Article surface morphology detection method and device

A technology of surface topography and detection method, applied in the field of surface topography detection of objects, can solve the problems of under-sampling effect, limit measurement speed, limit axial measurement accuracy, etc., so as to improve system stability, eliminate system vibration, and eliminate environmental problems. the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

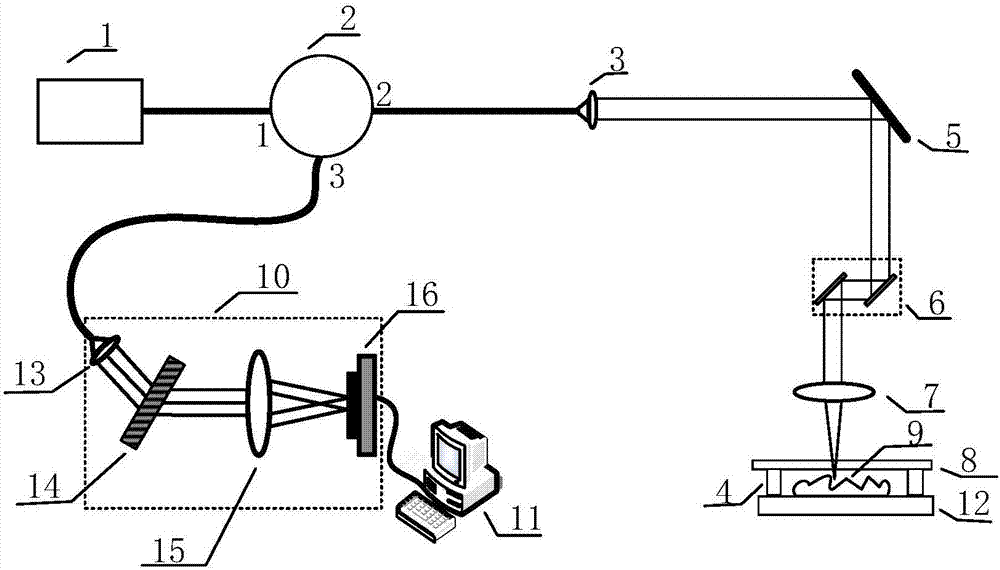

[0038] The technology will be further described below in conjunction with the accompanying drawings.

[0039] The object surface topography detection device includes: a low-coherence light source 1, a spectrometer, a three-terminal circulator 2, a first lens 3, a mirror 5, an x-y scanning galvanometer 6, a second lens 7 and a sample stage 12. The light emitted by the low-coherence light source 1 enters through the port 1 of the three-terminal circulator 2, and the light coming out of the port 2 of the three-terminal circulator 2 is collimated by the lens 3 and then hits the reflector 5, and the light after changing the direction hits x-y The x vibrating mirror of the scanning vibrating mirror 6 is shot from the x vibrating mirror to the y vibrating mirror of the x-y scanning vibrating mirror 6, and the light passing through the y vibrating mirror is focused by the second lens 7 onto the surface of the sample 9 to be measured, and passed through the scanning vibrating mirror 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com