Patents

Literature

105 results about "Tee connector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tee connector is an electrical connector that connects three cables together. It is usually in the shape of a capital T. It is usually used for coax cables and the three connector points can be either female or male gender, and could be different or the same standard, such as F type, BNC or N type.

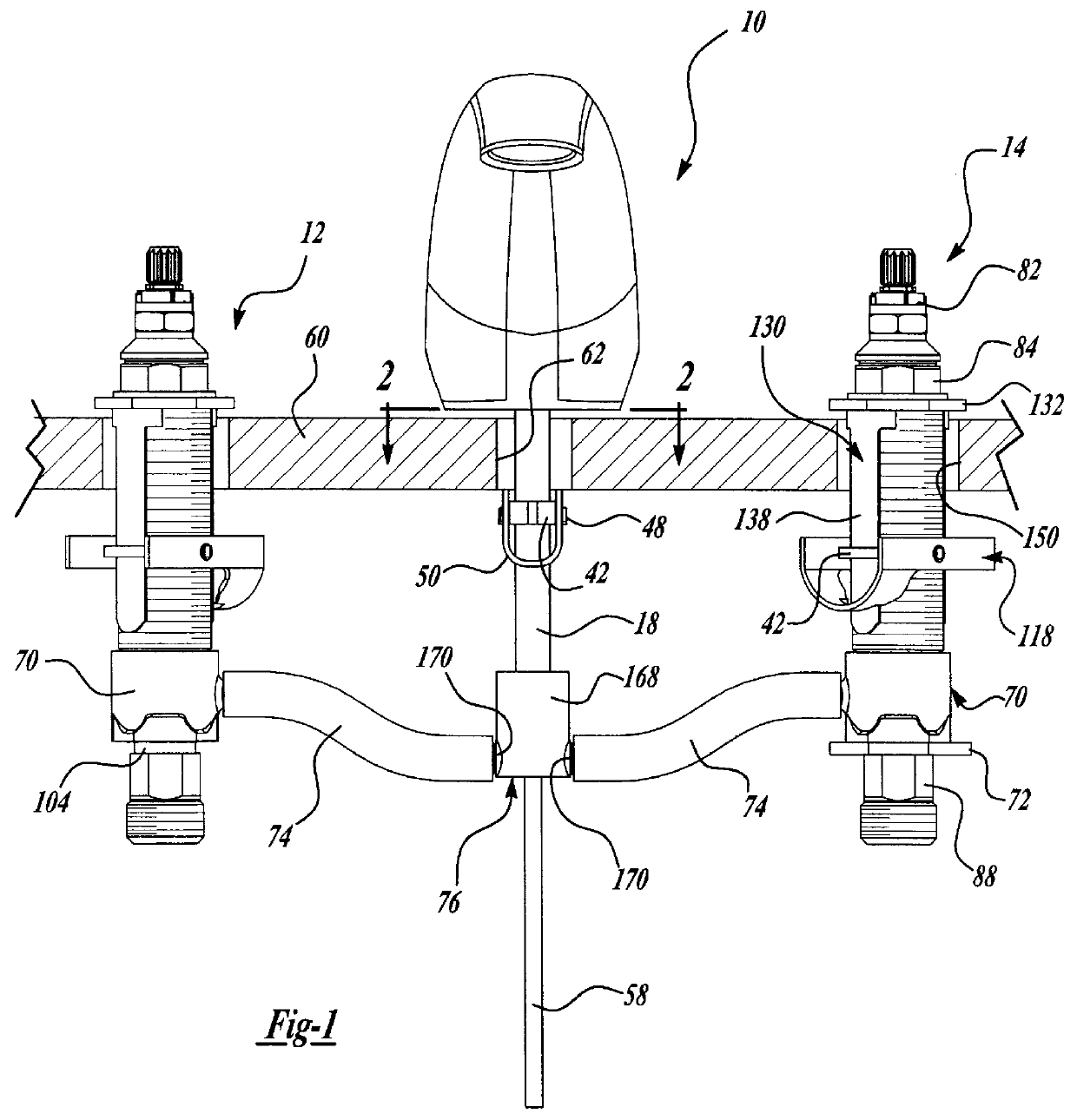

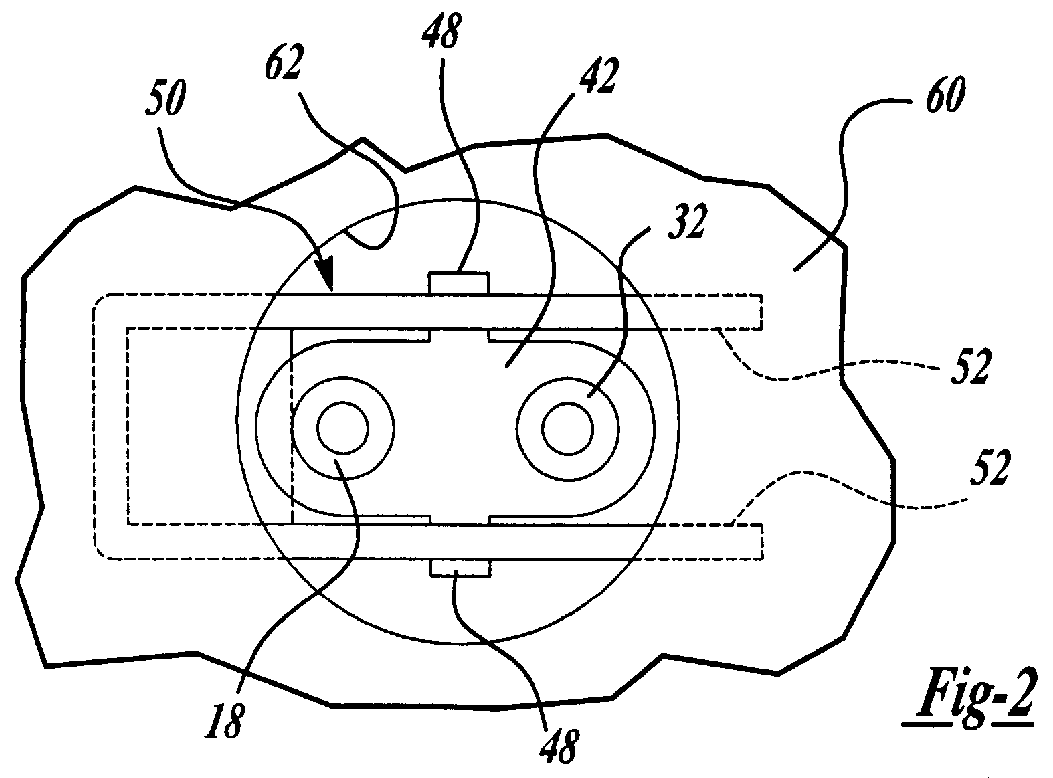

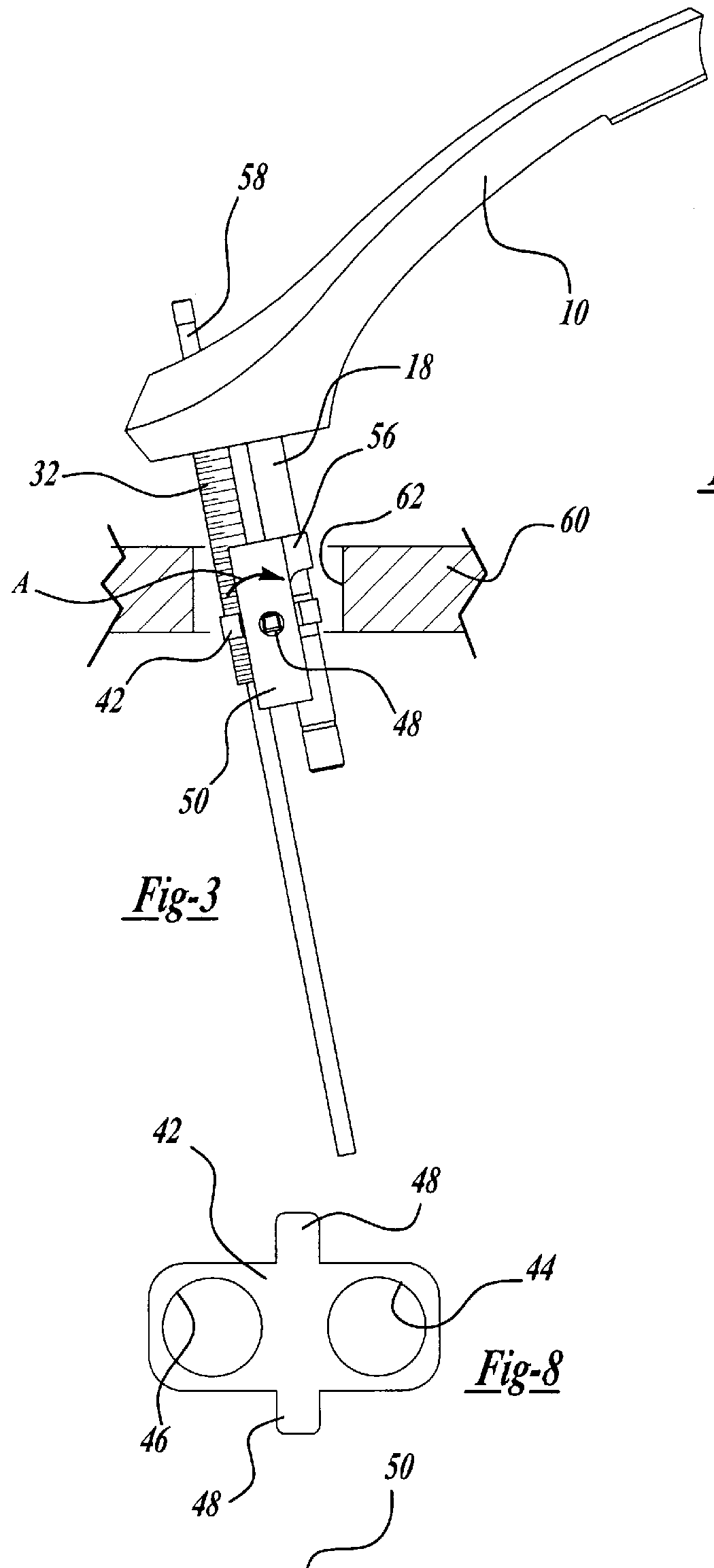

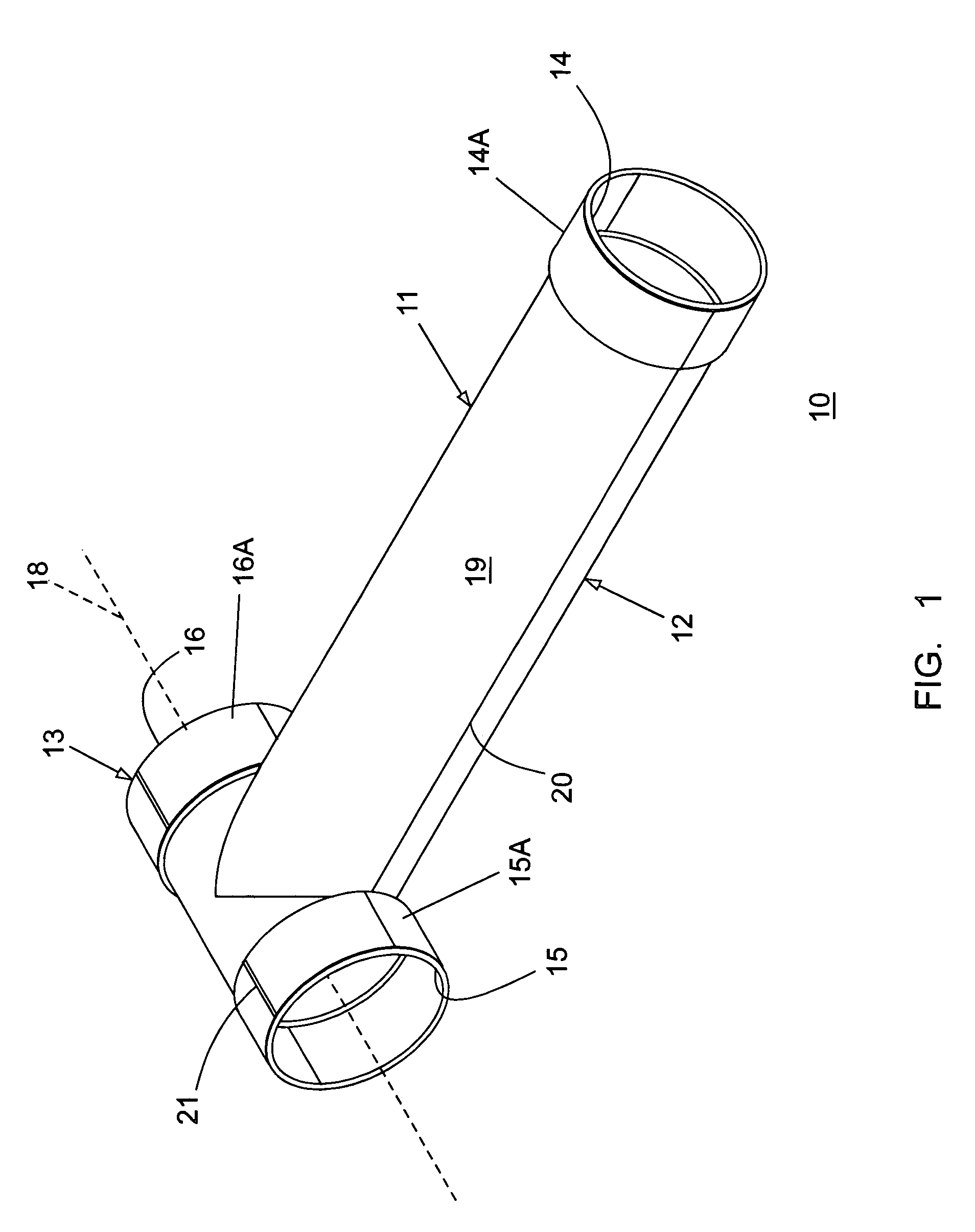

