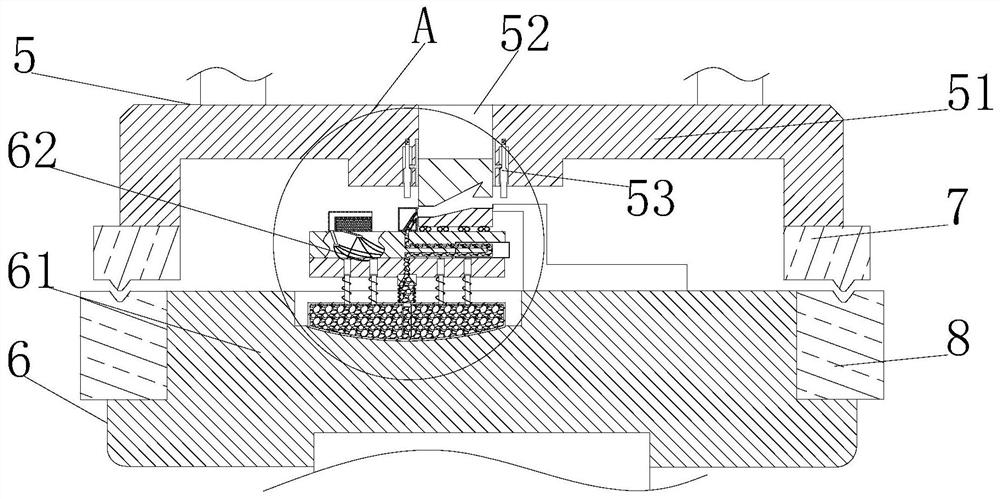

Equipment for optocoupler packaging structure and packaging method

ActiveCN113109907AReduce the use of laborReduce unqualifiedFinal product manufactureCoupling light guidesEngineeringOptical coupler

The invention belongs to the field of packaging equipment, and particularly relates to equipment for an optocoupler packaging structure. The equipment comprises a fixing shell, one end of the fixing shell is fixingly connected with the top of a base, a controller is arranged on one side of the fixing shell, a lifting device is fixingly connected to one side of the fixing shell, a movable clamp is fixingly connected to one end, away from the fixing shell, of the lifting device, a fixing clamp is fixingly connected to the middle of the side, close to the fixing shell, of the base, and glass plates are arranged on the two sides of the fixing shell, so that manual use is reduced, the production speed is increased, meanwhile, dislocation of optical couplers can be avoided, and unqualified products are reduced; according to an optocoupler packaging method, a clamping device exerts pressure on a fixed clamp, a glue injector in a glue injection mechanism injects packaging glue into a gap between an optocoupler upper die plate and an optocoupler lower die plate through the pressure, after glue injection is completed, the pressure is maintained for 5-8 seconds, then a controller controls a movable clamp to move upwards, packaging deviation caused by fatigue of workers is avoided, and the packaging is more convenient and faster.

