Preparation method of ultrafine tungsten carbide powder

A technology of ultra-fine tungsten powder and tungsten carbide powder, which is applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of unfavorable mass production, high production cost, and complicated equipment, so as to improve the effect and increase the combined carbon content , the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

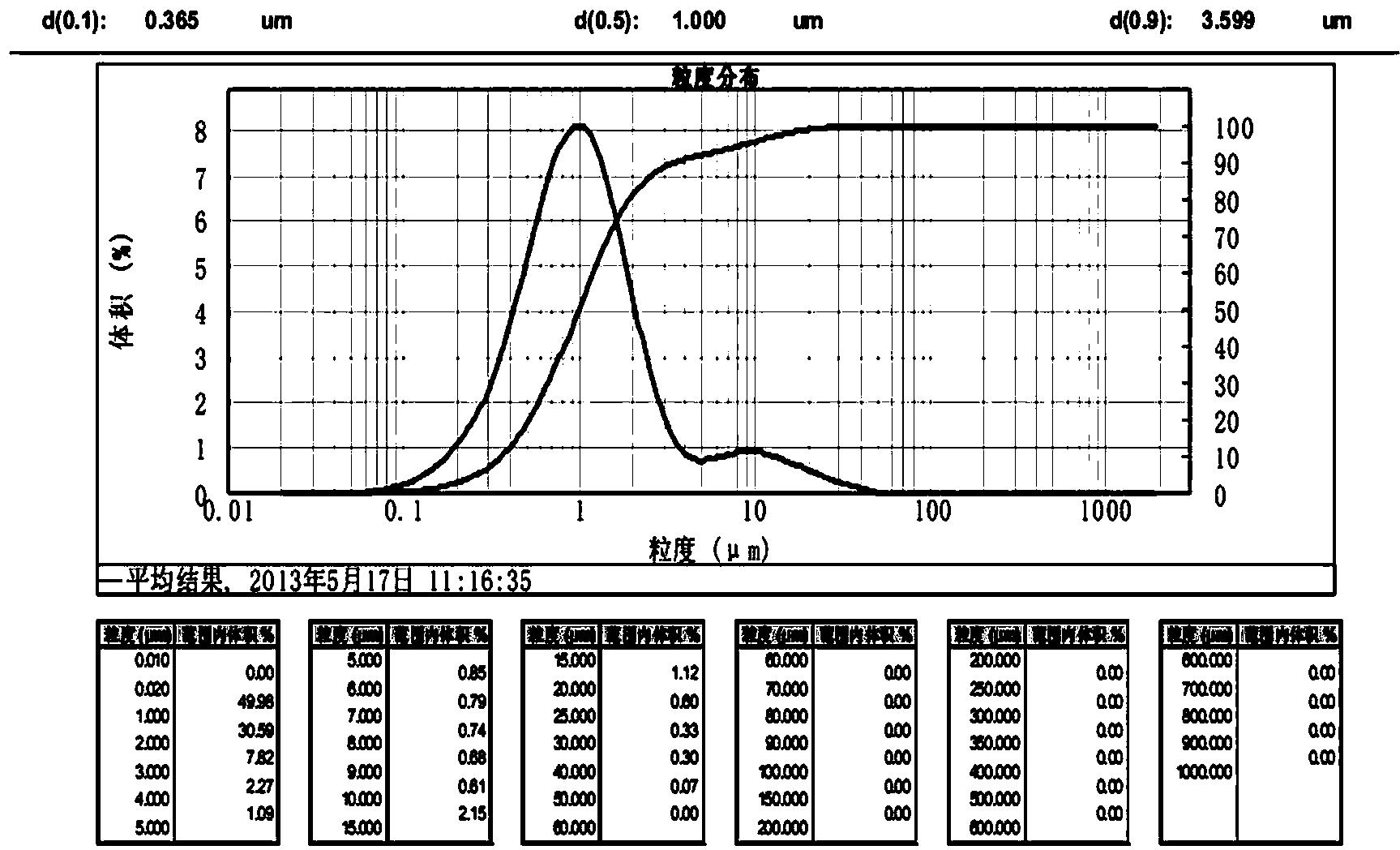

Image

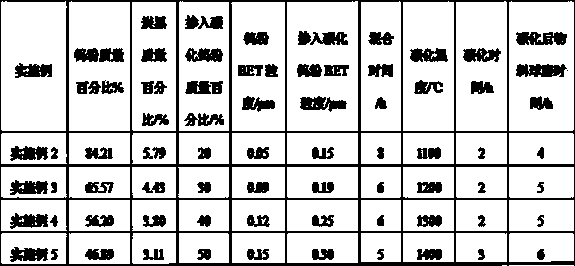

Examples

Embodiment 1

[0025] Example 1: Follow the steps below to superfine tungsten carbide powder:

[0026] (1) According to the following mass percentages, the ultrafine tungsten powder is 88.90% (BET particle size is 0.05μm), carbon black is 6.10%, and ultrafine tungsten carbide is 5% (BET particle size is 0.15μm). The oxygen content in the powder, the mass percentage of carbon black is 0.3% higher than the mass percentage of carbon calculated according to the WC stoichiometric ratio [that is, 6.10%-88.90% × (12 / 183.85) value is 0.3%], the above proportion of powder Put the materials into the ball mill, add stainless steel grinding balls, and then ball mill and mix for 8 hours to mix the materials evenly.

[0027] (2) Unload the mixed materials of the ball mill from the ball mill, and separate the balls, then put the materials into the graphite boat and carbonize in the carbonization furnace. The carbonization atmosphere is a non-oxidizing atmosphere, and the carbonization temperature is 1000°C. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com