High-power optical fiber laser for anhydrous cooling heat capacity

A fiber laser, high-power technology, applied to lasers, laser components, phonon exciters, etc., can solve problems that have not been reported in the field of laser temperature control, achieve good anti-vibration performance, stable thermal surface temperature, and reduce complexity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

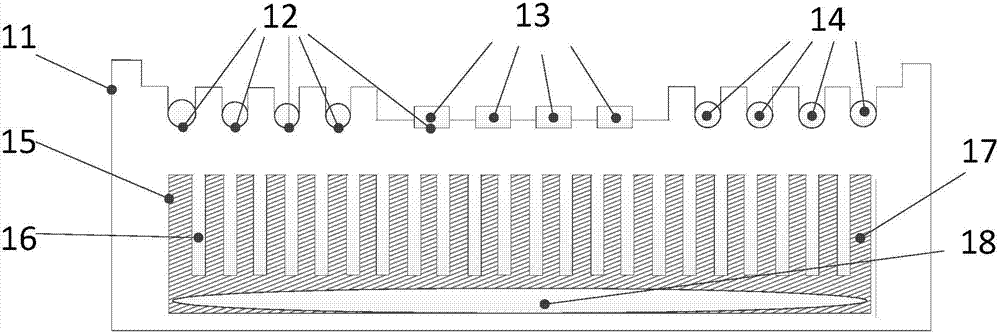

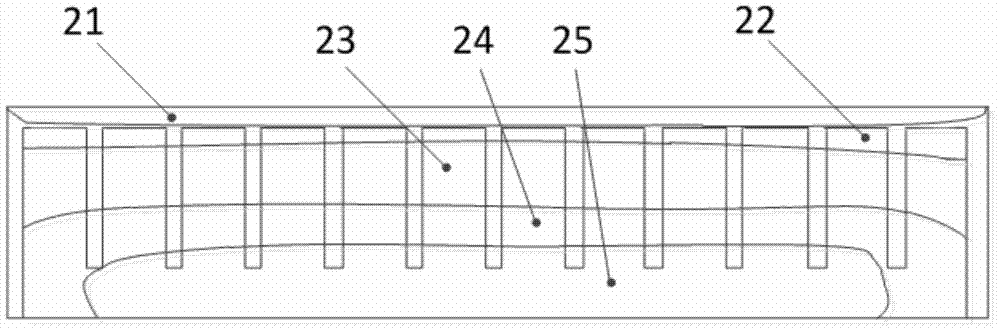

[0019] In the following, combined with the accompanying drawings, an optimal solution for water-free cooling of high-power fiber lasers with heat capacity is proposed, such as figure 1 As shown, a high-power fiber laser with water-free cooling heat capacity includes a substrate 11, a heat sink 12, an LD, a passive device 13, and an optical fiber 14. The upper surface of the substrate 11 is provided with a plurality of symmetrical heat sinks 12, LD and passive devices 13 and optical fibers 14 are placed on the substrate 11. The substrate 11 is provided with a hollow structure 15, a heat conduction sheet 16, a phase change material 17 and an air bag 18 filled with it. sheet 16, the lower end of the hollow structure 15 is placed with a flexible air bag 18, the density of the phase change material 17 is different in solid state and liquid state, and the phase change material 17 gradually changes from solid to liquid in the process of absorbing heat, the volume of the phase change m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com