Patents

Literature

56results about How to "Inherent problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

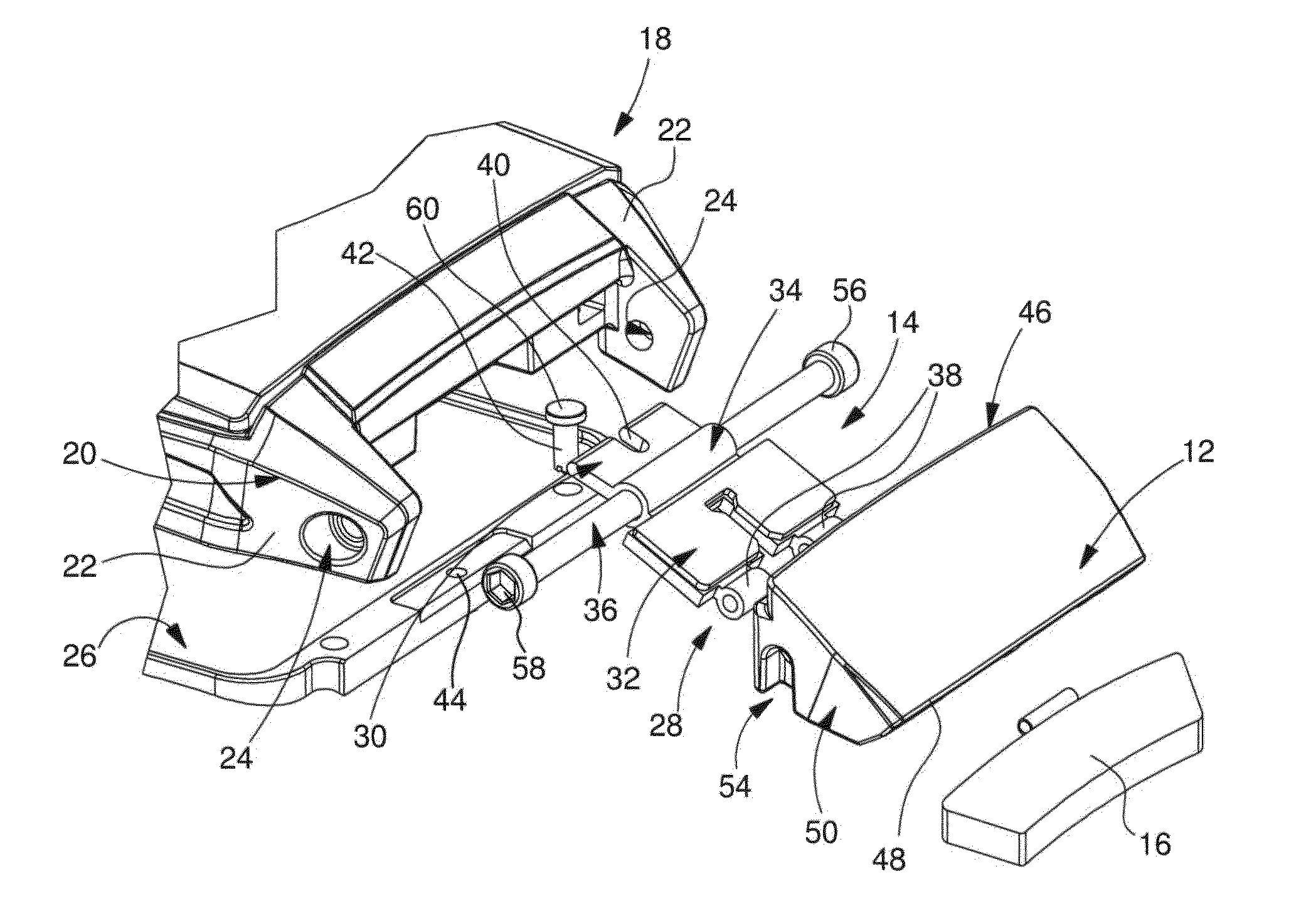

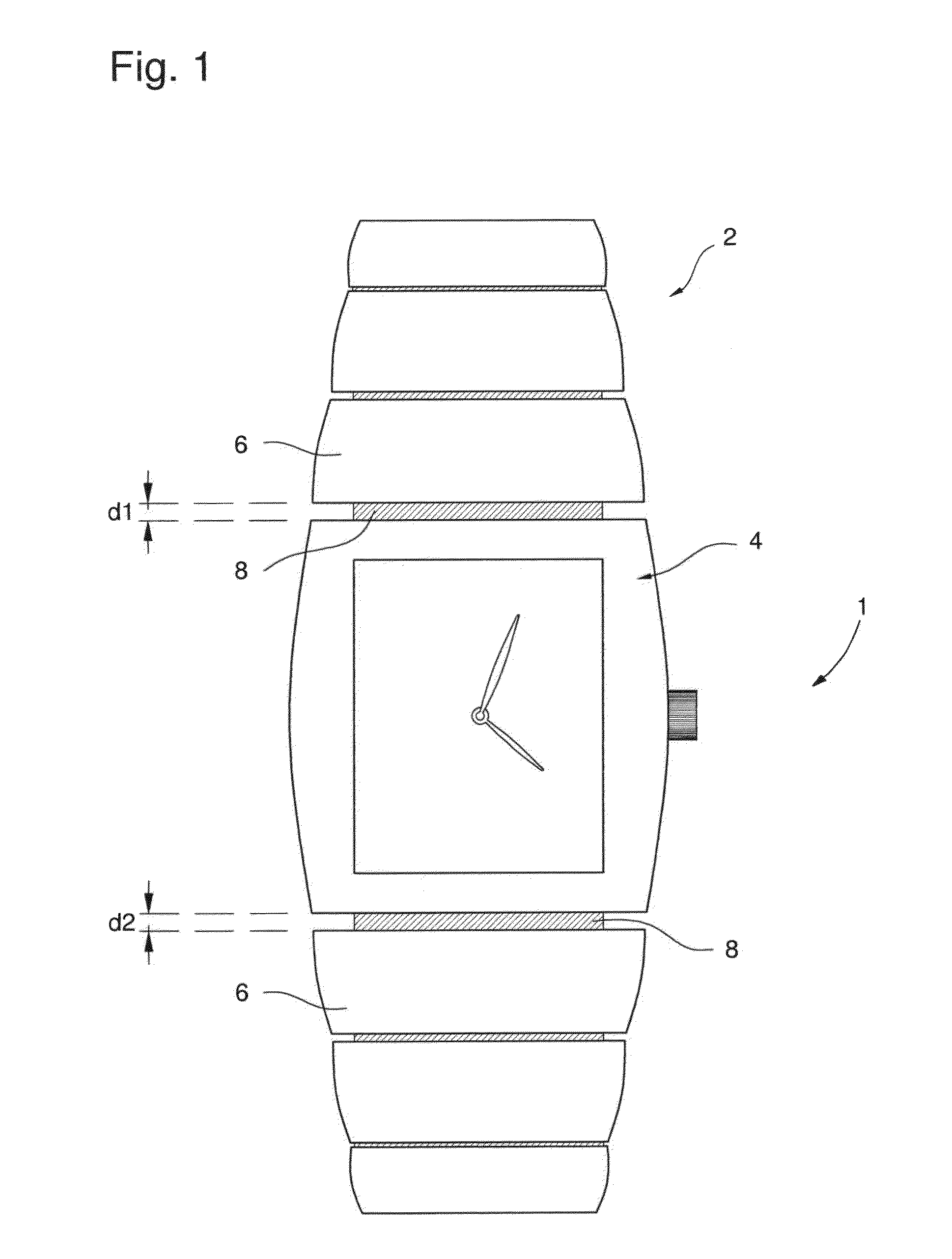

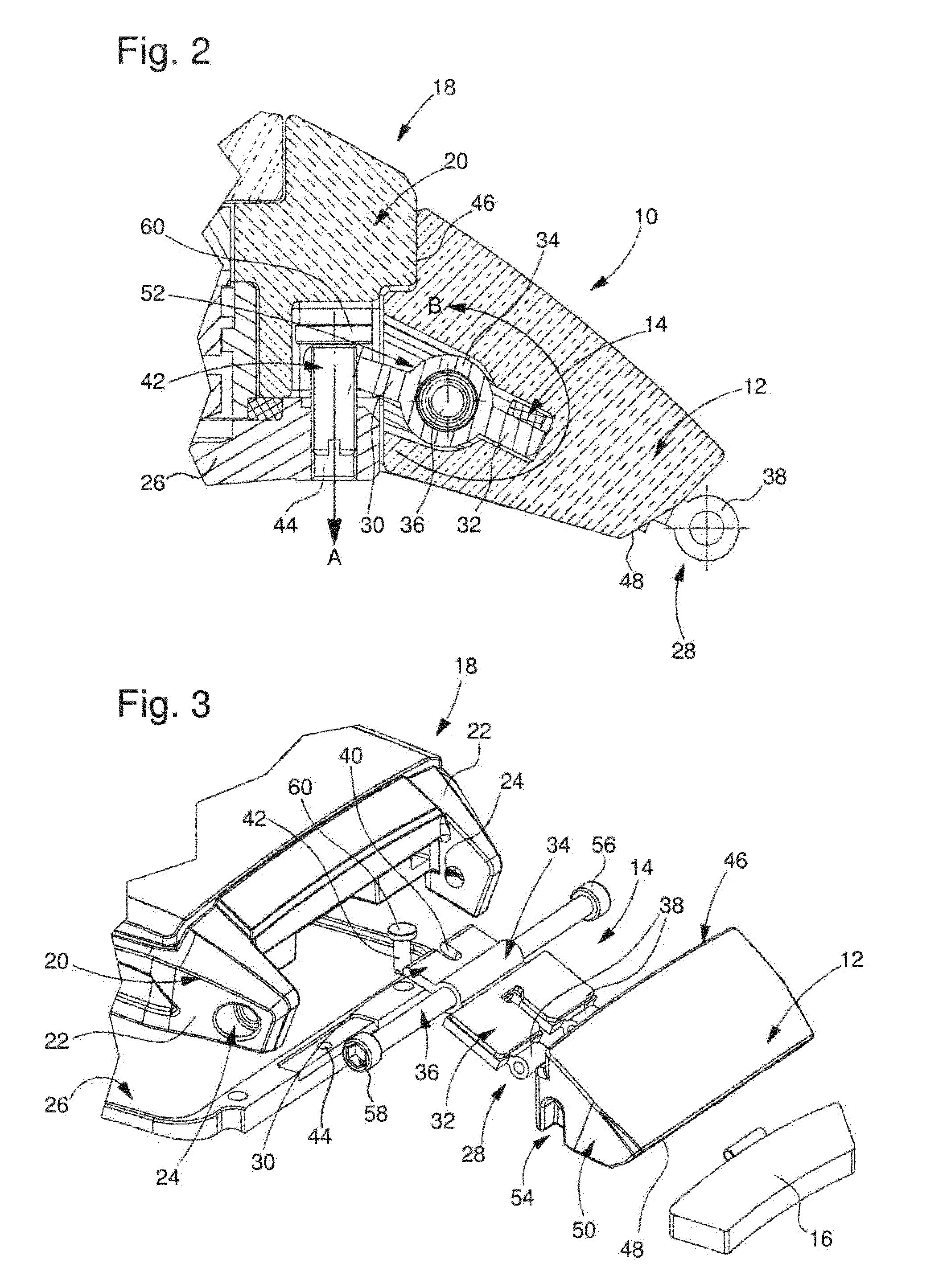

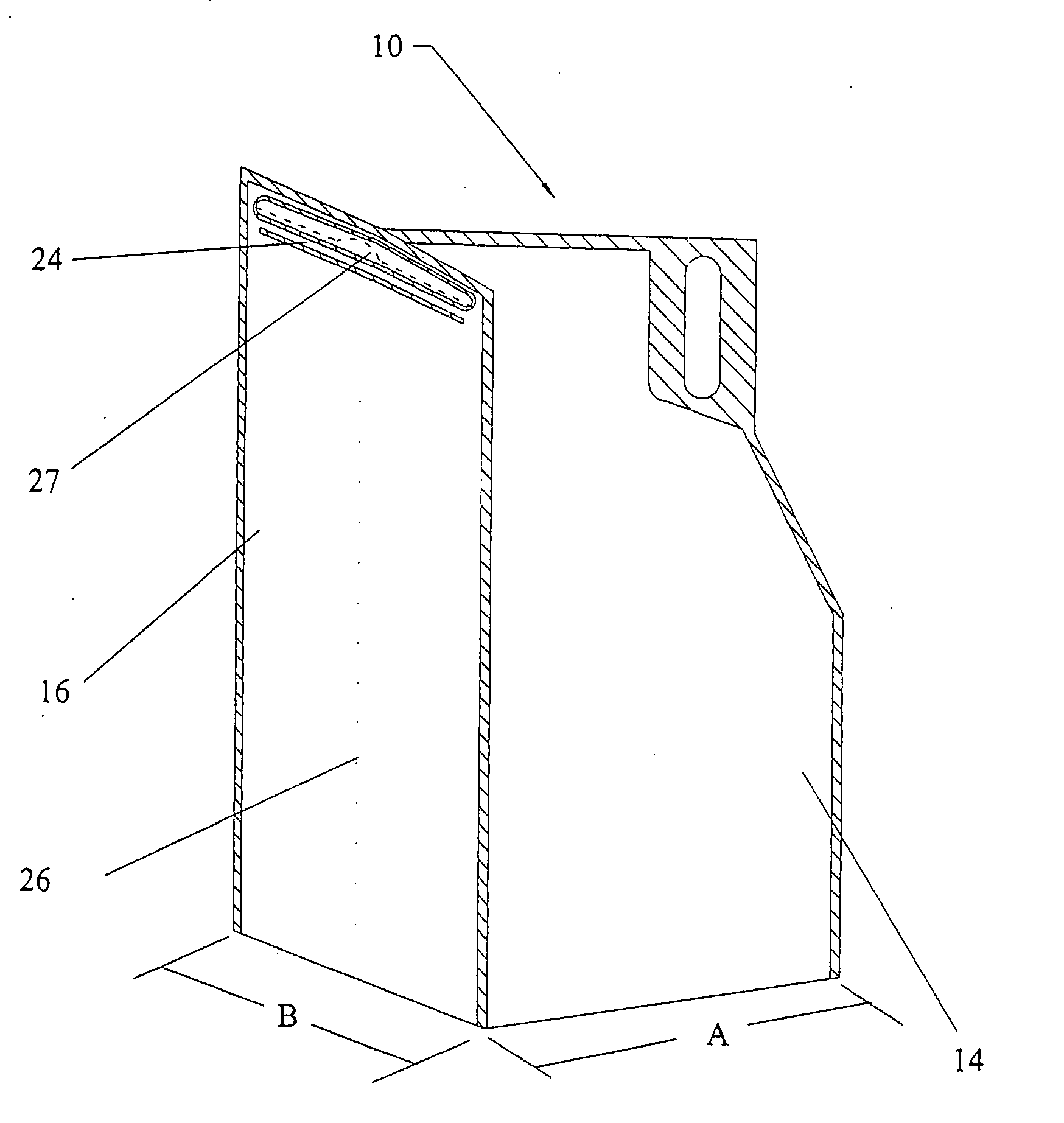

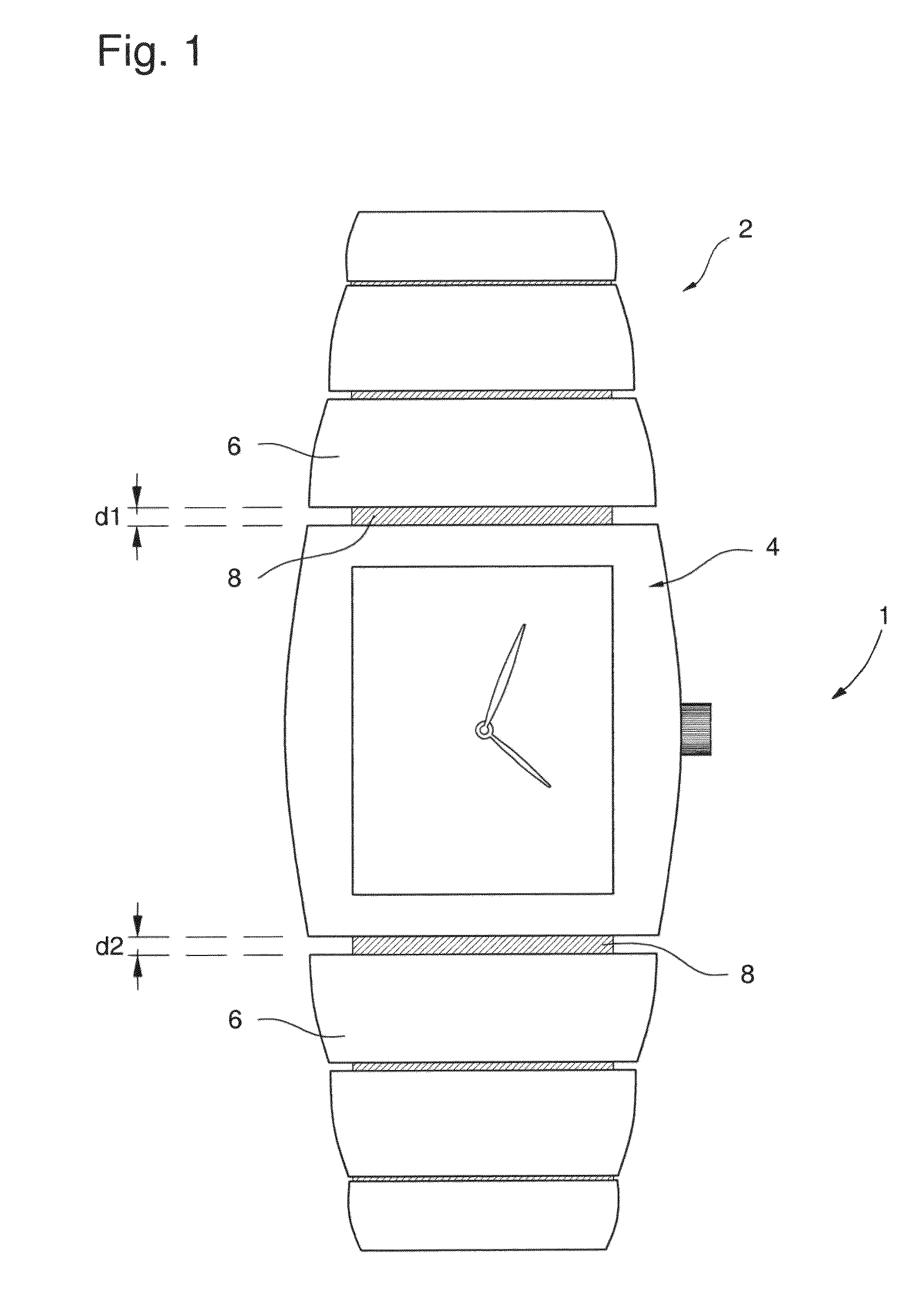

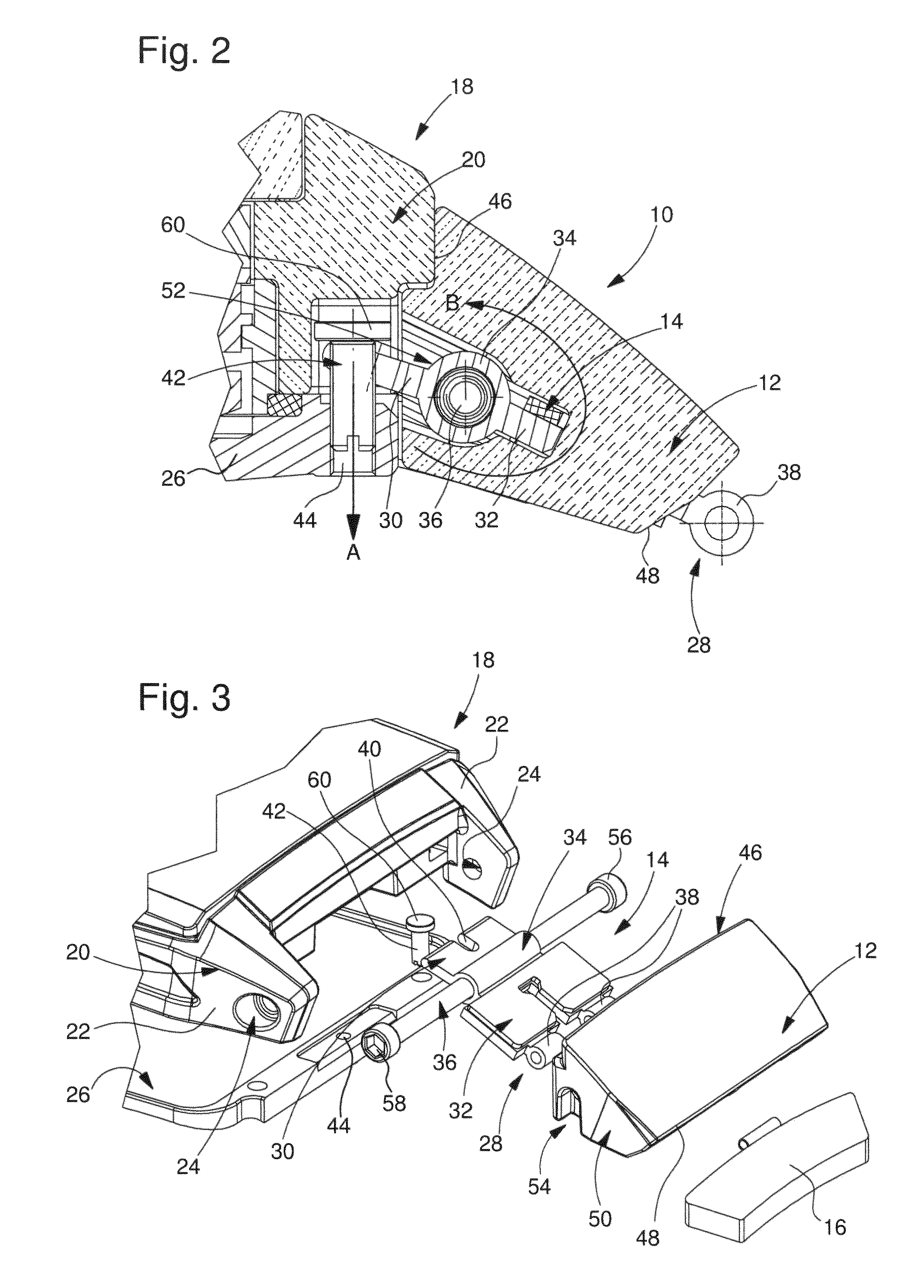

System for connecting a bracelet to a watch case

ActiveUS20140096345A1Adjustable positionInherent problemBraceletsClockwork casesTransverse axisEngineering

System for connecting a bracelet to a watch case by means of a link, the watch case comprising a caseband and a back cover, the link comprising a first hollow element and a second element partly nesting in the first hollow element, the first hollow element carrying a first means of fastening to the watch case and the second element carrying a second means of fastening to an adjacent bracelet link, characterized in that the watch case includes a mechanical device arranged to pivot the second element about a transverse axis to the longitudinal direction of the bracelet, the second element transmitting the pivoting motion thereof to the first element which pivots in turn and which is pressed against the caseband of the watch case.

Owner:THE SWATCH GROUP MANAGEMENT SERVICES

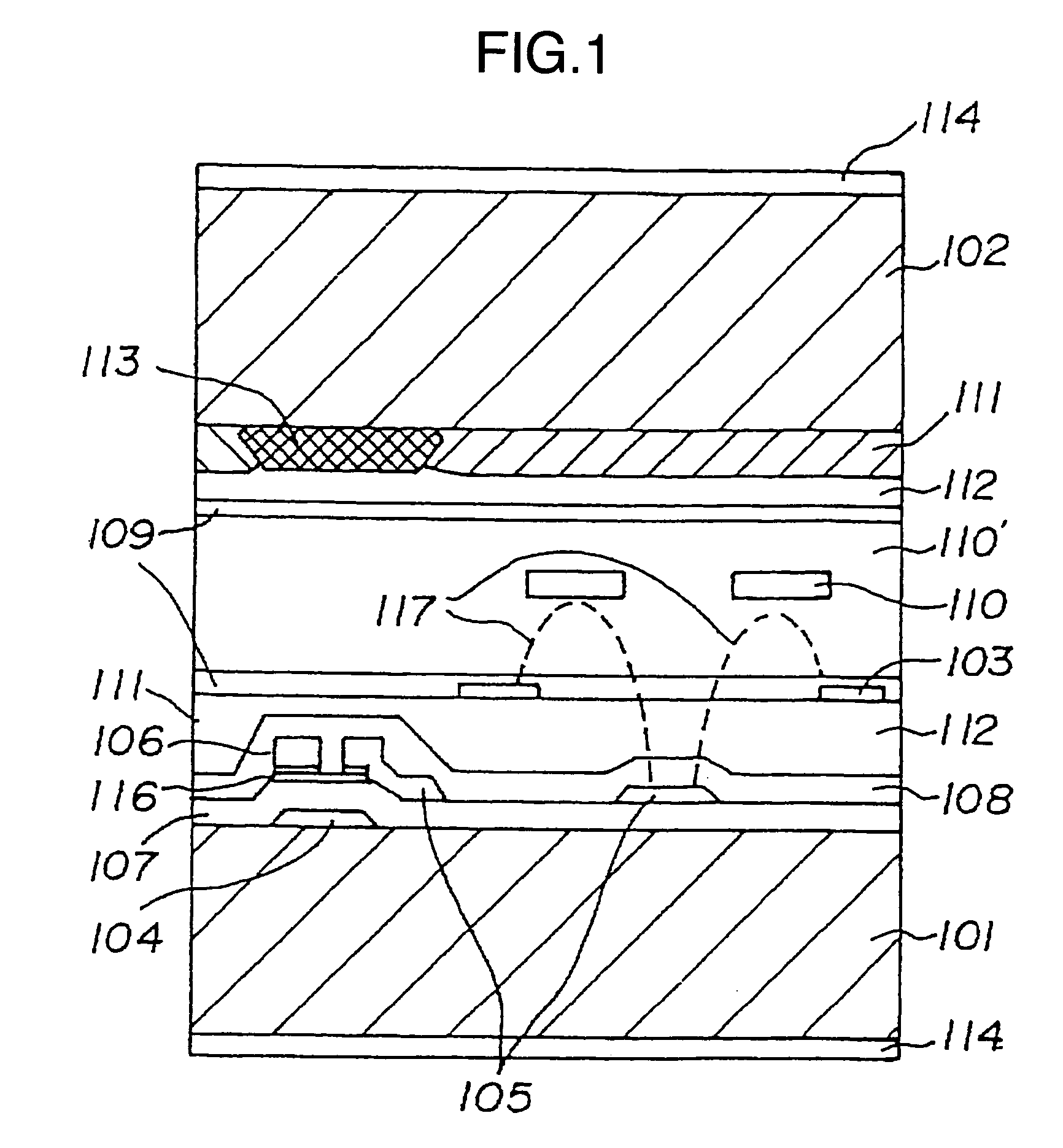

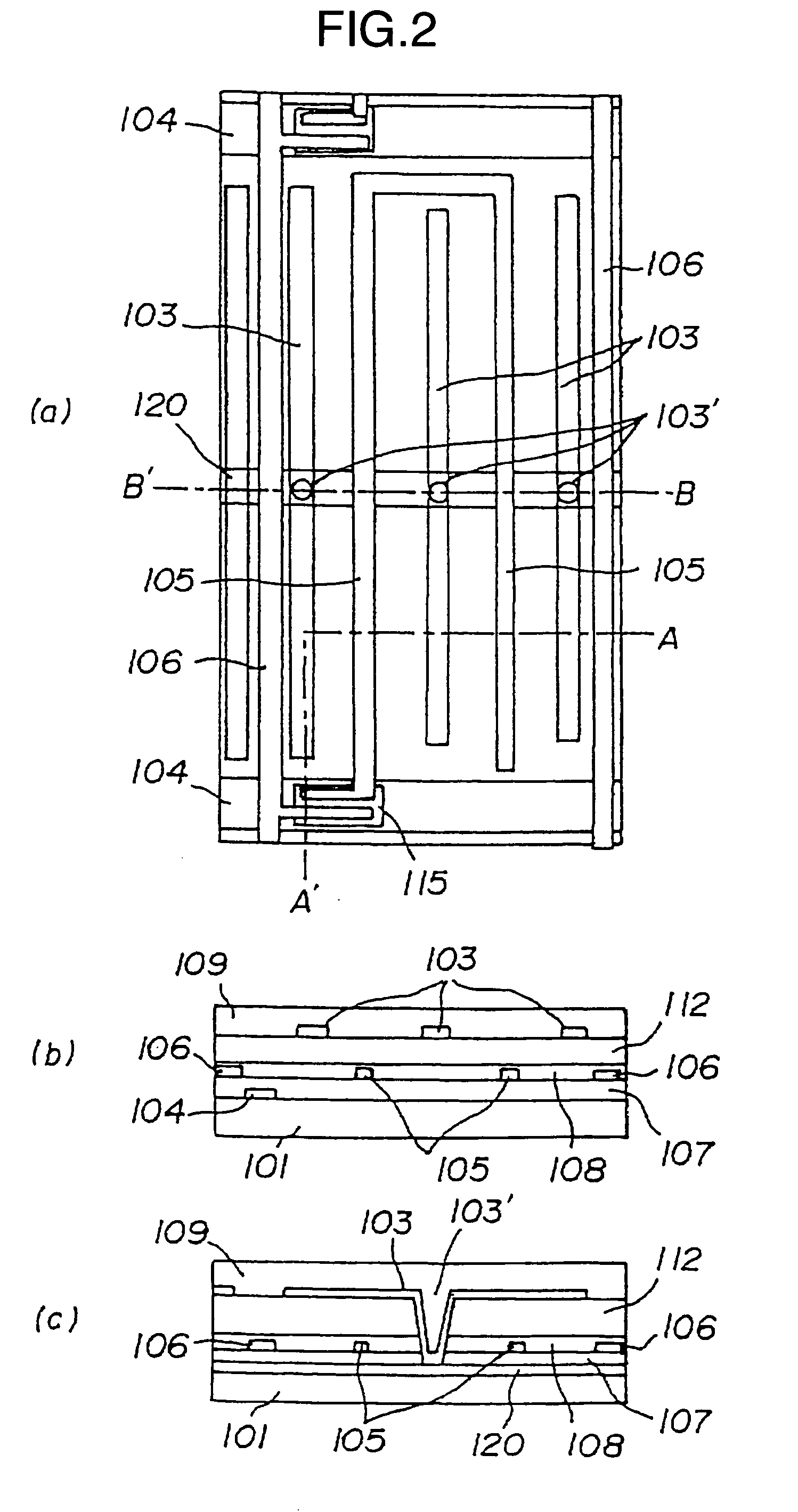

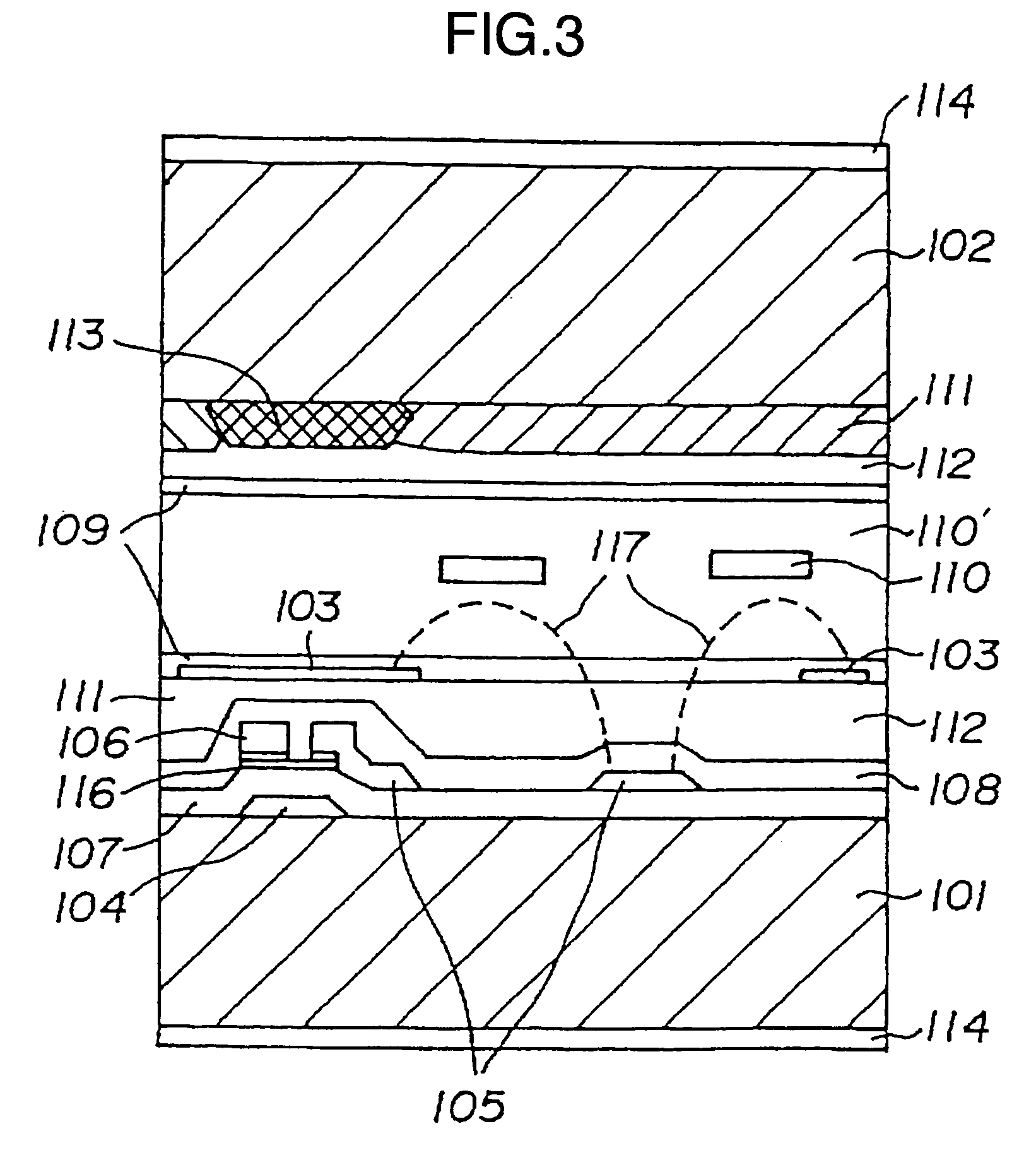

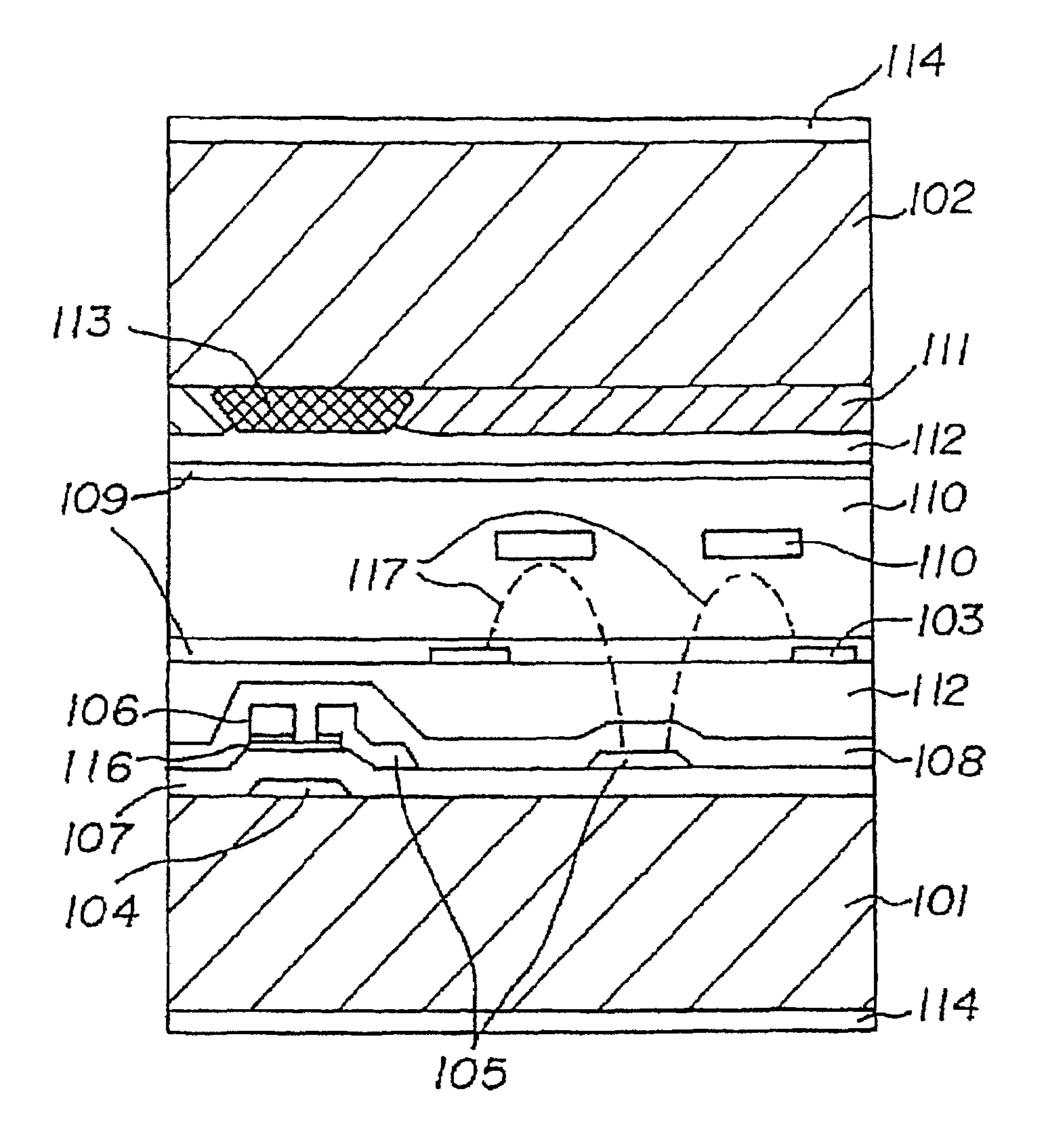

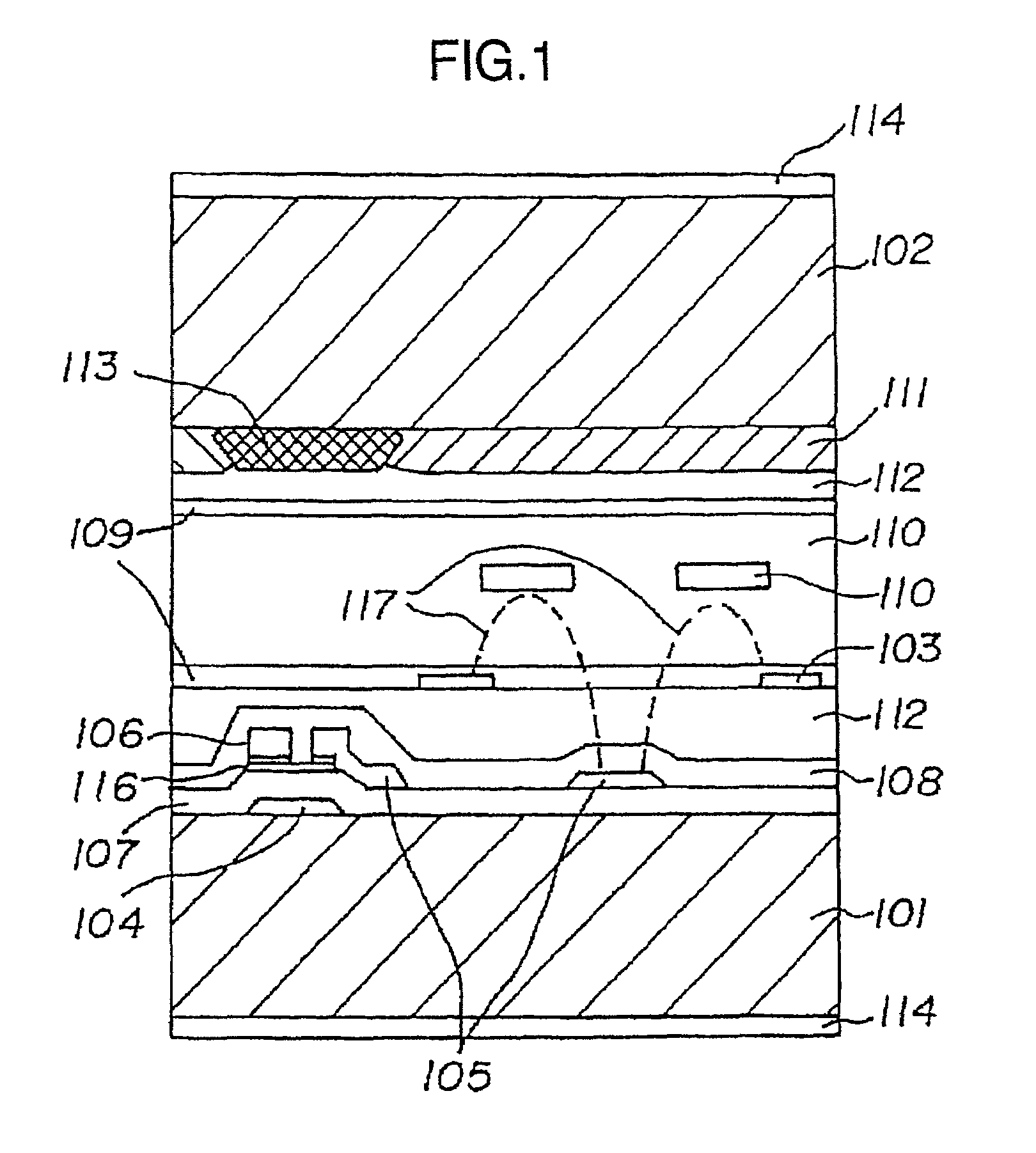

Liquid crystal display and method for manufacturing same

ActiveUS20060061719A1Improve light transmittanceImprove light efficiencyLiquid crystal compositionsCoatingsHigh contrastLiquid-crystal display

A liquid crystal display is provided which is capable of reducing the occurrence of defective display due to variations in the initial alignment direction of a liquid crystal alignment control film in a liquid crystal display of an IPS scheme, realizing the stable liquid crystal alignment, providing excellent mass productivity, and having high image quality with a higher contrast ratio. The liquid crystal display has a liquid crystal layer disposed between a pair of substrates, at least one of the substrates being transparent, and an alignment control film formed between the liquid crystal layer and the substrate. At least one of the alignment control films comprises photoreactive polyimide and / or polyamic acid provided with an alignment control ability by irradiation of substantially linearly polarized light.