Owner:NINGBO QUNXIN MICRO-ELECTRONICS CO LTD

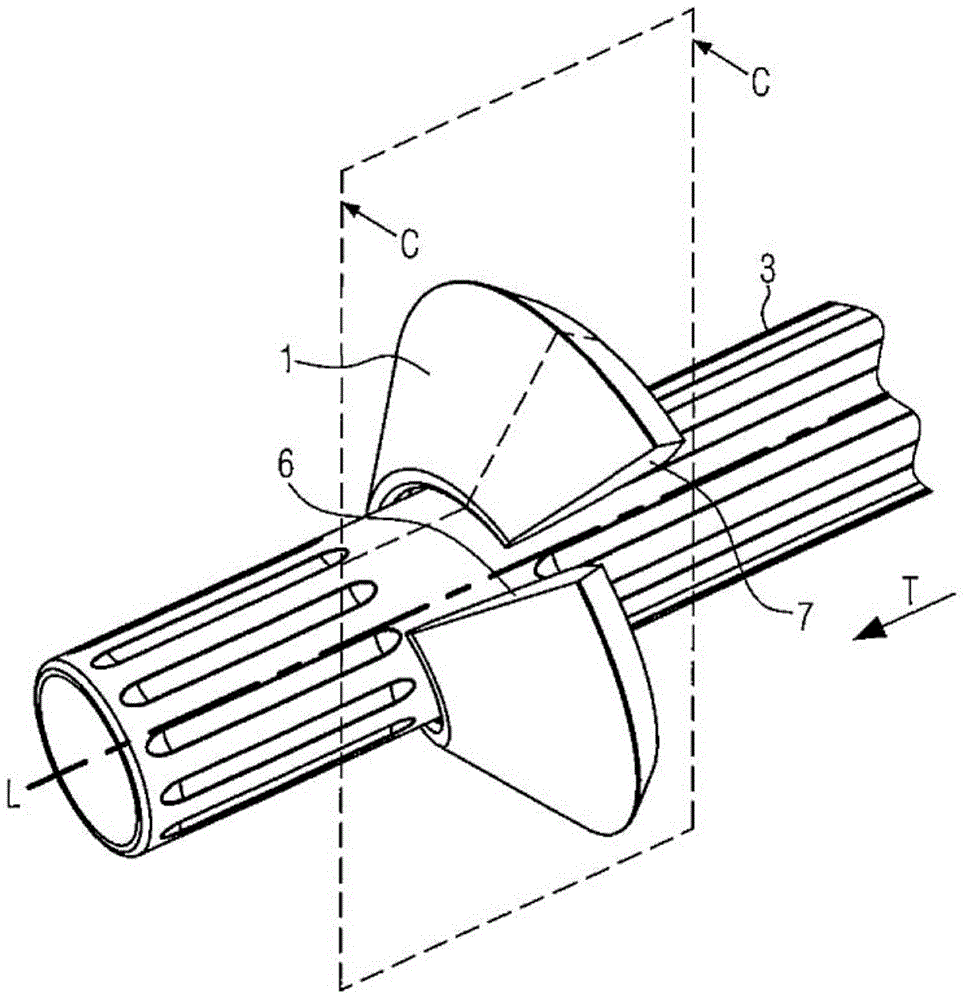

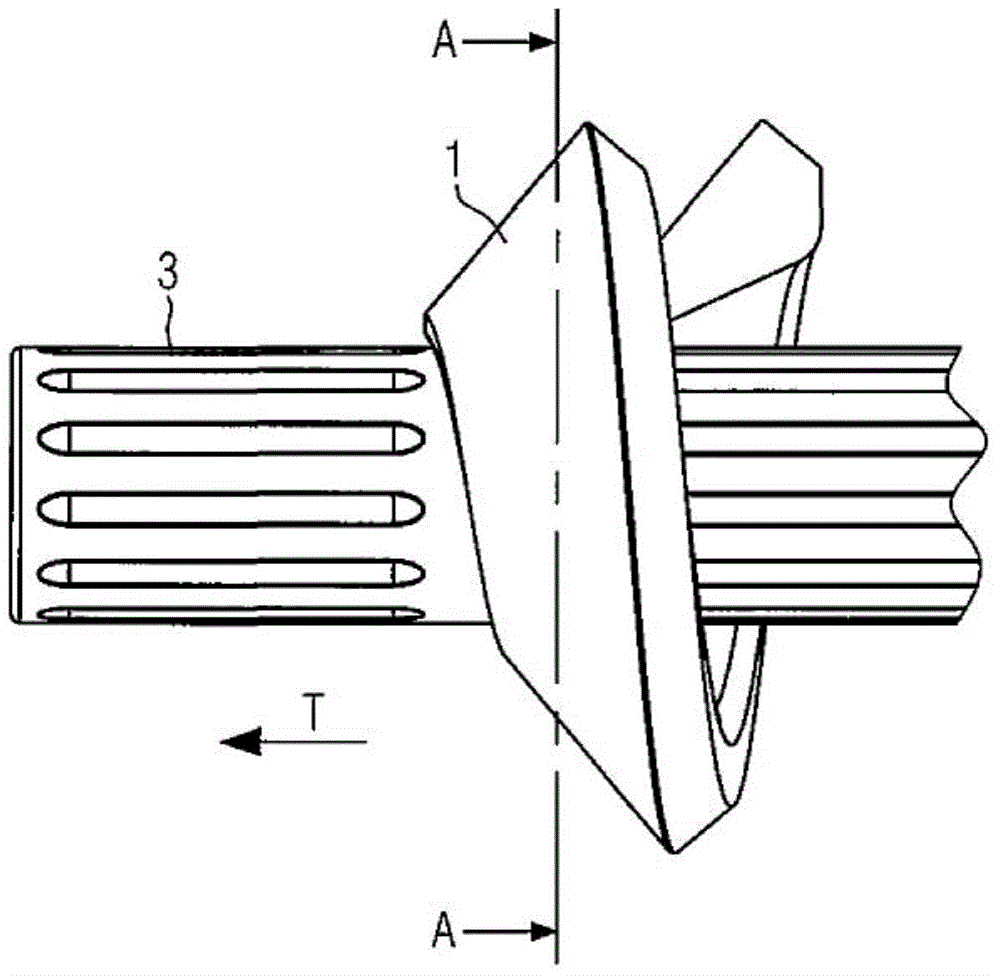

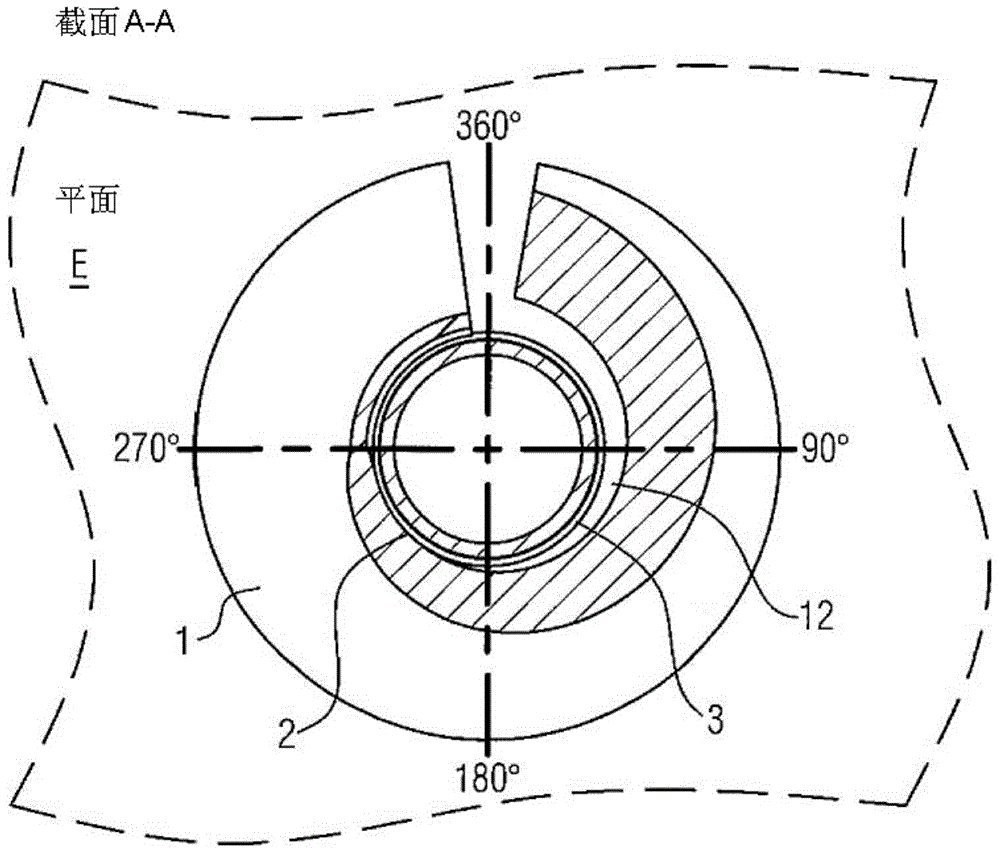

Brake ring

Various systems and methods are provided for the manufacture of sausages. In one example, a method for manufacturing sausages with a filling machine comprises ejecting a mass through a filling tube into a sausage casing ruffled on the filling tube, and exerting a brake force on the sausage casing via a sausage casing brake on a braking area of a brake ring pressing onto the sausage casing, wherein the braking area extends around a longitudinal axis of the filling tube such that the braking area presses onto a part, and not the entirety, of a circumference of the sausage casing in a plane perpendicular to the longitudinal axis, and wherein the brake force is distributed in a direction along the longitudinal axis.

