Novel swirl chamber for internal combustion engine

An internal combustion engine and combustion chamber technology, which is applied in the field of swirl combustion chambers of internal combustion engines, can solve the problem of high fuel consumption of internal combustion engines, and achieve the effects of complete gas mixture, fuel consumption reduction and emission control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

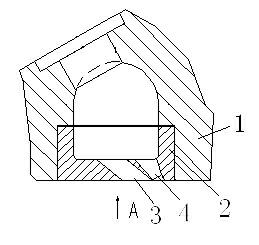

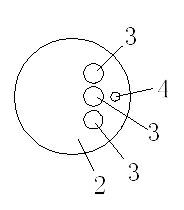

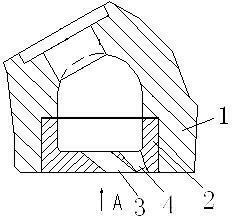

[0019] Reference figure 1 , figure 2 , A new type of internal combustion engine vortex combustion chamber, composed of a vortex chamber upper body 1 and a vortex chamber lower body 2. The vortex chamber lower body 2 is provided with three or two connecting channels 3, the vortex chamber through the connection The passage 3 communicates with the main combustion chamber. In this embodiment, there are three connecting channels 3, and the three connecting channels 3 are arranged in a row. Among the three connecting channels, the two connecting channels on both sides are symmetrical about the center line of the middle connecting channel. The angle between the centerline of the longitudinal section of the connecting channel 3 and the vertical centerline of the insert is 20o~70o. In this embodiment, it is 50°. Of course, it can also be 30°, 40°, etc., withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com