Owner:NISSAN CHEM IND LTD

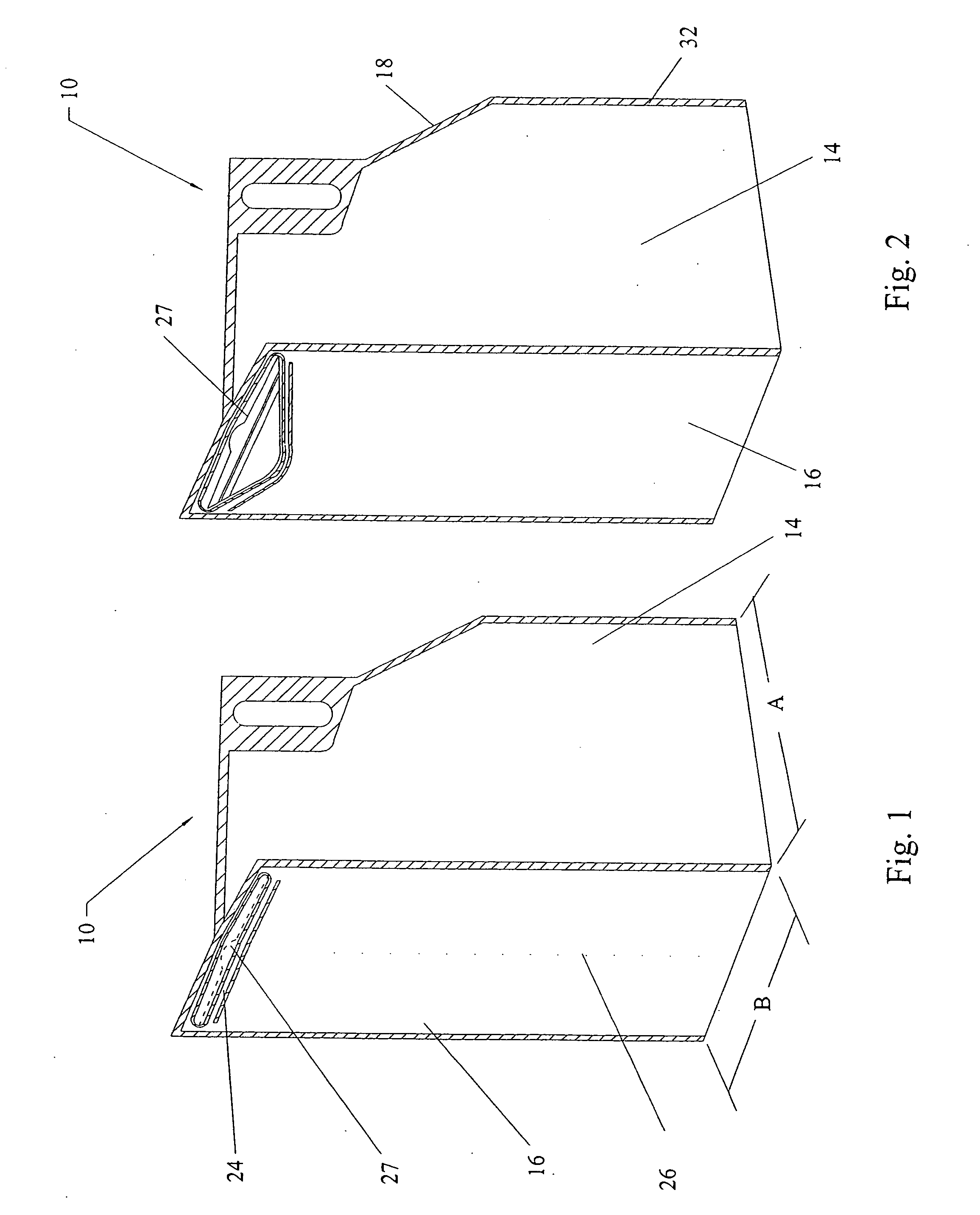

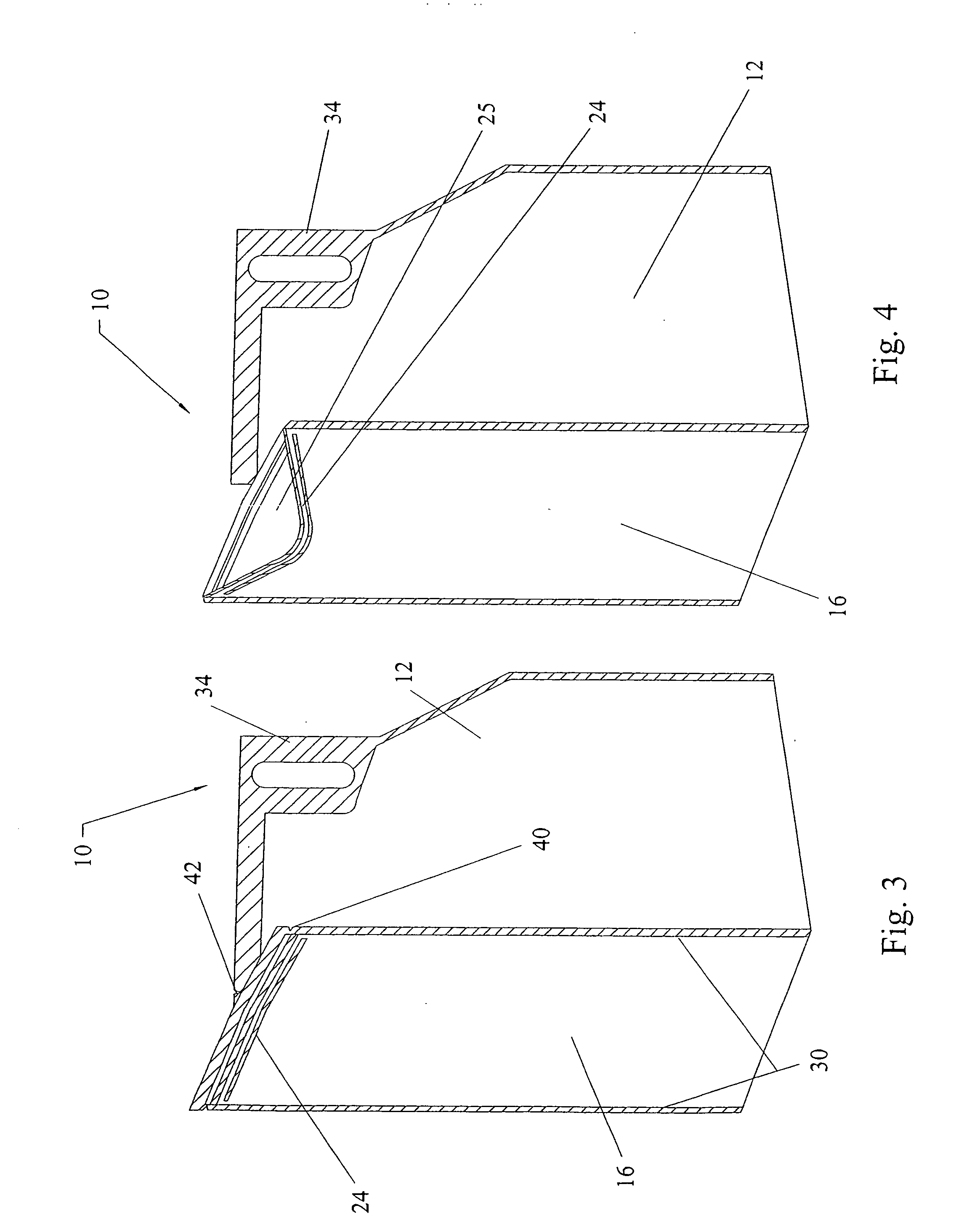

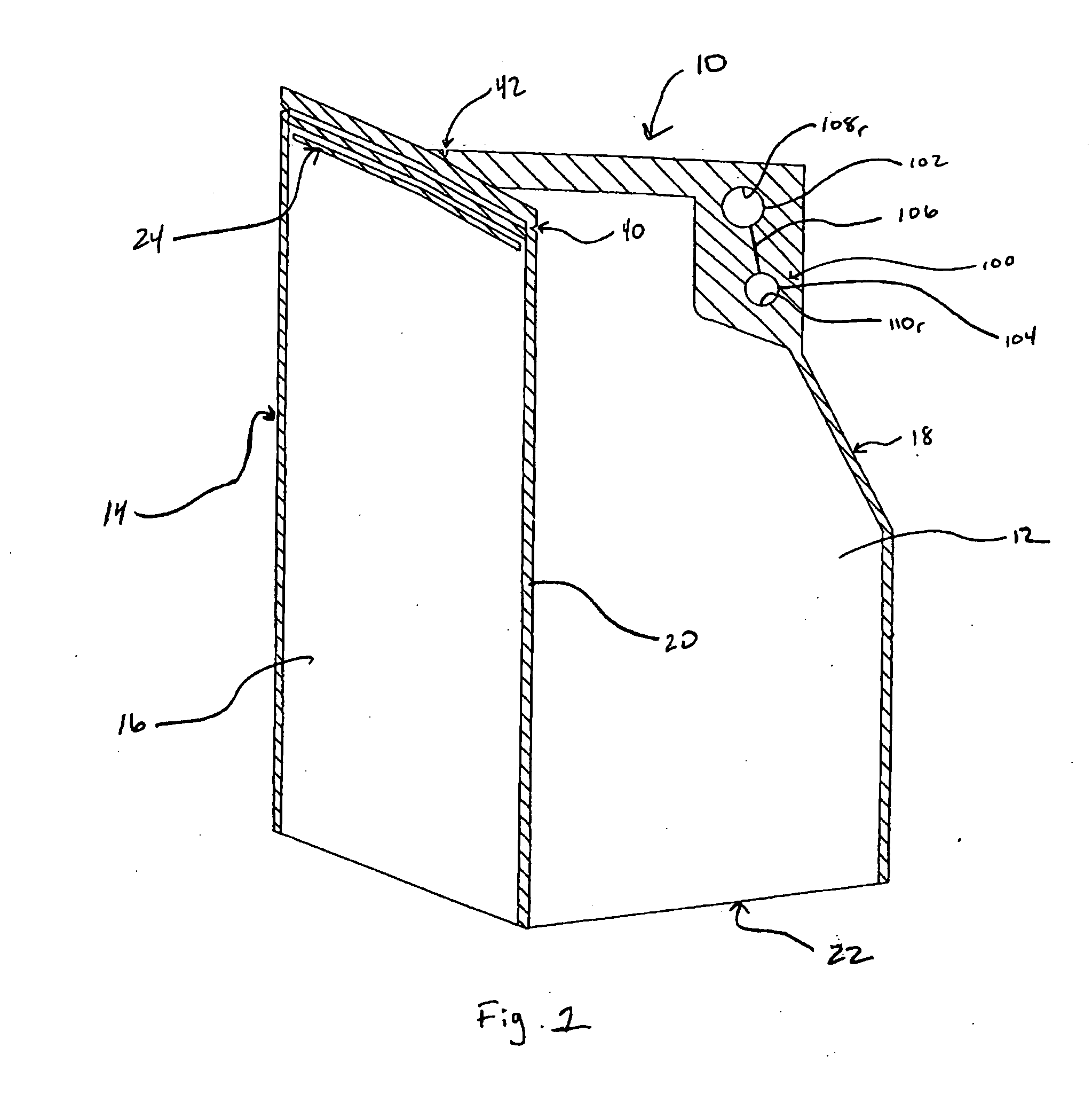

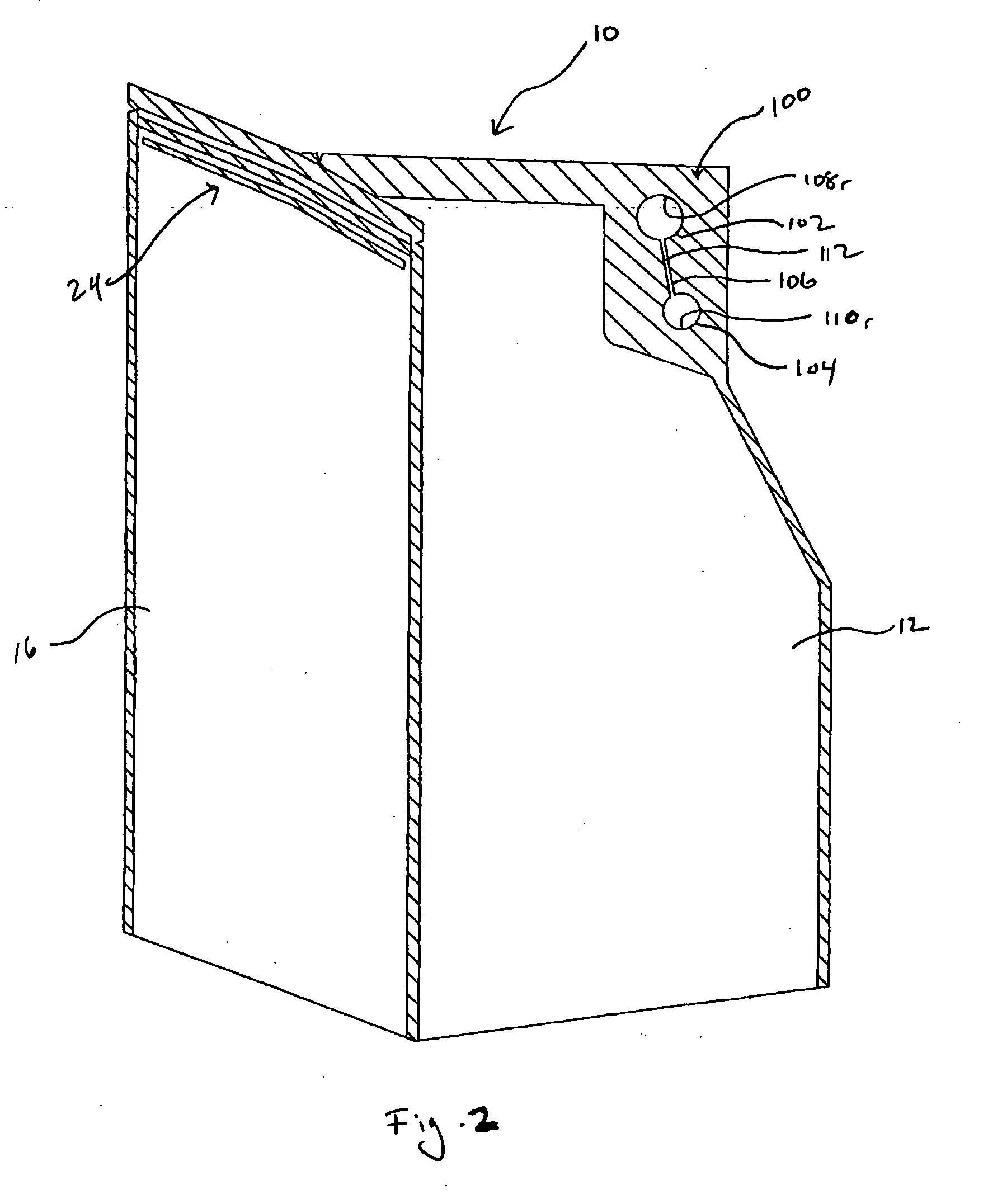

Flexible package with a transverse access panel device

InactiveUS20060215942A1Reducing available material holding capacityReduce capacityEnvelopes/bags making machineryFlexible coversAdhesiveEngineering

A flexible package generally including a front panel portion, a back panel portion, a first side panel portion, and at least one access device. The flexible package can further include a second side panel portion, a bottom panel portion, and a top panel portion. Additionally, one or more of the portions can be shaped and / or manufactured substantially as a gusset. Each of the panel portions comprise two longitudinal sides or edges. The access device can be attached to at least one surface of at least one of the side panel portions such that the device is in transverse orientation to the longitudinal sides. The device can be manually attached to the side portions, or attached with existing and / or specially designed manufacturing machinery. Attachment of the access device to a side portion of the package is achieved using heat bonding techniques, adhesives, and the like.

Owner:STEELE MARK

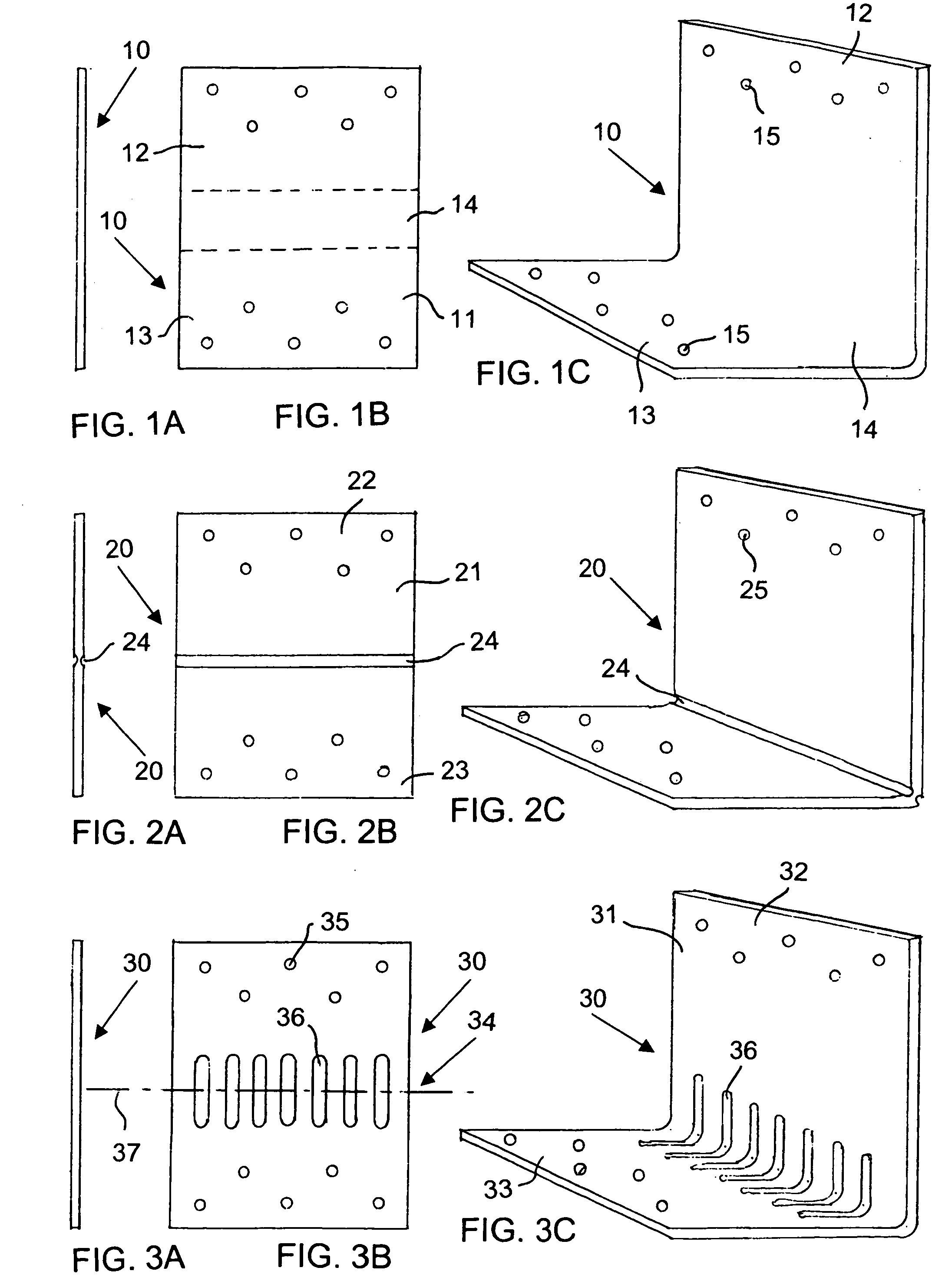

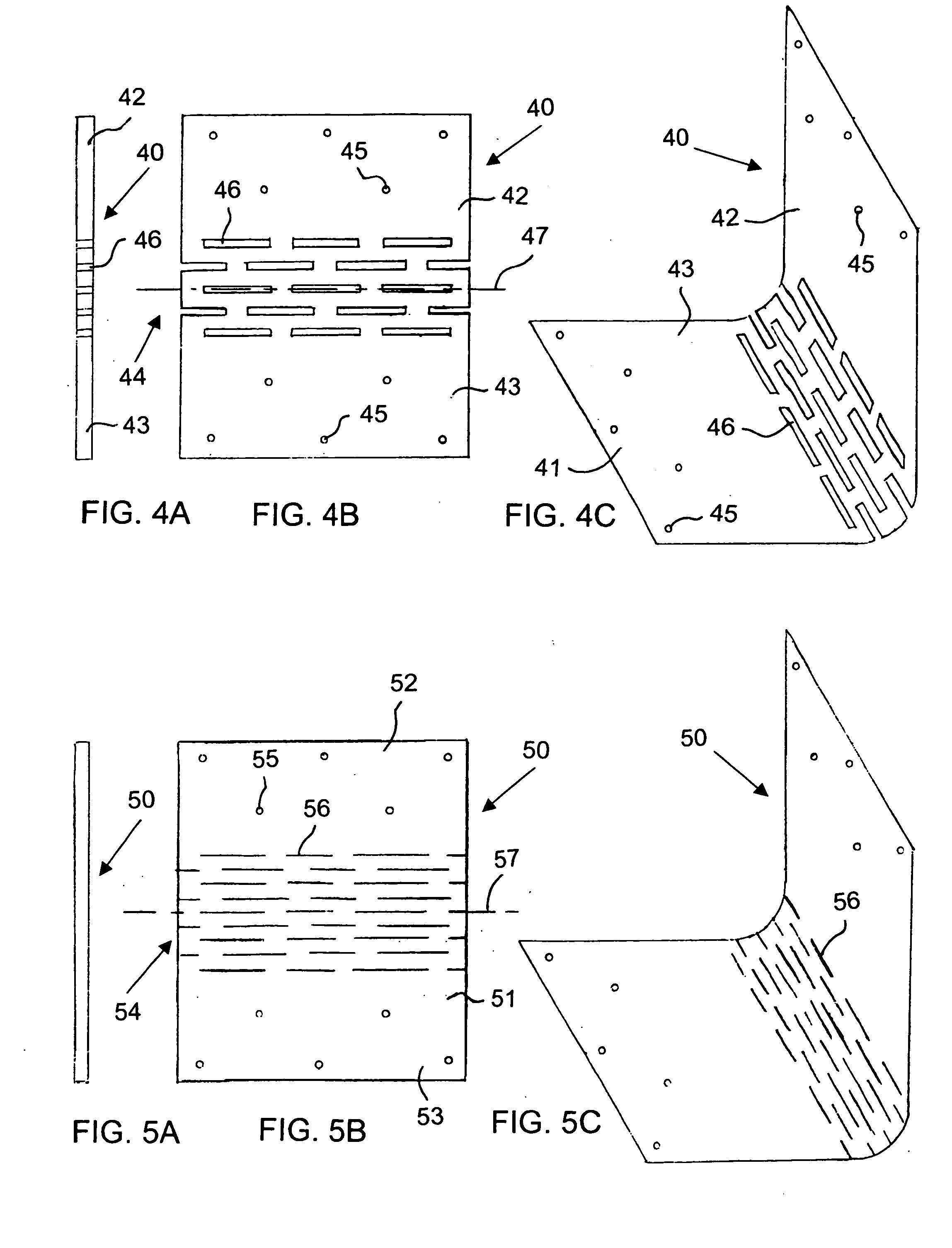

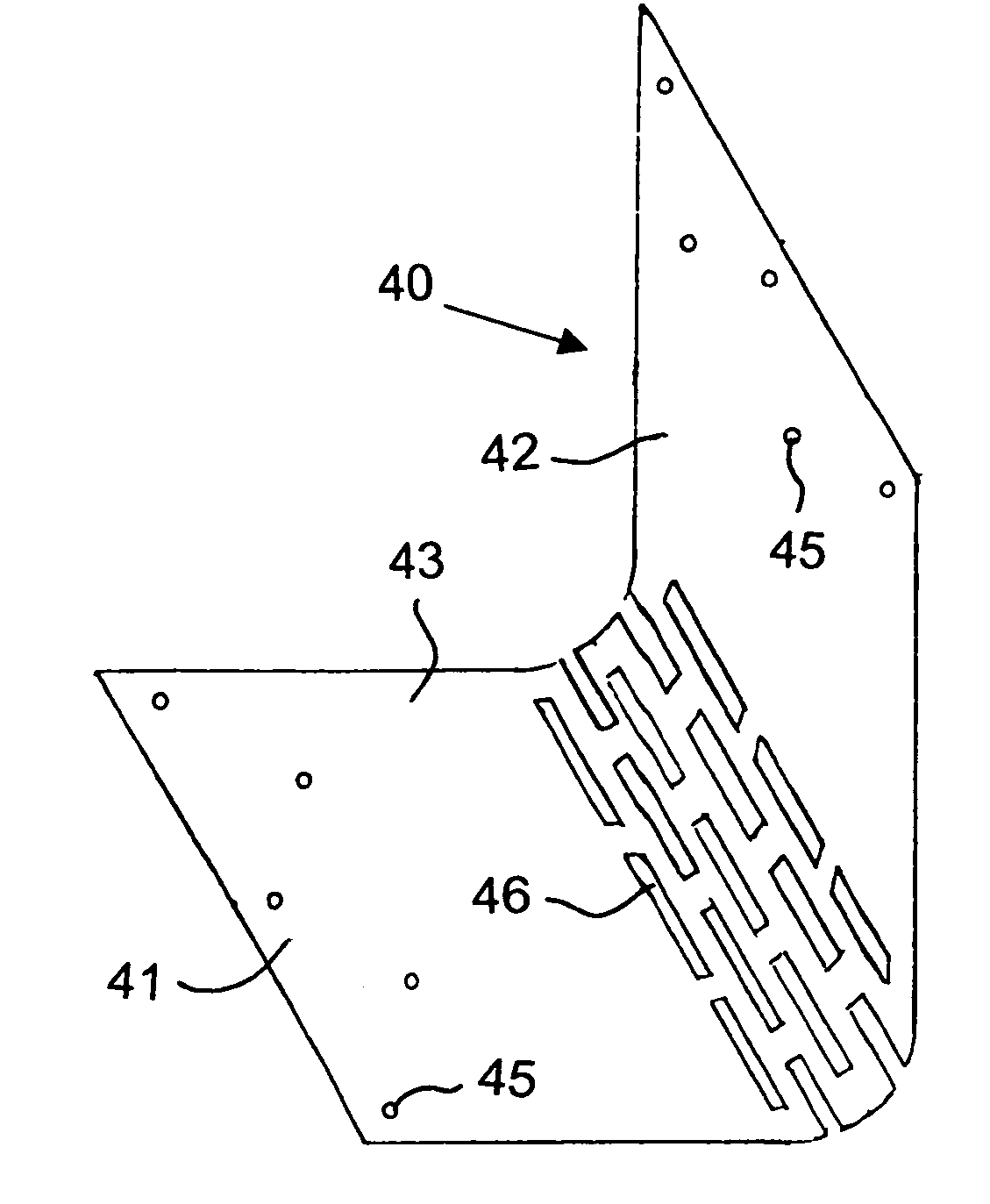

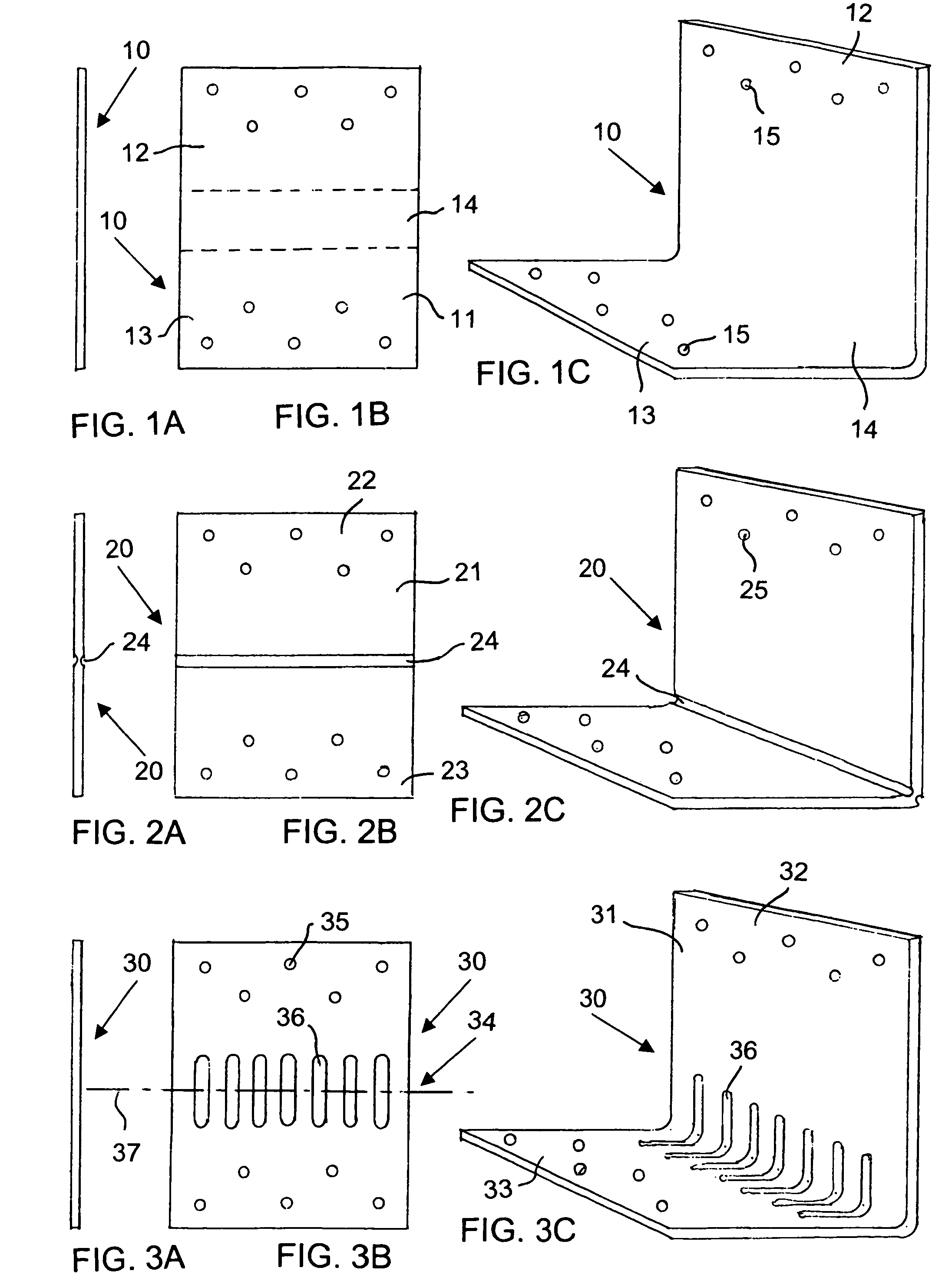

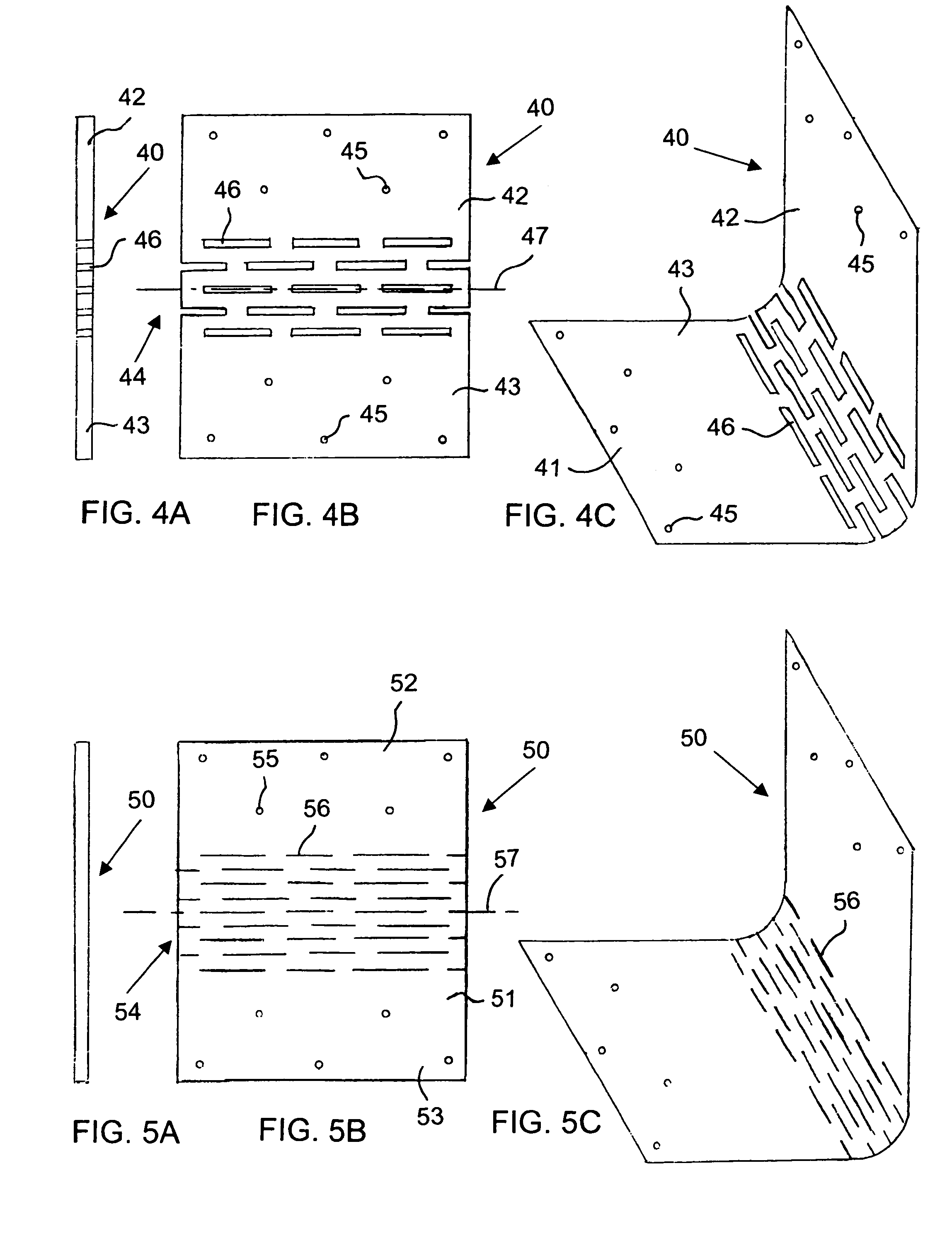

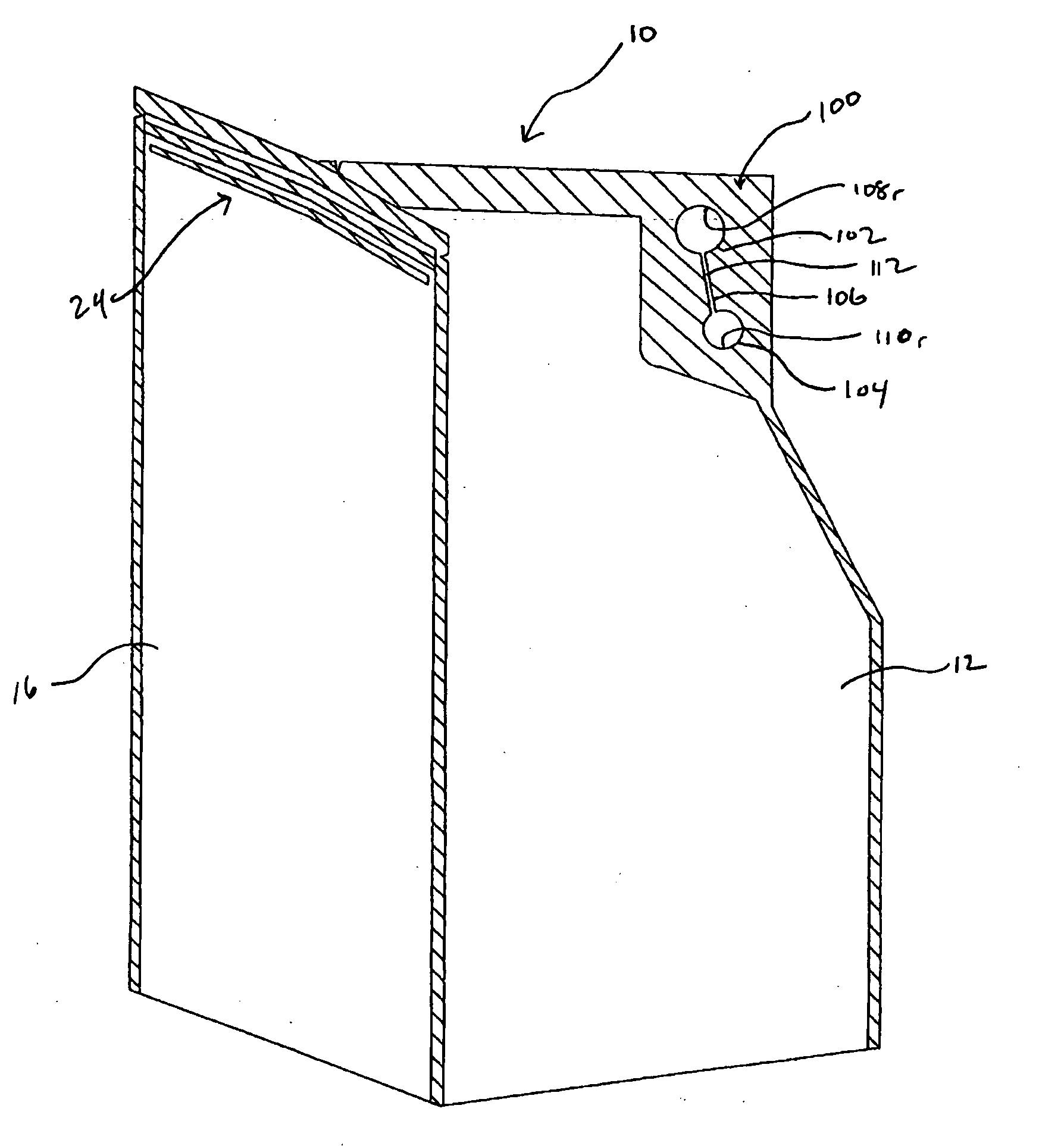

Living hinge

InactiveUS20070199176A1Improve reliabilityImprove stabilityPinless hingesMulti-purpose toolsEngineeringLiving hinge

A living hinge includes a hinge body formed of a material. The hinge body has attachment edges and a flexing zone between the attachment edges defining a flexing axis. The material of the hinge body has at least one separation formed therein in the flexing zone. The at least one separation describes an angle with the flexing axis being other than 90°.