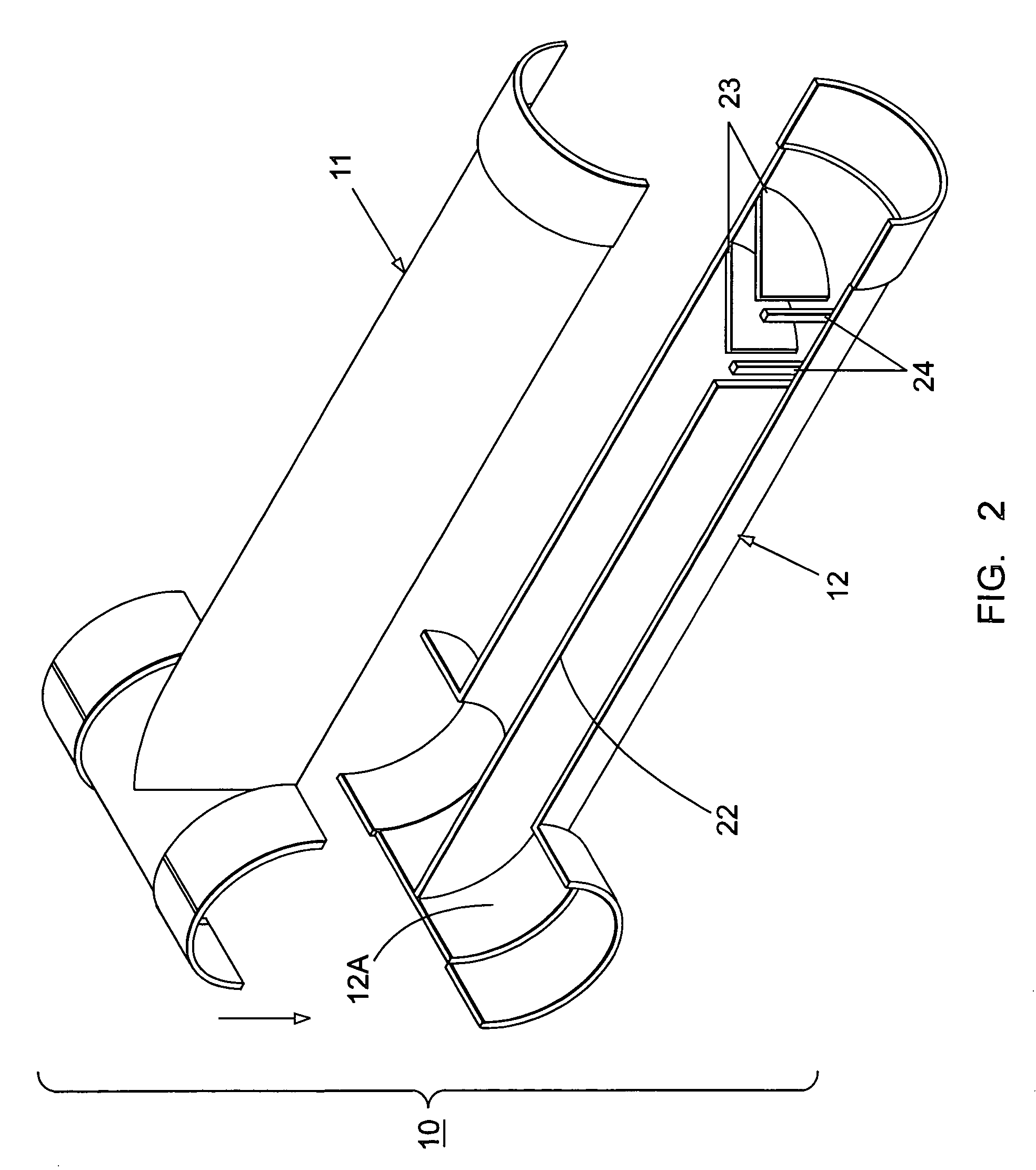

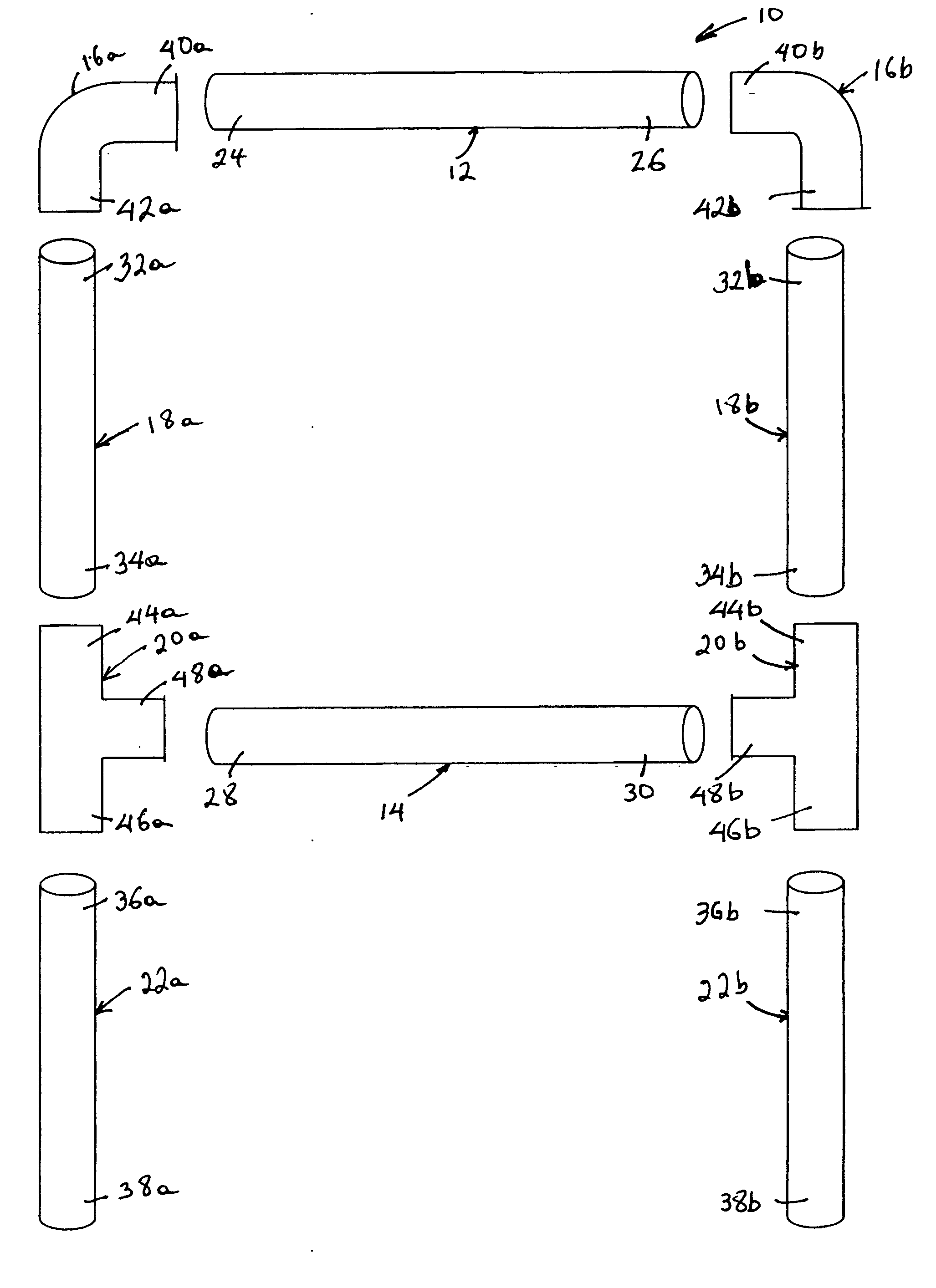

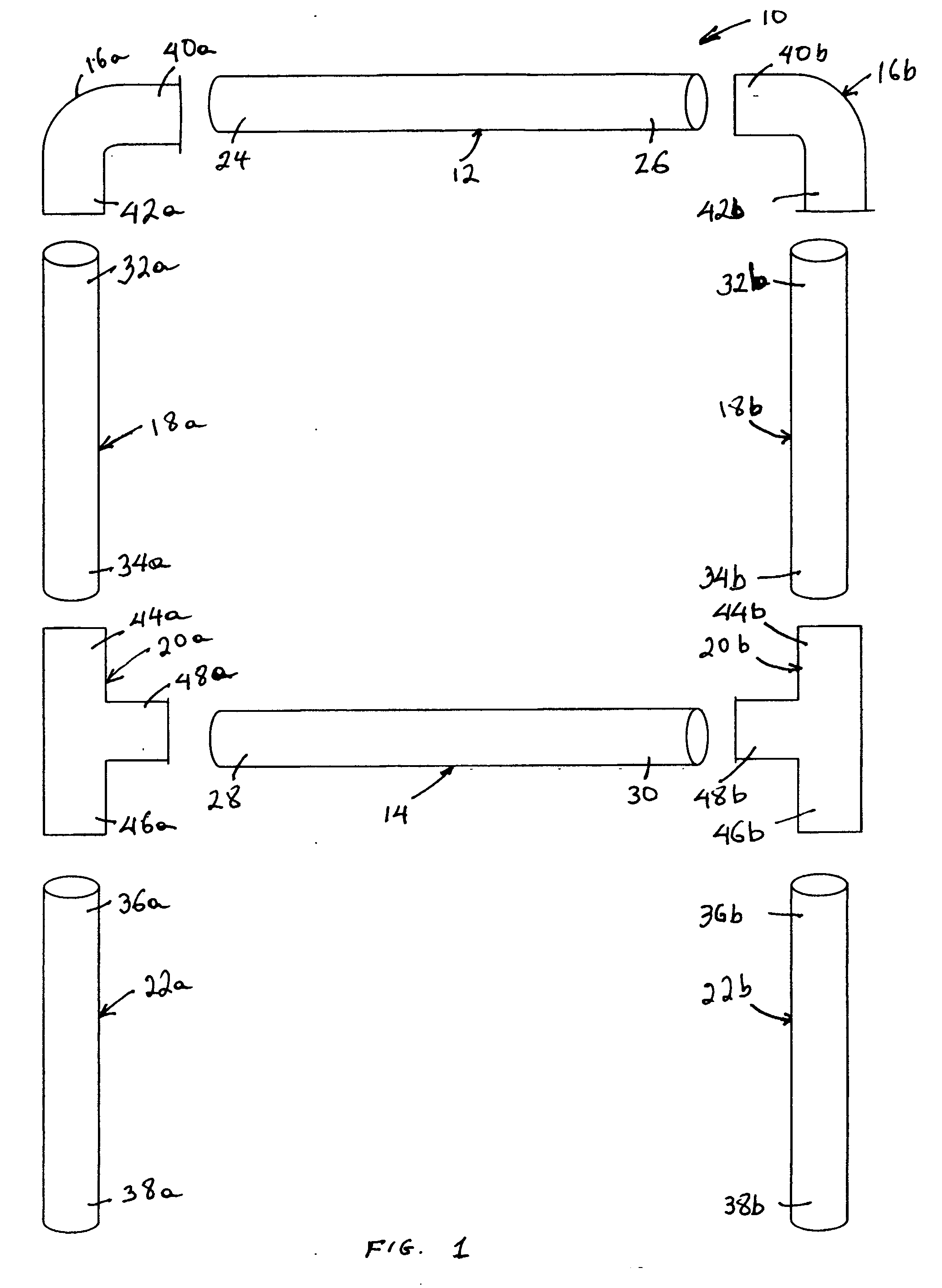

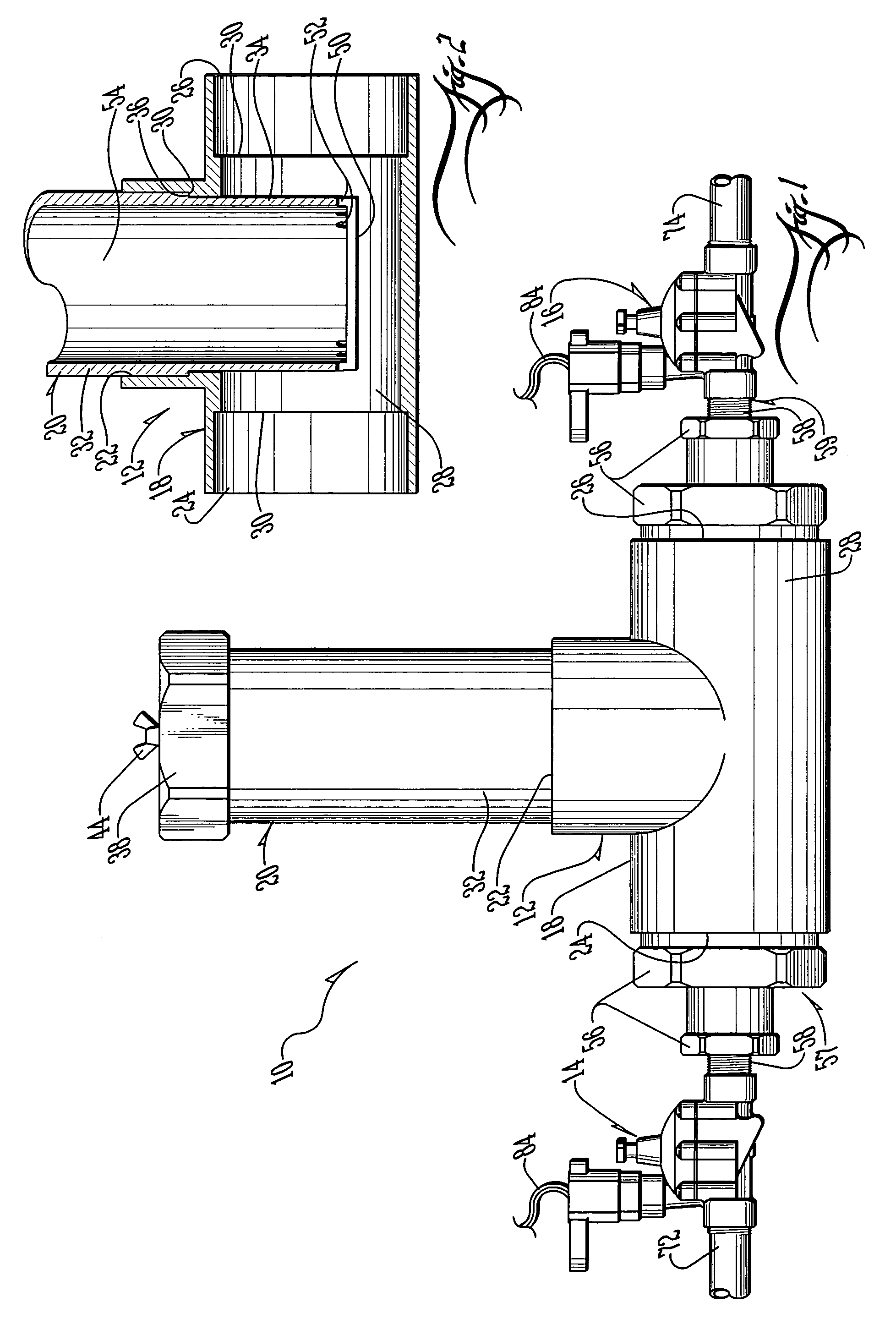

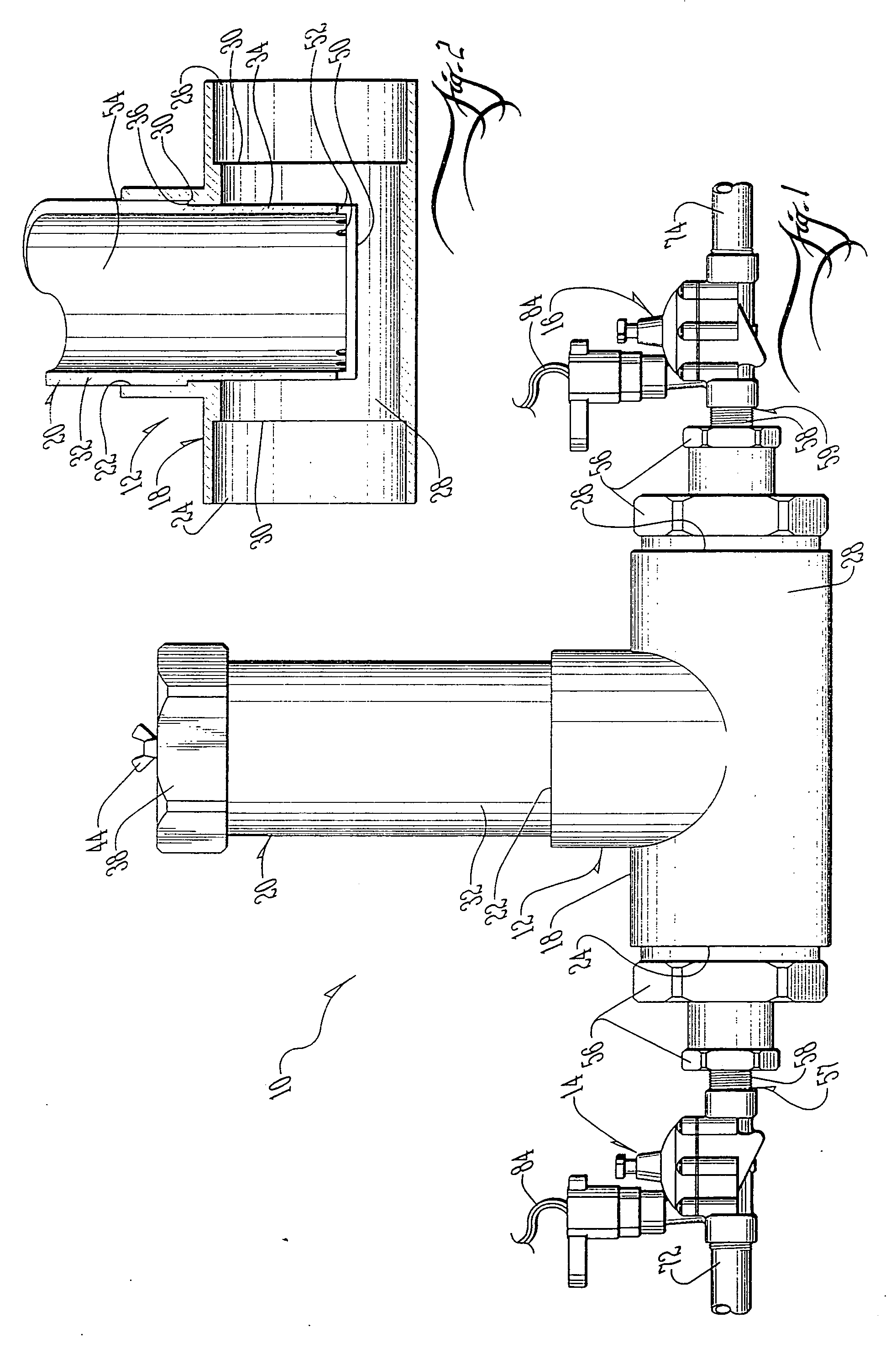

Quick connect hose assembly

InactiveUS6085784AShorten the timeReduce effortServomotor componentsDomestic plumbingMechanical engineeringTee connector

A quick connect hose assembly is provided for a widespread faucet including a spout and a pair of end bodies mounted to a deck at spaced locations from the spout. The quick connect hose assembly includes a T-connector slidably mounted on an end of a waterway tube connected to the spout. The T-connector includes a pair of serrated hose connecting portions. A pair of connector members are provided including a hollow body portion which slidably receives a bottom portion of the end bodies and an outwardly extending serrated hose connecting portion extending from the hollow body portion. A first hose is connected between the T-connector and one of the connector members and a second hose is connected between the T-connector and the other connector member.

