Magnetic thermal field cooperate with oxygen-enriched air generating device

An oxygen-enriched air generating device technology, applied in the direction of oxygen preparation, etc., to achieve the effect of simple device structure, low energy consumption and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

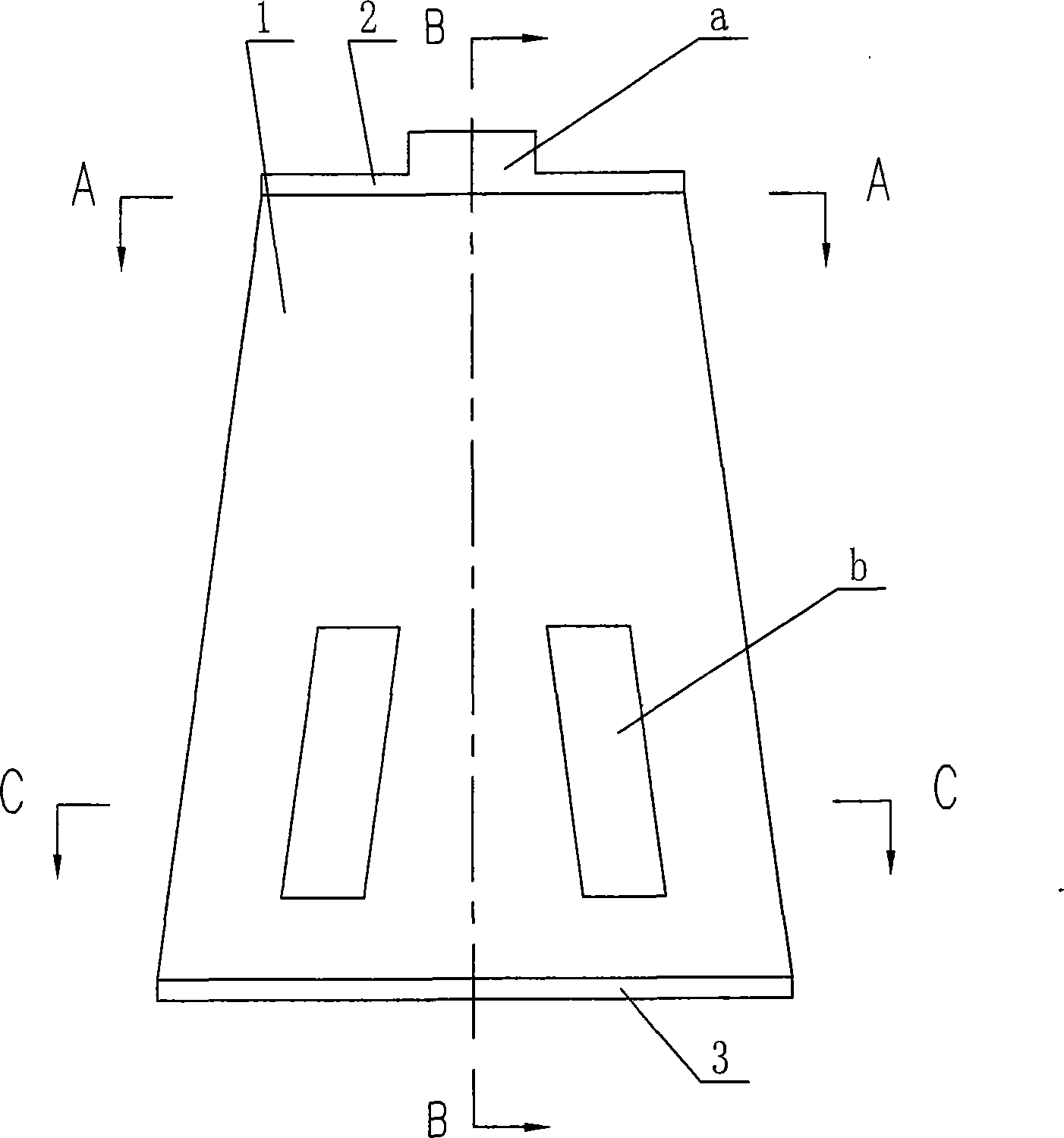