Owner:ALBERT HANDTMANN MASCHFABRICK

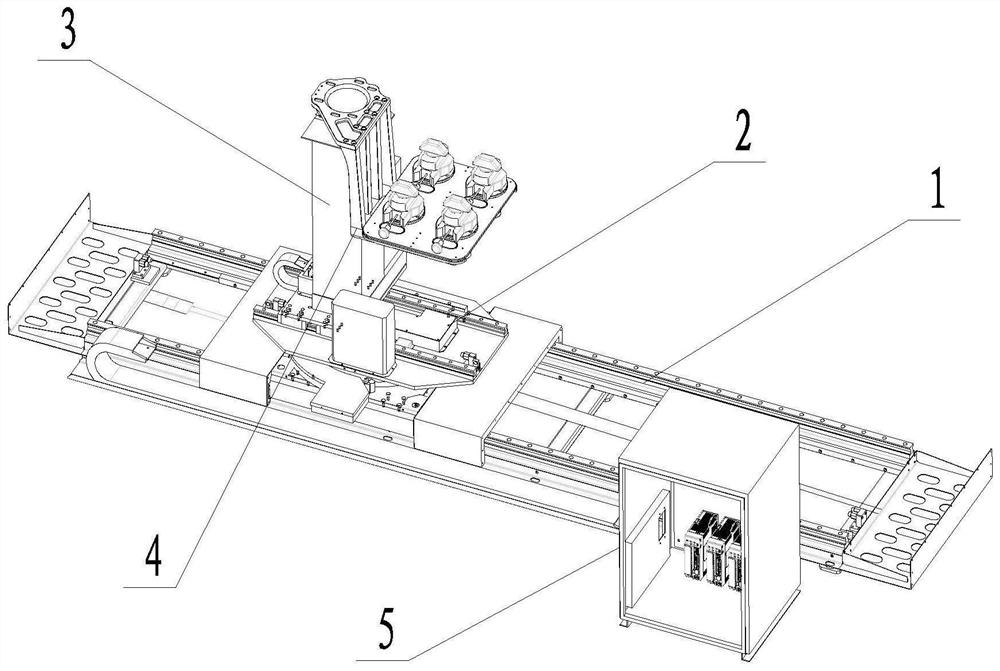

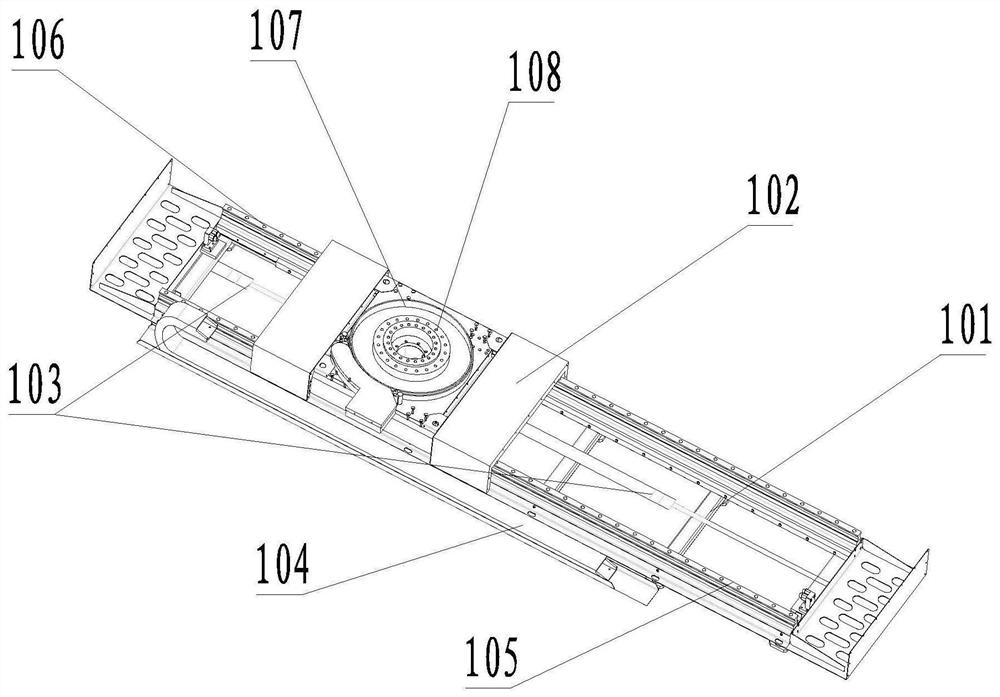

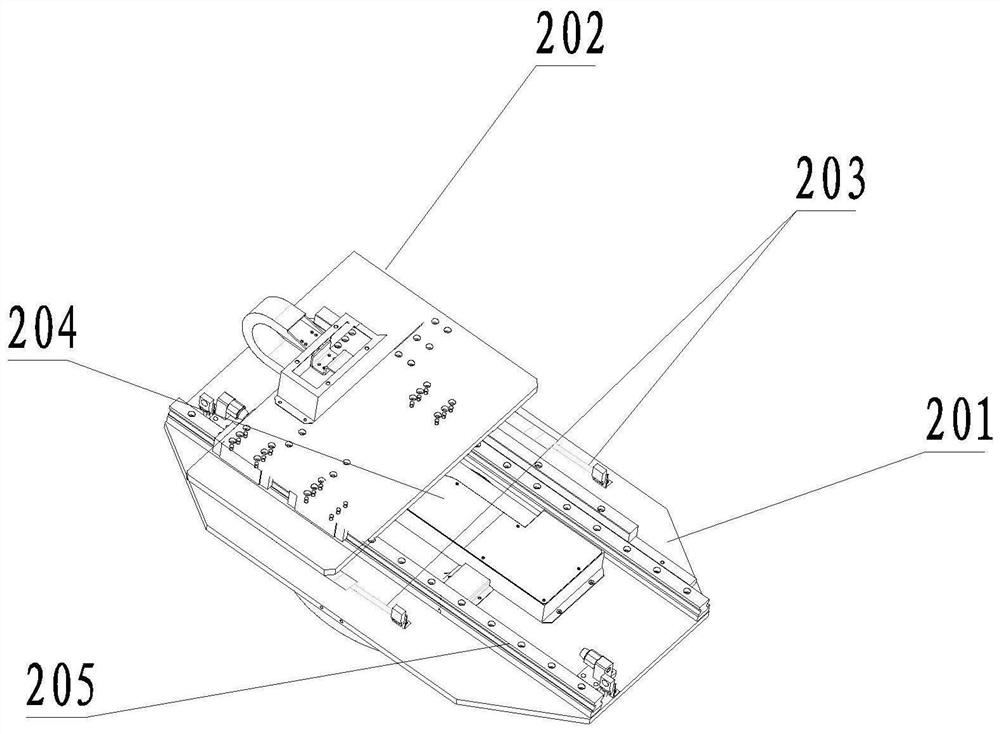

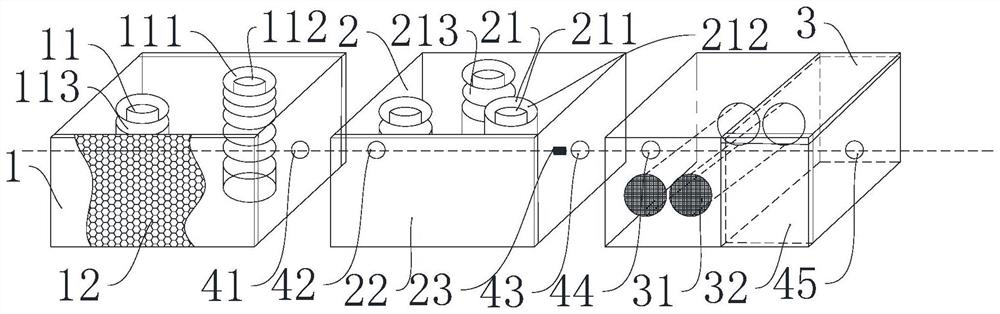

Automatic stacking and lifting traveling system for container locksets

PendingCN113173522AReduce wasteReduce unqualifiedLifting devicesStorage devicesElectric machineryAutonomation

The invention discloses an automatic stacking and lifting traveling system for container locksets. The automatic stacking and lifting traveling system comprises a sliding table assembly, a rotary table assembly, a lifting assembly, a pallet support and a control system. The automatic stacking and lifting traveling system can flexibly place a pallet with the locksets in a designated position of a goods shelf, and automatically runs in the whole process, so that manpower resource waste is reduced, the problem that stacking is unqualified or the locksets are damaged due to human factors is solved, the transportation cost is well reduced, the operation precision is improved by accurately controlling an operation strategy, and lockset transferring and stacking can be safely, efficiently and orderly completed; meanwhile, the device is a pioneering design, and adopts multi-stage air cylinder driving rather than traditional motor driving, thus avoiding the reliability problem that a motor is prone to have due to the fact that the motor is located in wet and corrosive seaside steam for a long time; and meanwhile, the device has the advantages of reliable structure, tight protection, modular assembly, adaptability to severe working conditions and environments and the like.