Owner:MC CLELLAN W THOMAS

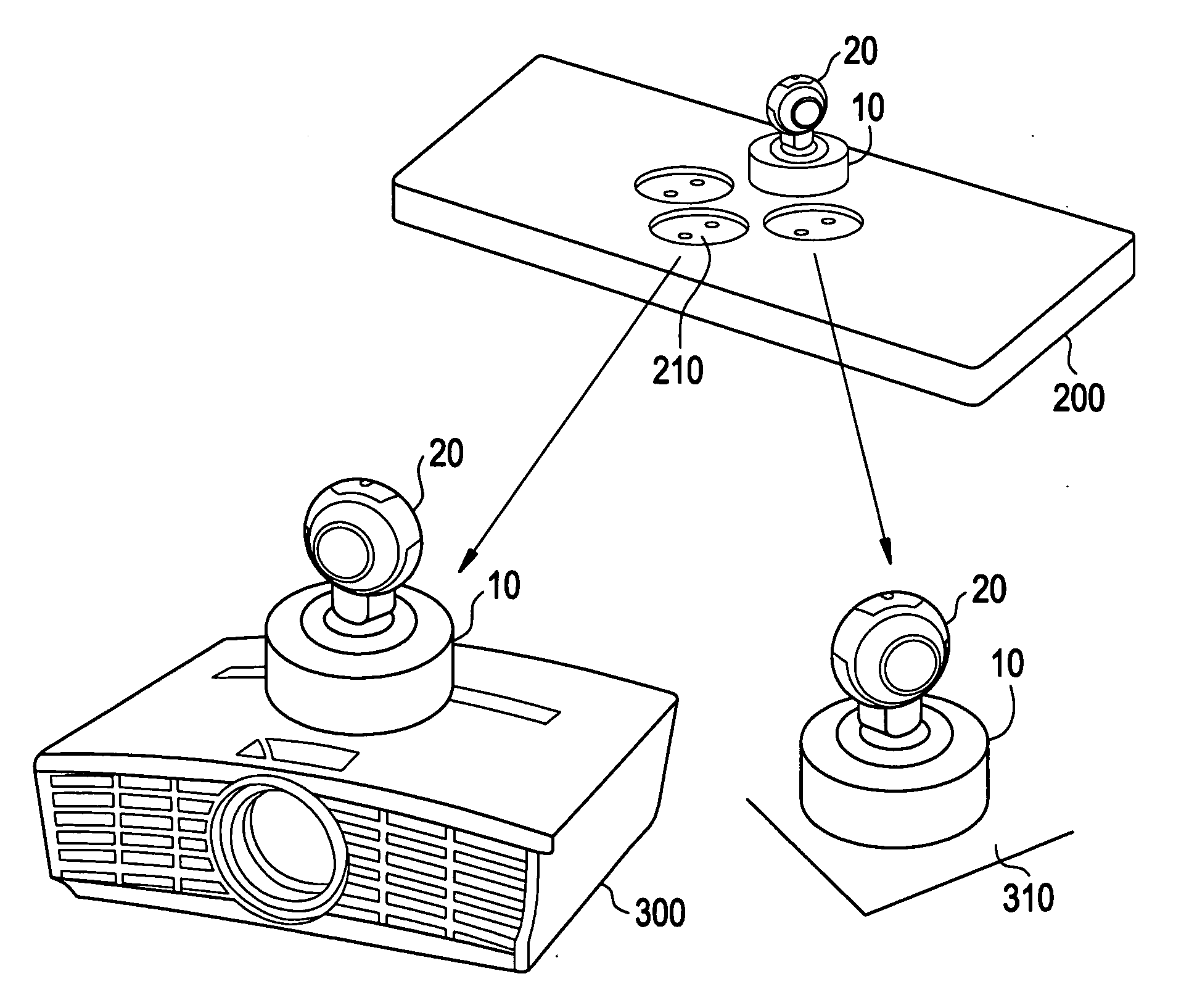

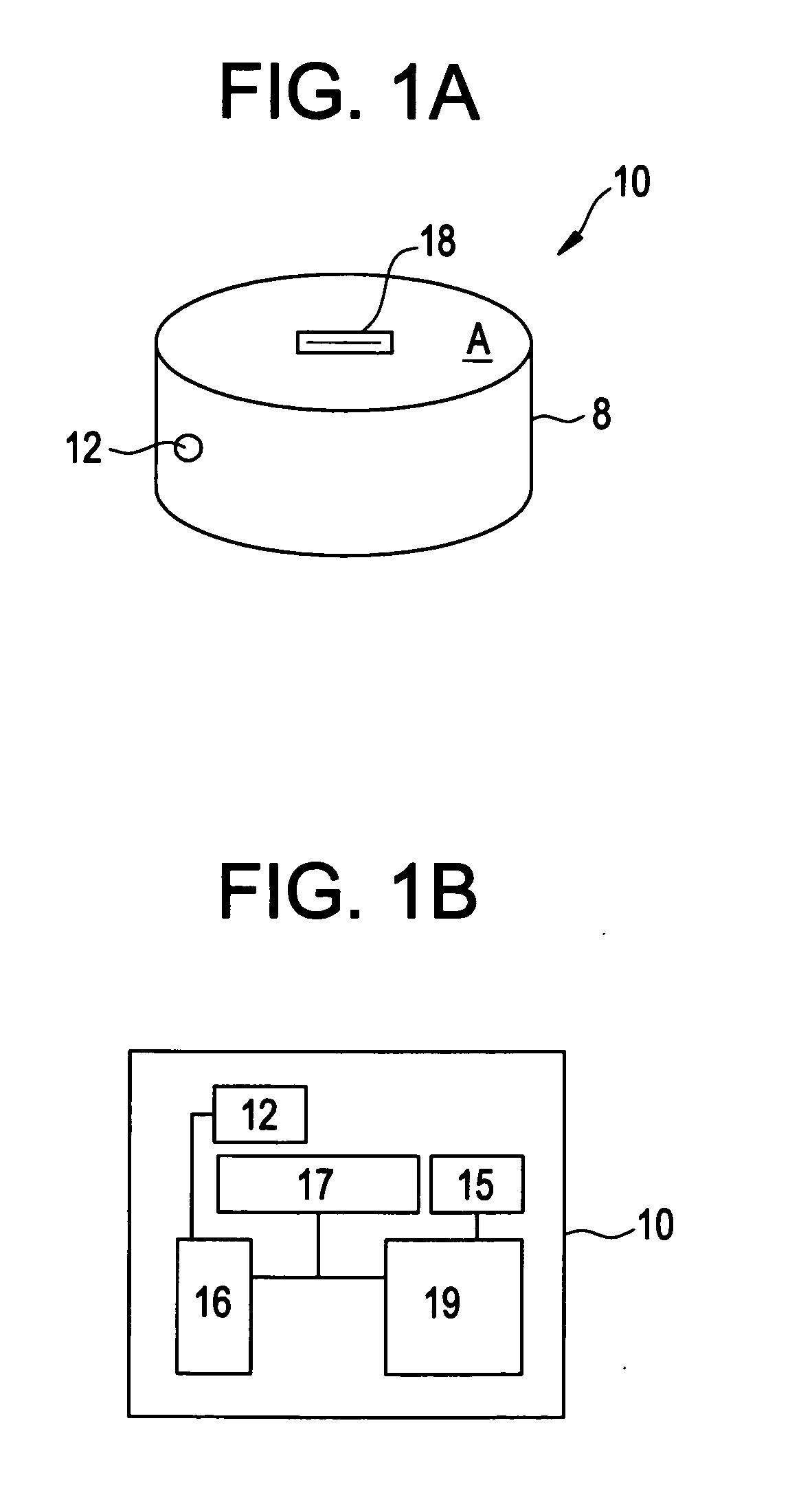

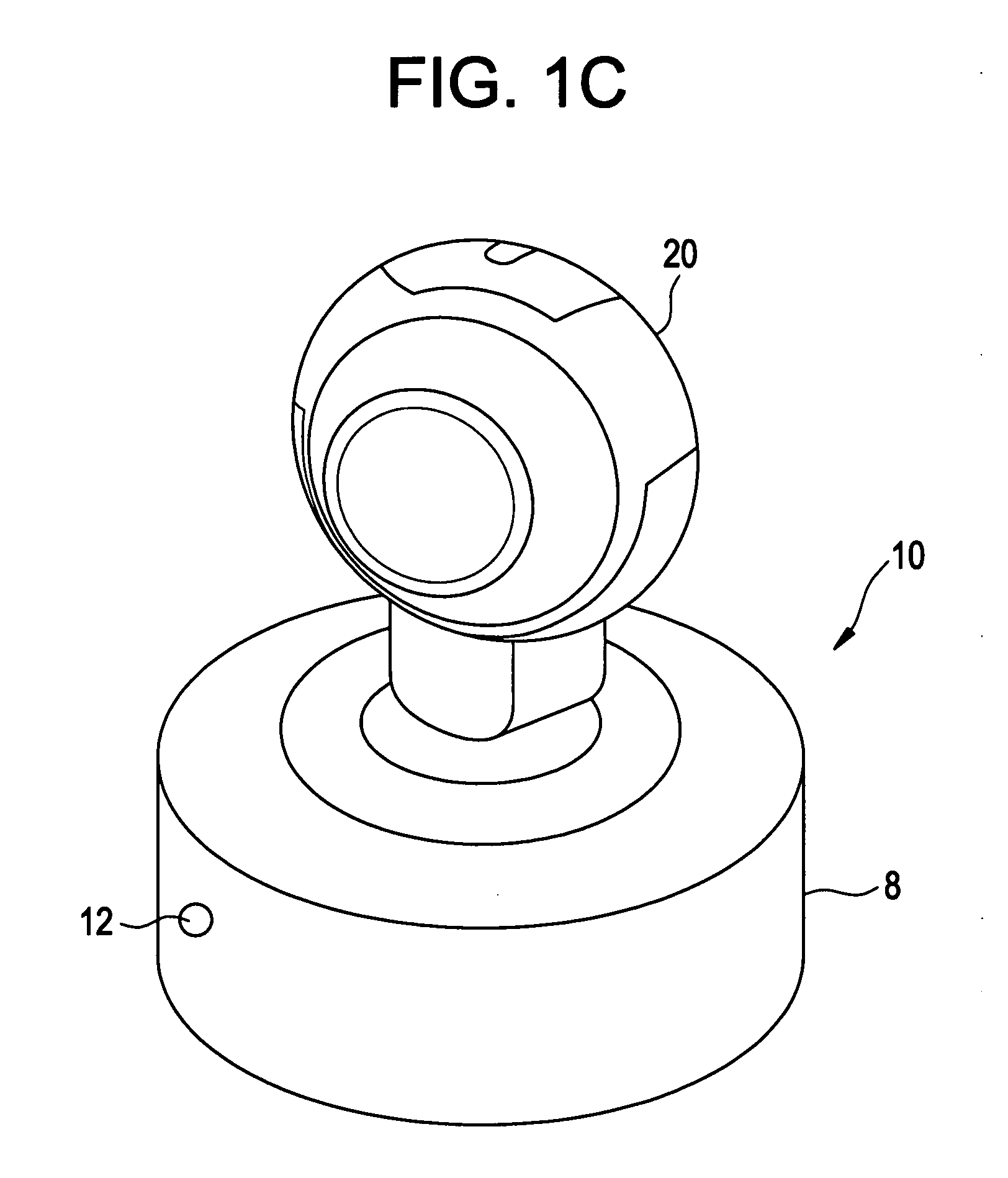

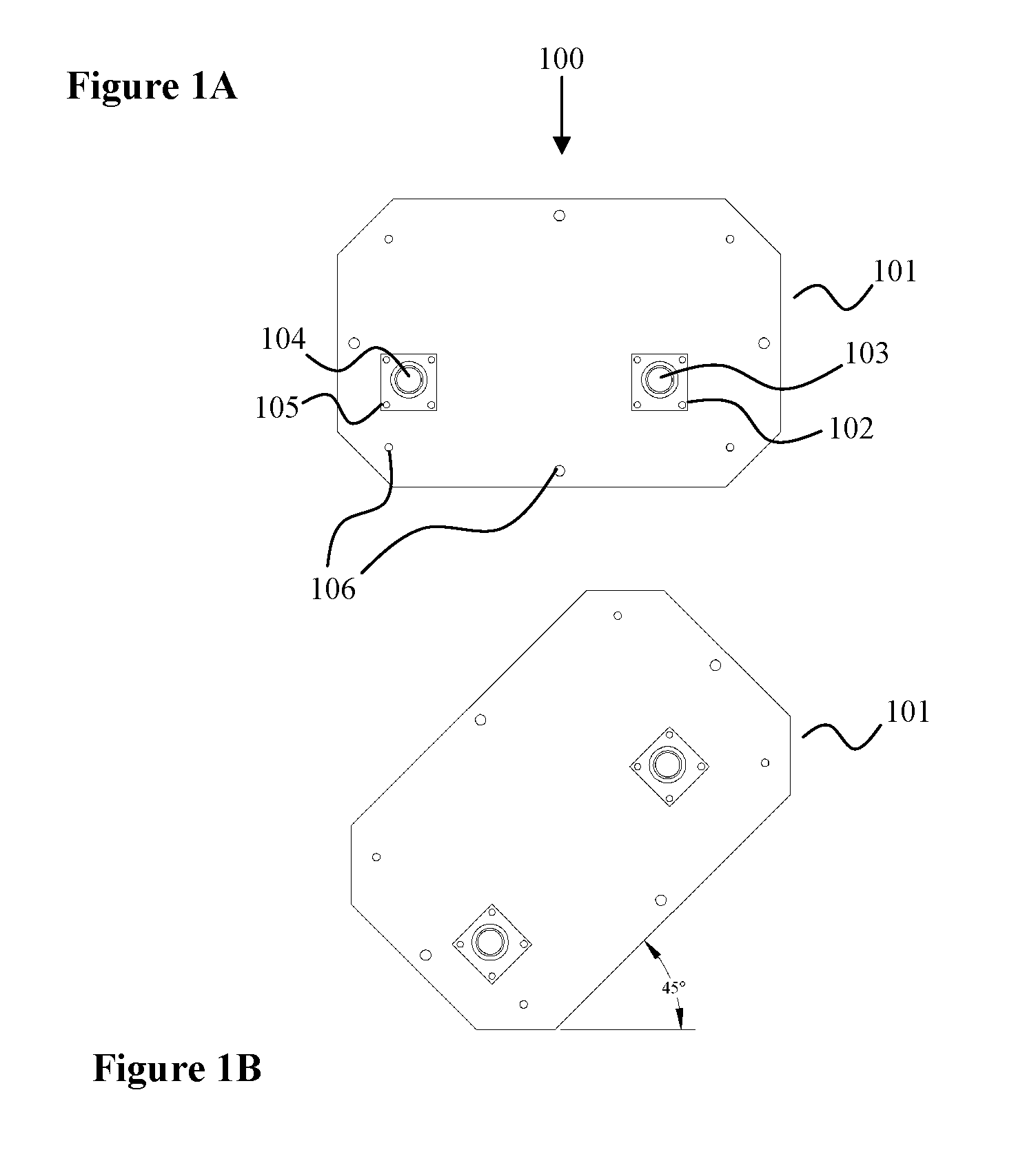

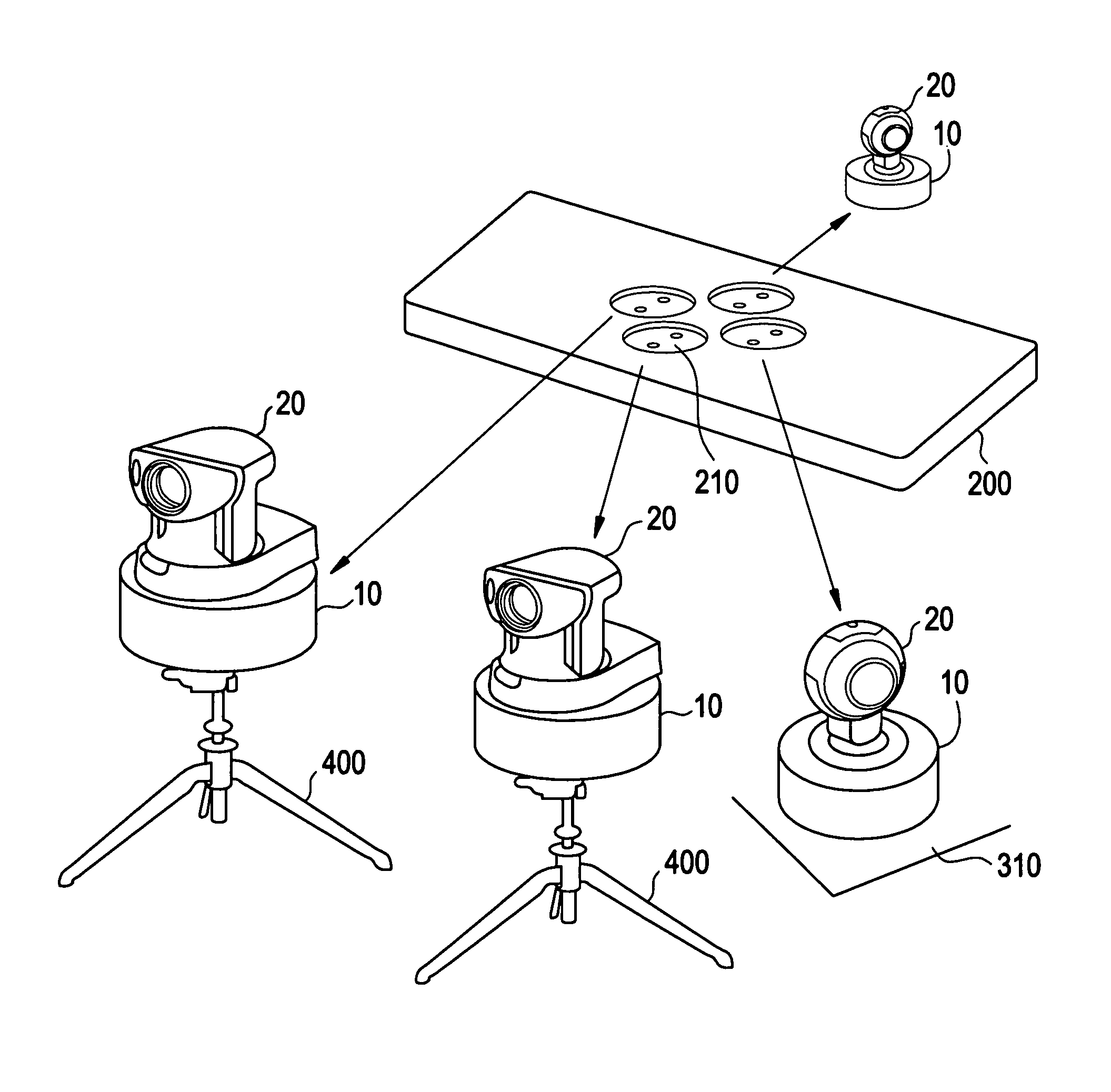

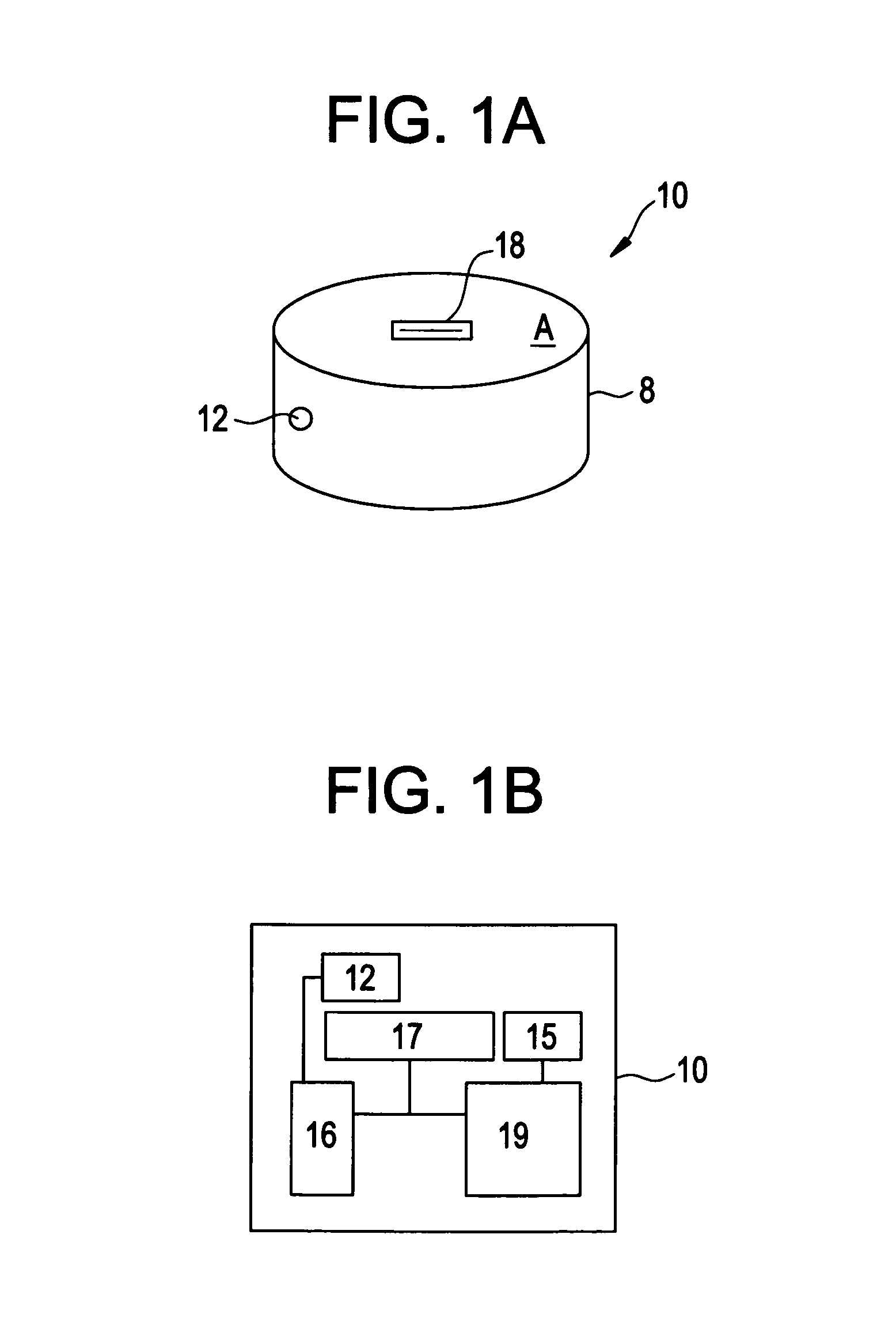

System to freely configure video conferencing camera placement

InactiveUS20100315479A1Reduce decreaseInherent problemTelevision conference systemsTwo-way working systemsCamera placementComputer science

Embodiments of the present invention are directed to cordless video conferencing camera adaptors and video conferencing systems including the camera adaptors. Embodiments of the present invention overcome some of the inherent problems of known video conferencing products by being a part of a portable and configurable video conferencing system, which can be used in various meeting rooms, laboratories, training rooms, and conference halls. For example, embodiments of the invention allow use of low cost (e.g., under $100) cameras to provide any angle of video coverage in any conference room setting.

Owner:ALCATEL LUCENT SAS

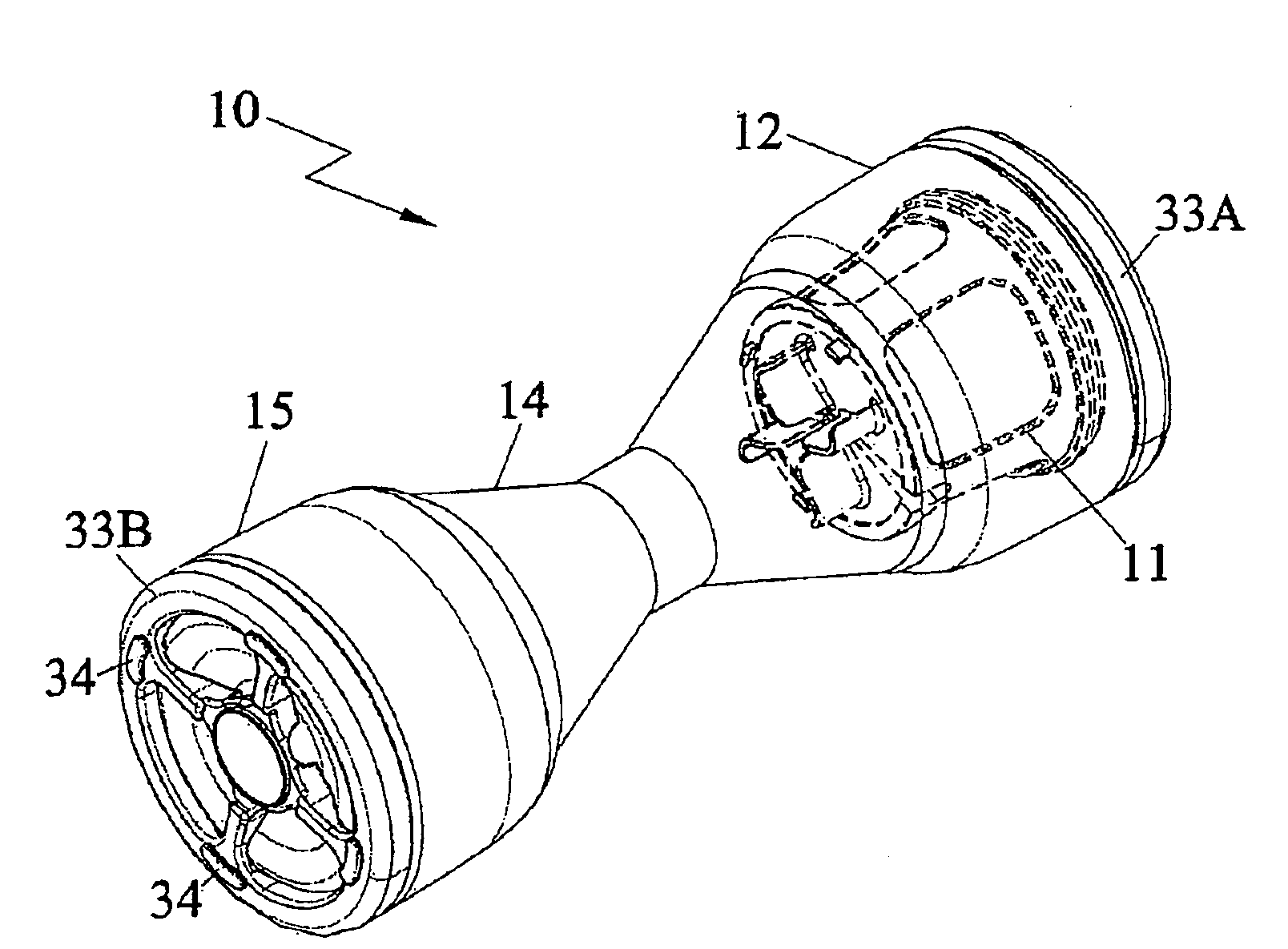

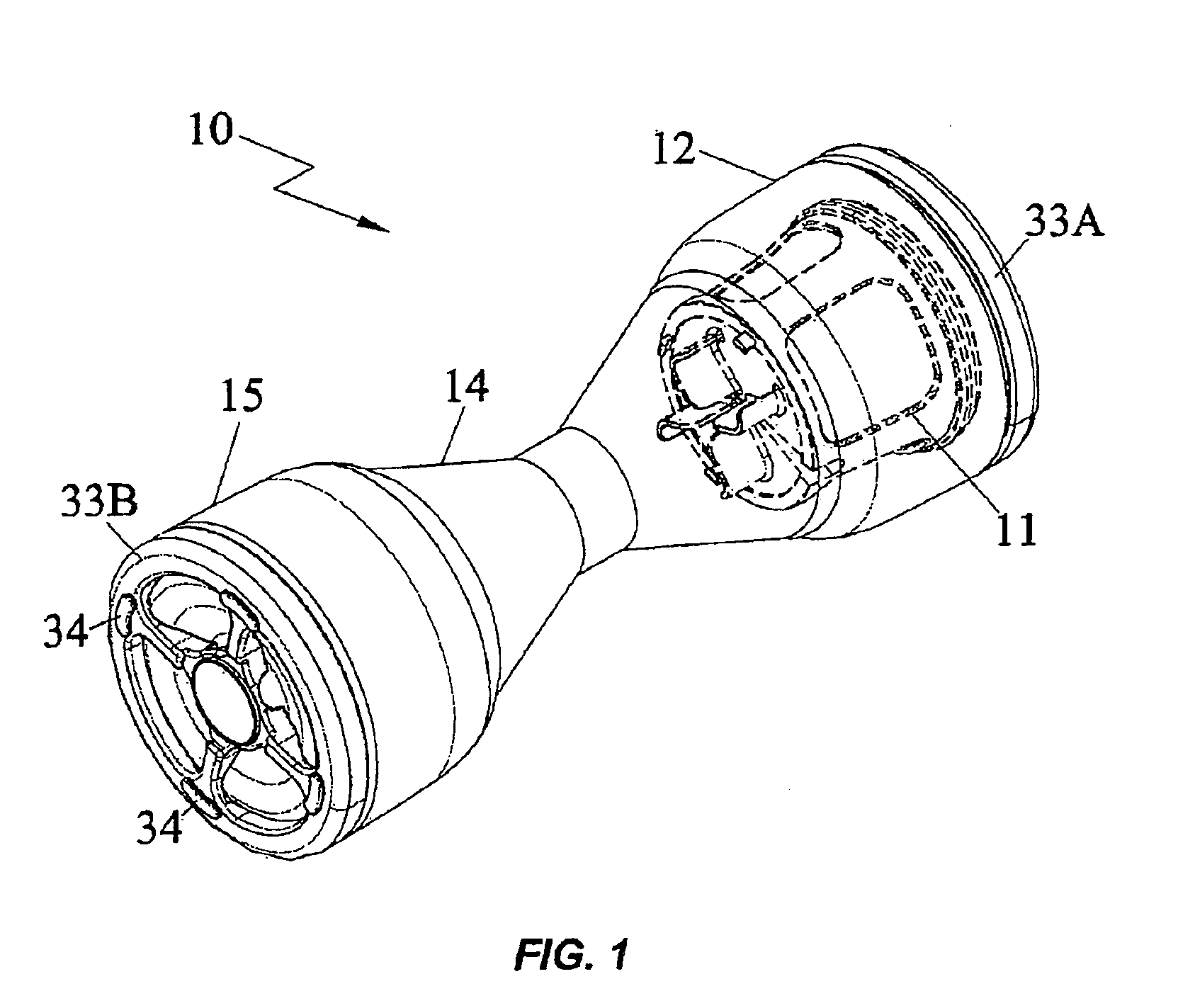

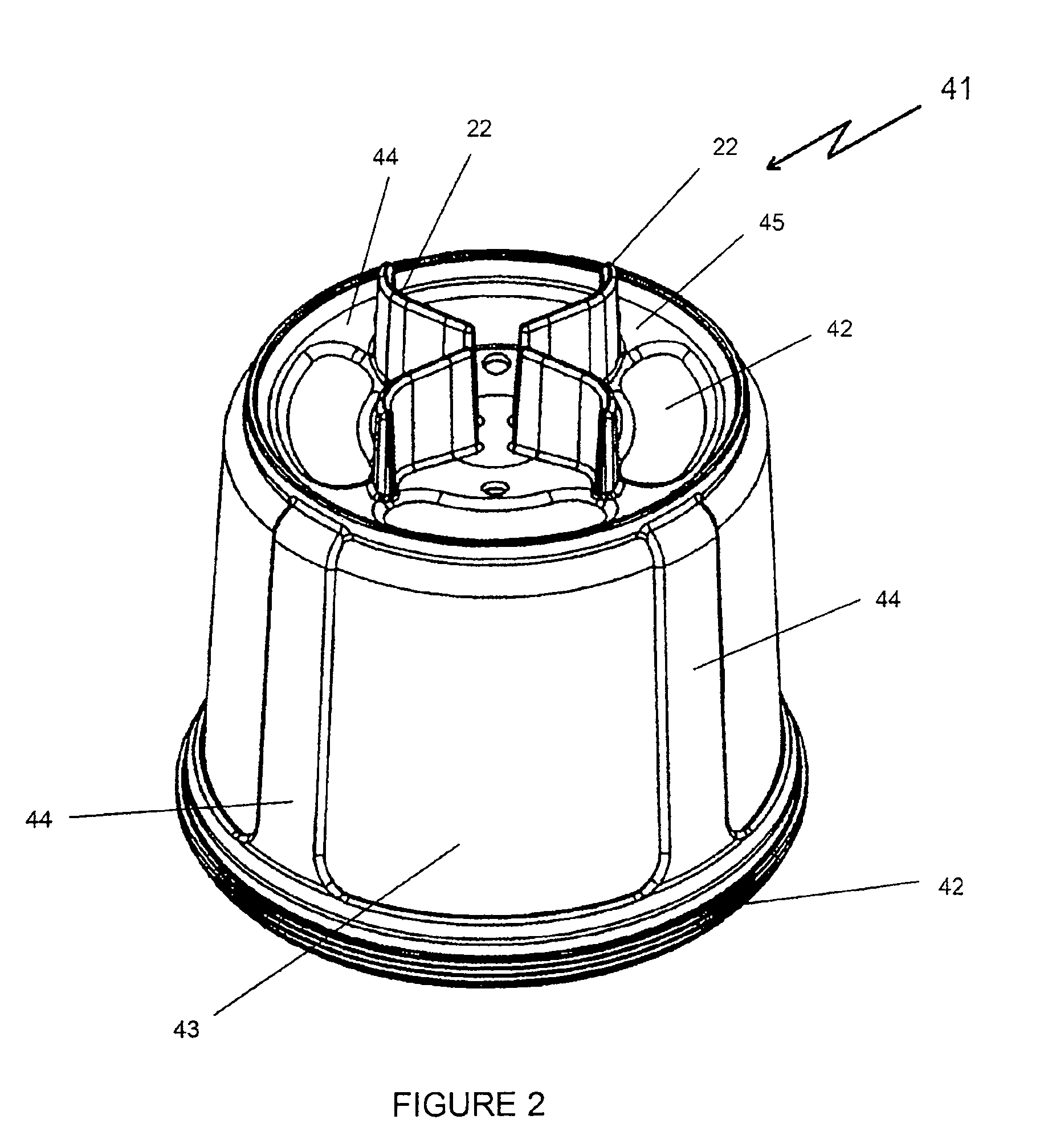

Apparatus for Extracting Cold-Brewed Coffee Concentrate

The invention provides an hourglass shaped apparatus for cold brewing coffee, comprising a brew chamber, and extract chamber and a middle unit connecting the brew and extract chambers. The extract and brew chambers comprise two ends of the hourglass shaped middle unit. The brew chamber houses a free-standing self-contained filter containing coffee grounds inside a water-permeable barrier. Water is poured into the brew chamber to generate coffee extract through cold water infusion. After the brewing process, the apparatus is inverted, and the coffee travels into the extract chamber through the middle unit for dispensing. Coffee brewed in this manner is less acidic and more flavorful than the conventionally hot-brewed beverage. All the components of the apparatus, the filter, the brew chamber, the extract chamber, and the middle unit, are detachable.

Owner:BL PATENTS LLC

Living hinge

InactiveUS7685676B2Increased durabilityImprove reliabilityPinless hingesMulti-purpose toolsEngineeringLiving hinge

A living hinge includes a hinge body formed of a material. The hinge body has attachment edges and a flexing zone between the attachment edges defining a flexing axis. The material of the hinge body has at least one separation formed therein in the flexing zone. The at least one separation describes an angle with the flexing axis being other than 90°.