Owner:RAYOVAC CORP

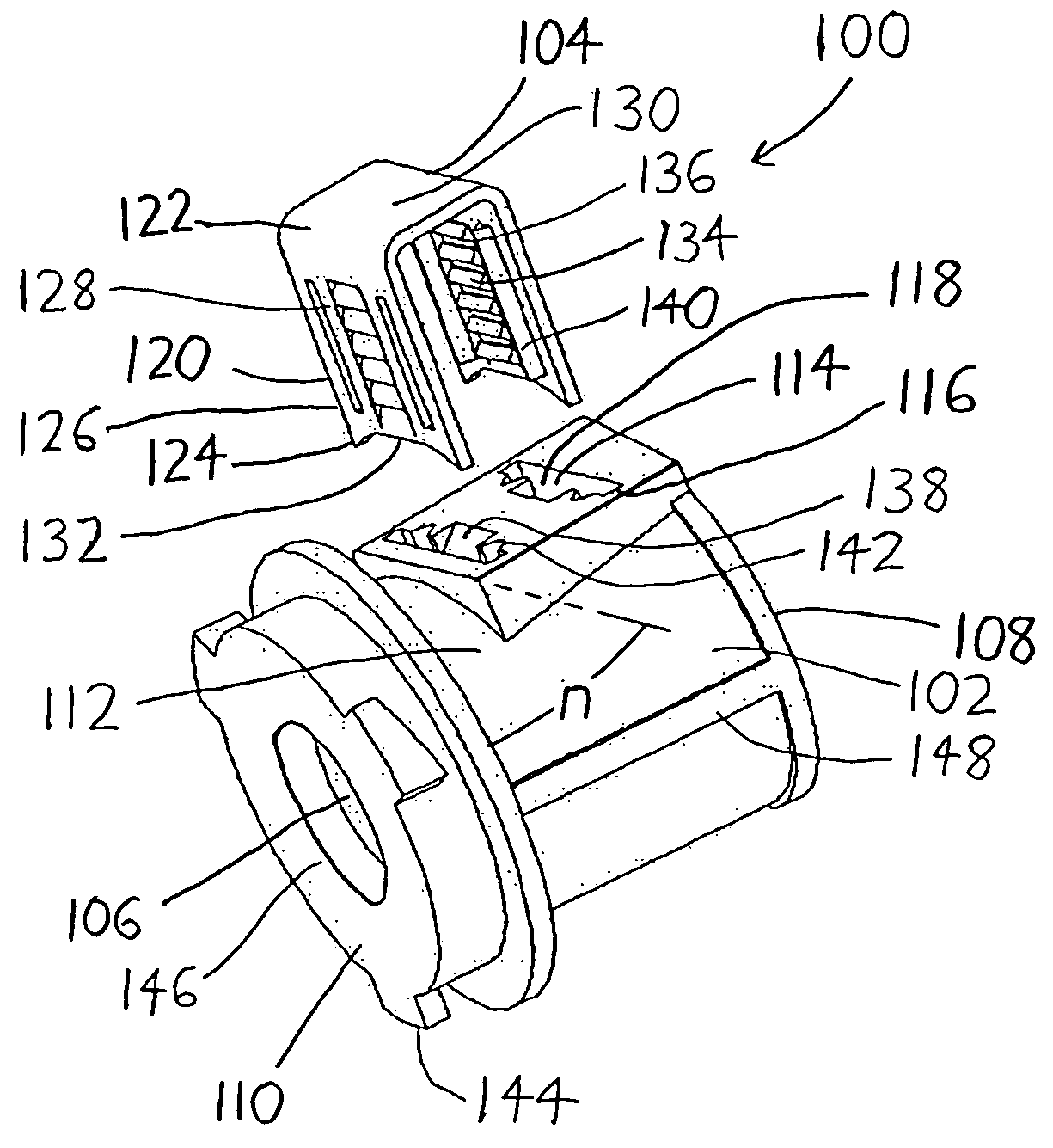

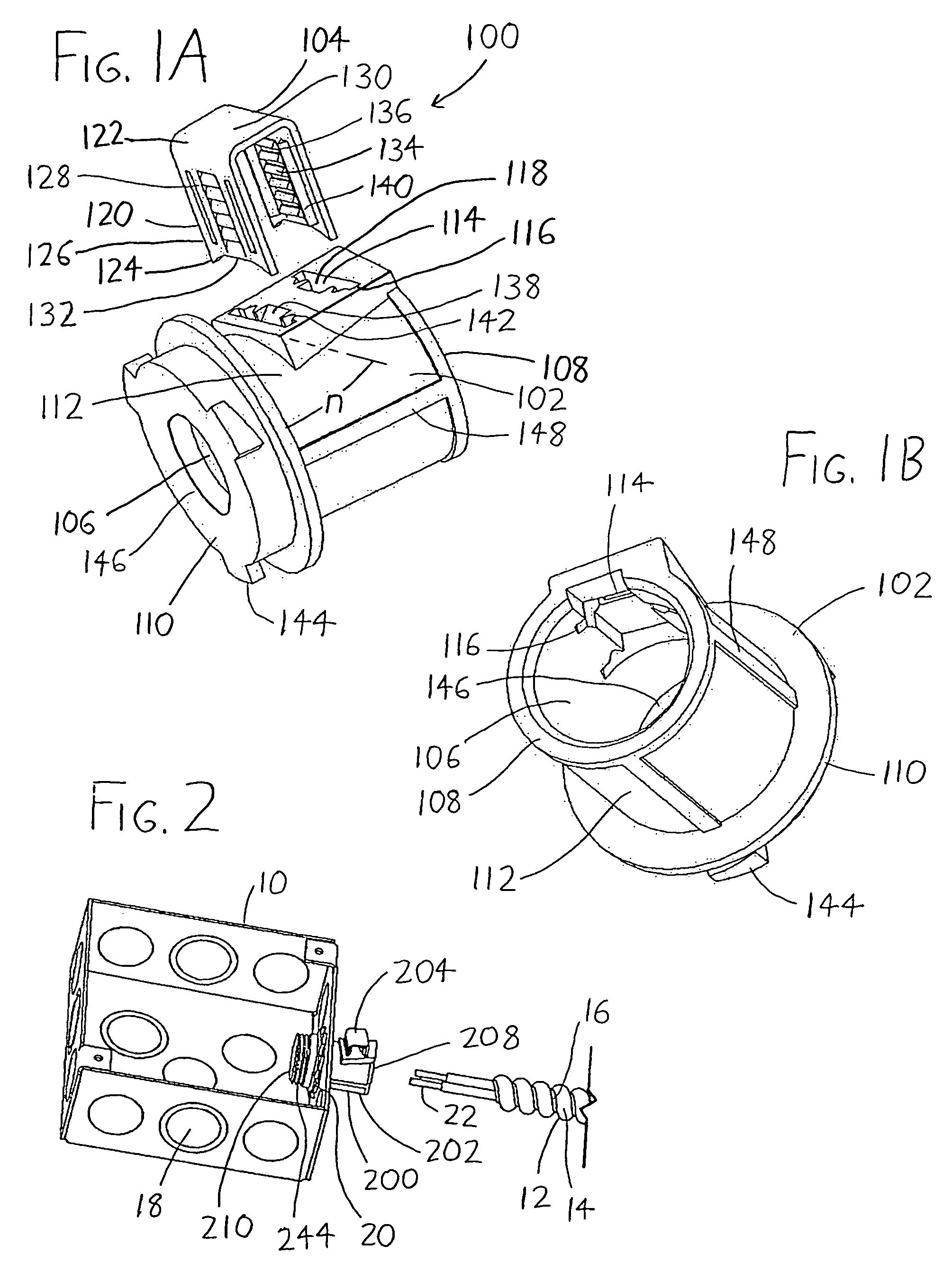

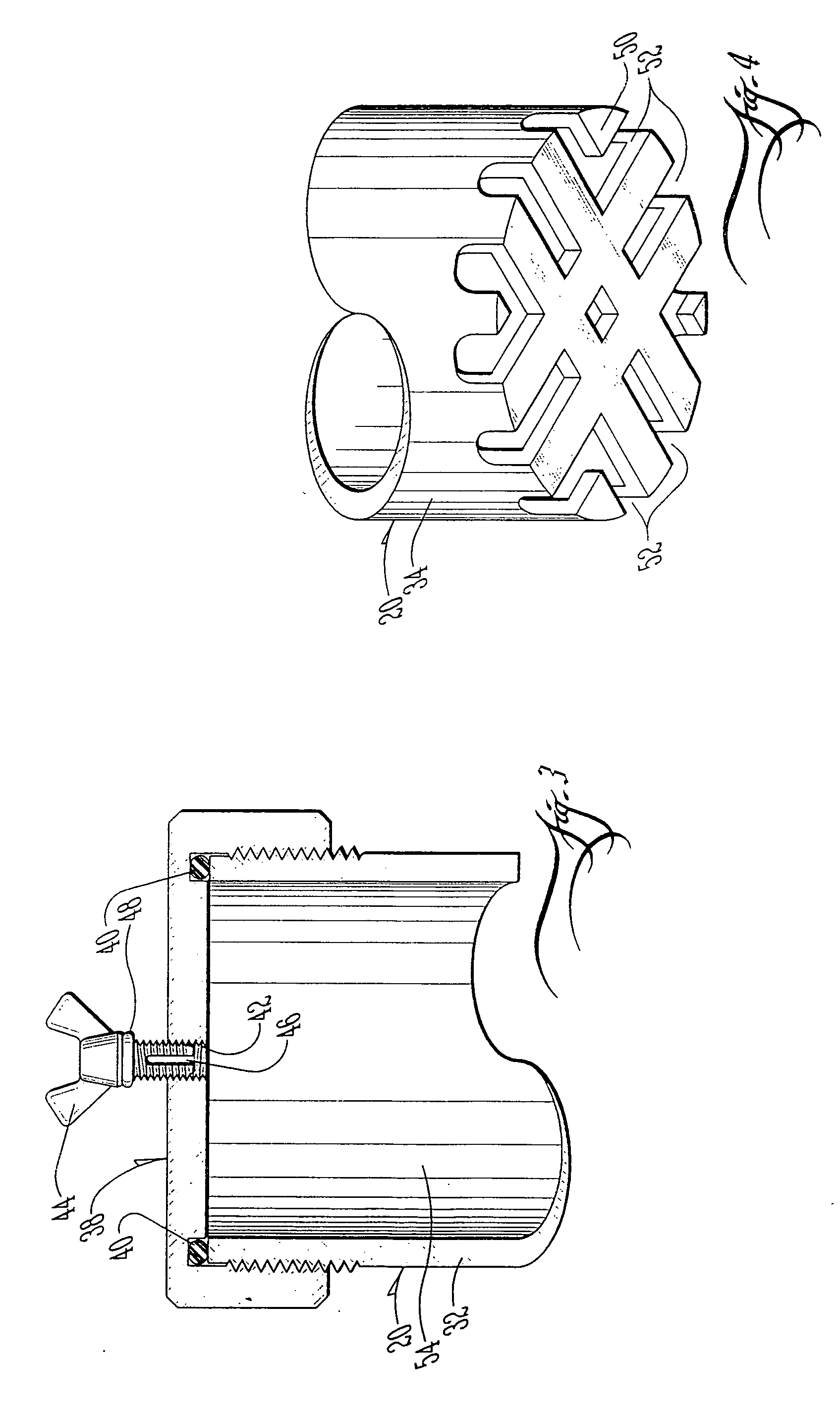

Connector for affixing cables within junction boxes

A connector for affixing cables (e.g., of the type having wires bundled within a corrugated cover) within an electrical or other junction box has a body with a first end into which the cable cover (and the wires therein) may be inserted, and a second end configured to affix to the entry of a junction box, and which is configured to allow the wires of the cable to leave the connector and extend into the junction box. The connector has an engagement member thereon with one or more engagement legs which extend into the body of the connector, and into the internal passage of the connector body into which the cable is fit, to engage the cable cover and fix the cable to the connector body.