Owner:南京俊东机器人有限公司

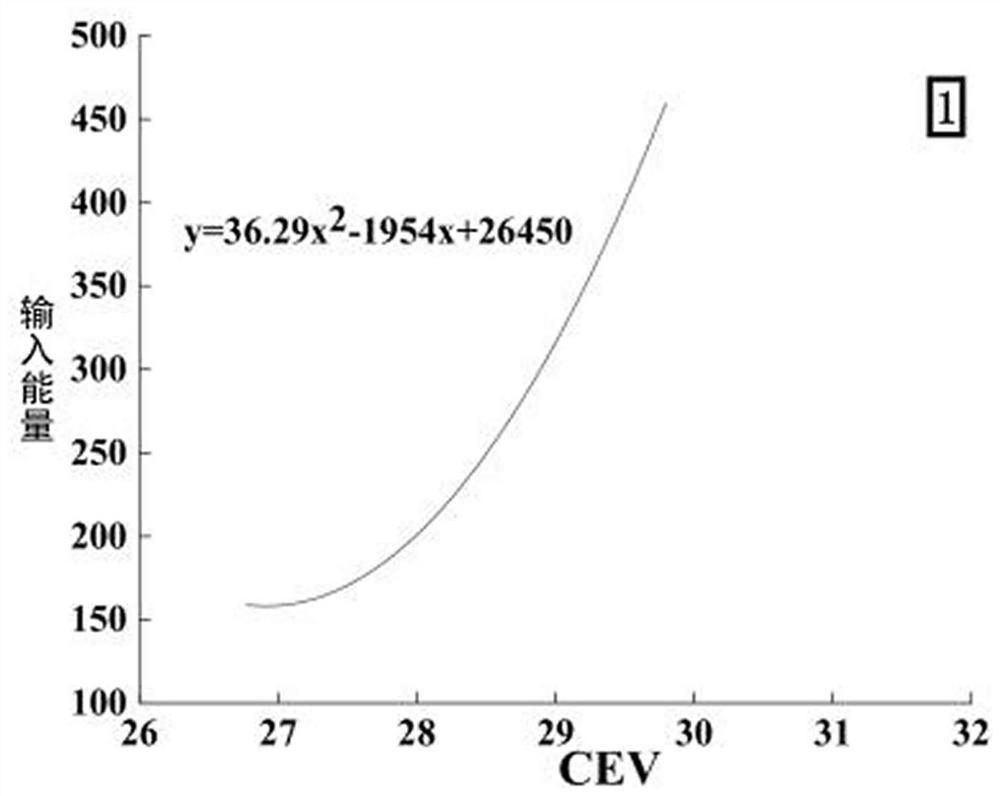

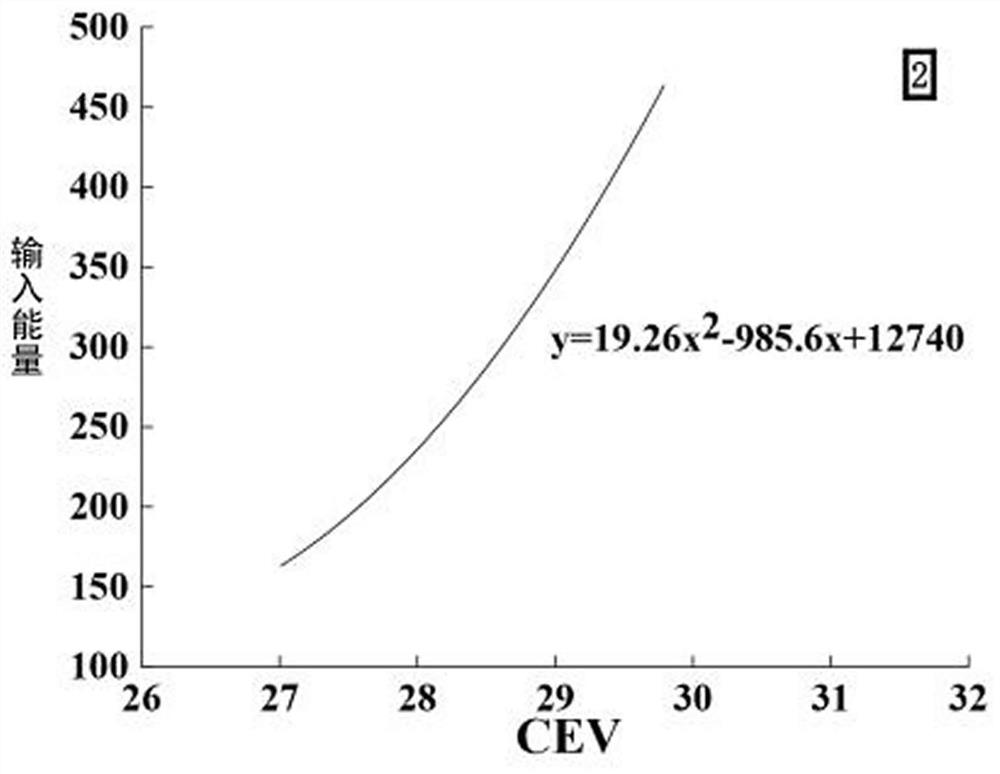

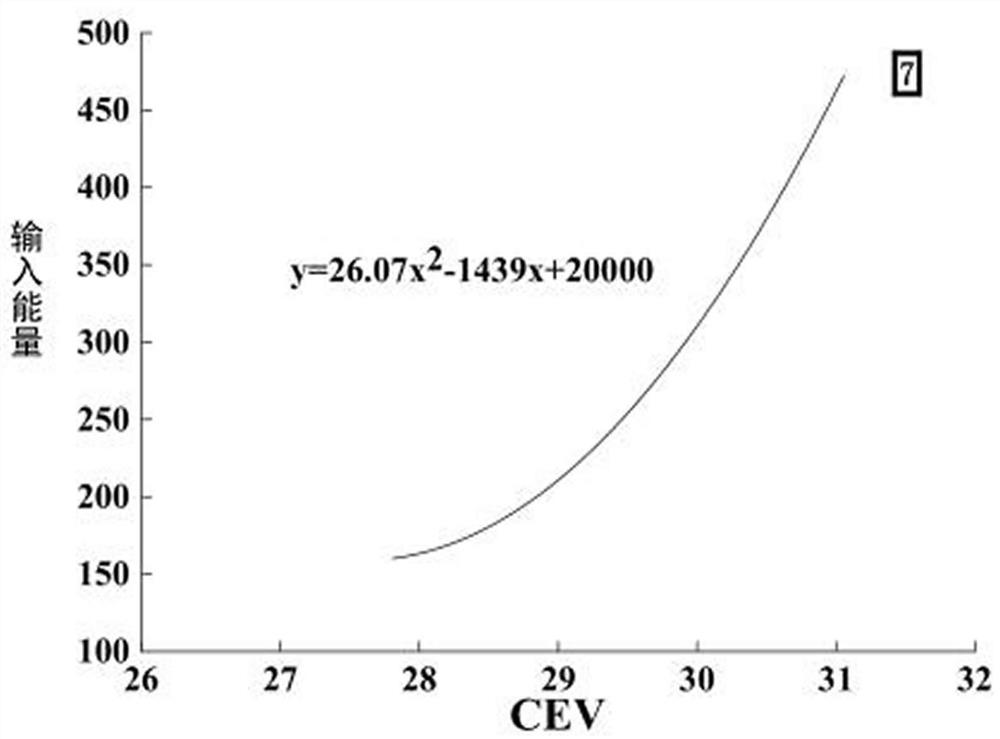

A roadbed compaction process planning method, device, equipment and readable storage medium

ActiveCN113158498BReduce unqualifiedEasy to judgeDesign optimisation/simulationSpecial data processing applicationsIndustrial engineeringSubgrade

The invention provides a subgrade compaction process planning method, device, equipment and readable storage medium, which relate to the technical field of high-speed railway subgrade compaction, including using the compaction energy index as the inspection index of the subgrade compaction quality, and through the secondary fitting Establish the relationship between the degree of compaction and the vibration input energy of the roller, and then predict the data through the artificial intelligence model to finally realize the calibration standard energy, achieve accurate compaction process planning, and reduce overpressure or underpressure resulting in unqualified construction technology chance of the situation happening.

