Patents

Literature

98results about How to "Mix completely" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective catalytic reduction of nox enabled by sidestream urea decomposition

InactiveUS7090810B2Well mixedAccurate temperatureNitrogen compoundsInternal combustion piston enginesParticulatesSuperheater

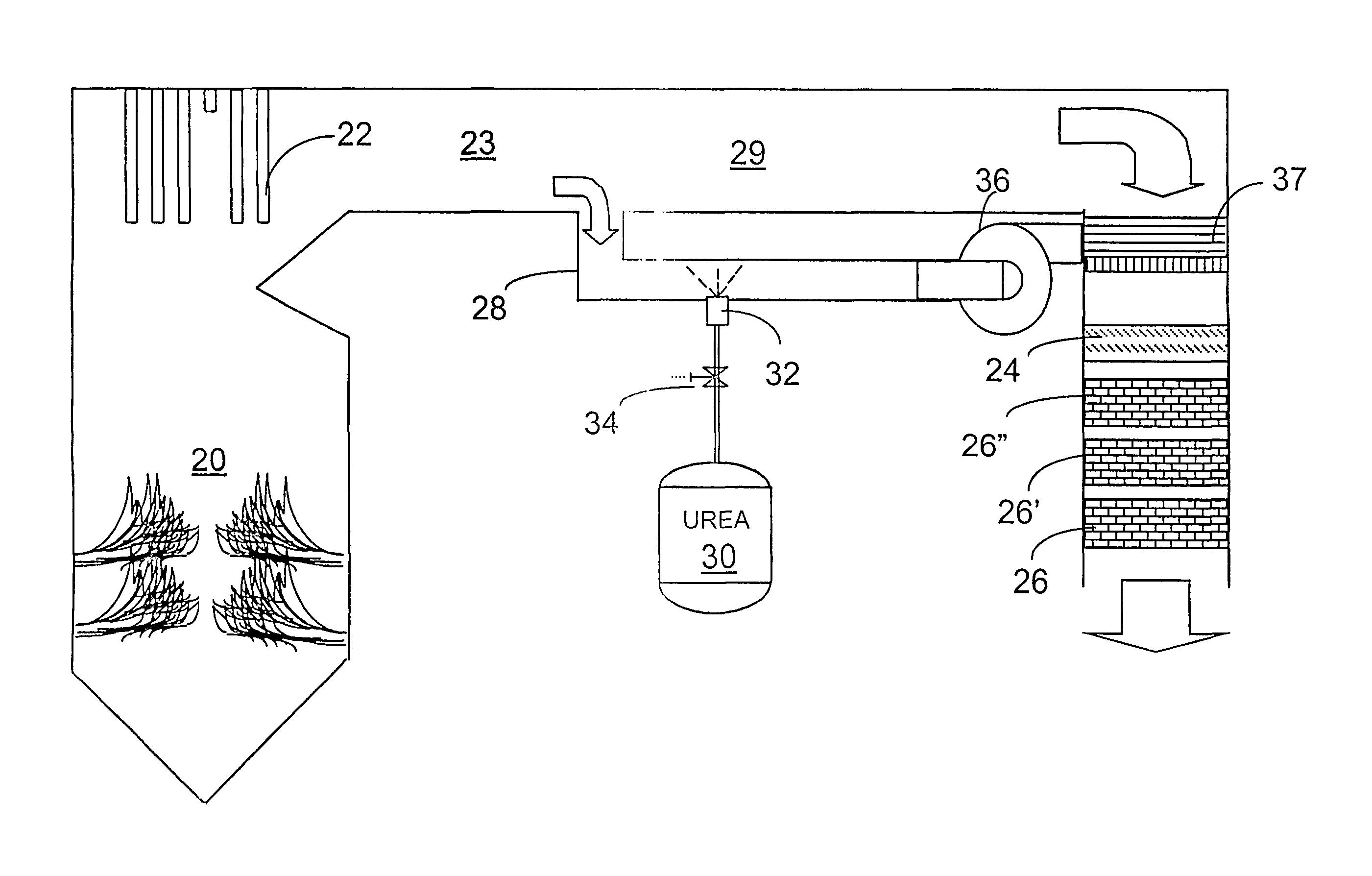

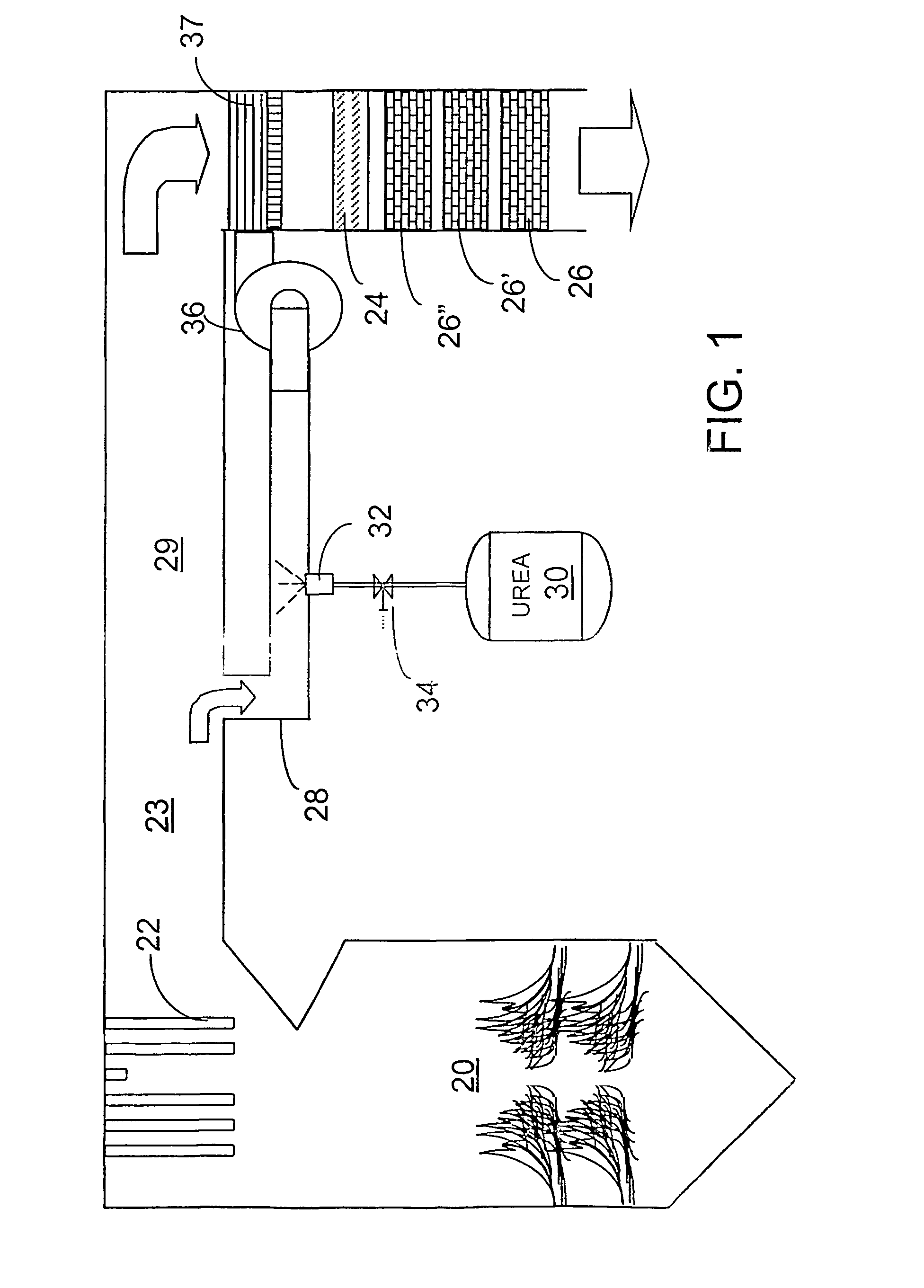

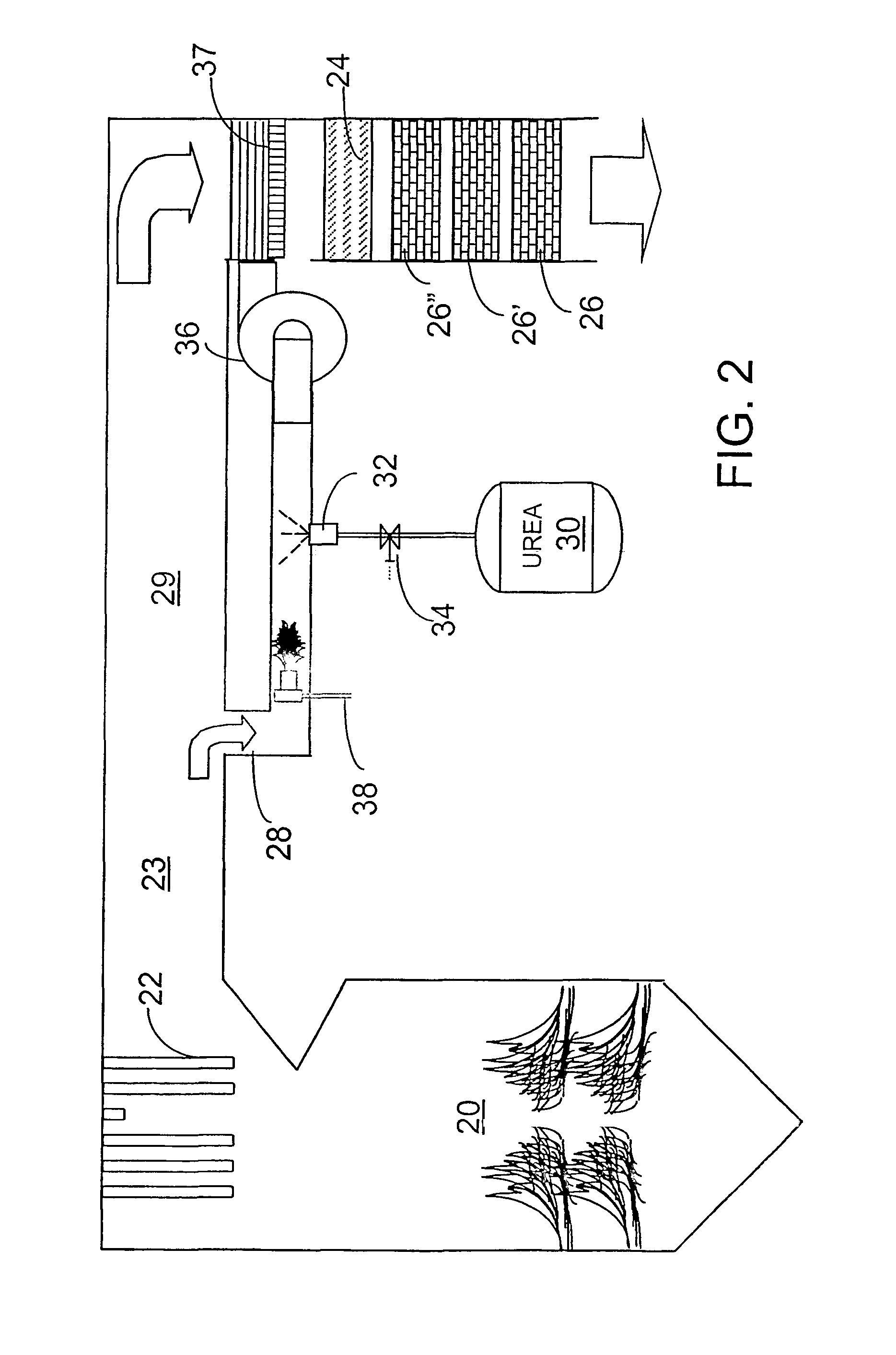

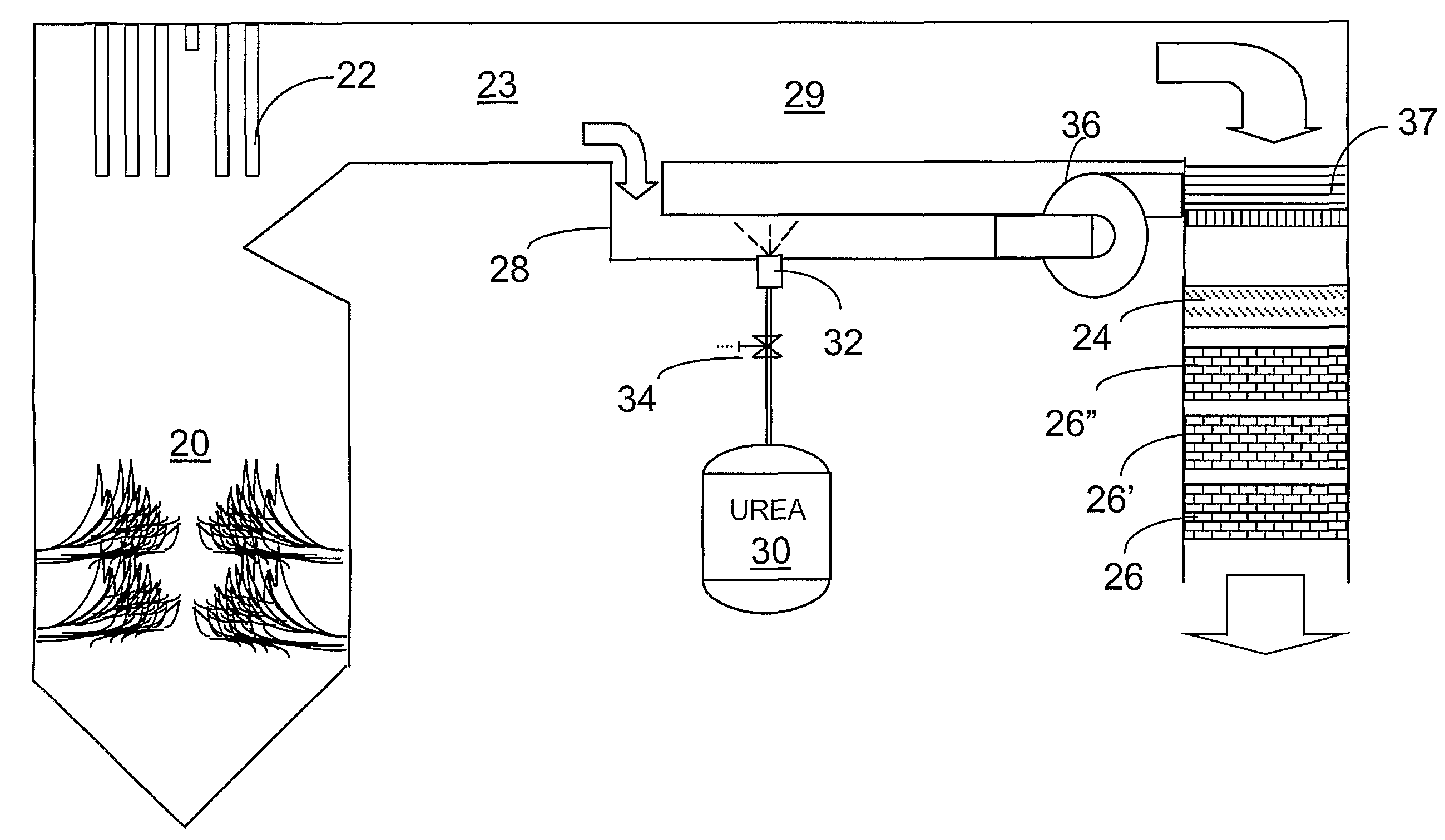

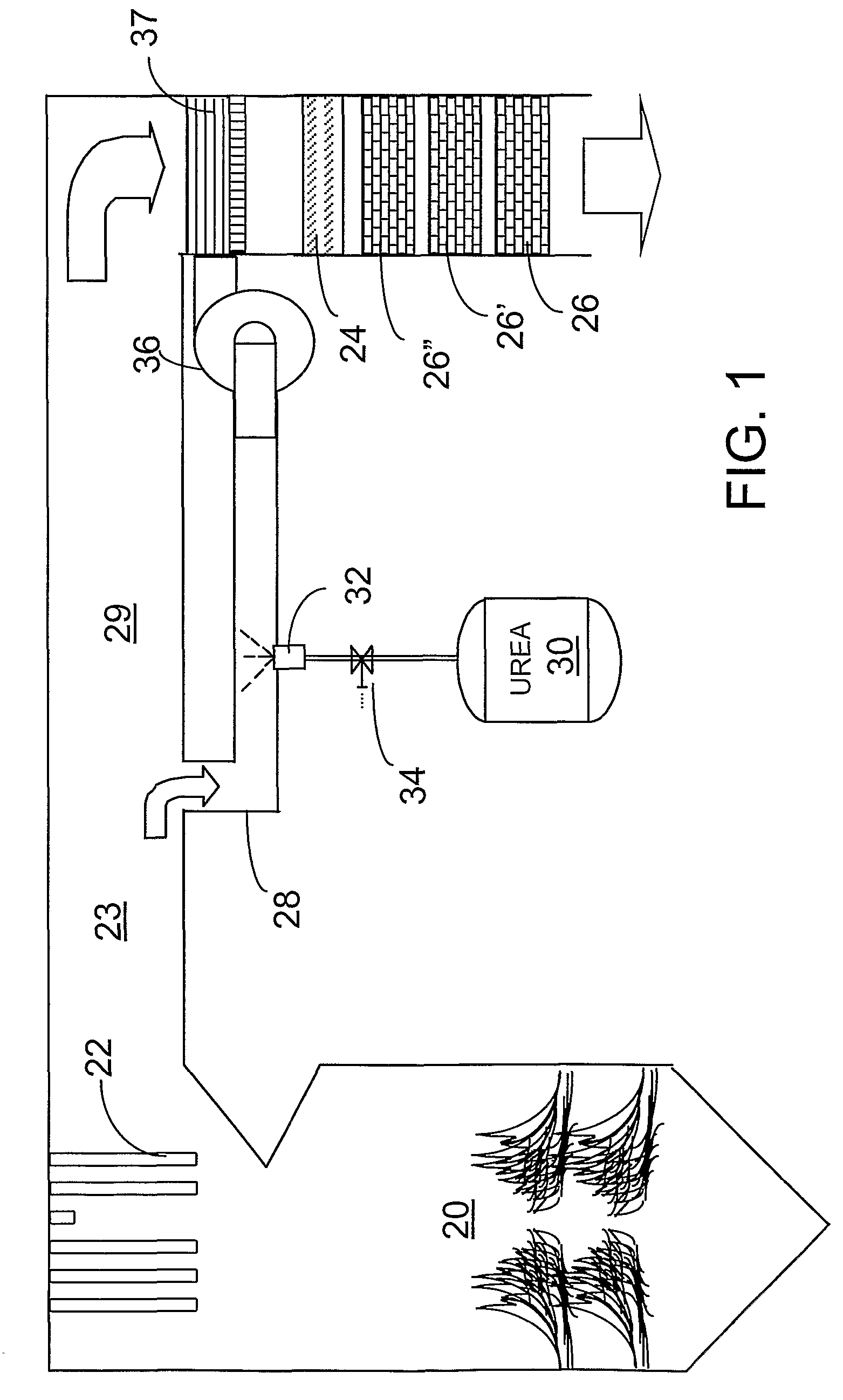

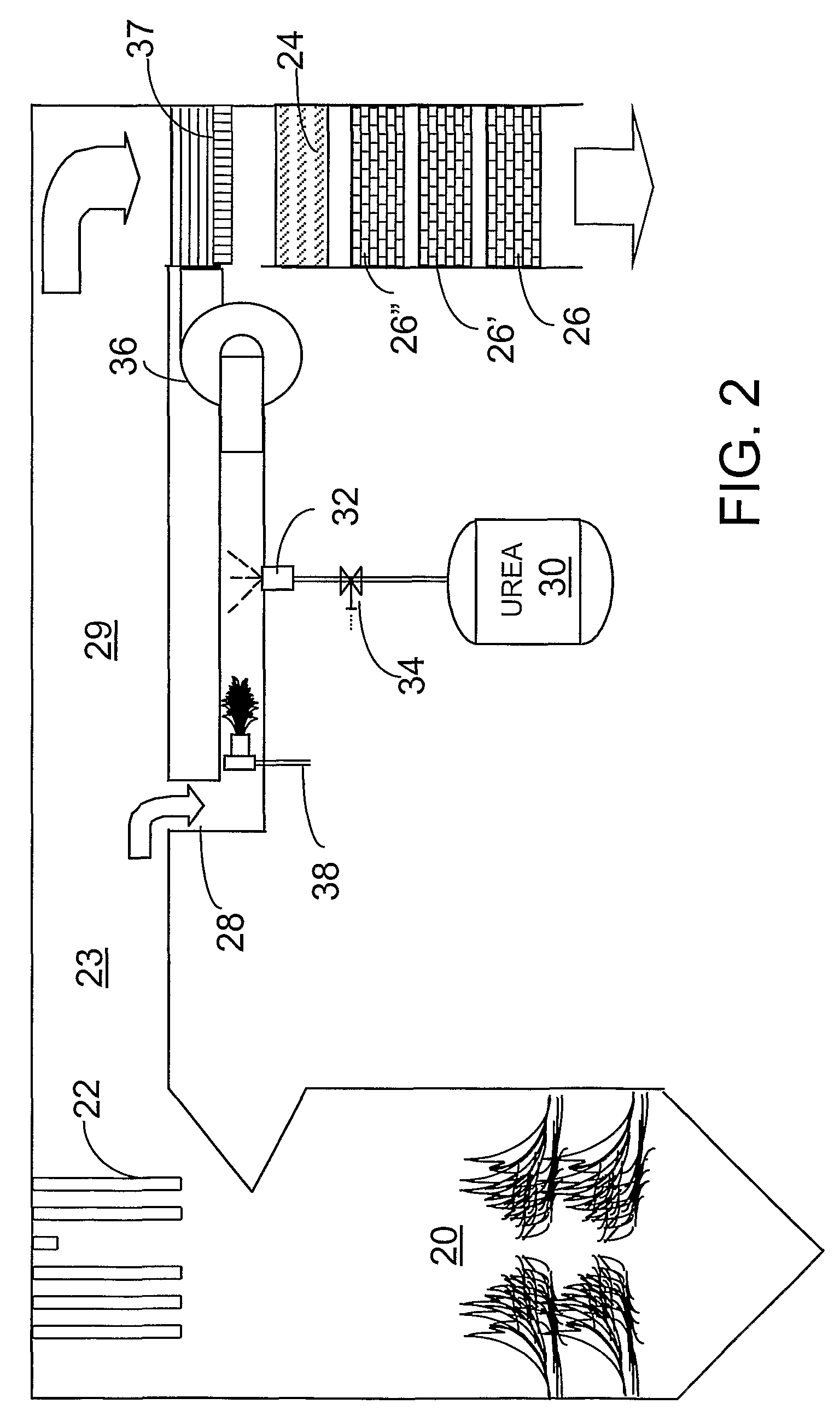

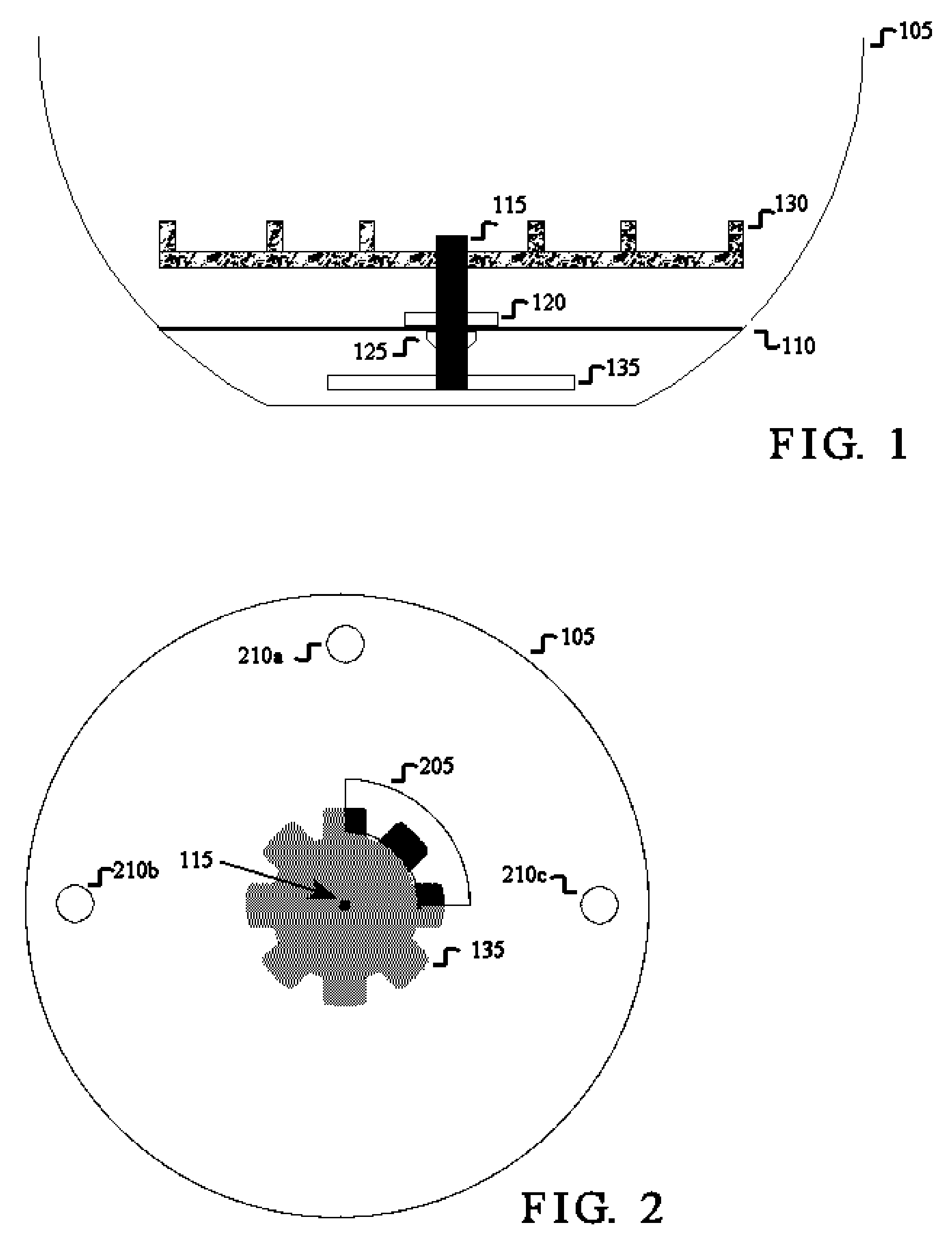

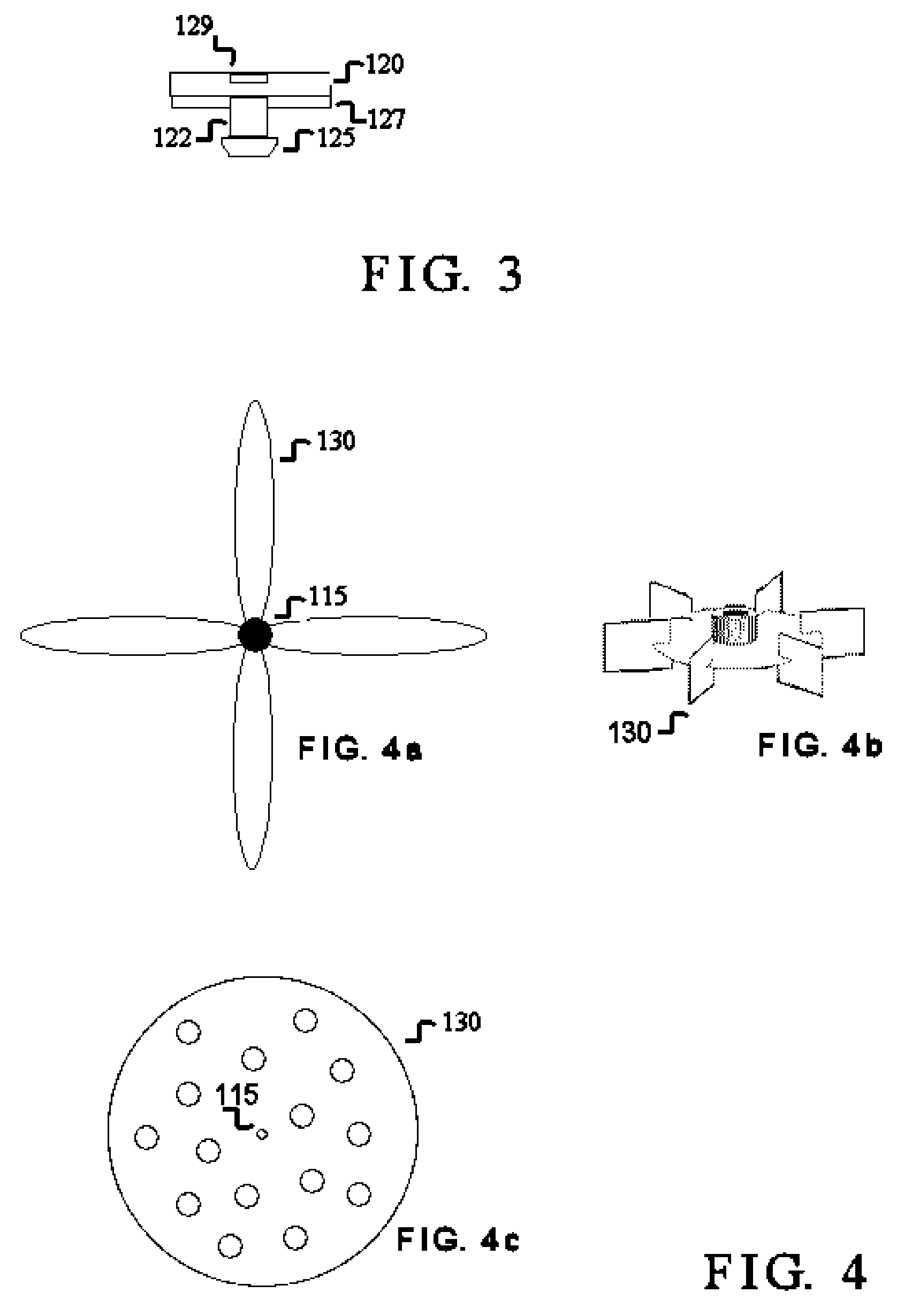

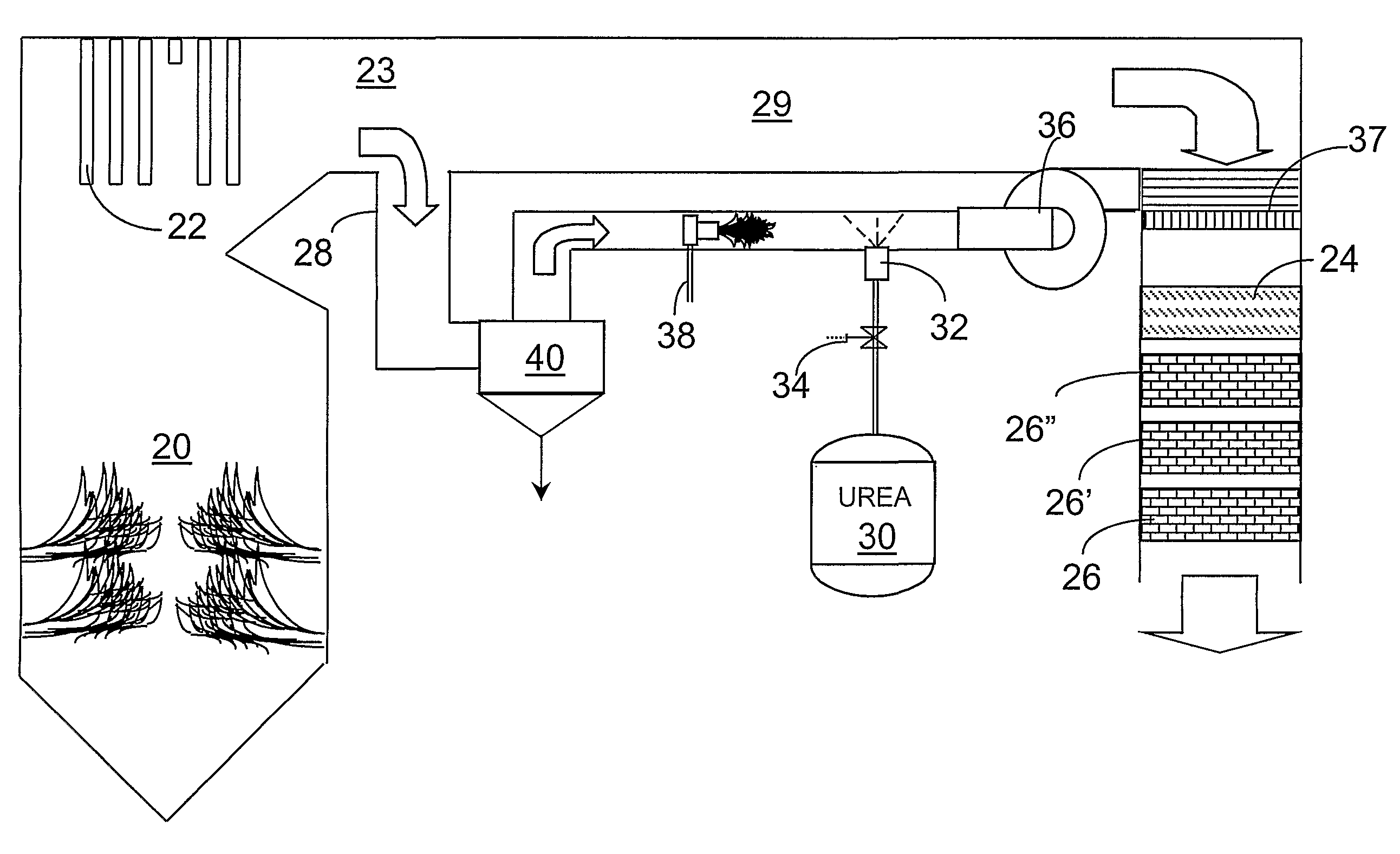

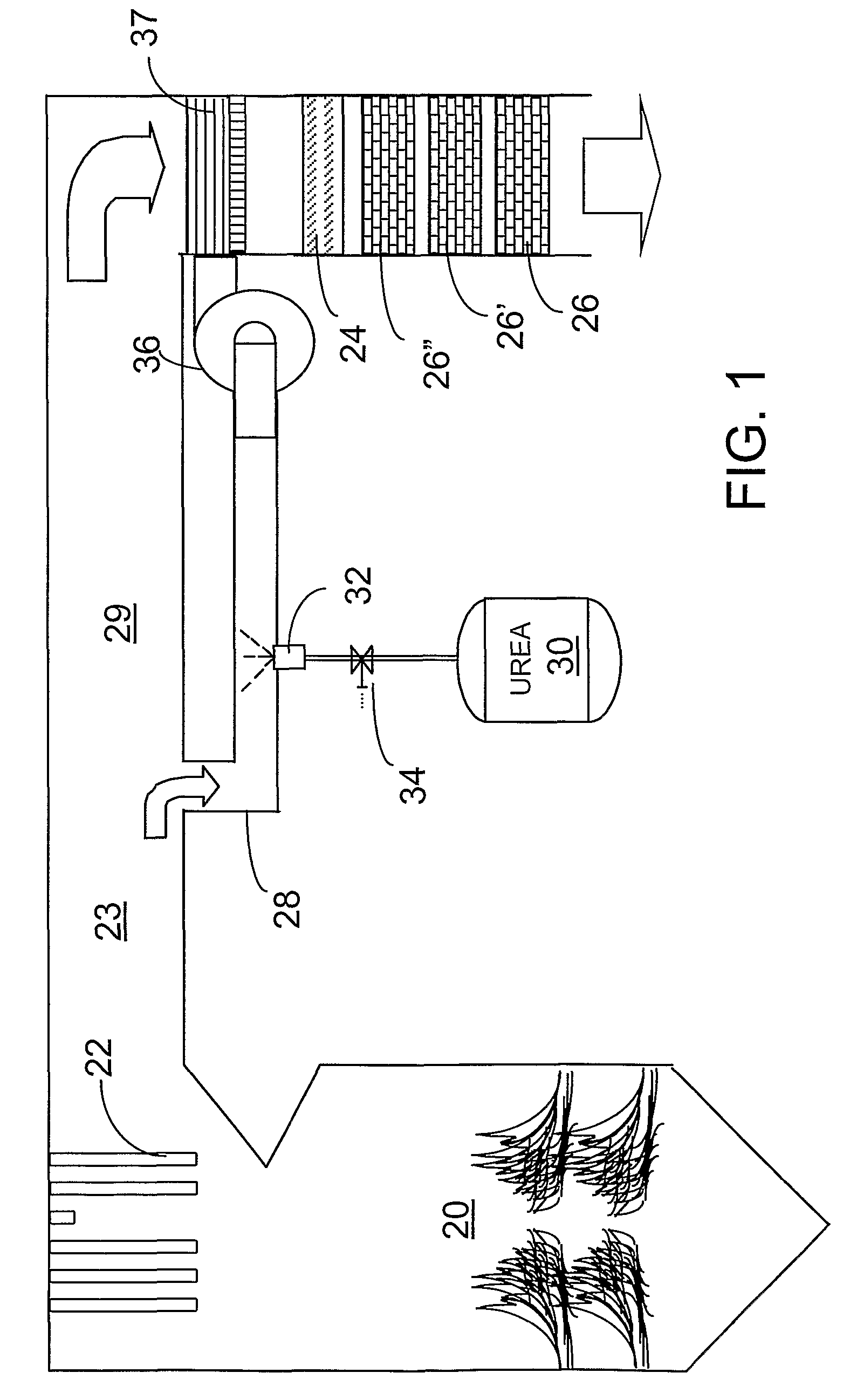

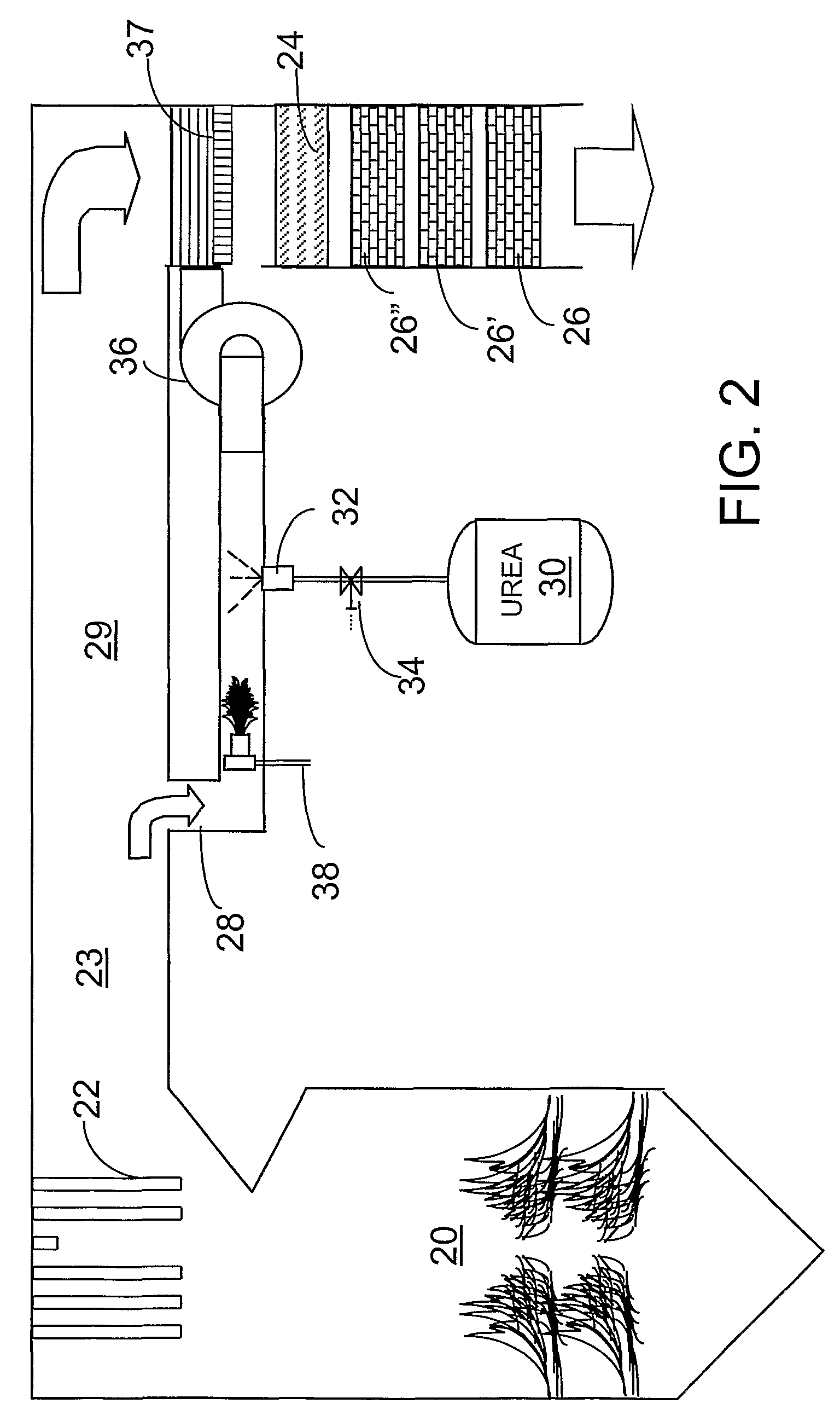

A preferred process arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140 ° C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