Owner:ATKORE STEEL COMPONENTS INC

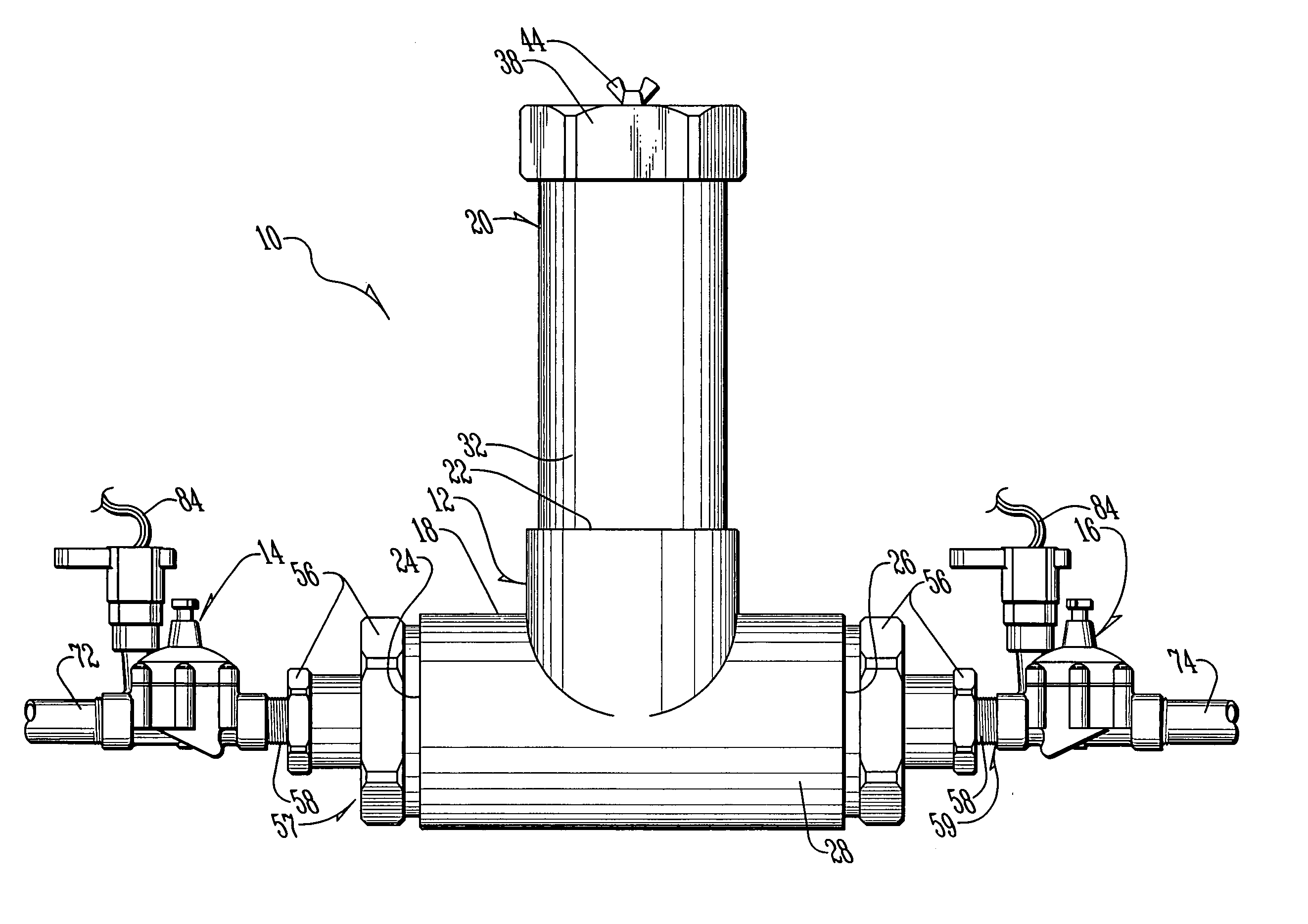

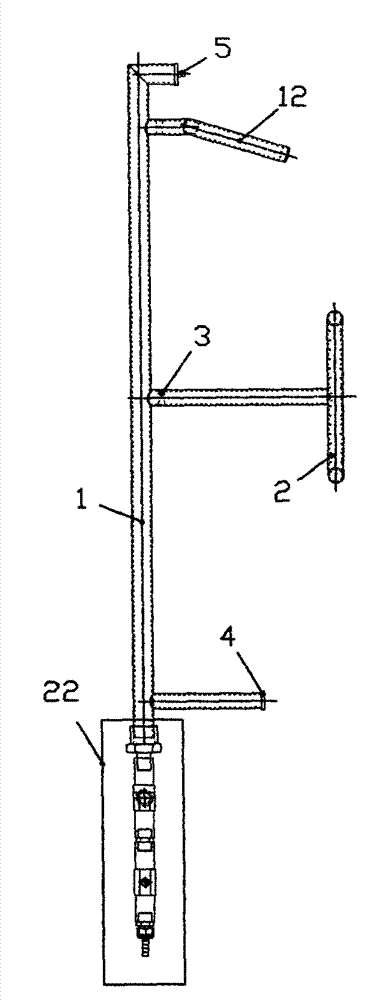

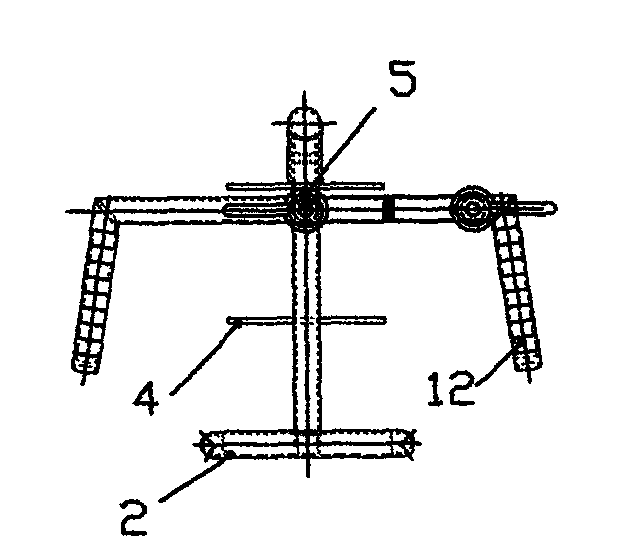

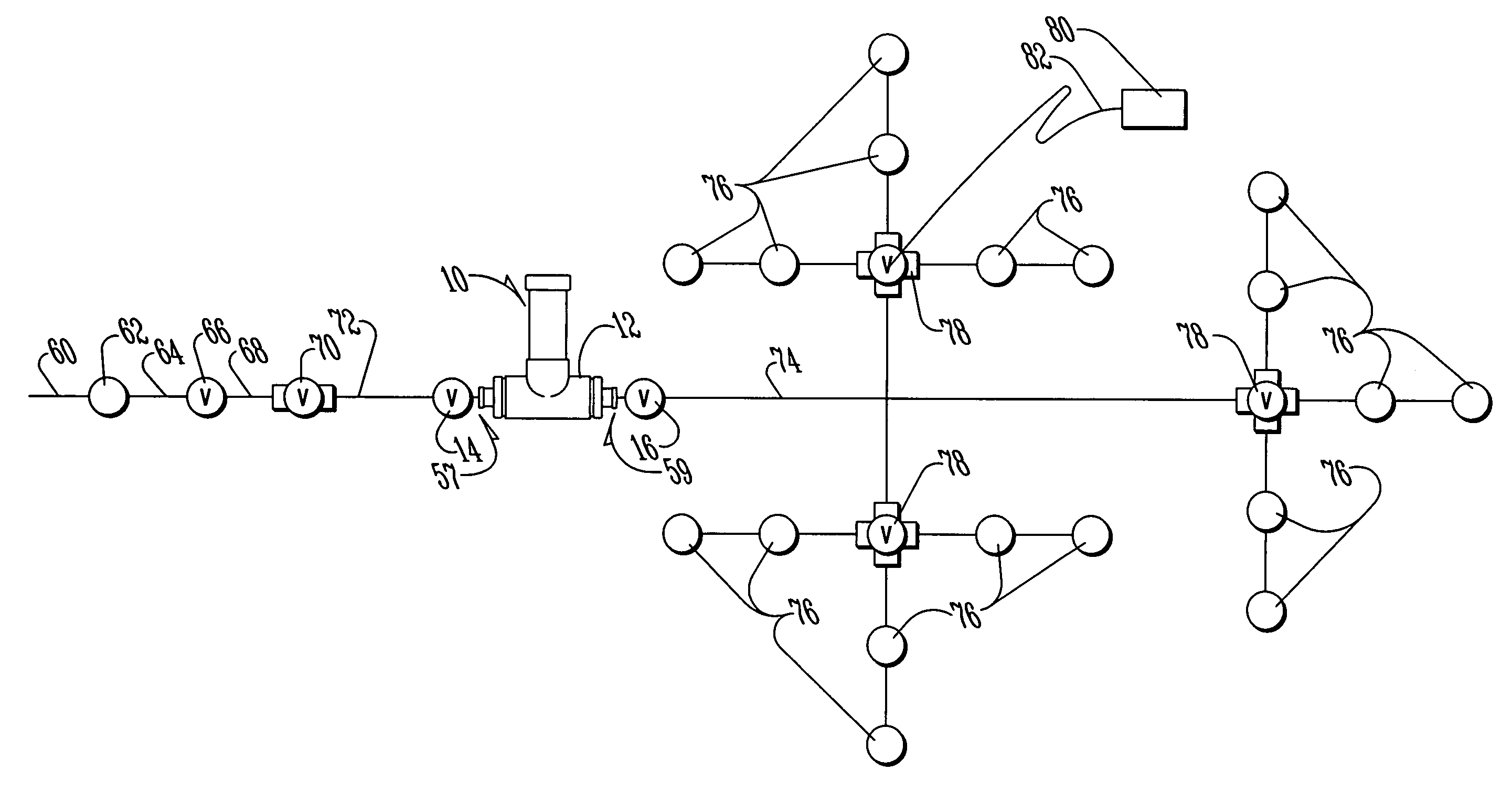

Lawn chemical application system

InactiveUS20050098649A1Easy and inexpensive to manufactureEasy and inexpensive to and installSelf-acting watering devicesWatering devicesCompound (substance)Water flow

