Method for breaking brittle material substrate

A technology of brittle material substrates and edge materials, applied in the direction of nonlinear optics, stone processing tools, stone processing equipment, etc., can solve the problems that the split surface is easy to break and it is difficult to enhance the strength of the end face, so as to reduce product failure and reduce load , The effect of enhancing the strength of the end face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, details of the breaking method of the present invention according to the present invention will be described in detail with reference to the drawings.

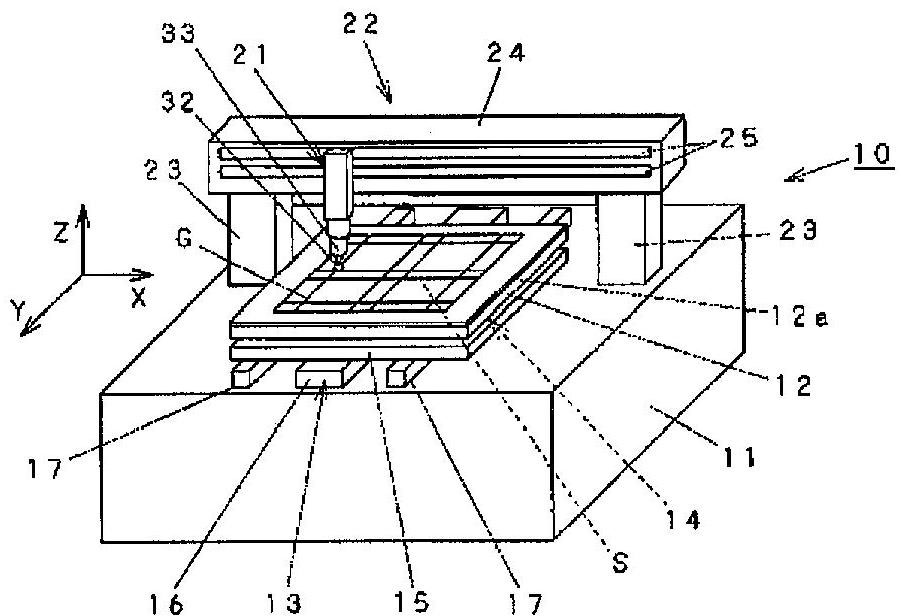

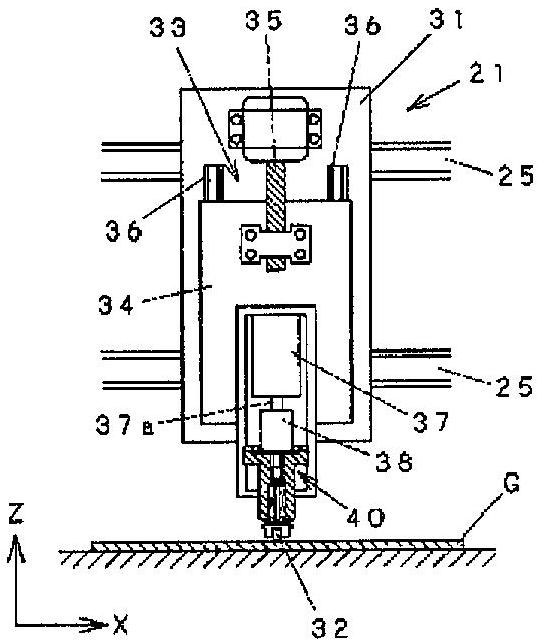

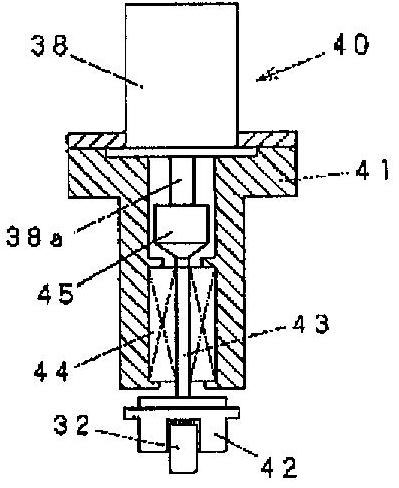

[0046] (fracture device) figure 1 It is a figure which shows the whole structure of the breaking apparatus 10 used when carrying out the breaking method of this invention. A scribing table 12 on which a substrate G is placed is provided on the base 11 . The scribing table 12 includes a Y-axis driving mechanism 13 for moving in the Y direction, and a scribing table rotating mechanism 14 installed below the scribing table 12 to rotate the scribing table 12 . Rubber 12a is laid on the upper surface of the scribing table 12, and when a load is applied to the substrate G from above, the substrate G is easily bent. The Y-axis drive mechanism 13 includes a Y stage 15 that supports the scribe table 12 via a scribe table rotation mechanism 14 , a linear motor 16 that drives the Y stage 15 in the Y direction, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com