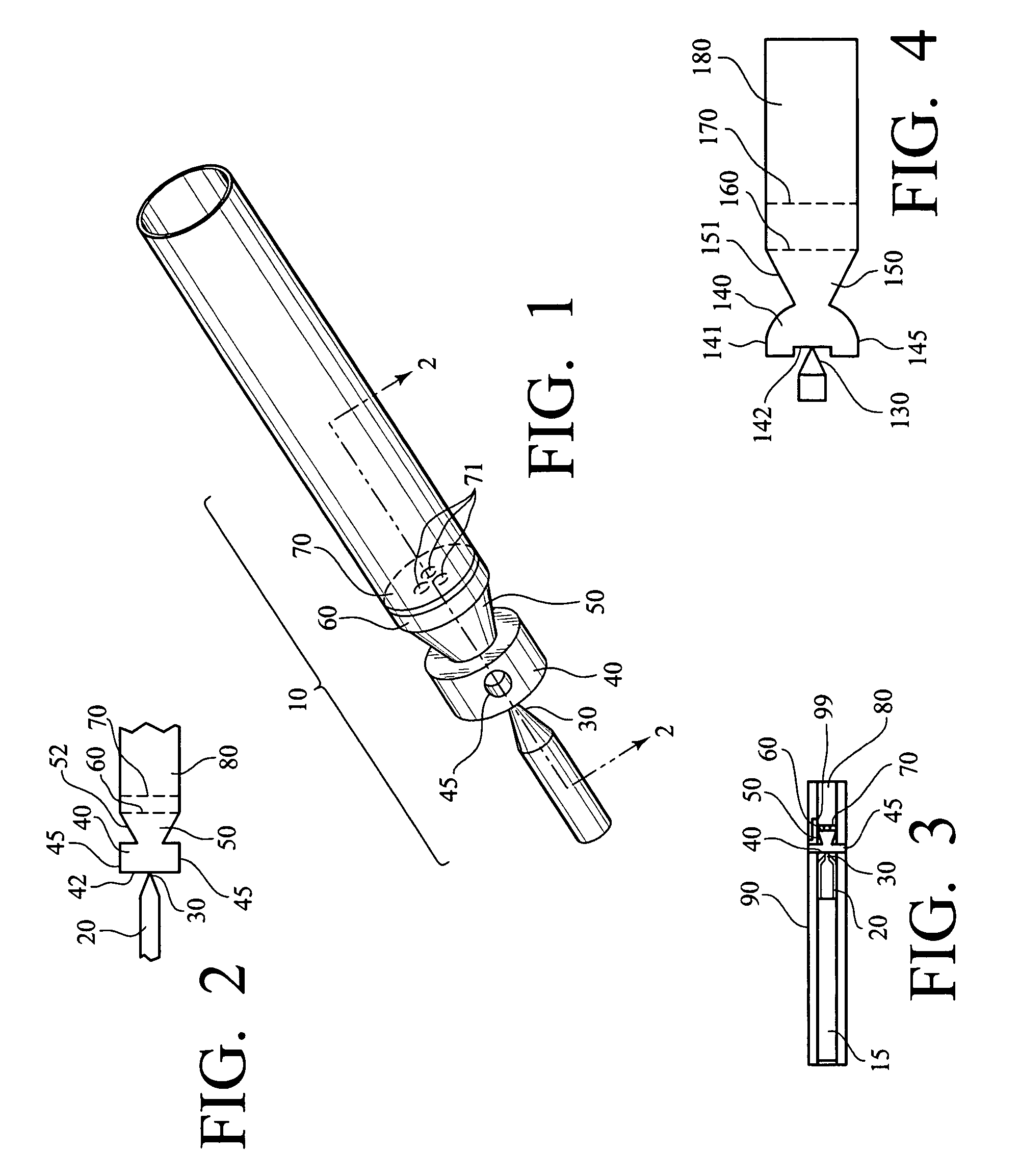

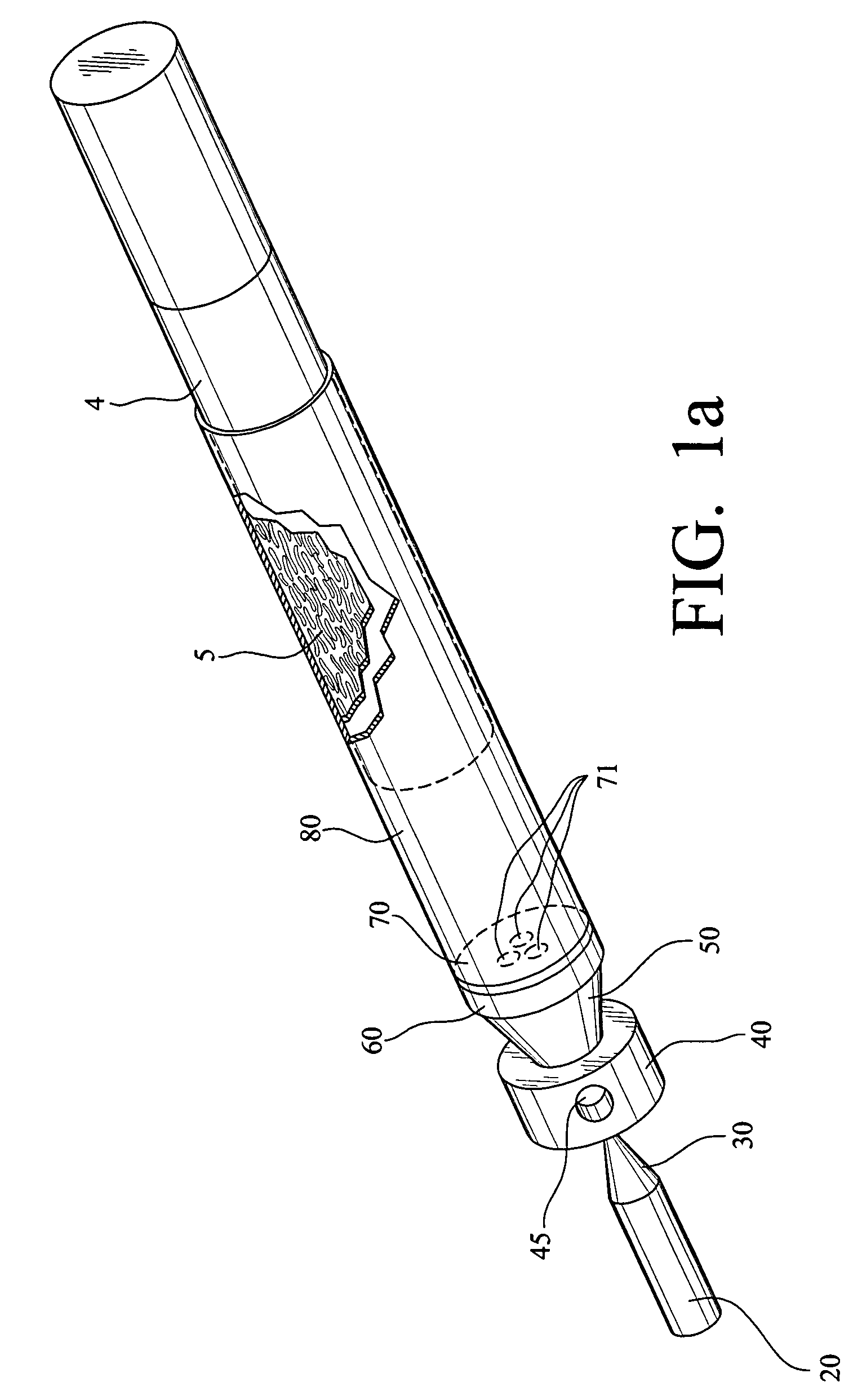

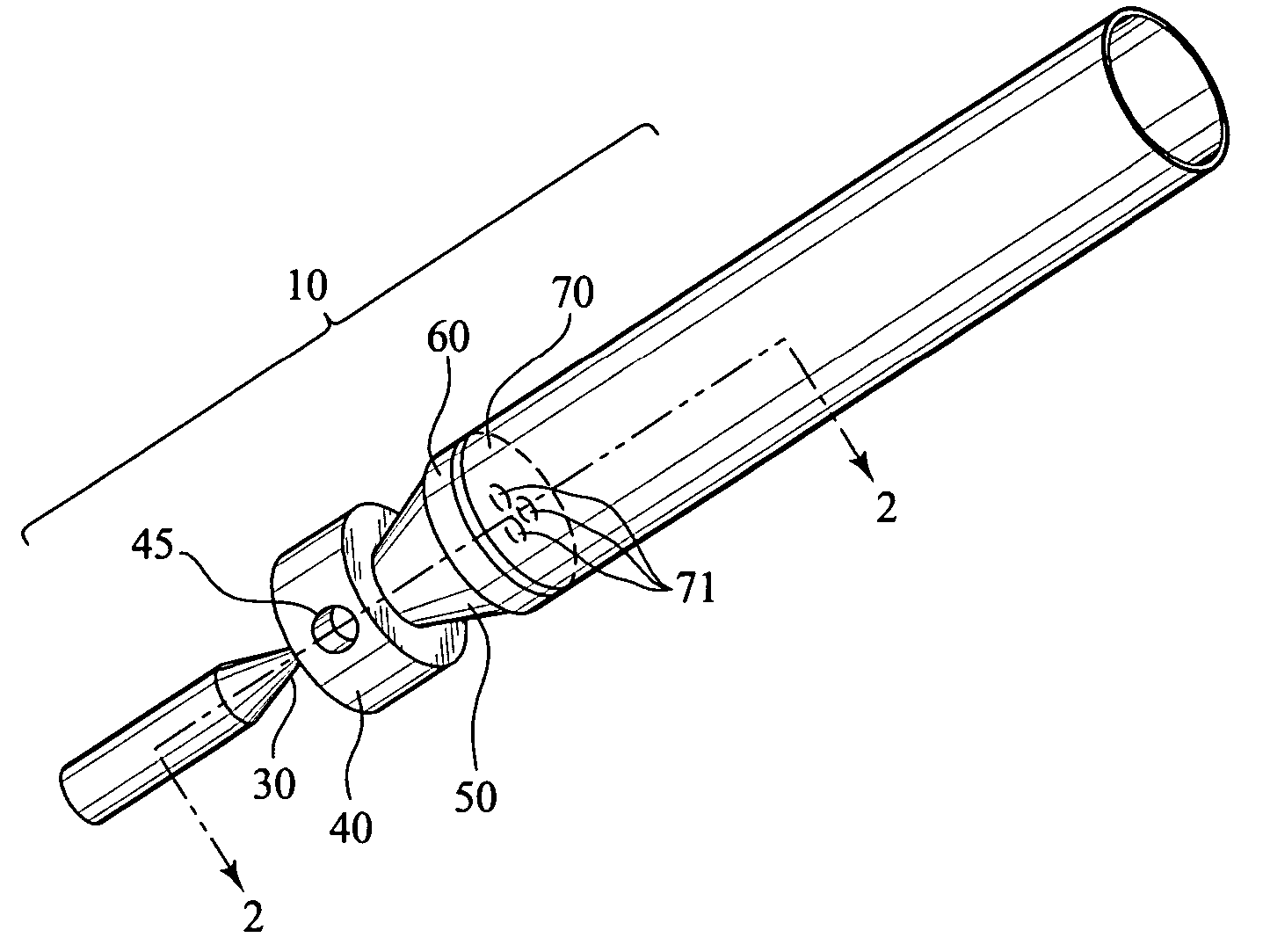

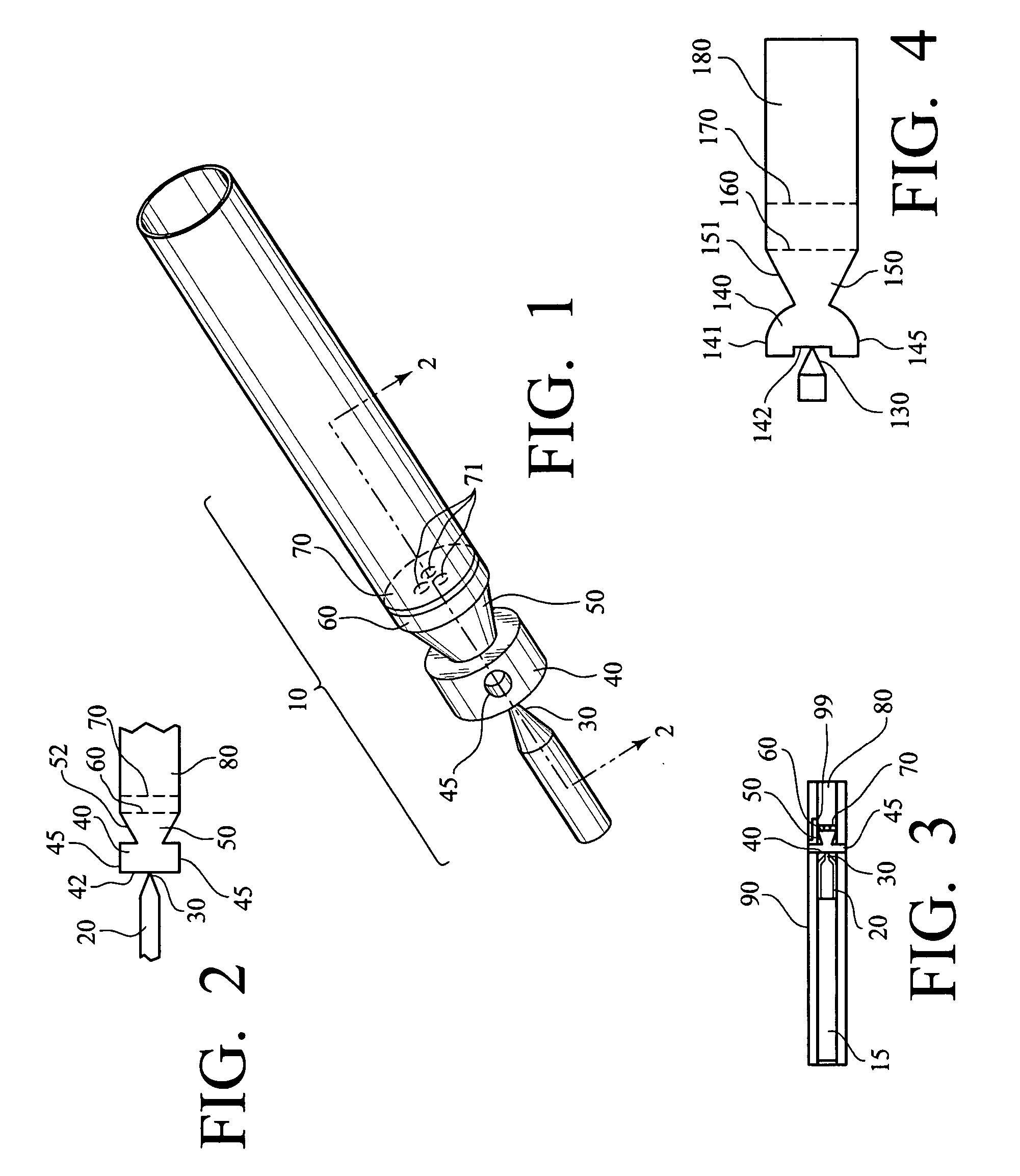

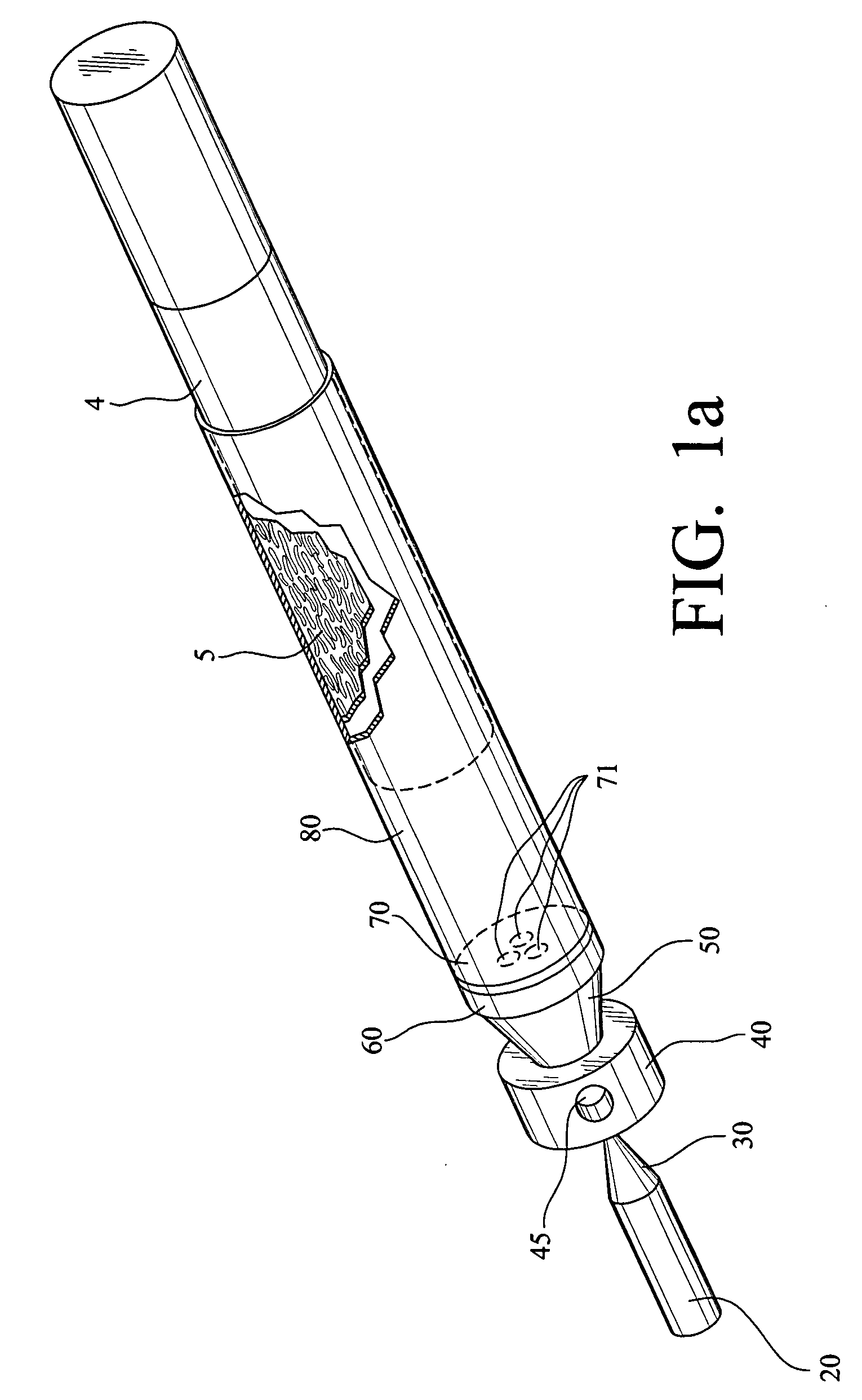

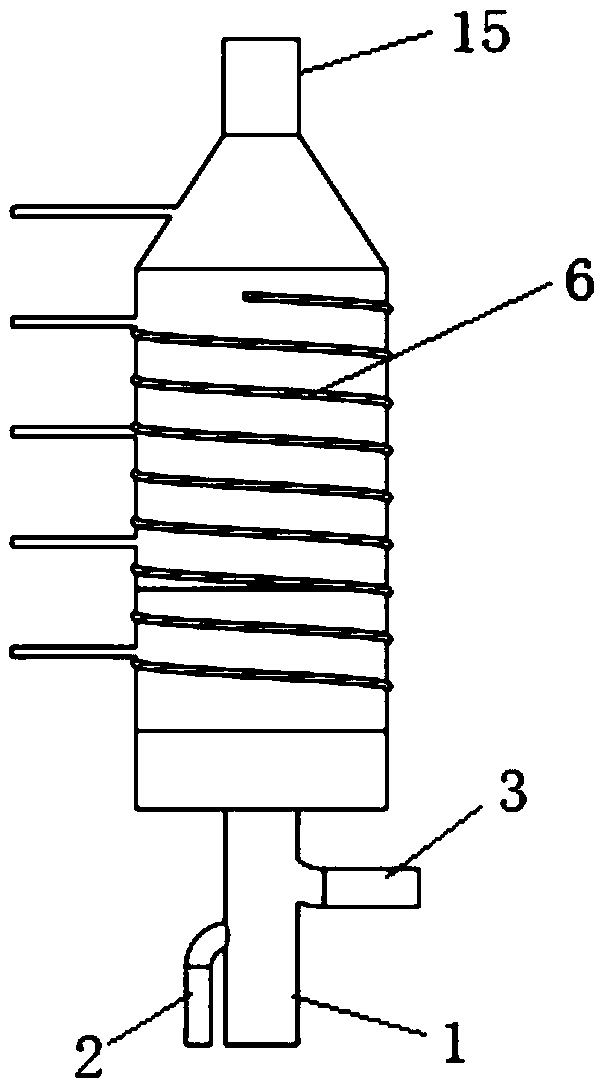

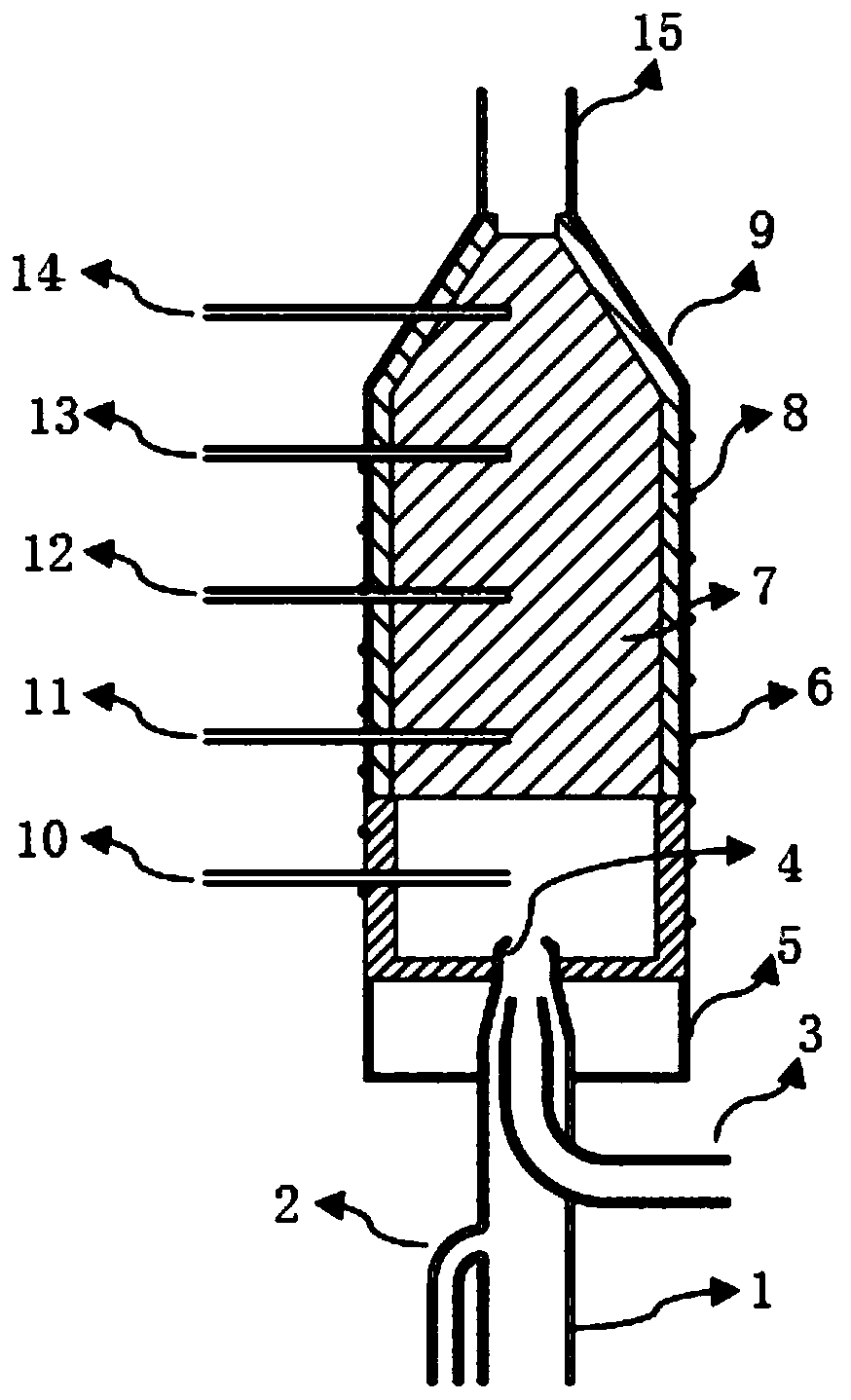

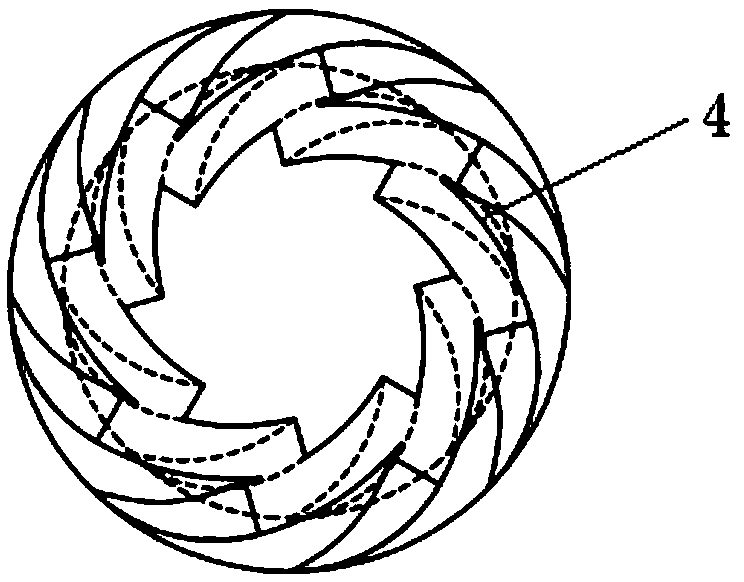

Gas micro burner

InactiveUS7488171B2Low mass flow rateSmall volumeFuel lightersBurner material specificationsProduct gasProcess engineering

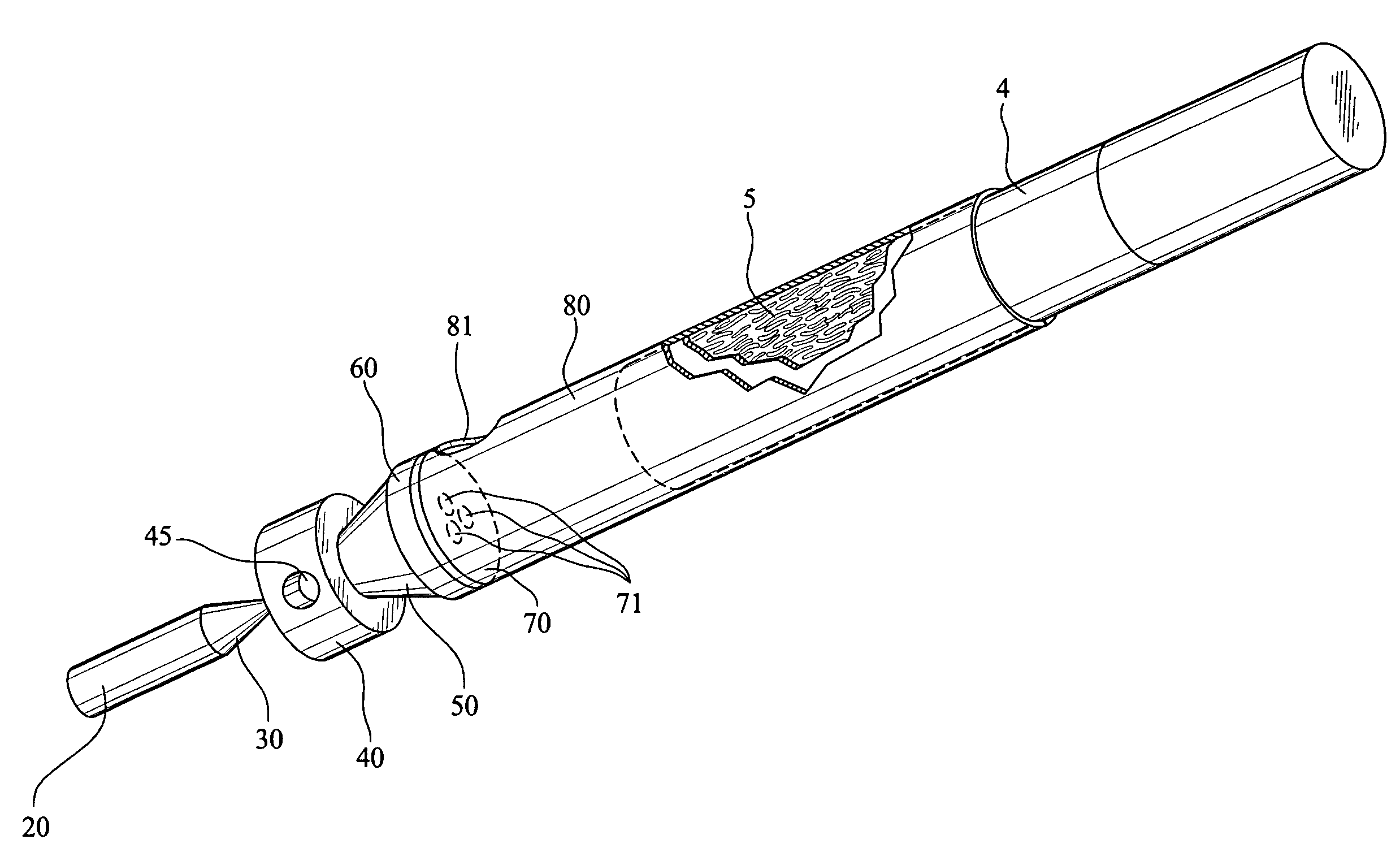

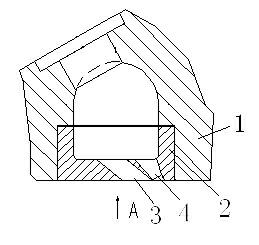

A micro gas burner is provided that generates a stable, pre-mixed flame that produces little to no soot or unburned hydrocarbons. The gas burner includes a fuel inlet, nozzle, oxygenation chamber with at least one air inlet, a mixing chamber having a frustoconical inner wall, at least one permeable barrier and a flame holder. The gas burner thoroughly mixes fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. The gas burner mixes the fuel and air so thoroughly that it requires a lower fuel flow rate than would otherwise be necessary to produce a stable, pre-mixed flame. The gas burner may include an optional flame tube with an optional exhaust port in which a flame is contained and sequestered from diffusing air.

Owner:R J REYNOLDS TOBACCO COMPANY

Gas micro burner

