Material spraying device for combusting and feeding biomass bagasse

A technology of biomass and material feeding, which is applied in the direction of combustion method, combustion equipment, fuel supply, etc., and can solve the problems of combustion in the furnace, incomplete combustion of bagasse, and reduction of boiler thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

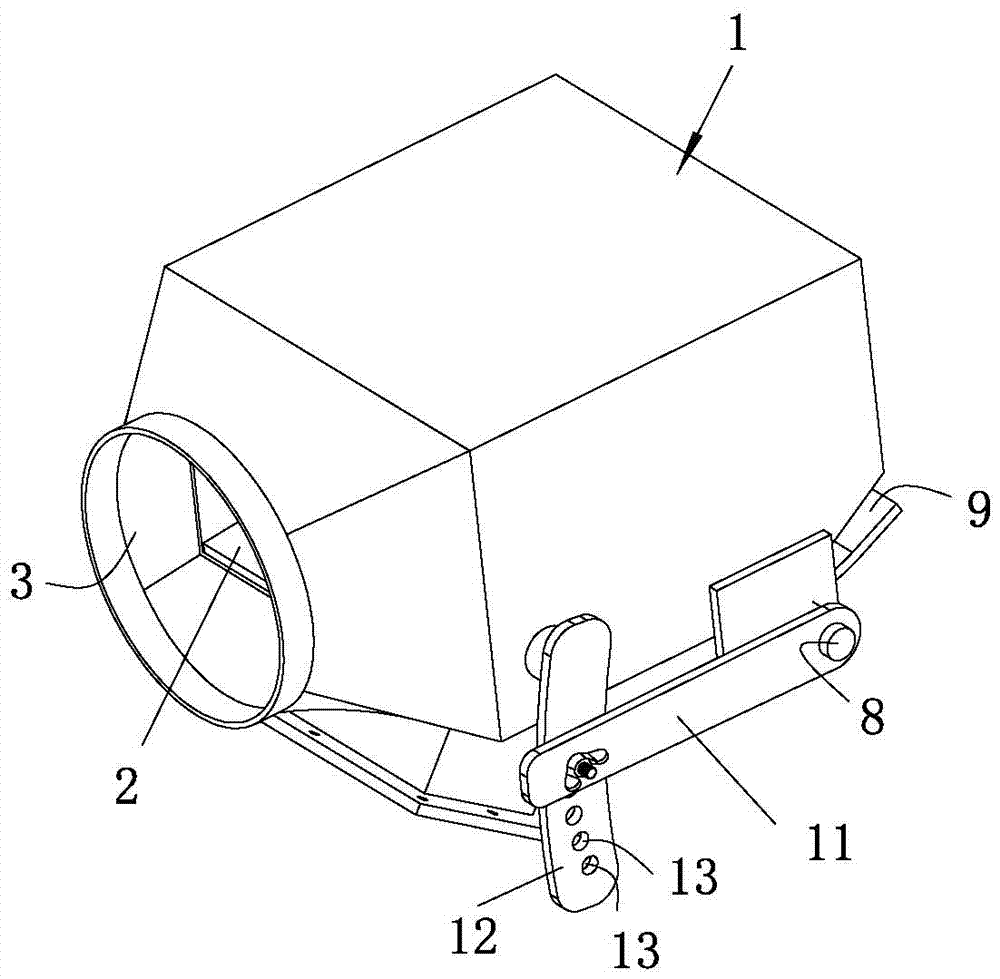

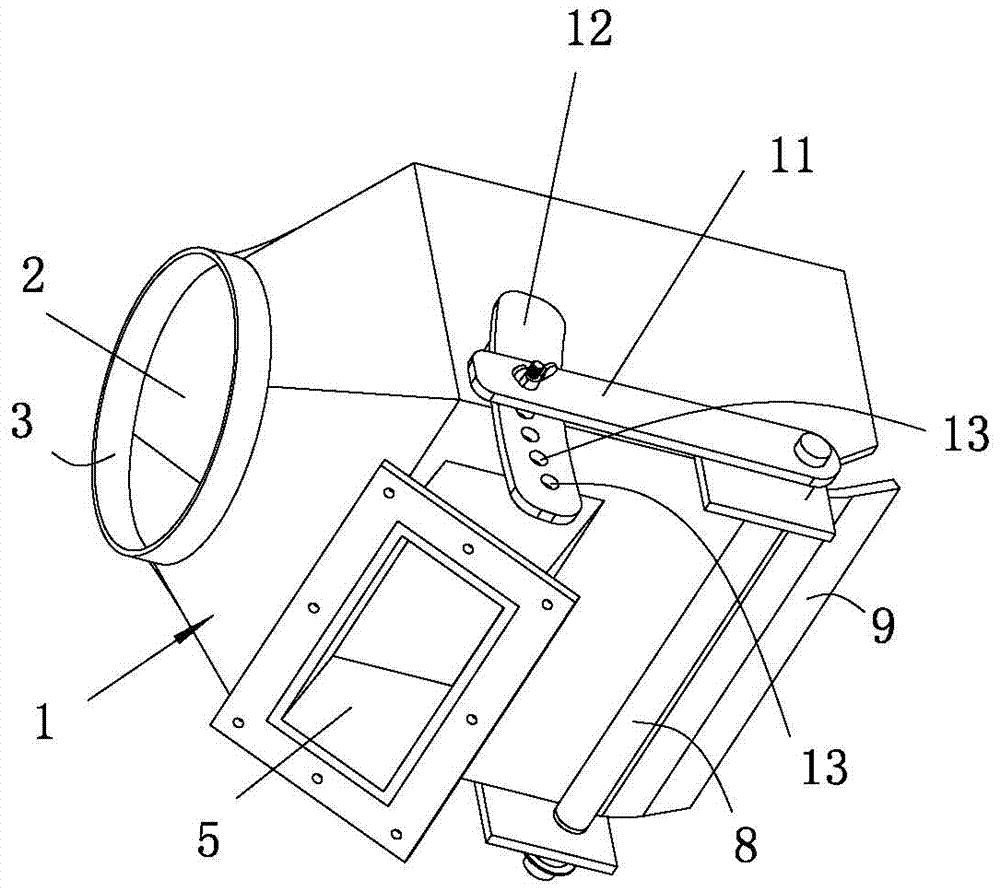

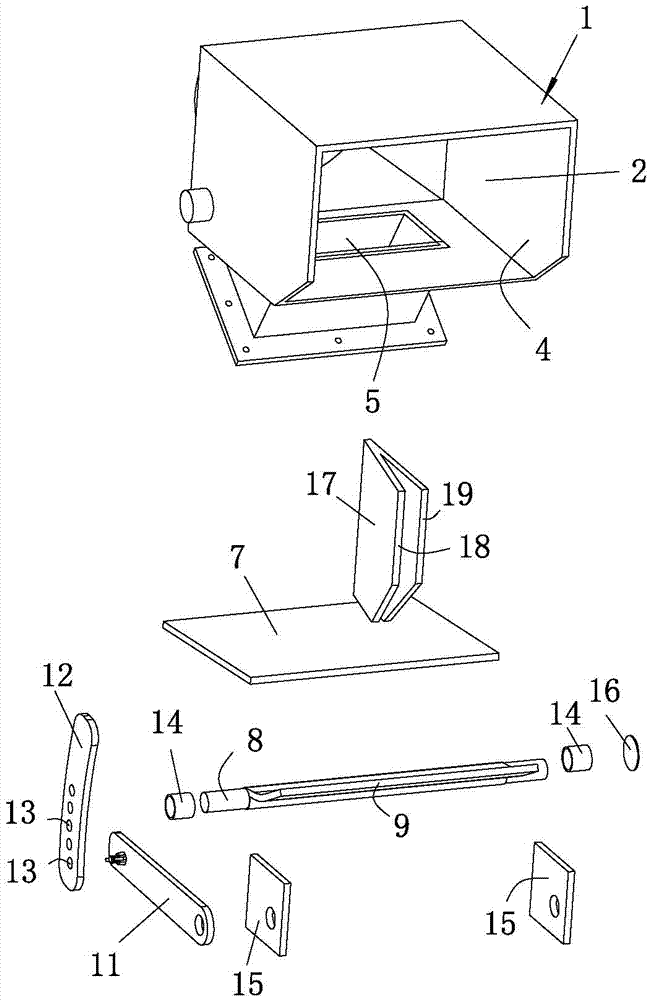

[0036] see Figure 1 to Figure 5 As shown, a feeder for biomass bagasse burning and feeding according to the present invention includes a housing 1, the housing 1 is provided with a feeding hole 2 penetrating through the housing 1, and the feeding hole 2 runs through the housing 1 along the left and right direction, The two ends of the feed hole 2 are respectively the feed port 3 and the discharge port 4. The housing 1 is also provided with an air inlet 5 connected to the feed hole 2. The end of the air inlet 5 away from the feed hole 2 is an air inlet. The end that the hole 5 communicates with the feed hole 2 is a communication port 6; the housing 1 is equipped with a