Owner:MC CLELLAN W THOMAS

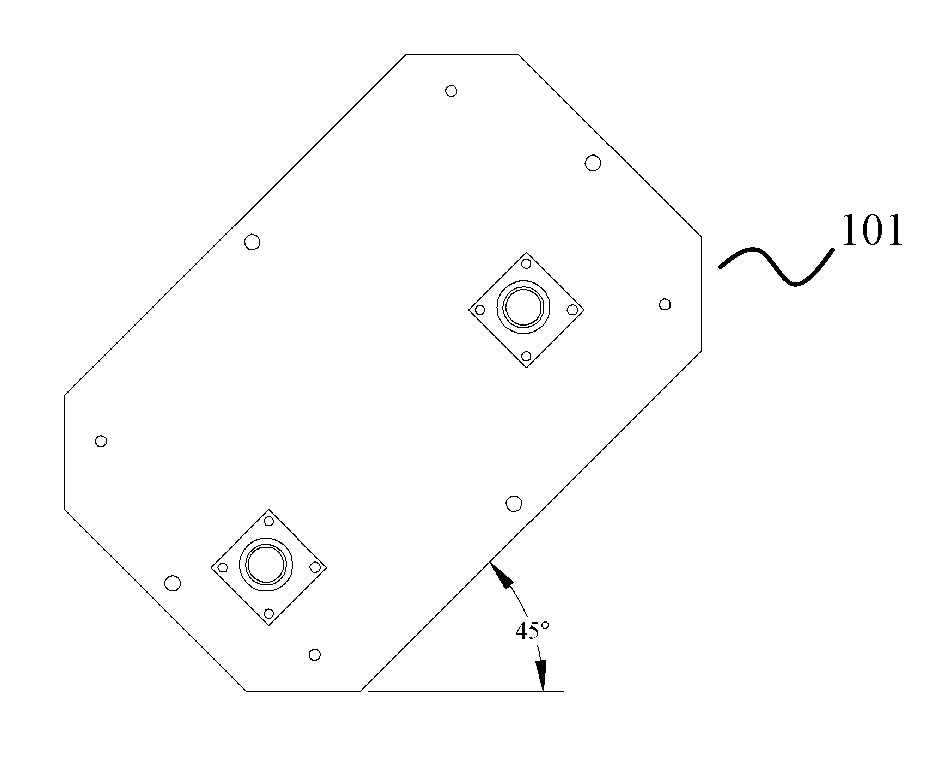

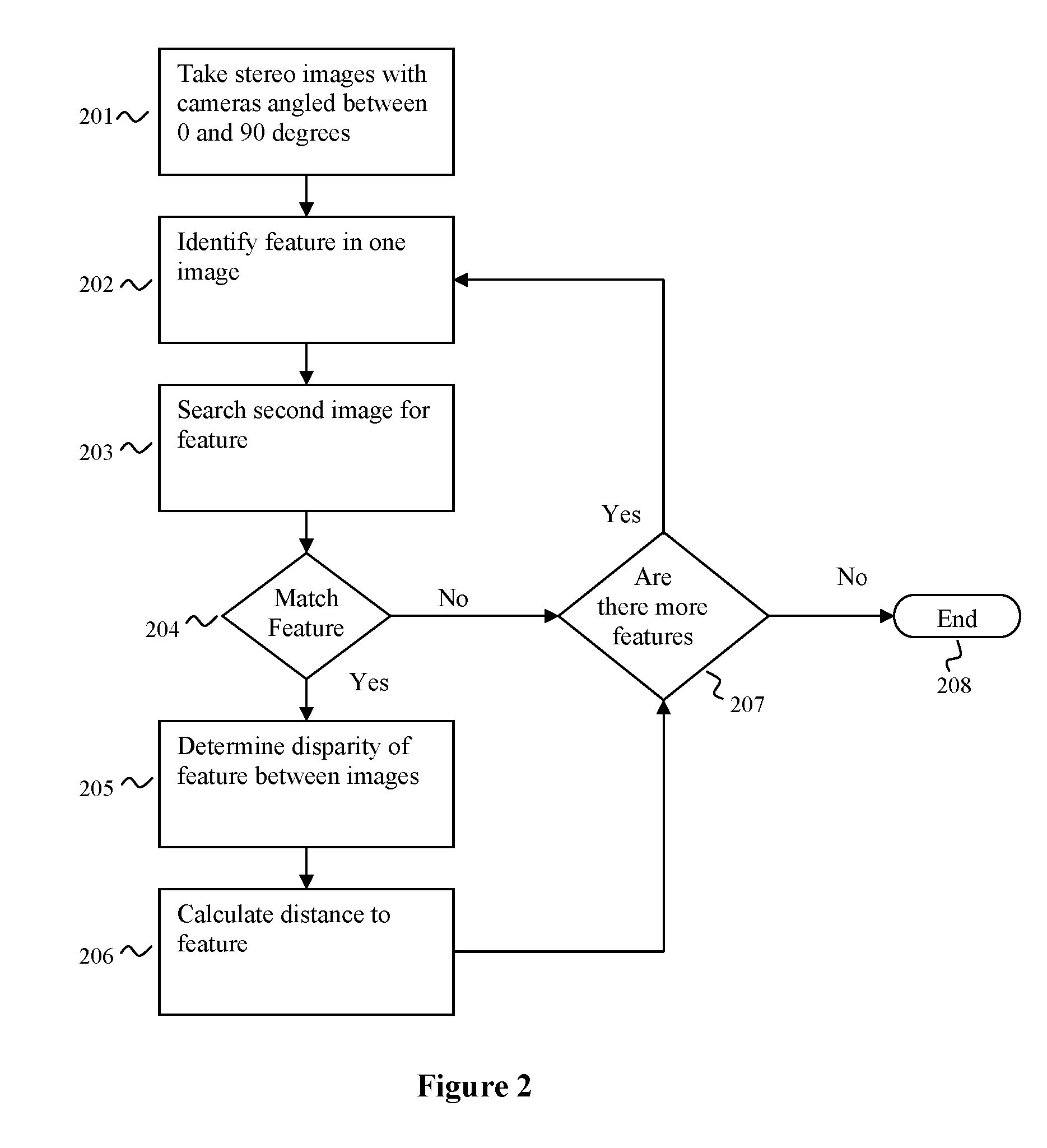

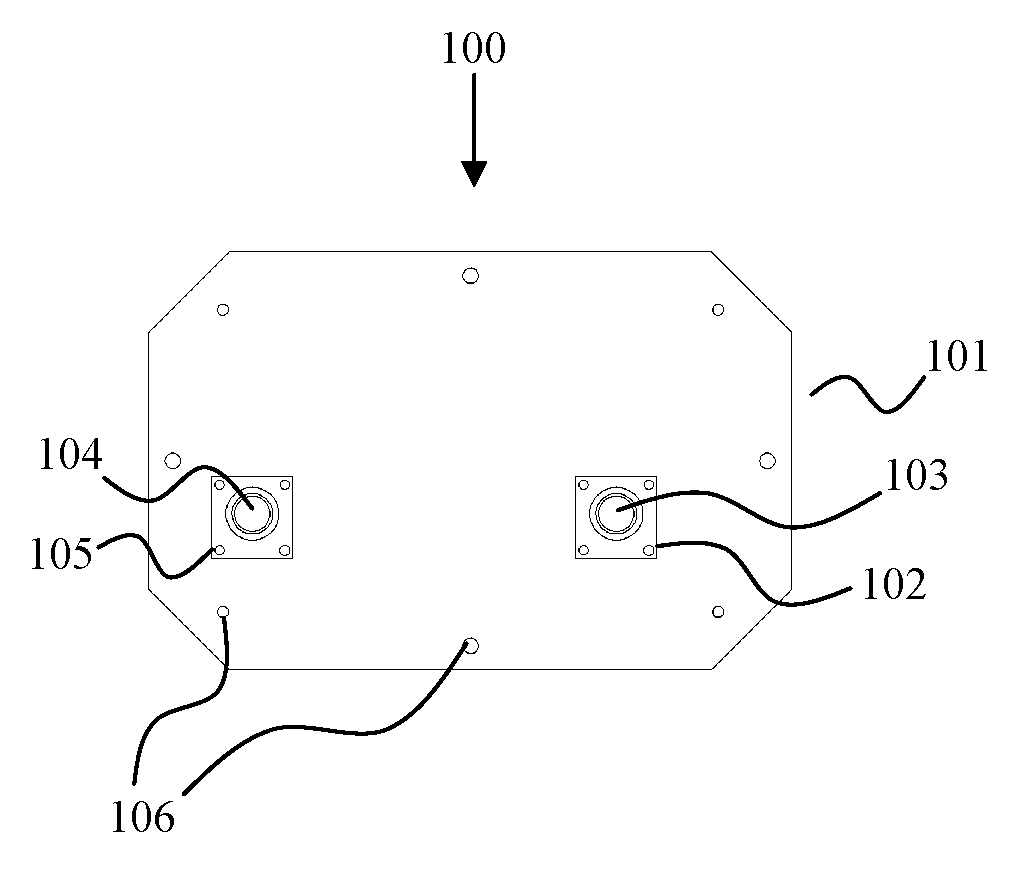

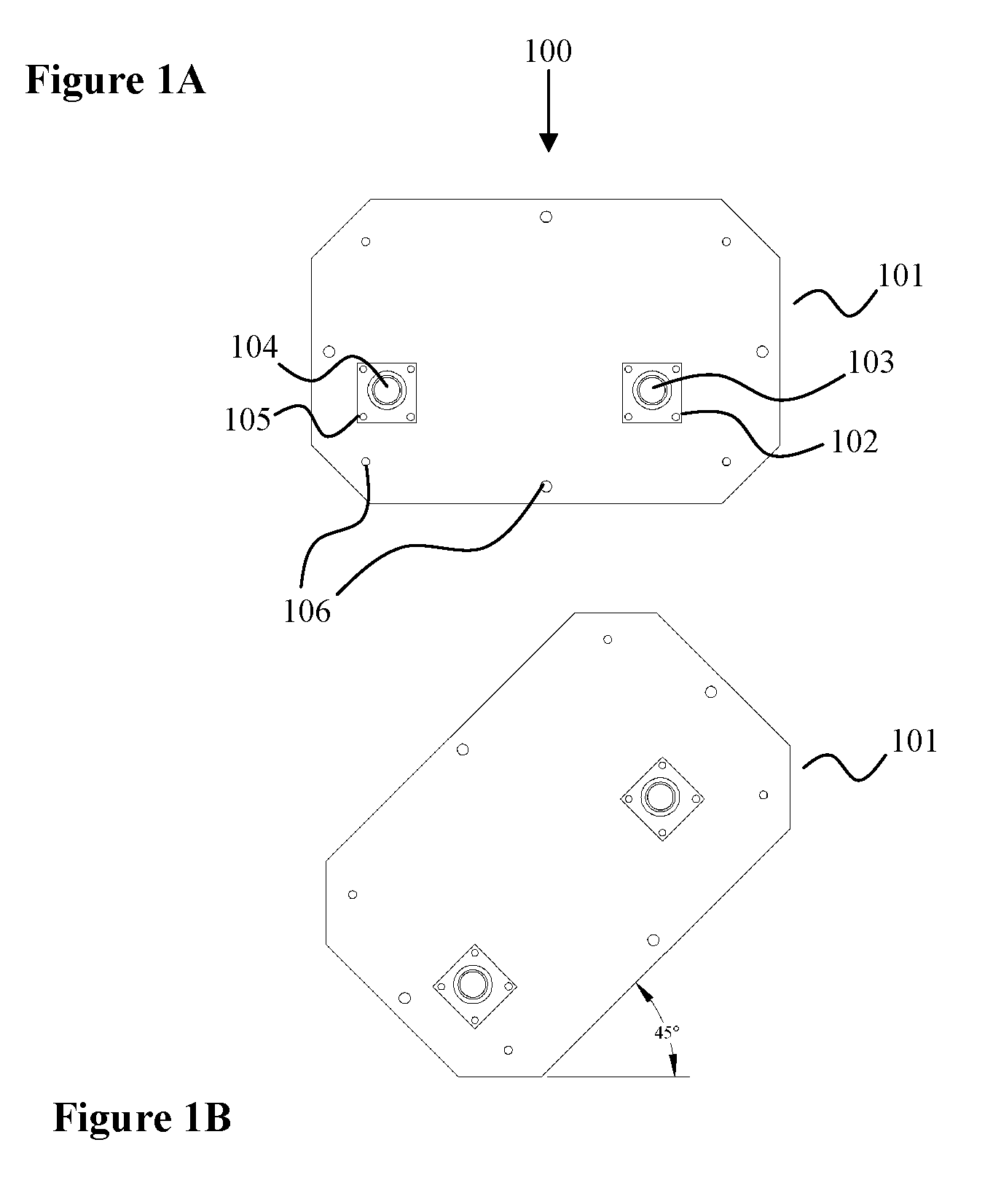

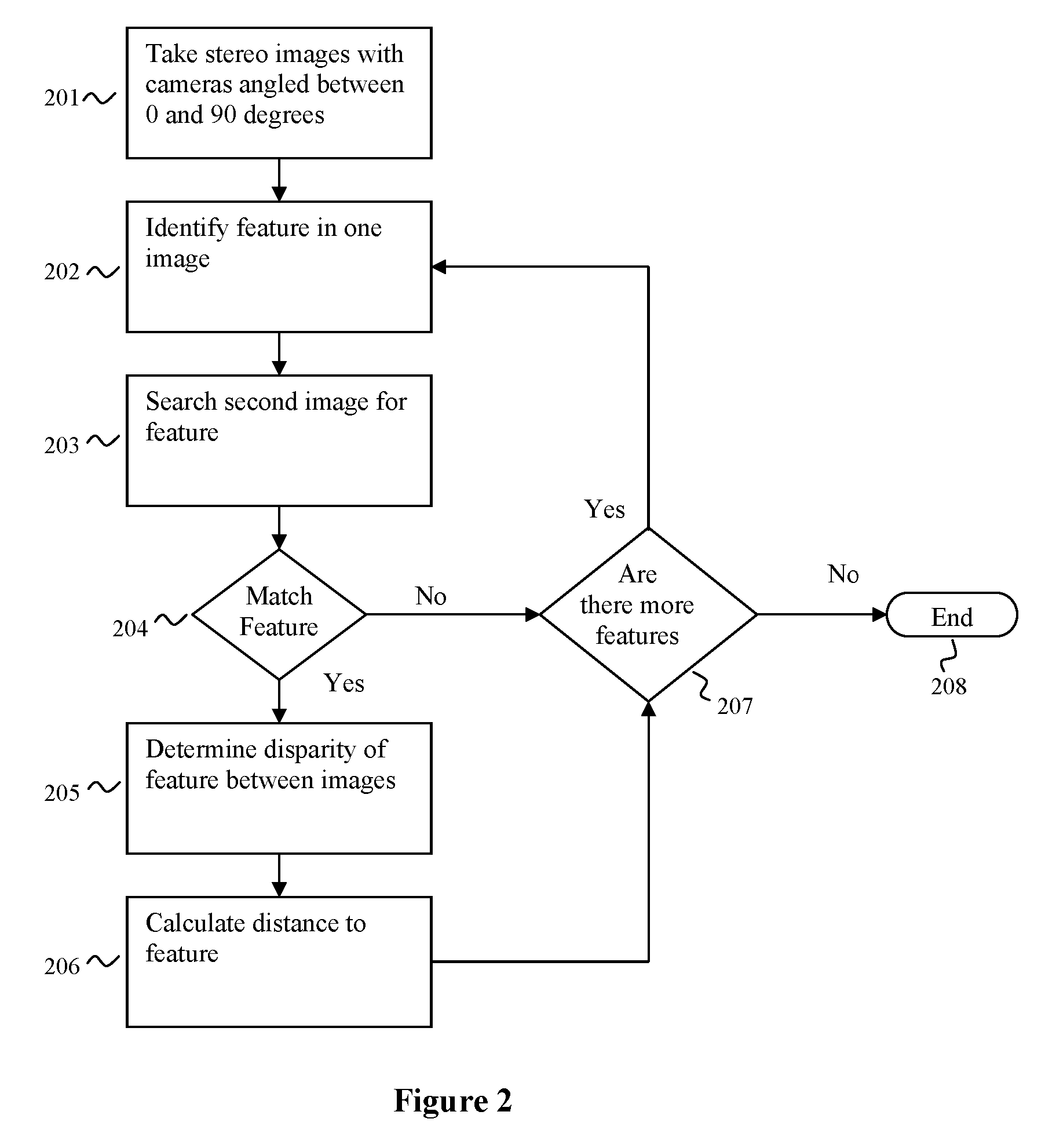

Angled axis machine vision system and method

InactiveUS20060012673A1Wide viewing angleSimple designImage enhancementImage analysisHorizontal and verticalMachine vision system

Embodiments of the invention comprise an angled axis machine vision system having a camera system angled with respect to an axis of the coordinate system of the environment. This configuration has all of the advantages of the horizontal alignment while eliminating the inherent problem of utilizing horizontal and vertical lines in an environment for distance calculations when the horizontal and vertical lines are parallel or close to parallel to an axis lying between camera centers of the camera system. With the camera centers angled about the roll axis, horizontal and vertical lines in the environment appear as angled lines in images taken from the cameras enabling more accurate distance calculations. With the camera centers angled downward about the pitch axis objects that are near are more readily observed. With angled axis rotation it is still possible for lines in the environment to be parallel to the axis defined between the camera centers, but these instances are rarer than horizontal or vertical lines in real world environments. Embodiments of the invention may comprise a camera mount that is rotatably mounted to a support wherein two sets of pictures from each of the cameras may either be utilized. In one embodiment the two sets are compared for the number of lines which are parallel to the axis of the camera centers and the set of pictures with the least lines parallel is used for distance calculations. In another embodiment, the two sets are utilized to correlate the distances derived from each set of pictures.

Owner:VISION ROBOTICS

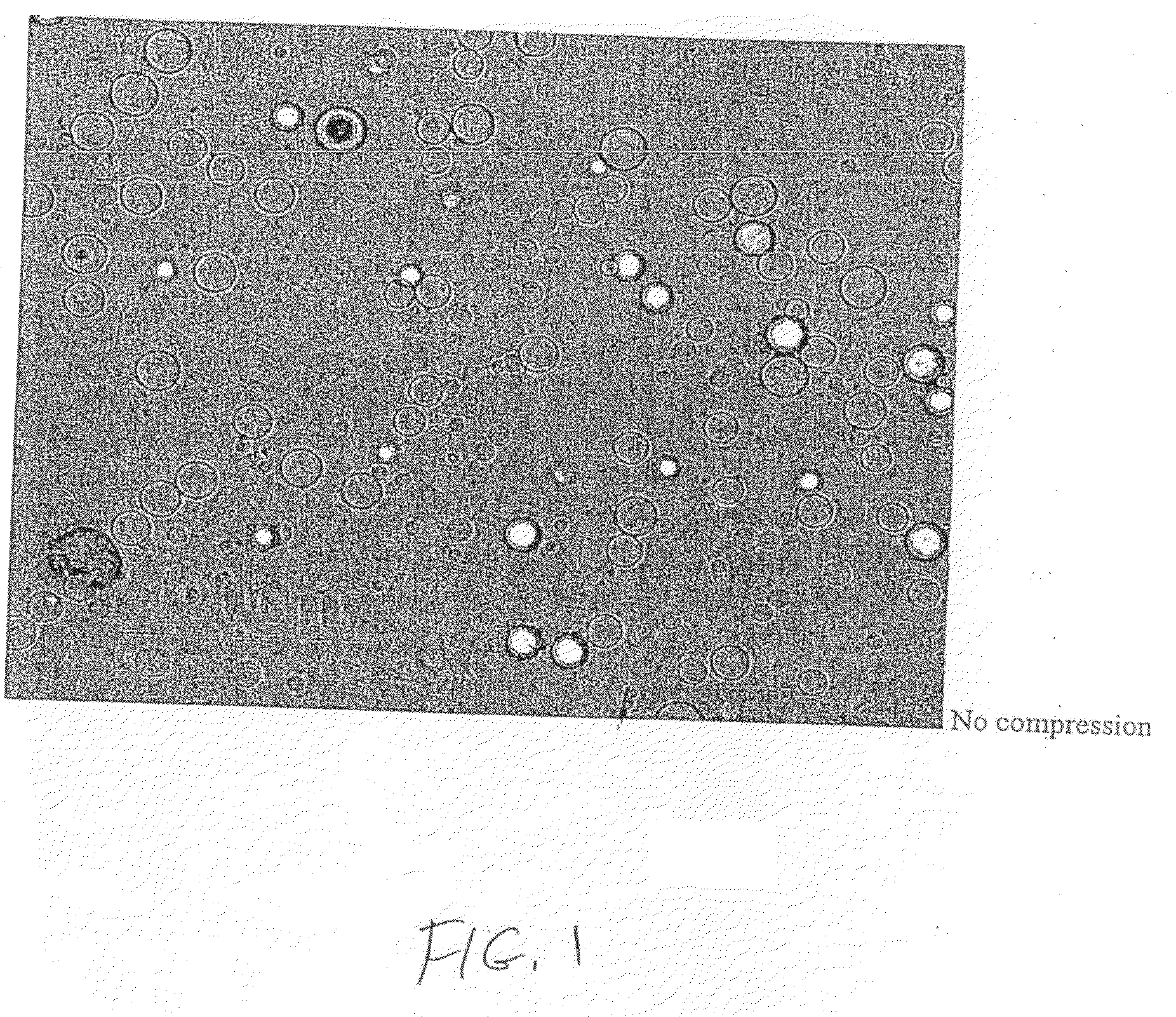

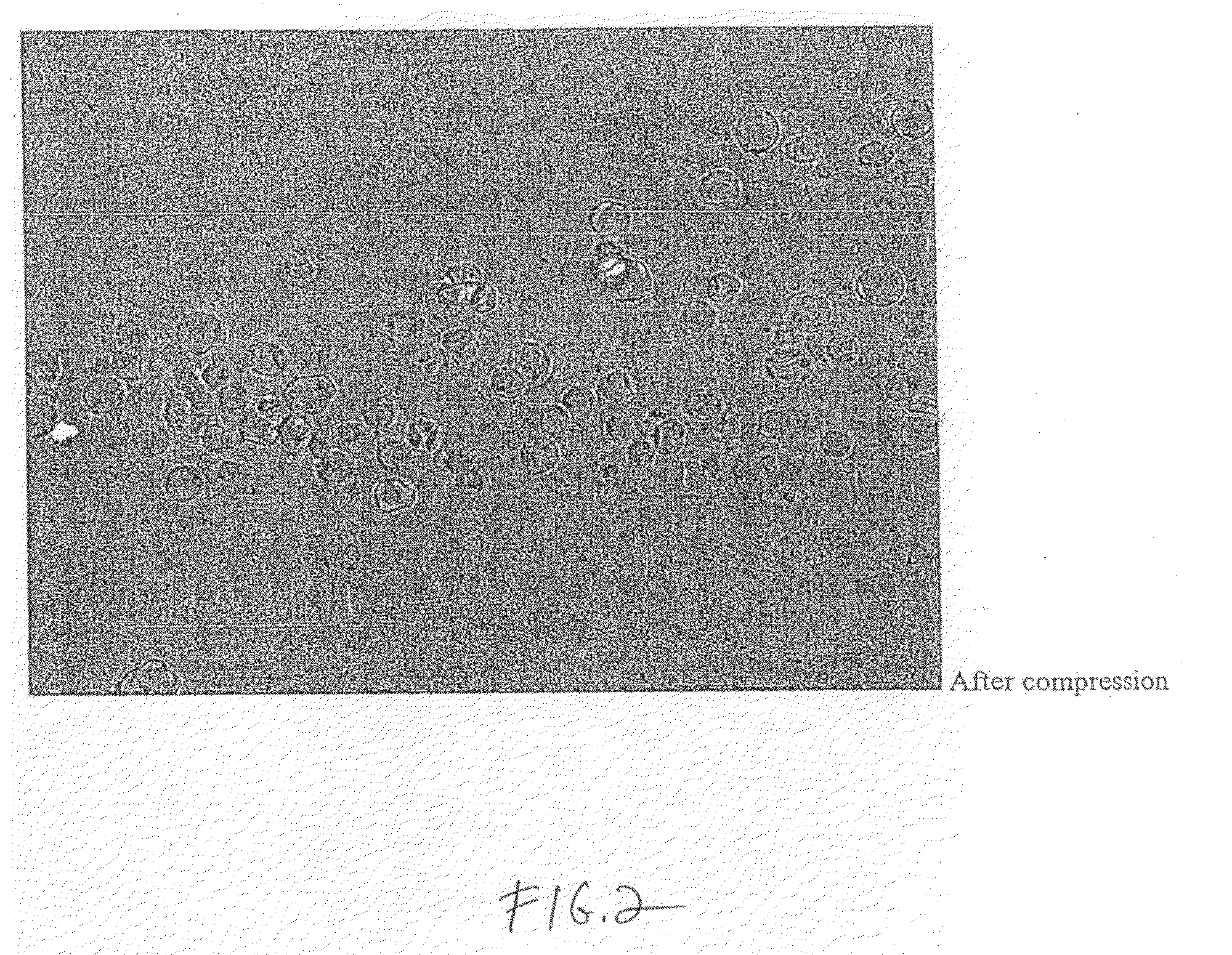

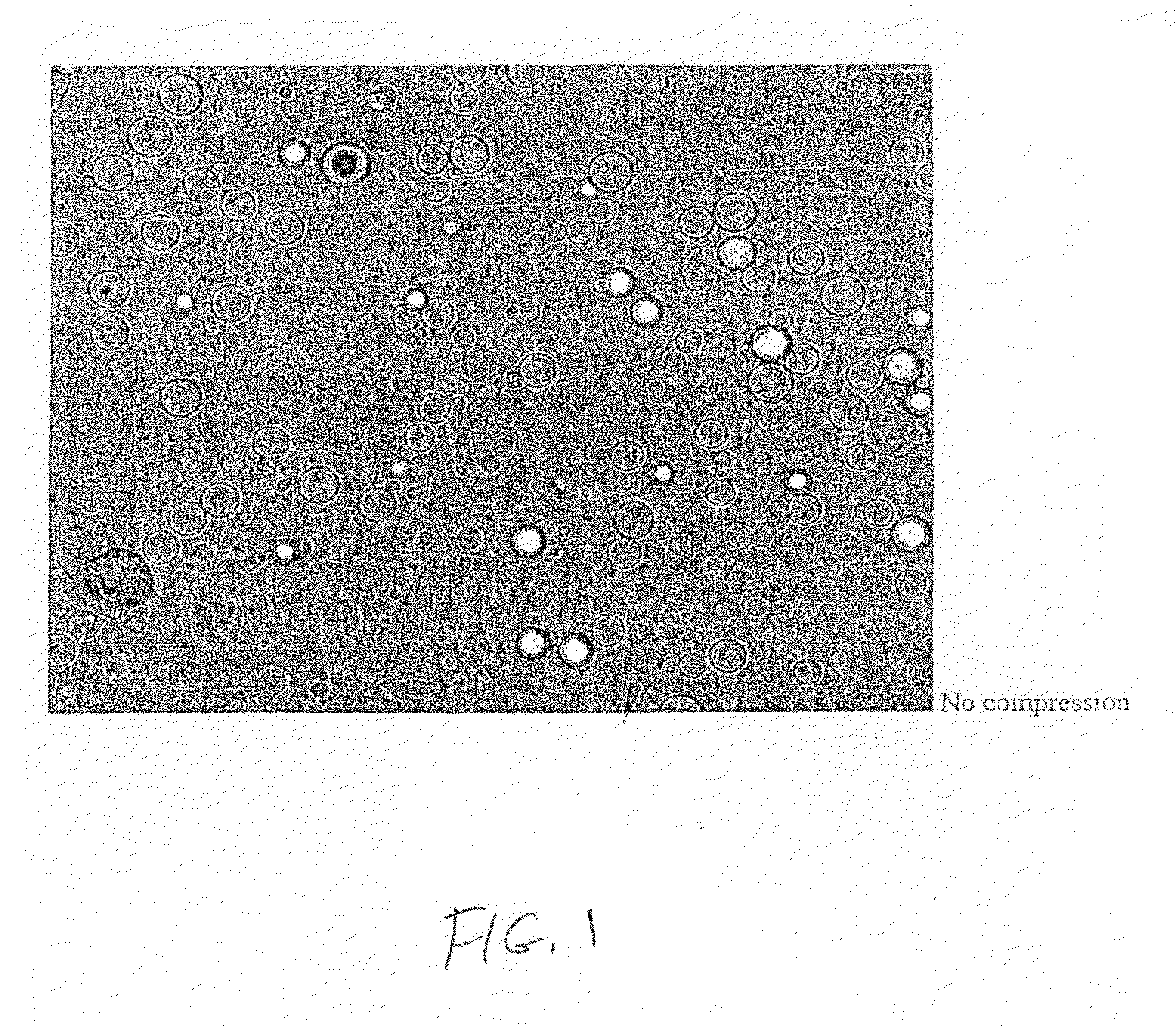

Controlled release implantable dispensing device and method

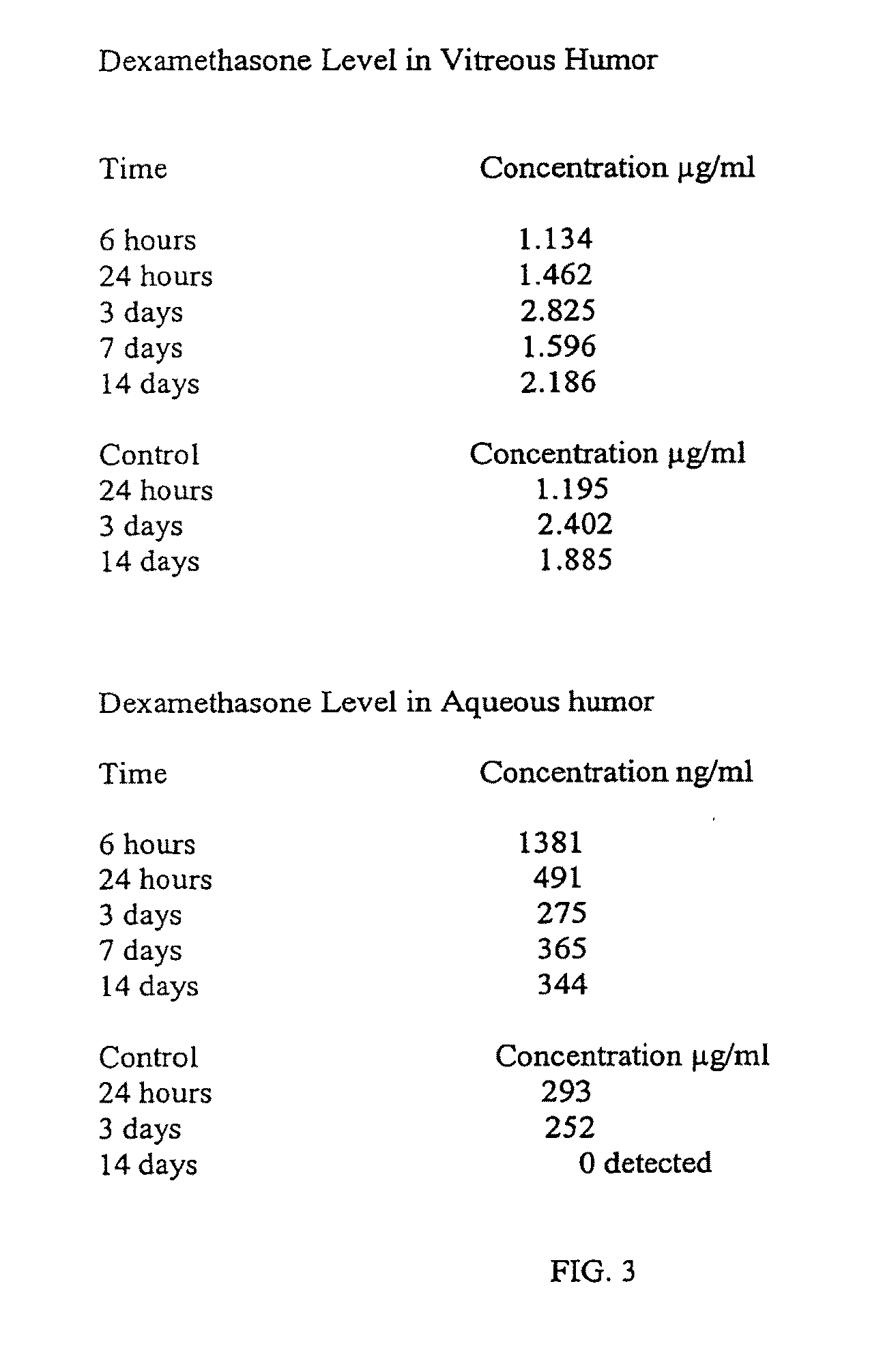

ActiveUS20090270308A1Easy to useOptimization rangePowder deliveryOrganic active ingredientsControl releaseNanoparticle

A dispensing device having a polymer which is combined with a therapeutic agent in the form of a microparticle or nanoparticle which is “hyper-compressed” to form a controlled release dispensing device and methods of locally administering a therapeutic agent using said microparticles.

Owner:SUSTAINED NANO SYST

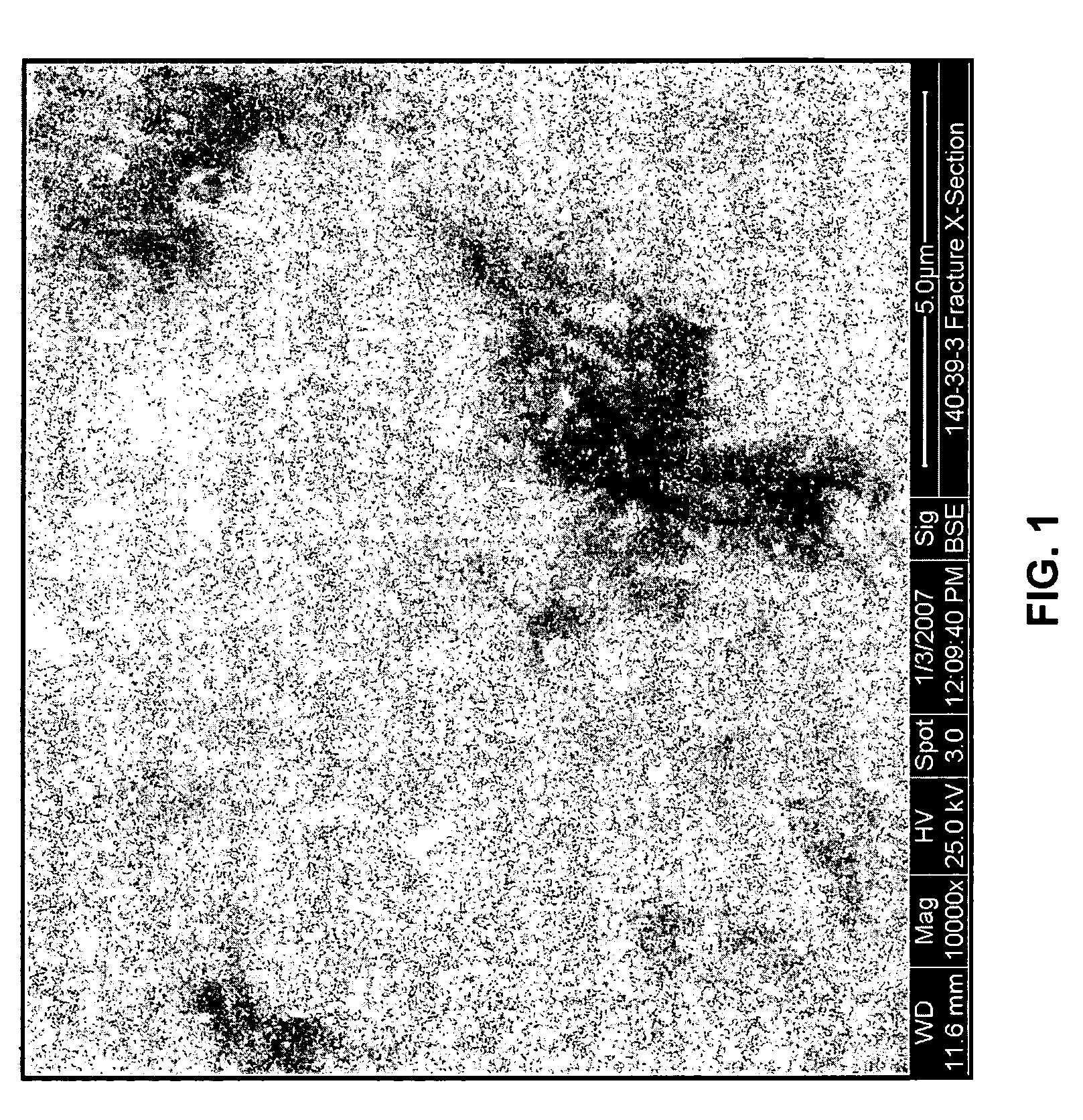

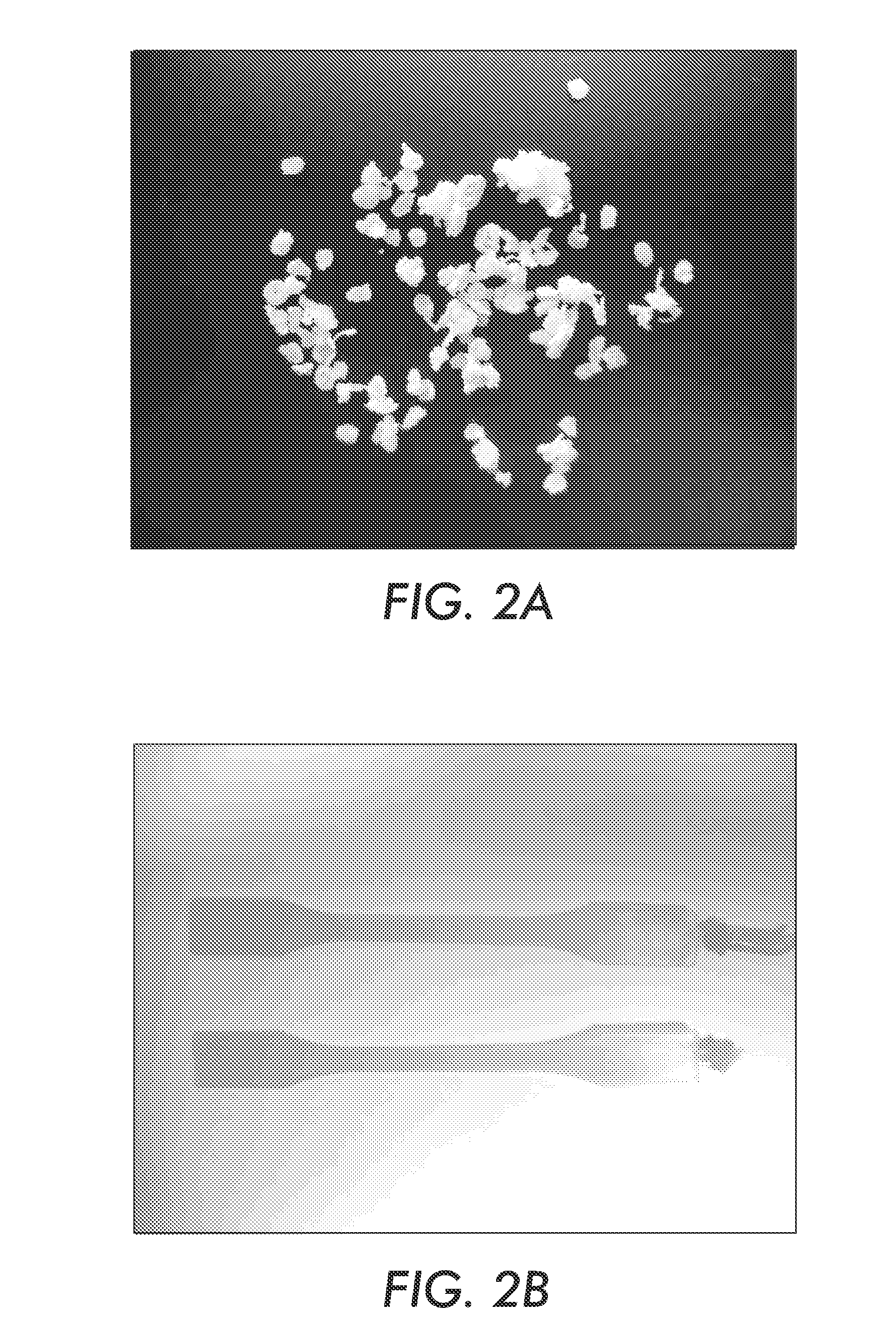

Nanocomposite method of manufacture

ActiveUS20080262126A1Improved and equivalent mechanical performanceImprove mechanical propertiesMaterial nanotechnologyCeramic shaping apparatusMasterbatchHigh concentration

Disclosed are systems and methods for the formation of a polymer nanocomposite material using a high-concentration masterbatch as a source of nanocomposite filler.

