Constant volume bomb combustion gas mixing system and control method

A technology of mixing system and constant volume ammunition, which is applied in the testing of measuring devices, instruments, machines/structural components, etc., can solve problems such as no gas mixing and no gas mixing device, etc., to achieve high practical value and reduce the risk of experiments. , the effect of high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

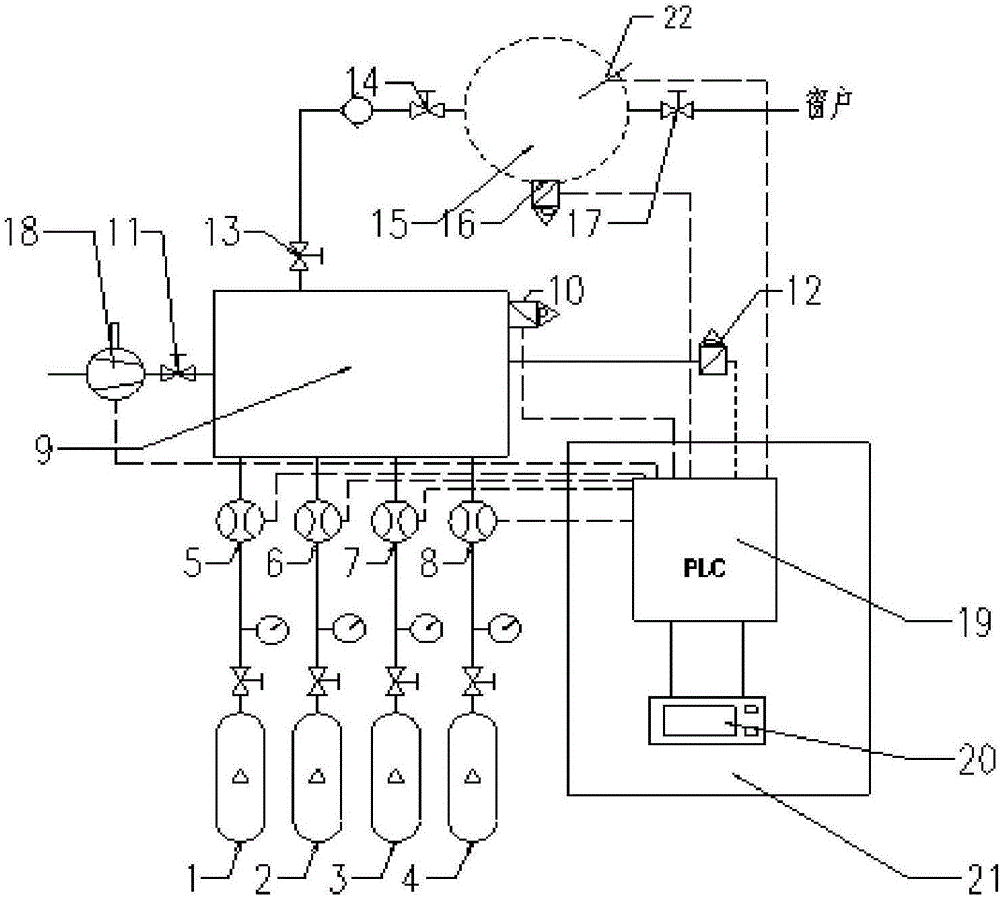

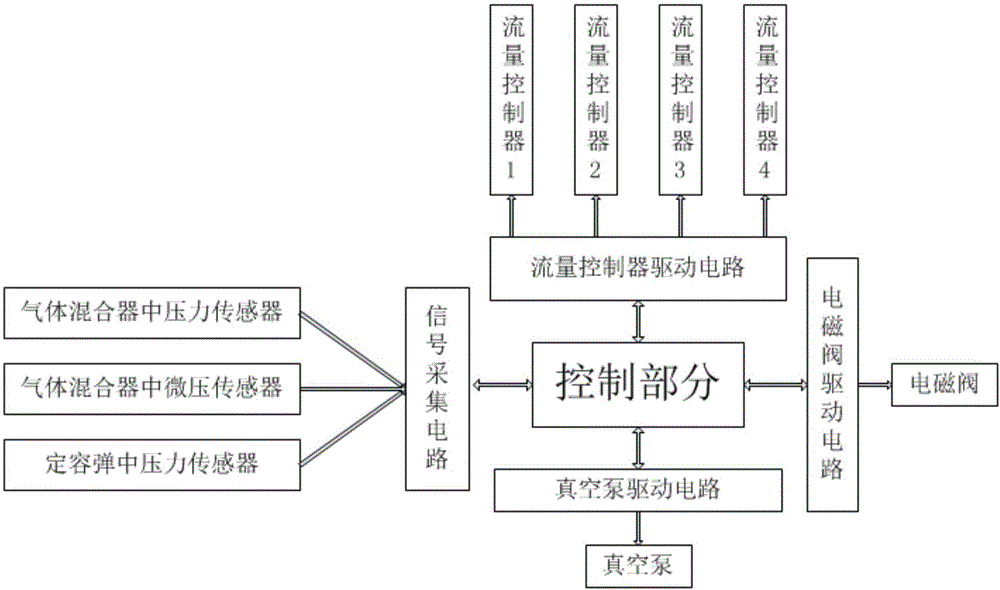

[0020] combine figure 1 with figure 2 , the gas mixing system of constant volume bombs of the present invention comprises gas cylinders 1, 2, 3, 4, flow controllers 5, 6, 7, 8, gas mixers 9, vacuum pumps 18, constant volume bombs 15 and The connection pipe between them is the control part 21 and the control circuit. Wherein the pressure of the gas cylinder is greater than the pressure of the gas mixer. The gas cylinders 1, 2, 3, 4 are respectively connected to the gas mixer 9 through pipelines. A corresponding flow controller 5 , 6 , 7 , 8 is provided between the connecting pipes of the gas cylinder and the gas mixer. The gas mixer 9 is connected to the constant volume bomb 15, and screw valves 13, 14 are arranged between them. The gas mixer is equipped with a pressure sensor 10 and a micro-pressure sensor 12, which are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com