InactiveUS20050069831A1Low fuel mass flow rate requirementLow mass flow rateFuel lightersBurner material specificationsGas burnerProcess engineering

A micro gas burner is provided that generates a stable, pre-mixed flame that produces little to no soot or unburned hydrocarbons. The gas burner includes a fuel inlet, nozzle, oxygenation chamber with at least one air inlet, a mixing chamber having a frustoconical inner wall, at least one permeable barrier and a flame holder. The gas burner thoroughly mixes fuel and entrained air to form a nearly stoichiometric mixture prior to combustion. The gas burner mixes the fuel and air so thoroughly that it requires a lower fuel flow rate than would otherwise be necessary to produce a stable, pre-mixed flame. The gas burner may include an optional flame tube with an optional exhaust port in which a flame is contained and sequestered from diffusing air.

Owner:R J REYNOLDS TOBACCO COMPANY

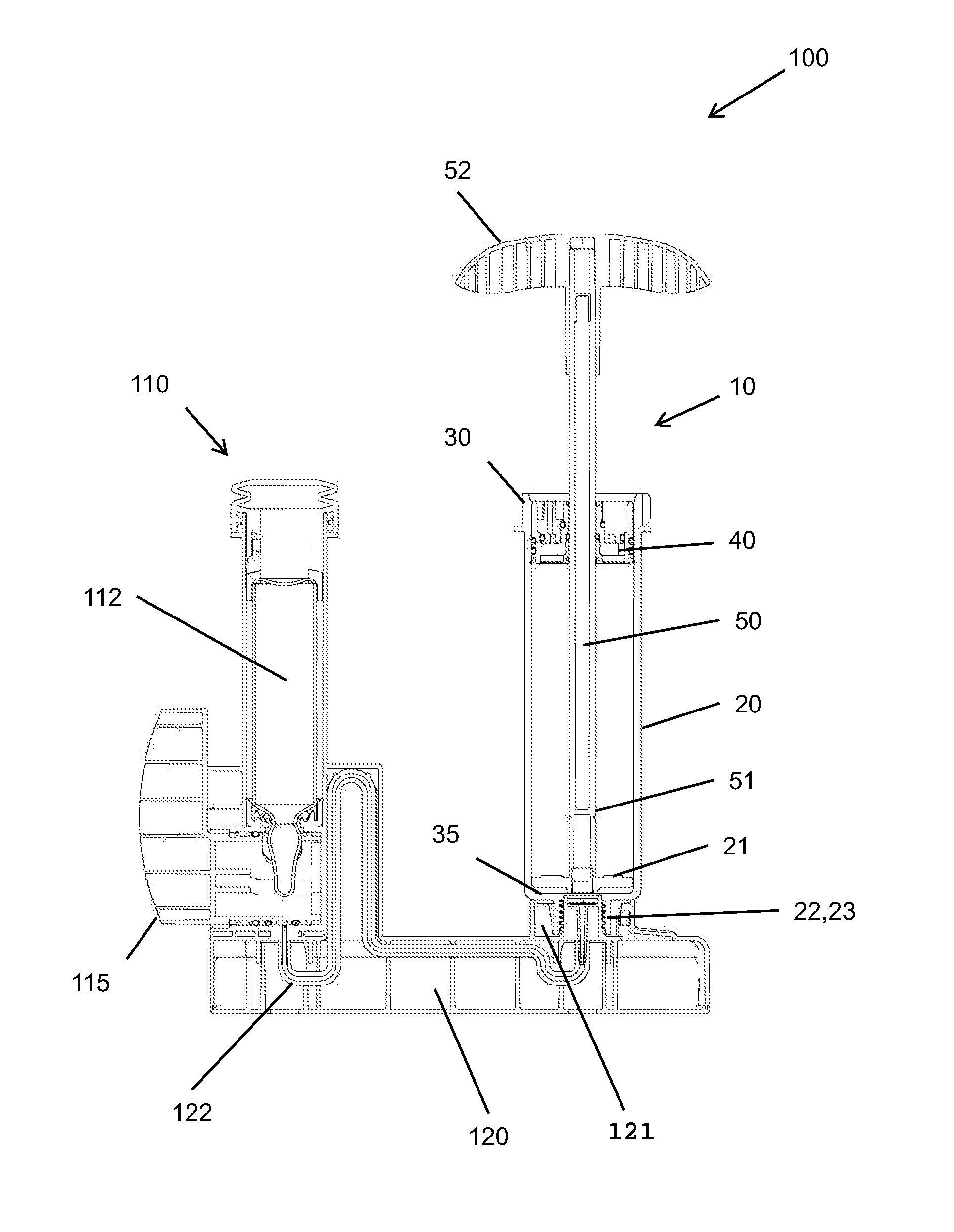

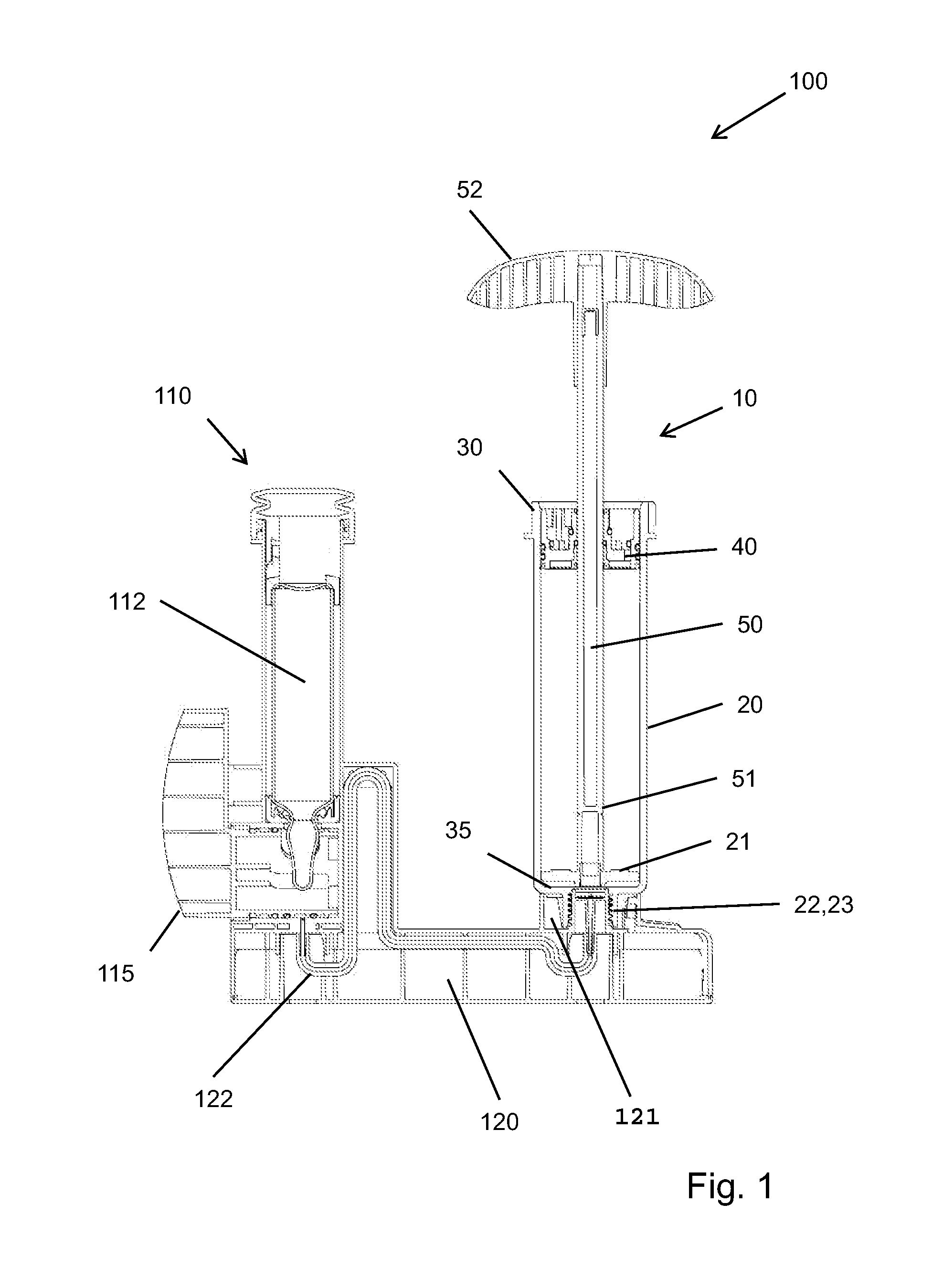

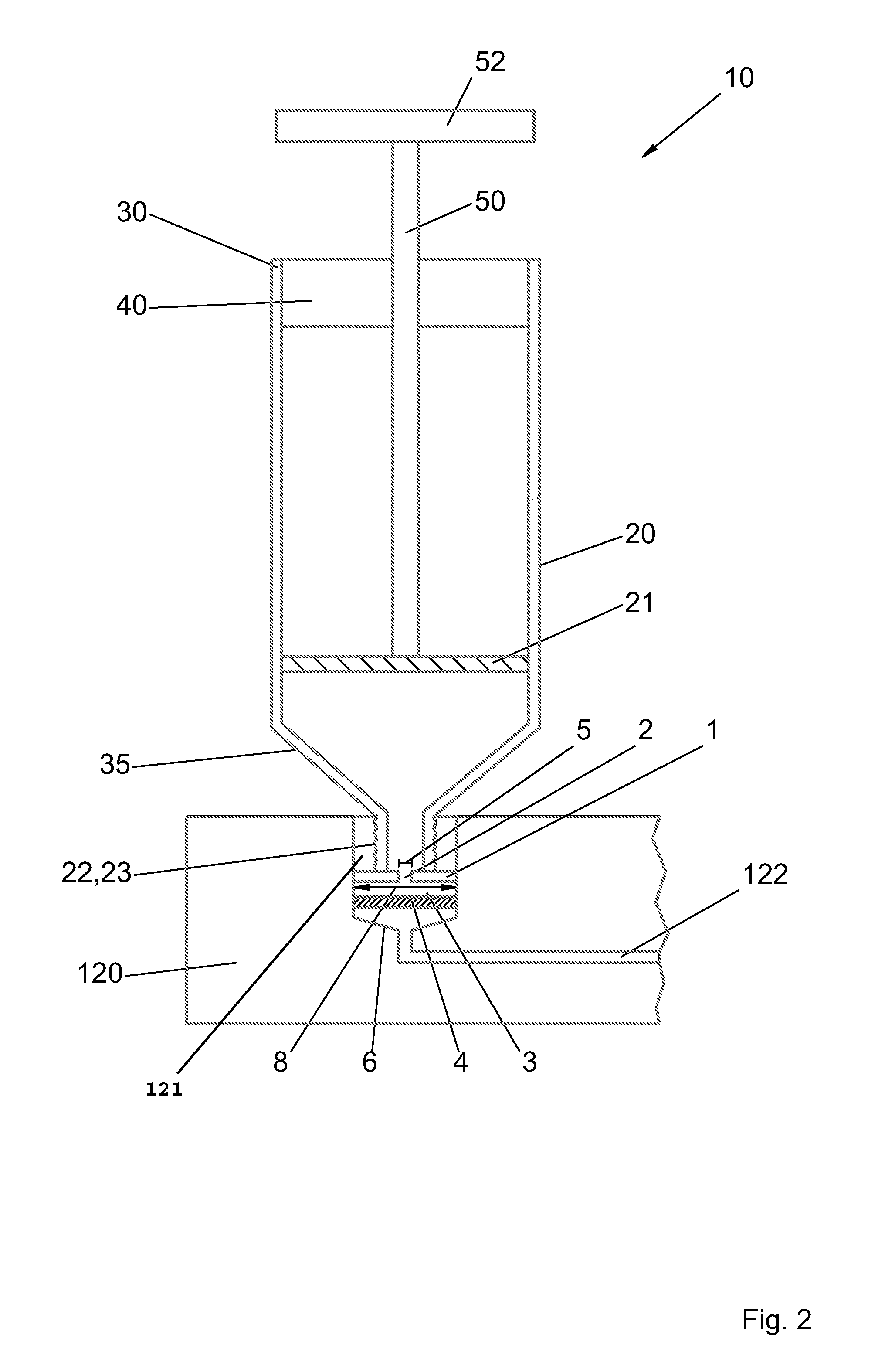

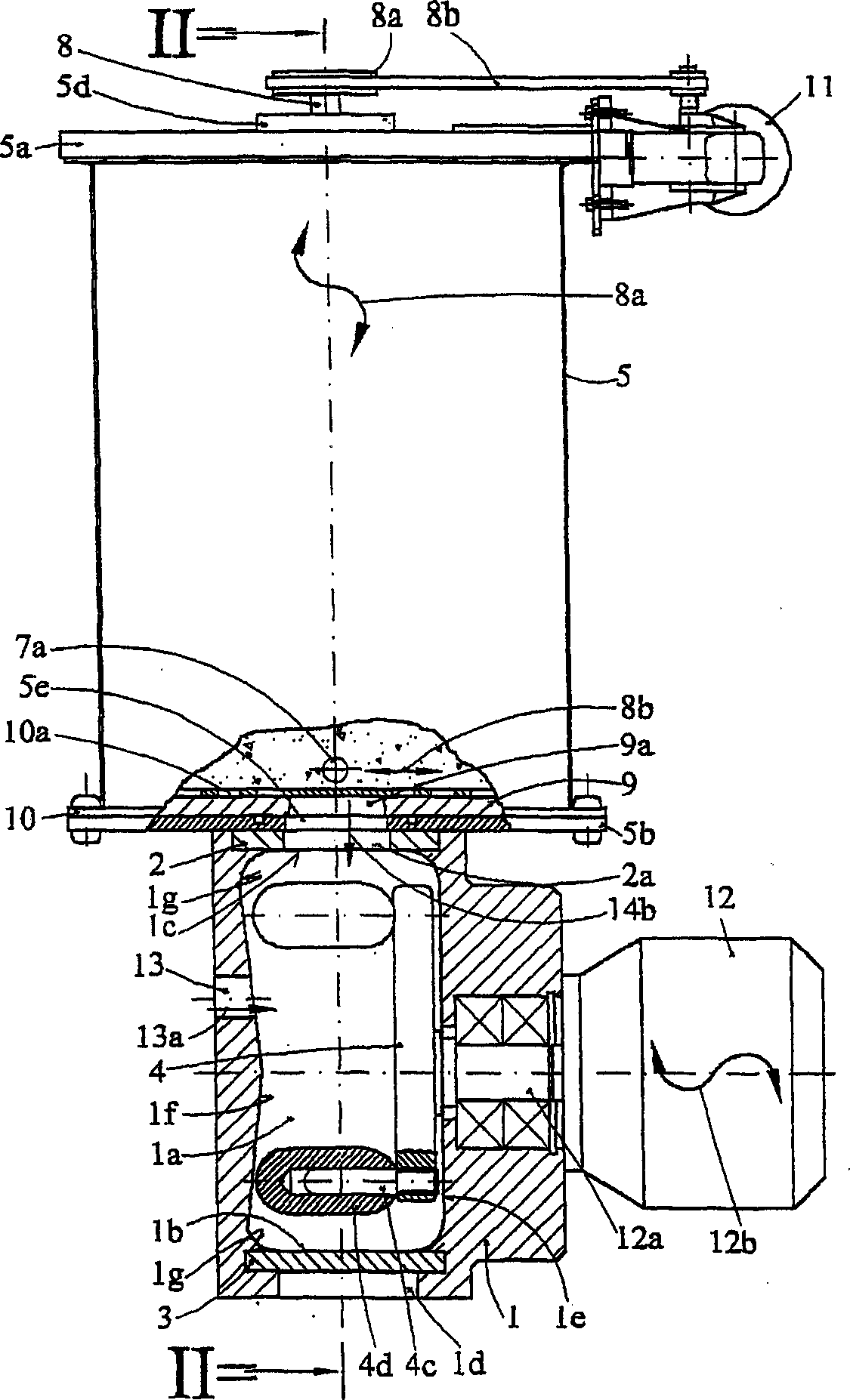

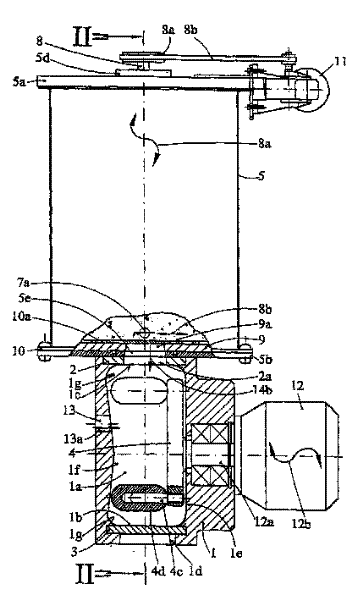

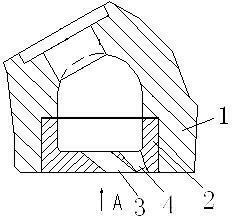

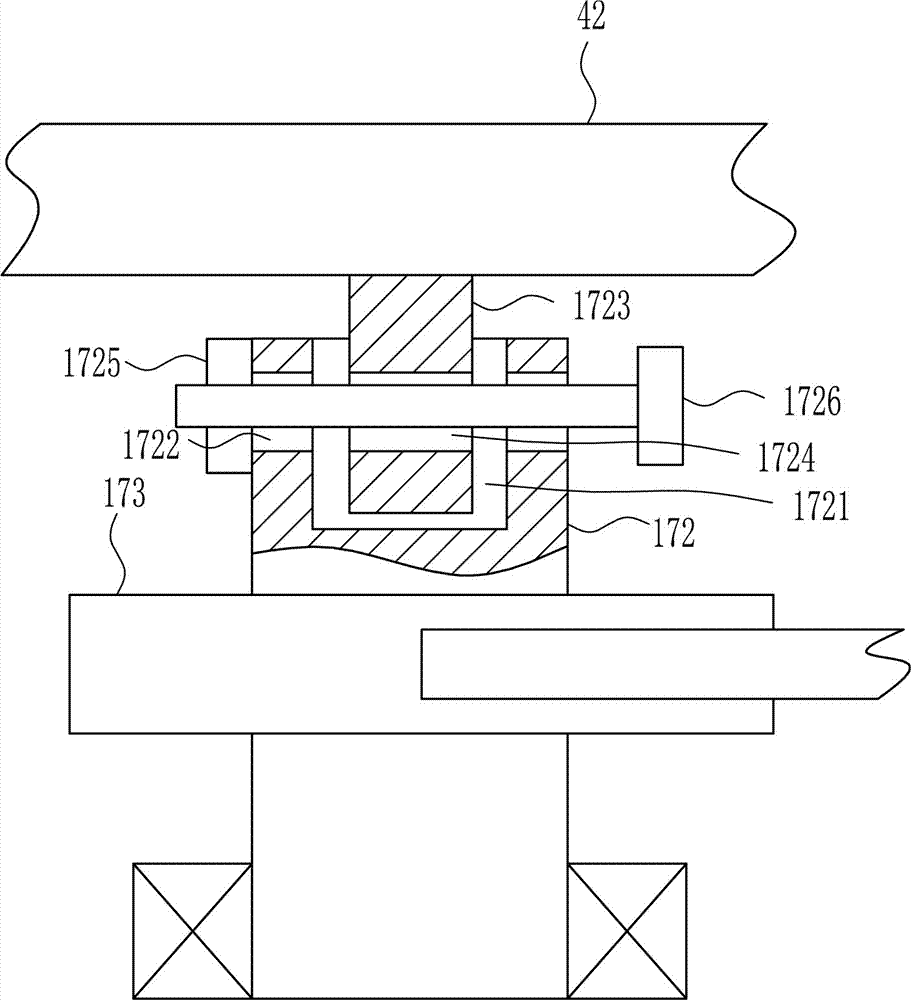

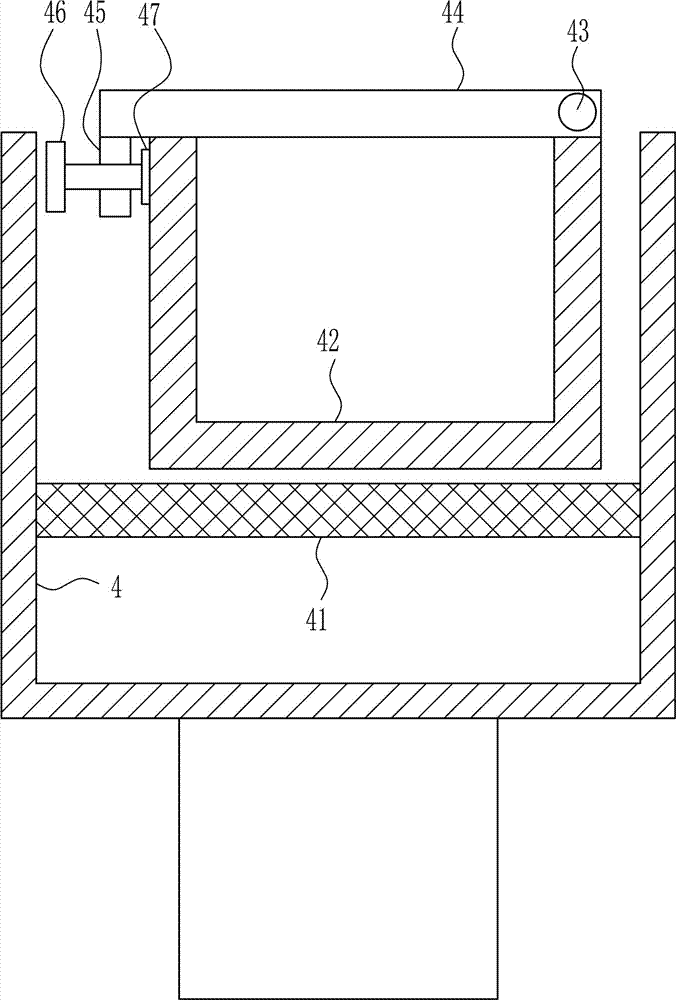

Bone cement system

ActiveUS8662736B2Avoid stickinessMore viscousFlow mixersTransportation and packagingBone cementBiomedical engineering