Owner:NATURALNANO CORP

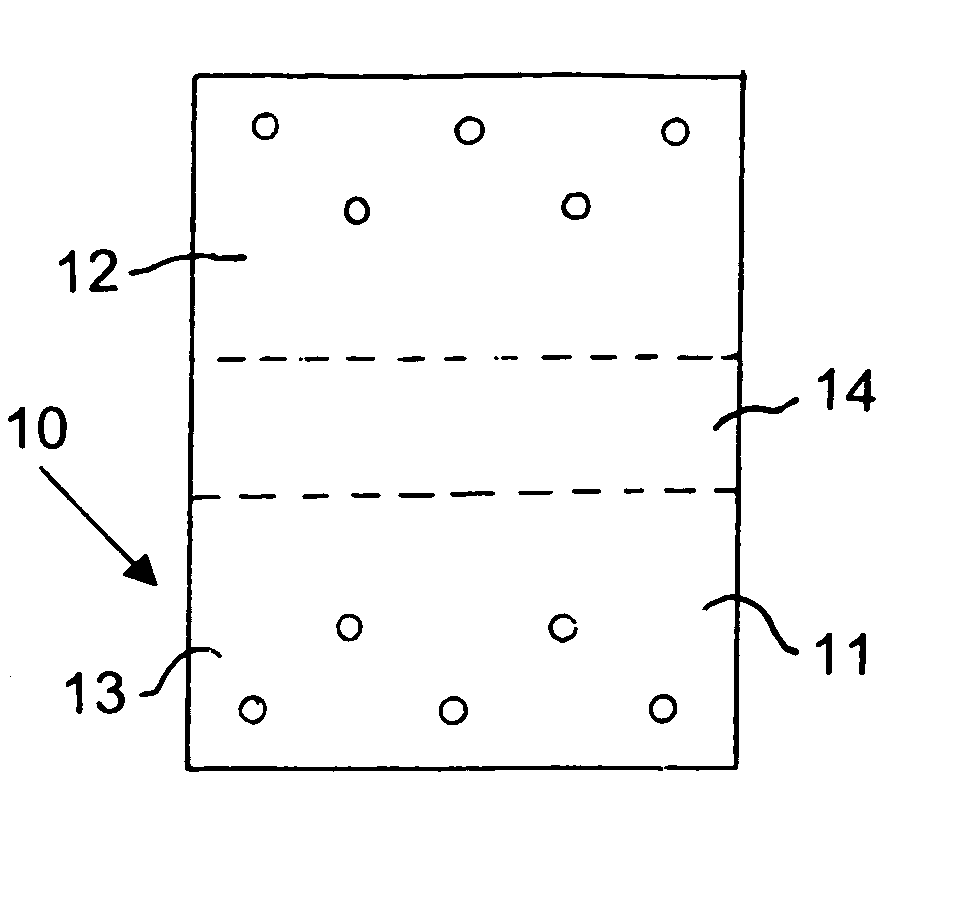

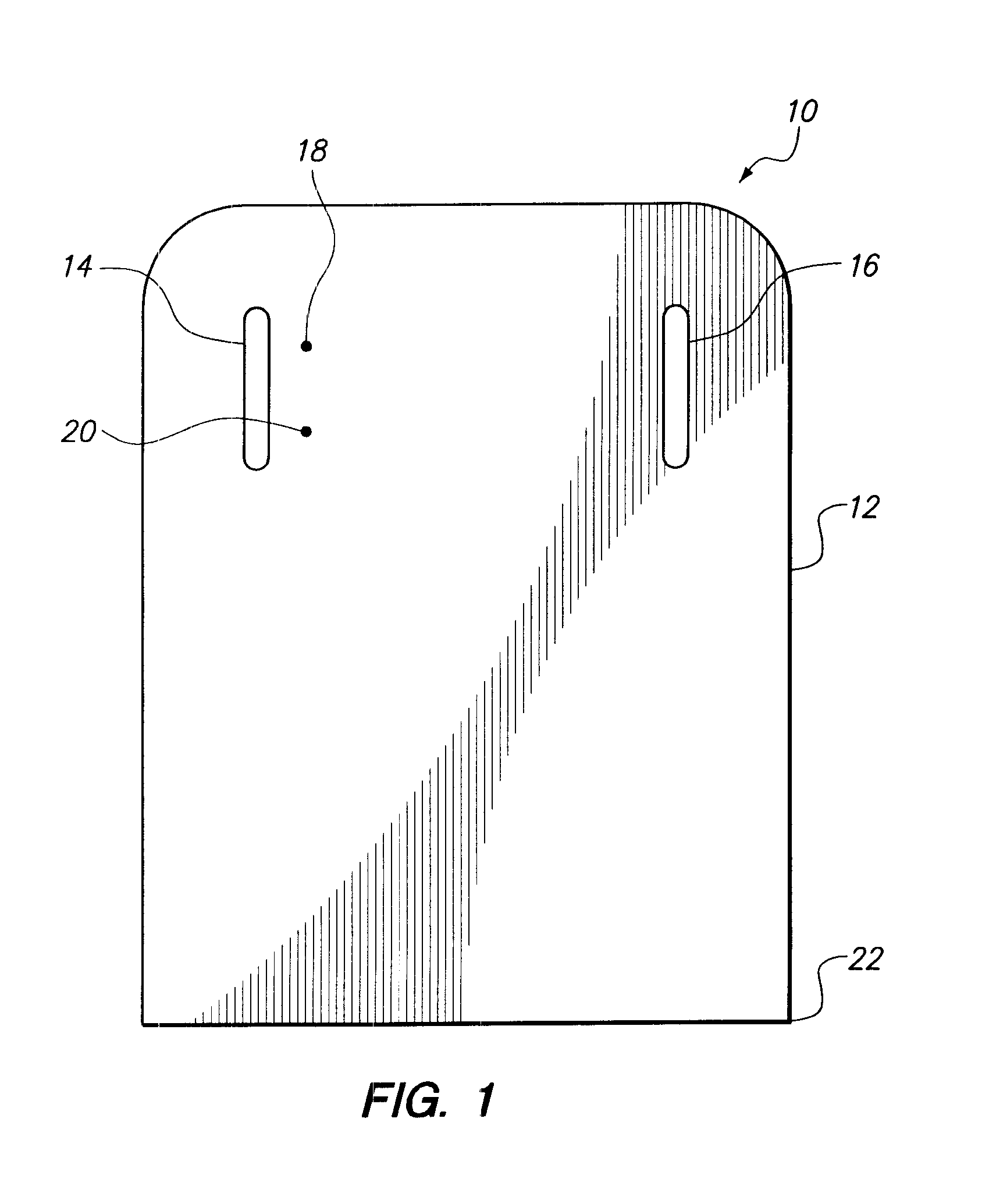

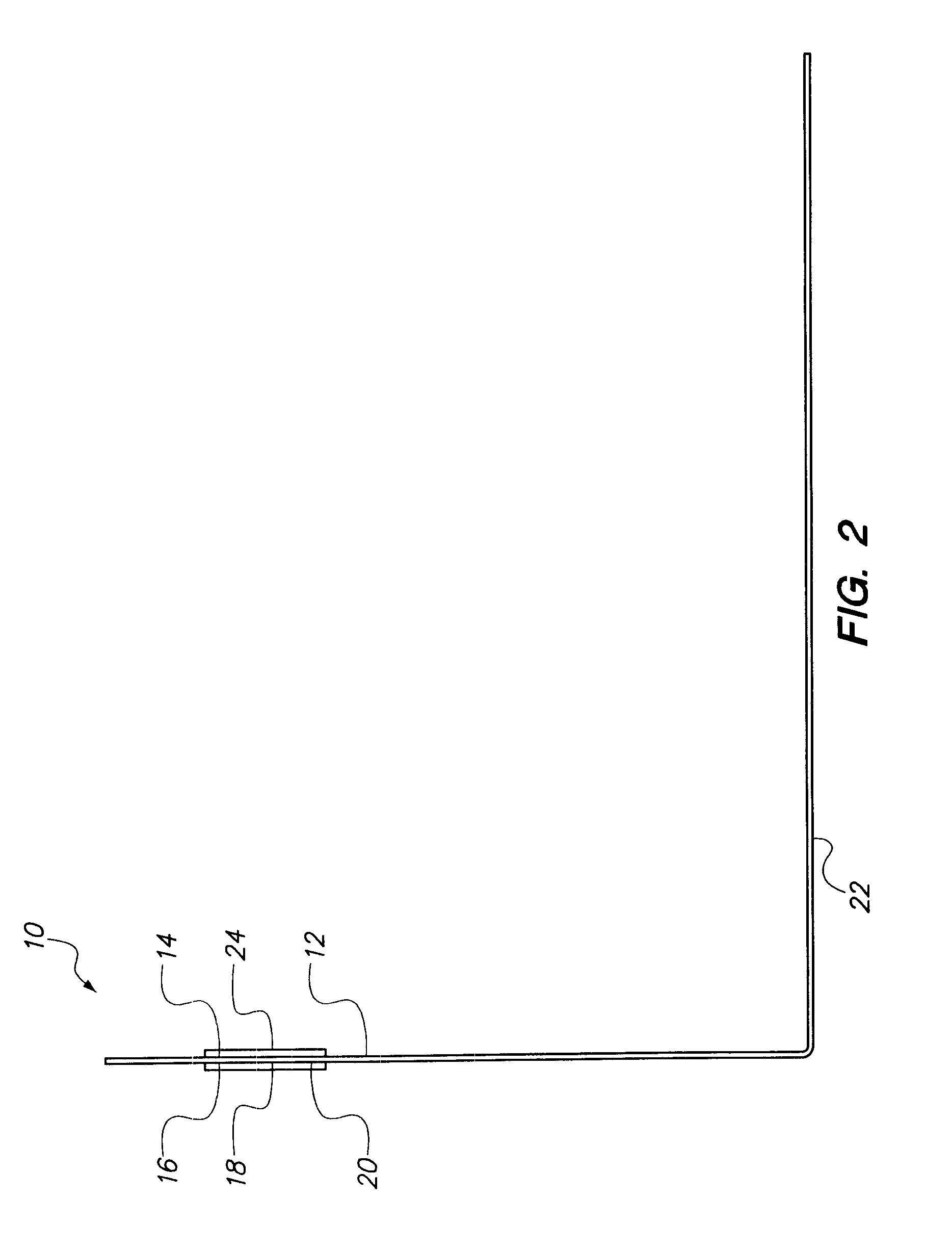

Package handle

InactiveUS20090180716A1Solve the real problemEasy to punchBagsSacksEngineeringMechanical engineering

A package having a handle portion is disclosed. The package generally includes opposing panel portions that at least partially define an interior cavity therebetween accessible through an access opening. The handle is generally formed by two or more openings or apertures punched or cut into a portion of the package. The handle can be further defined by a cut or slit line extending between and in communication with the apertures to provide a hingeable flap.

Owner:STEELE MARK

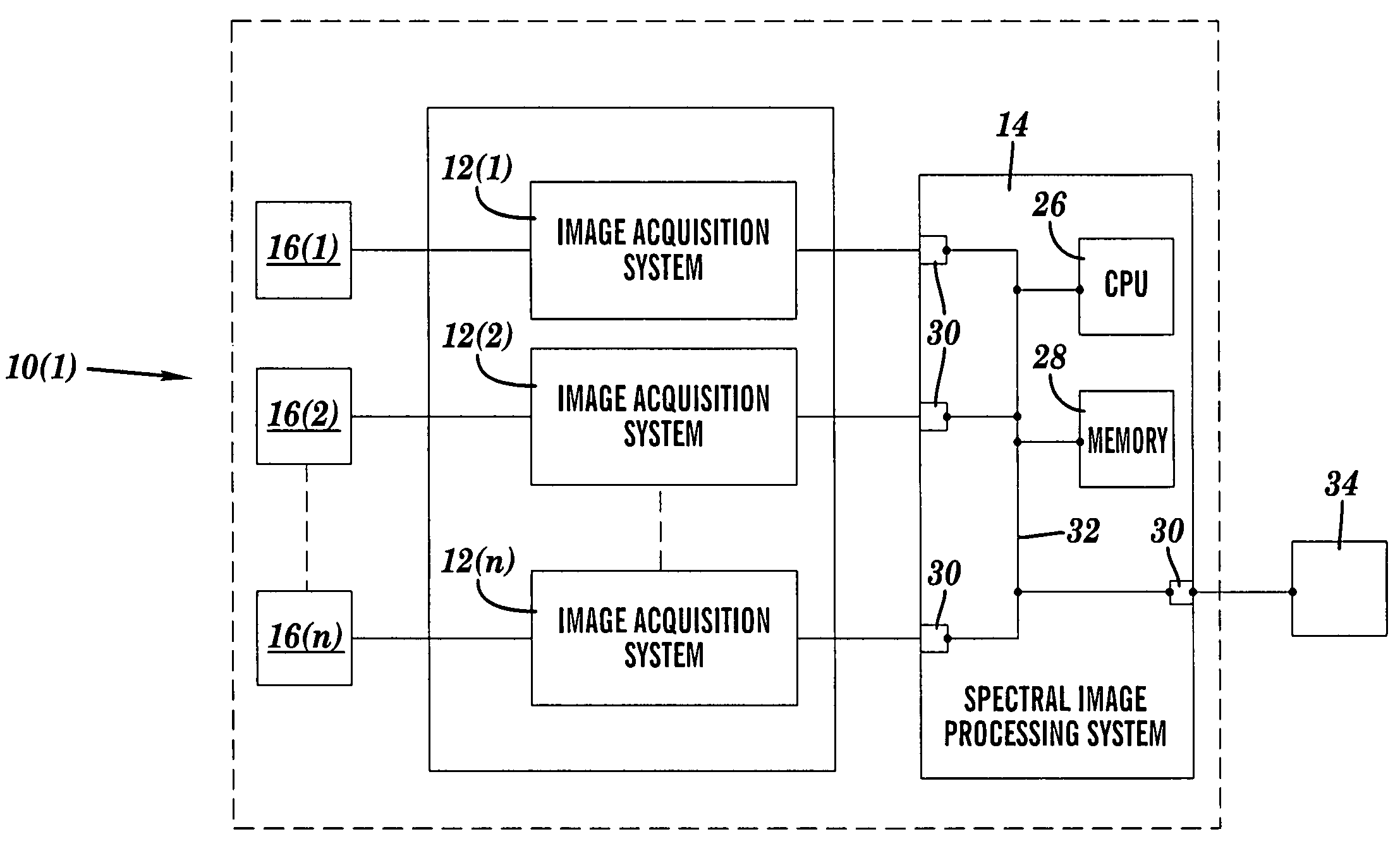

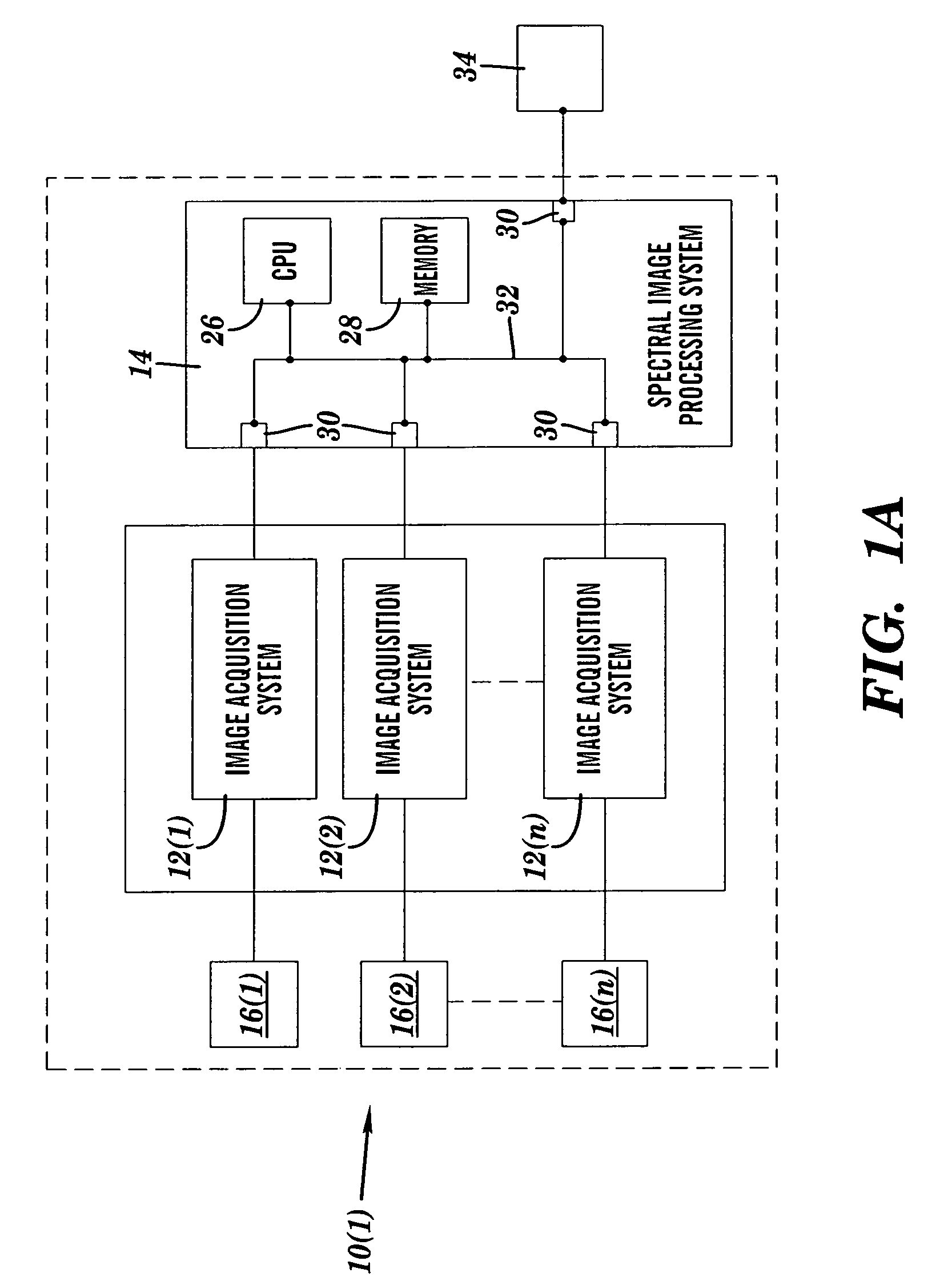

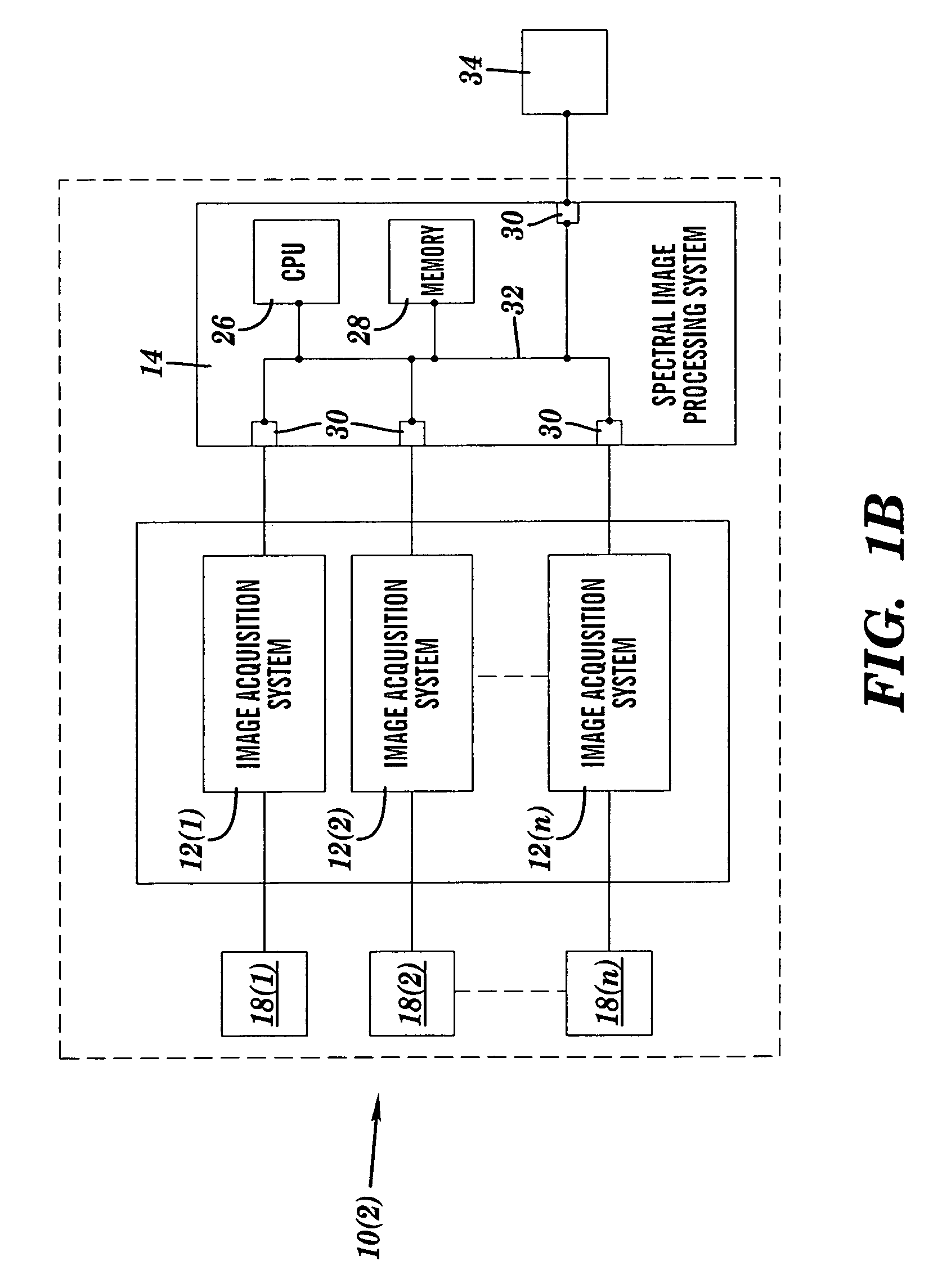

System and method for scene image acquisition and spectral estimation using a wide-band multi-channel image capture

InactiveUS7554586B1Accurate spectral estimationGood colorTelevision system detailsSpectrum investigationSpectral transmittanceMultispectral image

A system and method for multi-spectral image capture of a first scene includes acquiring a first series of images of the first scene with one or more image acquisition systems and filtering each of the first series of images of the scene with a different non-interference filter, illuminating each image of the first series of images with a different illuminant, or acquiring each of the images of the first series of images with a different image acquisition system. Each of the image acquisition systems has at least one color channel, each of the non-interference filters has a different spectral transmittance, and each of the illuminants has a different spectral power distribution.

Owner:ROCHESTER INSTITUTE OF TECHNOLOGY

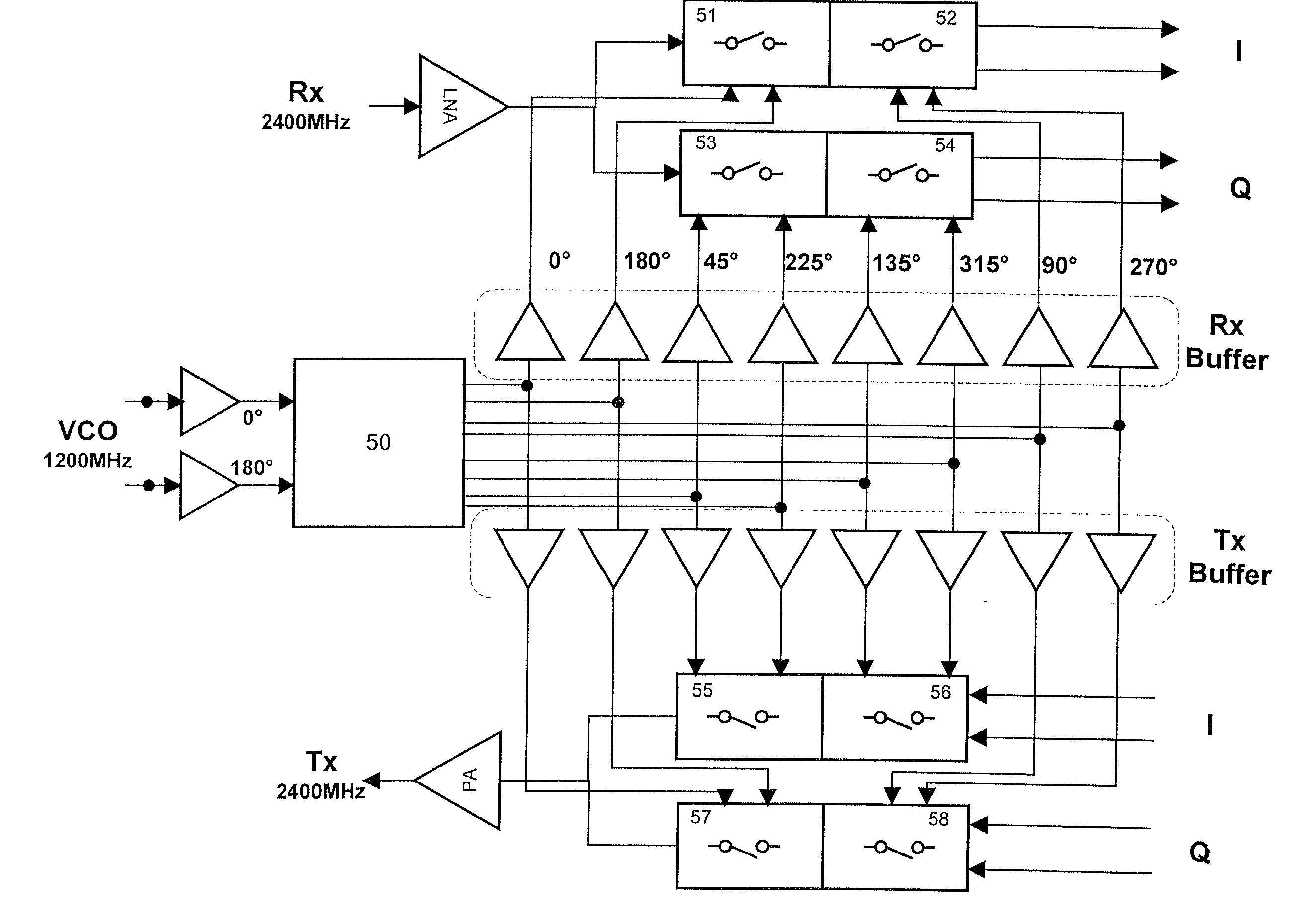

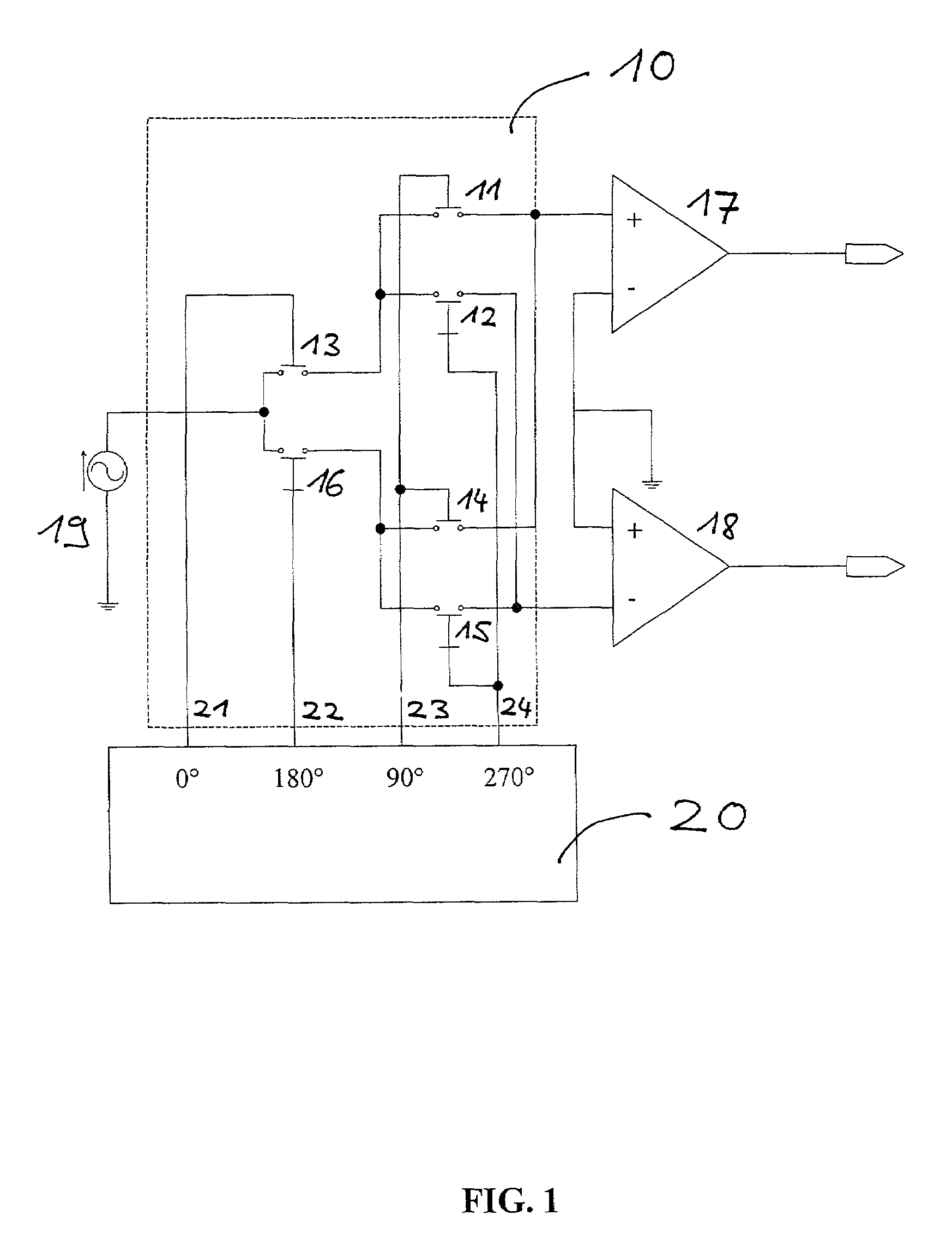

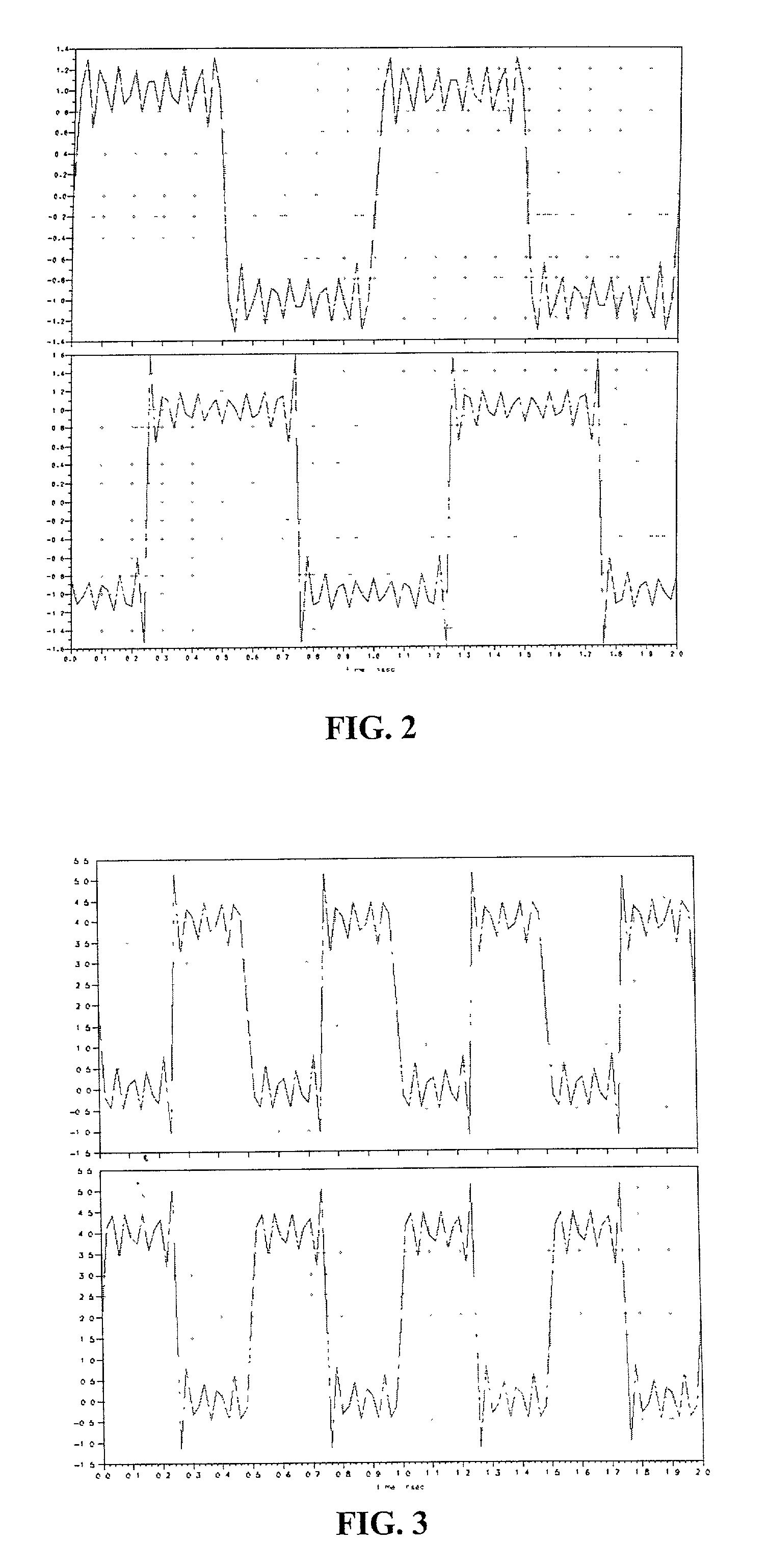

Harmonic mixer

InactiveUS7085548B1Simple circuit designHigh hardnessModulation transference balanced arrangementsAmplitude-modulated carrier systemsPhase shiftedHarmonic

The invention provides a harmonic direct conversion mixer having a multiplier circuit comprising first and second mixers and a generator for generating two first and two second control signals for controlling the first and second mixers. The control signals are balanced signals and are provided in four phases shifted by π / 2 in phase. The frequency of the control signals is different from the frequency of the mixer input signal.

Owner:MEDIATEK INC

Liquid crystal display and method for manufacturing same

ActiveUS7718234B2Reduce generationImprove batch productivityLiquid crystal compositionsStatic indicating devicesLiquid-crystal displayImaging quality

A liquid crystal display is provided which is capable of reducing the occurrence of defective display due to variations in the initial alignment direction of a liquid crystal alignment control film in a liquid crystal display of an IPS scheme, realizing the stable liquid crystal alignment, providing excellent mass productivity, and having high image quality with a higher contrast ratio. The liquid crystal display has a liquid crystal layer disposed between a pair of substrates, at least one of the substrates being transparent, and an alignment control film formed between the liquid crystal layer and the substrate. At least one of the alignment control films comprises photoreactive polyimide and / or polyamic acid provided with an alignment control ability by irradiation of substantially linearly polarized light.

Owner:NISSAN CHEM IND LTD

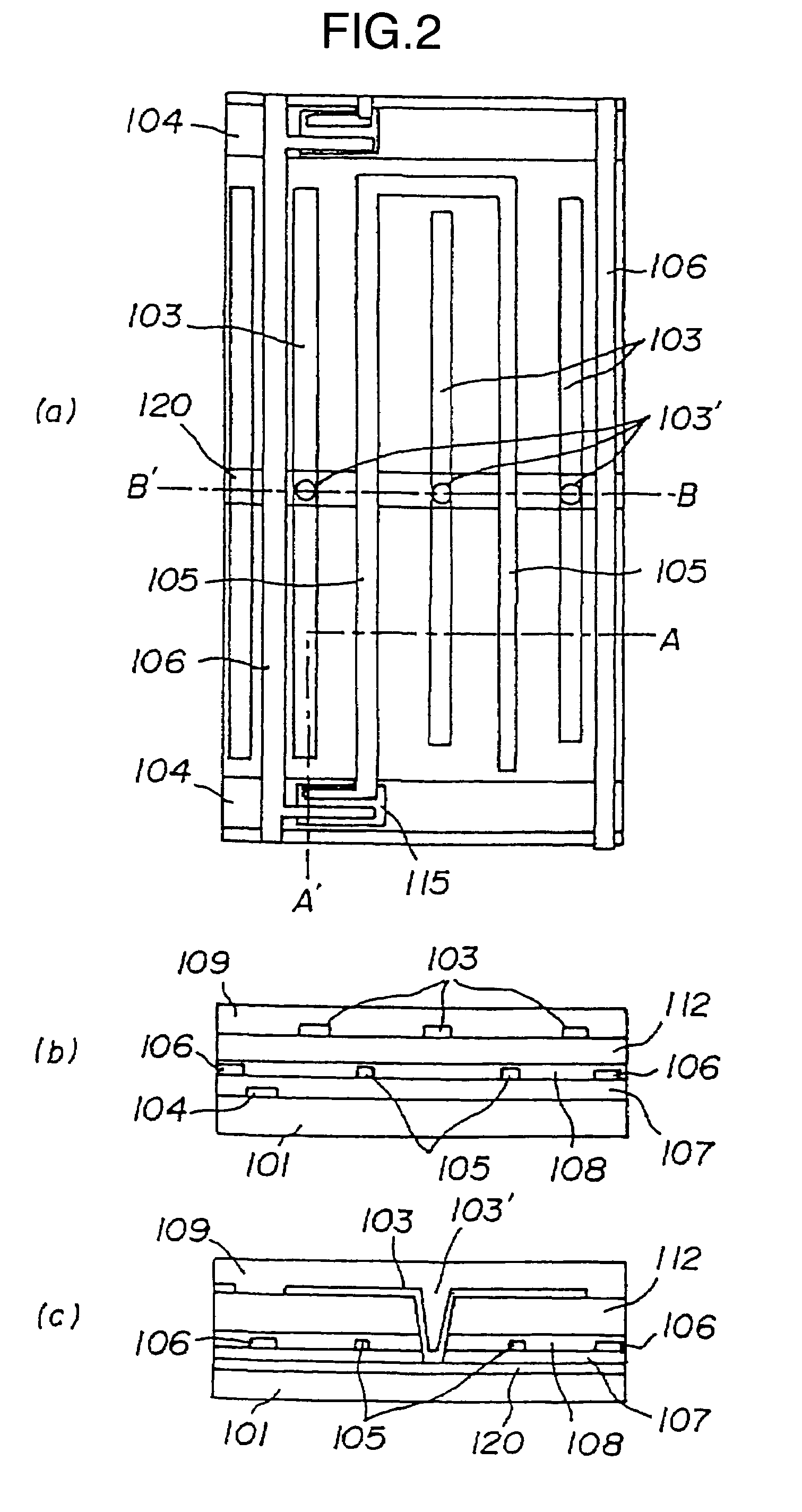

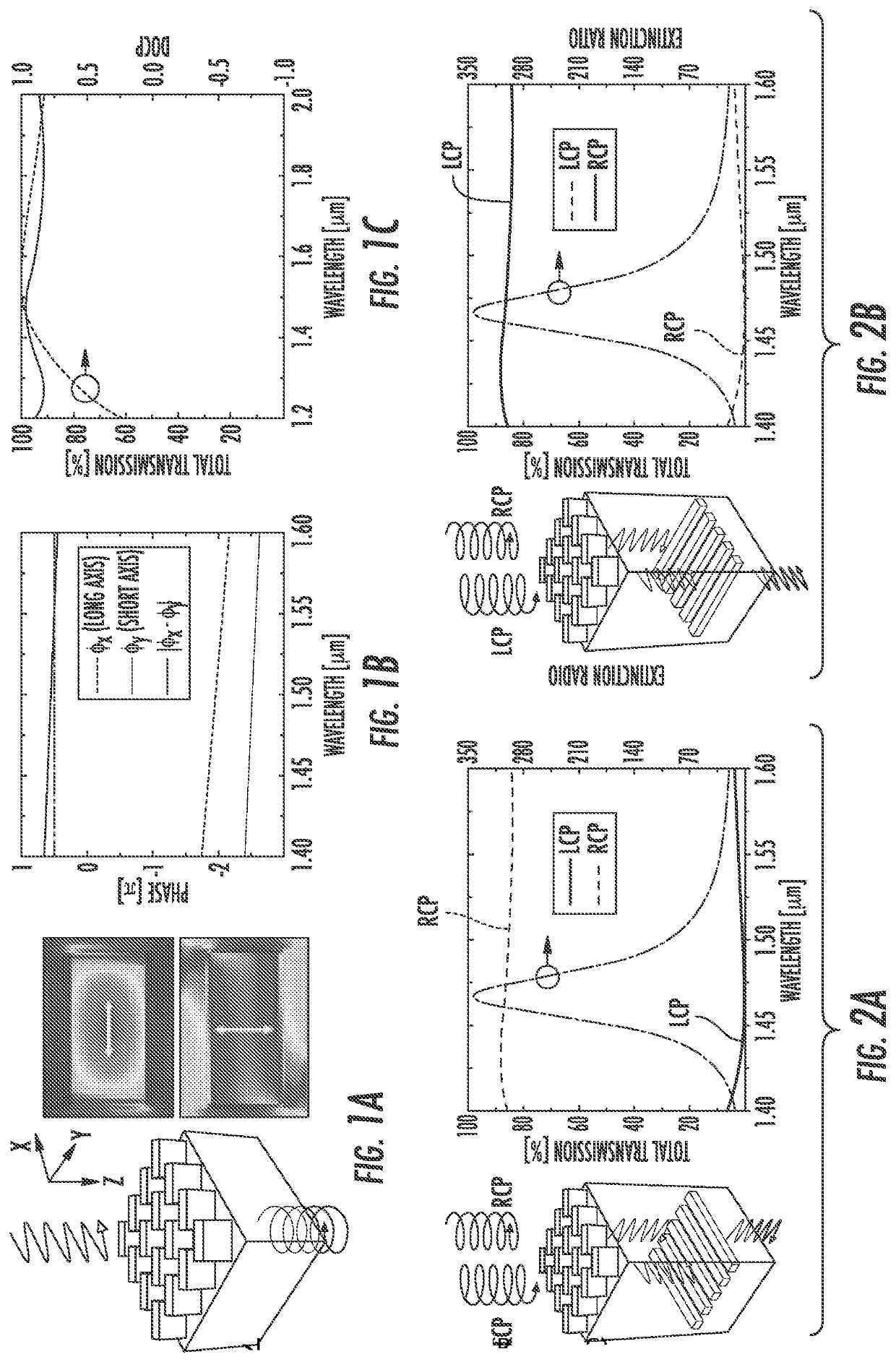

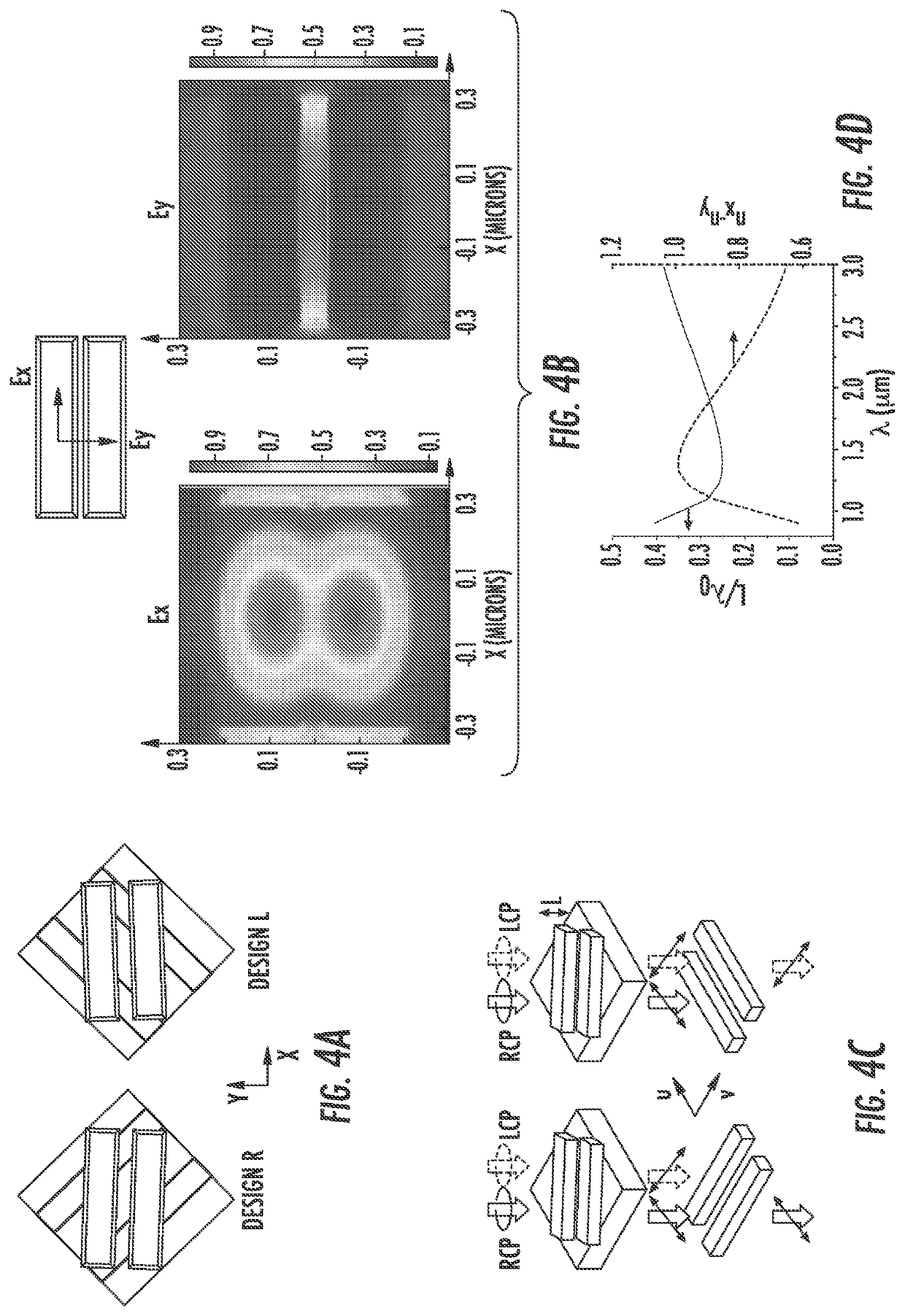

On-chip polarization detection and polarimetric imaging

ActiveUS20210190593A1Scalability to ultra-compact footprintReduce lossPolarising elementsNanoopticsPhotovoltaic detectorsPhotodetector

A polarization sensor is described. It includes a quarter-wave plate to convert circularly polarized light into linearly polarized light. The quarter-wave plate is realized as a metasurface. The sensor also includes a linear polarizer to analyze the light generated by the quarter-wave plate, and a photodetector to receive the analyzed light. The sensor may be combined with other linear polarization sensors to form a sensor capable of complete measurement of the polarization state of incident light. An array of these sensors can be integrated directly onto image sensors to form a polarimetric imager.

