Variable-compression-ratio mechanism of engine

A compression ratio and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of complex crankshaft or connecting rod structure and reduced reliability, and achieve the effect of ensuring safe operation and changing the compression ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

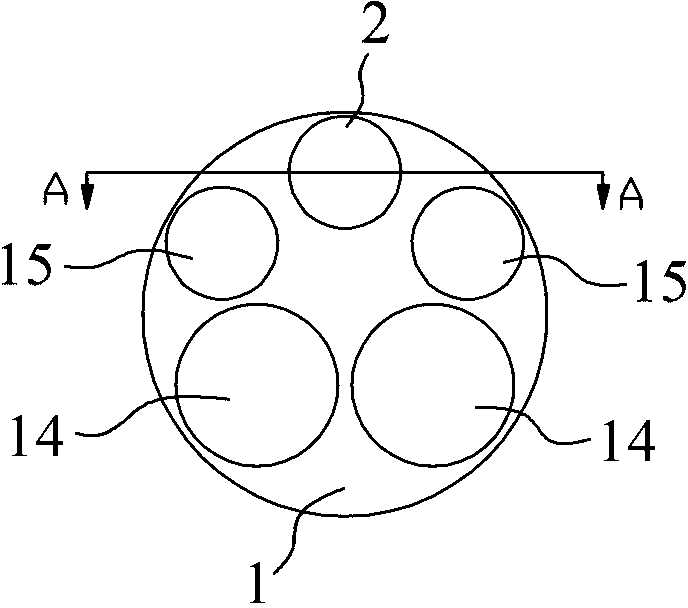

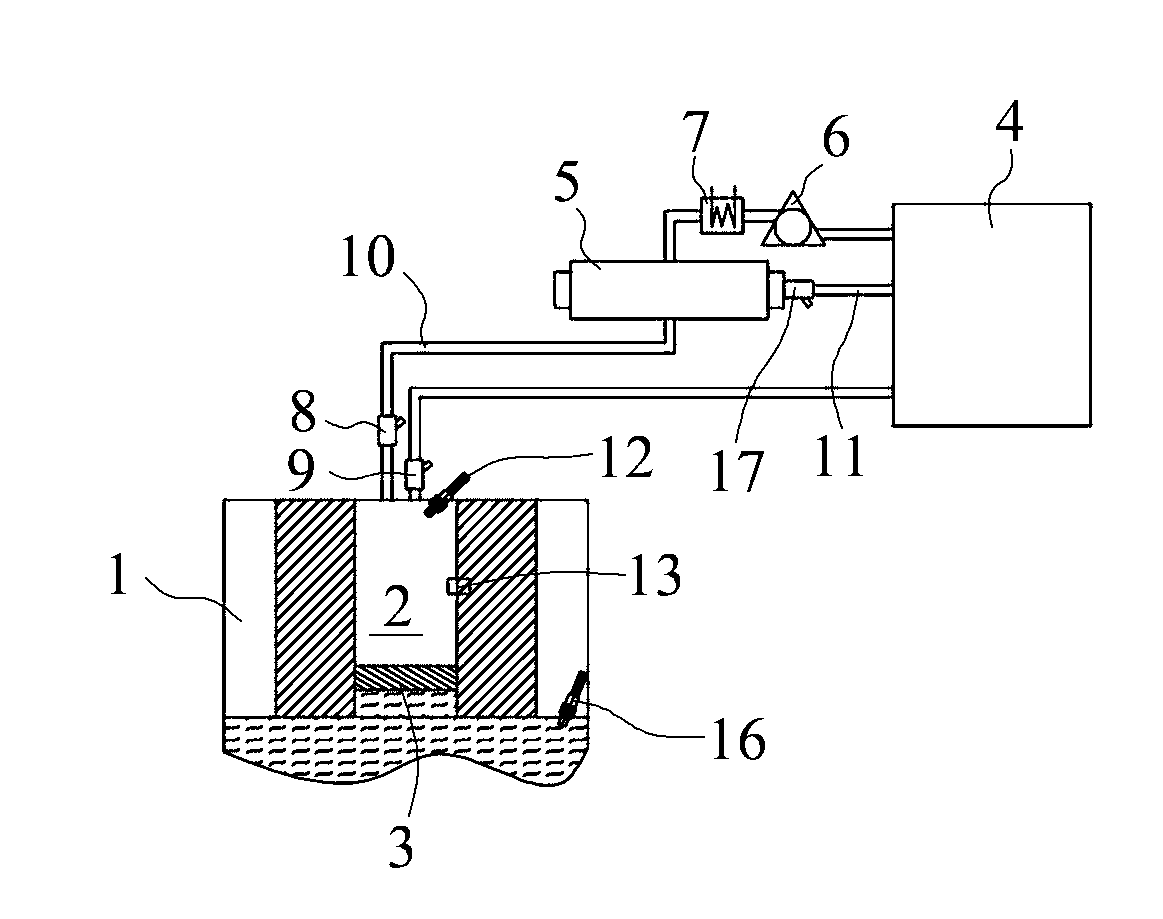

[0014] Such as figure 1 and figure 2 As shown, the engine variable compression ratio mechanism of the present invention includes a cylinder head 1 of the engine, and a hydraulic cylinder 2 communicating with the combustion chamber of the cylinder is arranged on the cylinder head 1. The hydraulic cylinder 2 is located between the engine intake valve 14 and the exhaust valve The space between the valves 15. A variable pressure piston 3 is arranged inside the hydraulic cylinder 2. Driven by the hydraulic device, the variable pressure piston 3 can slide up and down in the hydraulic cylinder 2, thereby changing the volume of the communication part between the hydraulic cylinder 2 and the combustion chamber. Because of being able to change the total volume of the combustion chamber.

[0015] The hydraulic device includes an oil storage tank 4, a high-pressure oil pipe 5, and a high-pressure oil pump 6 that supplies the hydraulic oil in the oil storage tank 4 to the high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com