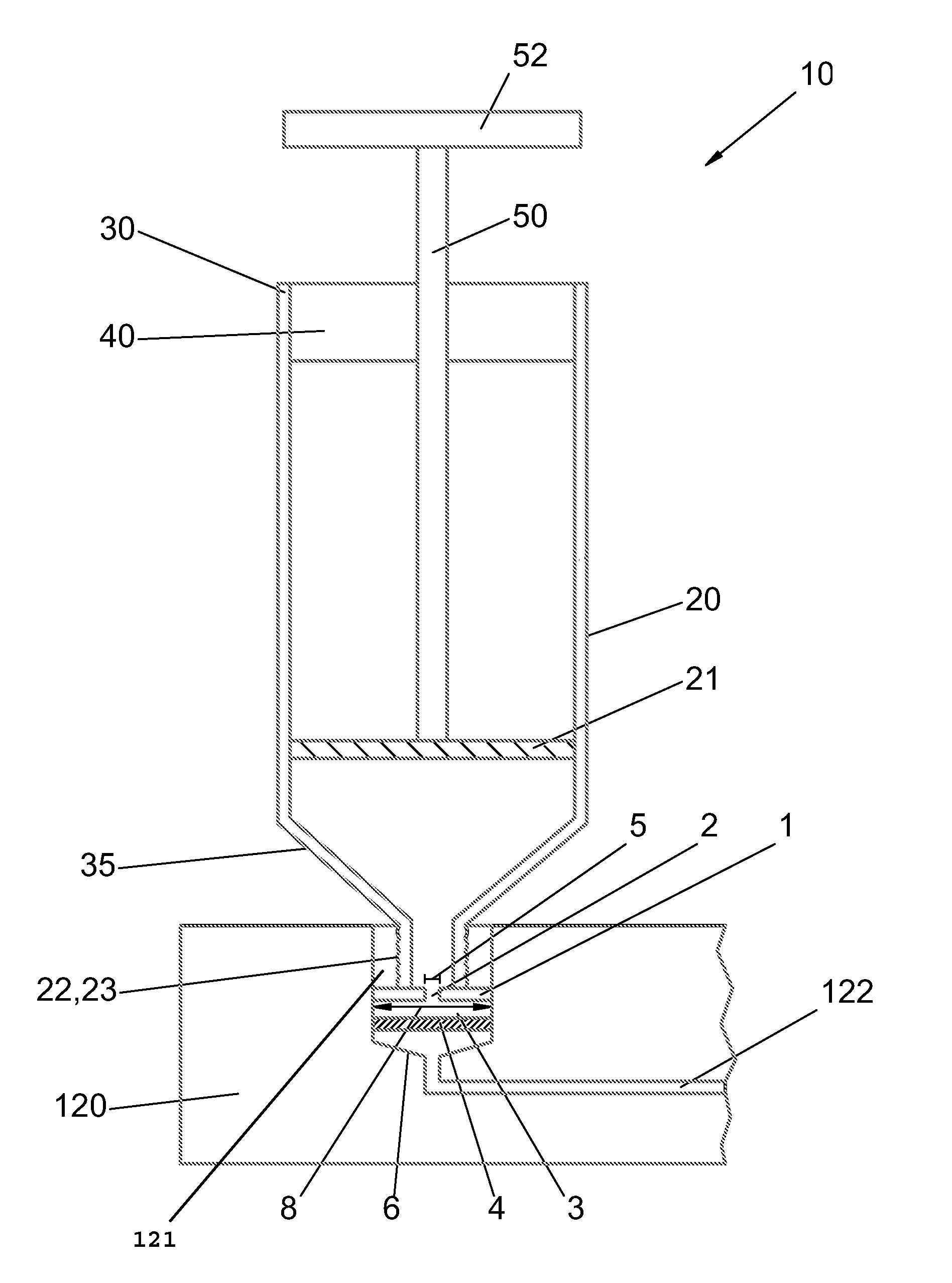

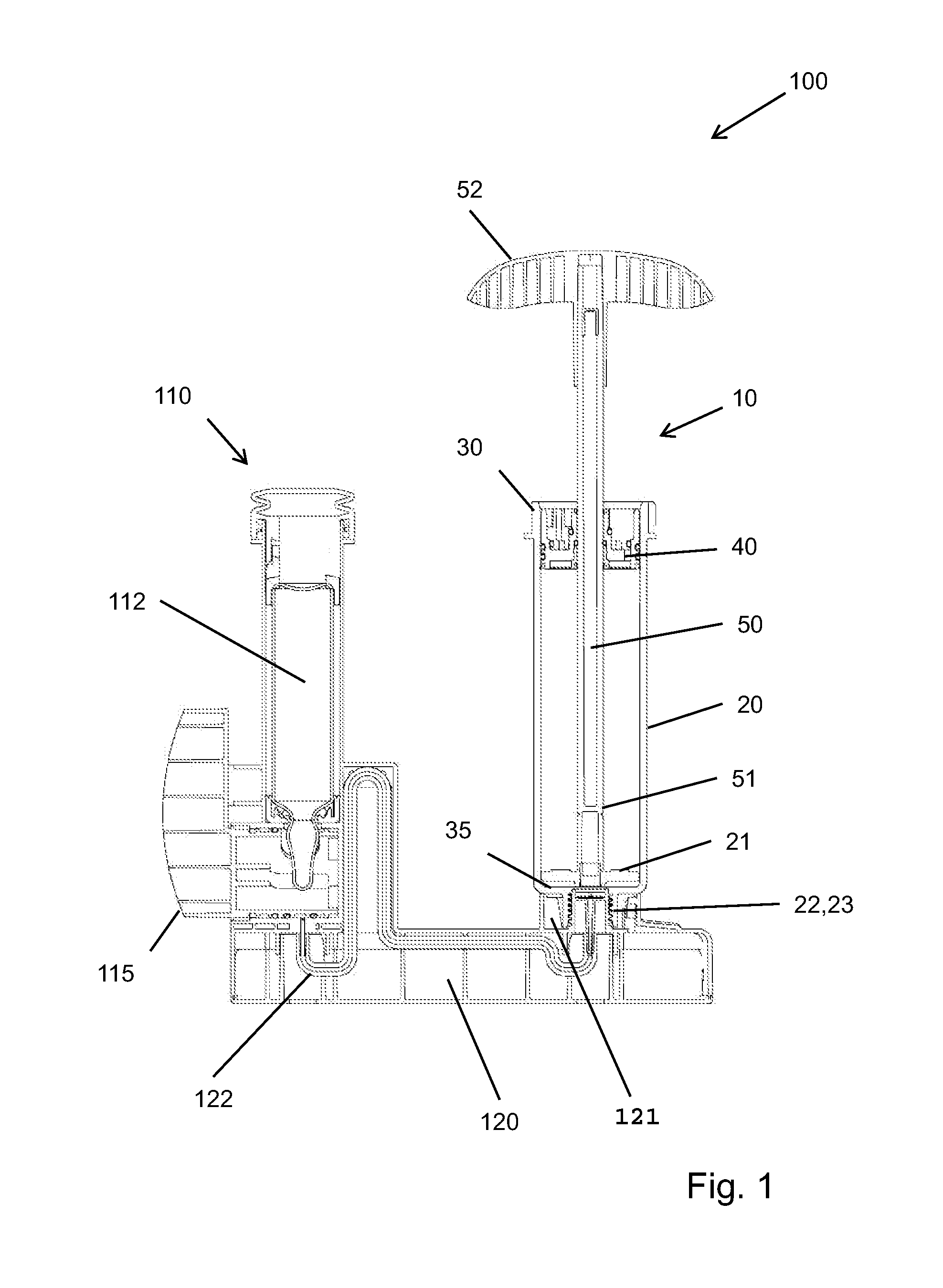

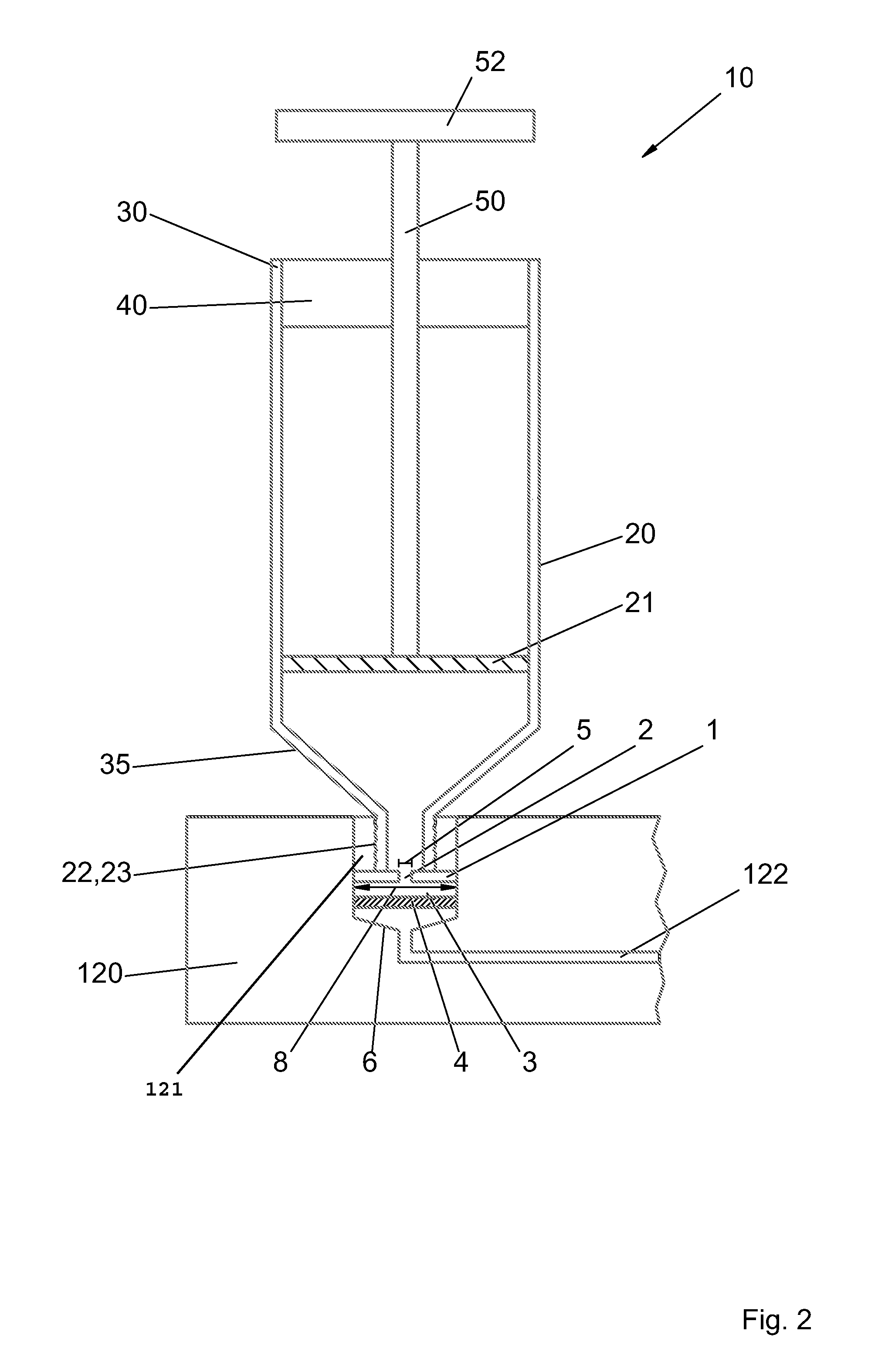

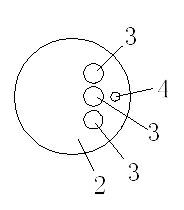

A bone cement system (100) is provided having a mixing facility (10) for mixing and dispensing of bone cement, a reservoir container (112) for a monomer, and a conveyor (122). The mixing facility (10) has a mixing cylinder (20), which stores a bone cement powder. The monomer can be conveyed from the reservoir container (112) into the mixing cylinder (20) by the conveyor (122). A sieve element is (4) is arranged between the reservoir container (112) and the mixing facility (10), in order to prevent ingress of the bone cement powder from the mixing cylinder (20) into the conveyor (122). The mixing device (10) included a dispensing opening (23) for dispensing a bone cement mixed from the bone cement powder and the monomer. The dispensing opening (23) includes a shield (1) having at least one through-opening (2). The ratio of the area of the through-opening (2) to the area of the sieve element (4) is at least 1 to 3, and the distance between the shield (1) and the sieve element (4) is at least 1 mm.

Owner:HERAEUS MEDICAL

SELECTIVE CATALYTIC REDUCTION OF NOx ENABLED BY SIDESTREAM UREA DECOMPOSITION

ActiveUS20060115402A1Well mixedAccurate temperatureCombination devicesNitrogen compoundsParticulatesSuperheater

A preferred apparatus arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140.degree. C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

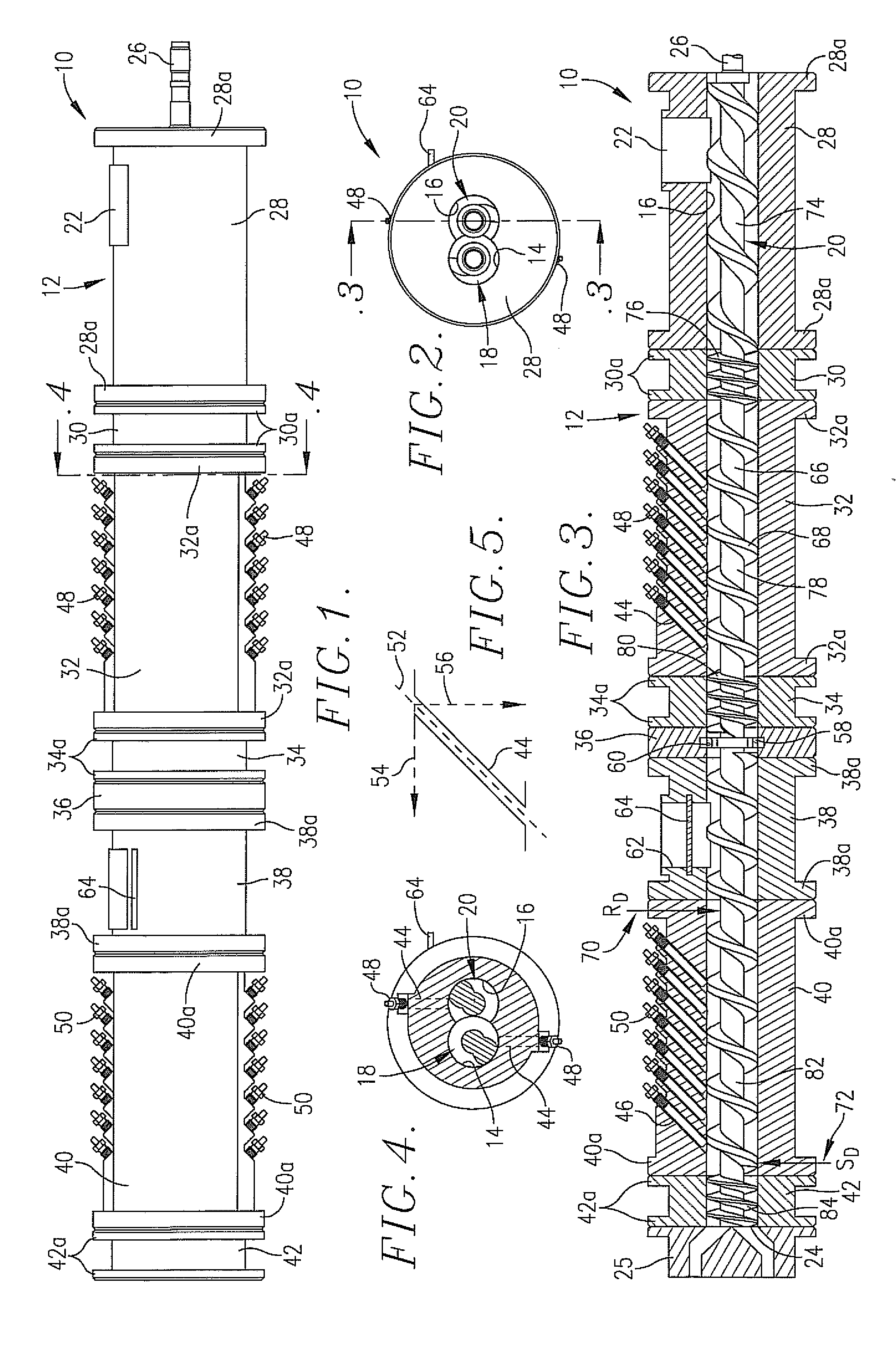

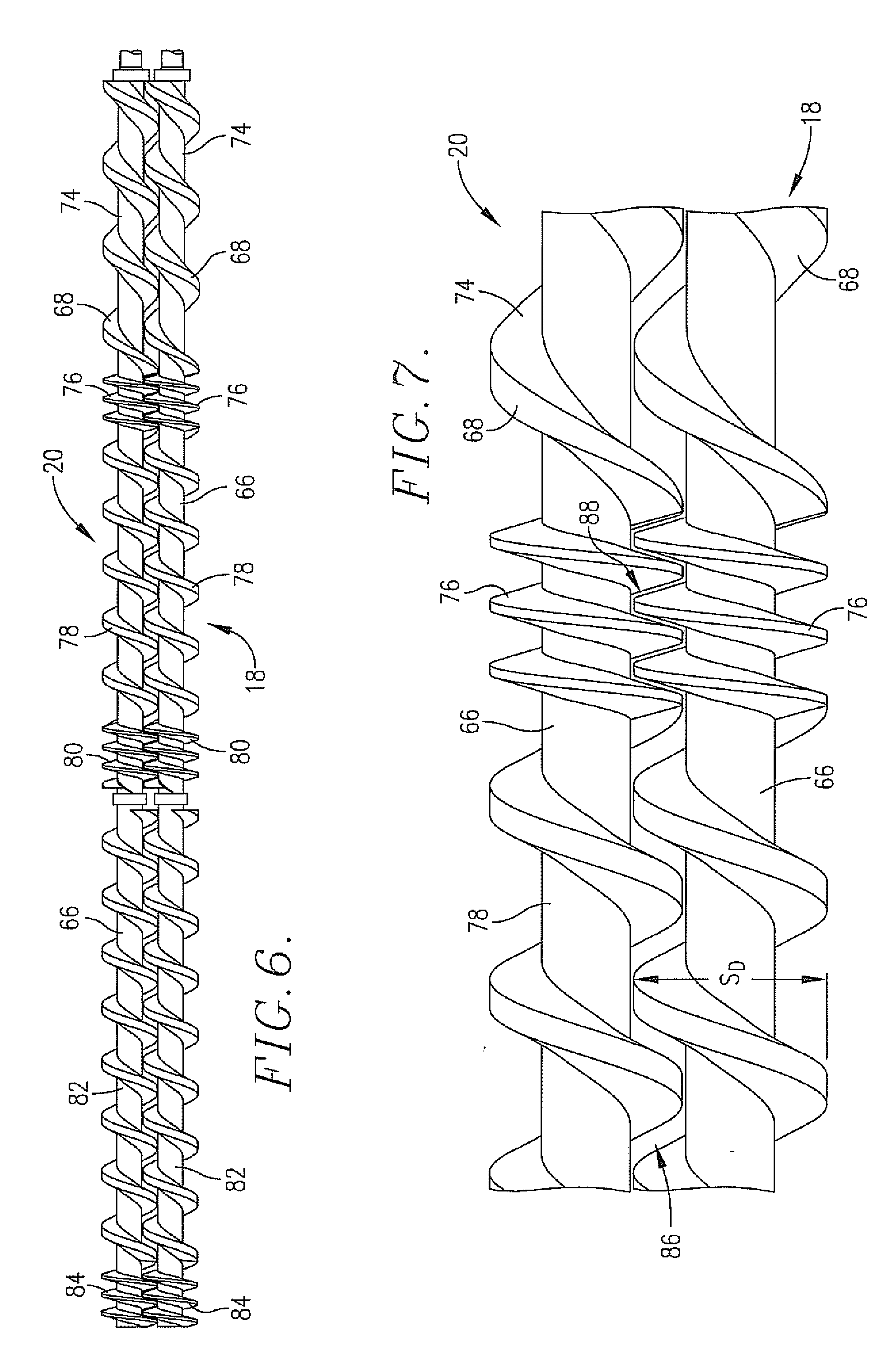

Method and apparatus for producing fully cooked extrudates with significantly reduced specific mechanical energy inputs

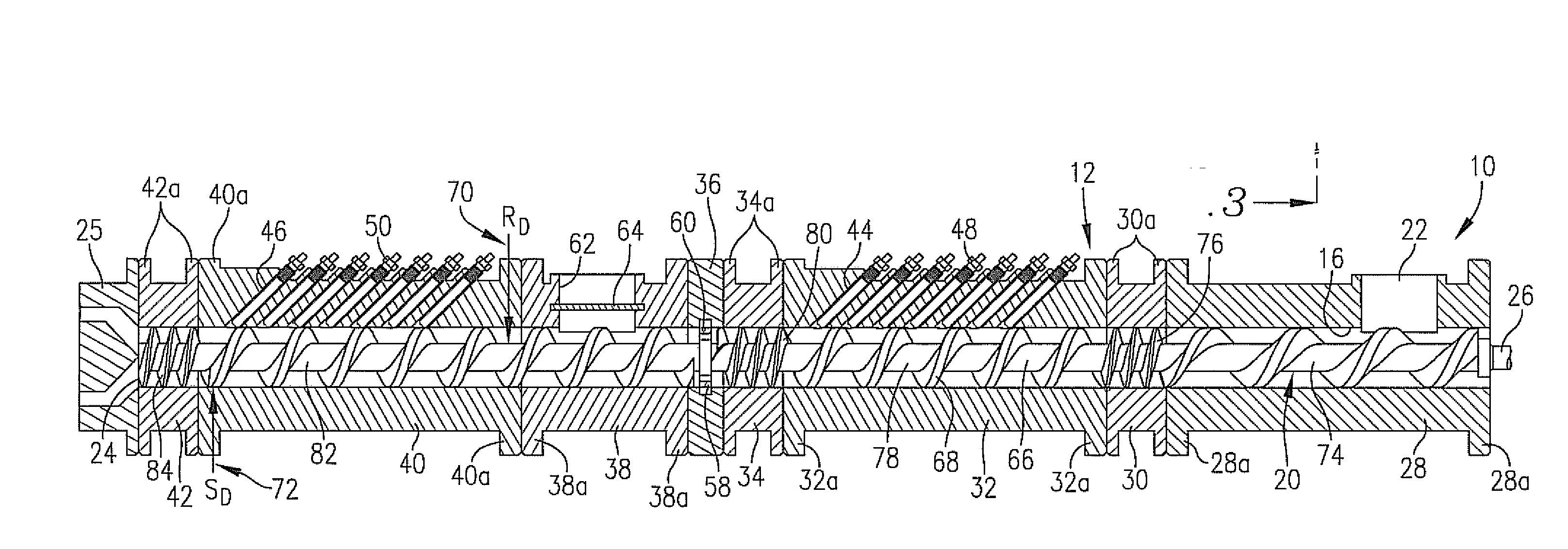

InactiveUS20100062093A1Avoid excessive wearLow costTailstocks/centresFeeding-stuffEngineeringPreconditioner

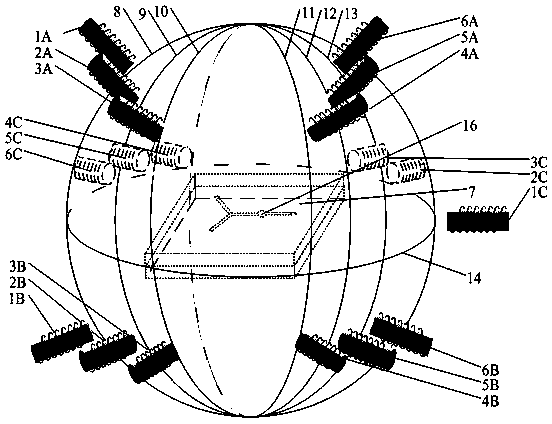

Improved extruders and methods for the extrusion cooking of comestible products such as human foods or animal feeds are provided wherein the products may be produced with very low specific mechanical energy (SME) inputs as compared with conventional processing. The methods preferably involve introduction of very high levels of steam into the extruder barrel (12) during processing, which concomitantly reduces necessary SME inputs required to achieve desired cook and expansion levels in the products. In accordance with the invention, fully-cooked pet foods can be fabricated with SME inputs of up to about 18 kWhr / T, whereas aquatic feeds can be fabricated with SME inputs of up to about 16 kWhr / T. In preferred forms, the extruder (10) includes specially configured, intermeshed extrusion screws (18, 20) and a plurality of obliquely oriented steam inlets (48, 50), and an upstream, dual-shaft preconditioner (90) is used having individual variable frequency drives (98, 100) which allow infinite variablility in the speed and rotational direction of the preconditioner shafts (94, 96).