Owner:ARIZONA STATE UNIVERSITY

Nanocomposite master batch composition and method of manufacture

Disclosed are a polymer nanocomposite material and methods for the formation of the polymer nanocomposite material.

Owner:NATURALNANO

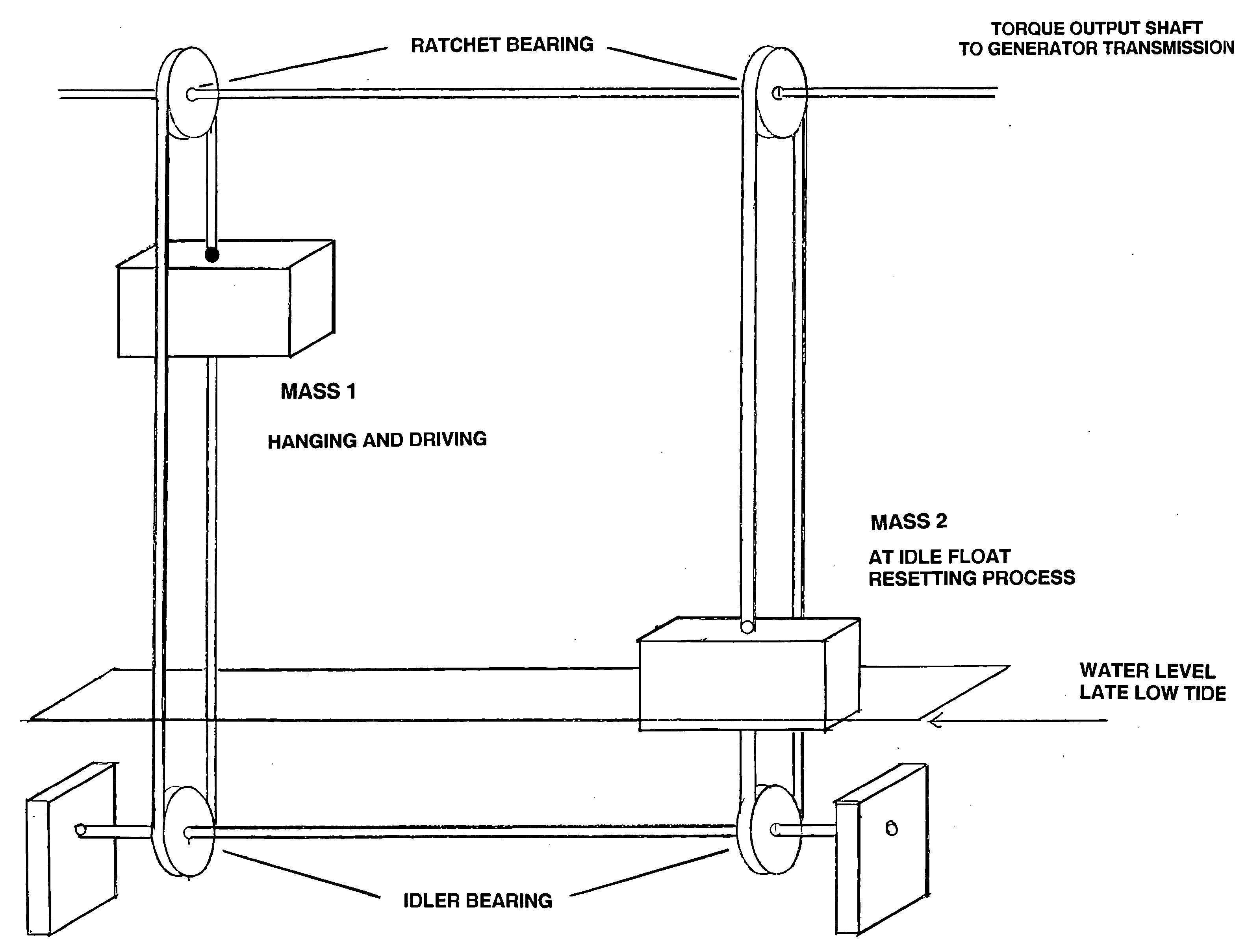

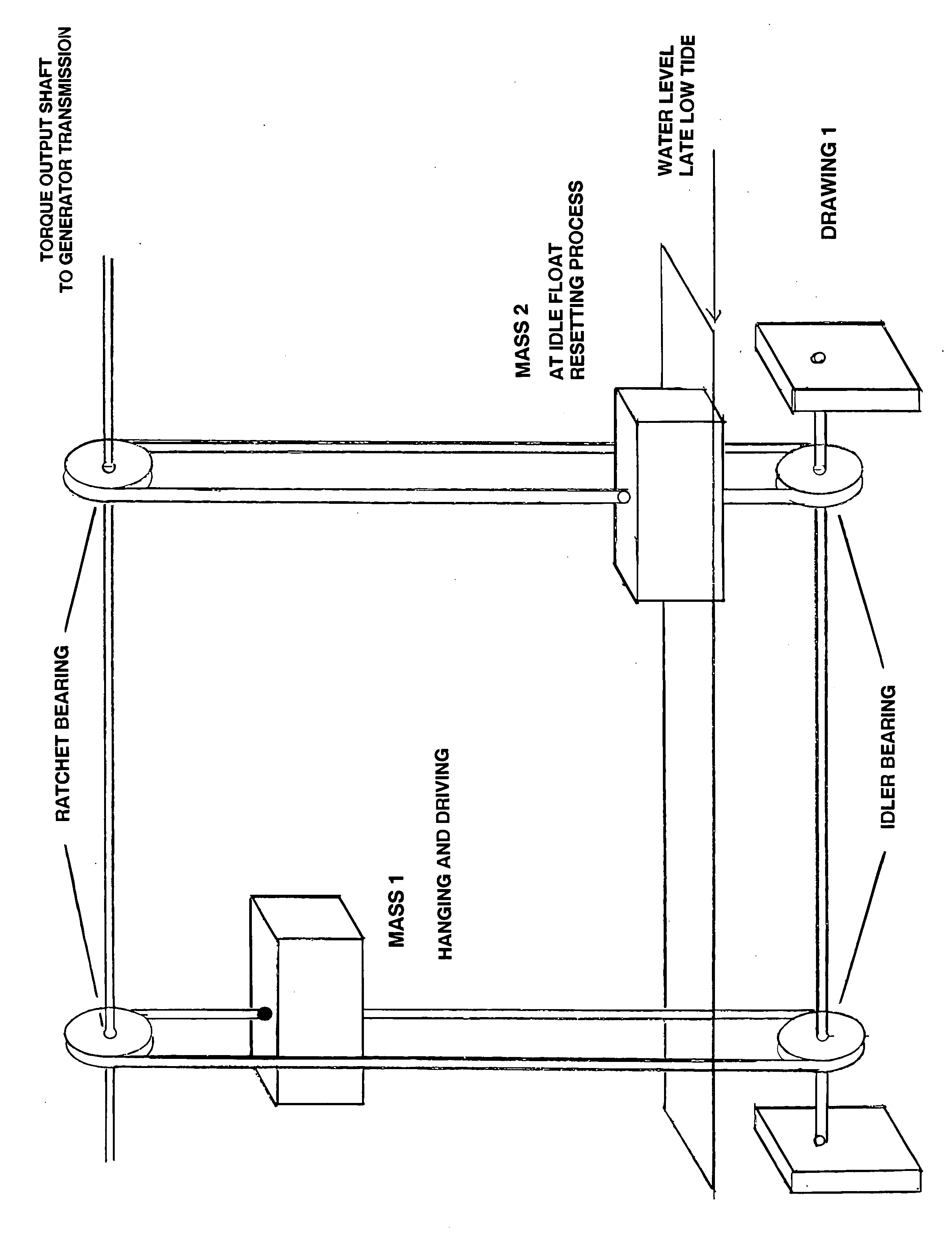

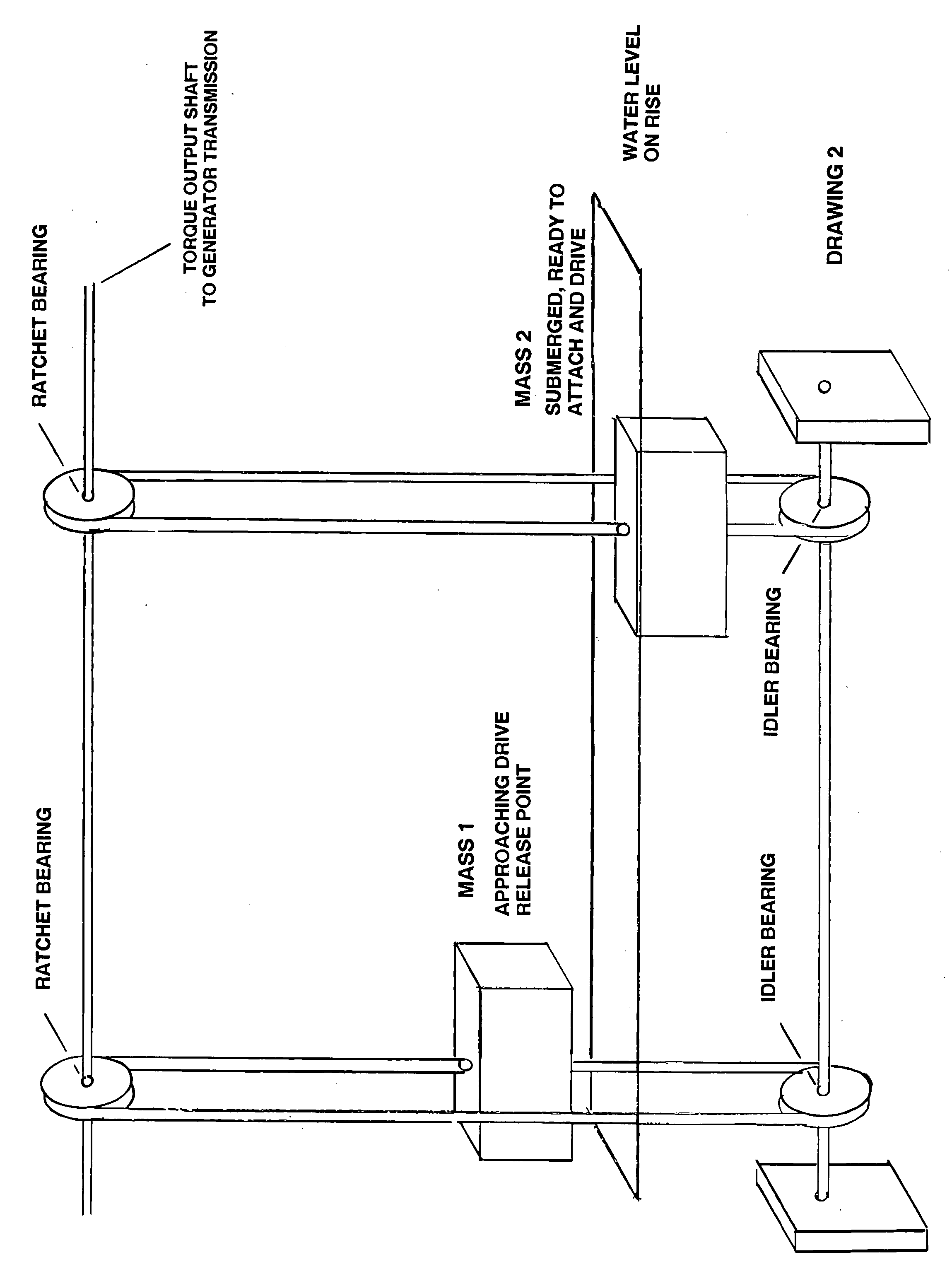

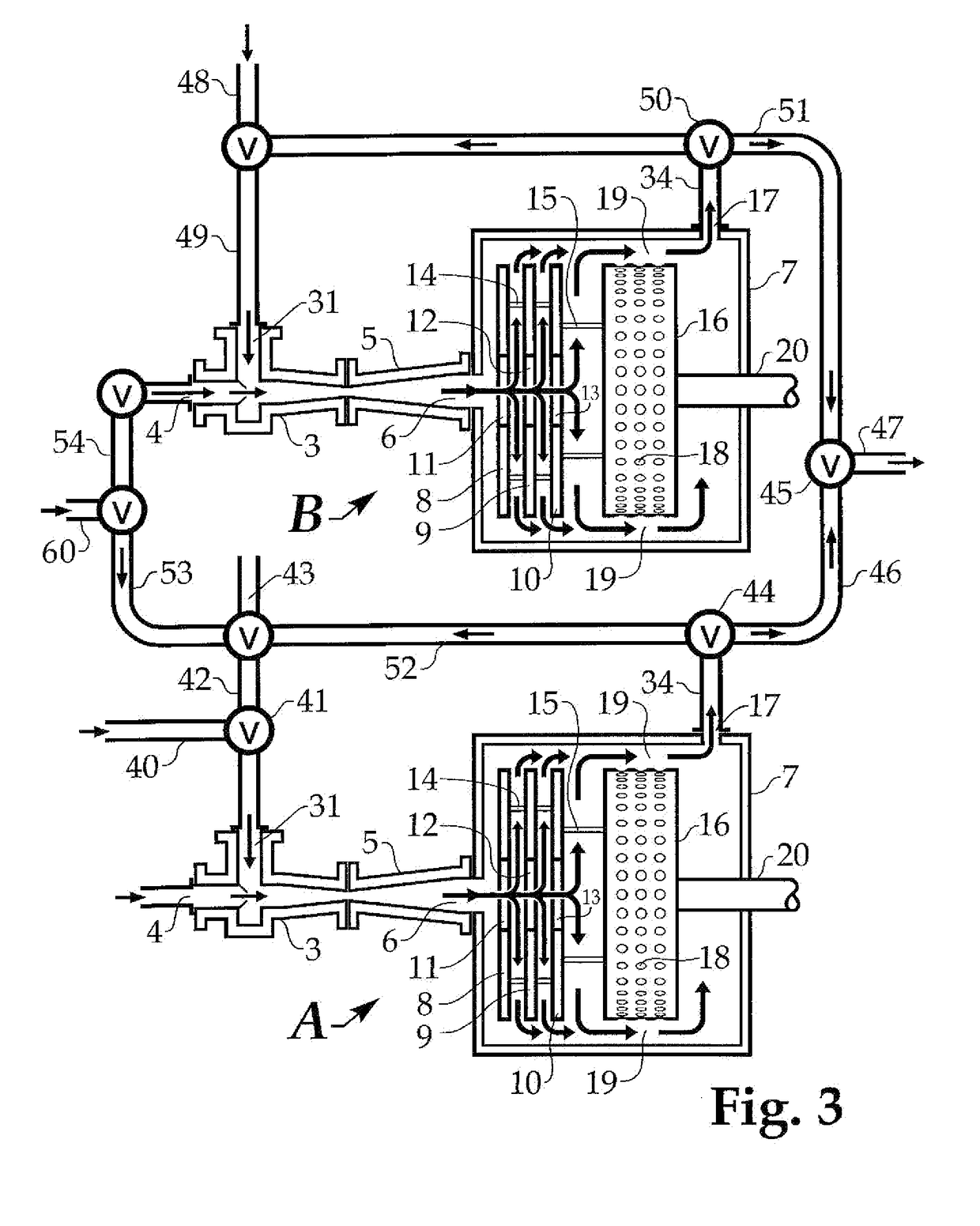

Tidal generator

InactiveUS20050035602A1Small possibilityImprove the level ofMachines/enginesEngine componentsWater levelControl theory

The basic function of this device is to use gravity effects on a fluid to cause energy to be developed in a manor different than the present hydro systems, alleviating the mechanical losses present in their design, as well as the limitations of placement, and layout that cause unnatural disturbances in surrounding natural systems. This design allows the device to be placed effectively on a low level system as well as a high, and still produce an effective output. This is accomplished by ganging low level hydro elevation differences. Territorial elevation differences such as Lake Erie versus Lake Ontario can be used for energy Production as well as tidal changes, as in the Bay of Fundy.

Owner:GARD TIMOTHY ALAN

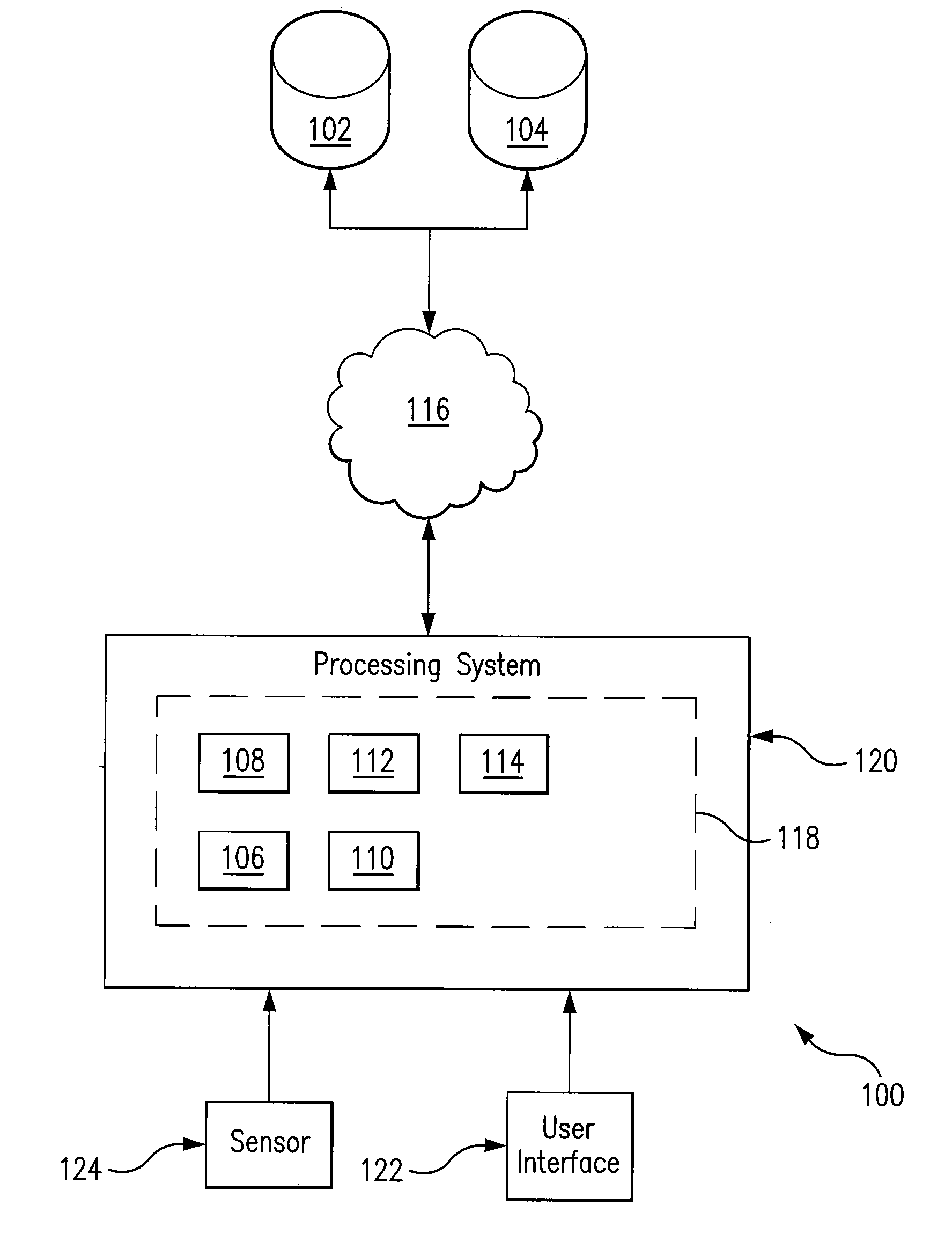

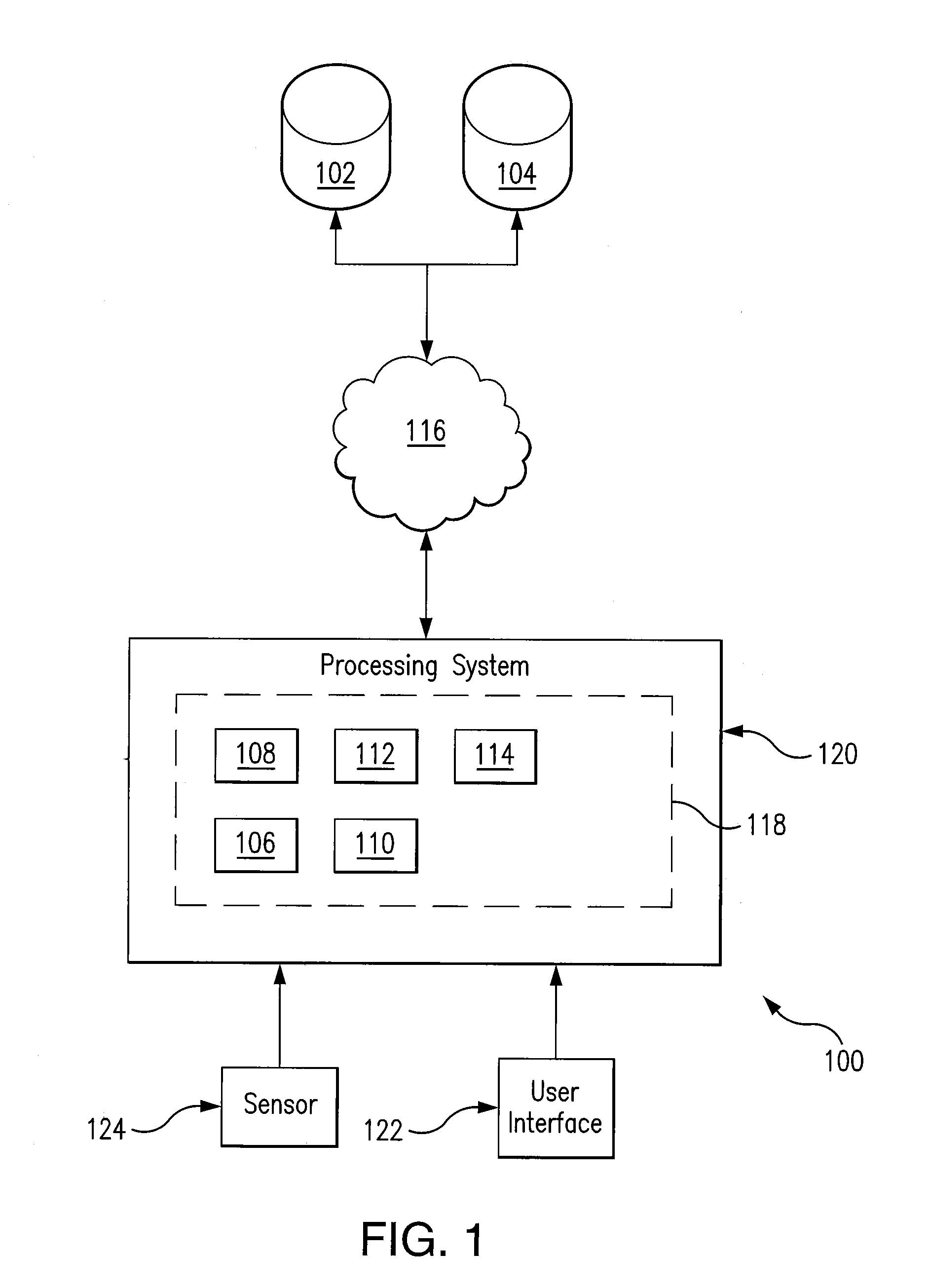

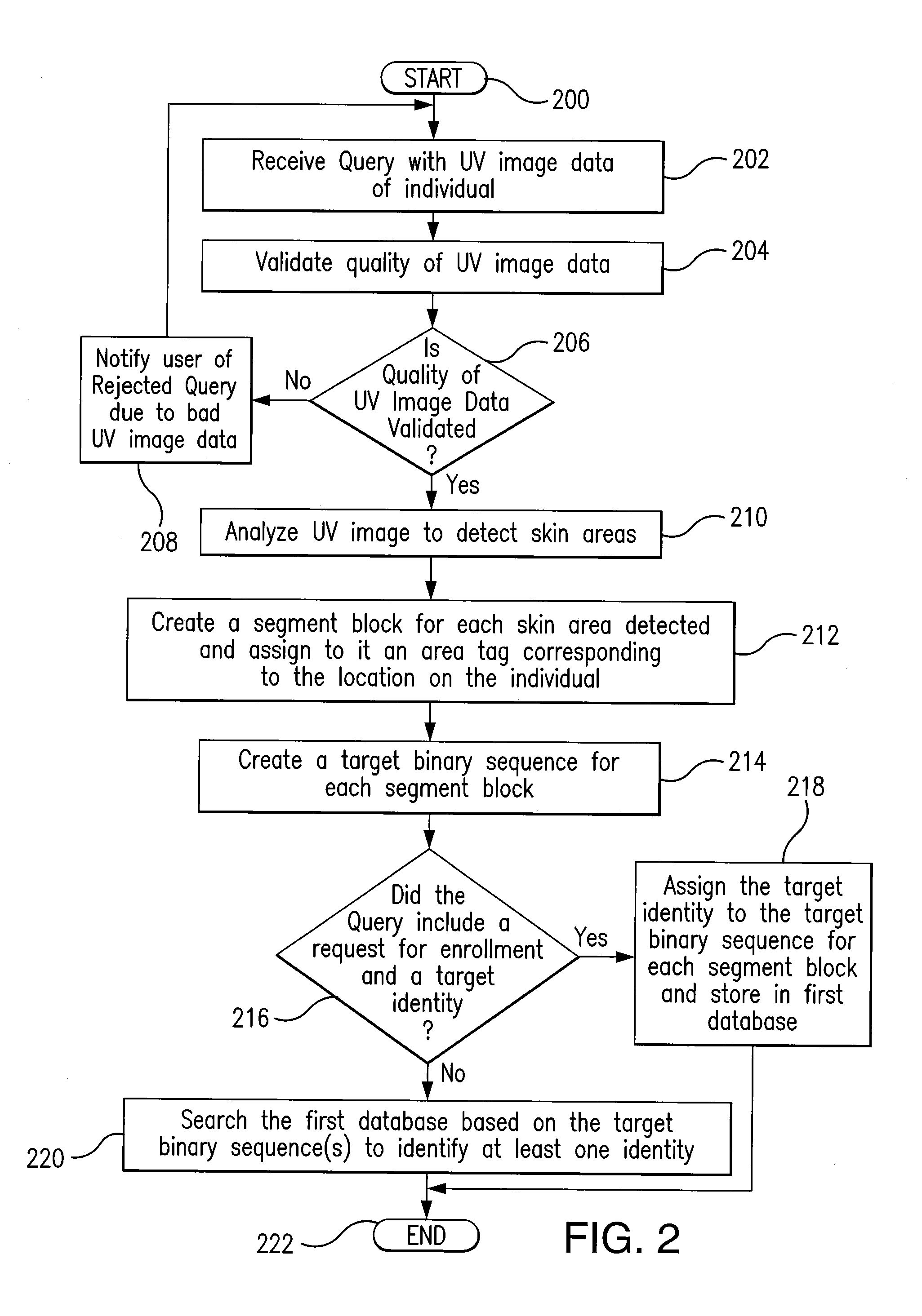

System and Method for Biometric Identification using Ultraviolet (UV) Image Data

ActiveUS20120250948A1Efficient and accurateAlleviate inherent problemBiometric pattern recognitionPattern recognitionUltraviolet

A system and method for biometric identification of a target individual based on a query containing UV image data of the target individual. In one embodiment, the system includes a first database, a query module, a detection module, a sequence module and a match module. The first database includes a plurality of identities with each identity having at least one binary sequence representative of a skin area of that identity. The query module receives the query and validates the UV image data. The detection module detects at least one skin area in the UV image data. The sequence module forms at least one target binary sequence corresponding to the at least one skin area. The match module searches the first database based on the at least one target binary sequence to identify at least one identity thereby facilitating biometric identification of the target individual.

Owner:RAYTHEON CO

System for connecting a bracelet to a watch case

ActiveUS9010593B2Adjustable positionInherent problemOther accessoriesClockwork casesTransverse axisEngineering

System for connecting a bracelet to a watch case by means of a link, the watch case comprising a caseband and a back cover, the link comprising a first hollow element and a second element partly nesting in the first hollow element, the first hollow element carrying a first means of fastening to the watch case and the second element carrying a second means of fastening to an adjacent bracelet link, characterized in that the watch case includes a mechanical device arranged to pivot the second element about a transverse axis to the longitudinal direction of the bracelet, the second element transmitting the pivoting motion thereof to the first element which pivots in turn and which is pressed against the caseband of the watch case.

Owner:THE SWATCH GROUP MANAGEMENT SERVICES

Angled axis machine vision system and method

InactiveUS7196719B2Accurate calculationInherent problemImage enhancementImage analysisHorizonComputer science

Owner:VISION ROBOTICS

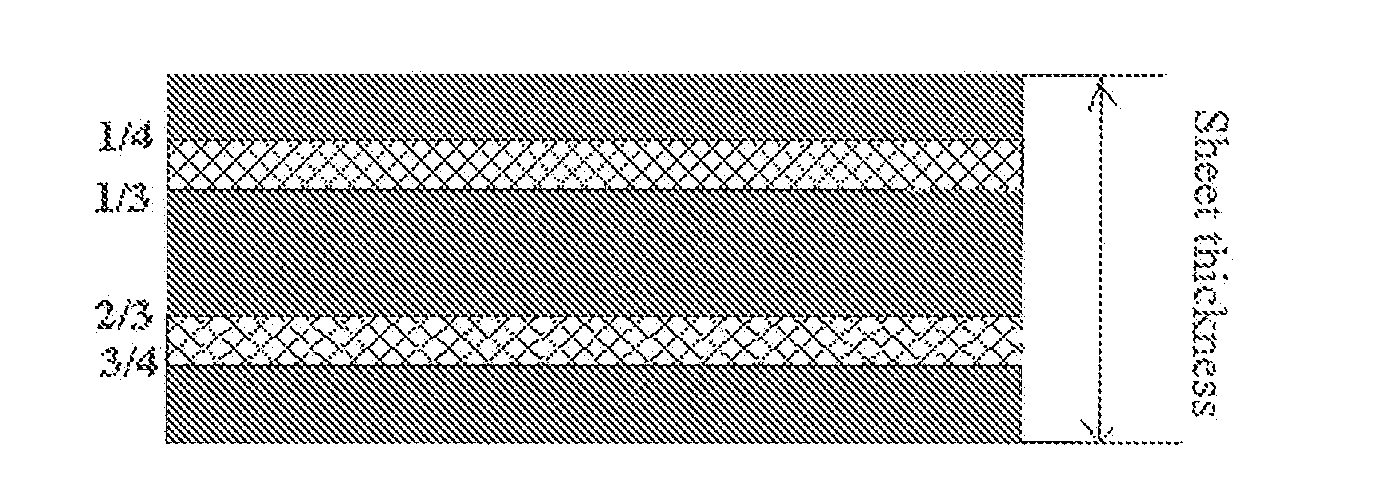

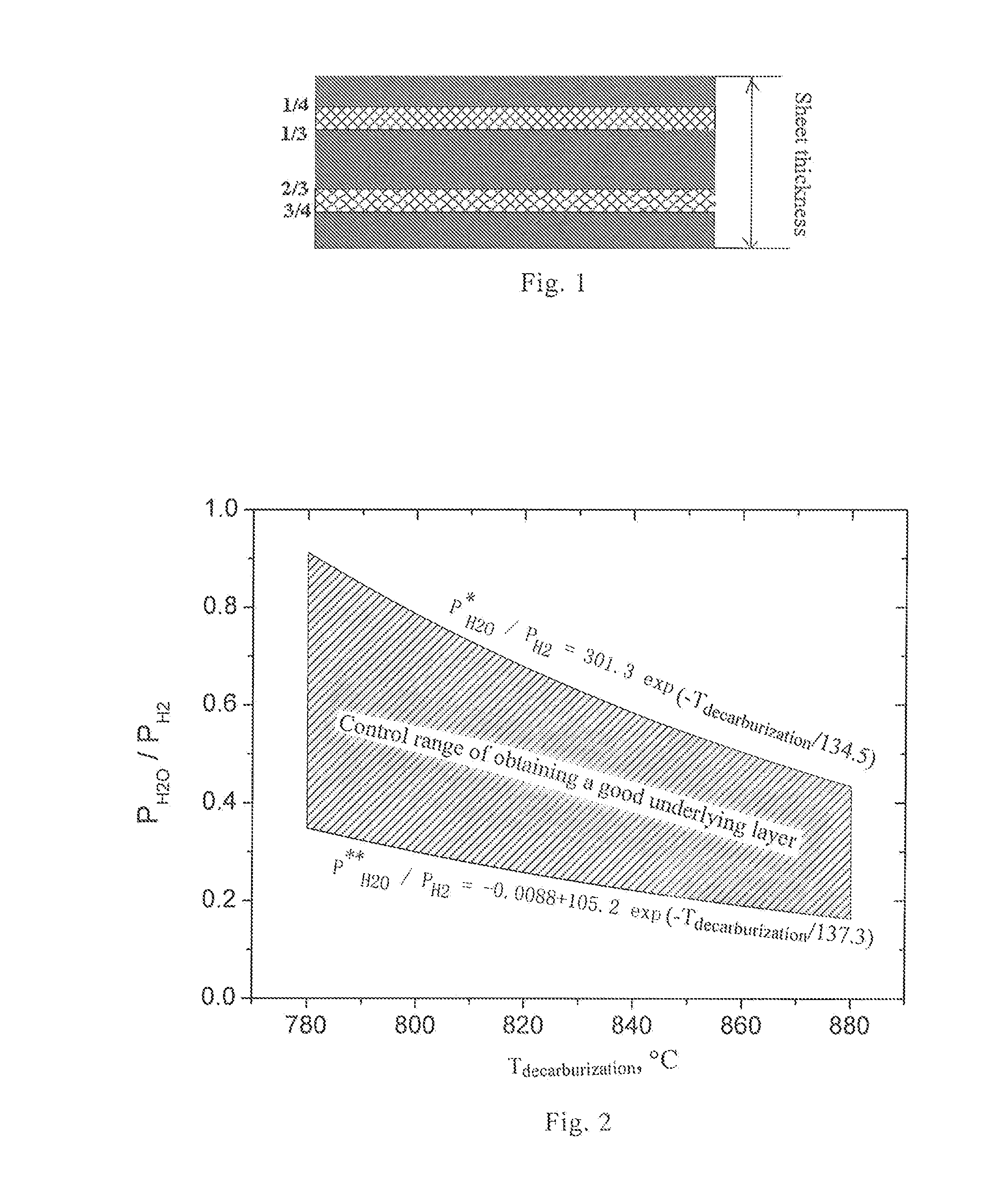

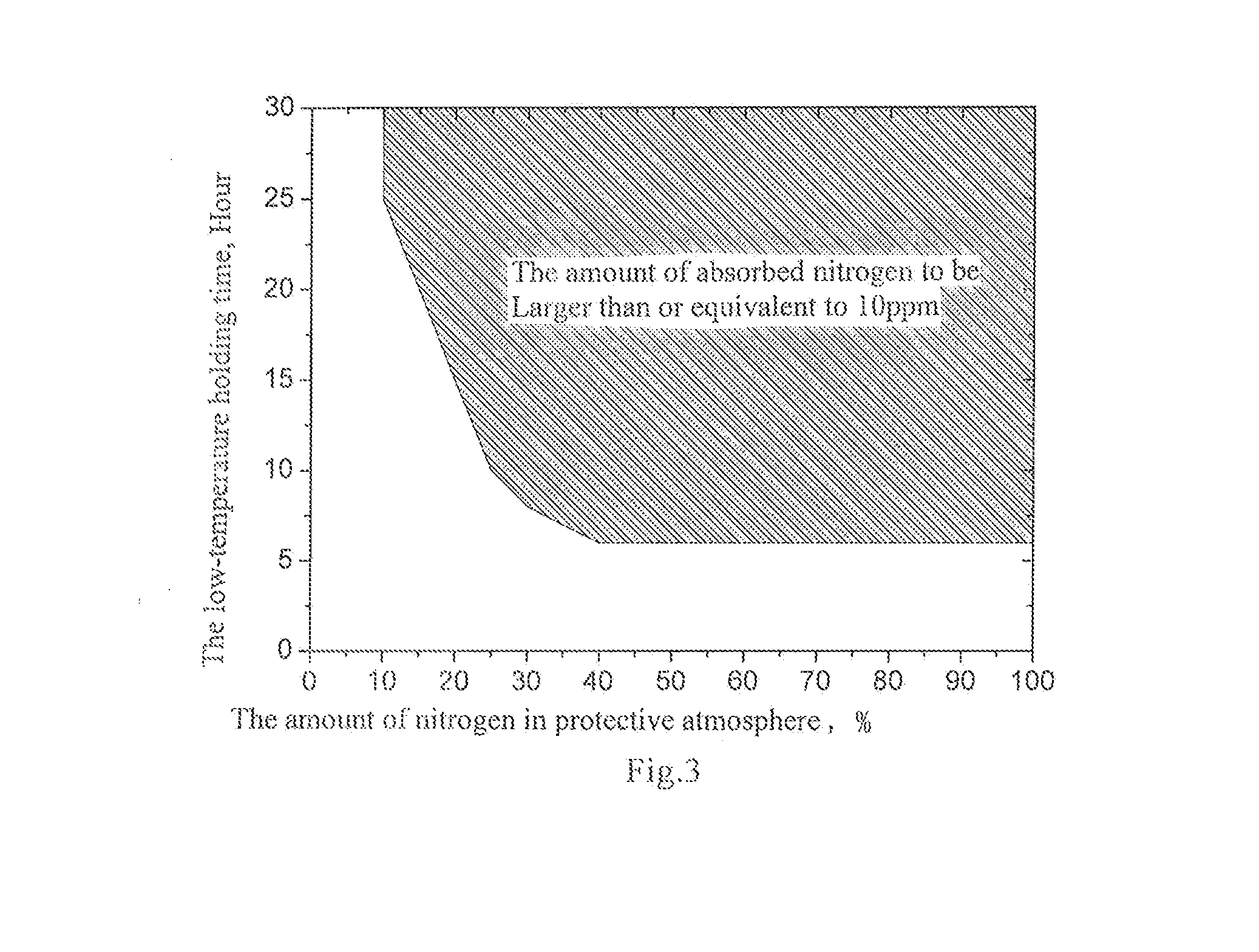

Method for manufacturing grain-oriented silicon steel with single cold rolling

The invention provides a method for producing grain-oriented silicon steel with single cold rolling, comprising: 1) smelting, refining and continuous casting to obtain a casting blank; 2) hot rolling; 3) normalization, i.e. normalizing annealing and cooling; 4) cold-rolling, i.e. single cold rolling at a cold rolling reduction rate of 75-92%; 5) decarburizing annealing at 780-880° C. for 80-350 s in a protective atmosphere having a due point of 40-80° C., wherein the total oxygen [0] in the surface of the decarburized sheet: 171 / t≦[O]≦313 / t (t represents the actual thickness of the steel sheet in mm), the amount of absorbed nitrogen: 2-10 ppm; 6) high temperature annealing, wherein the dew point of the protective atmosphere: 0-50° C., the temperature holding time at the first stage: 6-30 h, the amount of absorbed nitrogen during high-temperature annealing: 10-40 ppm; 7) hot-leveling annealing. The invention may control the primary recrystallization microstructure of steel sheet effectively by controlling the normalization process of hot rolled sheet to form sufficient favorable (Al, Si)N inclusions from nitrogen absorbed by slab during decarburizing annealing and low-temperature holding of high-temperature annealing, facilitating the generation of stable, perfect secondary recrystallization microstructure of the final products. In addition, the invention avoids the impact of nitridation using ammonia on the underlying layer in prior art, and thus the formation of a good glass film underlying layer is favored.

