Tunable capacitor and switch using mems with phase change material

A technology of phase change materials and dielectric materials, applied in the field of MEMS, can solve the problems of MEMS, large capacitor size, high tunability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

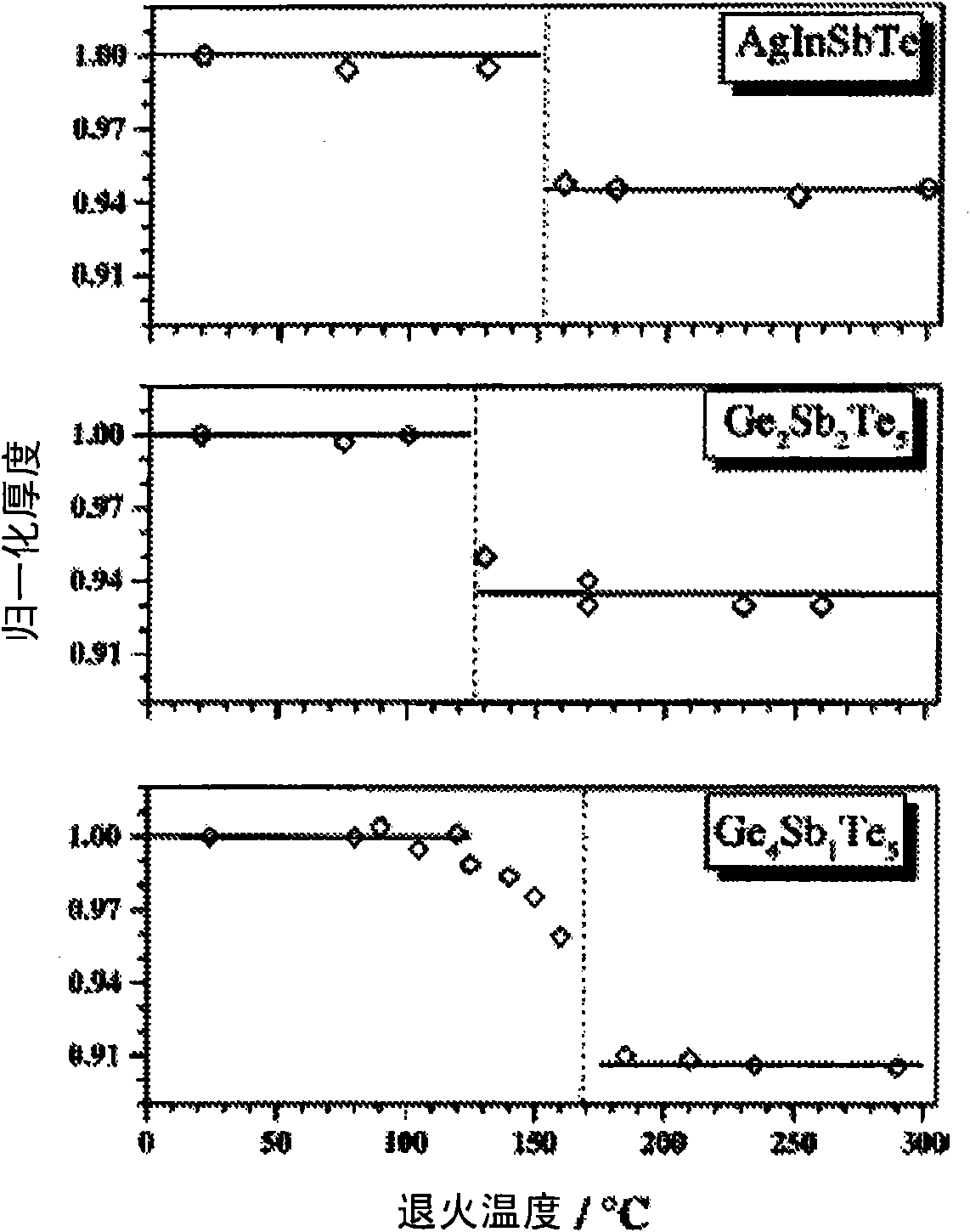

[0075] Figure 1 shows the temperature dependence on the volume of phase change materials .

[0076] AgInSbTe, Ge 2 Sb 2 Te 5 and Ge 4 Sb 1 Te 5 The film thickness is a function of increasing annealing temperature. Crystallization leading to a sudden decrease in film thickness was observed at 155 °C for AgInSbTe and for Ge 2 Sb 2 Te 5 Observed at 130°C, for Ge 4 Sb 1 Te 5Observed at 170°C. To facilitate comparison of different data sets, all thicknesses were normalized relative to the thickness of the as-deposited films. Crystallization leads to a 5.5% reduction in the thickness of AgInSbTe, Ge 2 Sb 2 Te 5 The thickness is reduced by 6.5%, Ge 4 Sb 1 Te 5 The thickness is reduced by 9%.

