Intelligent tester and testing method for testing gas ratio and heat capacity ratio

A technology of specific heat ratio and test method, applied in the field of gas specific heat ratio test, can solve the problems of intuitive understanding of unfavorable physical phenomena and complicated operation, and achieve the effect of easy observation and understanding, good repeatability, and convenient observation of experimental data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

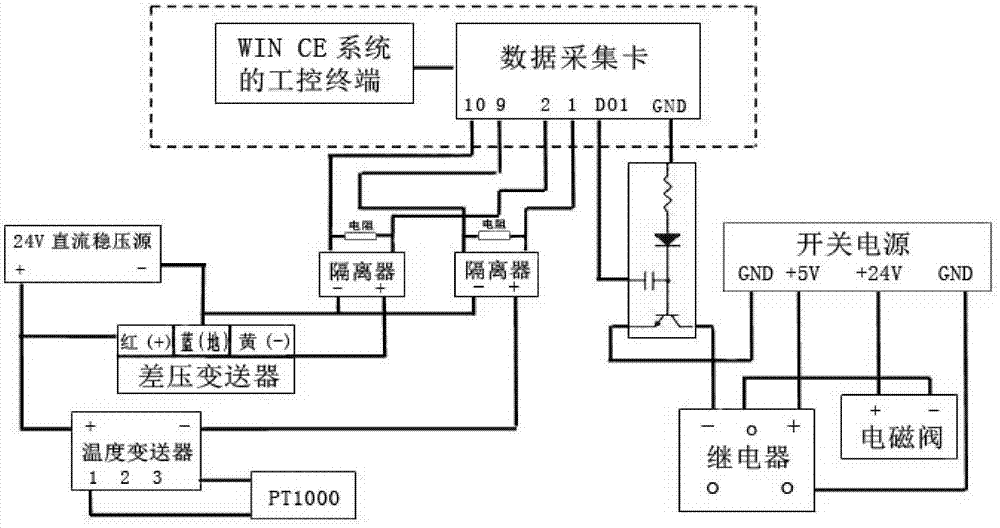

Embodiment 1

[0061] Such as figure 1 Shown, the gas specific heat capacity ratio intelligent tester of the present invention comprises gas storage unit, control unit and gas injection unit (syringe), and wherein gas storage unit comprises gas storage bottle (glass bottle), sealing plug (rubber stopper) and air guide tube; The unit includes differential pressure sensor (wind pressure transmitter), temperature sensor (PT1000 temperature sensor), data acquisition unit (NET0724 Ethernet data acquisition card), industrial control terminal (integrated with Ethernet controller, serial port, SD card controller, USBHost controller), touch screen, solenoid valve and solenoid valve control circuit and power supply module; the sealing plug is installed on the upper mouth of the gas storage bottle, the signal acquisition ends of the differential pressure sensor and the temperature sensor are respectively inserted in the gas storage bottle, and the signal output end is installed in the gas storage bottl...

Embodiment 2

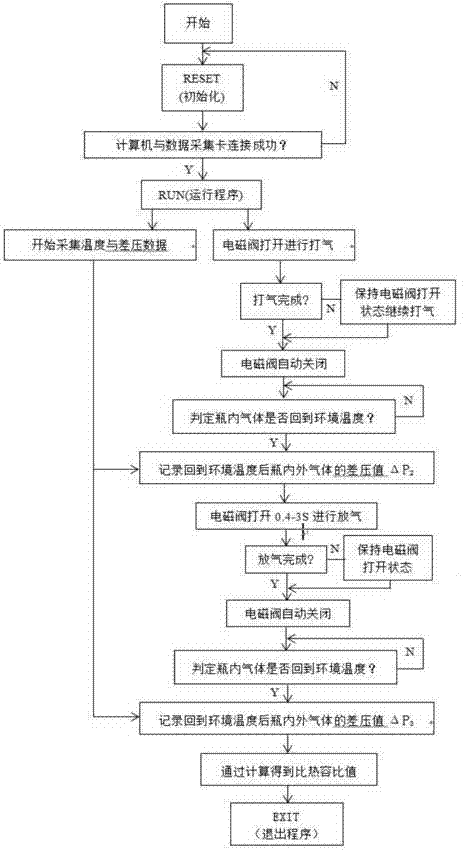

[0063] The test method of gas specific heat capacity ratio of the present invention, test process step is as follows, as figure 2 Shown:

[0064] 1) Power on the system and start the gas specific heat capacity ratio tester;

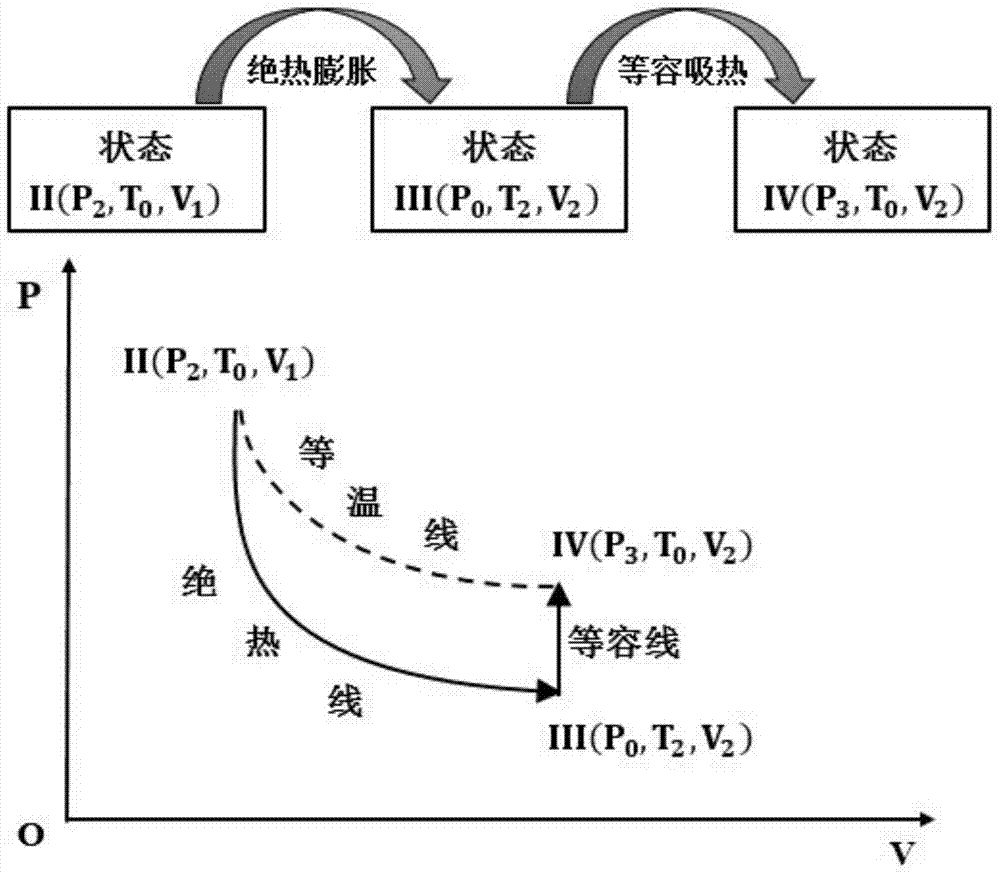

[0065] 2) Run the experimental program on the industrial control terminal, the solenoid valve is opened, the gas in the gas storage cylinder is communicated with the outside atmosphere, and the gas to be tested under normal temperature and pressure (P 0 ,T 0 ) is injected through the air guide tube on the solenoid valve to a volume of V 1 If the gas to be measured is not air, it needs to be vacuumed and injected; after the injection is completed, the solenoid valve will automatically close, and the state of the gas in the gas cylinder is I(P 1 ,T 1 , V 1 ), disconnect the gas injection unit and the air duct, and prepare to deflate;

[0066] 3) Isovolumetric exothermic process: After the previous step, the gas in the gas storage cylinder begins to u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com