Microbial composite treatment for gold ore tailings and application method

A technology of composite treatment and application method, applied in the field of microbial composite treatment and application of gold tailing slag, can solve the problems of low production efficiency, little effect of gold tailing slag production speed, serious environmental pollution, etc., and achieves good biocompatibility, Effectively remove cyanide without secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

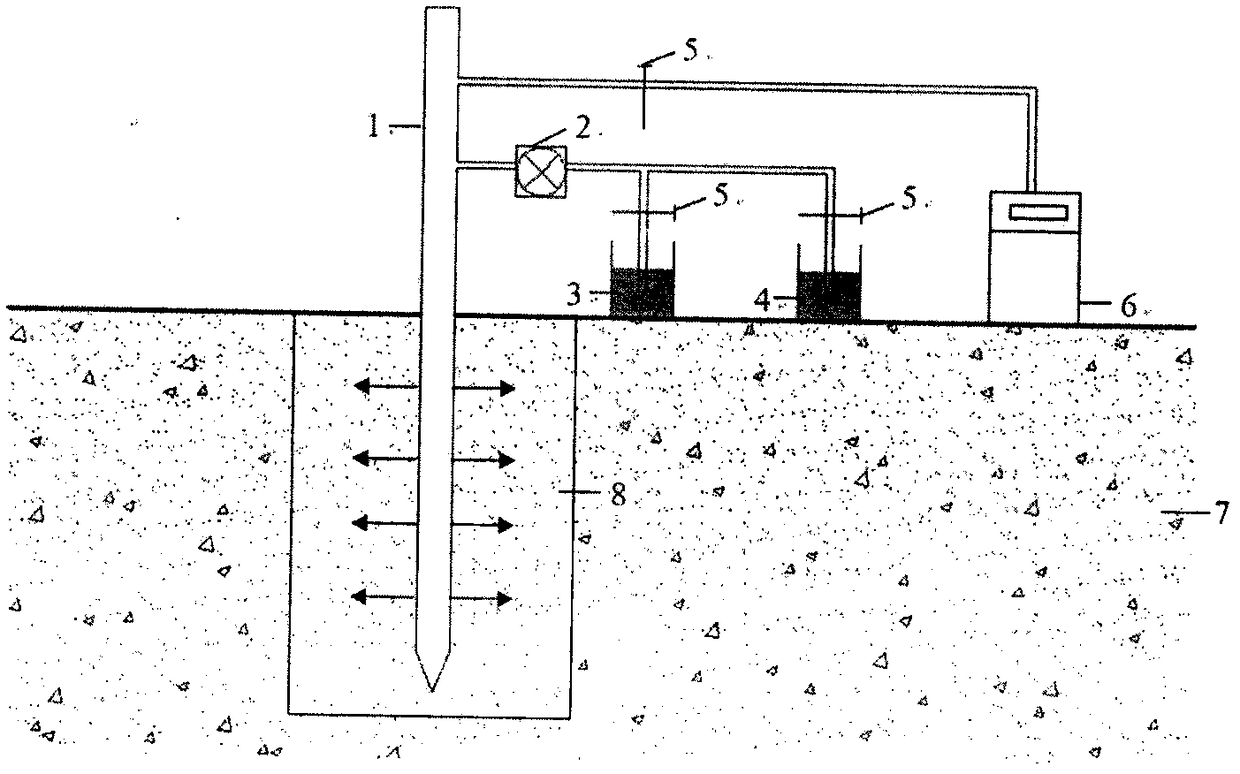

Image

Examples

Embodiment 1

[0046] In this example, the gold tailings slag microbial composite treatment and application method is used to treat the tailings slag foundation, and the method includes the following steps:

[0047] (1) Grinding: crushing and grinding the agglomerated tailings slag;

[0048] (2) Bacterial strain collection and cultivation: Collect cyanide-reducing bacteria from the surface soil near the tailings slag containing cyanide in the tailings pond, put them into the liquid medium, and inoculate Bacillus pasteurianus in it, and separate them by streaking and different gradients After the domestication and cultivation of the cyanide-containing culture solution, the strains are expanded step by step to obtain the domesticated composite flora, which consists of Bacillus pasteurii, Bacillus subtilis, Bacillus pumilus ) or one or a combination of Bacillus megaterium. 1L of liquid medium contains 5.0g of soybean peptone, 15.0g of tryptone, 5.0g of sodium chloride and 10g of urea. The pH o...

Embodiment 2

[0059] In this example, the gold tailings slag microbial composite treatment and application method is used to treat the tailings slag foundation, and the method includes the following steps:

[0060] (1) Grinding: crushing and grinding the agglomerated tailings slag;

[0061] (2) Bacterial strain collection and cultivation: Collect cyanide-reducing bacteria from the surface soil near the tailings slag containing cyanide in the tailings pond, put them into the liquid medium, and inoculate Bacillus pasteurianus in it, and separate them by streaking and different gradients After the domestication and cultivation of the cyanide-containing culture solution, the strains are expanded step by step to obtain the domesticated composite flora, which consists of Bacillus pasteurii, Bacillus subtilis, Bacillus pumilus ) or one or a combination of Bacillus megaterium. 1L of liquid medium contains 5.0g of soybean peptone, 15.0g of tryptone, 5.0g of sodium chloride and 10g of urea. The pH o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com