Aza-graphene and manganese dioxide hybrid aerogel, preparation method and application thereof

A technology of graphene oxide and graphene hydrogel, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of destroying the close contact between electrode materials and current collectors, the attenuation of electrochemical performance, and the detachment of electrode materials. Good cycle stability, improved electrical conductivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Ammonia (4mL, 28wt%) was added to the graphene oxide aqueous dispersion (18mL, 5mgmL –1 ), and then the mixture was placed in a stainless steel reactor, and it was hydrothermally reacted at 180°C for 12h.

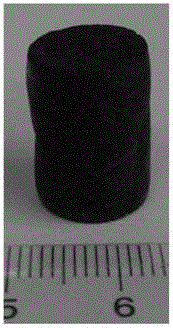

[0064] After the reaction was completed and the temperature of the reaction system dropped to room temperature, the above mixture formed a black azagraphene hydrogel. The above-mentioned hydrogel is replaced with a large amount of water to obtain pure aza-graphene hydrogel.

[0065] At room temperature, the azagraphene hydrogel was soaked in a mixed solution of 0.1M potassium permanganate and 0.1M sodium sulfate. After 30 minutes, the above-mentioned azagraphene and manganese dioxide hybrid hydrogel was replaced with a large amount of water to obtain pure azagraphene and manganese dioxide hybrid hydrogel.

[0066] After freeze-drying the azagraphene and manganese dioxide hybrid hydrogel, the azagraphene and manganese dioxide hybrid aerogel can be obtained.

Embodiment 2

[0068] Ammonia (4mL, 28wt%) was added to the graphene oxide aqueous dispersion (18mL, 5mgmL –1 ), and then the mixture was placed in a stainless steel reactor, and it was hydrothermally reacted at 180°C for 12h.

[0069] After the reaction was completed and the temperature of the reaction system dropped to room temperature, the above mixture formed a black azagraphene hydrogel. The above-mentioned hydrogel is replaced with a large amount of water to obtain pure aza-graphene hydrogel.

[0070] At room temperature, the azagraphene hydrogel was soaked in a mixed solution of 0.1M potassium permanganate and 0.1M sodium sulfate. After 60 min, the above-mentioned azagraphene and manganese dioxide hybrid hydrogel was replaced with a large amount of water to obtain pure azagraphene and manganese dioxide hybrid hydrogel.

[0071] After freeze-drying the azagraphene and manganese dioxide hybrid hydrogel, the azagraphene and manganese dioxide hybrid aerogel can be obtained.

Embodiment 3

[0073] Ammonia (4mL, 28wt%) was added to the graphene oxide aqueous dispersion (18mL, 5mgmL –1 ), and then the mixture was placed in a stainless steel reactor, and it was hydrothermally reacted at 180°C for 12h.

[0074] After the reaction was completed and the temperature of the reaction system dropped to room temperature, the above mixture formed a black azagraphene hydrogel. The above-mentioned hydrogel is replaced with a large amount of water to obtain pure aza-graphene hydrogel.

[0075] At room temperature, the azagraphene hydrogel was soaked in a mixed solution of 0.1M potassium permanganate and 0.1M sodium sulfate. After 120 minutes, the above-mentioned azagraphene and manganese dioxide hybrid hydrogel was replaced with a large amount of water to obtain pure azagraphene and manganese dioxide hybrid hydrogel.

[0076] After freeze-drying the azagraphene and manganese dioxide hybrid hydrogel, the azagraphene and manganese dioxide hybrid aerogel can be obtained.

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com