Owner:BAOSHAN IRON & STEEL CO LTD

Controlled release implantable dispensing device and method

InactiveUS20100173000A1Easy to useGreat dose rangeOrganic active ingredientsPowder deliveryControl releaseNanoparticle

A dispensing device having a polymer which is combined with a therapeutic agent in the form of a microparticle or nanoparticle which is “hyper-compressed” to form a controlled release dispensing device and methods of locally administering a therapeutic agent using said microparticles.

Owner:SUSTAINED NANO SYST

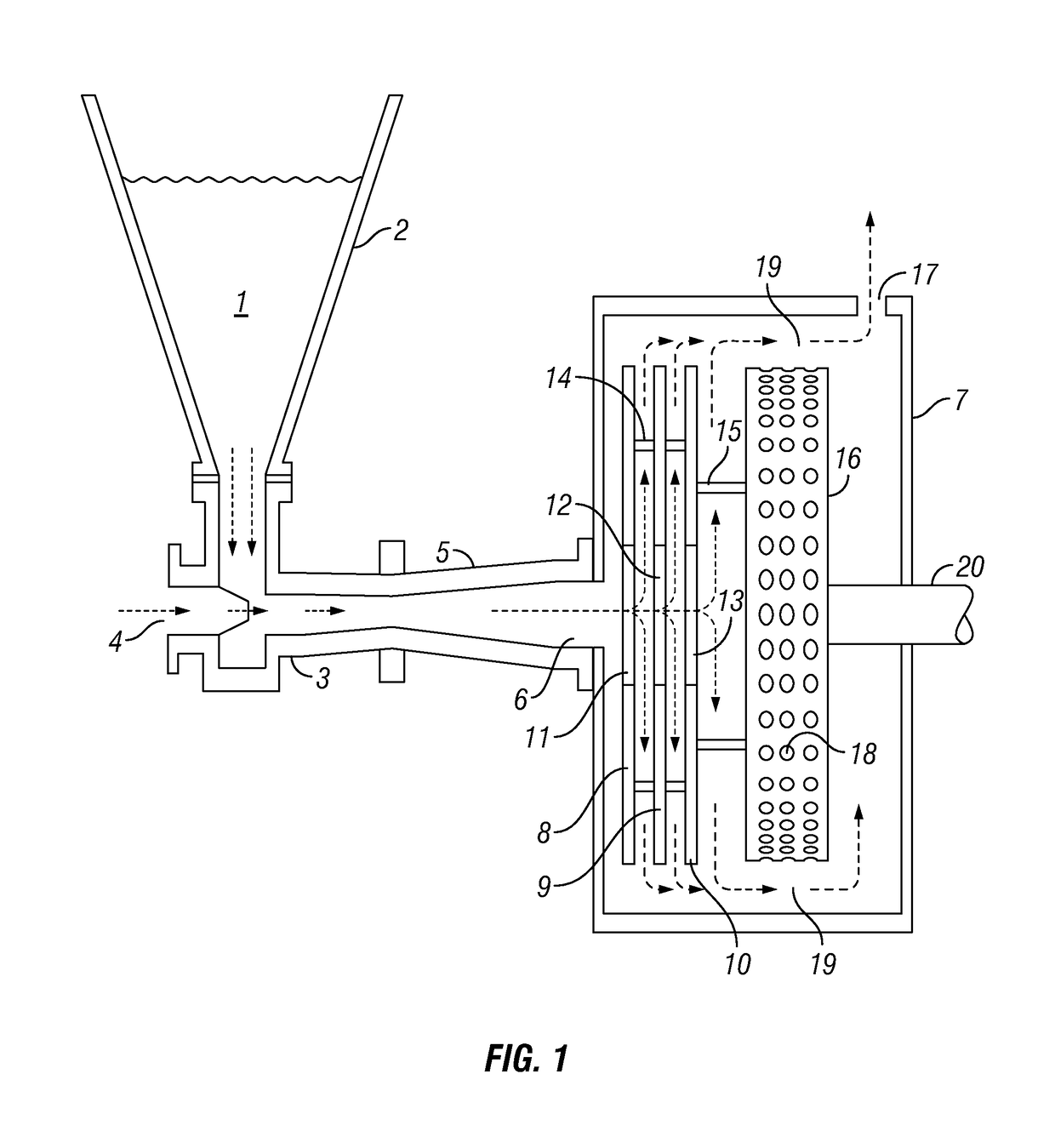

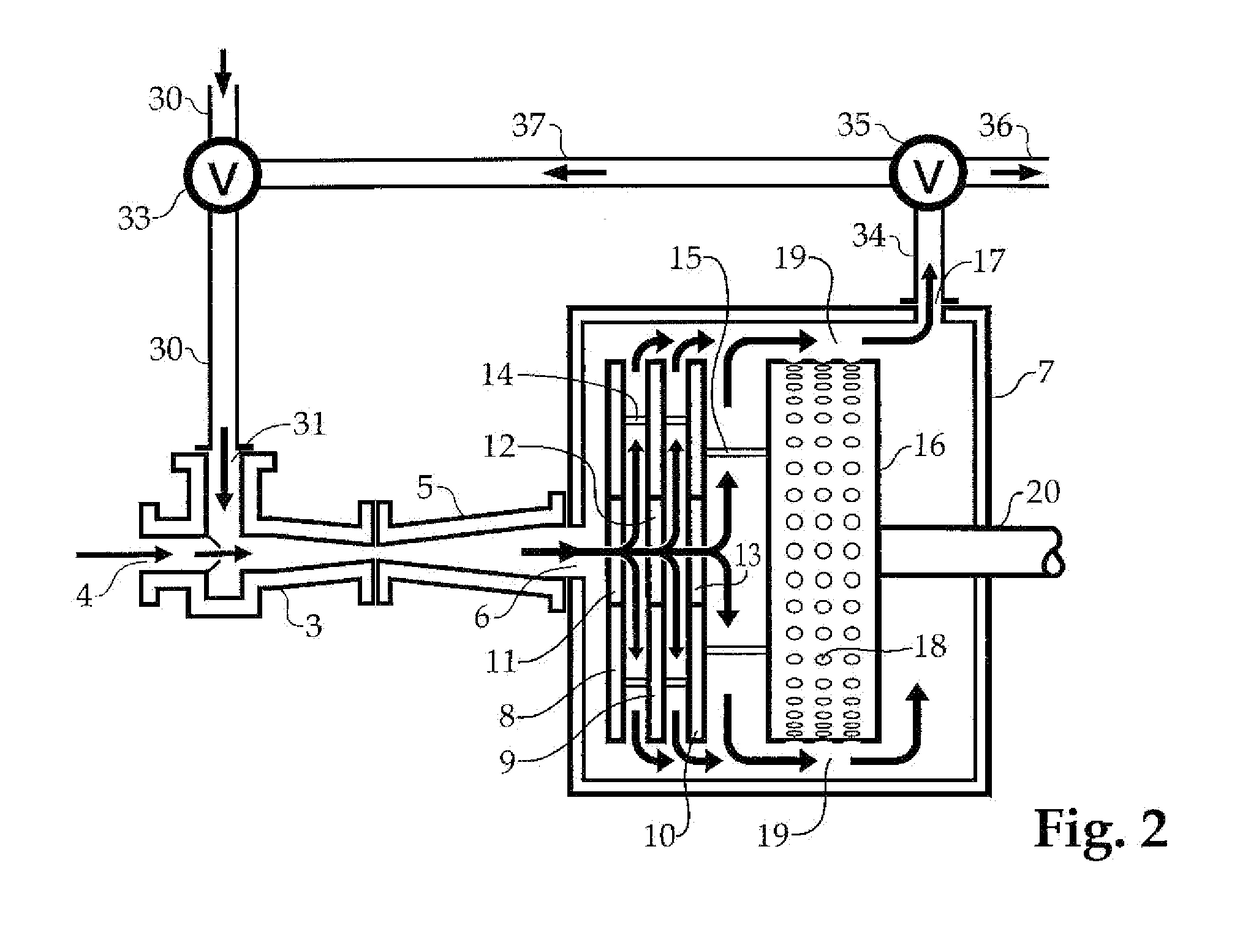

Hydrating and Dissolving Polymers

InactiveUS20190031793A1Maximize intimate contactMore energyFlow mixersRotary stirring mixersCavitationGuar gum

Polyacrylamides, guar gum (sometimes “guar”), xanthan gum, carboxymethylcellulose, hydroxyethylcellulose, and other water-soluble polymers are dissolved and hydrated in aqueous solutions, including especially recycled drilling, fracturing, and other oilfield fluids having significant salt contents, by passing the water-soluble polymer together with the aqueous medium to a cavitation device including an integrated disc pump. The integration of a disc pump with the cavitation device reduces the risk of gumming by applying a negative pressure at the feed point. The ability to use water-soluble polymers with the salty recycled oilfield fluids has significant environmental benefits, namely (1) fresh water is not needed, (2) disposal of the environmentally undesirable returned fluids is not needed, (3) difficultly degradable synthetic polymers may not be needed, and, in particular, (4) the enhanced ability to use guar, which, being a natural product, is biodegradable, is environmentally favored. Although the invention is most beneficial for use with salt or brackish water, its high efficiency points to beneficial use where fresh water is the only available choice for the aqueous medium. Where dry polymer is used, the invention's benefits are especially realized in terms of logistics and handling, since viscous and bulky solutions need not be prepared and stored in advance, thus also minimizing health, safety and environmental risks

Owner:HIGHLAND FLUID TECH

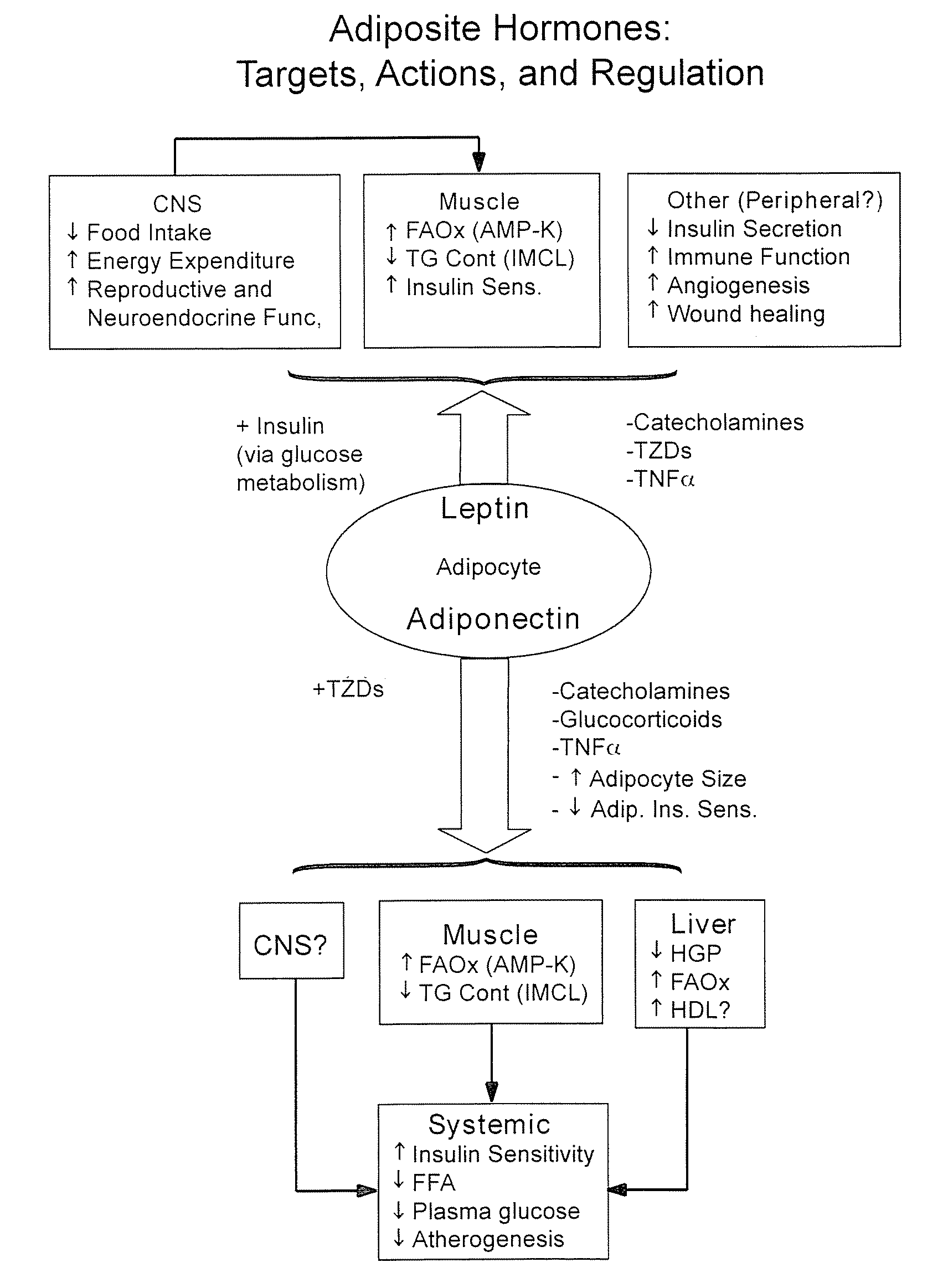

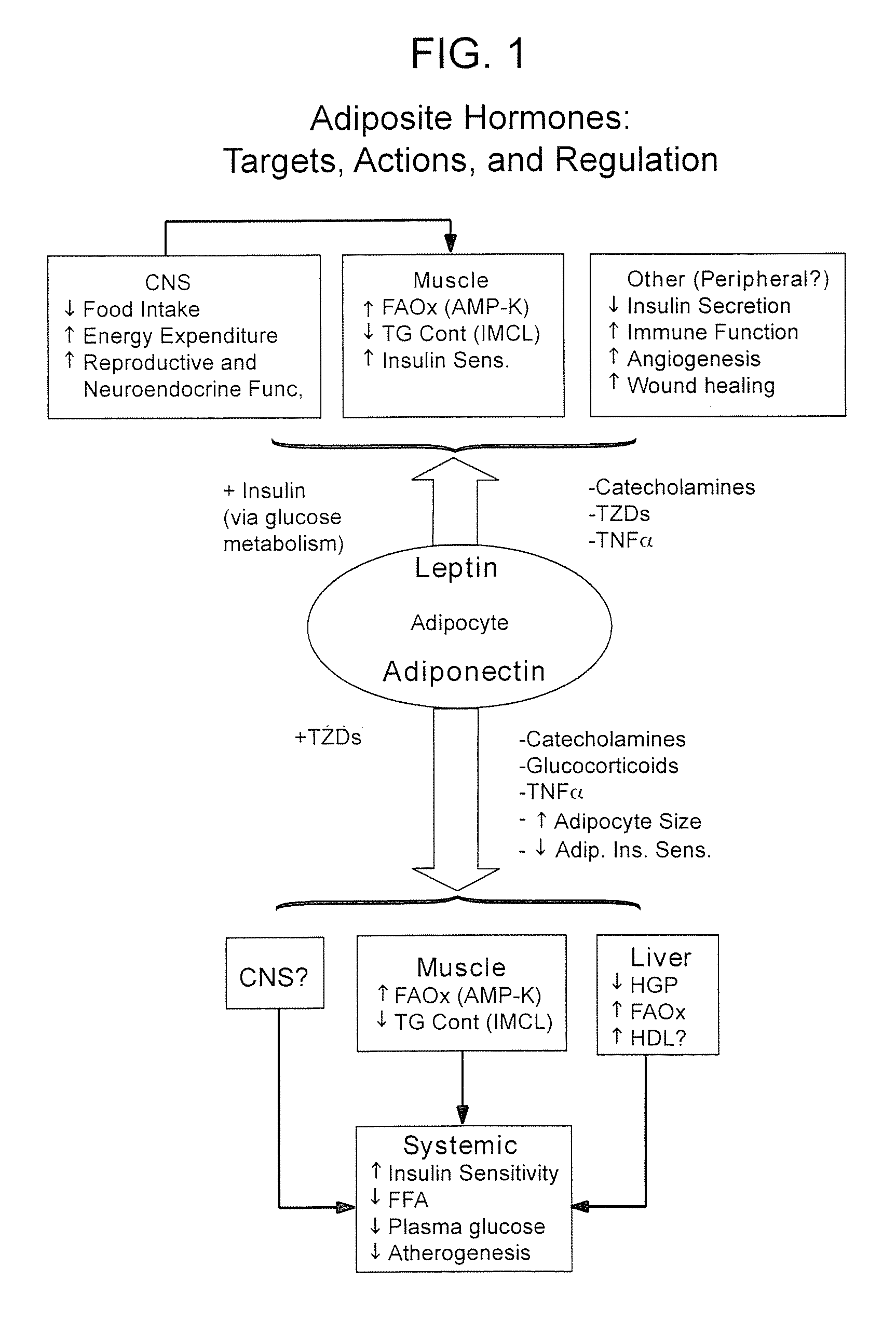

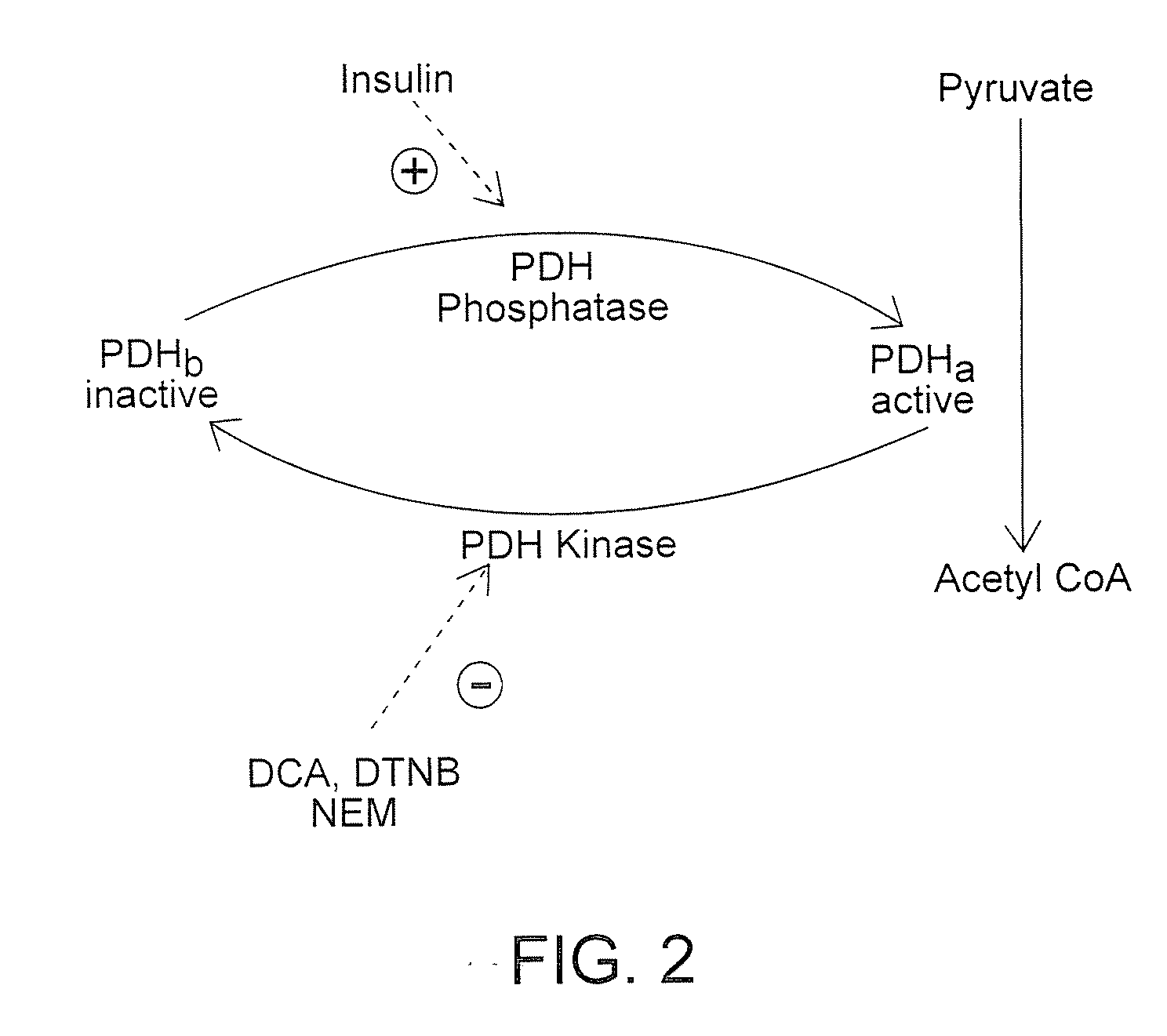

Method of increasing endogenous adiponectin production and leptin production

InactiveUS20070203225A1Improve the level ofLimited efficacyBiocideAnimal repellantsAdiponectin secretionSecretion

A formulation for and method of enhancing adiponectin and leptin secretion is disclosed. The method comprises contacting living cells with an inhibitor of the enzyme pyruvate dehydrogenase kinase (PDHK). The PDHK inhibitor causes the cells it contacts to increase adiponectin secretion as well as increasing the production of leptin. The increased levels of adiponectin alone (or in a synergistic combination with increased leptin) provides a range of desired results including weight loss and the prevention of weight.

Owner:RGT UNIV OF CALIFORNIA +1

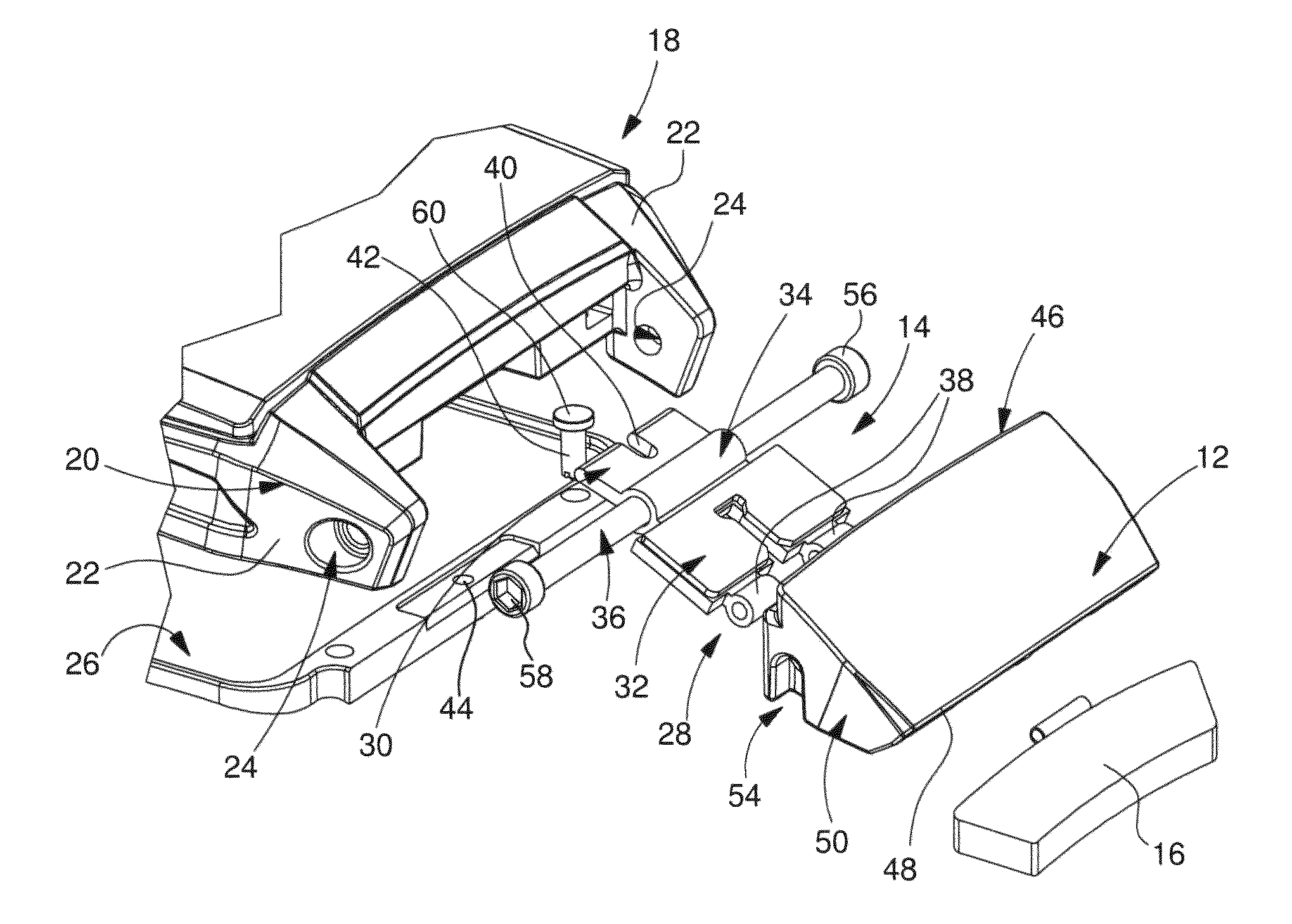

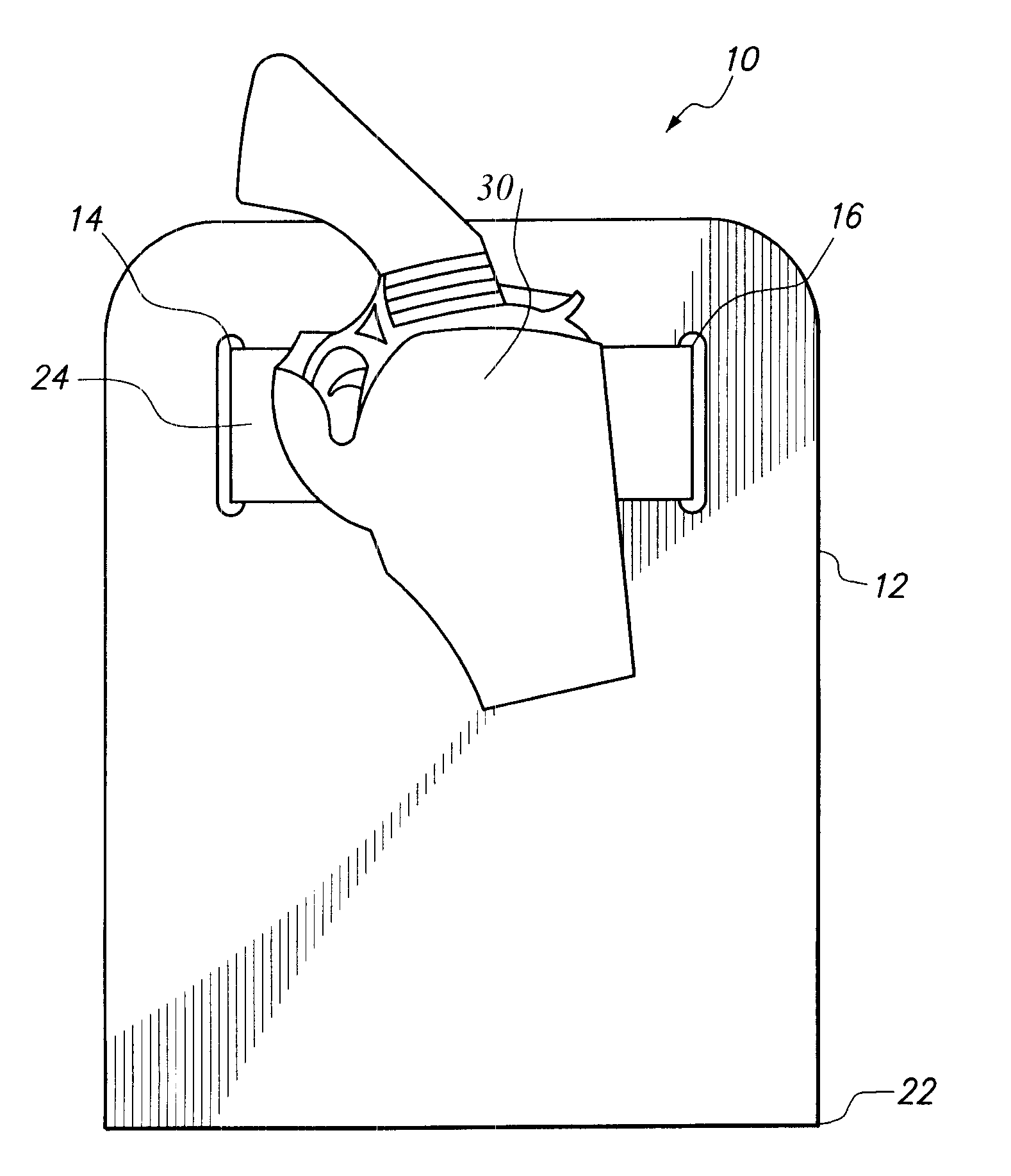

Handgun holster mounting system

InactiveUS20110272539A1Easy accessEasy to removeCandle holdersLighting support devicesFastenerEngineering

A mounting system for securing a handgun holster to furniture, comprising a holster having a pistol receiving pouch and an attachment element, a mounting bracket having a horizontal plate portion connected to a vertical plate portion, the vertical plate portion having at least one opening, and a fastener for securing said attachment element to said mounting bracket at the opening. This handgun holster safely and reversibly secures a handgun to furniture to allow a user to store a handgun conveniently nearby for ready access without the risk of the holster falling off of the mounting system and unintentionally discharging the weapon.

Owner:YAGI GEORGE

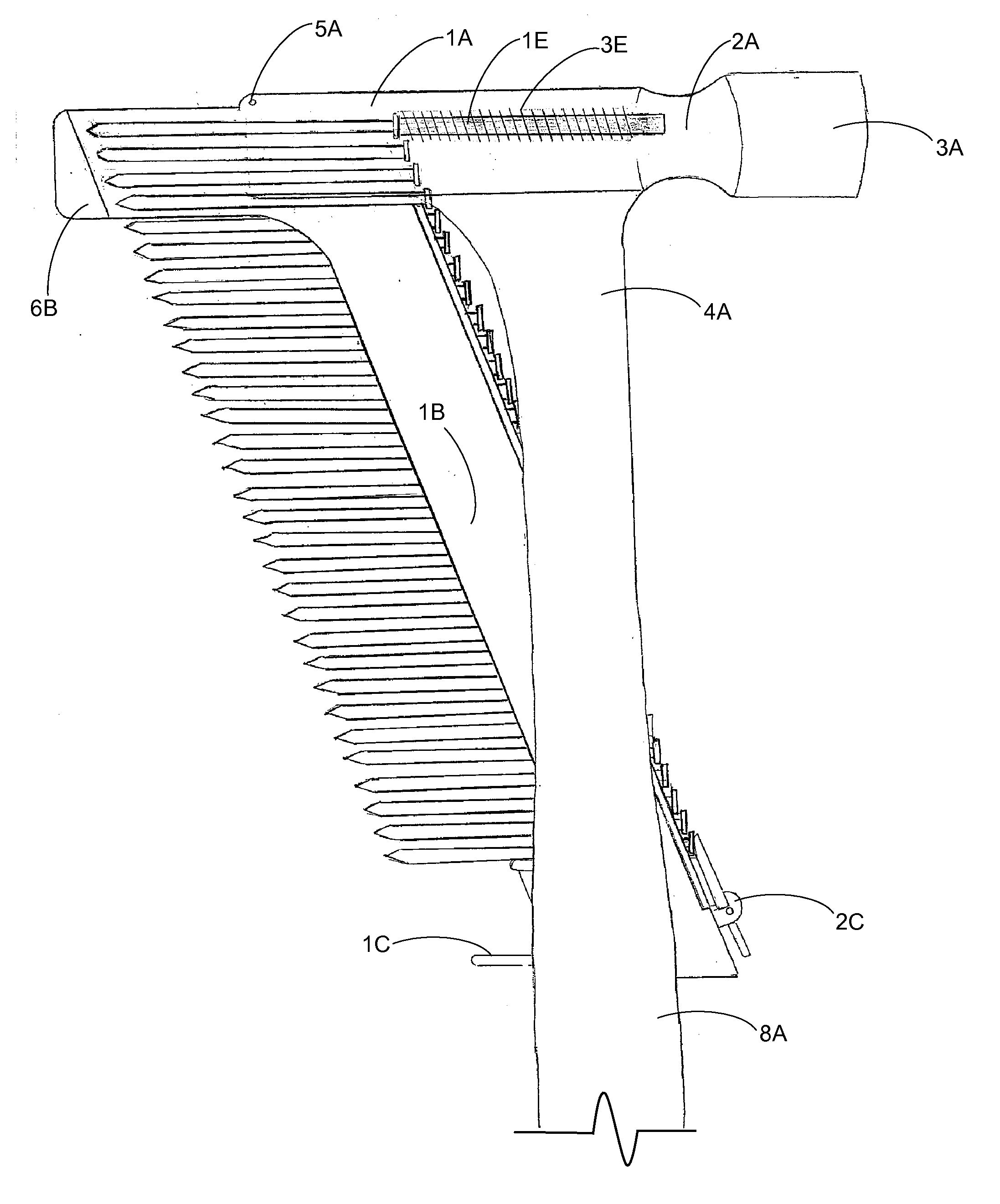

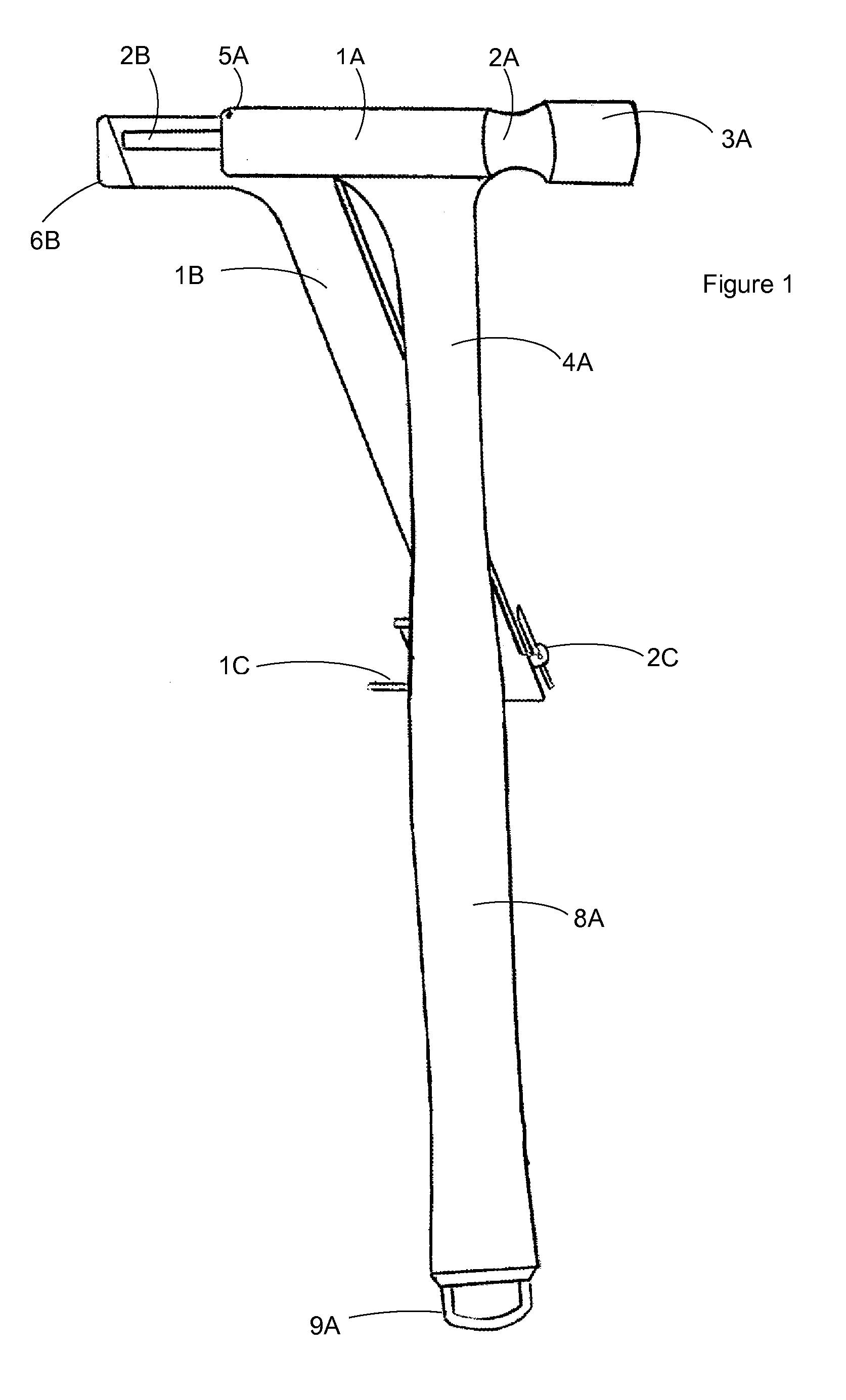

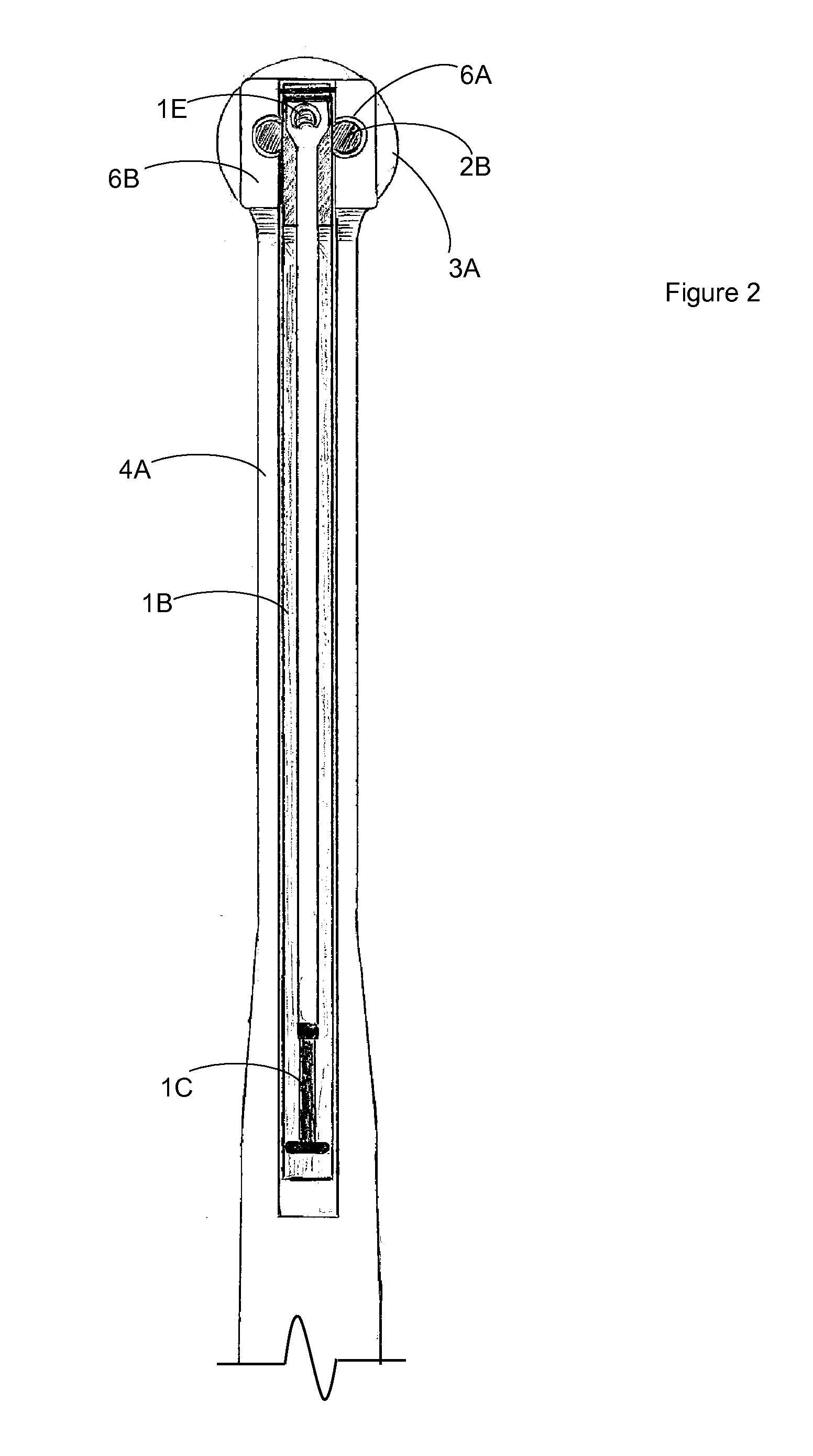

Automatic Hammer

InactiveUS20150336254A1Eliminate needSufficient forceStapling toolsDispensing apparatusMechanical engineeringEngineering

A framing hammer including an automatic feeding magazine supported within the hammerhead by guide rails with a self-loading magazine. Through the center of the upper portion of the hammer handle lies the self-loading reciprocating magazine. The top end of the magazine actuates due to the force of the impact of the tool through its natural operation. The magazine is inclined at 21° relative to the handle and is spaced in the center of the handle from the rear of the nail driving face. Structure is provided for individually driving a nail from a magazine contained row of commercially available 21° collated nails toward the rearward facing end of the hammerhead. Upon impact the tool dispenses and sets a nail up to a 1½″ into the work surface, upon disengagement the tool reciprocates to resets to its resting position whereupon the tool is ready to repeat the action.

