Special desoxidant for petroleum tube steel

A technology of petroleum pipes and deoxidizers, which is applied in the field of steel for petroleum pipes, can solve problems such as increased costs, achieve the effects of reducing smelting power consumption and shortening smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Al 22%, AI2O3 28%, SiO? 0.1, C 0.1, non-water-soluble binder 0.1, additive 5%, the balance is Fe, and the particle size of Al and AI2O3 is 1mm.

Embodiment 2

[0012] Al 33%, AI2O3 43%, SiO? 3%, C 2%, non-water-soluble binder 0.3%, additive 18%, the balance is Fe, and the particle size of Al and AI2O3 is 3mm.

Embodiment 3

[0014] Al 25%, AI2O3 35%, SiO? 1.5%, C 1.2%, non-water-soluble binder 0.2%, additive 10%, the balance is Fe, and the particle size of Al and AI2O3 is 5mm.

[0015] Example 3

[0016] Al 30%, AI2O3 38%, SiO? 2.5%, C 1.5%, non-water-soluble binder 0.2%, additive 15%, the balance is Fe, and the particle size of Al and AI2O3 is 4mm.

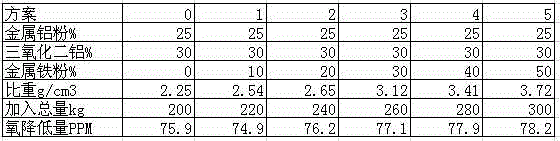

[0017] The following table shows that in schemes 0-5, with the increase of iron powder, the specific gravity increases, and the deoxidation effect continues to improve:

[0018]

[0019] In a 200-ton ladle in a steel plant, the steel type is SPHC, and under the condition of adding 200kg of aluminum and iron, the deoxidation is compared with 0-5 of the present invention, and it is found that when the specific gravity increases, the deoxidation effect is improved. The specific gravity of the deoxidizer is increased, the phenomenon of metal aluminum burning on the slag surface is reduced, the utilization rate of metal aluminum is improved, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com