Foamed liquid silicon rubber and preparation method thereof

A liquid silicone rubber and polysiloxane technology, which is applied in the field of foamed silicone rubber and its preparation, can solve the problem that powder foaming agent and silicone rubber are not mixed evenly, specific gravity, elasticity, hardness and other properties cannot meet requirements, etc. problem, to achieve the effect of complete foaming, smooth surface and high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

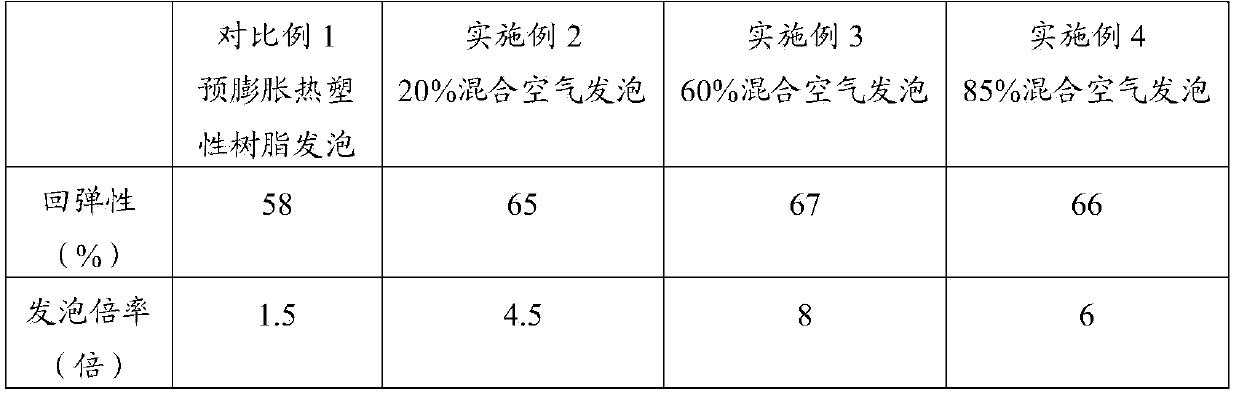

Examples

Embodiment 2

[0044] Example 2: Preparation of foamed liquid silicone rubber with 20% mixed air blowing agent (wt%)

[0045] Step 1): Add I. Polysiloxane with a viscosity of 5000-10000mPa·s (25°C) and a vinyl content of 0.25%-0.5% (wt%) in a strong stirring mixer, the addition amount is 20 parts; and Ⅱ. The amount of polysiloxane with a viscosity of 10000-40000mPa·s (25°C) and a vinyl content of 0.15%-0.5% (wt%) is 20 parts.

[0046] Further, hexamethyldisilazane coupling agent was added as fumed silica for hydrophobic treatment, 20 parts were added, and stirred and mixed for 1 hour to form agglomerates.

[0047]Then heat up to about 150°C and stir at constant temperature and pressure for 2 hours, then vacuum stir at about 150°C for 3 hours and then stop the vacuum.

[0048] After cooling down to 90°C, add Ⅰ. Polysiloxane with a viscosity of 5000-10000mPa·s (25°C) and a vinyl content of 0.25%-0.5% (wt%), add 15 parts, mix evenly and discharge Grind into a base material, ie a low molecular...

Embodiment 3

[0052] Example 3: Preparation of foamed liquid silicone rubber with 60% mixed air blowing agent (wt%)

[0053] Step 1): Add III. Polysiloxane with a viscosity of 1000-2000mPa·s (25°C) and a vinyl content of 0.3%-1.0% (wt%) in a strong stirring mixer, the addition amount is 30 parts; and Ⅱ. The dosage of polysiloxane with a viscosity of 10000-40000mPa·s (25℃) and a vinyl content of 0.15%-0.5% (wt%) is 20 parts, and the dosage is 15 parts;

[0054] Further, hexamethyldisilazane coupling agent was added as fumed silica for hydrophobic treatment, 20 parts were added, and stirred and mixed for 1 hour to form agglomerates.

[0055] Then heat up to about 150°C and stir at constant temperature and pressure for 2 hours, then vacuum stir at about 150°C for 3 hours and then stop the vacuum.

[0056] After cooling down to 90°C, add Ⅰ. Polysiloxane with a viscosity of 5000-10000mPa·s (25°C) and a vinyl content of 0.25%-0.5% (wt%), add 15 parts, mix evenly and then discharge and grind For...

Embodiment 4

[0060] Example 4: Preparation of foamed liquid silicone rubber with 80% mixed air blowing agent (wt%)

[0061] Step 1): Add III. Polysiloxane with a viscosity of 1000-2000mPa·s (25°C) and a vinyl content of 0.3%-1.0% (wt%) in a strong stirring mixer, the addition amount is 30 parts, and Ⅰ. Polysiloxane with a viscosity of 5000-10000mPa·s (25°C) and a vinyl content of 0.25%-0.5% (wt%), the dosage is 15 parts.

[0062] Add hexamethyldisilazane coupling agent as fumed silica for hydrophobic treatment, add 20 parts, stir and mix for 1 hour.

[0063] Then heat up to about 150°C and stir at constant temperature and pressure for 2 hours, then vacuum stir at about 150°C for 3 hours and then stop the vacuum.

[0064] After cooling down to 90°C, add Ⅳ. Polysiloxane with a viscosity of 1000-5000mPa·s (25°C) and a vinyl content of 1.0%-10% (wt%), add 5 parts, mix evenly and then discharge and grind into the base material; and divide the base material into two equally;

[0065] Step 2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com