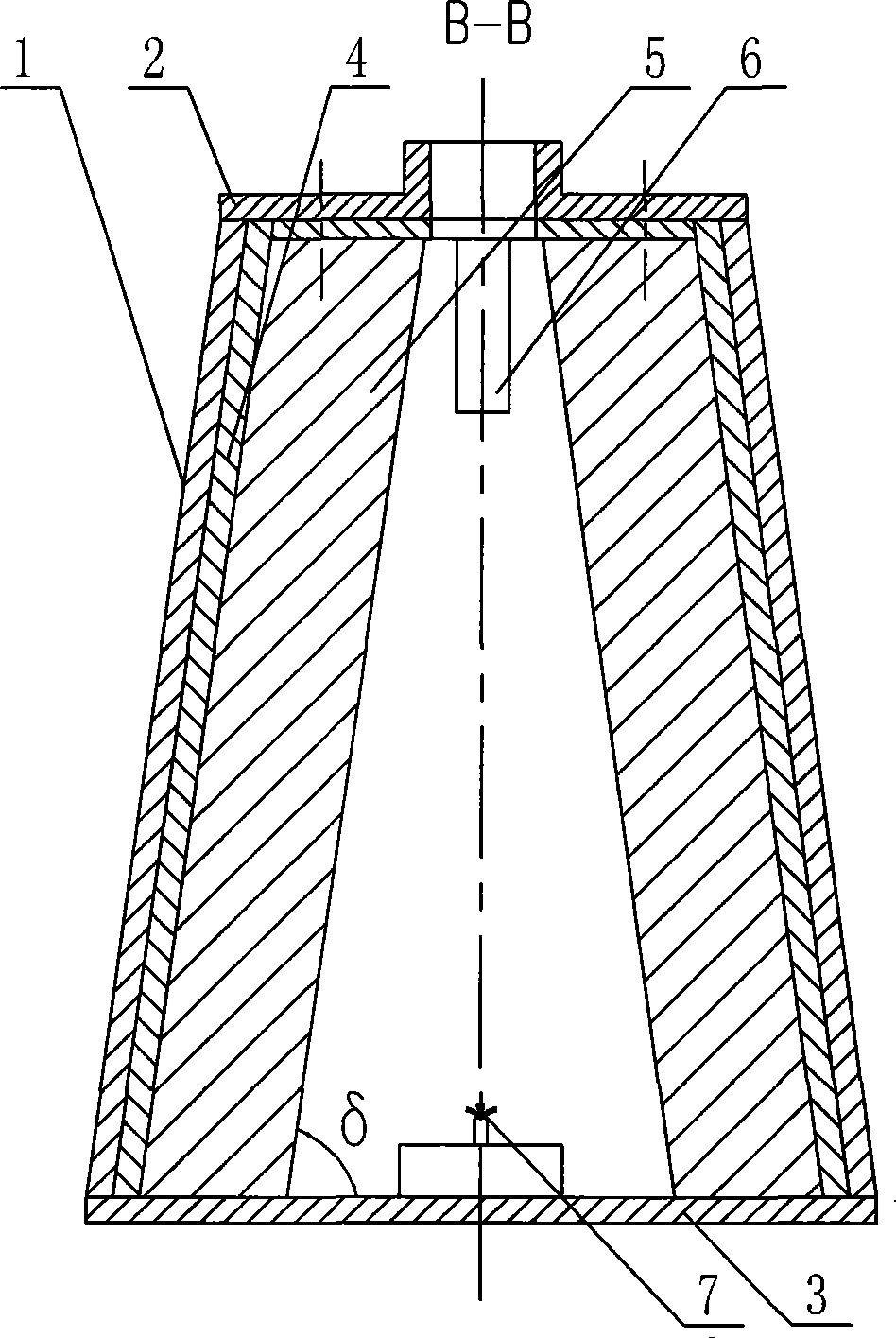

[0027] exist Figure 1~4 Among them, the magnetothermal field cooperative oxygen-enriched air generating device of this embodiment is composed of a housing 1, an upper cover 2, a base 3, a permanent magnet 4, a magnetic shoe 5, a heater 6, and an air negative ion generator 7.

