Flexible package with a transverse access panel device

a transverse access panel and flexible technology, applied in the field of flexible packaging, can solve the problems of merely introducing different problems, reducing the introducing complexity into the manufacturing and use of the product, so as to reduce the available material holding capacity of the package, reduce material and manufacturing costs, and limit volumetric capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

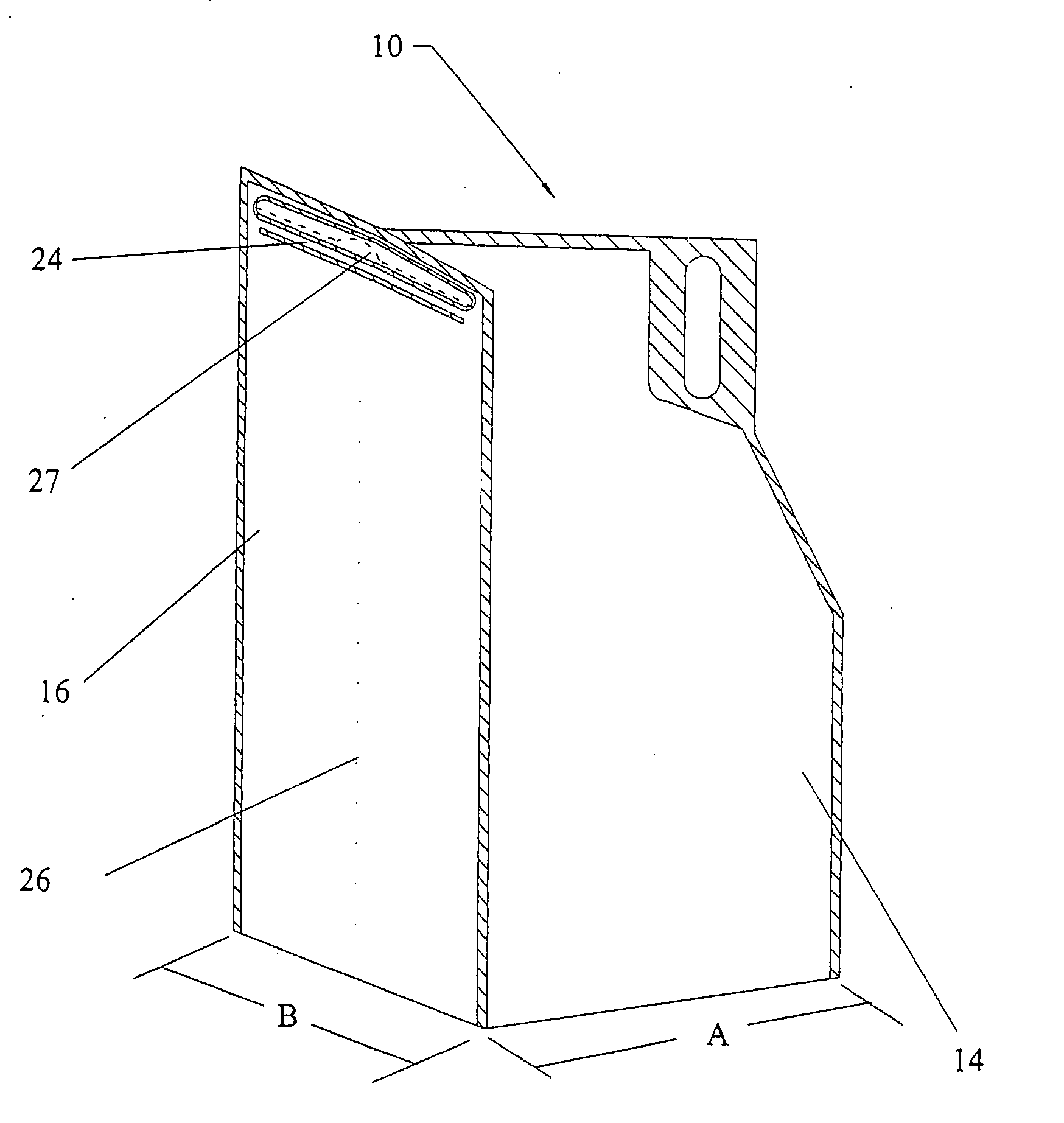

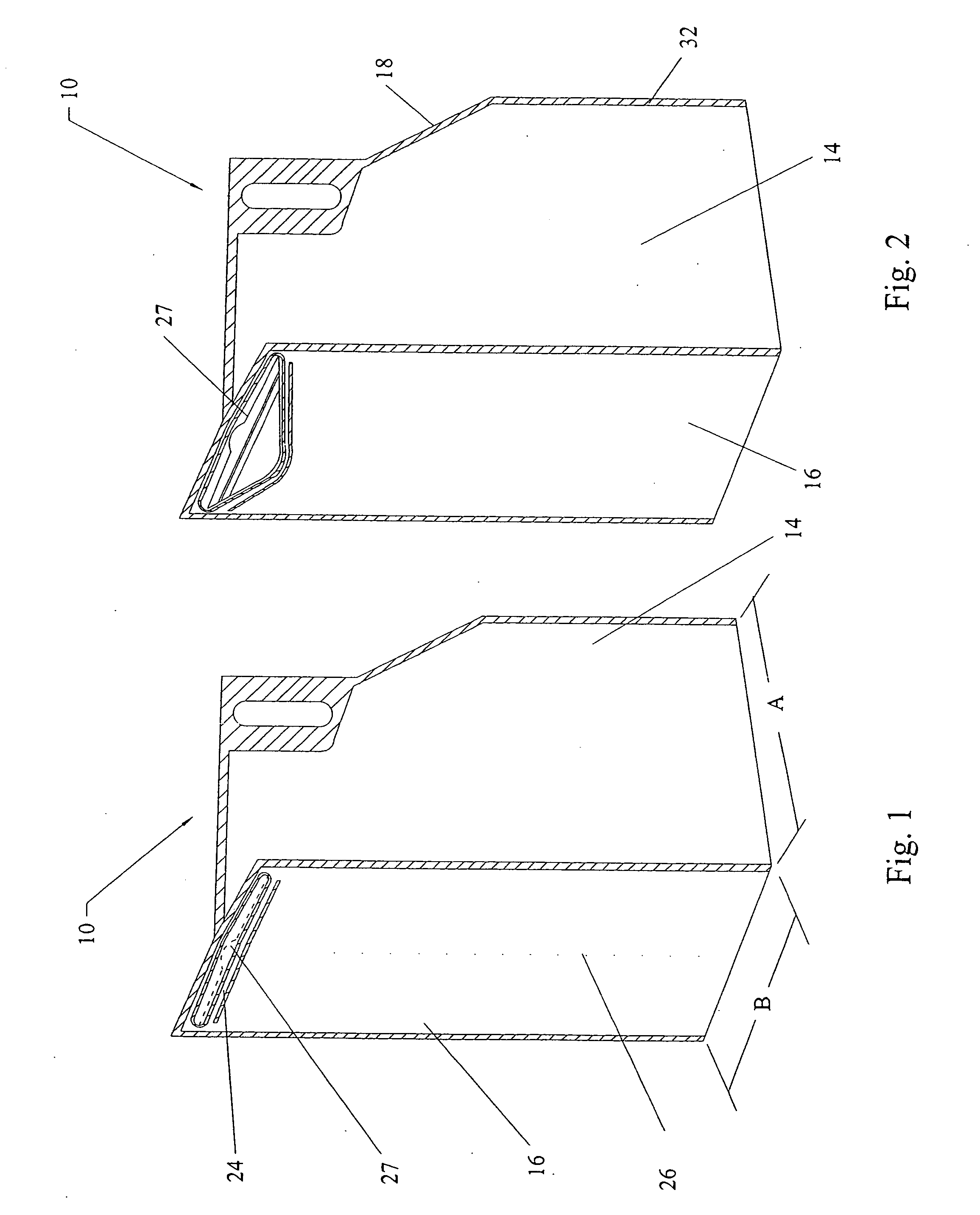