Owner:WENGER MANUFACTURING INC

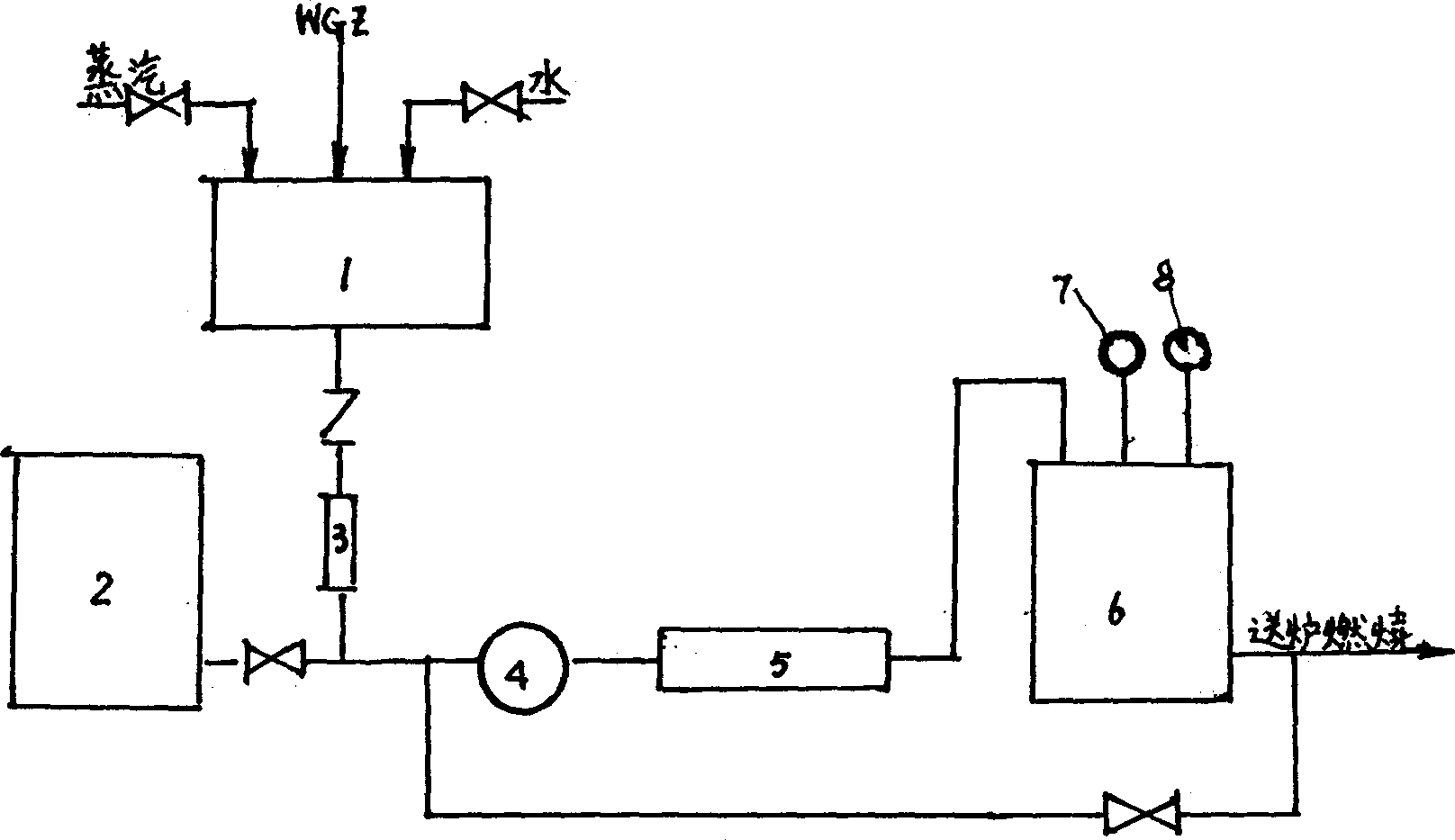

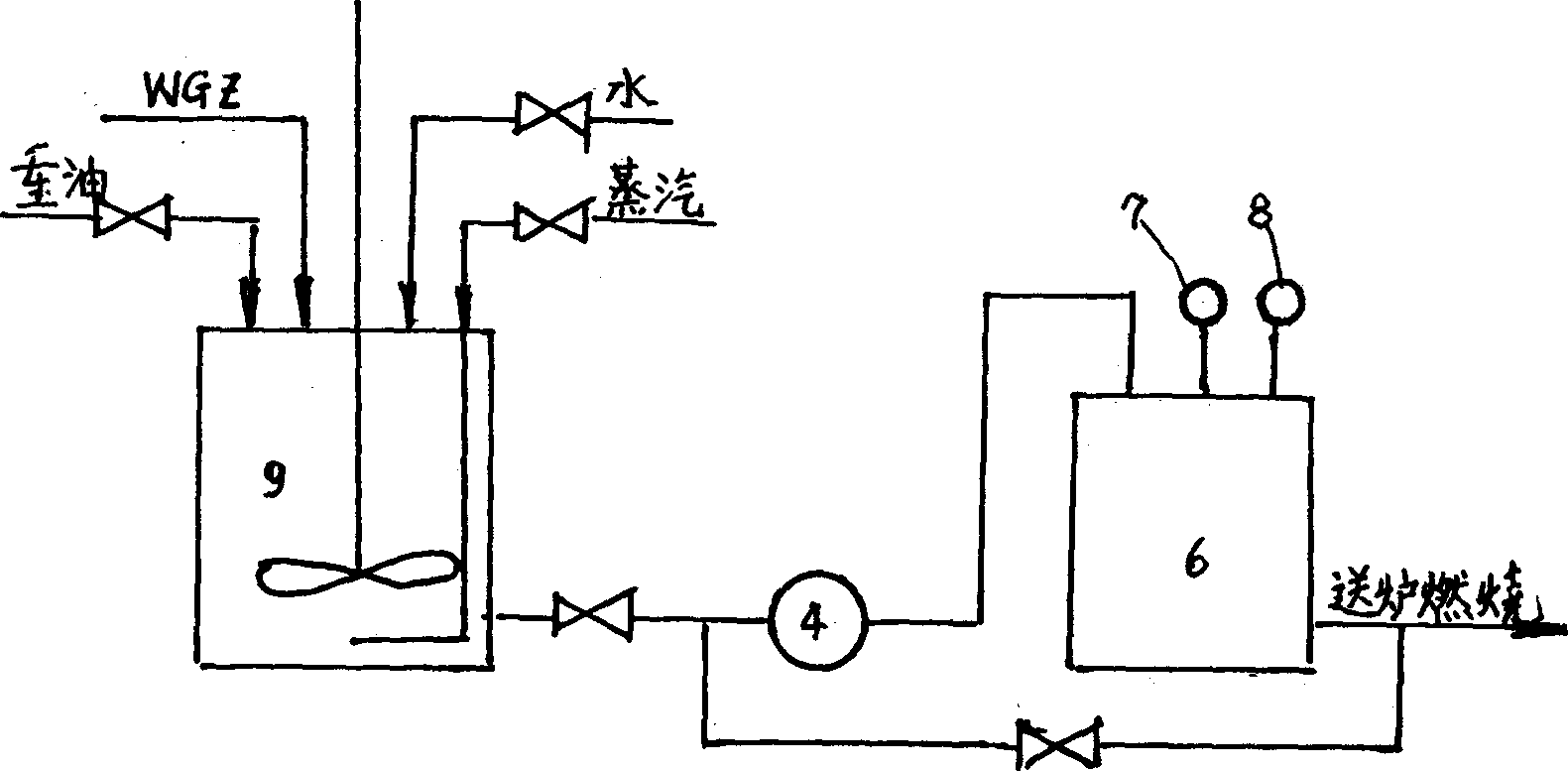

Multifunctional heavy oil and fuel oil additive, preparation and use thereof in preparing emulsified oil

InactiveCN1401745AWide emulsification rangeMix well and evenlyLiquid carbonaceous fuelsFuel oilDisperser

An oil-soluble multifunctional additive for heavy oil or fuel oil contains more surfactants, composite catalytic combustion adjuvant and detergent disperser, and is characterized by saving oil by 10-25%, increasing added water to 10-30% and eliminating black smoke. A process for preparing emulsified heavy oil or fuel oil is also disclosed.

Owner:WUHAN UNIV OF TECH

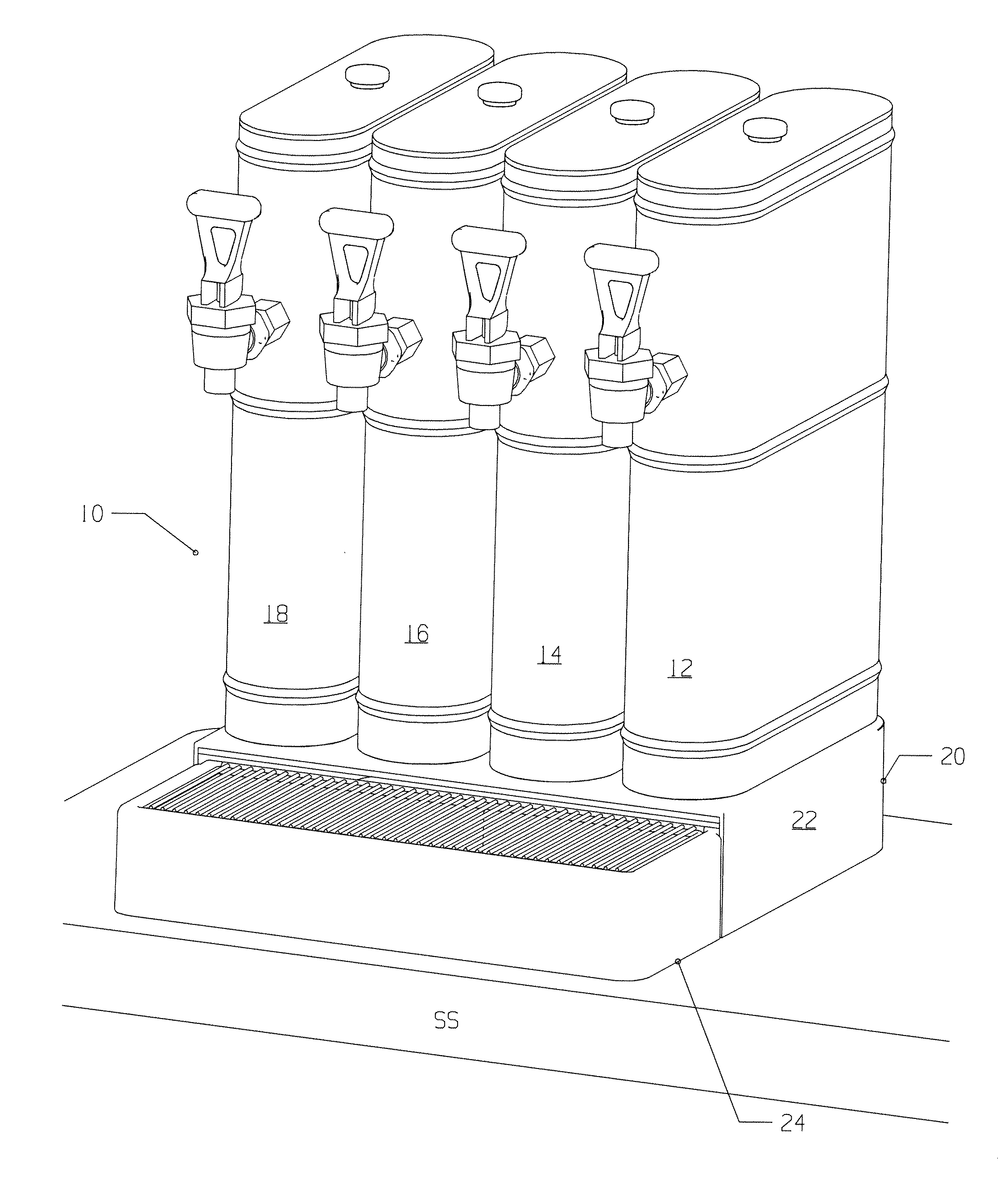

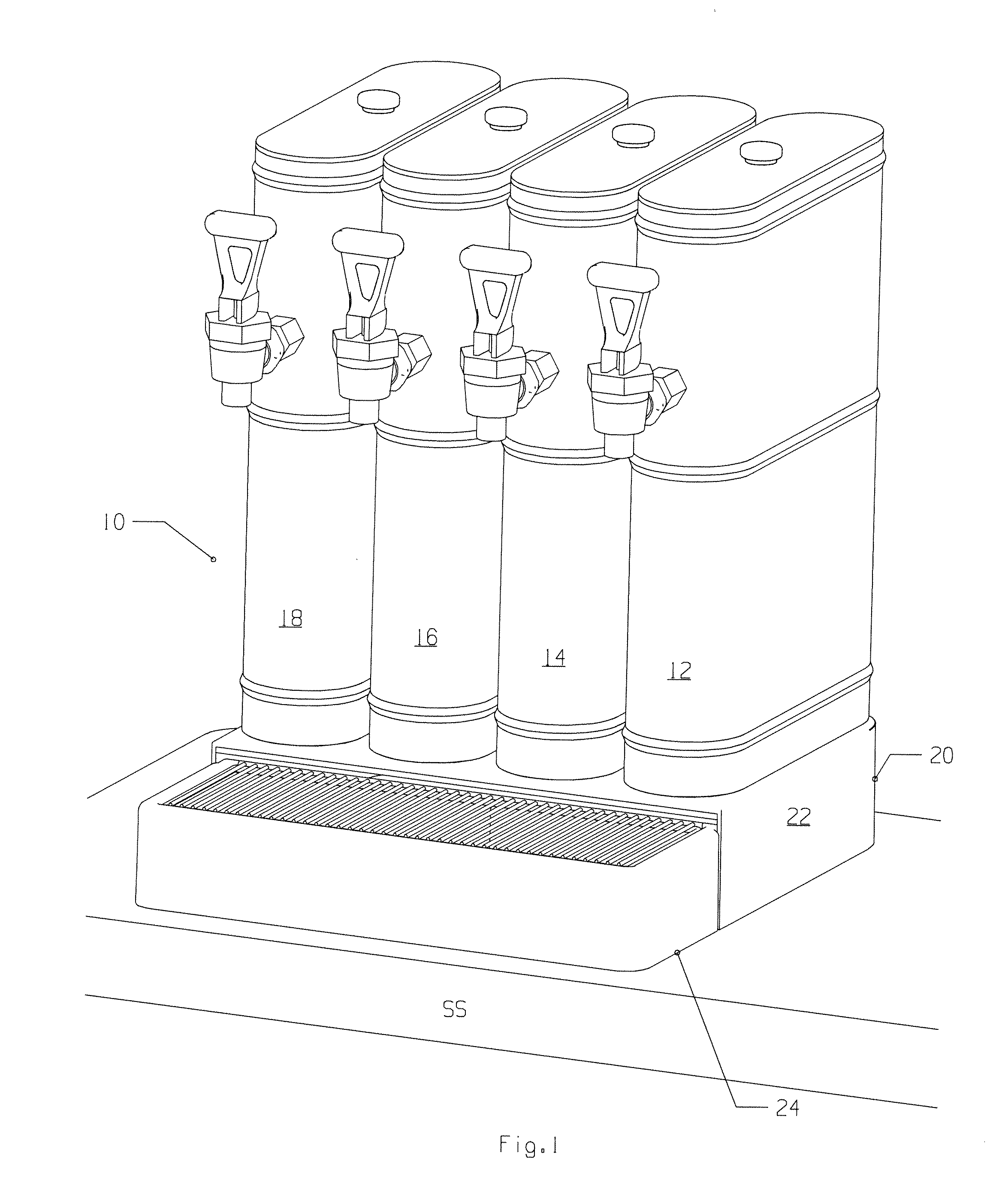

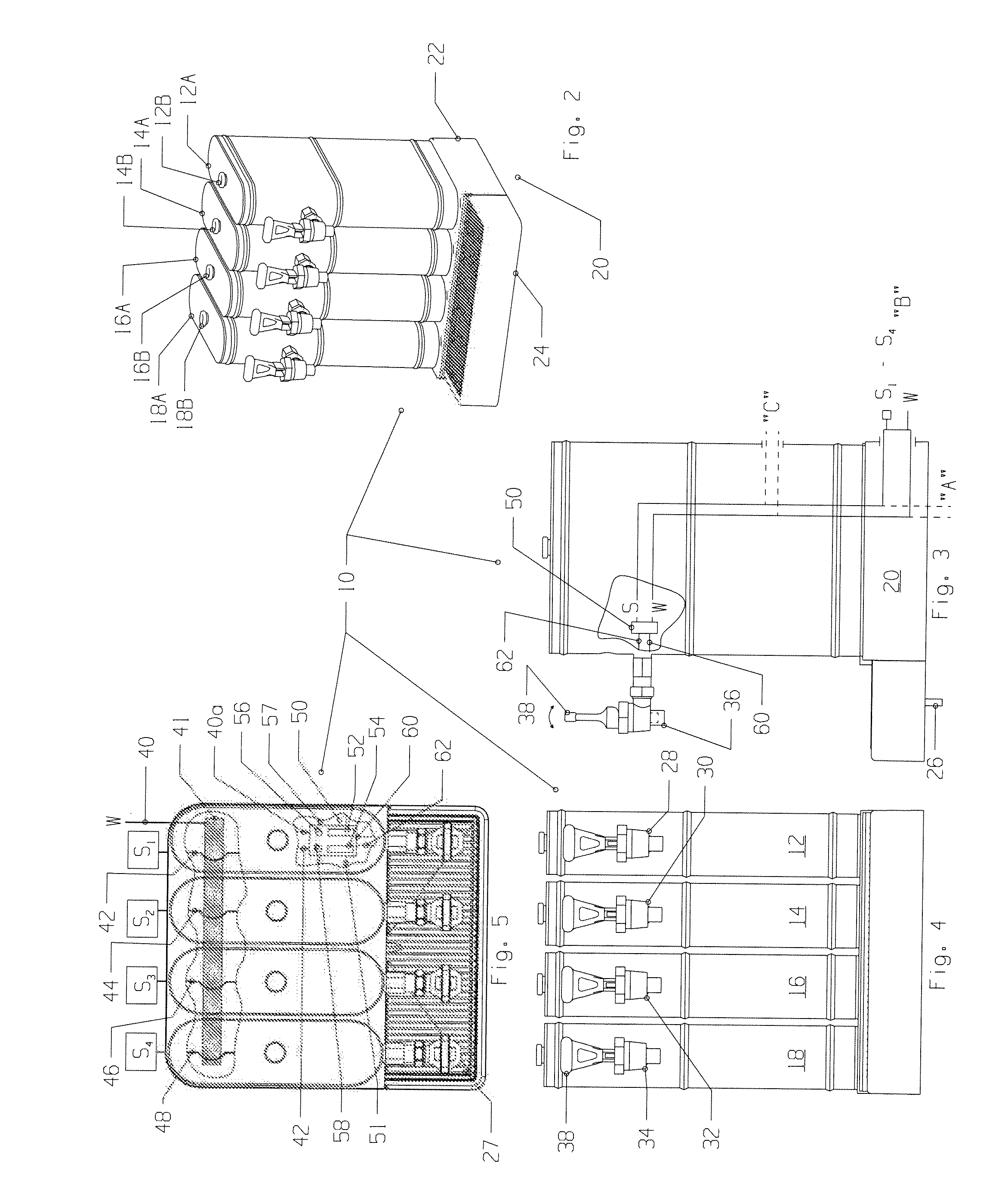

Post-mix dispenser assembly

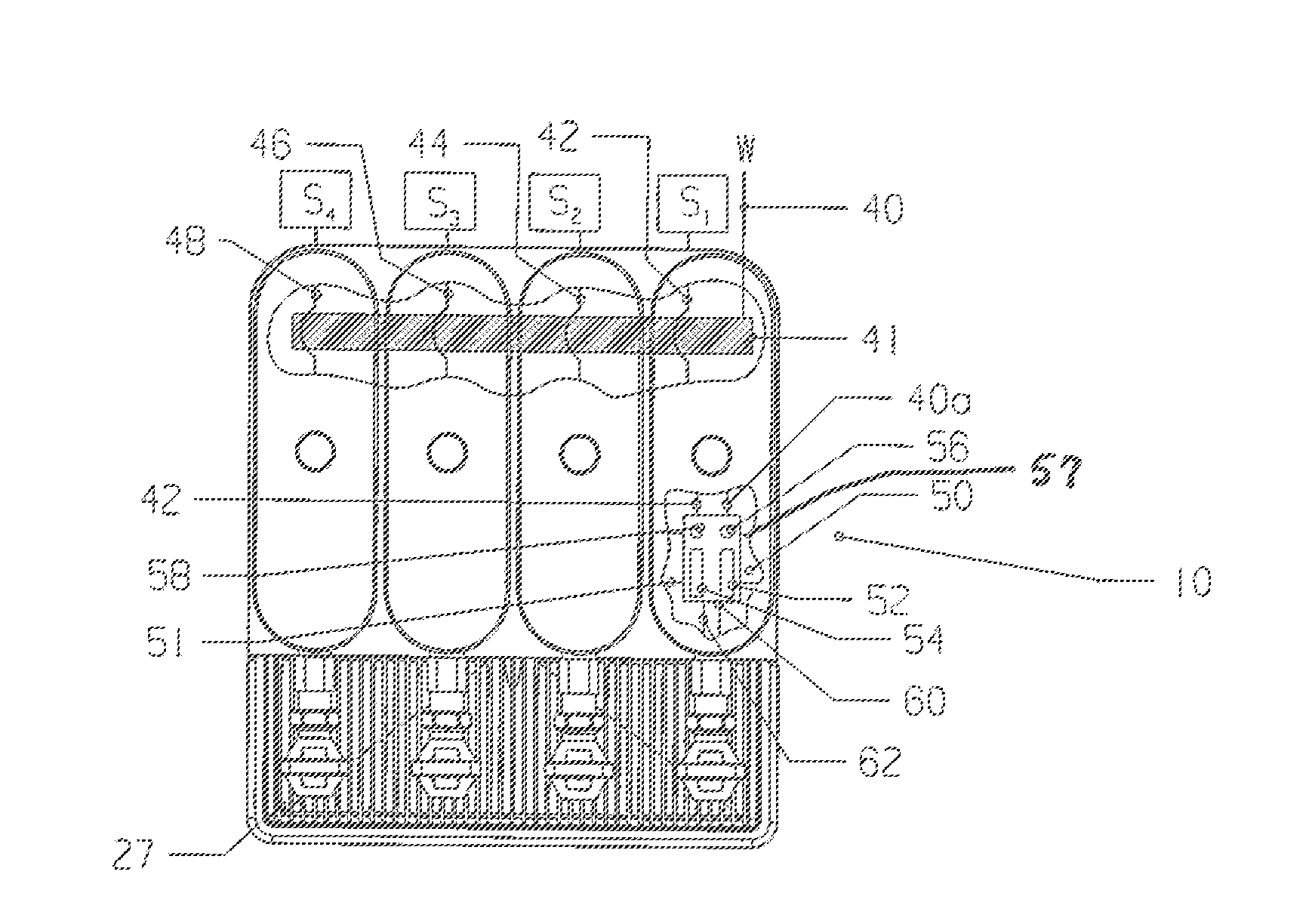

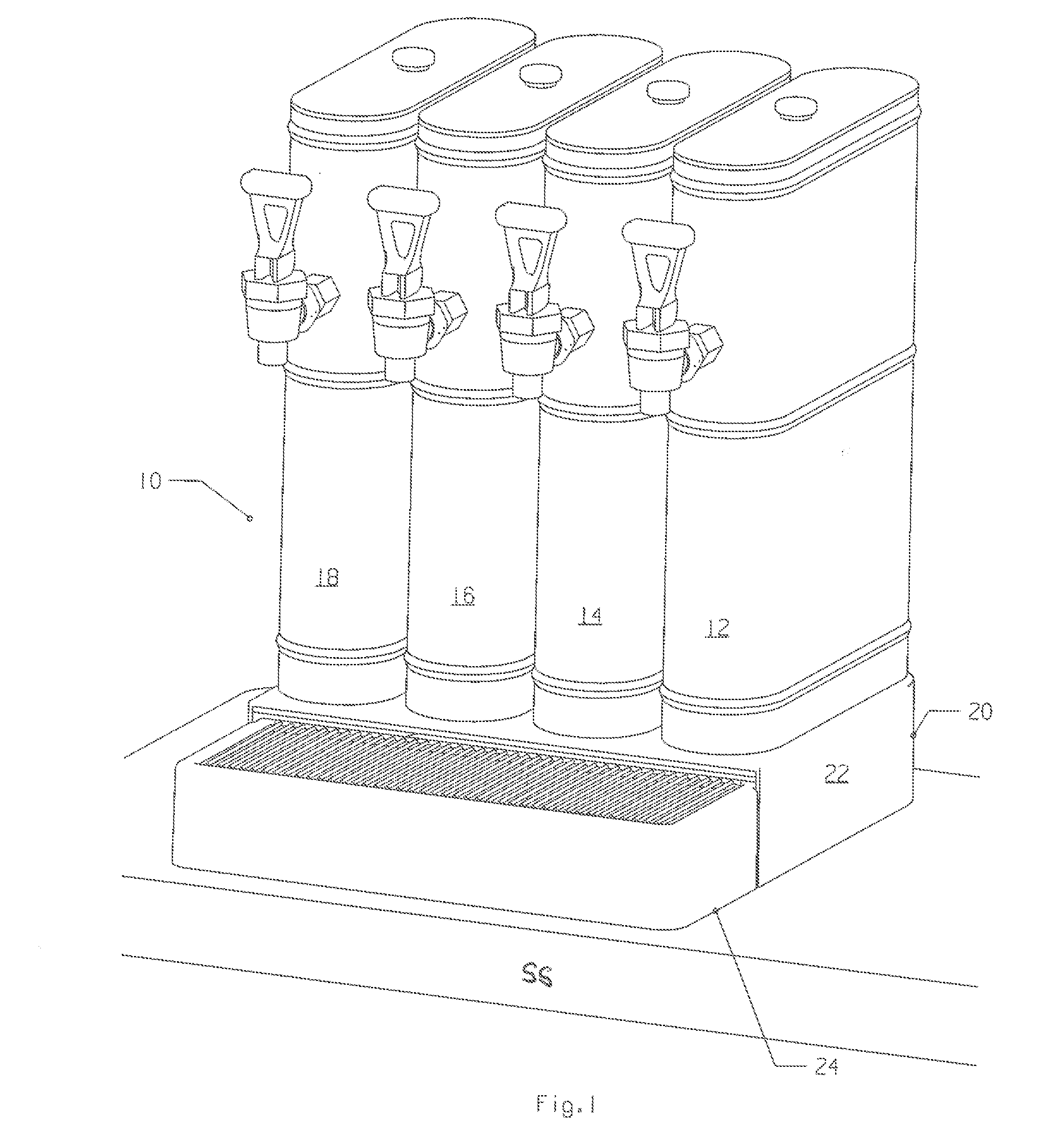

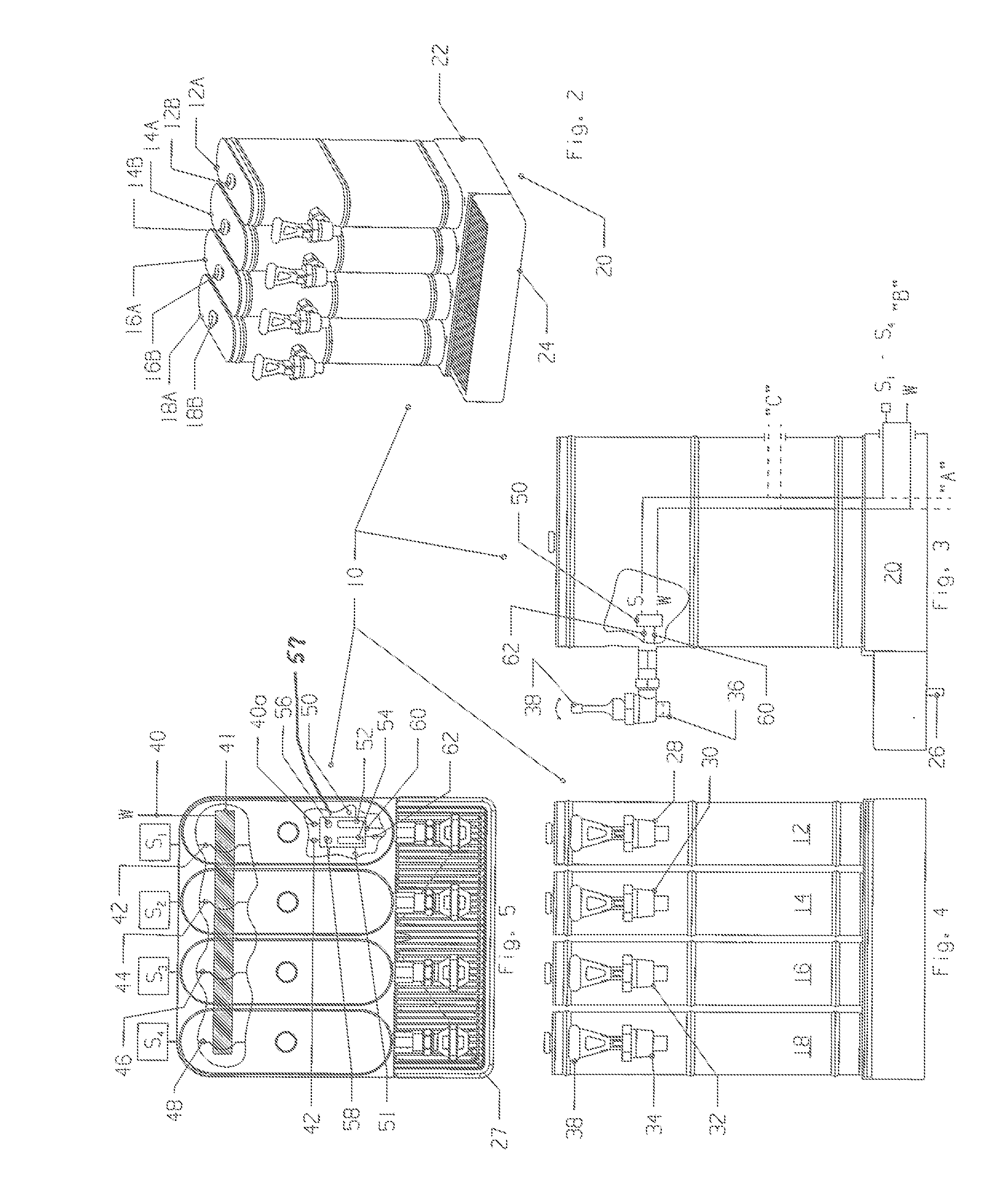

InactiveUS20100187258A1Firmly connectedEasy to emptyLiquid flow controllersLiquid transferring devicesLine tubingEngineering

A beverage dispensing assembly which has one or more urns to which a manual, post-mix valve is engaged, on front walls thereof. The urn or urns do not contain fluid, rather, at least, a pair of fluid lines carrying pressurized fluid to the post-mix valve, which may be a “T” valve. The two fluid lines carry fluid from a first and a second fluid source, typically pressurized, which sources are remote from the urn or urns. If the assembly is comprised of more than one urn, it may include a base, designed to hold the urns in side-by-side alignment.