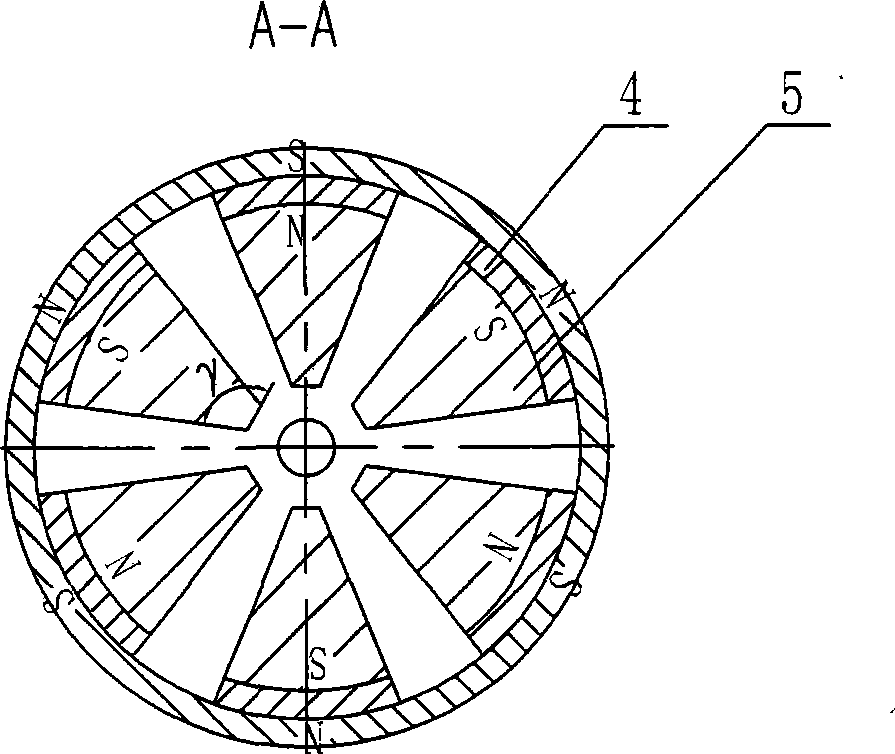

[0028] The shape of the housing 1 of this embodiment is a circular truncated tubular housing, which is a housing made of magnetically conductive material. The upper end of the housing 1 is fixedly connected with a loam cake 2. The loam cake 2 is a loam cake made of non-magnetic material. The center position is processed with an air outlet a, the lower end of the housing 1 is fixedly connected with a base 3, the base 3 is a non-magnetic material base 3, the inner wall of the housing 1 is evenly distributed in the circumferential direction with 6 permanent magnets 4, and the permanent magnet 4 at the lower part of the side wall There are 6 air inlets b processed between them, and the shape of the air inle...

Embodiment 2

[0030] The shape of the casing 1 of this embodiment is a truncated conical tubular casing. The inner wall of the casing 1 is evenly distributed with 6 permanent magnets 4 in the circumferential direction, and 6 air inlets b are processed between the permanent magnets 4 at the lower part of the side wall. The shape is the same as in Example 1. The shape of the permanent magnet 4 cross-section is a tile-shaped body structure, and the length ratio of the outer circular arc line of the upper and lower end faces of the tile-shaped permanent magnet 4 is 1. The inner surface of the permanent magnet 4 is adsorbed with a magnetic shoe 5, and the radial side of the permanent magnet 4 and the magnet. The radial side of the shoe 5 is in the same plane, the angle γ between the radial side of the upper end of the magnetic shoe 5 and the inner end surface is 110°, the angle δ between the inner surface of the magnetic shoe 5 and the base 3 is 45°, adjacent There is a gap communicating with th...

Embodiment 3

[0032]The shape of the housing 1 of this embodiment is a truncated conical tubular housing, and the shape of the housing 1 is a truncated circular tubular housing. The inner wall of the housing 1 is evenly distributed circumferentially with 6 permanent magnets 4, and between the permanent magnets 4 at the bottom of the side wall There are 6 air inlets b processed, and the shape of the air inlets b is the same as that of embodiment 1. The shape of the permanent magnet 4 cross-section is a tile-shaped body structure, and the length ratio of the outer circular arc line of the upper and lower end faces of the tile-shaped permanent magnet 4 is 1. The inner surface of the permanent magnet 4 is adsorbed with a magnetic shoe 5, and the radial side of the permanent magnet 4 and the magnet. The radial sides of the shoe 5 are in the same plane, the angle γ between the radial side of the upper end of the magnetic shoe 5 and the inner end surface is 110°, the angle δ between the inner surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com