Owner:SOUTHWEST JIAOTONG UNIV

Dyer and device for detecting working state of draught fan of dryer and dryer

ActiveCN103234341BAvoid affecting service lifeSimple structureDrying gas arrangementsPressure senseEngineering

The invention discloses a dryer and a device for detecting a working state of a draught fan of the dryer. The device comprises a guide pipe and a pressure sensing device, wherein pressure sensing device is arranged at the outer part of a drying oven of the dryer; and one end of the guide pipe is communicated to an air outlet end of the draught fan in the drying oven while the other end of the guide pipe is connected to the pressure sensing device. The device for detecting the working state of the draught fan of the dryer has the advantages of being simple in structure, convenient to manufacture, and convenient to assemble, disassemble, debug as well as maintain. The dryer is provided with the device for detecting the working state of the draught fan of the dryer.

Owner:TRUKING TECH LTD

A 3D printing monitoring and error correction method based on three views

ActiveCN104407823BReduce unqualifiedSimple compositionHardware monitoringCharacter and pattern recognitionView basedImaging processing

The invention provides a monitoring and error correction method for a 3D printer, which is used to monitor whether an error occurs during the printing process of the 3D printer, and make timely and appropriate corrections. It is characterized in that the system includes: 3 cameras for three-view monitoring , 3 cameras correspond to 3 viewing angles; the monitoring and error correction software uses image processing to compare the expected three views of each step in the printing process, judges whether the monitoring printing is wrong, and makes timely corrections to small repairable errors. Discard errors that cannot be corrected to save printing time. This system has the advantages of improving the printing accuracy rate and saving the average time for printing qualified products.

Owner:FUZHOU UNIV

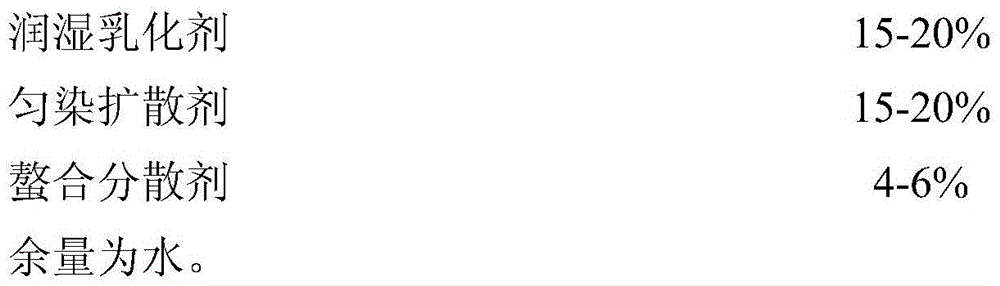

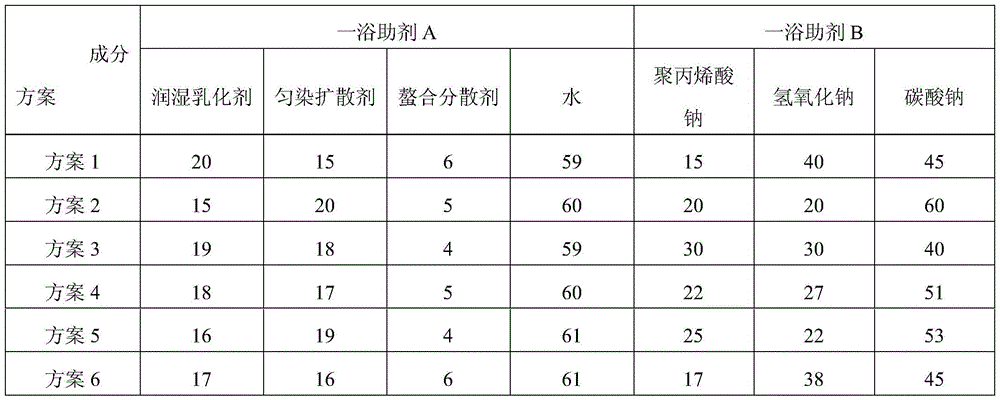

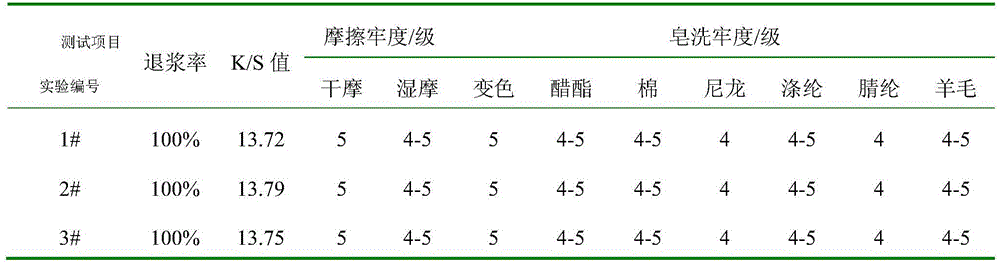

One-bath desizing and dyeing method of polyester pulp-containing fabric and its special auxiliary agent

ActiveCN104195850BGuaranteed qualityShort processDry-cleaning apparatus for textilesDyeing processPolyesterWarm water

The invention discloses a one-bath process-based desizing dyeing method of size-containing polyester fabrics and special auxiliaries for the dyeing method. The method comprises the following steps: putting the size-containing polyester fabrics in water, adding one bath auxiliary A to the water, mixing thoroughly and then adding a dye to the water, mixing thoroughly again and then orderly performing heating, heat preservation and cooling treatment on the obtained system containing the fabrics; next, adding one bath auxiliary B and sodium hydrosulfite to the cooled system for reductive cleaning; and finally, discharging residual liquid and cleaning with warm water, thereby obtaining the desized and dyed polyester fabrics. The one bath auxiliary A comprises the following components in percentage by mass: 15%-20% of wetting emulsifier, 15%-20% of level dyeing diffusant, 4%-6% of chelating disperse agent and the balance being water. The one bath auxiliary B comprises the following components in percentage by mass: 15%-30% of sodium polyacrylate, 20%-40% of sodium hydroxide and 40%-60% of sodium carbonate. The one-bath process-based desizing dyeing method of the size-containing polyester fabrics is only carried out in one bath, and therefore, the processing time is obviously shortened and the quality of the fabrics can be guaranteed favorably; a low amount of water is used and water can be saved by 80%; the energy consumption is low; few types of auxiliaries are utilized.