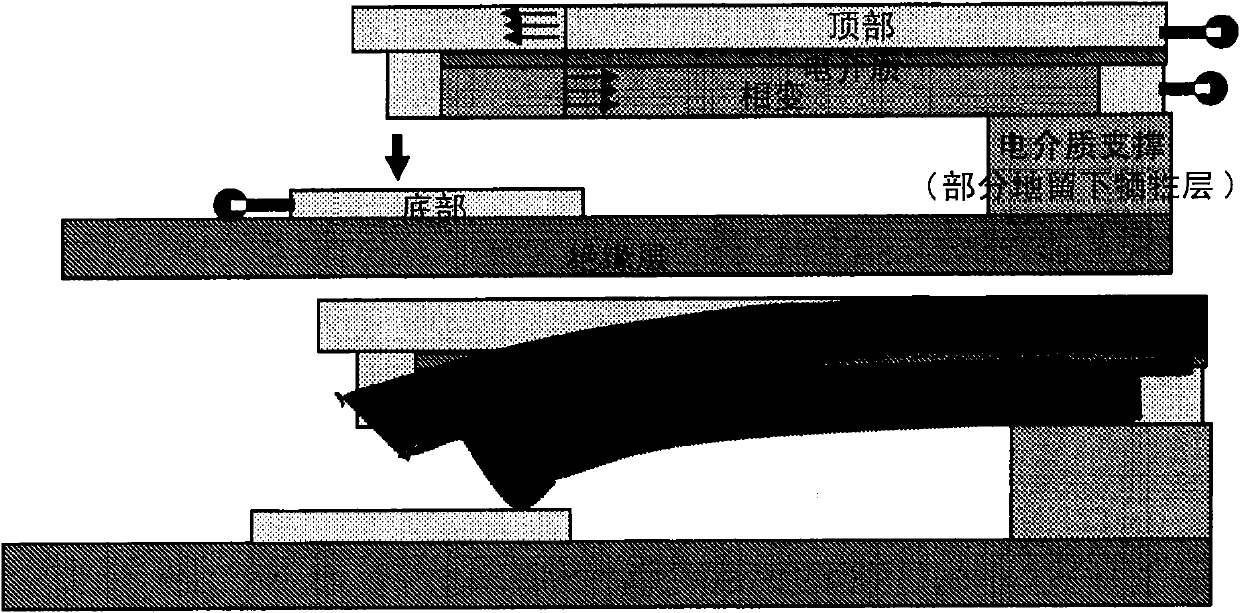

[0077] Figure 2a shows the structure of the proposed tunable capacitor, a single beam structure. (X section).

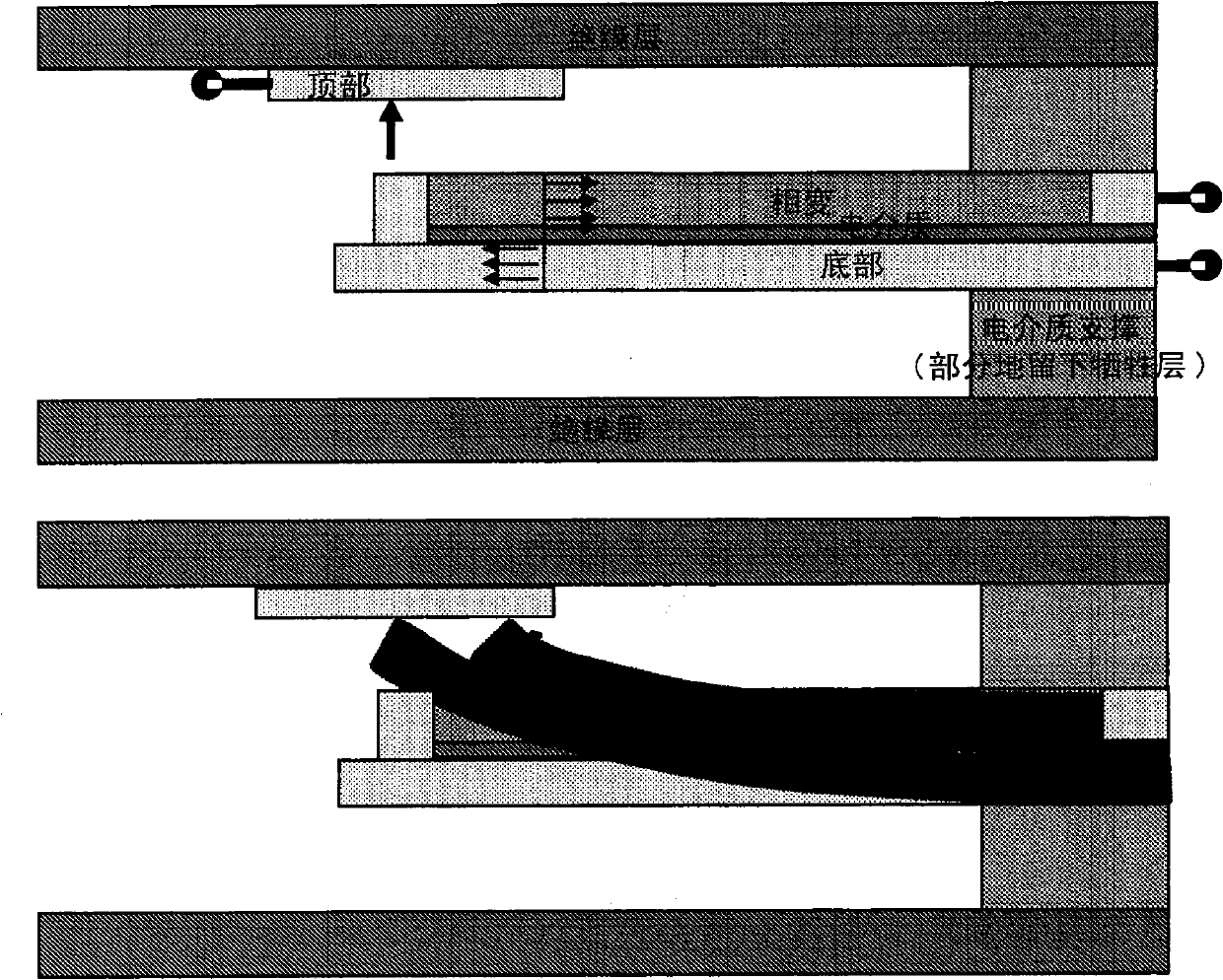

[0078] Figures 2a, 2b show X-sectional views of the proposed structure. The beams are supported by dielectric insulation, which may be a sacrificial layer inten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com