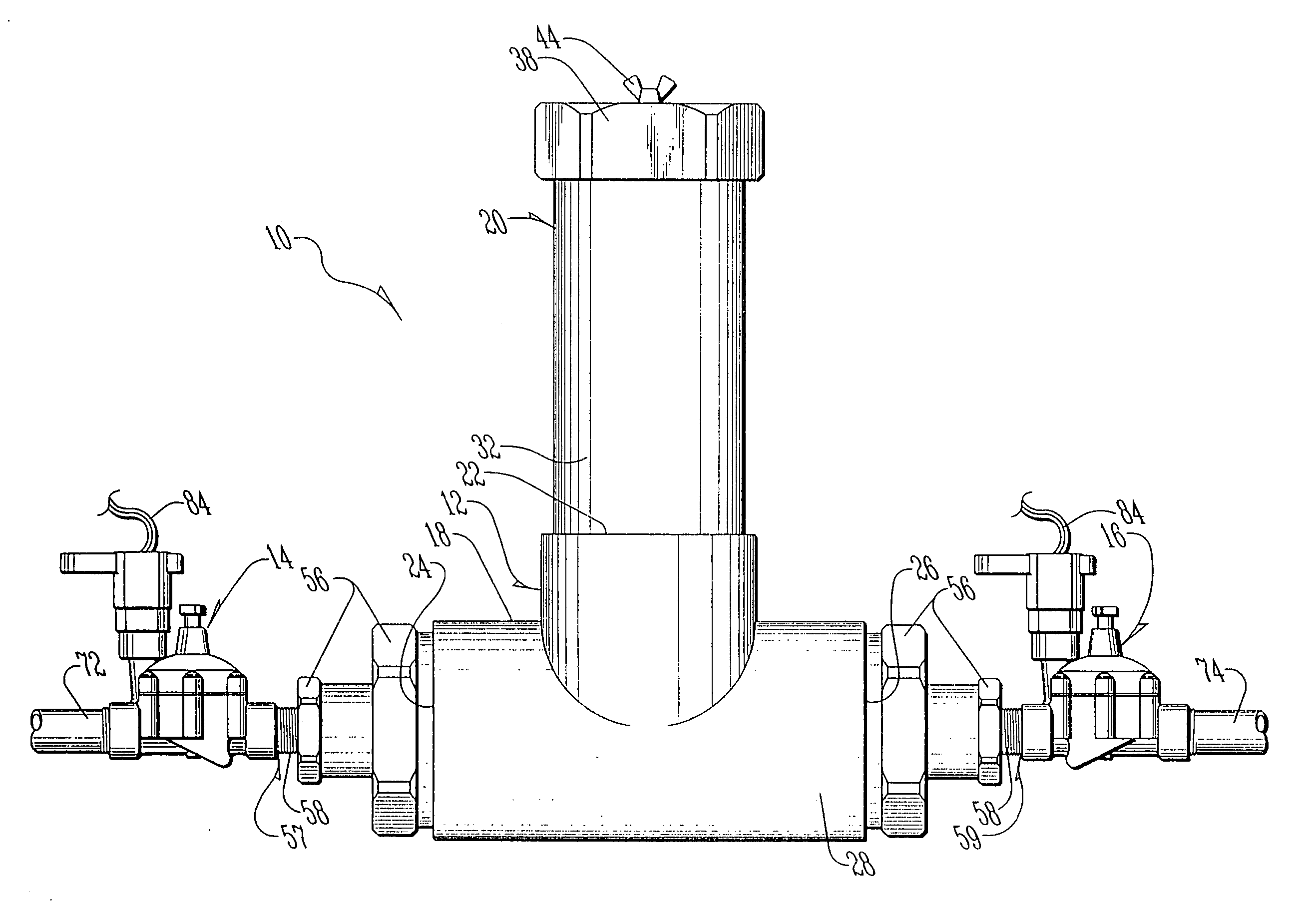

A lawn chemical application system is disclosed. The system comprises a dispenser having a lower chamber, an upper chamber, an upstream opening, and a downstream opening. The dispenser may be formed by a tee connector and a cylinder secured to an upper opening of the tee connector. Powered valves are operably connected to the upstream and downstream openings of the dispenser. The powered valves may be wired to open and close simultaneously. A lower portion of the upper chamber may be disposed below an upper portion of the lower chamber and above a lower portion of the lower chamber, leaving the lower portion of the lower chamber unobstructed over substantially its entire length. The lower portion of the upper chamber may have a plurality of openings to provide for adequate mixing of water with the chemicals stored in the upper chamber. In operation, soluble matter or other chemicals are placed in the upper chamber of the dispenser, and the two valves are opened simultaneously. Water flows through the first powered valve and into the dispenser, where the water is mixed with soluble matter or other chemicals stored in the upper chamber of the tee. The solution or mixture then passes from the dispenser, through the second powered valve, to one or more sprinkler heads of the irrigation system. When the application is finished, the valves are closed simultaneously.

Owner:THORNTON BRIAN

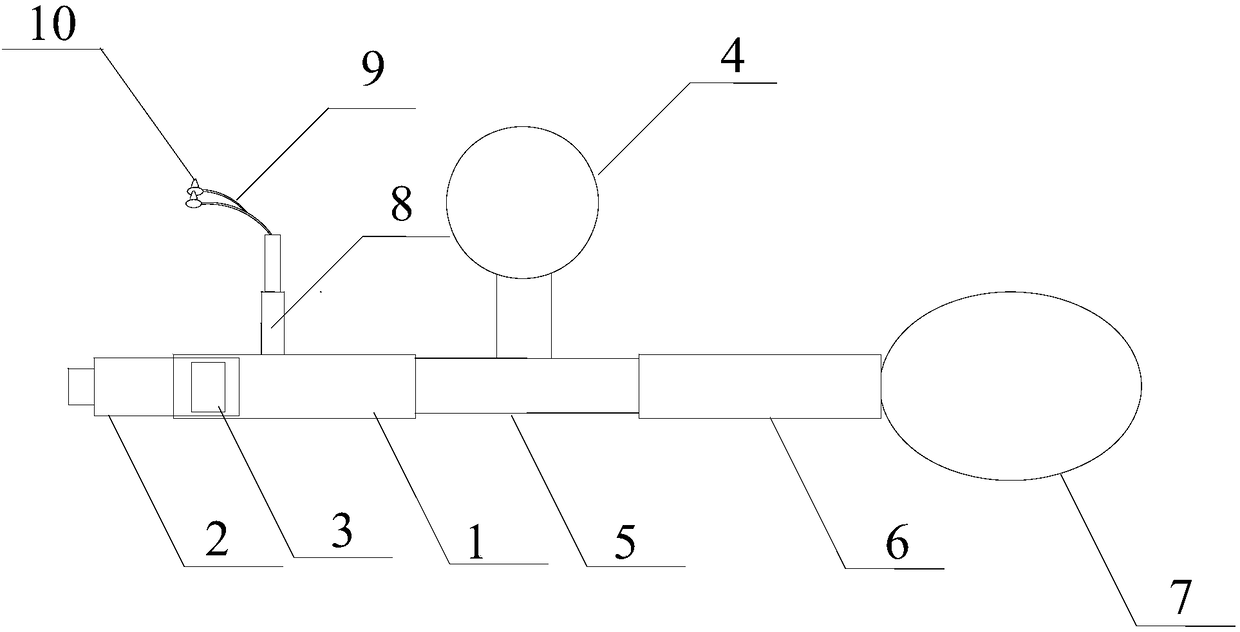

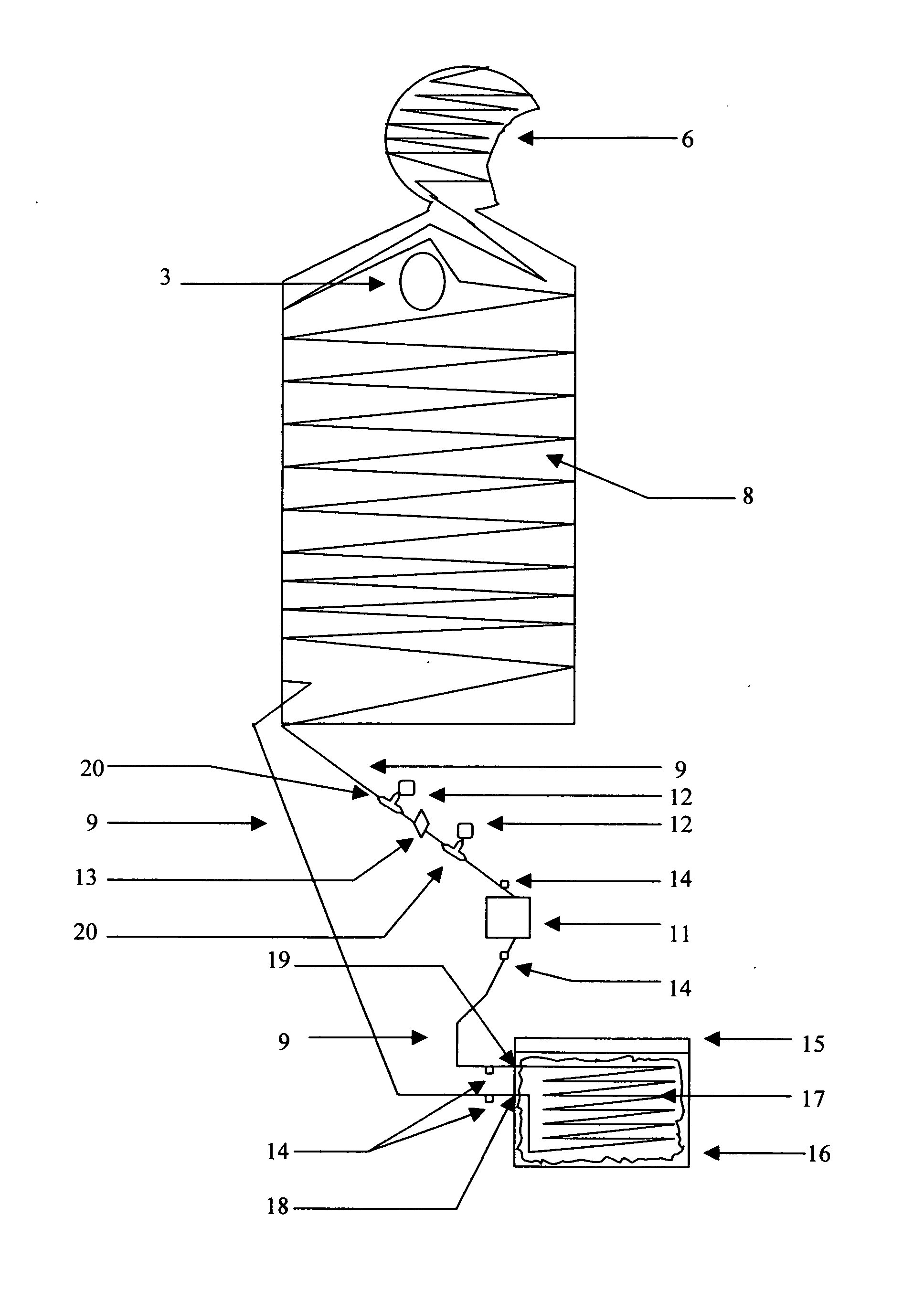

Reagent supply system for DNA (deoxyribonucleic acid) sequencer and control method

ActiveCN102707078AImprove sequencing efficiencyTimely and accurate supplyMaterial analysisPeristaltic pumpDNA sequencer

The invention discloses a reagent supply system for a DNA (deoxyribonucleic acid) sequencer. The reagent supply system comprises a preparing pipeline, a buffer pipeline, a main pipeline, a first multi-pass reversing valve, a second multi-pass reversing valve, a first peristaltic pump for extracting a sequencing reaction reagent and a second peristaltic pump for extracting buffer liquid, wherein the preparing pipeline, the buffer pipeline and the main pipeline are connected through a tee connector, inlets of the first multi-pass reversing valve are respectively communicated with reagent bottles; an outlet of the first multi-pass reversing valve is connected with the preparing pipeline through the first peristaltic pump; an outlet of the second peristaltic pump is connected with the buffer pipeline; an inlet of the second multi-pass reversing valve is connected with the main pipe, and outlets of the second multi-pass reversing valve are respectively communicated with a liquid inlet of areaction cabin and a waste liquor bucket. The invention also discloses a control method of the reagent supply system. According to the reagent supply system disclosed by the invention, the reagent and buffer liquid can be immediately and accurately supplied to a plurality of reaction cabins, so a plurality of reactions are carried out at the same time, a plurality of samples can be sequenced at the same time, and the sequencing efficiency of the DNA is greatly improved.

