Hydrogen plasma deoxidation method for chromium powder

A technology of hydrogen plasma and chromium powder is applied in the field of ion deoxidation, which can solve the problems of small processing capacity, long time and sintering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

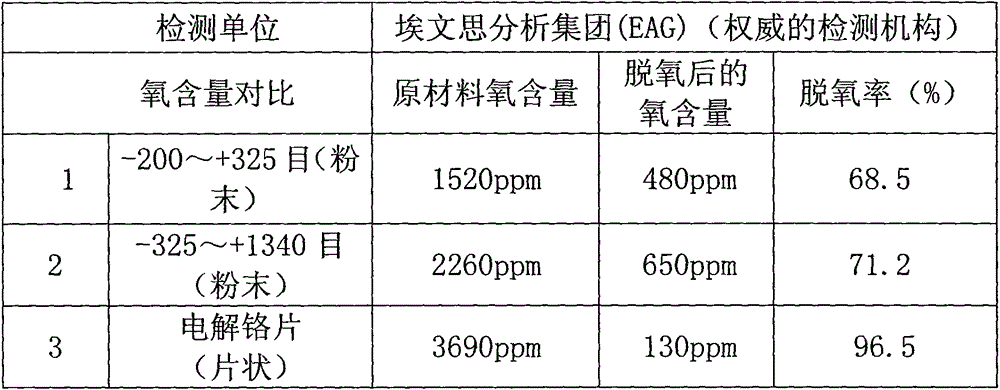

Examples

Embodiment 1

[0026] A hydrogen plasma deoxidation method of chromium powder, comprising the following steps:

[0027] 1) Select the metal chromium block, remove the surface skin, oxide film and nitrogen film; then use the hydraulic coarse crusher with circulating water cooling device to mechanically crush the chromium block to make it into particles below 3mm;

[0028] 2) Using the low-temperature brittleness of chromium, immerse the metal chromium particles in liquid nitrogen, and perform low-temperature vibration grinding at the same time. The low-temperature vibration grinding uses nano-Al 2 o 3 with ZrO 2 The vibrating mill cylinder liner and grinding body made of mixed high-toughness ceramic materials are carried out for 3 hours;

[0029] 3) Wash the metal chromium powder ground by low-temperature liquid nitrogen three times with ethanol, each time with an amount of 600ml, then use a vacuum system with filter paper to filter, and then in a vacuum oven, at 80°C and a vacuum of 94.5KP...

Embodiment 2

[0033] A hydrogen plasma deoxidation method of chromium powder, comprising the following steps:

[0034] 1) Select the metal chromium block, remove the surface skin, oxide film and nitrogen film; then use the hydraulic coarse crusher with circulating water cooling device to mechanically crush the chromium block to make it broken into particles below 3mm;

[0035] 2) Using the low-temperature brittleness of chromium, immerse the metal chromium particles in liquid nitrogen, and perform low-temperature vibration grinding at the same time. The low-temperature vibration grinding uses nano-Al 2 o 3 with ZrO 2 The vibrating mill cylinder liner and grinding body made of mixed high-toughness ceramic materials are carried out for 5 hours;

[0036] 3) Wash the metal chromium powder ground by low-temperature liquid nitrogen three times with ethanol, each dosage is 500ml, then use a vacuum system with filter paper to filter, and then in a vacuum oven, at 80°C and a vacuum of 96.5KPa Dry...

Embodiment 3

[0040] A hydrogen plasma deoxidation method of chromium powder, comprising the following steps:

[0041] 1) Select the metal chromium block, remove the surface skin, oxide film and nitrogen film; then use the hydraulic coarse crusher with circulating water cooling device to mechanically crush the chromium block to make it broken into particles below 3mm;

[0042] 2) Using the low-temperature brittleness of chromium, immerse the metal chromium particles in liquid nitrogen, and perform low-temperature vibration grinding at the same time. The low-temperature vibration grinding uses nano-Al 2 o 3 with ZrO 2 The vibrating mill cylinder liner and grinding body made of mixed high-toughness ceramic materials are carried out for 4 hours;

[0043] 3) Wash the metal chromium powder ground by low-temperature liquid nitrogen three times with ethanol, each dosage is 550ml, then use a vacuum system with filter paper to filter, and then in a vacuum oven, at 80°C and a vacuum of 95.5KPa Dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com