sandwich plate 7 located in the feed hole 2, and the sandwich plate 7 blocks the communication between the feed port 3 and the communication port 6, and the air intake The hole 5 communicates with the discharge port 4 via the gap between the interlayer plate 7 and the housing 1 .

[0037] In actual use, the bio...

Embodiment 2

[0054] In this embodiment, preferably, the shell 1 is a metal alloy shell, and the metal alloy for the shell is composed of the following components by weight percentage: Cr 16%, Ni 8%, Si 2%, Mn 0.6%, Ti 0.02%, Sc 0.03%, Ce 0.1%, Nb 0.02%, Mo 0.02%, Cu 0.25%, P 0.02%, S 0.01%, N 0.12%, C 0.04%, and the balance is Fe.

[0055] Preferably, the preparation method of the metal alloy for the shell comprises the following steps:

[0056] (1) Add other components except Sc and Ce according to the above ratio, and melt in a vacuum induction furnace. After all the components are melted, add a deoxidizer Ca of 0.08% by weight of the alloy melt to deoxidize the alloy melt ; Add Sc and Ce alloy melts after deoxidation, and keep stirring for 3 minutes; after standing for 2 minutes, pour the alloy melt into a casting mold to form an ingot. Alloy ingots released;

[0057] (2) Forging the alloy ingot out of the furnace at a temperature of 1050°C; then hot rolling the forged alloy ingot at ...

Embodiment 3

[0062] In this embodiment, the shell 1 is a metal alloy shell, and the metal alloy for the shell is composed of the following components in weight percentage: Cr 18%, Ni 5%, Si 3%, Mn 0.2%, Ti-0.04% , Sc 0.06%, Ce0.05%, Nb 0.04%, Mo0.01%, Cu 0.35%, P 0.01%, S 0.02%, N 0.08-0.12%, C 0.0.07%, and the balance is Fe.

[0063] Preferably, the preparation method of the metal alloy for the shell comprises the following steps:

[0064] (1) Add other components except Sc and Ce according to the above ratio, and melt in a vacuum induction furnace. After all the components are melted, add a deoxidizer Ca of 0.15% by weight of the alloy melt to deoxidize the alloy melt. ; Add Sc and Ce alloy melts after deoxidation, and stir continuously for 5 minutes; after standing for 4 minutes, pour the alloy melt into a casting mold to form an ingot. The casting temperature is 1600 ° C. After the mold is cooled, the Alloy ingots released;

[0065] (2) Forging the alloy ingot out of the furnace at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com