Method for two frequency point sound measurement of heat capacity of ideal gas

An ideal gas and sound measurement technology, applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve problems such as systematic errors, and achieve the effect of avoiding systematic errors

- Summary

- Abstract

- Description

- Claims

- Application Information

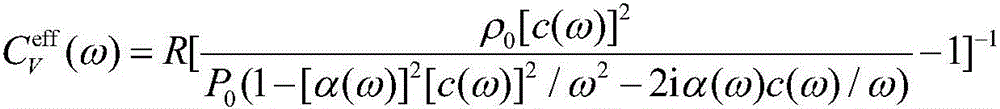

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

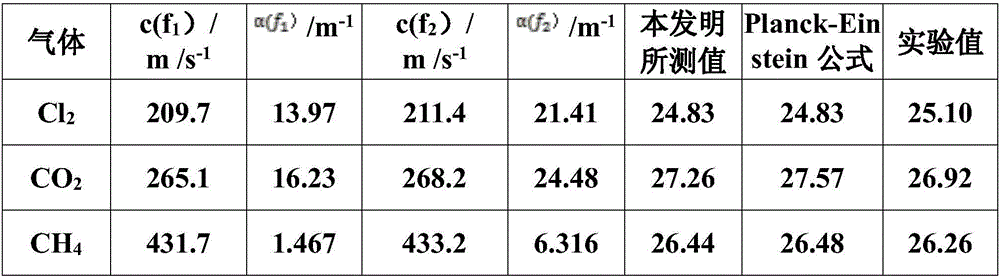

Embodiment 1

[0035] Embodiment 1: a two-frequency point-acoustic measurement method for ideal gas heat capacity, comprising the following steps:

[0036] (1) A dual-frequency signal generator is used to generate dual-frequency signals with sound frequencies of 40 kHz and 125 kHz respectively;

[0037] (2) the dual-frequency signal in the step (1) is converted into ultrasonic waves by the ultrasonic sending probe respectively;

[0038] (3) Ultrasonic wave in step (2) is passed through pure Cl 2 The medium (P=1atm, temperature T=273.15K) in the gas cavity propagates and the electrical signal converted by the ultrasonic receiving probe triggers the interrupt timer in the control module, calculates the time interval between sending and receiving of the signal, and measures the sound velocity c(ω 1 ) and c(ω 2 ) are 209.7m / s and 211.4m / s respectively; the signals received simultaneously and before attenuation enter the dual-channel peak detection module to complete the peak detection process ...

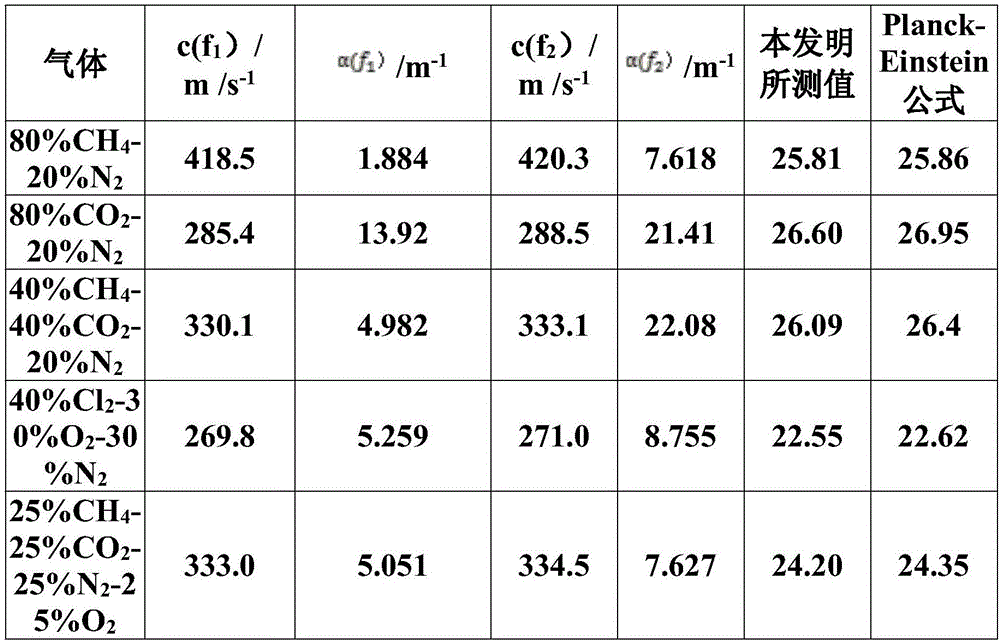

Embodiment 2

[0044] Embodiment 2: a two-frequency point-acoustic measurement method for ideal gas heat capacity, comprising the following steps:

[0045] (1) A dual-frequency signal generator is used to generate dual-frequency signals with sound frequencies of 40kHz and 125kHz respectively;

[0046] (2) the dual-frequency signal in the step (1) is converted into ultrasonic waves by the ultrasonic sending probe respectively;

[0047] (3) Ultrasound in step (2) passes through 80% CH 4 -20%N 2 The medium (P=1atm, temperature T=273.15K) in the gas chamber propagates and the electrical signal converted by the ultrasonic receiving probe triggers the interrupt timer in the control module, calculates the time interval between sending and receiving of the signal, and measures the sound velocity c(ω 1 ) and c(ω 2 ) are 418.5m / s and 420.3m / s respectively; the signal received at the same time and the signal before attenuation enter the dual-channel peak detection module to complete the peak detecti...

Embodiment 3

[0053] Embodiment 3: a two-frequency point-acoustic measurement method for ideal gas heat capacity, comprising the following steps:

[0054] (1) A dual-frequency signal generator is used to generate dual-frequency signals with sound frequencies of 60kHz and 100kHz respectively;

[0055] (2) the dual-frequency signal in the step (1) is converted into ultrasonic waves by the ultrasonic sending probe respectively;

[0056] (3) Ultrasound in step (2) passes through 80% CO 2 -20%N 2 The medium (P=1atm, temperature T=273.15K) in the gas chamber propagates and the electrical signal converted by the ultrasonic receiving probe triggers the interrupt timer in the control module, calculates the time interval between sending and receiving of the signal, and measures the sound velocity c(ω 1 ) and c(ω 2 ) are 287.0m / s and 288.2m / s respectively; the signal received at the same time and the signal before attenuation enter the dual-channel peak detection module to complete the peak detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com