Laser mould pressing alcohol soluble aluminizing transfer paint and preparation method and application thereof

A transfer coating, alcohol-soluble technology, applied in the direction of coating, printing of special varieties of printed matter, printing process, etc., can solve the problem of not getting rid of the influence of harmful solvent volatilization and residue, achieve excellent adhesion, reduce pollution, peel off good transferability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for preparing an environment-friendly laser moldable alcohol-soluble aluminized transfer coating comprises the following process steps:

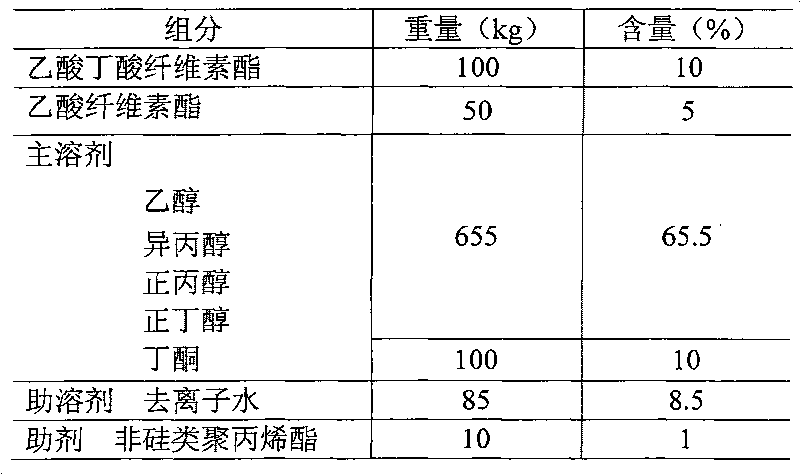

[0054] (1) prepare raw materials according to the following components and content (weight %):

[0055]

[0056] Among the above raw materials: cellulose acetate butyrate molecular weight MW n e is 20,000, the hydroxyl content is 5%, and the Tg value is 135°C; the molecular weight of cellulose acetate is MW n e is 40,000, the hydroxyl content is 4%, and the Tg value is 150°C; the weight ratio of alcohol solvent in the main solvent: ethanol 10-20, isopropanol 20-30, n-propanol 6-15, n-butanol 8- 15.

[0057] (2) Add the main solvent and co-solvent into the reaction kettle in sequence, stir and heat to about 50°C;

[0058] (3) Add cellulose acetate butyrate and cellulose acetate into the reaction kettle, and stir at a high speed of 500-700 rpm for 30-40 minutes to completely dissolve them;

[0059] (4) Add the additive...

Embodiment 2

[0073] A method for preparing an environment-friendly laser moldable alcohol-soluble aluminized transfer coating comprises the following process steps:

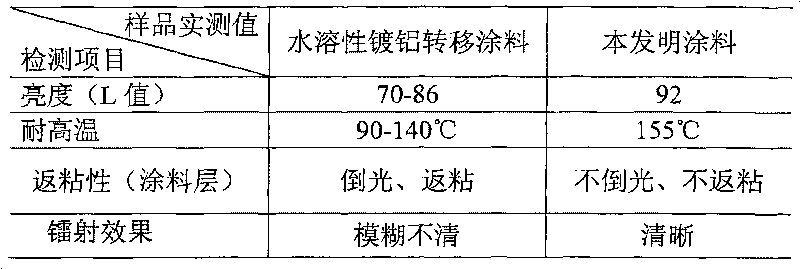

[0074] (1) prepare raw materials according to the following components and content (weight %):

[0075]

[0076] Among the above raw materials, the molecular weight of cellulose acetate propionate MW n e It is 15,000, the hydroxyl content is 5%, and the Tg value is 155°C; the acrylic resin is a copolymer of methyl methacrylate and epoxy acrylate, and its molecular weight MW n e is 55,000, the acid value is 40mg KOH / g, and the Tg value is 95°C; the weight ratio of alcohol solvent in the main solvent: ethanol 15-20, isopropanol 20-25, n-propanol 6-10, n-butyl 9 Alcohol 8-18.

[0077] (2) Add the main solvent and co-solvent into the reaction kettle in sequence, stir and heat to about 60°C;

[0078] (3) Add cellulose acetate propionate into the reaction kettle and stir at high speed for about 40 minutes (500-700 rpm) to m...

Embodiment 3

[0087] A method for preparing an environment-friendly laser moldable alcohol-soluble aluminized transfer coating comprises the following process steps:

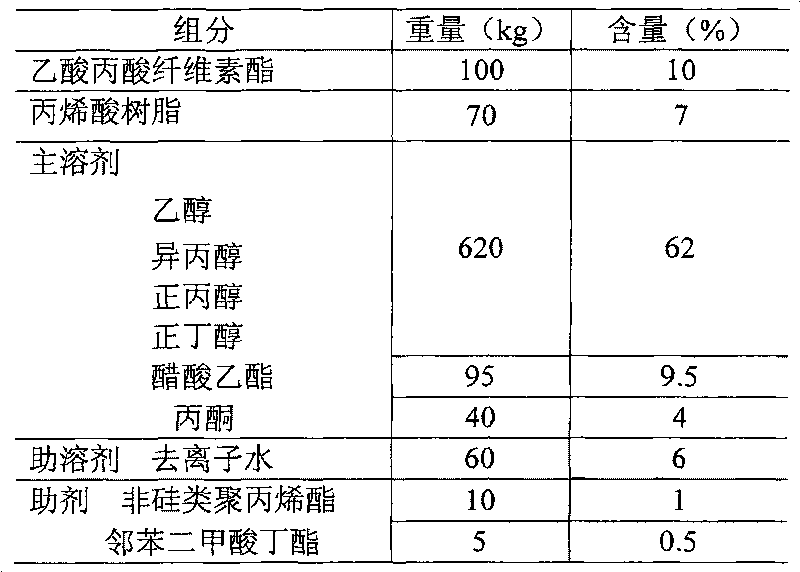

[0088] (1) prepare raw materials according to the following components and content (weight %):

[0089]

[0090] Among the above-mentioned raw materials, the acrylic resin is a copolymer of methyl methacrylate, epoxy acrylate and ethylene methyl acrylate, and its molecular weight MW n e is 125,000, the acid value is 60mg KOH / g, and the Tg value is 150°C; the weight ratio of the alcohol solvent in the main solvent is: ethanol 20-30, isopropanol 15-25, n-propanol 5-10, n-butyl Alcohol 5-15.

[0091] (2) Add the main solvent and co-solvent into the reaction kettle in sequence, stir and heat to about 65°C;

[0092] (3) After it is completely dissolved, add acrylic resin and stir at high speed (500-700 rpm) for about 60 minutes to completely dissolve it;

[0093] (4) Add the additives into the reaction kettle and stir at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com