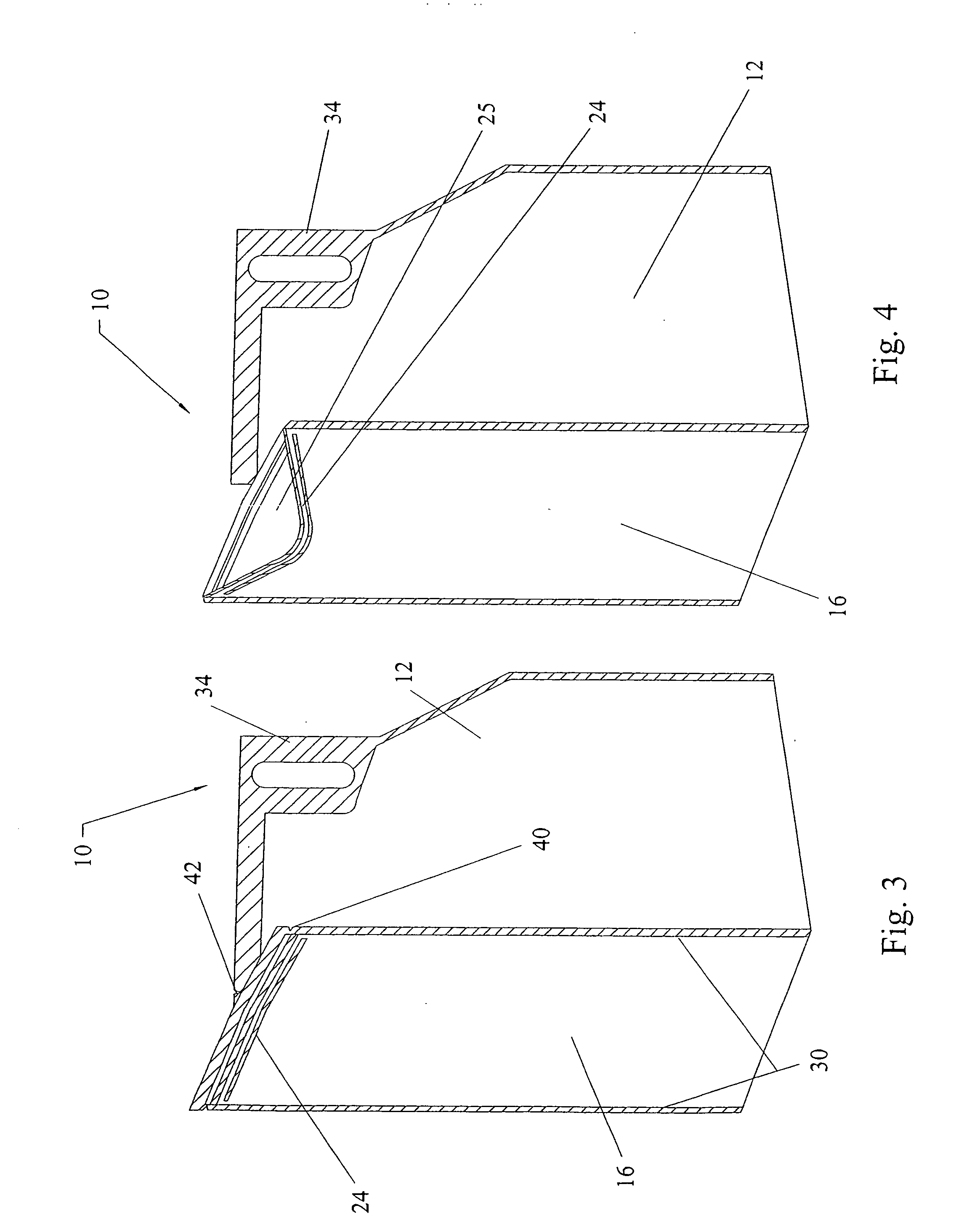

[0038] Referring to FIGS. 1-24, a flexible package 10 and components and configurations in accordance with embodiments of the present invention are shown. The package 10 generally includes a front panel portion 12, a back panel portion 14, a first side panel portion 16, and an access device 24. In addition, the package 10 can include a second side panel portion 18, a top panel portion 20, and a bottom panel portion 22. The joining and / or shaping of the above-referenced panels (as will be discussed in greater detail herein) define the package 10 with an internal cavity 25, having an adjustable internal volume capacity. The panels 12-22 are often referred to as “webs.” Each panel can be formed from an individual web or, alternatively, each of the panels can be portions of a larger single web, wherein the large web is folded, cut and / or shaped to define the individual panel portions and, ultimately, the shape and size of the package 10. Further, in one embodiment, the top 20 and bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com