Owner:BEIJING CTA TEX CHEM

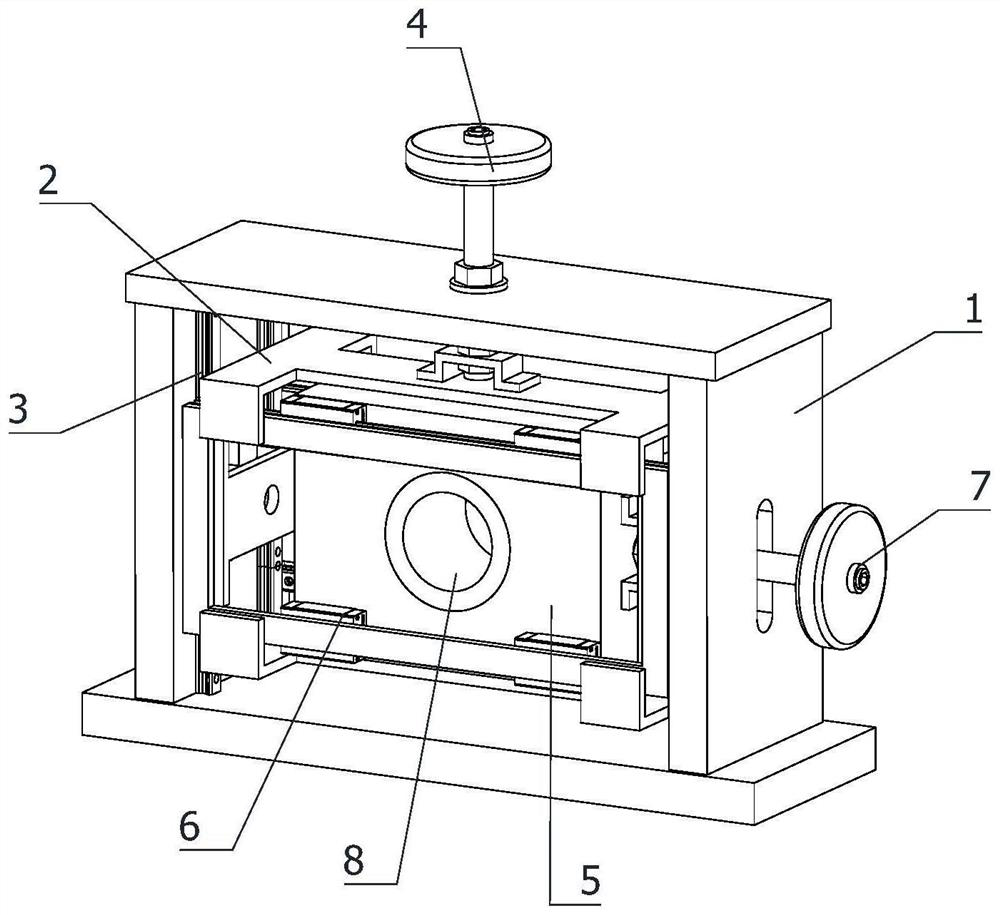

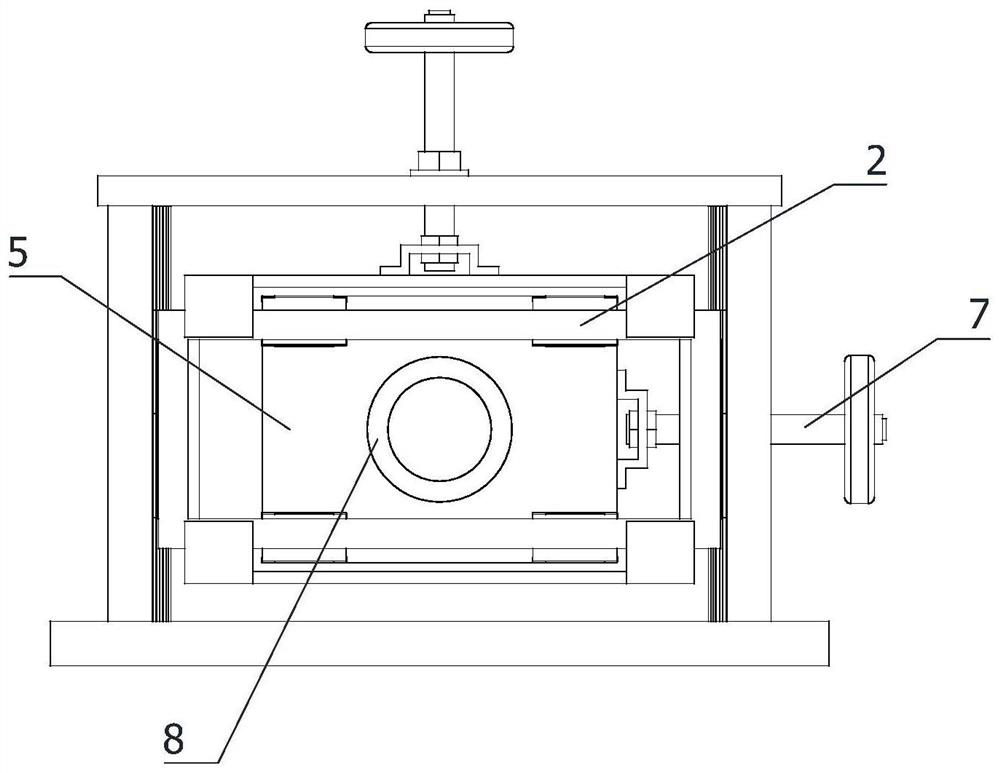

A direction-adjustable tow bag sizing die tooling

ActiveCN112289501BFirmly connectedEasy to disassembleCable/conductor manufactureClassical mechanicsStructural engineering

The invention relates to the field of sizing die tooling, in particular to a direction-adjustable sizing die tooling for towed bags, which is used for installing sizing dies or cross tooling dies. The tooling includes: a closed iron frame, and the frame mouth is placed horizontally on the On the bag frame; the lifting iron frame is vertically slid in the closed iron frame frame opening through the lifting and sliding component, and the first screw adjustment component penetrating through the top of the closed iron frame is vertically arranged on the top of the lifting iron frame; the translational iron frame, the The translational iron frame is horizontally slid and set in the lifting iron frame through the translational sliding assembly, and a second screw adjustment assembly is vertically provided on one side of the translational iron frame, which penetrates the side of the closed iron frame and is vertically slidingly matched with it; nylon Warehouse, the axis is horizontally set on the translational iron frame for coaxial installation of sizing dies or cross tooling dies, the cross tooling dies are set at the closing position of the product through the tooling, and the tooling can adjust the sizing in the vertical and horizontal directions Die position, and can prevent defective product cross frame from entering the next process.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