Owner:BEIJING INST OF GENOMICS CHINESE ACAD OF SCI CHINA NAT CENT FOR BIOINFORMATION +1

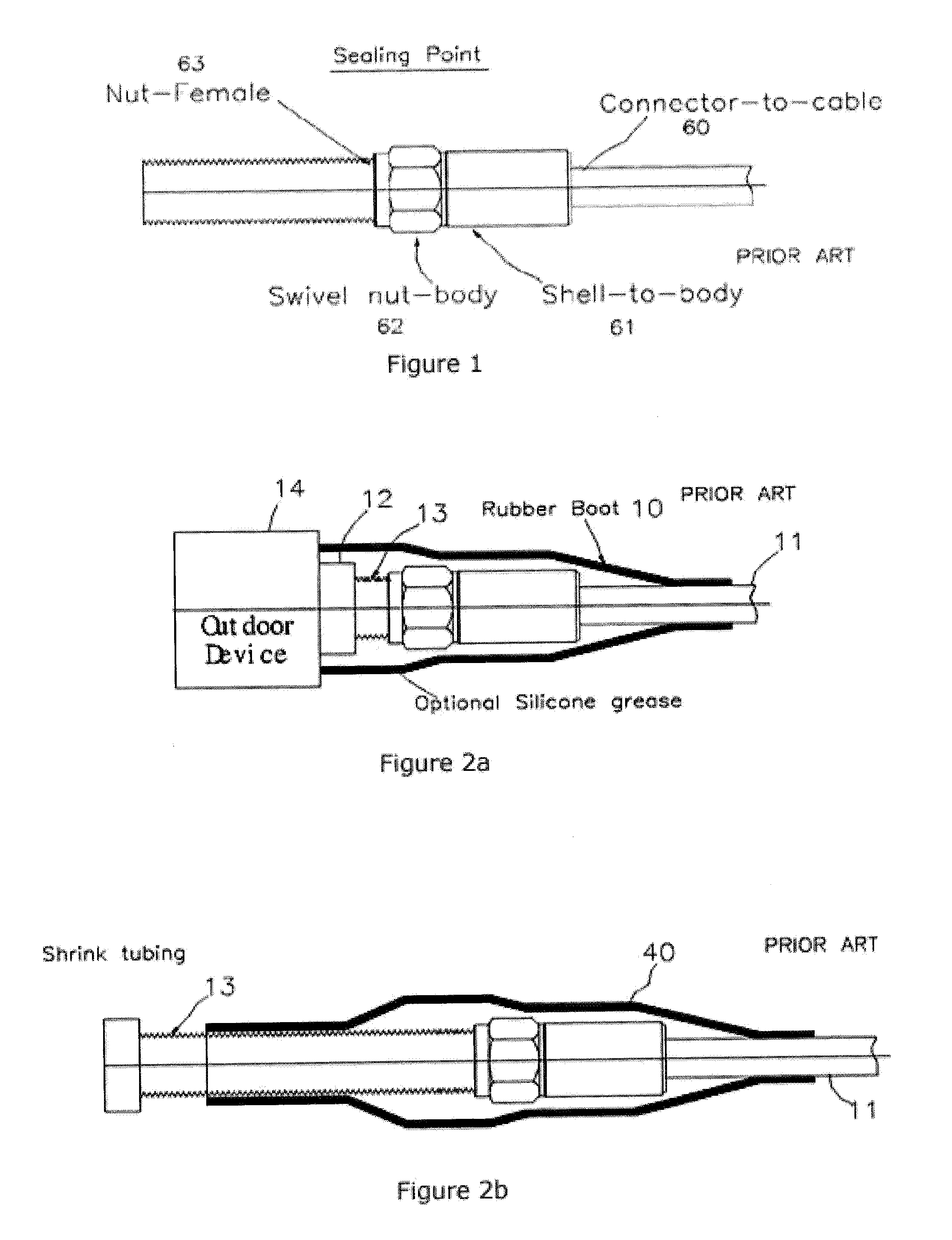

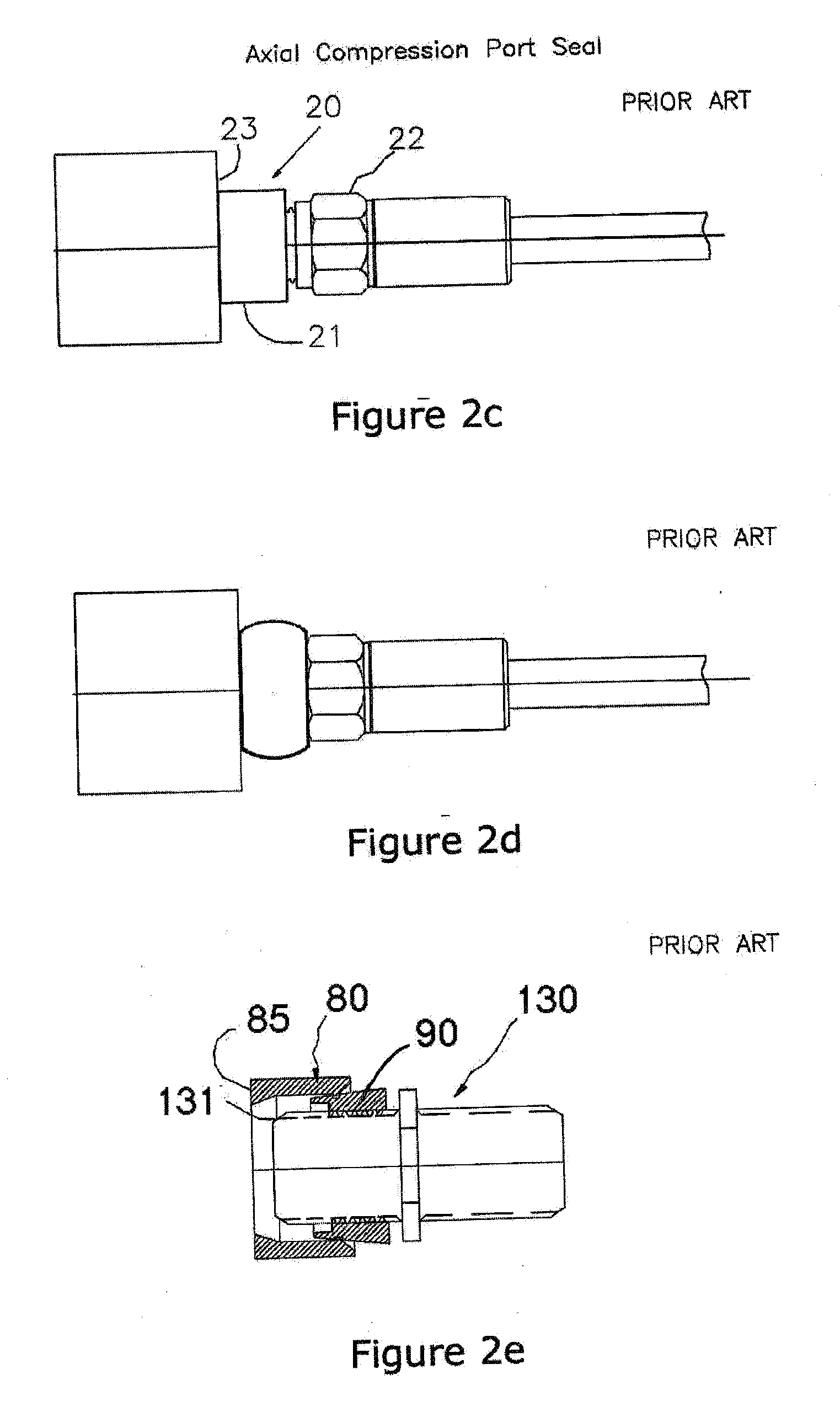

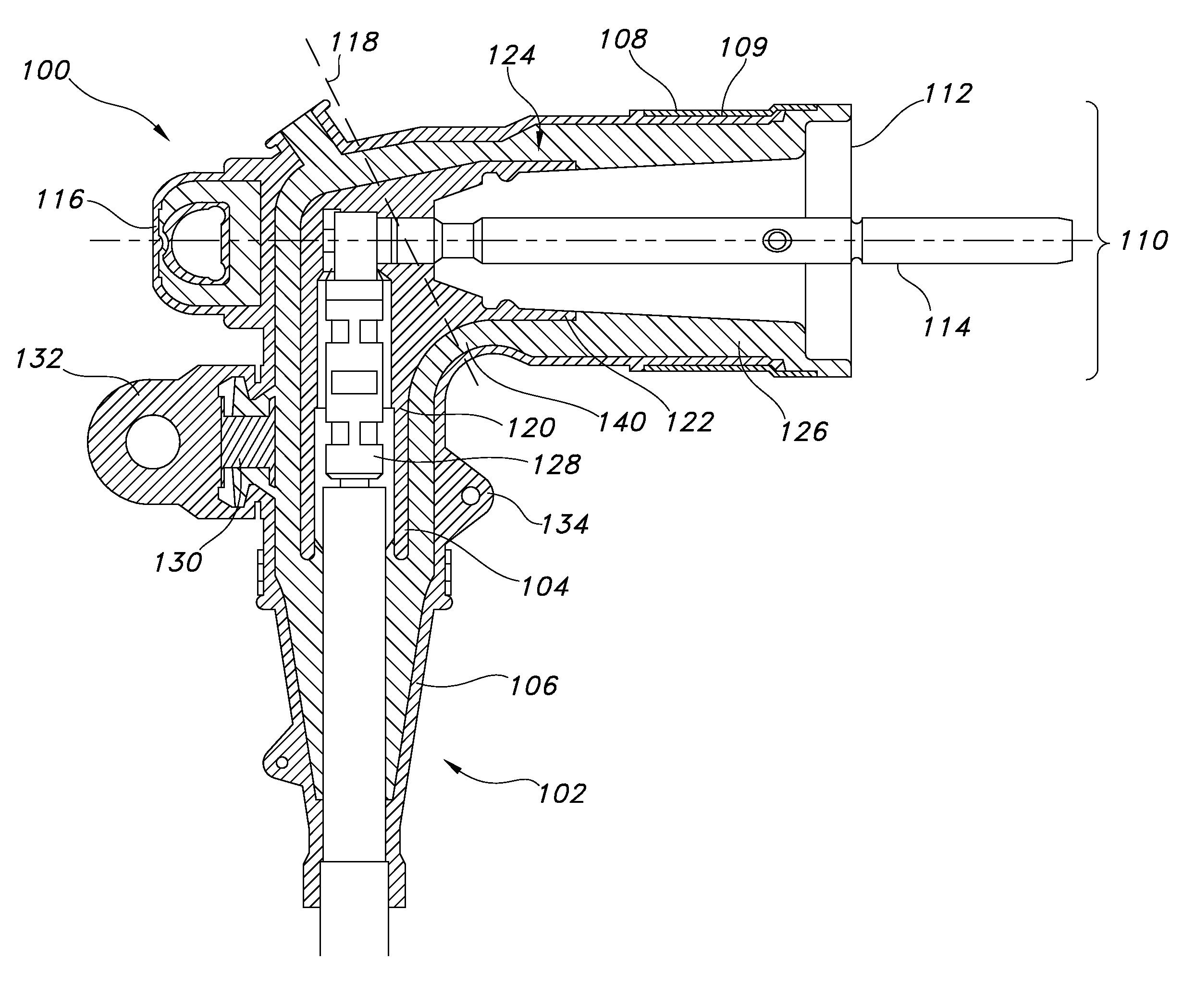

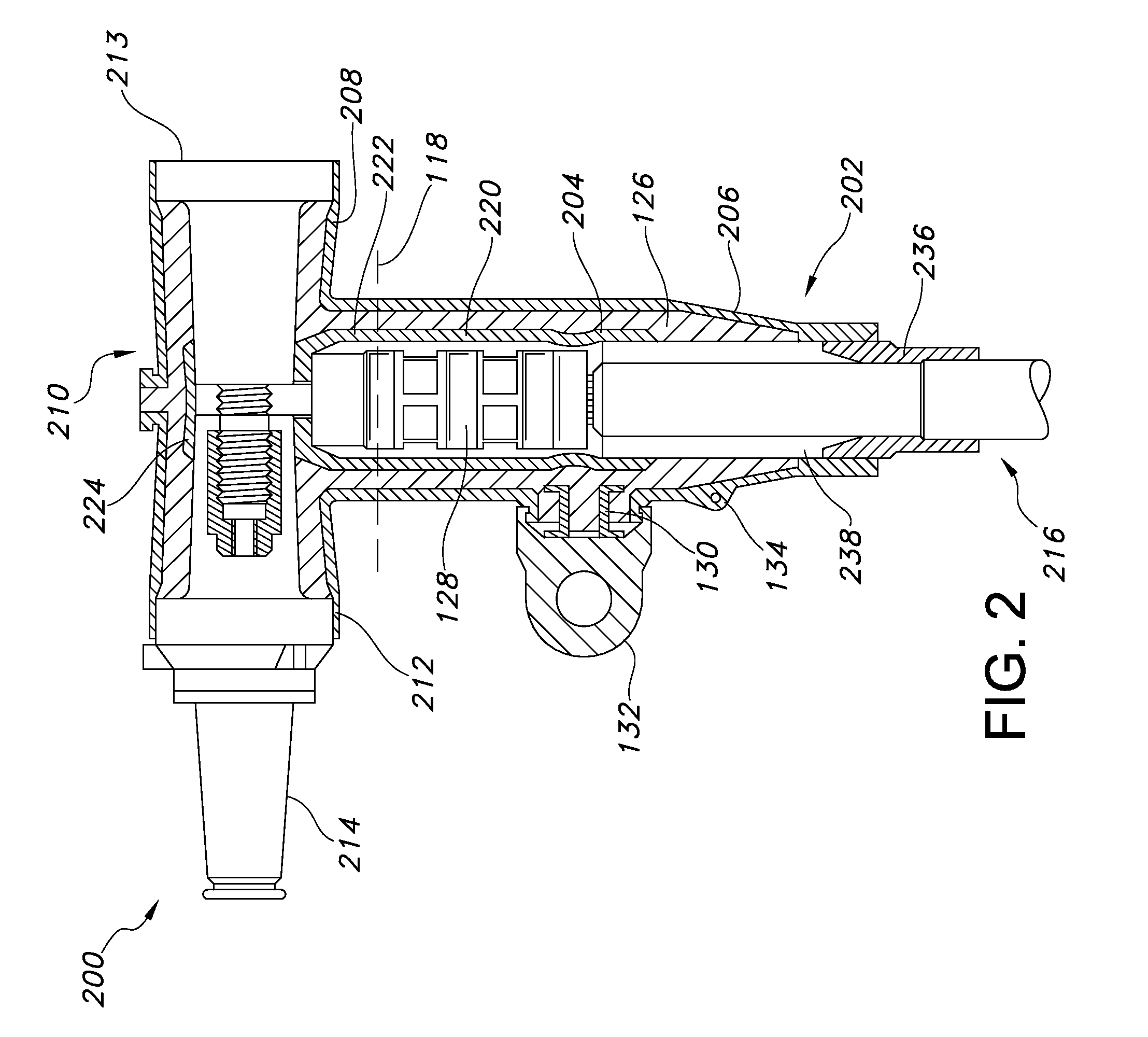

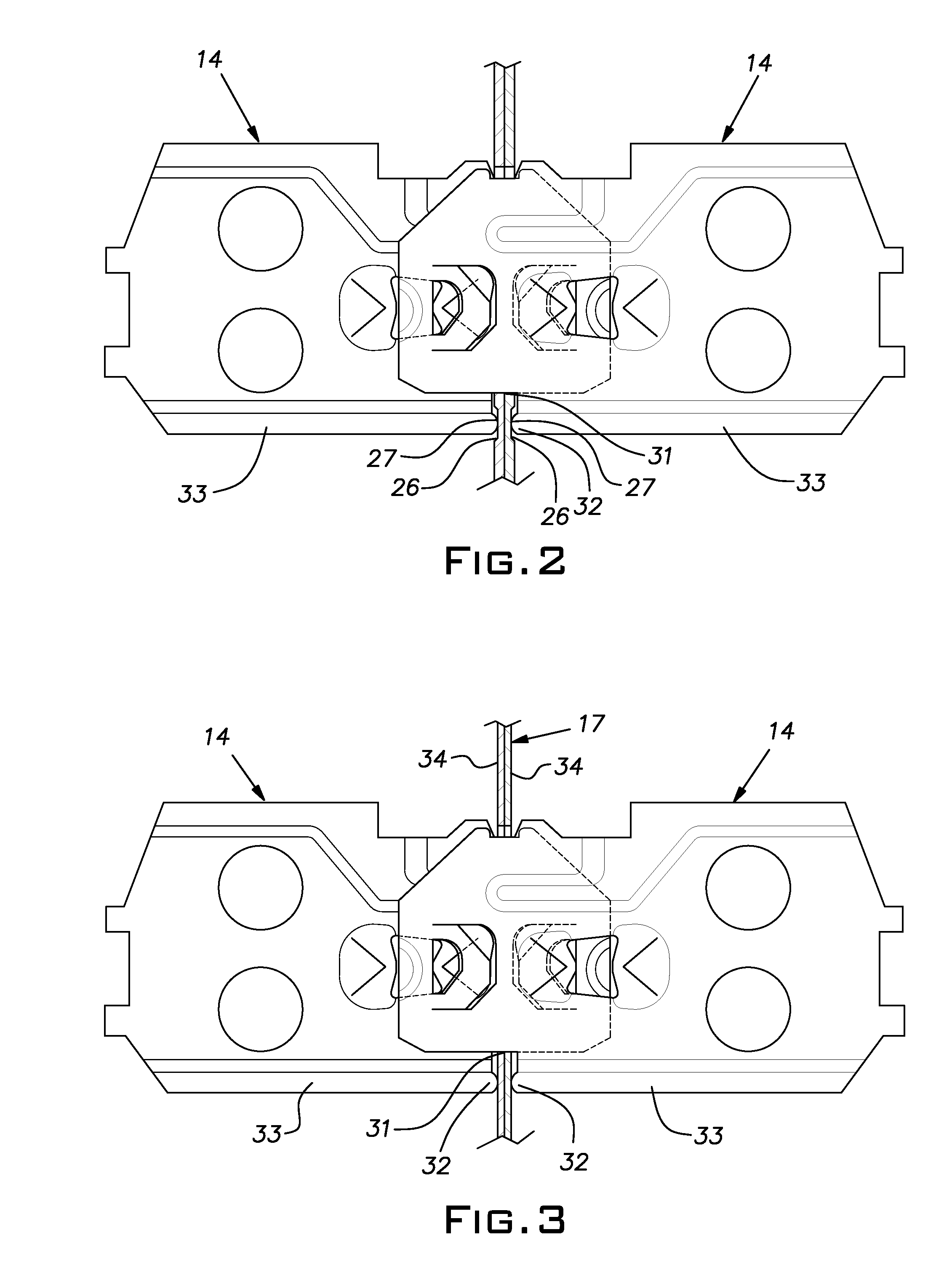

Coaxial cable connector with internal pressure seal

ActiveUS20090114424A1Prevent moistureLine/current collector detailsTwo pole connectionsInternal pressureCoaxial cable

A coaxial cable connection incorporating F-Type connectors and including a male connector for connecting an RG-6 or smaller coaxial cable incorporates an internal element for preventing moisture ingress and / or preventing loosening of a male connector from a female connector.

Owner:HOLLAND ELECTRONICS

Two-material separable insulated connector

ActiveUS20090215299A1Reduce disadvantagesGood flexibilityContact member cases/bases manufactureWave amplification devicesPliabilityEngineering

