Manufacturing method of pressing mould turner, turning device and turning method

A technology for pressing molds and manufacturing methods, which is applied in the field of flipping auxiliary equipment, can solve problems such as smashing hands and feet, unsafety, etc., and achieves the effects of easy operation, reduced work injuries, and stable flipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

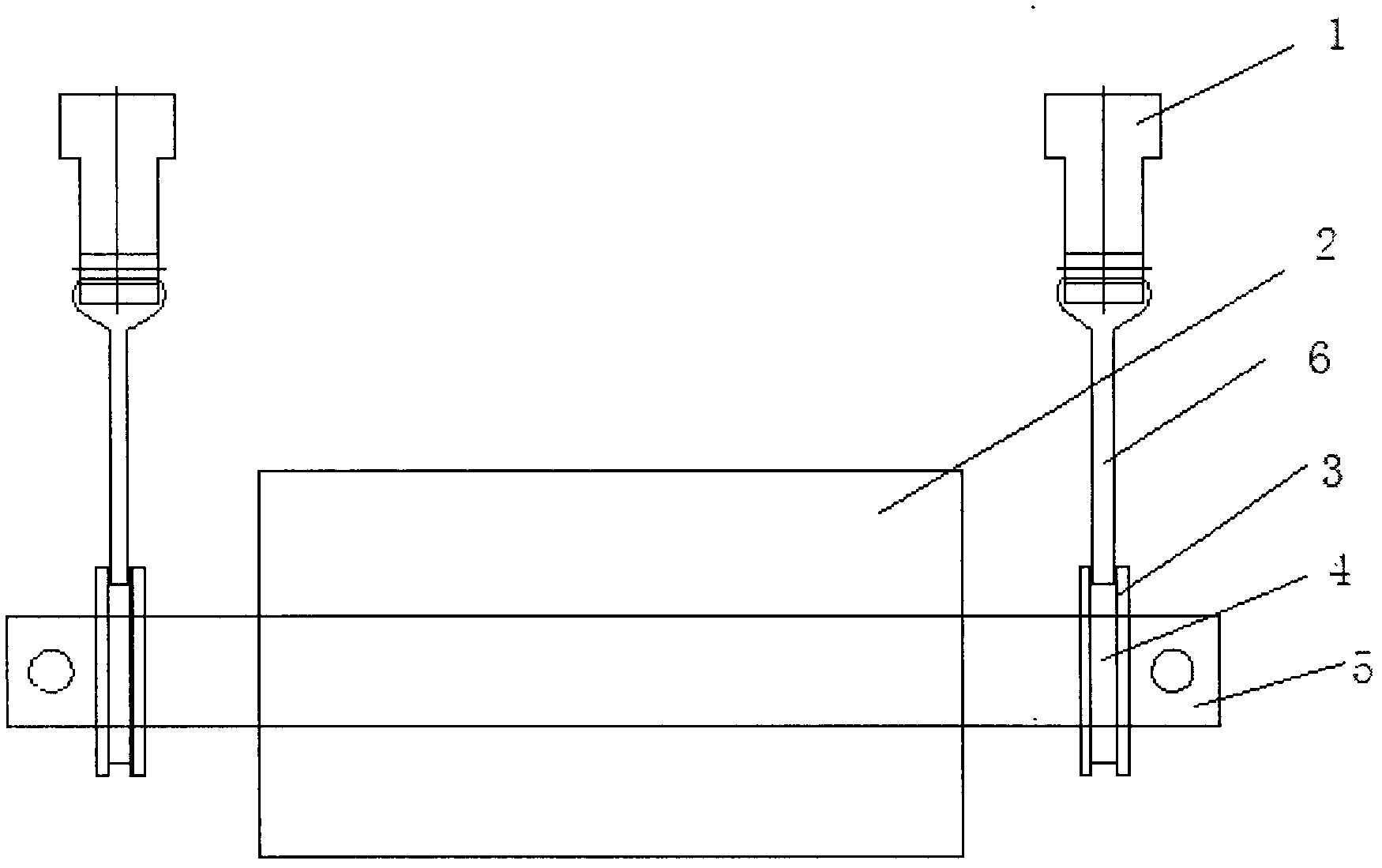

[0031] A method of manufacturing a press mold turner, characterized in that it comprises the following steps:

[0032] (1) Preparation of raw materials: prepare a metal plate with a thickness of 6mm, prepare two steel wire ropes with a diameter of 4mm, industrial belts, four semicircular snap rings, two T-shaped blocks as sliding hanging blocks, and screw rods;

[0033] (2) cutting the flat plate described in step (1) into a width of 20mm is made into an arc-shaped clamp according to the size of the mould;

[0034] (3) Wrap a layer of industrial belt on the hoop to get the hoop, and fix the hoop on the screw rod;

[0035] (4) Clamp a hoop with two snap rings and tighten it with a nut to make a T-shaped slot sliding block;

[0036] (5) Hoop the two T-slot sliders on both ends of the screw respectively;

[0037] (6) Use steel wires to connect the T-shaped groove sliding block and the T-shaped block at both ends of the screw rod as a sliding hanging block to press the mold turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com