Stirring device for producing herbicide

A stirring device and herbicide technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve problems such as low production efficiency, poor effect, and easy damage to mixing blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

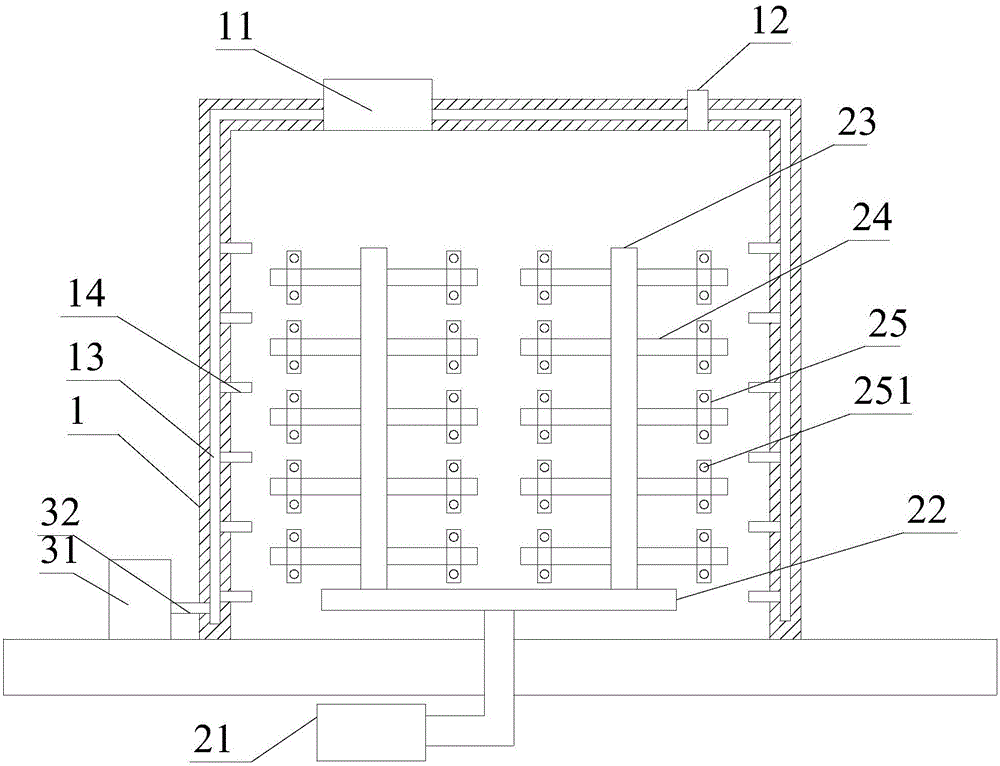

[0018] refer to figure 1 , the present invention proposes a stirring device for herbicide production, including a stirring drum 1, a stirring device and an air guiding device, wherein,

[0019] The mixing drum 1 is provided with a feed inlet 11 and an air outlet 12, and the mixing drum 1 is provided with a passage 13, and the inner side walls of the feed inlet 11 and the air outlet 12 can respectively connect the feed inlet 11, the air outlet 12 and the passage 13. Sealed and isolated, the inner wall of the mixing drum 1 is distributed with air nozzles 14, the inlet of the air nozzles 14 is connected to the passage 13, and the air nozzles 14 are provided with flow valves, which can adjust the flow rate of the air nozzles 14 according to the actual herbicide production requirements. Air flow for optimum agitation for herbicide production.

[0020] Stirring device comprises driving mechanism 21, rotating disk 22 and a plurality of stirring racks 23, and rotating disk 22 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com