Owner:SCHROEDER INDS L L C

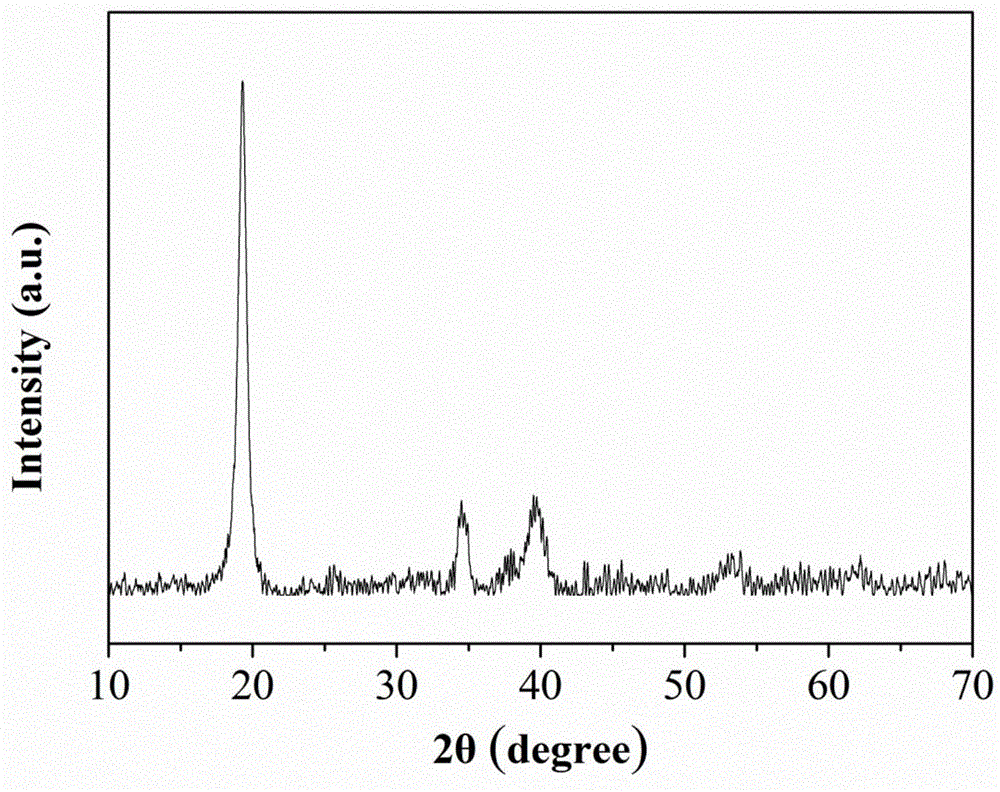

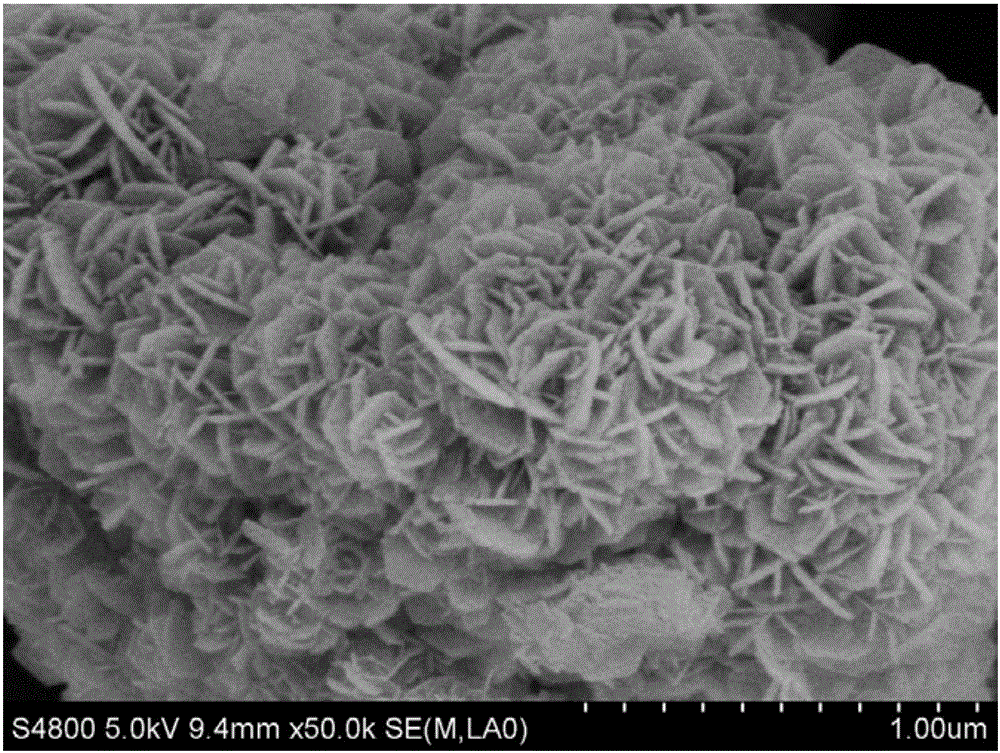

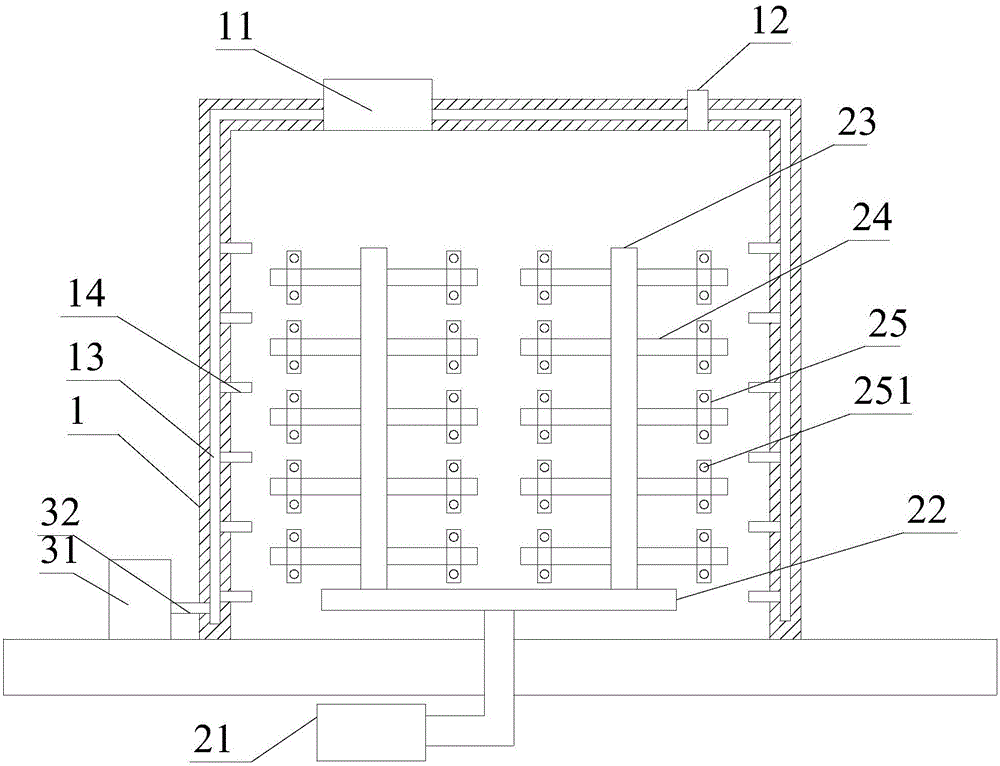

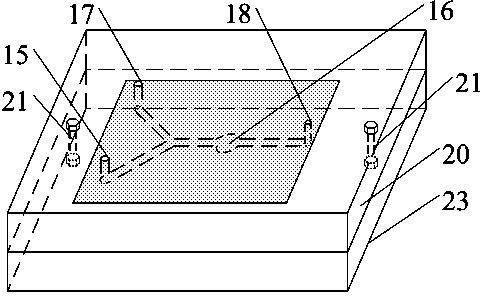

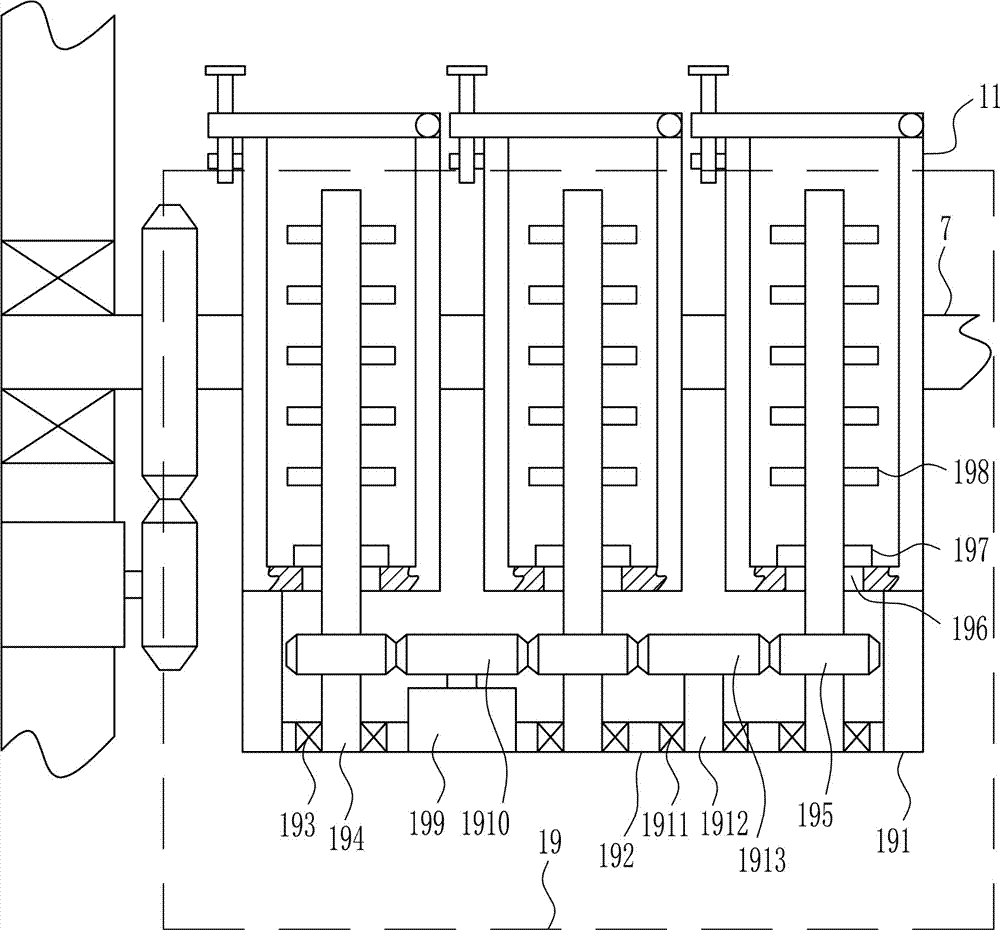

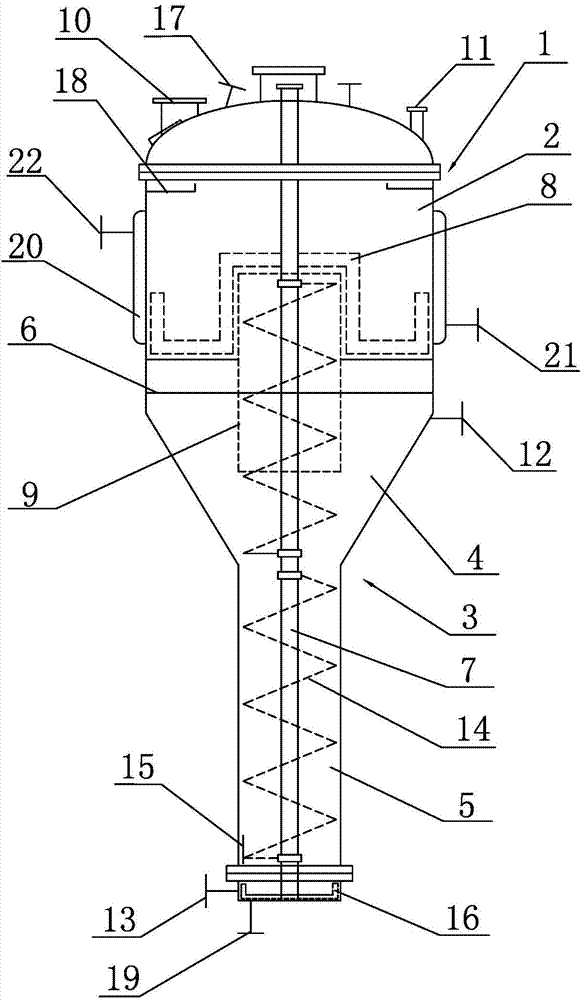

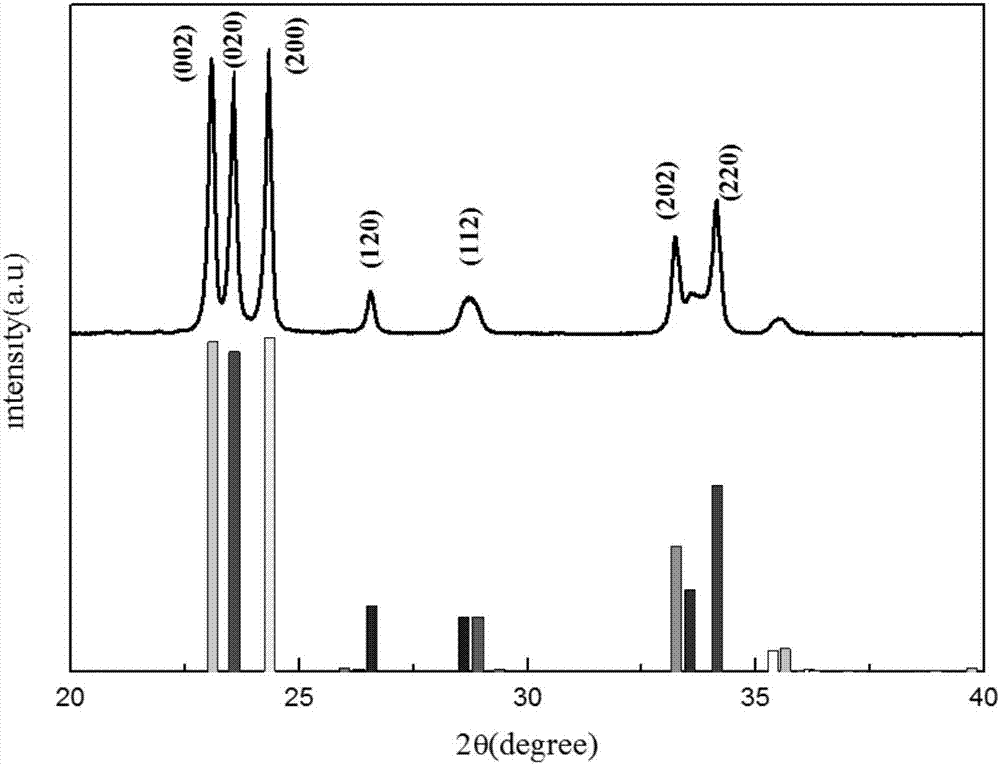

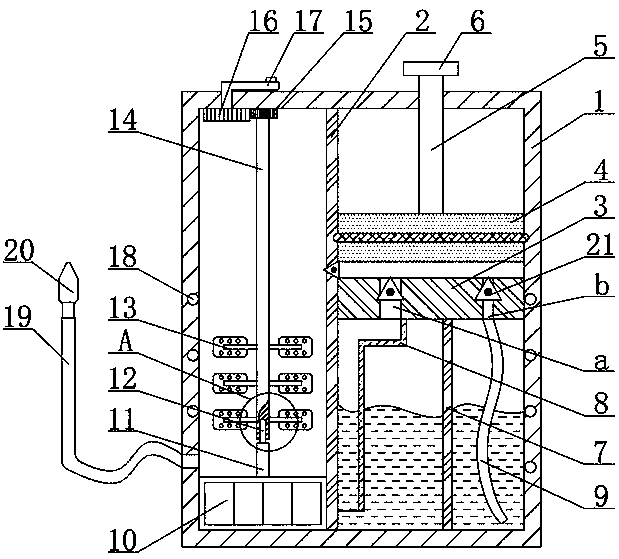

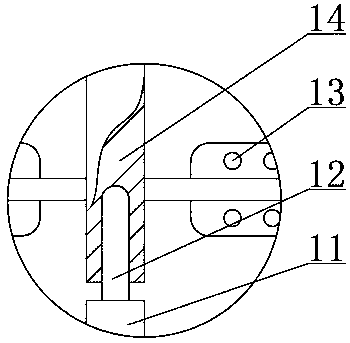

Method for continuously preparing nanoflower lithium ion battery layered anode material and reaction kettle thereof

InactiveCN106058237AWell mixedImprove the flow fieldMaterial nanotechnologyCell electrodesPrecipitationReagent

The invention provides a method for continuously preparing a nanoflower lithium ion battery layered anode material and a reaction kettle realizing the method. The method includes: (1), preparing a: preparing raw materials according to a chemical formula LiNixCoyMn1-x-yO2; (2), co-precipitating: using a co-precipitation method to obtain a reaction product, and subjecting the reaction product to aging, filtering, washing and drying to obtain precursor particles of a nanoflower structure; (3), calcining:calcining the precursor particles at high temperature to obtain the nanoflower lithium ion battery layered anode material. A template agent does not need to be added in the preparation process, and the particles are controllable in size, uniform in distribution and high in uniformity. Three layers of stirring paddles are arranged in the reaction kettle and stir at the same time, so that the materials are quick and uniform in reaction, and the particles are uniform and high in fluidity. By using the method, the lithium ion battery anode material in special nanoflower shape; the method is simple to operate, the reaction kettle is stable and reliable in structure, and industrial production is facilitated.

Owner:成都翔羽科技有限公司

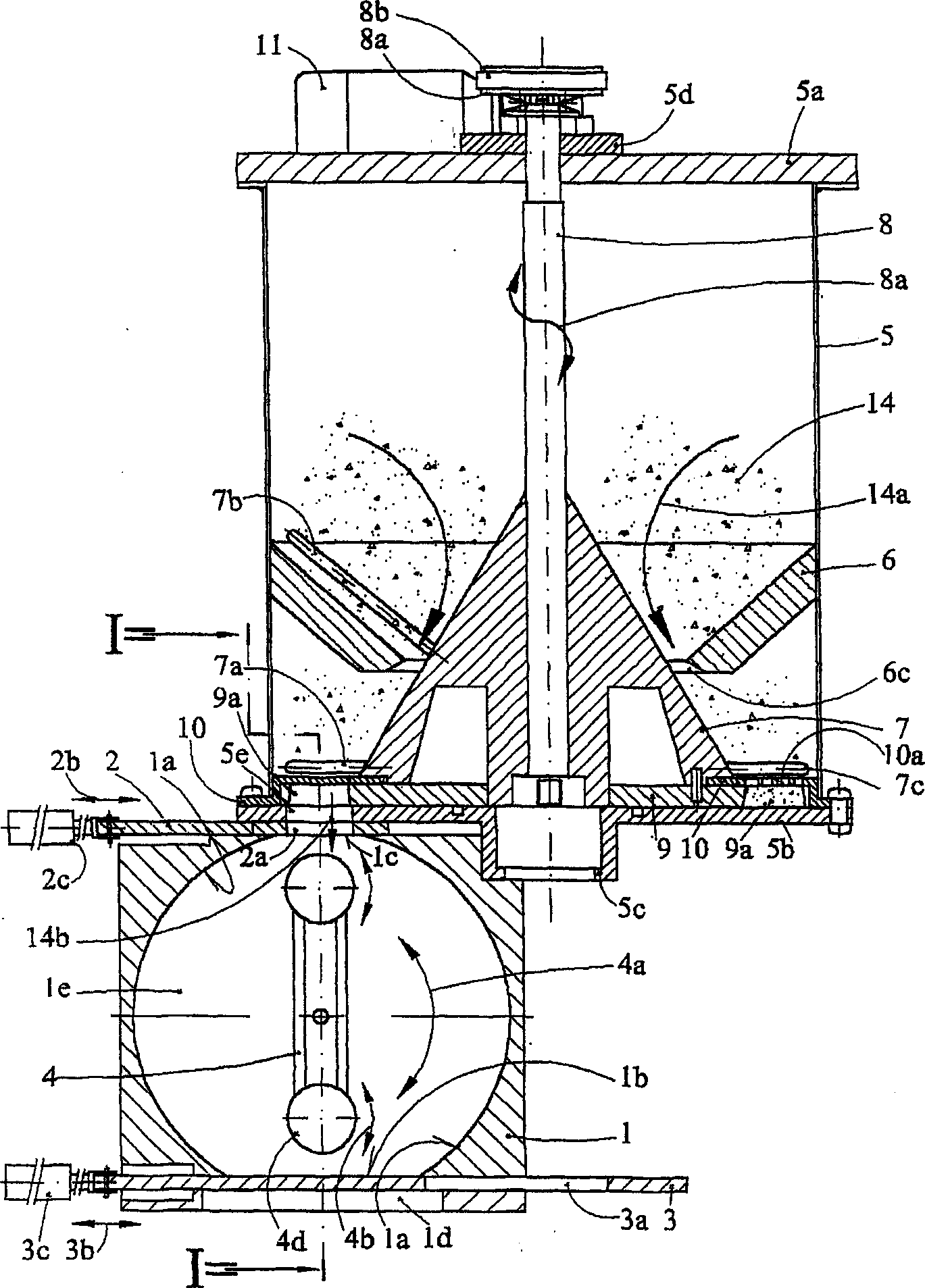

Kneading machine with dosing device

InactiveCN1372489AAbsorb evenlyMix completelyMixing/kneading structural elementsRotary stirring mixersRotational axisVertical plane

A dough or pastry mixer assembly has a main mixing chamber (5) discharging into a high speed single portion lower kneading chamber (1). In one horizontal plane the kneading chamber has essentially ring-shaped sidewalls with mixer paddles rotating through the vertical plane. At right angles to the first horizontal plane, the chamber has two circular facing sidewalls, one slightly conical and the other flat. The top and bottom of the kneading chamber are slightly flattened. The top has an inlet aperture which is kept free of food particles by a slide closure. The chamber bottom has a slide closure for discharge of the kneaded mixture. The slightly conical chamber sidewall terminates in a rounded tip parallel to the axis of mixer paddle rotation.

Owner:ARTOS SA

Stirring device for producing herbicide

InactiveCN105964172AStir wellStir completelyRotary stirring mixersTransportation and packagingSpray nozzleProcess engineering

The invention provides a stirring device for producing a herbicide. The stirring device comprises a stirring barrel, a stirring unit and a gas guiding unit, wherein a feed opening and a gas outlet are formed in the stirring barrel; a passage is formed inside the stirring barrel; the inner side walls of the feed opening and the gas outlet can isolate the feed opening and the gas outlet from the passage in a sealed way respectively; gas spraying nozzles are distributed on the inner side wall of the stirring barrel; inlets of the gas spraying nozzles are communicated with the passage; the stirring unit comprises a driving mechanism, a turnplate and a plurality of stirring frames; the turnplate is in transmission connection with the driving mechanism; the plurality of stirring frames are arranged on the turnplate; a plurality of stirring rods are distributed on each stirring frame; an angle beta is formed between each stirring rod and the corresponding stirring frame; a stirring plate is arranged at the end, away from the corresponding stirring frame, of each stirring rod; an angle theta is formed between each stirring plate and the corresponding stirring rod; and the gas guiding unit is used for guiding gas into the passage. The stirring device is simple in structure, can stir raw materials completely and uniformly, and is good in stirring effect and high in production efficiency.

Owner:安徽省圣丹生物化工有限公司

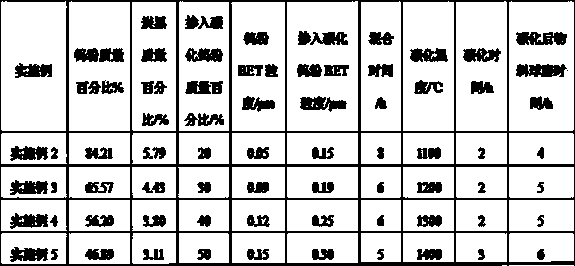

Preparation method of ultrafine tungsten carbide powder

ActiveCN103408015AImprove uniformityAvoid uneven mixingTungsten/molybdenum carbideTungstenCarbon black

The invention relates to a preparation method of ultrafine tungsten carbide powder. A mixture of ultrafine tungsten powder, carbon black and ultrafine tungsten carbide powder used as an initial reactant is subjected to carbonization reaction in a non-oxidizing atmosphere to prepare the ultrafine tungsten carbide powder. The ultrafine tungsten carbide powder prepared by the method has the advantages of small particle size, uniform particle size distribution, favorable dispersity, no pellet and high combined carbon content; and the production technique can easily control the quality and can implement mass production.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Post-mix dispenser assembly

InactiveUS20110107918A1Avoid flowMix completelyLiquid transferring devicesLiquid dispensingMechanical engineeringEngineering

A beverage dispensing assembly which has one or more urns to which a manual, post-mix valve is engaged, on front walls thereof. The urn or urns do not contain fluid, rather, at least, a pair of fluid lines carrying pressurized fluid to the post-mix valve, which may be a “T” valve. The two fluid lines carry fluid from a first and a second fluid source, typically pressurized, which sources are remote from the urn or urns. The urns have walls defining an interior volume. The interior volume is adapted to receive lines carrying a pressurized concentrate and a pressurized base fluid, such as water. The lines are adapted to be contained at least partly within the inner volume of the urn or urns of the urn assembly and engage a near end of the post-mix “T” valve where the post-mix “T” valve engages the front wall of the urn. If the assembly is comprised of more than one urn, it may include a base, designed to hold the urns in side-by-side alignment.

Owner:SCHROEDER INDS L L C

Bone cement system

ActiveUS20120026825A1Avoid stickinessMore viscousFlow mixersTransportation and packagingBone cementBiomedical engineering

A bone cement system (100) is provided having a mixing facility (10) for mixing and dispensing of bone cement, a reservoir container (112) for a monomer, and a conveyor (122). The mixing facility (10) has a mixing cylinder (20), which stores a bone cement powder. The monomer can be conveyed from the reservoir container (112) into the mixing cylinder (20) by the conveyor (122). A sieve element is (4) is arranged between the reservoir container (112) and the mixing facility (10), in order to preventingress of the bone cement powder from the mixing cylinder (20) into the conveyor (122). The mixing device (10) included a dispensing opening (23) for dispensing a bone cement mixed from the bone cement powder and the monomer. The dispensing opening (23) includes a shield (1) having at least one through-opening (2). The ratio of the area of the through-opening (2) to the area of the sieve element (4) is at least 1 to 3, and the distance between the shield (1) and the sieve element (4) is at least 1 mm.

Owner:HERAEUS MEDICAL

Beverage Container With Integrated Mixing Device

InactiveUS20060158958A1Prevent liquid leakageHigh viscosityRotary stirring mixersKitchen equipmentEngineeringMechanical engineering

A portable beverage container with an integrated mixing device to homogenize its contents. The container includes a mixing element which can be connected to an external mixing base or operated via a manually operated crank or stick. The mixing element can require a minimum breaking force to prevent premature mixing of the contents. This breaking element can also incorporate a liquid impervious storage area to keep some ingredients separate from the fluid prior to mixing.

Owner:ROMANIK PHILIP

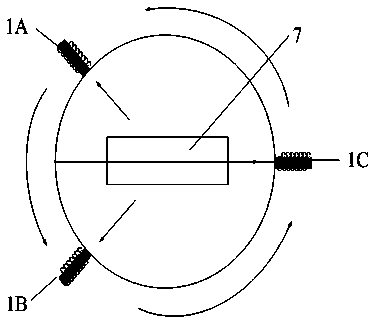

Novel swirl chamber for internal combustion engine

InactiveCN102691564AMix completelyEmission controlInternal combustion piston enginesCombustion chamberInternal combustion engine

A novel swirl chamber for an internal combustion engine comprises an upper swirl chamber body and a lower swirl chamber body, wherein three or two connecting passages are arranged on the lower swirl chamber body; and the novel swirl chamber is communicated with a main combustion chamber through the connecting passages. Through the adoption of the novel swirl chamber, the mixing of fuel gases is more complete, so as to achieve the purposes of controlling the emission of the internal combustion engine and reducing oil consumption.

