A kind of cast steel deoxidation alloy and its processing method and using method

A technology for deoxidizing alloys and cast steel, applied in the field of molten steel smelting, can solve problems such as poor use of deoxidizers and affect the performance of cast steel, reduce or eliminate free carbides, improve molten steel properties, and refine grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

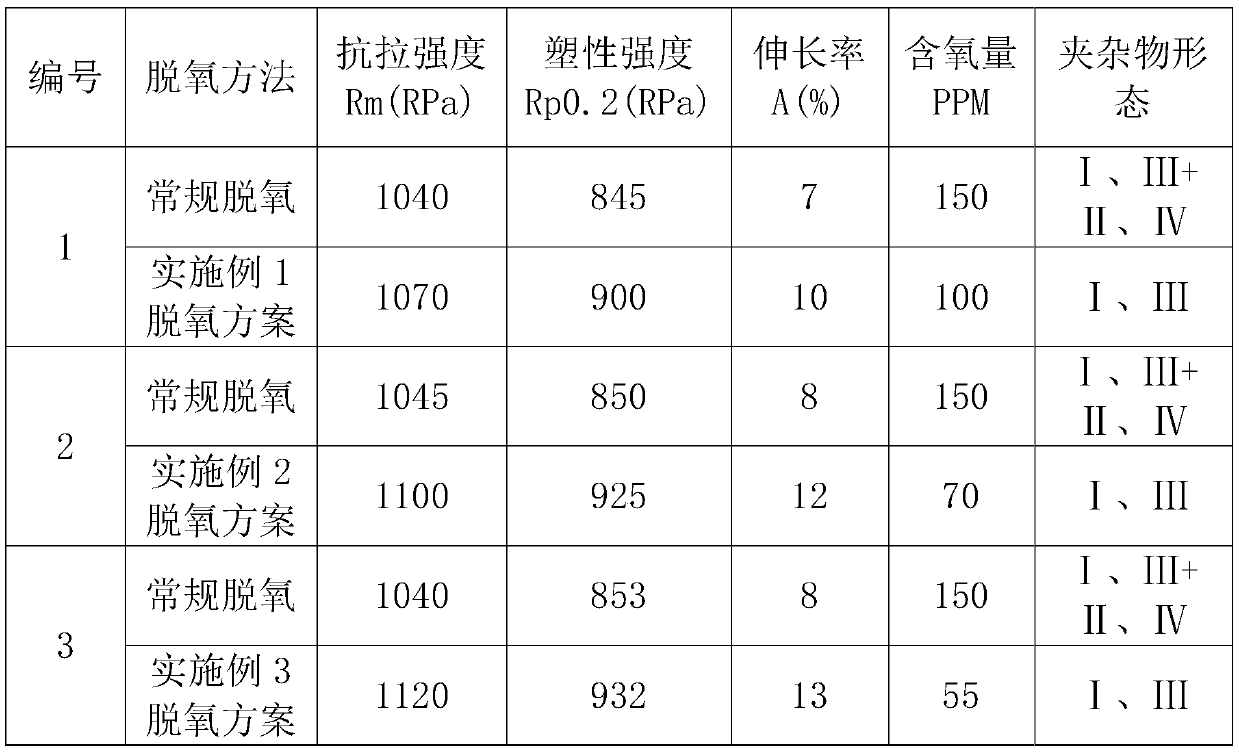

Embodiment 1

[0038] A kind of cast steel deoxidation alloy of this embodiment comprises the following components according to mass percentage:

[0039] Re (rare earth): 20%, Ca: 15%, Ba: 10%, Ti: 15%, Zr: 15%, Si: 10%, Mg: 1.5%, and the balance is Fe.

[0040]The Re rare earth is light rare earth composed of lanthanum rare earth and cerium rare earth, and the mass percentage between lanthanum rare earth and cerium rare earth is 70% and 30% respectively; silicon, calcium, and barium are metal elements, and calcium, barium, silicon Combination elements have high-efficiency deoxidation and grain refinement effects in cast steel, and the oxygen-sulfur compounds generated in the molten steel are dispersed in a spherical shape. The inclusions in this form are beneficial to exclude and improve the performance of cast steel; and the three The contents are coordinated with each other, the calcium content is 1.5 times that of barium, and the calcium content is 1.5 times that of silicon. During deoxi...

Embodiment 2

[0053] A cast steel deoxidation alloy in this embodiment is basically the same as in Embodiment 1, except that the components of the deoxidation alloy in this embodiment include Re: 25%, Ca: 12%, and Ba: 8 by mass percentage. %, Ti: 18%, Zr: 15%, Si: 12%, Mg: 2%, and the balance is Fe.

[0054] Among them, Re rare earth adopts light rare earth composed of lanthanum rare earth and cerium rare earth, and the mass percentage between lanthanum rare earth and cerium rare earth is 75% and 25% respectively; the quality of Ca is 1.5 times of the quality of Ba, and the quality of Ca is the quality of Si 1 times that of Zr; the mass of Ti is 1.2 times that of Zr; the mass ratio of (Re+Mg):(Ca+Ba+Si):(Ti+Zr) is 1:1.2:1.2.

[0055] The processing method of deoxidation alloy in the present embodiment is as follows:

[0056] Step 1. Add steel scrap into the melting furnace, melt it for 15 minutes under 300KW power, then add 150 kg of ferrosilicon, after the ferrosilicon is melted, add 150 ...

Embodiment 3

[0063] A cast steel deoxidation alloy in this embodiment is basically the same as in Embodiment 1, except that the components of the deoxidation alloy in this embodiment include Re rare earth: 18%, Ca: 15%, Ba: 10% by mass percentage. %, Ti: 15%, Zr: 5%, Si: 10%, Mg: 2.5%, and the balance is Fe.

[0064] Wherein Re rare earth adopts yttrium-based heavy rare earth, and the mass percentage of yttrium rare earth in this heavy rare earth is greater than 90%, and the balance can be any rare earth; The quality of Ca is 1.5 times of the quality of Ba, and the quality of Ca is 1 / 2 of the quality of Si 1.5 times; the content of Ti is 3 times that of Zr; the mass ratio of (Re+Mg):(Ca+Ba+Si):(Ti+Zr) is 1:1.75:1.

[0065] The processing method of deoxidation alloy in the present embodiment is as follows:

[0066] Step 1. Add steel scrap to the melting furnace, melt it for 10 minutes under 200KW power, then add 100 kg of ferrosilicon, after the ferrosilicon is melted, add 100 kg of molten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com