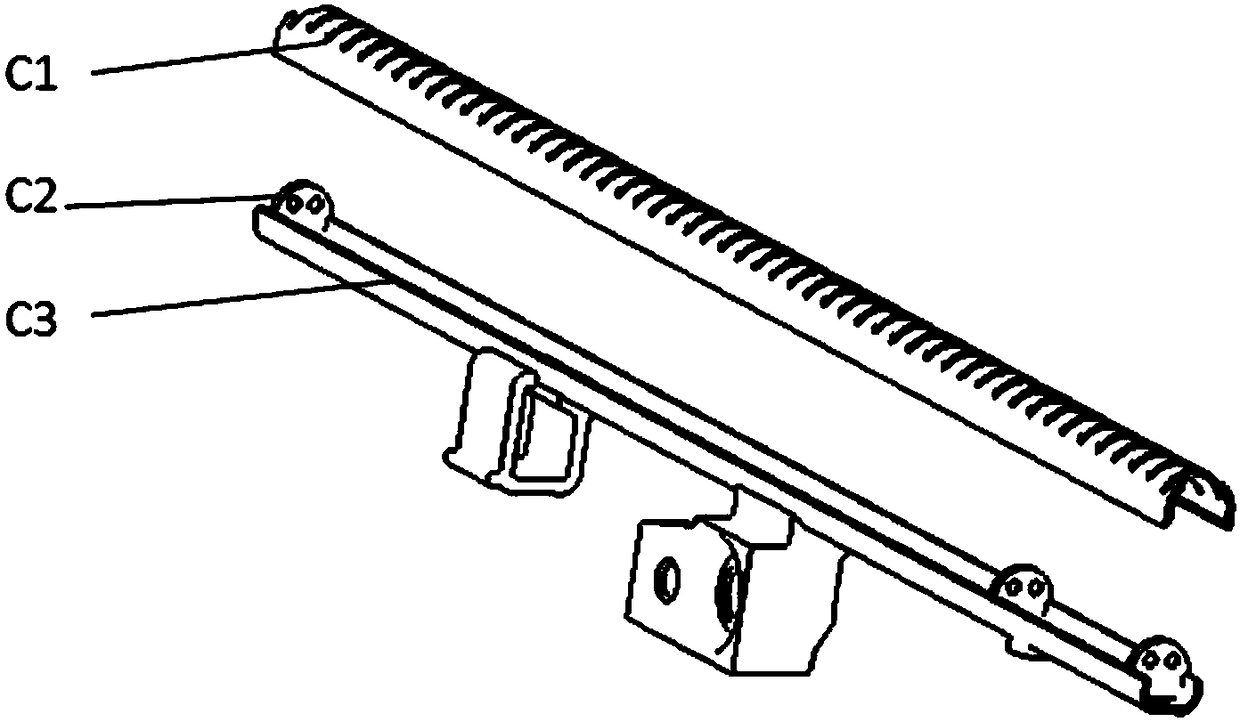

Car condenser header main piece prefabricating tool

ActiveCN108246899ALow investment costReduced operating requirementsShaping toolsHeat exchange apparatusEngineering

The invention provides a car condenser header main piece prefabricating tool comprising an upper mold and a lower mold. A condenser header lower mold is mounted on the lower mold, a condenser header comprises a main piece, a partition piece and a sealing cover assembly, the upper mold is connected with a power air cylinder on equipment, and a main guiding column and a main guiding sleeve on an upper mold base plate are cooperatively connected with the upper mold and the lower mold. A transverse punching centre mechanism is mounted on the upper mold through a branched guiding column, a main limiting column for limiting the contact stroke of the upper mold and the lower mold is mounted at the lower end of the upper mold base plate, and the left side and the right side of the lower end of theupper mold base plate are each provided with an upper mold oblique jacking mechanism. Supporting parts are mounted on a lower mold bottom plate, and the lower end of the main guiding column is mounted on a guiding column seat. By adopting the debugging-free design, the worker can directly mount the tool on the equipment for production, the debugging time is saved, the requirement for the operating capacity of the workers is reduced, the quality problem caused by horizontal debugging cannot occur, and the stability of the product quality can be effectively ensured.

Owner:SHANGHAI BEHR THERMAL SYST

Device and packaging method for optocoupler packaging structure

ActiveCN113109907BReduce the use of laborReduce unqualifiedFinal product manufactureCoupling light guidesMechanical engineeringElectrical and Electronics engineering

The invention belongs to the field of packaging equipment, in particular to a device for an optocoupler packaging structure. One side of the lifting device is fixedly connected with a lifting device, the end of the lifting device away from the fixed shell is fixedly connected with a moving fixture, the middle of one side of the base close to the fixed shell is fixedly connected with a fixed fixture, and both sides of the fixed shell are provided with a glass plate at one end to reduce manual use It can improve the production speed and avoid the dislocation of the optocoupler and reduce unqualified products; a method for optocoupler packaging, through the pressure of the clamping device on the fixed fixture, the glue injector in the glue injection mechanism will seal the package through the pressure. The glue is injected into the gap between the upper template of the optocoupler and the lower template of the optocoupler. After the glue injection is completed, the pressure is maintained for 5-8 seconds and then the controller is used to control the moving fixture to move up, so as to avoid the deviation of the packaging caused by worker fatigue and make the packaging More convenient and faster.

Owner:NINGBO QUNXIN MICRO-ELECTRONICS CO LTD

Silk-screen printing device

InactiveCN101045360BImprove yieldImprove printing qualityPrinted circuit assemblingScreen printersScreen printingBaseboard

Provided is a screen printing apparatus. In the forming of the protrude electrode using the screen printing method, resulting the adhesive force of the solder paste which is transferred by many opening-part groups and the metal mask, the departing of the printing board starts from the perimeter part, finally the middle part of the metal mask departs from the printing board, the occurring of this phenomenon is the main reason for the defective printing which concludes the thickness error of the printing film ,the printing deficiency and so on. Using the different thickness of the mentioned mask component sheet, or the different material, or the different elastic coefficient, connect every mask component sheet which is set on the accessory pattern of the printing baseboard or at all the patterns formed in the scheduled area, and the adjusting equipment which accords to the mentioned connection status and can reproduce random curve is also provided.

Owner:HITACHI LTD

Direction-adjustable ladle dragging sizing die tool

ActiveCN112289501AFirmly connectedEasy to disassembleCable/conductor manufactureStructural engineeringMechanical engineering

The invention relates to the field of sizing die tools, in particular to a direction-adjustable ladle dragging sizing die tool which is applied to installation of a sizing die or a cross-shaped tool die. The tool comprises a closed iron frame with a frame opening horizontally arranged on a ladle dragging frame, a lifting iron frame, a translation iron frame, and a nylon bin. The lifting iron frameis vertically arranged in the frame opening of the closed iron frame in a sliding mode through a lifting sliding assembly, and a first lead screw adjusting assembly penetrating through the top of theclosed iron frame is vertically arranged at the top end of the lifting iron frame; the translation iron frame is horizontally arranged in the lifting iron frame in a sliding mode through a translation sliding assembly, and a second lead screw adjusting assembly which penetrates through the side portion of the closed iron frame and is in vertical sliding fit with the closed iron frame is vertically arranged on one side of the translation iron frame; the axis of the nylon bin is horizontally arranged on the translation iron frame, the nylon bin is used for coaxially installing a sizing die or across-shaped tool die, the cross-shaped tool die is arranged at the product coiling position through the tool, the tool can adjust the position of the sizing die in the vertical direction and the horizontal direction, and defective cross-shaped frameworks can be prevented from entering the next procedure.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

Dehumidifying, drying, preheating and powder coating integrated device

ActiveCN114273102AReduce distancePreserve the warm-up effectLiquid spraying plantsSpray boothsElectrical conductorPowder talcum

The invention relates to a dehumidifying, drying, preheating and powder coating integrated device, and belongs to the technical field of cable processing equipment. The device comprises a shell, and a dehumidifying and drying module, a preheating module and a powder coating module which are adjacently arranged in the shell. The dehumidifying, drying, preheating and powder coating integrated device is compact in structure, the space utilization rate and the use utilization rate can be increased, and the device can complete the functions of preheating, drying and powder coating at a time. And the conductor is dehumidified and dried, so that the probability that a processed product is unqualified due to the fact that the conductor is affected with damp can be reduced. And the preheating module and the powder coating module are arranged adjacently, so that the distance required by the preheated conductor entering the powder coating process is shortened, and the conductor preheating effect can be reserved to the maximum extent. And the talcum powder outside the conductor can be uniformly adsorbed by using electrostatic powder spraying, and the peeling effect after subsequent insulation extrusion molding is optimized.