Owner:慈溪三环柴油机有限公司

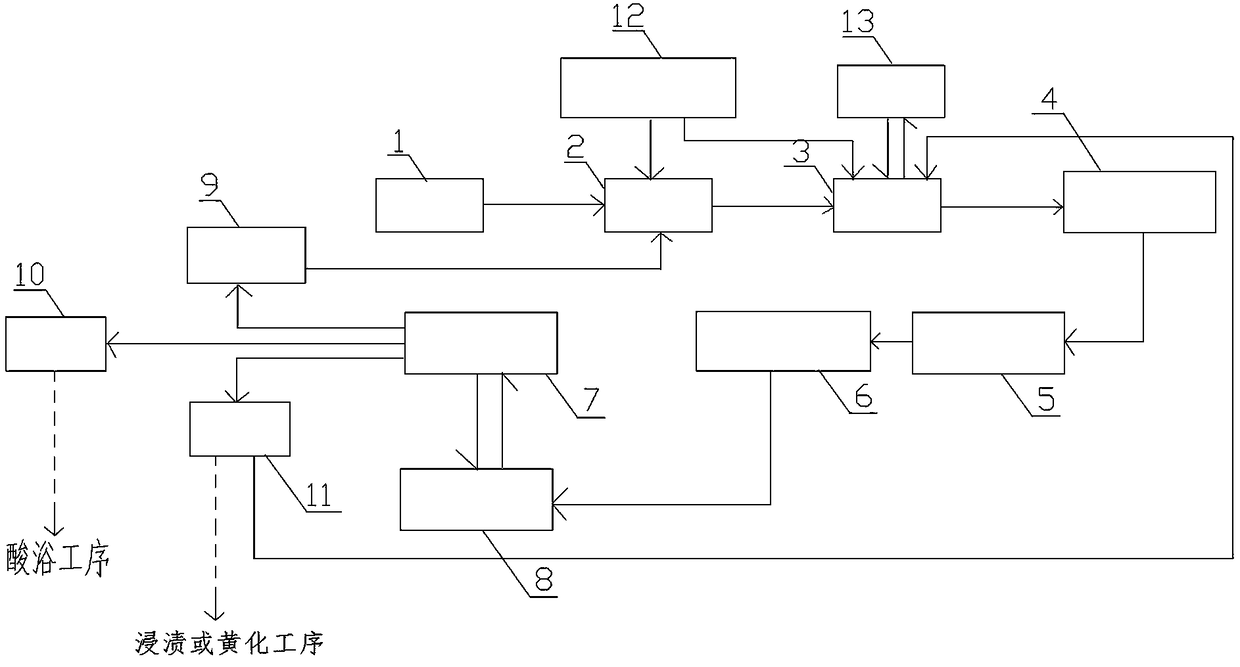

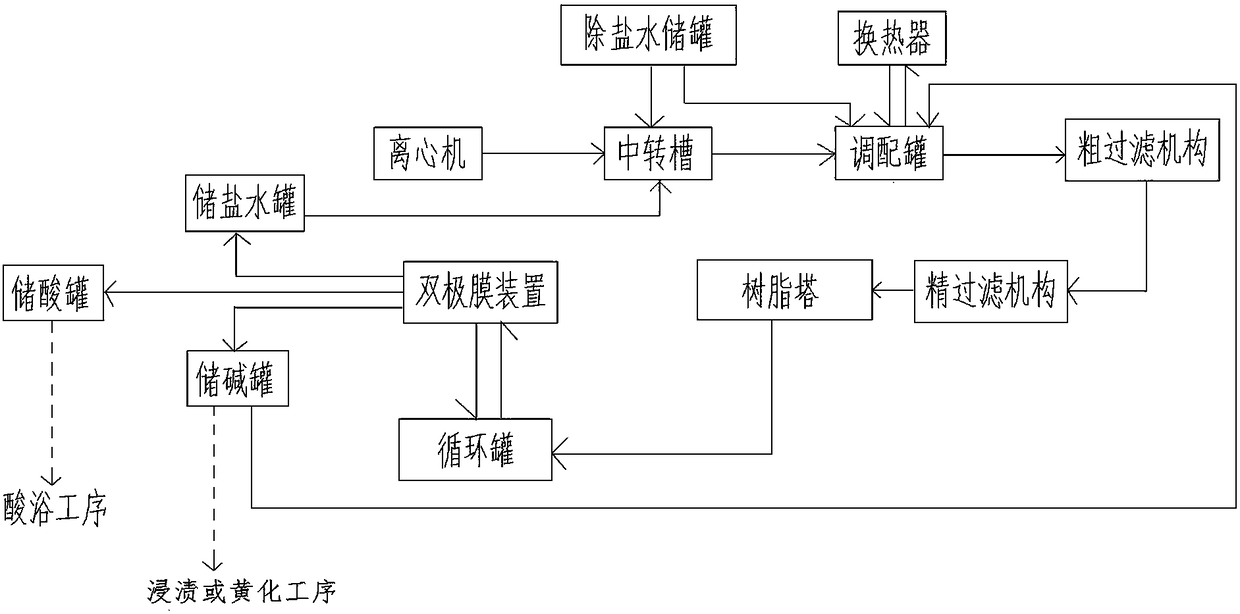

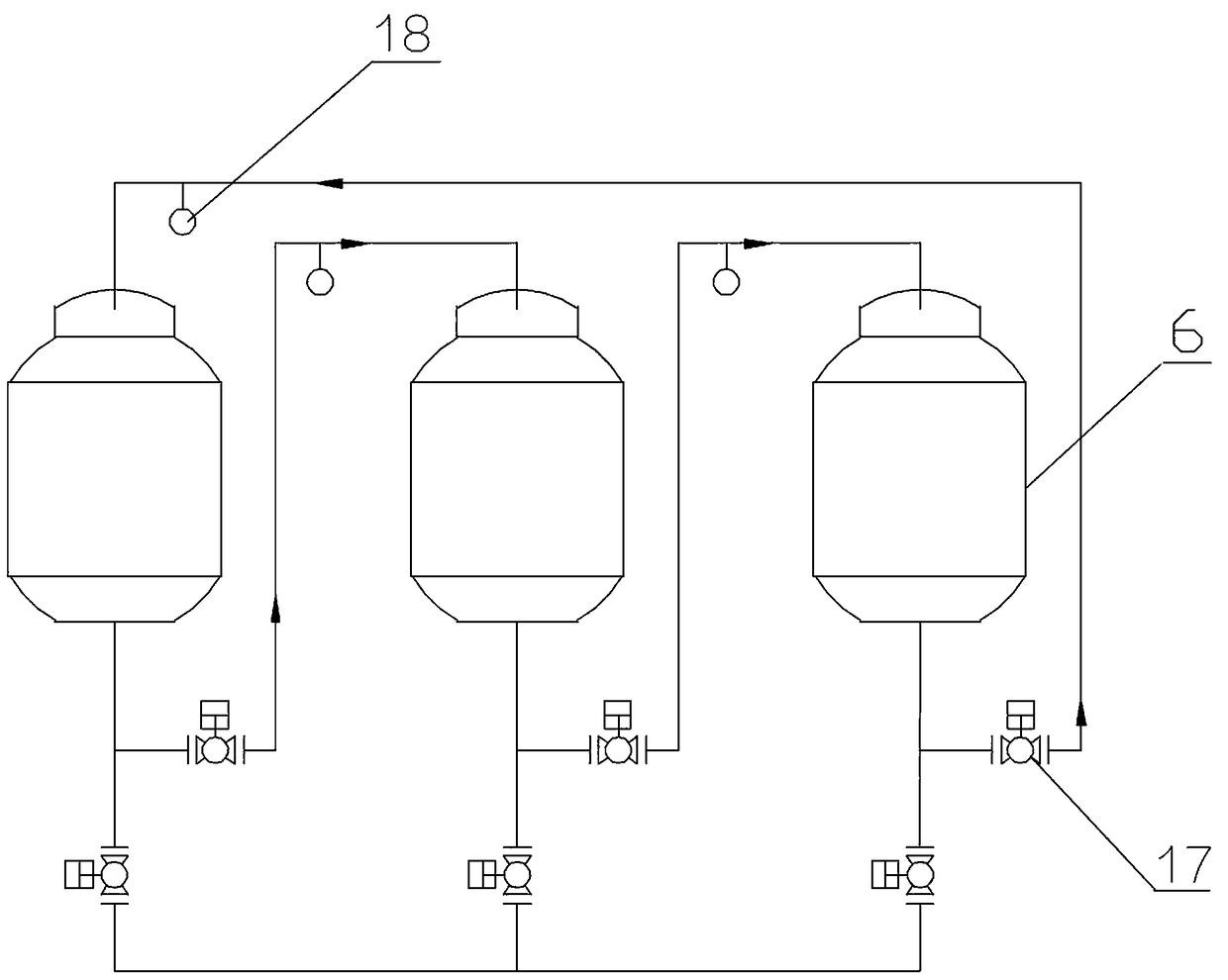

Circulating environment-friendly treatment process and circulating environment-friendly treatment system for waste viscose liquid

PendingCN109133448AGuaranteed purityGuaranteed concentrationWater/sewage treatment by centrifugal separationGeneral water supply conservationLiquid wasteFiltration

Owner:YIBIN HIEST FIBER +2

Selective catalytic reduction of NOx enabled by sidestream urea decomposition

ActiveUS7829033B2Well mixedAccurate temperatureCombination devicesNitrogen compoundsParticulatesSuperheater

A preferred apparatus arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140 .degree. C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH INC

Micro-fluidic chip magnetic-bead chaotic mixing method and apparatus

Owner:JIANGSU UNIV

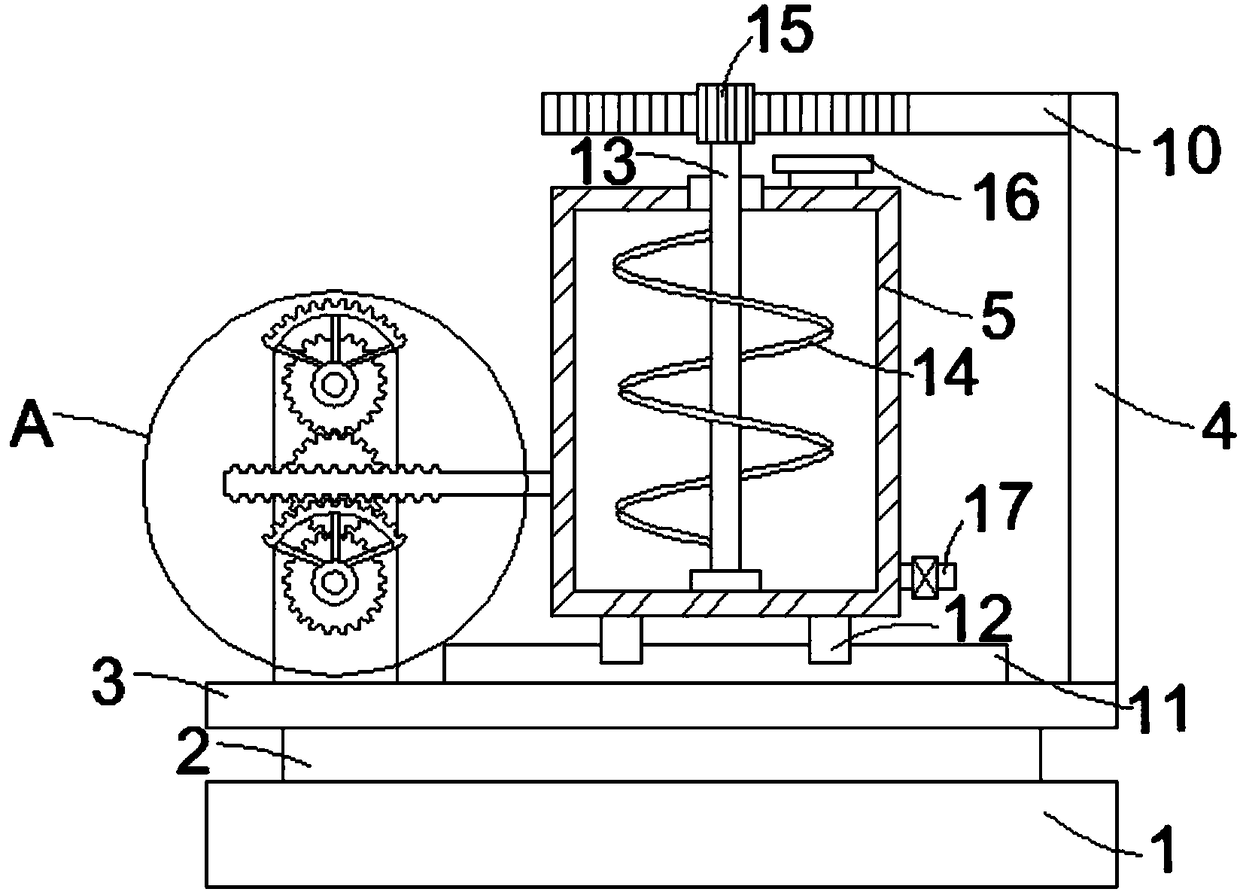

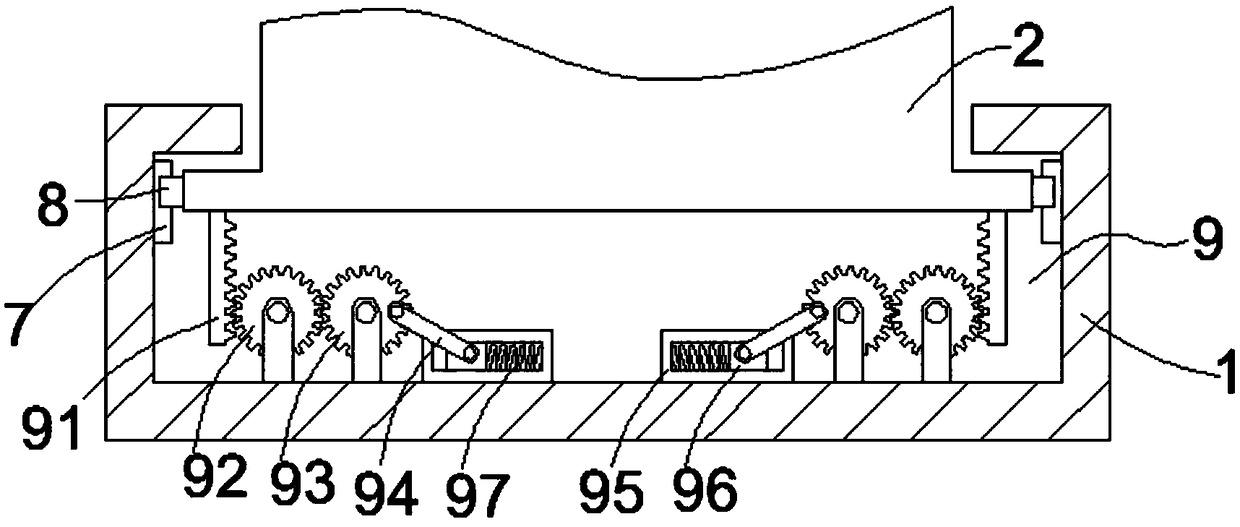

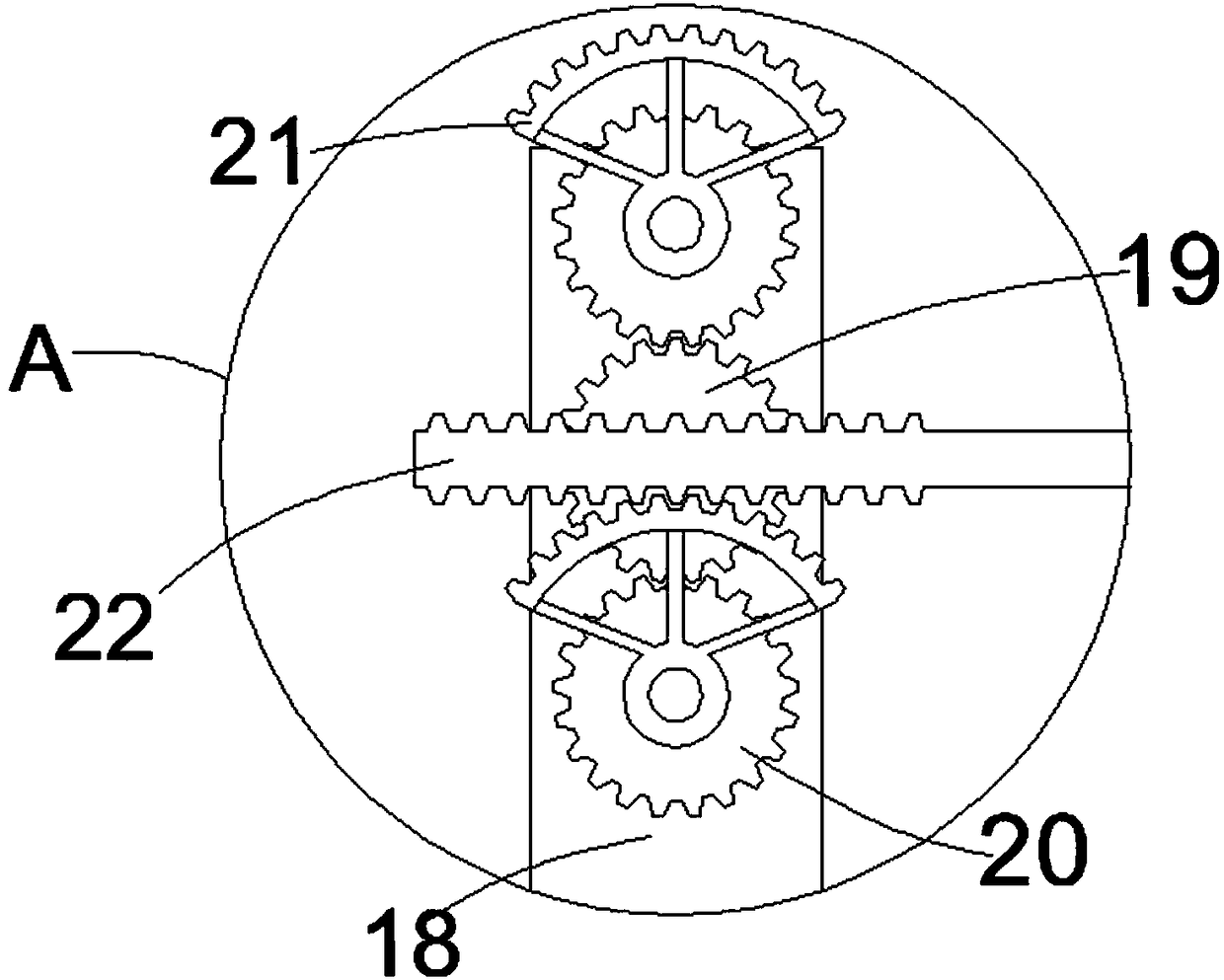

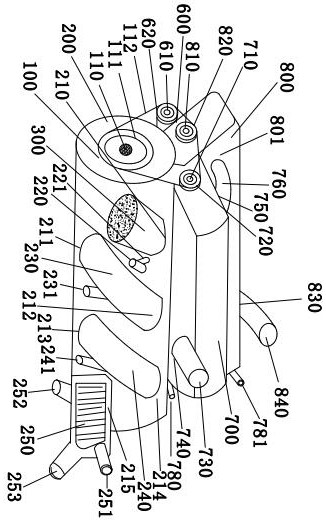

Efficient rare earth stirring, mixing and extracting equipment

ActiveCN107201454AImprove work efficiencyAvoid inaccurate manual blankingProcess efficiency improvementRare earthSediment

The invention relates to rare earth extracting equipment, in particular to efficient rare earth stirring, mixing and extracting equipment. According to the technical aims, the efficient rare earth stirring, mixing and extracting equipment is high in mixing and stirring speed, and mixing of rare earth materials and an extraction agent are relatively complete. In order to achieve the technical aims, the efficient rare earth stirring, mixing and extracting equipment is provided and comprises a base plate, a first sliding rail, a first sliding block, a first sediment box, supporting plates, a first bearing block, a first rotating rod, a first gear, a first motor, a second gear and the like; the first sliding rail is installed in the base plate in a bolt connecting manner, the first sliding block is connected into the first sliding rail in a sliding manner, the first sediment box is installed on the upper side of the first sliding block in a bolt connecting manner, and the supporting plates are installed on the left and right sides of the base plate in a welding manner. By means of the efficient rare earth stirring, mixing and extracting equipment, the effects of being high in mixing and stirring speed, and complete in mixing of rare earth materials and the extraction agent are achieved.

Owner:浙江立盛新型墙体材料有限公司

Combustion chamber of solid oxide fuel cell and automatic temperature control method thereof

ActiveCN108649245AStable temperatureThorough responseFuel cell heat exchangeCombustion chamberReaction temperature

The invention discloses a combustion chamber of a solid oxide fuel cell, comprising an inlet gas mixing unit and a combustion chamber unit, wherein the inlet gas mixing unit comprises a combustion chamber air duct, a cold air bypass duct, a combustion chamber fuel duct, a gas rotator and a bottom fixing shell; the combustion chamber unit comprises an electrically heating wire, a heat storage material, a heat insulating material, a combustion chamber outer wall, and a chamber temperature measuring thermocouple. The combustion chamber of the solid oxide fuel cell in the invention automatically monitors the temperature when the solid oxide fuel cell system performs state switching, and turns on the electric heating device when the temperature is too low, and raises the temperature of the combustion chamber; when the temperature is too high, the cold air bypass duct is turned on, the combustion chamber is cooled, so as to maintain the combustion chamber in the combustion reaction temperature range, so that the combustible gas mixture can be completely burned under the thin concentration condition, and complete combustion and temperature balance of the combustion chamber under the system state switching is ensured. The invention also discloses a method for automatically controlling the temperature of the combustion chamber of the solid oxide fuel cell.

Owner:武汉华科福赛新能源有限责任公司

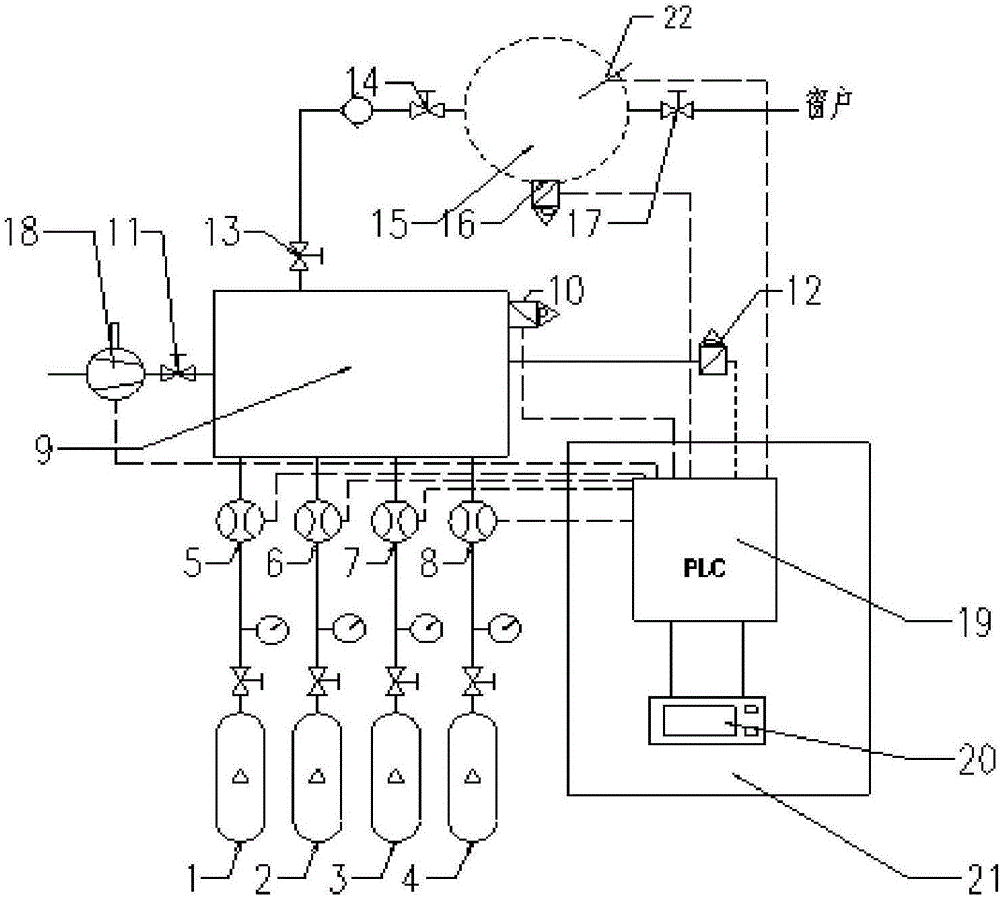

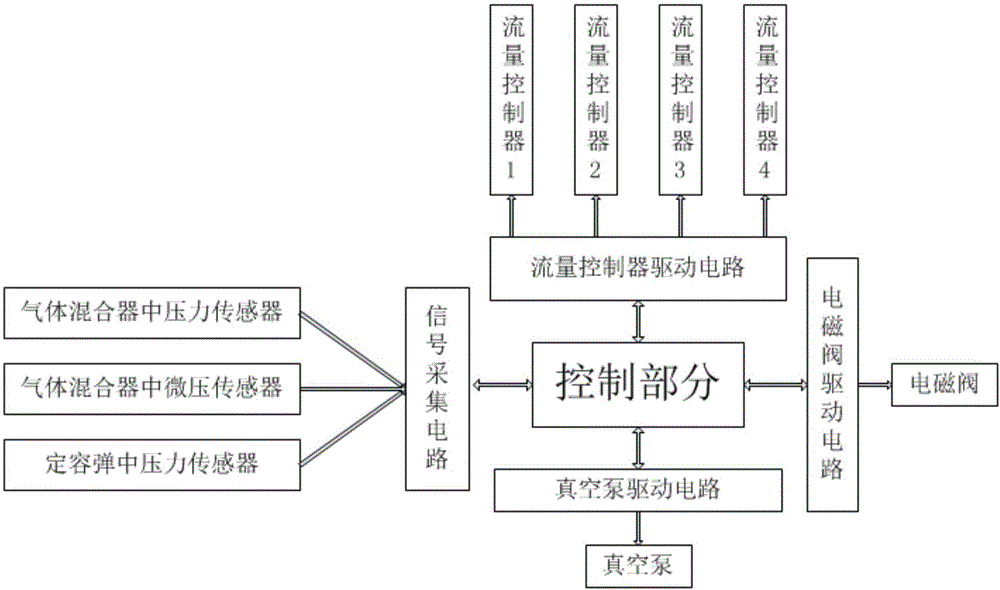

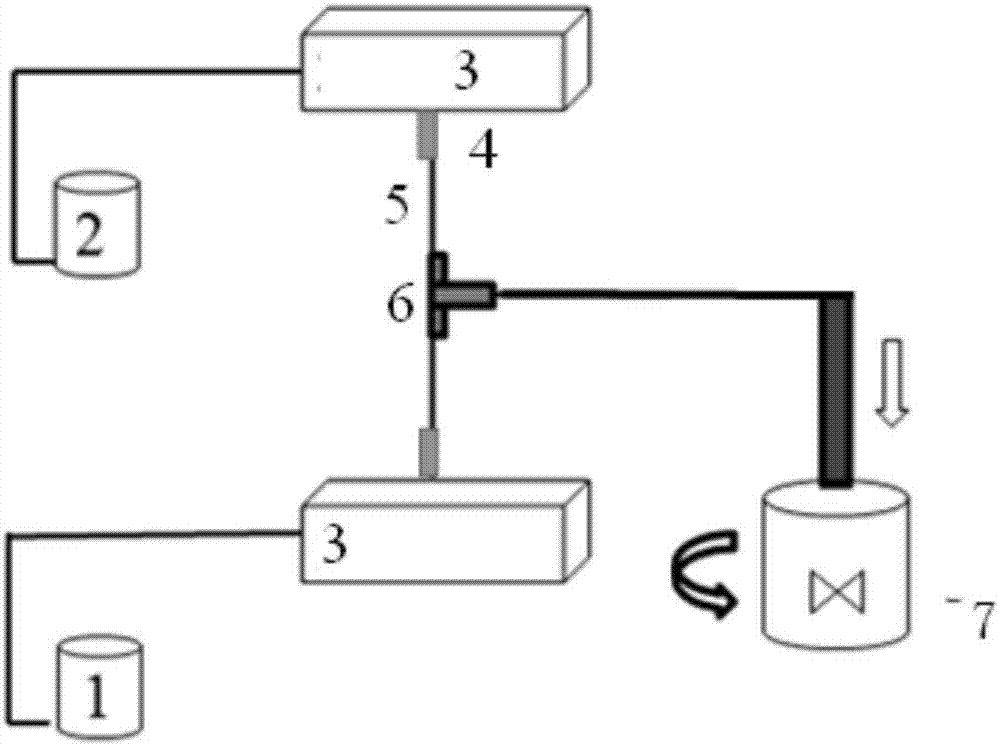

Constant volume bomb combustion gas mixing system and control method

InactiveCN106441909APrecise molar volume ratio controlMix completelyEngine testingGas cylinderEngineering

The present invention provides a constant volume bomb combustion gas mixing system and a control method. The system comprises gas cylinders of various types of gases, flow controllers, a gas mixer, a vacuum pump, a constant volume bomb, connecting pipes, a control part and a control circuit, wherein the connecting pipes are arranged between the gas cylinders, the flow controllers, the gas mixer, the vacuum pump and the constant volume bomb; the control circuit includes a vacuum pump driving circuit, a flow controller driving circuit, a signal acquisition circuit and a spark plug driving circuit; and the vacuum pump, the flow controllers, a pressure sensor which is arranged on the gas mixer, a micro pressure sensor, a pressure sensor which is arranged on the constant volume bomb, and a spark plug are all connected with the control part through the control circuit so as to be controlled, wherein the micro pressure sensor is arranged on the gas mixer, and the spark plug is arranged on the constant volume bomb. With the control method of the system adopted, precise molar volume ratio control on pre-combustion mixed gases can be realized, complete and controllable pre-combustion can be realized, a reliable environment can be provided for the search of the spray combustion characteristics of a diesel, experimental risk can be deceased, and high practicality can be realized.

Owner:HARBIN ENG UNIV

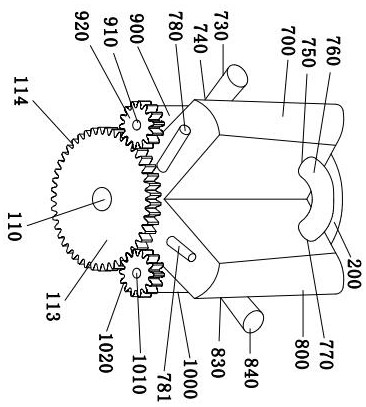

Continuous activation separator for raney nickel catalyst

ActiveCN103920440AIncrease effective contactMix completelyChemical/physical/physico-chemical processesRaney catalystsEngineeringThree-phase

The invention discloses a continuous activation separator for a raney nickel catalyst, which comprises a sealed kettle body, and the separator is characterized in that the kettle body comprises a reaction active region and a separating zone at the lower part, the separating zone comprises a settling section in an inverted frustum shape and a concentration section in a cylindrical shape, the settling section is fixedly connected to the reaction active region through a horizontal separator plate, the settling section is communicated to the concentration section at the lower part, a rotatable thickener is passed through a center shaft of the kettle body, a rake frame stirrer is arranged on the thickener, the frame stirrer is positioned in the reaction active region and rotates with the thickener, a hollow sleeve used for communicating with the reaction active region and settling section and sleeved outside the thickener is fixedly arranged on the horizontal separator plate, a reactant inlet and a gas outlet are arranged at the upper end of the reaction active region, a waste liquid outlet is arranged at the upper part of the settling section, a product outlet is arranged at the bottom of the concentration section, and the continuous activation separator has the advantages that the materials can be completely mixed, reaction is fully carried out, and gas-liquid-solid three phases continuous separation after reaction can be simultaneously realized.

