Hydraulic pressure suspension polishing method and device thereof

A polishing device and hydraulic pressure technology, applied in the direction of grinding drive device, grinding automatic control device, grinding/polishing equipment, etc., can solve the problem that the processing efficiency cannot meet the production needs, the processing efficiency is difficult to meet the requirements, the speed of the polishing disc, etc. Low-level problems, to achieve the effect of high transmission efficiency and processing efficiency, strong anti-seismic ability, and good platform stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

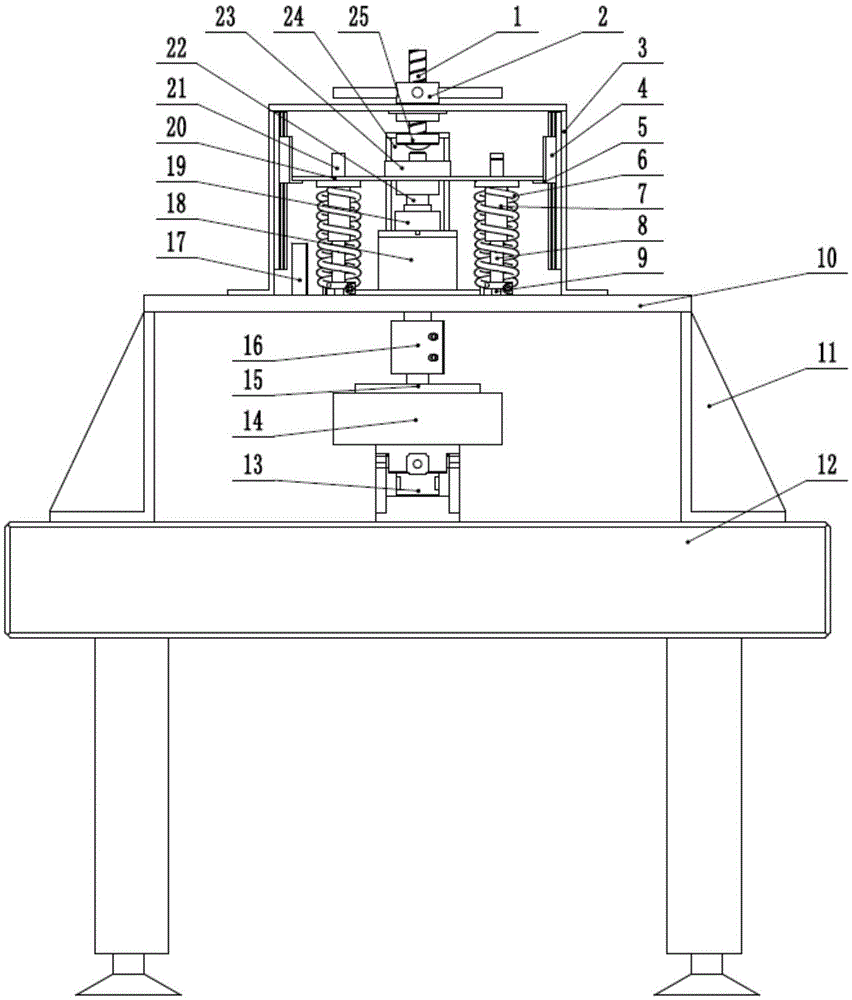

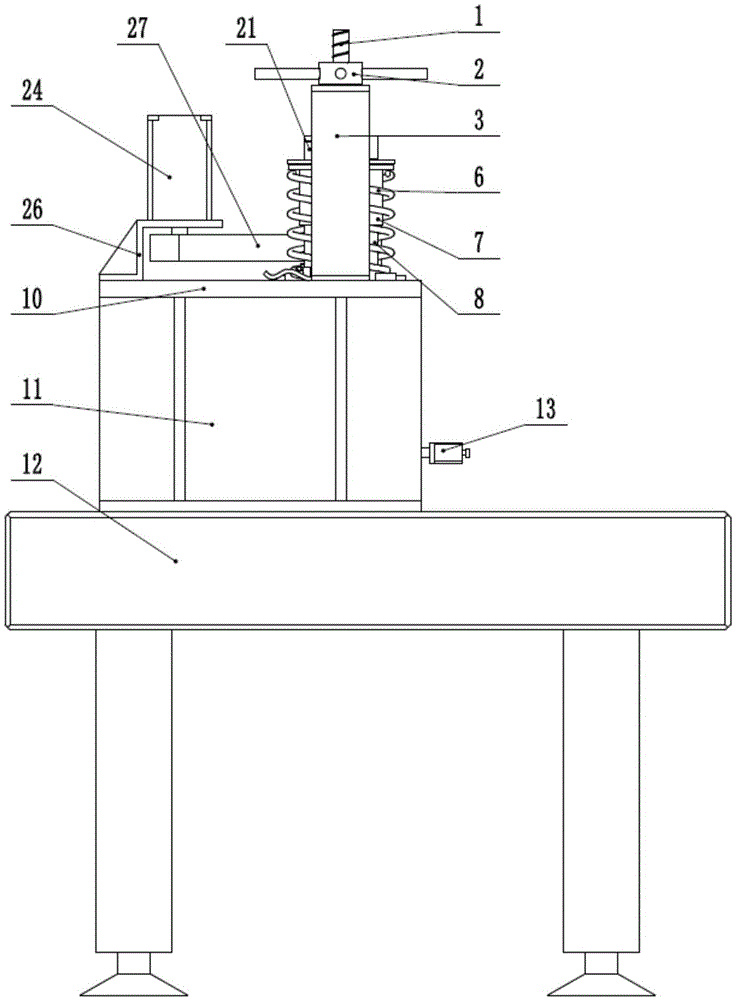

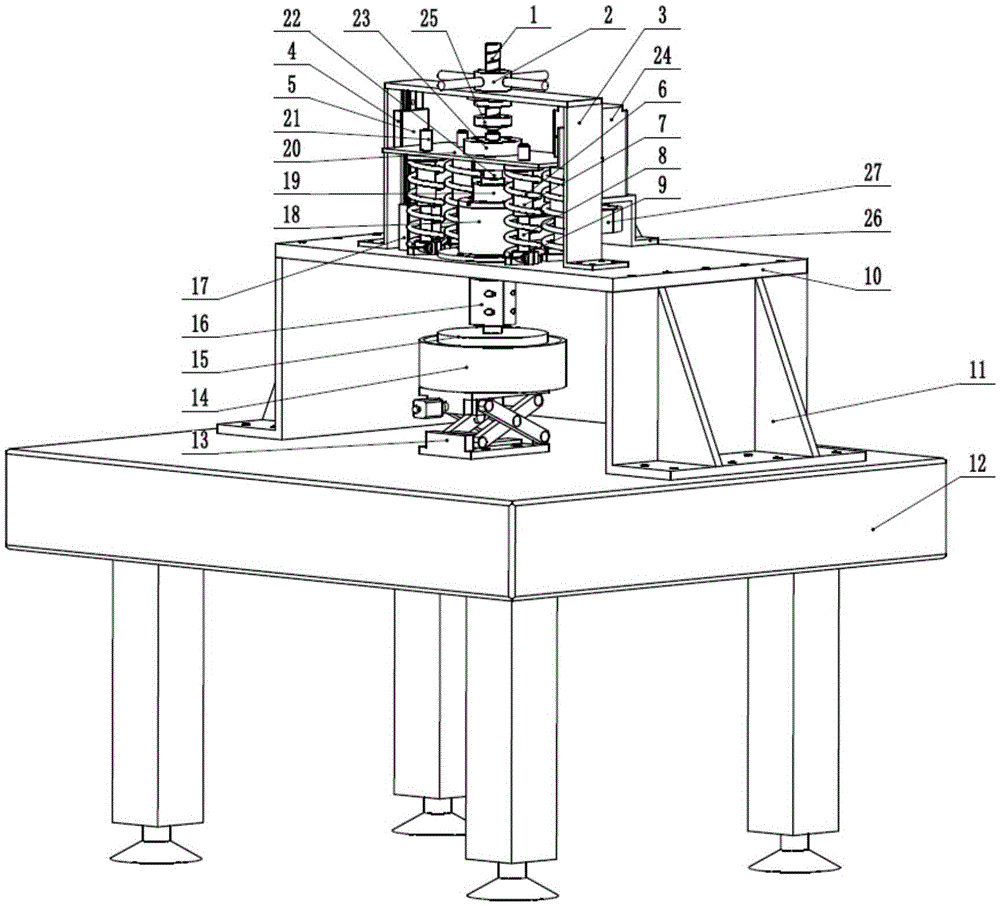

[0023] Such as Figure 1-7 As shown, the present invention includes a polishing disc 15, a hydraulic suspension device, a lifting device and a supporting device. The surface of the polishing disc 15 is divided into several basic units, and each basic unit surface includes Workpiece patch area, wedge-shaped area, reservoir and constraint boundary; Described supporting device comprises marble platform 12, base plate 10, side plate 11 and support frame 3, and support frame 3 is fixed on the described base plate 10, and described base plate 10 Supported on the marble platform 12 by the side plates 11 on both sides; The hydrodynamic suspension device includes a polishing disc 15, a ball spline shaft 22, a shaft sleeve 19, a servo motor 24, a balance plate 20, a support seat 23 and multiple groups of gravity overcoming mechanisms, and the ball spline shaft 22 sets 19 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com