Owner:JIANGSU ZHONGLI GRP CO LTD +1

Concrete stirring device capable of achieving quantitative discharging and preventing condensation

InactiveCN111976000AImprove efficiencyImprove stirring efficiencyDischarging apparatusMixing operation control apparatusStructural engineeringMechanical engineering

Owner:FUQING LIHENG TECH CO LTD

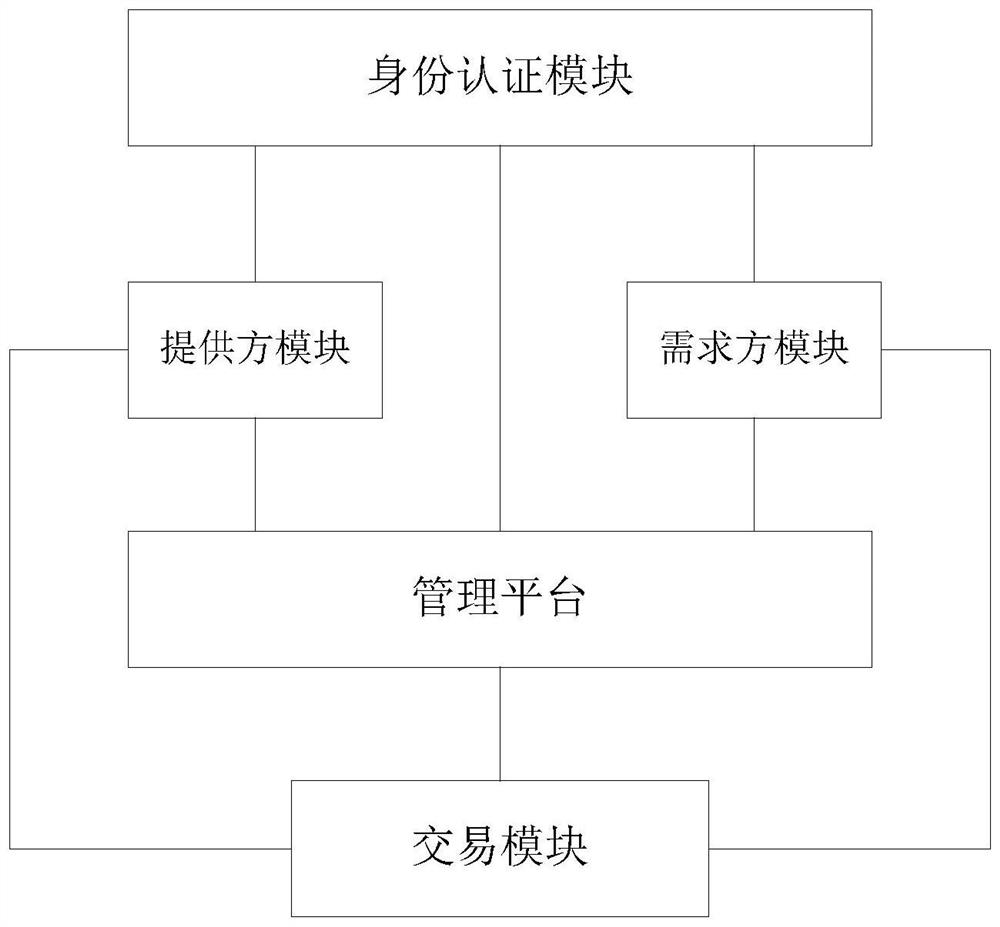

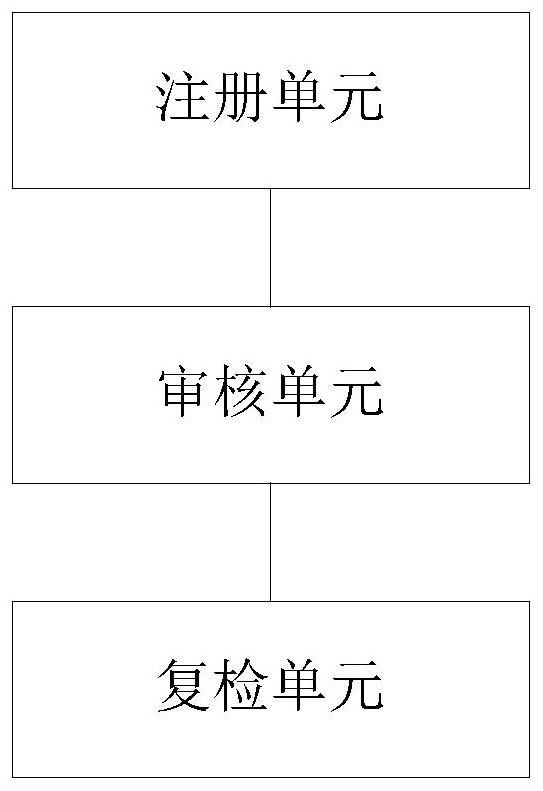

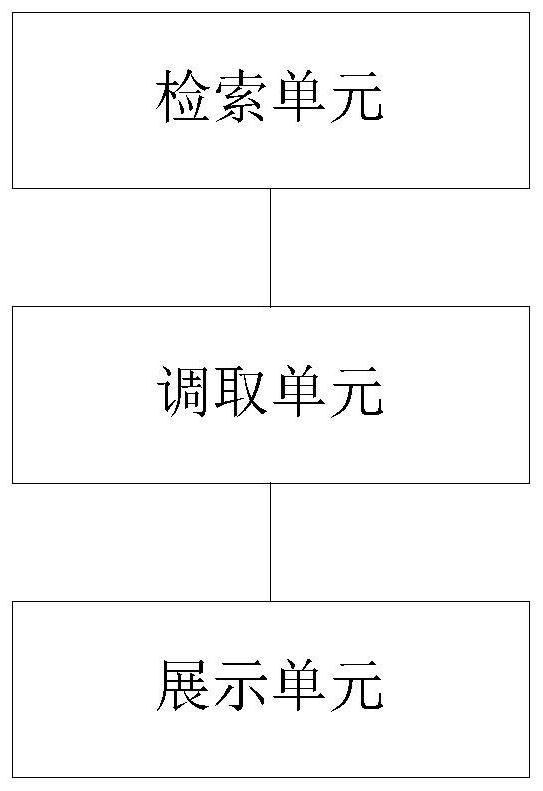

Data transaction system and method based on data empowerment

PendingCN114511320AReduce unqualifiedReduce Breach DataPayment protocolsResourcesData providerData needs

The invention discloses a data transaction system and method based on data empowerment, and the system comprises an identity authentication module which is used for receiving input identity information of a provider or a demander, and obtaining a score matched with the identity information of the provider or the demander; the provider module is used for registering data matched with the score of the data provider according to the score of the data provider; the demander module is used for calling data matched with the score of the data demander according to the score of the data demander and generating a transaction request according to the selected to-be-transacted data; the management platform is used for storing the registered data and the user information, classifying and grading the stored data, scoring the user information and feeding back a score matched with a provider or a demand side to the identity authentication module; and the transaction module is used for auditing the transaction request and the information of both parties of the transaction, sending the demand side information and the transaction request to the provider after the auditing is passed, and completing the data transaction and empowerment after the provider verifies.

Owner:成都中科大旗软件股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com