Owner:SEDIN NINGBO ENG

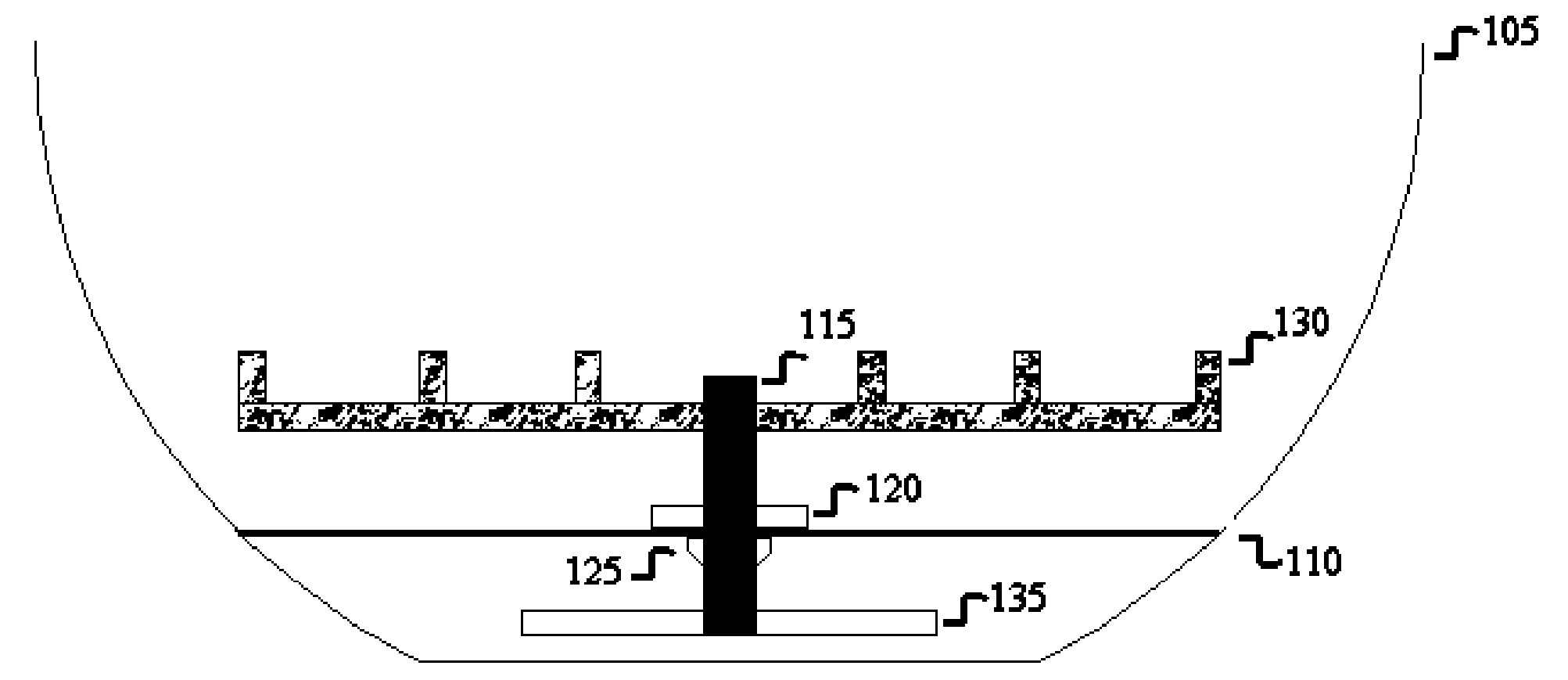

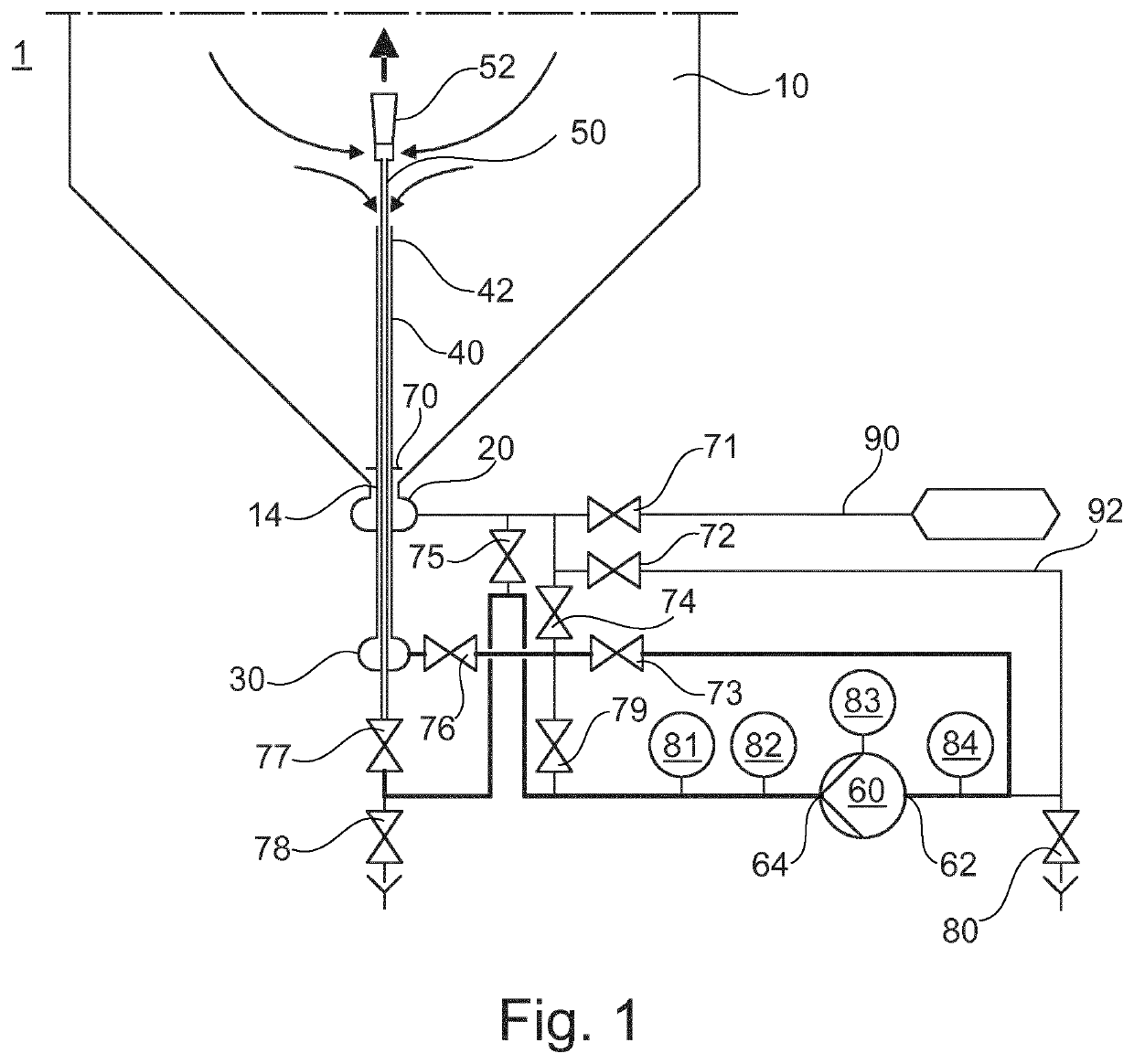

Device and method for mixing the contents of a tank

ActiveUS20190358596A1Prevent precipitationEasy to useFlow mixersTransportation and packagingMixing tankFlange

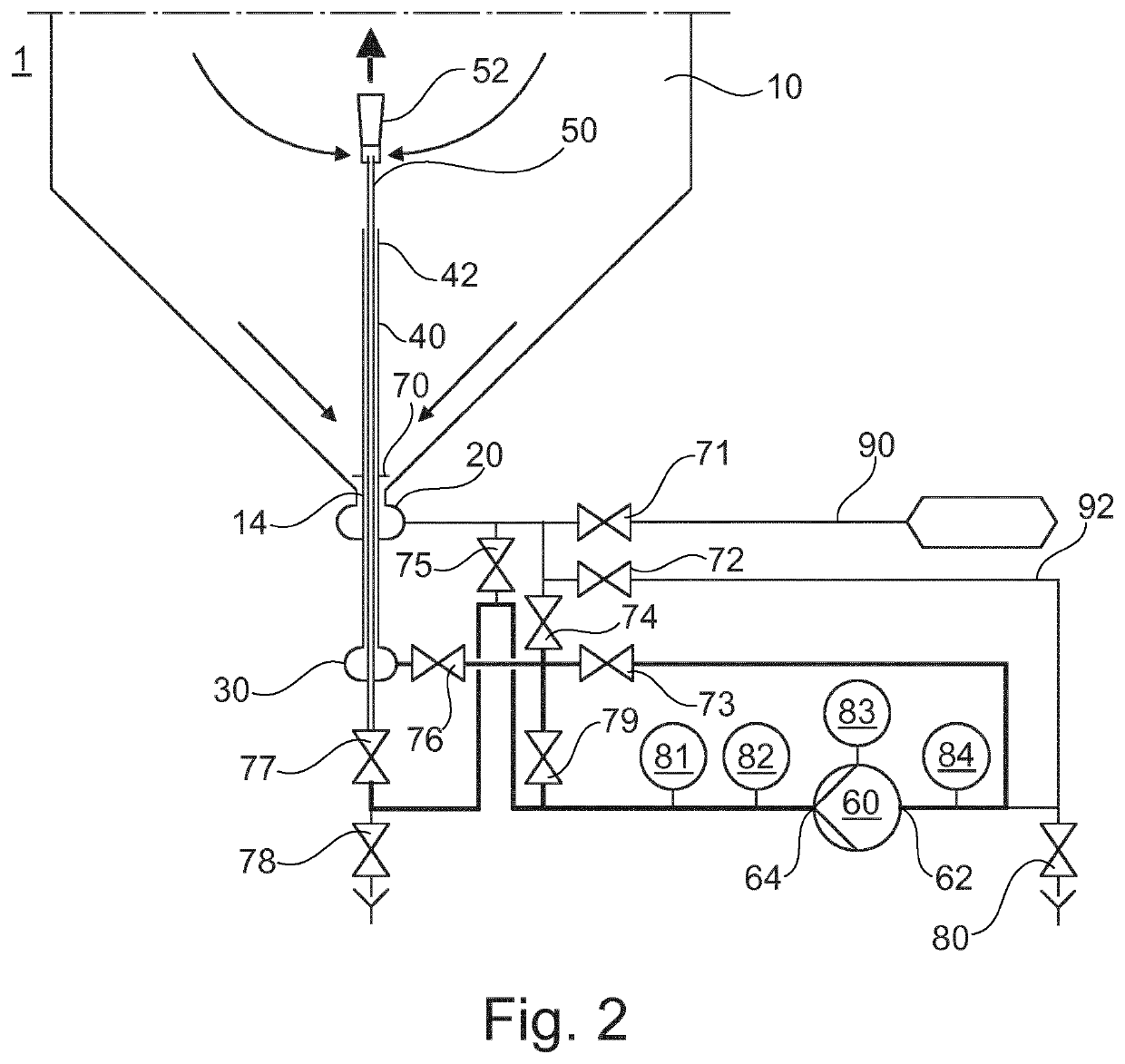

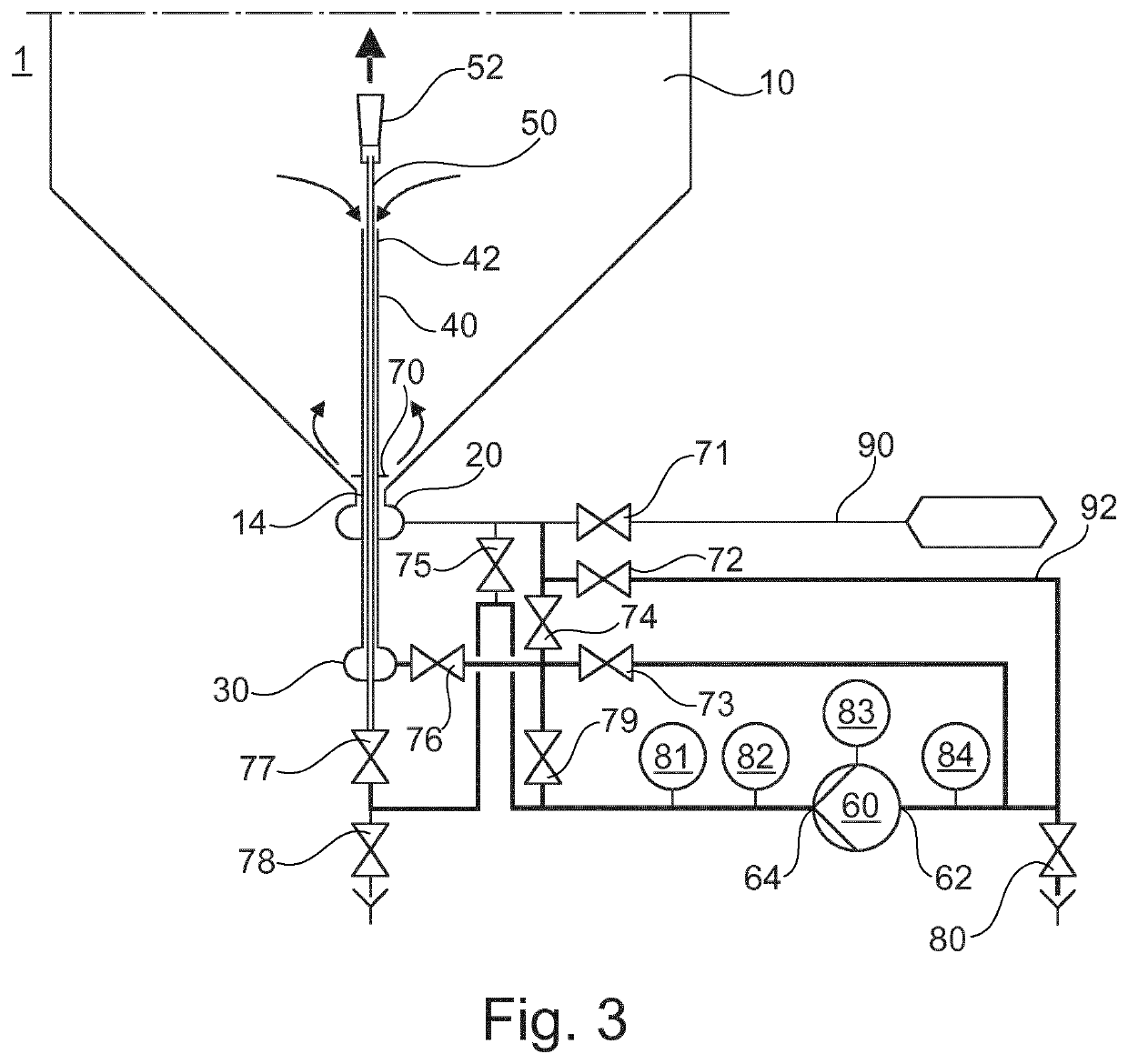

Device 1 for mixing the contents of a tank 10 comprising a first pipe connecting body 20 arranged on a connecting flange 14 of a tank 10; a riser pipe 40 extending through the first pipe connecting body 20 into the tank; a mixing pipe 50 extending through said first pipe connecting body 20 into said tank; and a pump 60 whose outlet 64 can be connected at least to the mixing pipe 50 and whose inlet 62 can be connected both to the first pipe connecting body 20 and to the riser pipe 40. Further a method for mixing the contents of a tank is claimed.

Owner:GEA BREWERY SYST

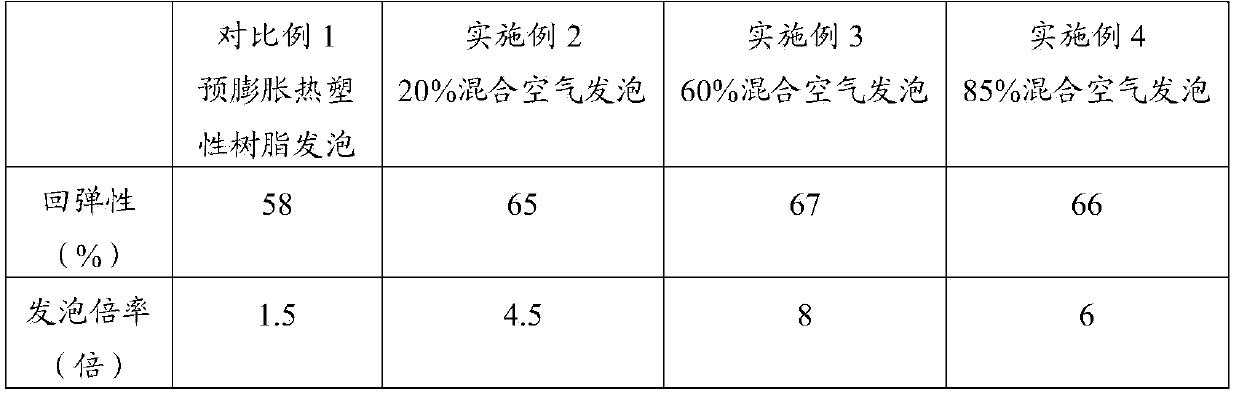

Foamed liquid silicon rubber and preparation method thereof

The invention discloses a preparation method of foamed liquid silicon rubber. The preparation method comprises the steps as follows: 1) a basic material is prepared frompolysiloxane composition and reinforcing filler and divided into two parts; 2) a catalyst is added to one part to prepare a material A; 3) an inhibitor and a cross-linking agent are added to the other part to prepare a material B; 4) the material A and the material B are mixed, a gas mixture with the weight ratio of 20-85%, preferably, 60% is added, the gas mixture consists of air, oxygen and CO2, and a finished foamed liquid silicon rubber product is obtained after heating and curing. According to the preparation method, the prepared foamed rubber is even in foam size, complete in foaming, high in elasticity, high in toughness, smooth in surface, capable of saving the production cost and widely applicable to various production fields of the industrial injection molding process.

Owner:NINGBO YINRUI ORGANO SILICON TECH DEV

Production process for spectacle frame made from composite plate

The invention discloses a production process for a spectacle frame made from a composite plate. The production process comprises the following steps: carrying out preheating drying on raw materials for producing the plate according to a certain proportion at first, and then uniformly mixing the raw materials in a high-speed mixing machine; then carrying out heating melting on the raw materials through a heating device to enable the raw materials to achieve a viscous state, and then placing the raw materials in a die and continuing to heat; carrying out precooling treatment on an obtained plate blank through a cooling production line; immediately feeding the plate blank subjected to the precooling treatment into a pattern forming device with the production line, and forming patters on a surface of the plate blank through pressing; and carrying out adequate cooling on the plate blank, and then carrying out traction trimming treatment on the plate blank to enable the edge of the plate blank to be smooth and burr-free. The spectacle frame produced by the production process disclosed by the invention is complete in plate mixing, not liable to break, and long in life; and moreover, production is assembly-line, free from time waste and labor waste of manual work, and fast and convenient.

Owner:浙江方氏眼镜制造有限公司

Mixing equipment for processing irradiation crosslinked coiled material

InactiveCN108339480AImprove uniformityMix thoroughlyShaking/oscillating/vibrating mixersTransportation and packagingDrive motorElectric energy

The invention relates to the technical field of mixing equipment, in particular to mixing equipment for processing an irradiation crosslinked coiled material. The mixing equipment comprises a base, abuffer board, a bottom plate, a side plate, a box body and a driving motor. An inner cavity is formed in the base. First sliding rails are arranged on the side wall of the inner cavity of the base, and are matched with first sliding blocks. The first sliding blocks are arranged at two ends of the bottom of the buffer board. A damping mechanism is arranged at the bottom of the buffer board. The bottom plate is arranged at the upper end of the buffer board. The side plate is arranged on the right side of the bottom plate. A first rack bar is arranged at the upper end of the side plate. A secondsliding rail is arranged at the top of the bottom plate on the left side of the side plate. According to the mixing equipment provided by the invention, the driving motor is used as a driving device to realize efficient mixing of all raw materials for processing the irradiation crosslinked coiled material and reduce the using phenomenon of multiple driving motors, so that consumption of electric energy is reduced, and in addition, the mixing equipment is novel in structure, reasonable in design, low in manufacturing cost, and convenient to use.

Owner:ZHEJIANG YIJIA NEW MATERIAL CO LTD

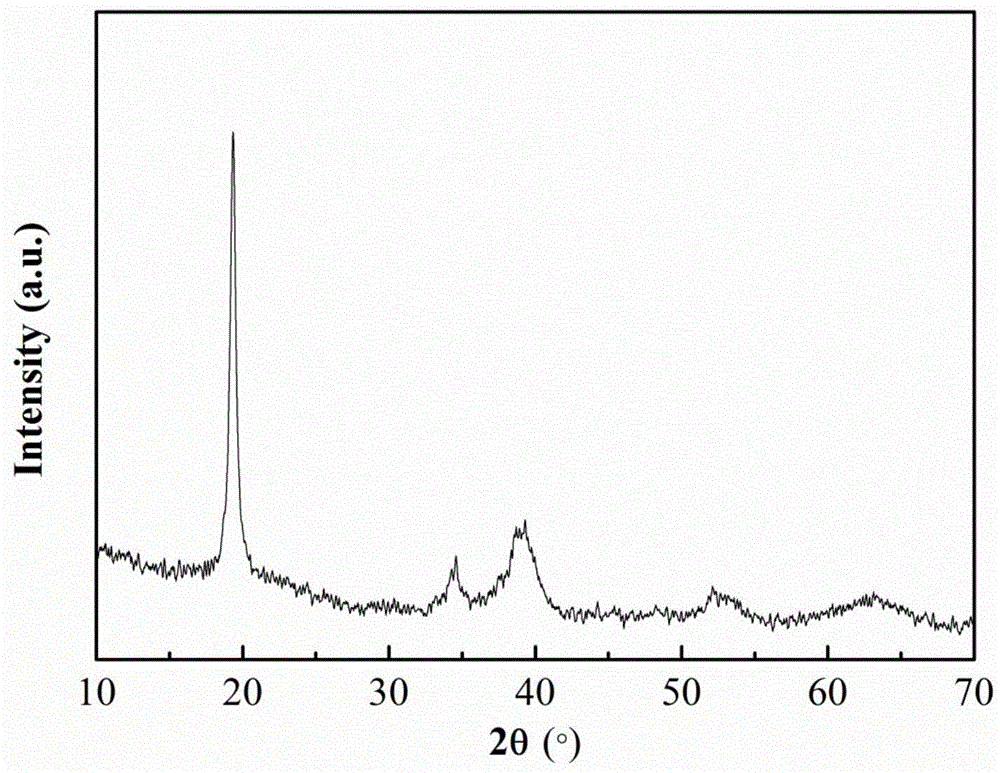

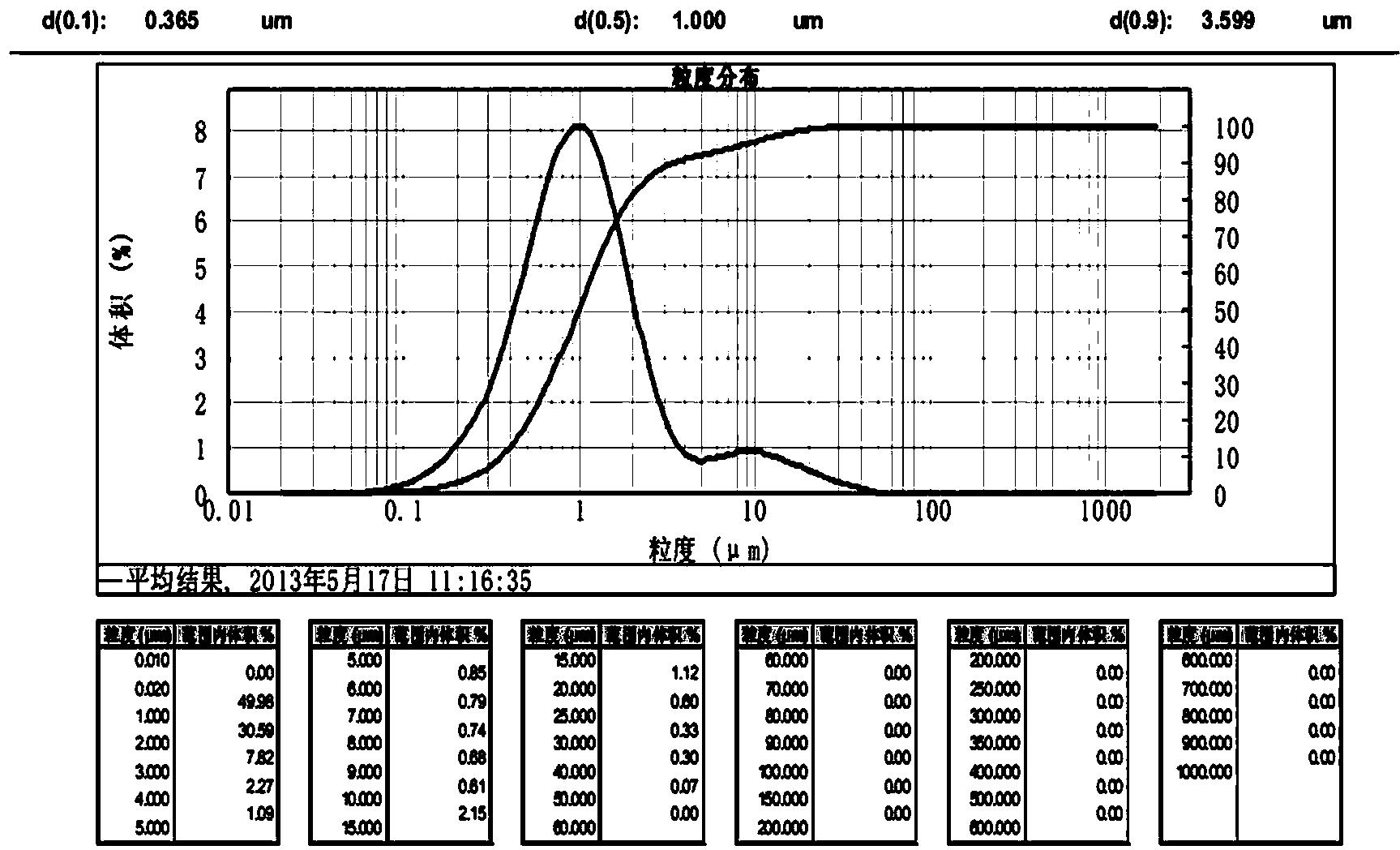

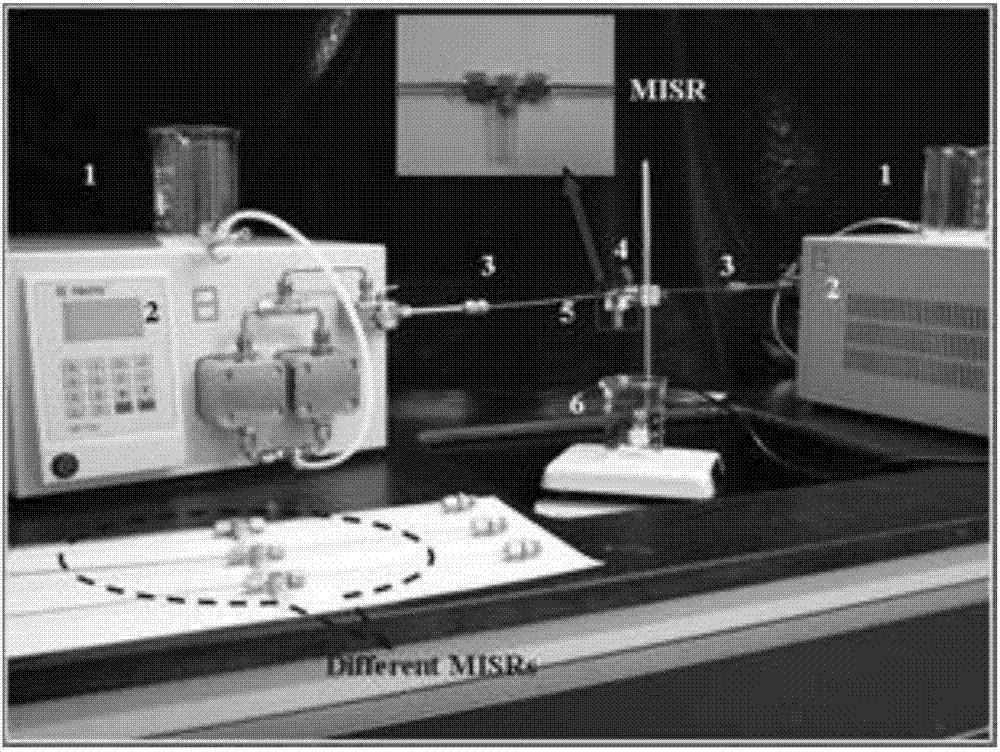

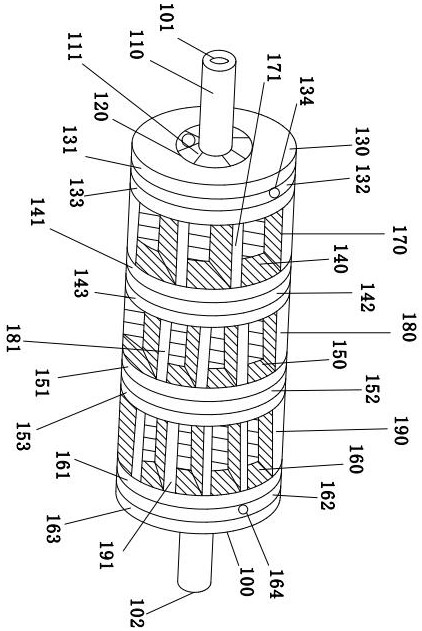

Apparatus and method for preparing ultrafine WO3

InactiveCN107500360AEnhanced Mixed Reaction ProcessWell mixedTungsten oxides/hydroxidesNanotechnologyTungstateEngineering

The invention discloses an apparatus and a method for preparing ultrafine WO3, and belongs to the technical field of powder metallurgy, and the apparatus and the method can be applied to the preparation of the ultrafine WO3 powder. The apparatus comprises two liquid reservoirs for storage of reaction liquids and constant-flux pumps which are respectively connected with the liquid reservoirs, the constant-flux pumps are connected with a T-type tee by capillary tubes, the vertical end of the T-type tee is a reaction liquid outlet, and the apparatus belongs to a micro impinging stream reactor. The reaction method is as follows: a hydrochloric acid solution and a tungstate solution are impacted and mixed through the T-type tee connector to synthesize precursor tungstic acid, and the precursor tungstic acid is calcined to obtain the ultrafine WO3 powder. The preparation method and the apparatus can be used to strengthen the mixing reaction process of components to obtain the WO3 with a regular morphology, small particle size and narrow particle size range. The method has the advantages of simple process, high control precision, continuous production and many other advantages, and has a good industrialization prospect.

Owner:BEIJING UNIV OF CHEM TECH

Auxiliary equipment of impeller cylinder combined engine

PendingCN113958408ALarge intake and exhaust volumeMeet gas supply requirementsRotary/oscillating piston combinations for elastic fluidsContinuous combustion chamberCombustion chamberHeat conservation

The invention discloses auxiliary equipment of an impeller cylinder combined engine. A cylinder is provided with a multi-stage air compressor for providing an air source for the engine and is provided with a high-pressure air storage tank; a first air injection hole outside the cylinder is provided with a heat preservation type combustion chamber and is connected with a group of air combustion switches for controlling; conditions are created for controlling the firepower and the air combustion ratio of the engine and doing work after air absorbs heat; one end of a first flow guide pipe and one end of a second flow guide pipe outside the cylinder are provided with a first flow guide branch pipe and a second flow guide branch pipe for heat preservation respectively; lubricating oil in the cylinder and the multi-stage air compressor is discharged into a first heat preservation type heat exchanger for heat exchange and then can be recycled; and a third exhaust hole outside the cylinder is provided with a second heat preservation type heat exchanger, and high-pressure air is subjected to heat absorption and pressurization by the two heat exchangers under the regulation and control of the air combustion switches and then returns into the cylinder through the two flow guide branch pipes for power assistance and work doing, so that the heat efficiency is higher. The heat engine belongs to an upgraded product of an internal combustion engine.

Owner:刘天锡

Sprayer used for pest prevention in agriculture

ActiveCN108651417AAvoid wastingReduce use costRotary stirring mixersTransportation and packagingImpellerSprayer

The invention relates to the technical field of agricultural environmental protection, and in particular relates to a sprayer used for pest prevention in agriculture. The sprayer comprises a shell anda first partition plate; the inner side of the shell is fixedly connected with the vertically-arranged first partition plate, the right end surface of the first partition plate is fixedly connected with a fixing plate, and a piston is slidably connected right on the fixing plate; the inner side of the fixing plate is provided with a first through hole and a second through hole which are arrangedleft and right, the bottom end of the first through hole is fixedly connected with a water pipe, and the bottom end of the second through hole is fixedly connected with a hose; the left side of the bottom end of the first partition plate is fixedly connected with a battery, and the top end of the battery is provided with a fixing rod; the top end of the fixing rod is provided with a convex block,and a vertically-arranged connecting rod sleeves the outer side of the convex block; the outer side of the connecting rod is fixedly connected with impellers, and the top end of the connecting rod isprovided with a first gear; and the left side of the first gear is provided with a second gear. The sprayer provided by the invention has great economic benefits and broad market prospects, and is worthy of promotion and applications.

Owner:余姚市永星喷雾器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com