Owner:STETSON JEREMY CHARLES +1

System to freely configure video conferencing camera placement

InactiveUS8405701B2Reduce decreaseInherent problemTelevision conference systemsTwo-way working systemsCamera placementConference room

Embodiments of the present invention are directed to cordless video conferencing camera adaptors and video conferencing systems including the camera adaptors. Embodiments of the present invention overcome some of the inherent problems of known video conferencing products by being a part of a portable and configurable video conferencing system, which can be used in various meeting rooms, laboratories, training rooms, and conference halls. For example, embodiments of the invention allow use of low cost (e.g., under $100) cameras to provide any angle of video coverage in any conference room setting.

Owner:ALCATEL LUCENT SAS

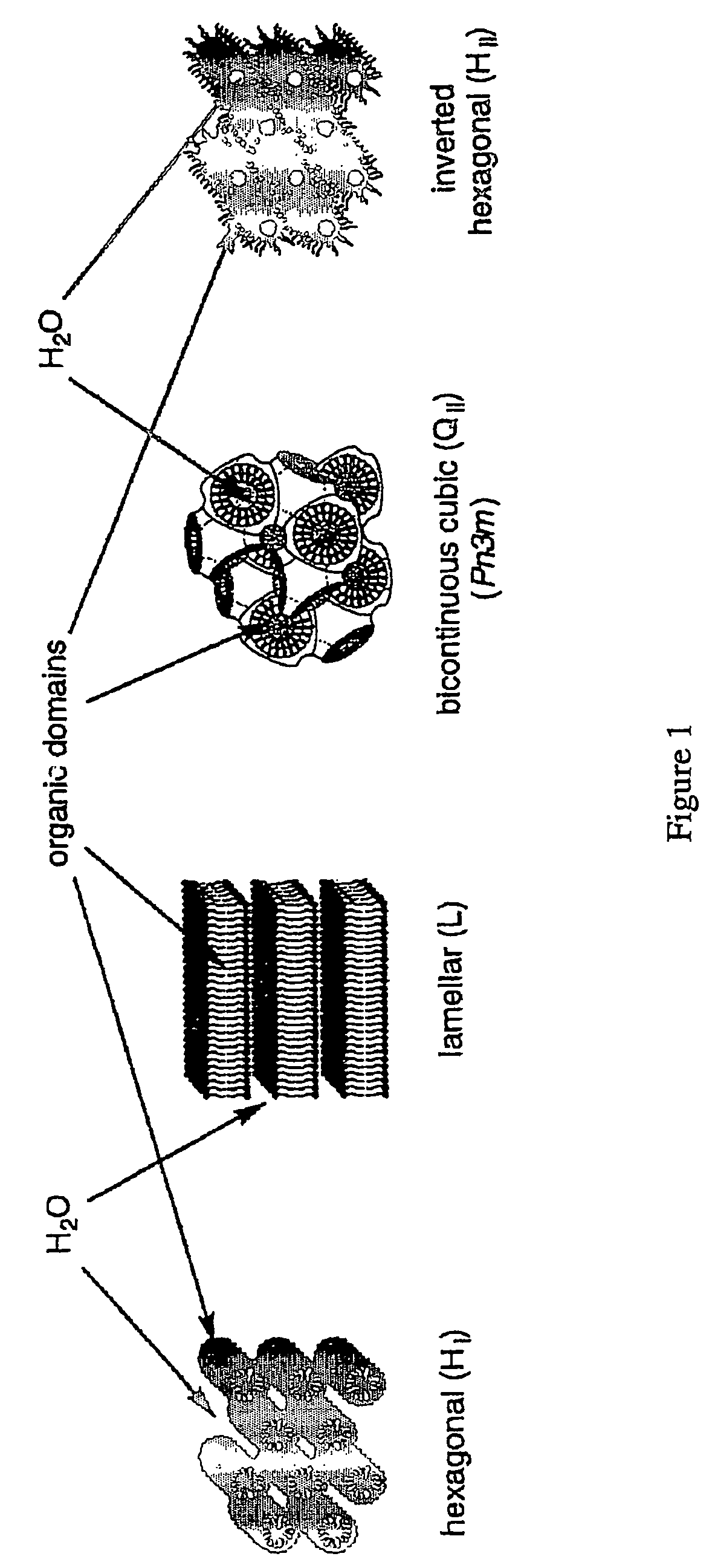

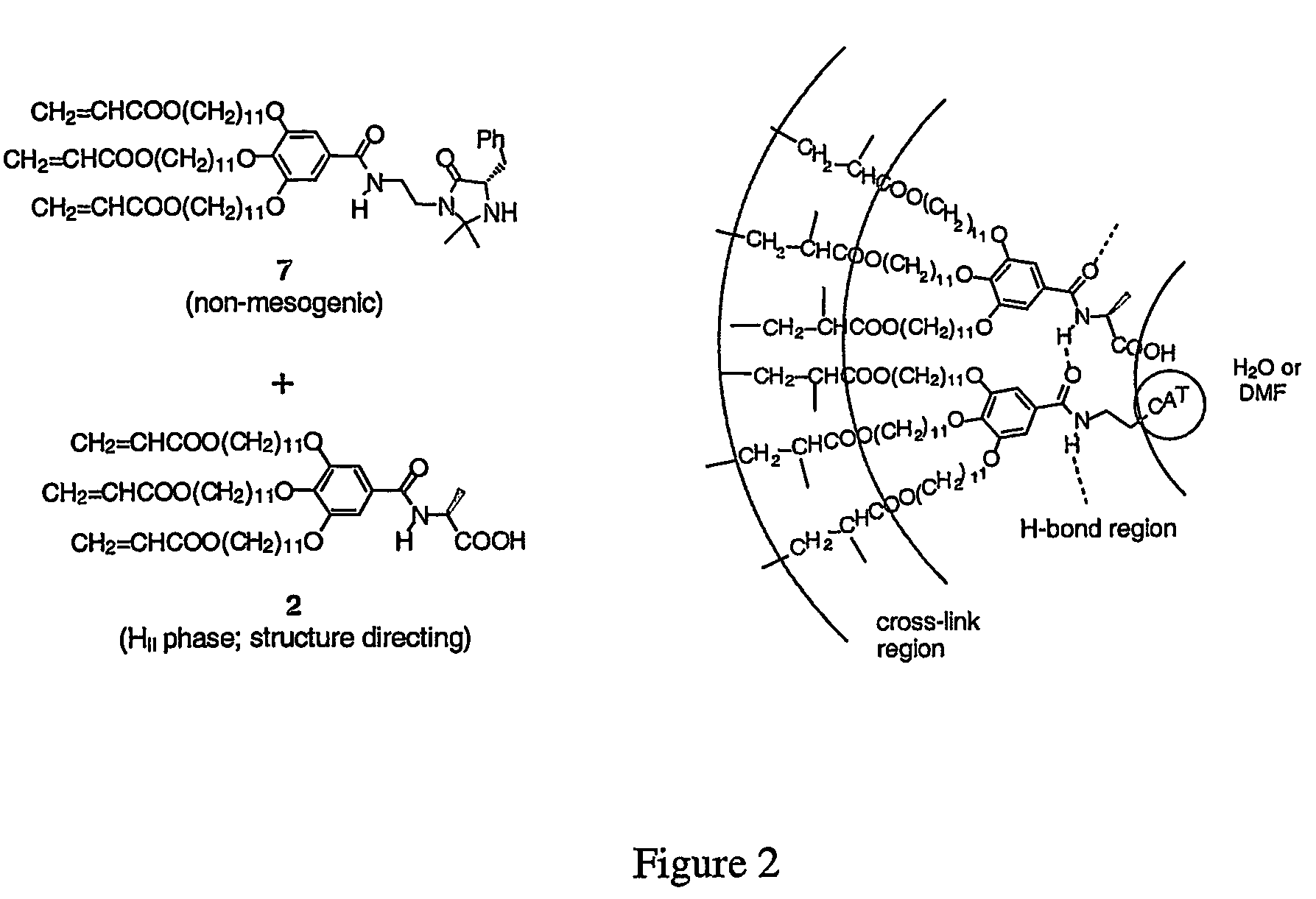

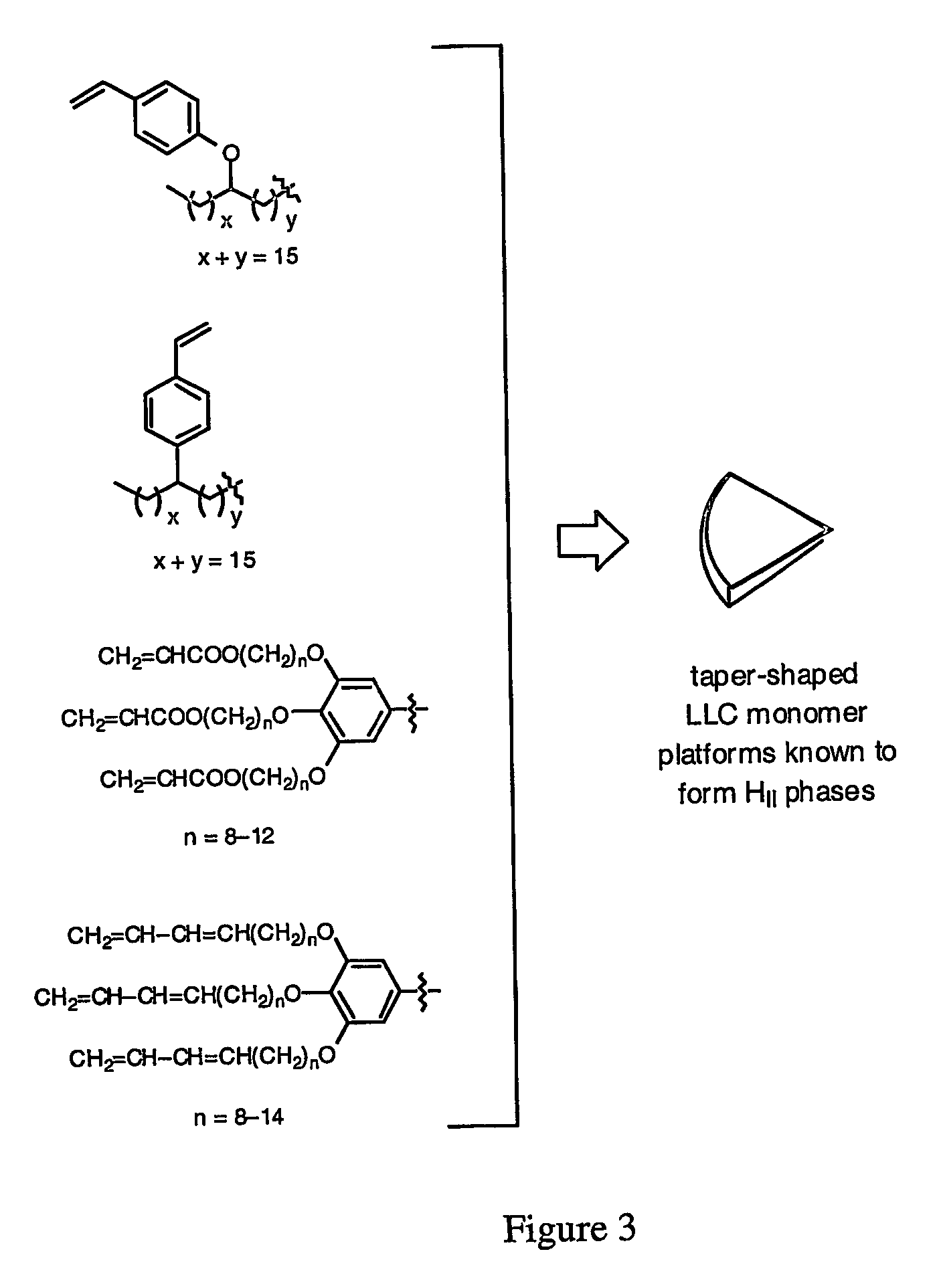

Functionalized nanostructured lyotropic liquid crystal polymers

InactiveUS7521003B2Improve utilizationInherent problemLiquid crystal compositionsMaterial nanotechnologyCross-linkSolvent

The invention provides cross-linked lyotropic liquid crystal (LLC) copolymers having ordered nanometer-sized pores lined with functional groups. The copolymers are formed by copolymerizing LLC monomers with strong LLC character and functionalized monomers with no or weak LLC character to form an LLC phase. Both the LLC monomers and the functionalized monomers contain hydrogen-bonding groups and hydrogen-bonding is believed to assist in the formation of the LLC phase of the blended mixture. Different classes of functional groups useful for the invention include, but are not limited to, acidic groups, basic groups, catalytic groups, oxidizing agents, reducing agents, polymerization initiators, binding agents, optically active groups, and electrically active groups. The invention also provides methods for making the cross-linked LLC copolymers of the invention. In these methods, the LLC monomer and the functionalized monomer are blended in a polar solvent, thereby allowing self-assembly of the first and second monomer into an LLC phase. The LLC phase in then cross-linked with retention of the LLC microstructure.

Owner:UNIV OF COLORADO THE REGENTS OF

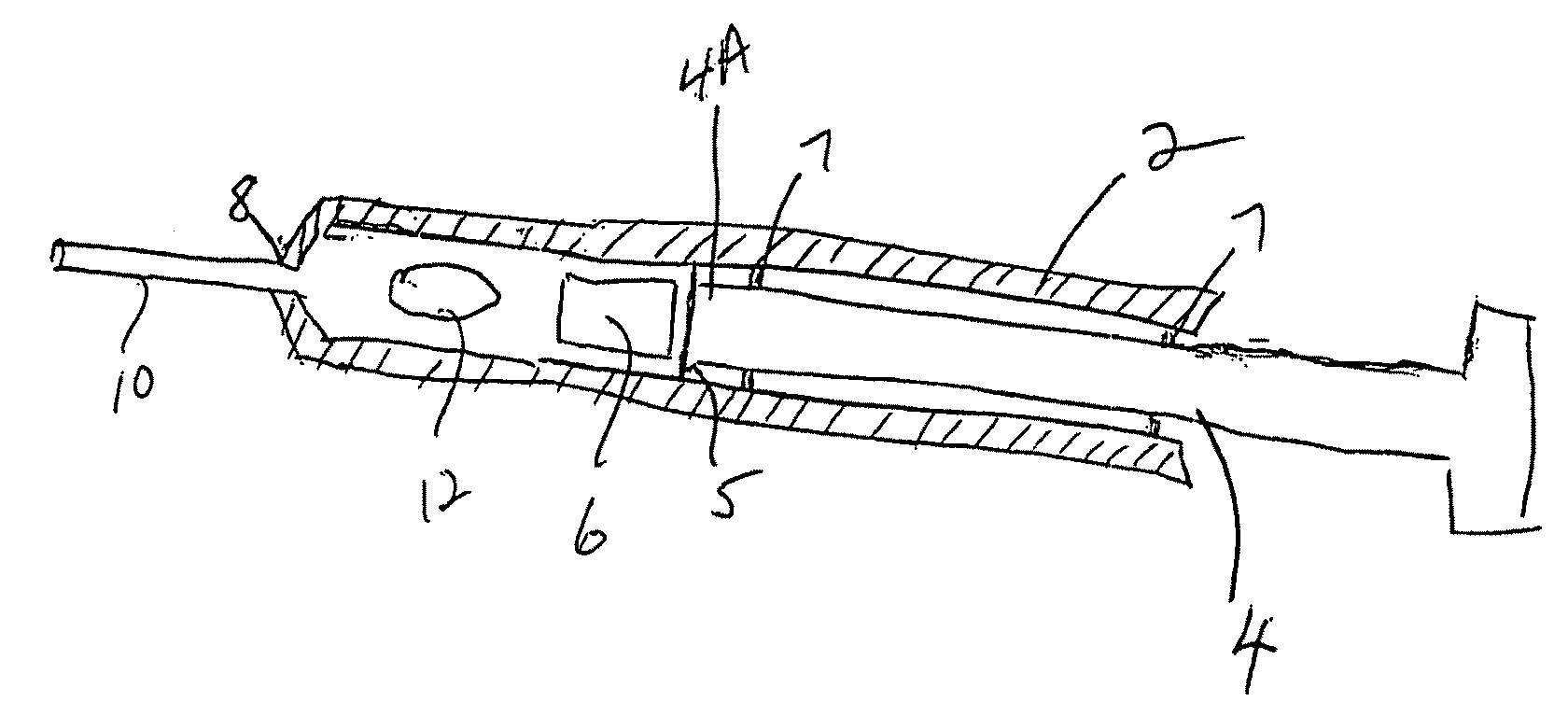

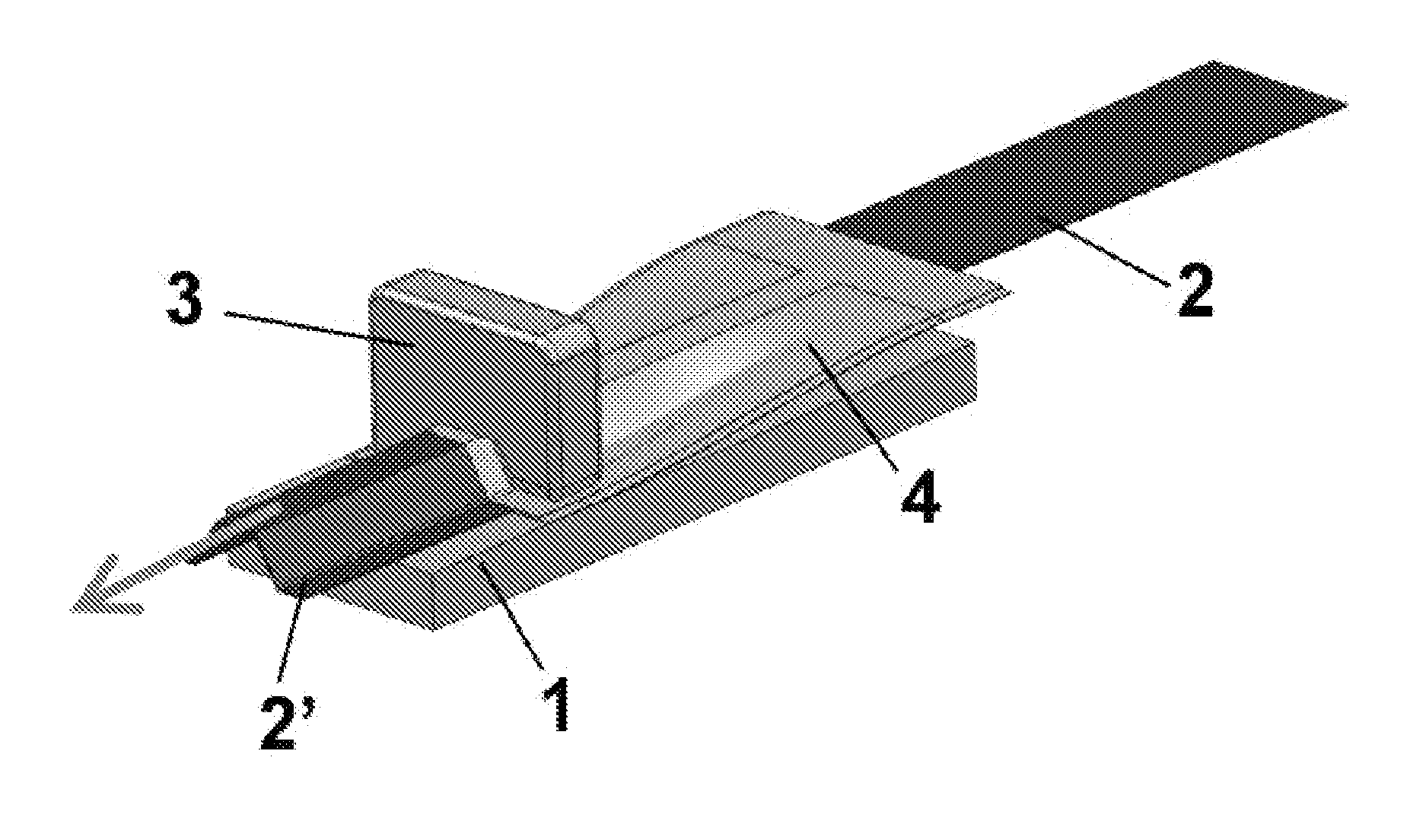

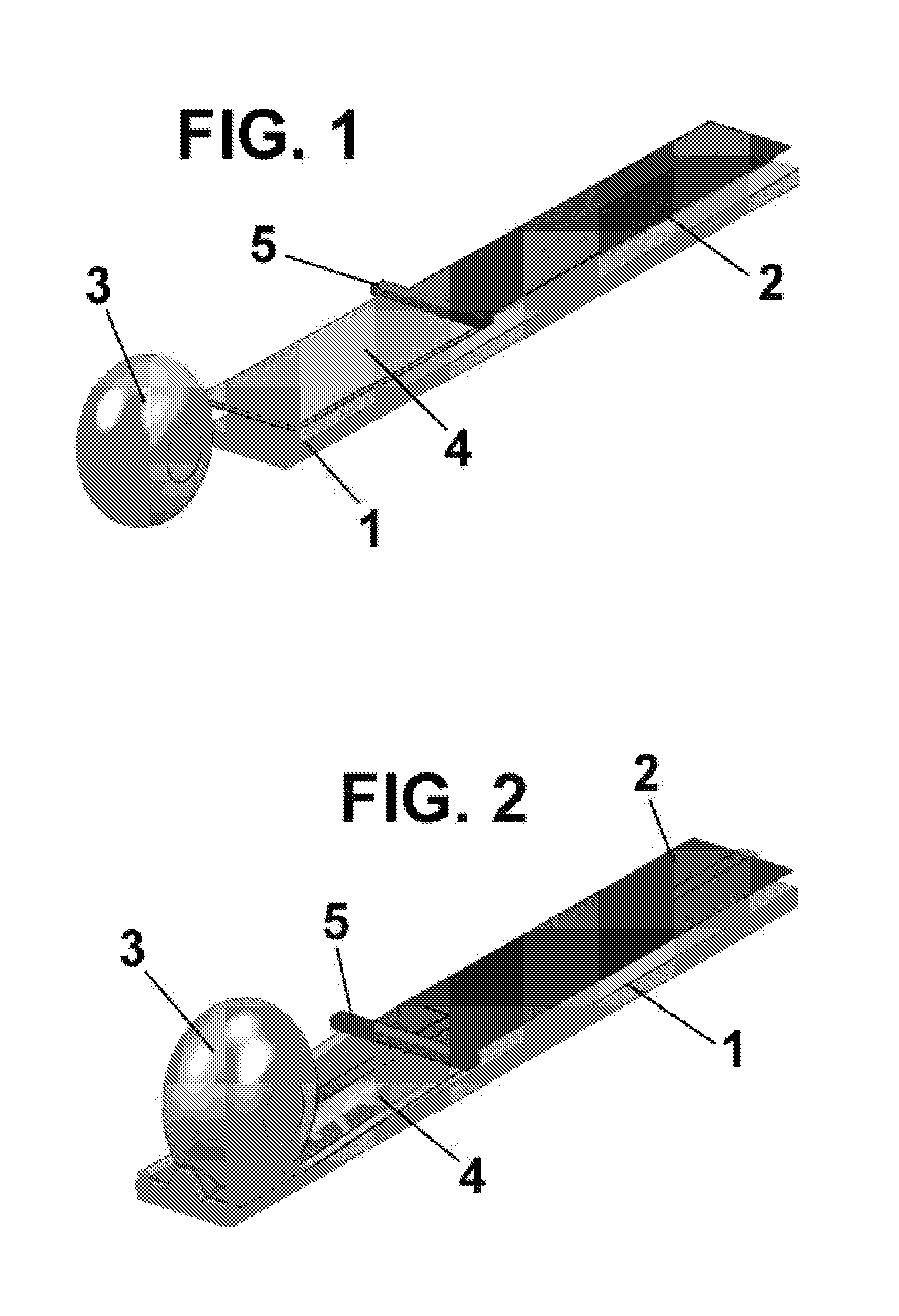

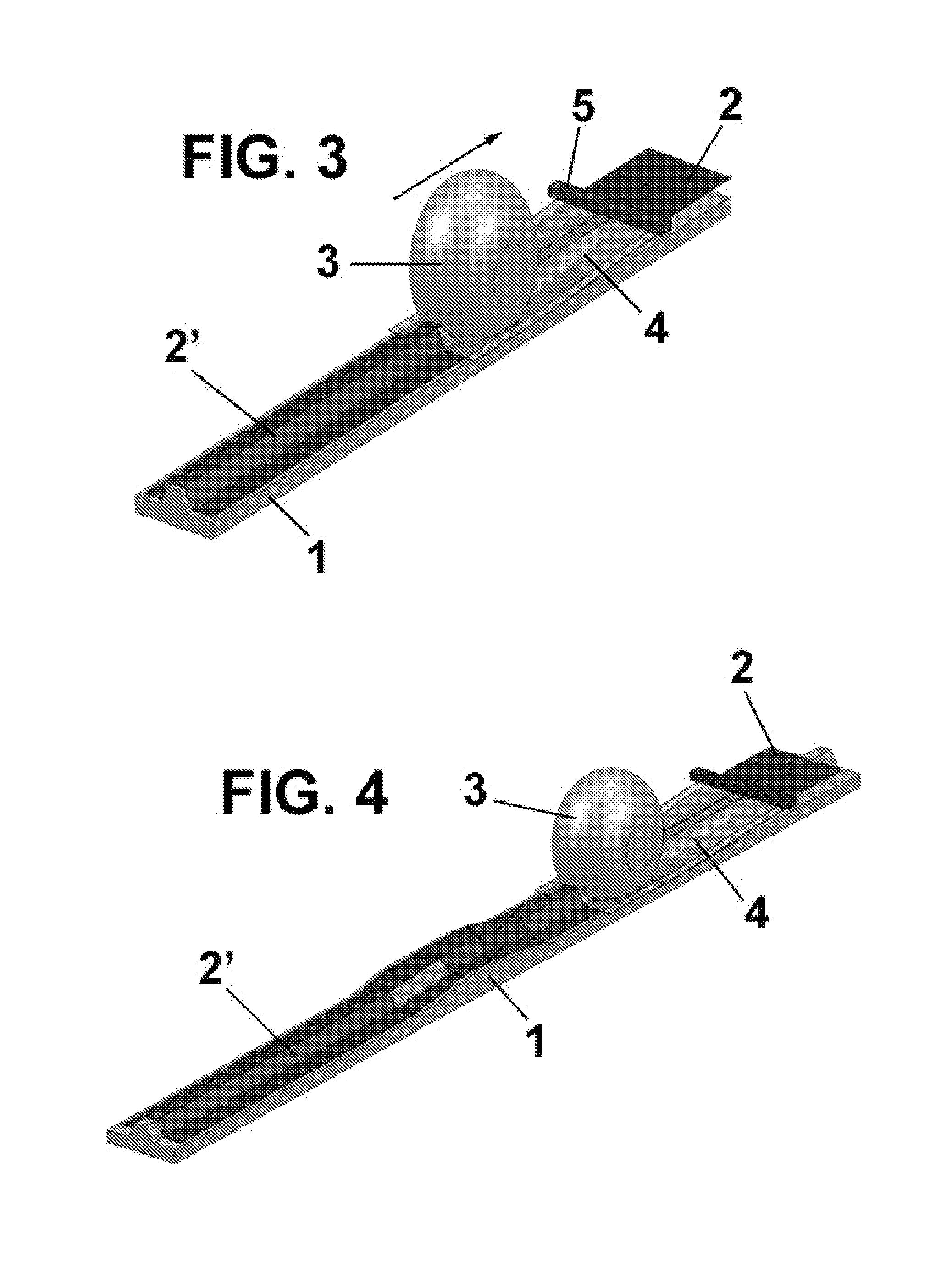

System for Forming Stacks of Composite Materials

ActiveUS20160082675A1Automatically performPrevent occurrenceMechanical working/deformationFlat articlesEngineeringVariable geometry

The system for forming stacks of composite materials comprises a form (1) which defines the section that is desired to provide to a stack (2) of composite material placed thereon to obtain a formed stack (2′); a counter-form (3), which together with the form (1), forms and obtains the formed stack (2′); and it is characterized in that the system also comprises transition elements (4) deformable, that adopt a variable section from an initial section in one of its ends and the end section defined by the form (1) in the other end.It allows changing the geometry during the forming of the laminate, to obtain laminates of variable section along its length. For this purpose, the form and counter-form must have a variable geometry at will.

Owner:APPLUS SERVICIOS TECHCOS

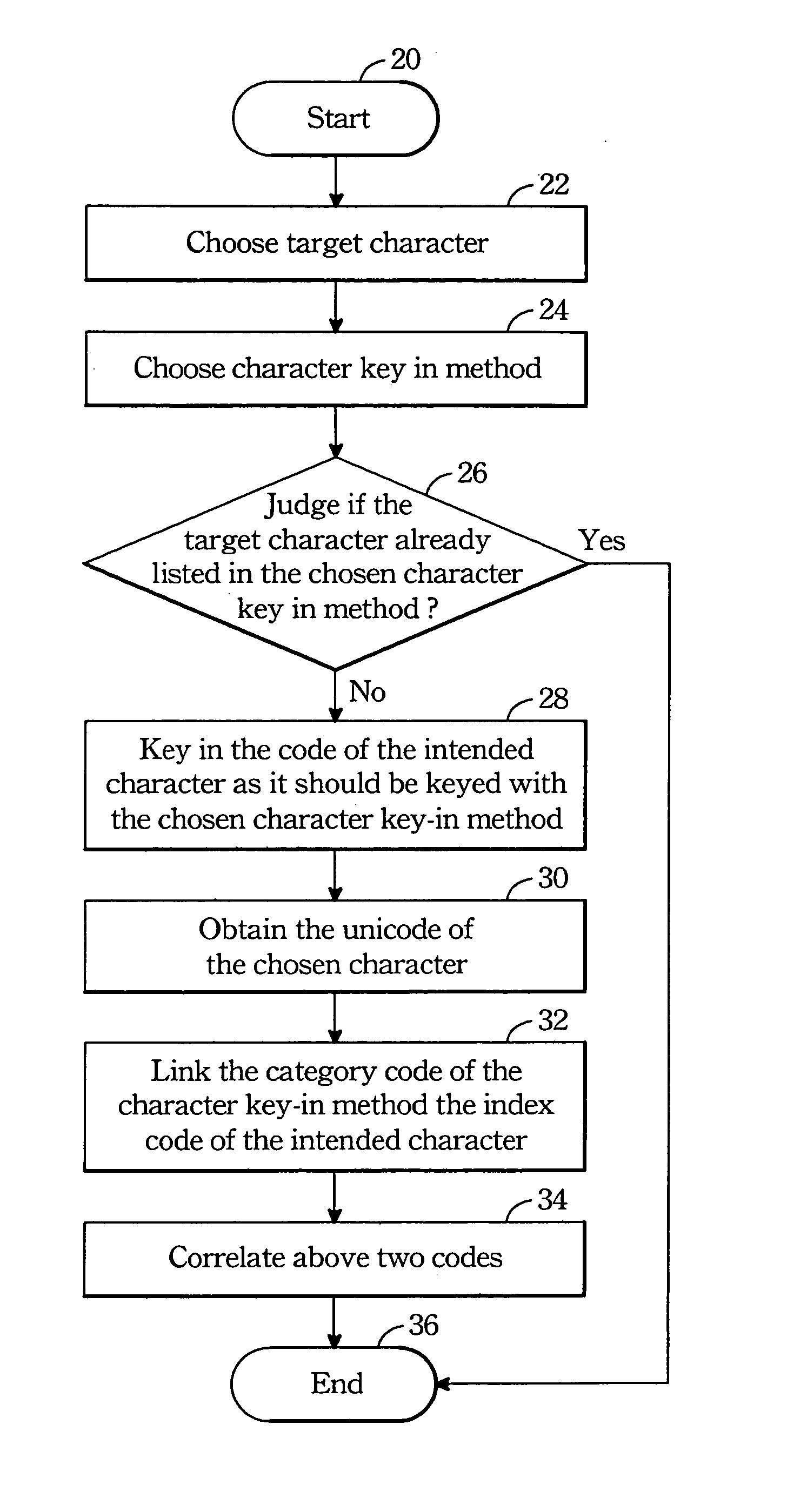

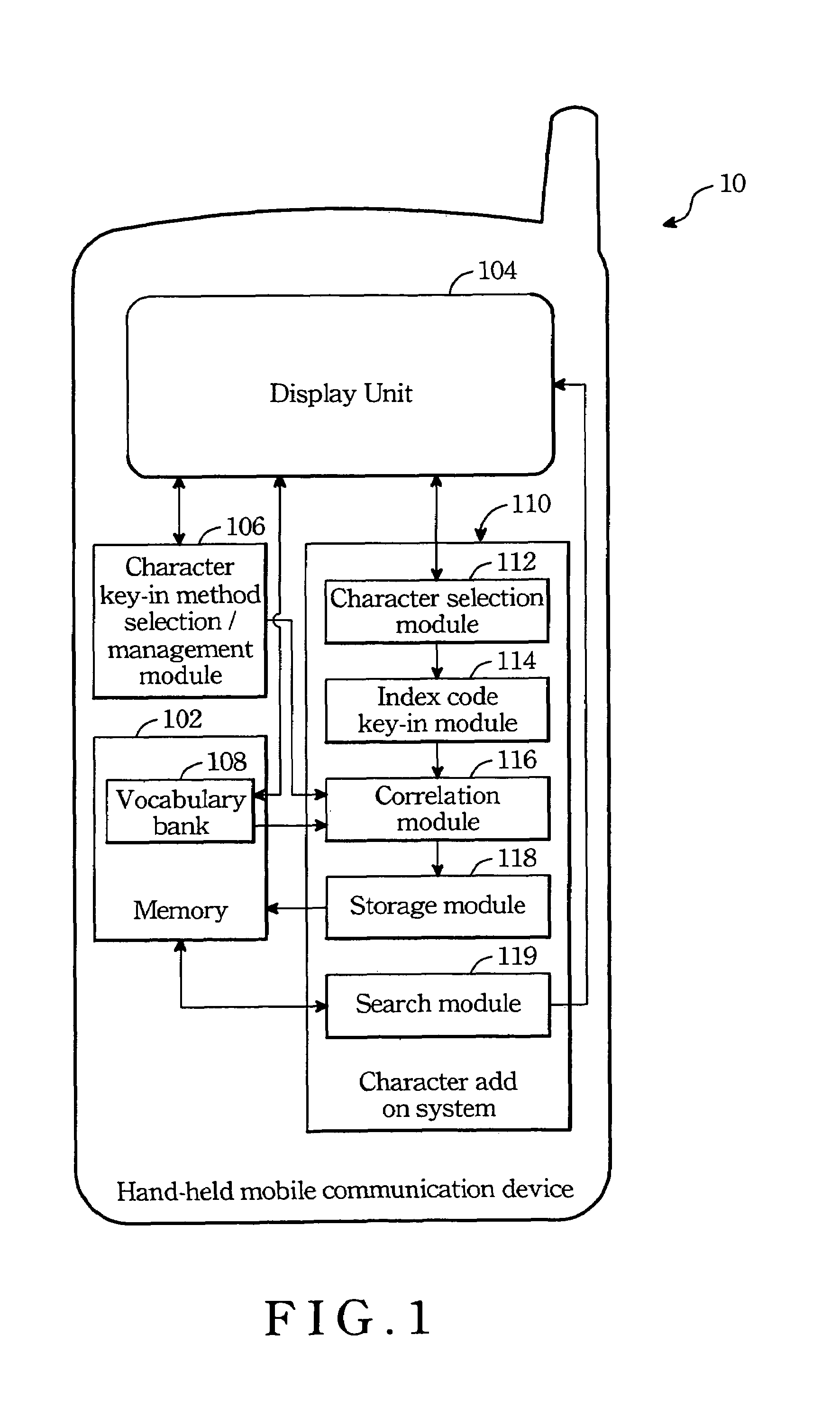

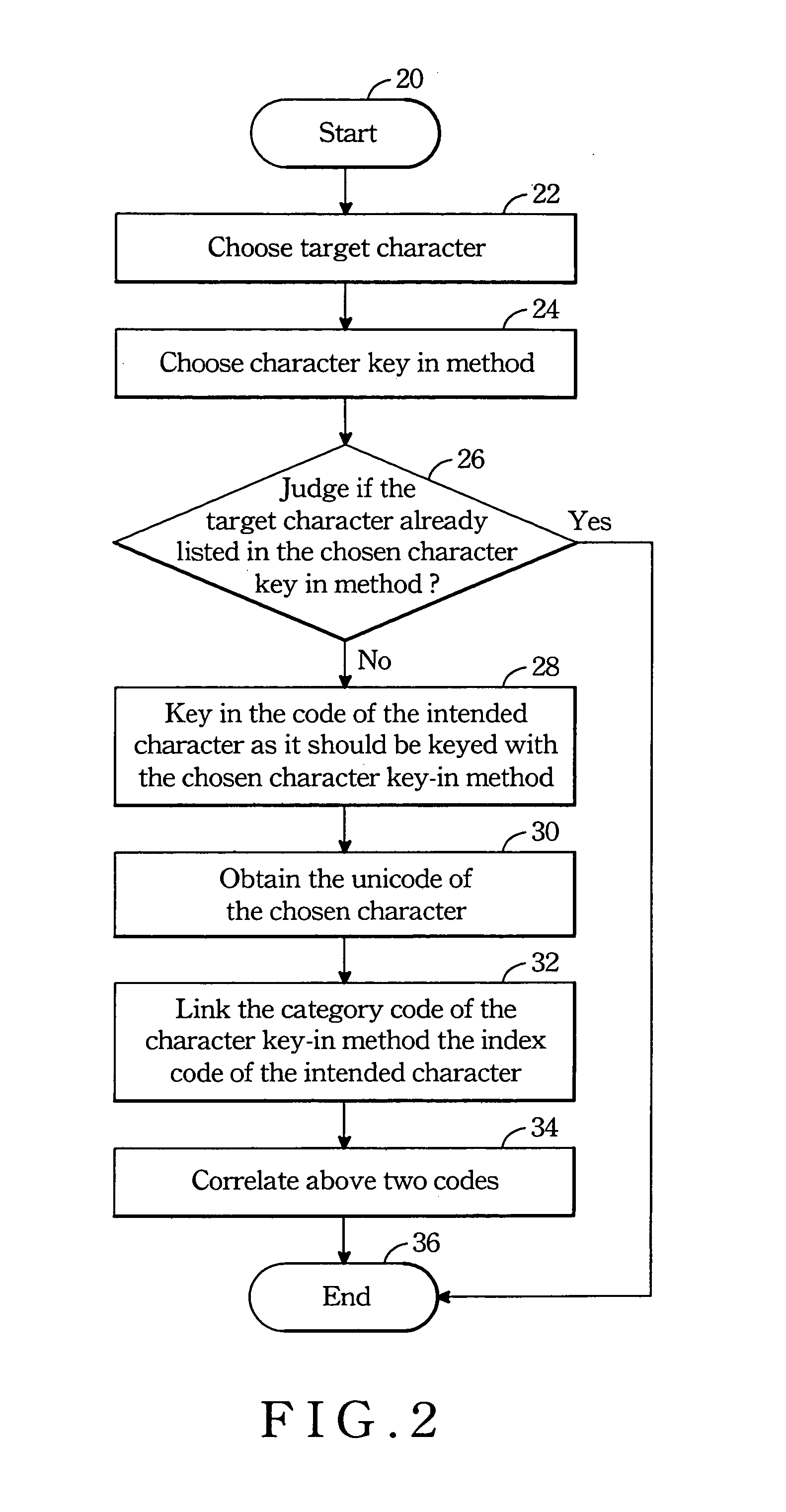

System for adding extra characters to a vocabulary list of a selected character key-in method in hand-held mobile communication devices

ActiveUS7386644B2Good compatibilityImprove convenienceCode conversionAlphabetical characters enteringHand heldSelection system

A system to be used to add non-listed characters (i.e., characters not listed in character key-in methods) to the vocabulary banks of character-key-in methods used in hand-held mobile communication devices is disclosed. Users of a mobile communication device can select a character or characters which are built in the system but not indexed by a certain character-key-in method (that is, the characters cannot be keyed in with that character-key-in method), index the aforesaid characters, using the indexing system / method of the character-key-in method, and then add them to the key-in method's character-indexing system so that subsequent users of the mobile communication device can use said character-key-in method to key in said (originally non-indexed / listed) characters.

Owner:INVENTEC APPLIANCES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com