Helmholtz silencer for automobile air inflow and exhaust debugging

A technology of muffler and muffler chamber, applied in intake muffler, combustion air/combustion-air treatment, muffler device, etc., can solve the problem of high cost of intake and exhaust debugging, single frequency of Helmholtz muffler, not arbitrary Changes and other issues to achieve the effect of shortening the development time cycle, saving manufacturing costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

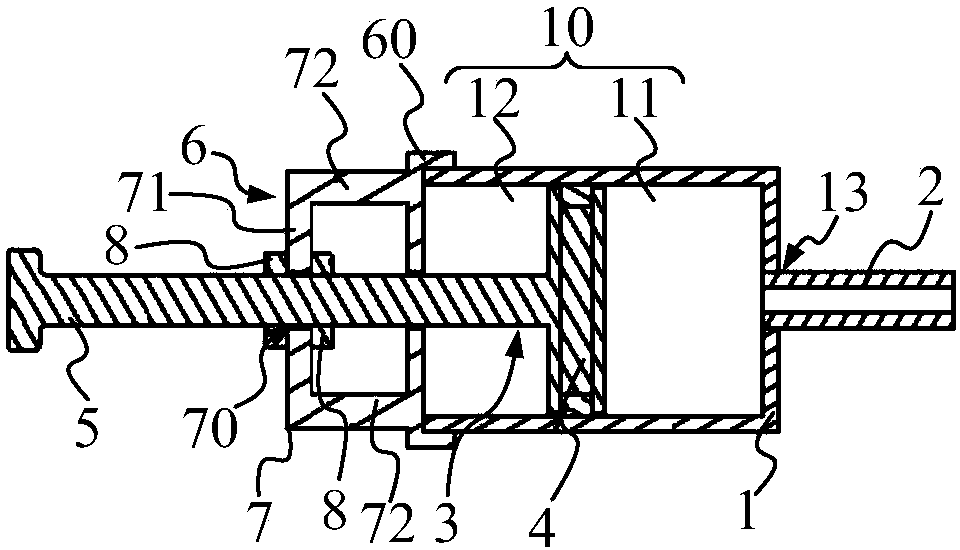

[0017] In order to make the above objects, features and advantages of the present invention more clearly understood, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

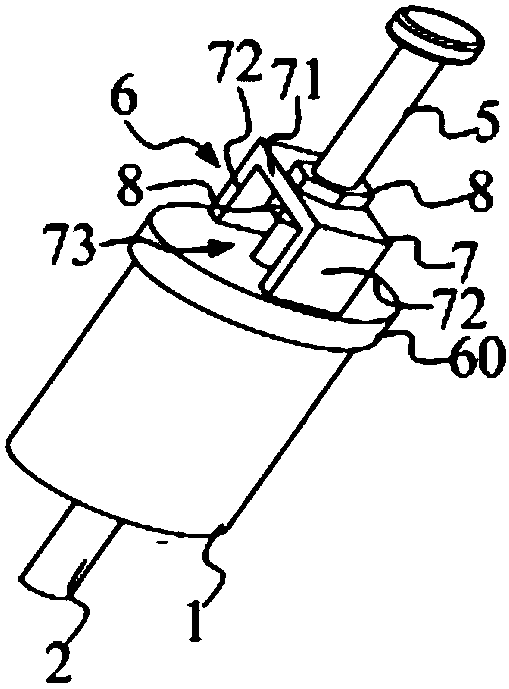

[0018] refer to figure 1 , A Helmholtz muffler for vehicle air intake and exhaust debugging includes: a housing 1 with a muffler cavity 11 and a connecting pipe 2 located outside the muffler cavity 11 and communicated with the muffler cavity 11 . The Helmholtz muffler further includes an adjustment part 3, and the adjustment part 3 has a plurality of adjustment positions, and corresponding to the plurality of adjustment positions, the muffler cavity 11 has different volumes.

[0019] According to the frequency formula of the anechoic cavity 11: Where f is the frequency, and V is the volume of the muffler cavity 11 . In this technical solution, by changing the adjustment position of the adjustment part 3 , the volume V of the muffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com