Stiff and soft materials each provide certain advantages when used in the manufacture of separable insulated connectors, such as elbow and T-body connectors. Utilizing a shell or an insert that includes one section made from a stiff material and one section made from a soft material can provide a separable insulated connector that capitalizes on the advantages associated with both types of materials. The stiff materials and soft materials can be placed strategically on the shell or insert of the separable insulated connector to maximize the advantages of each material. For example, the stiff material can be used to form a section of the separable insulated connector where strength and durability is most desirable, and conversely, the soft material can be used to form a section of the connector where flexibility is desirable.

Owner:EATON INTELLIGENT POWER LIMITED

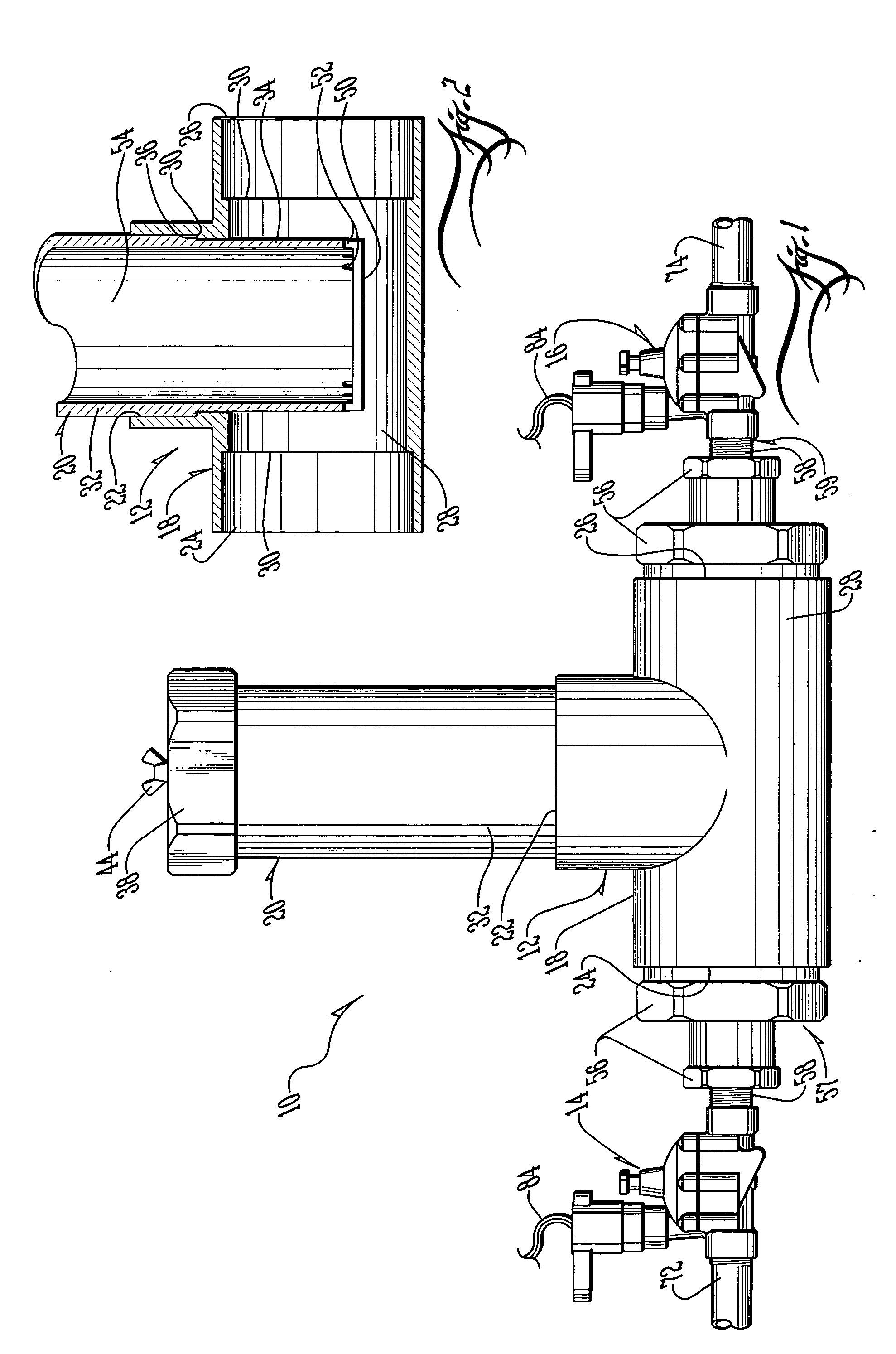

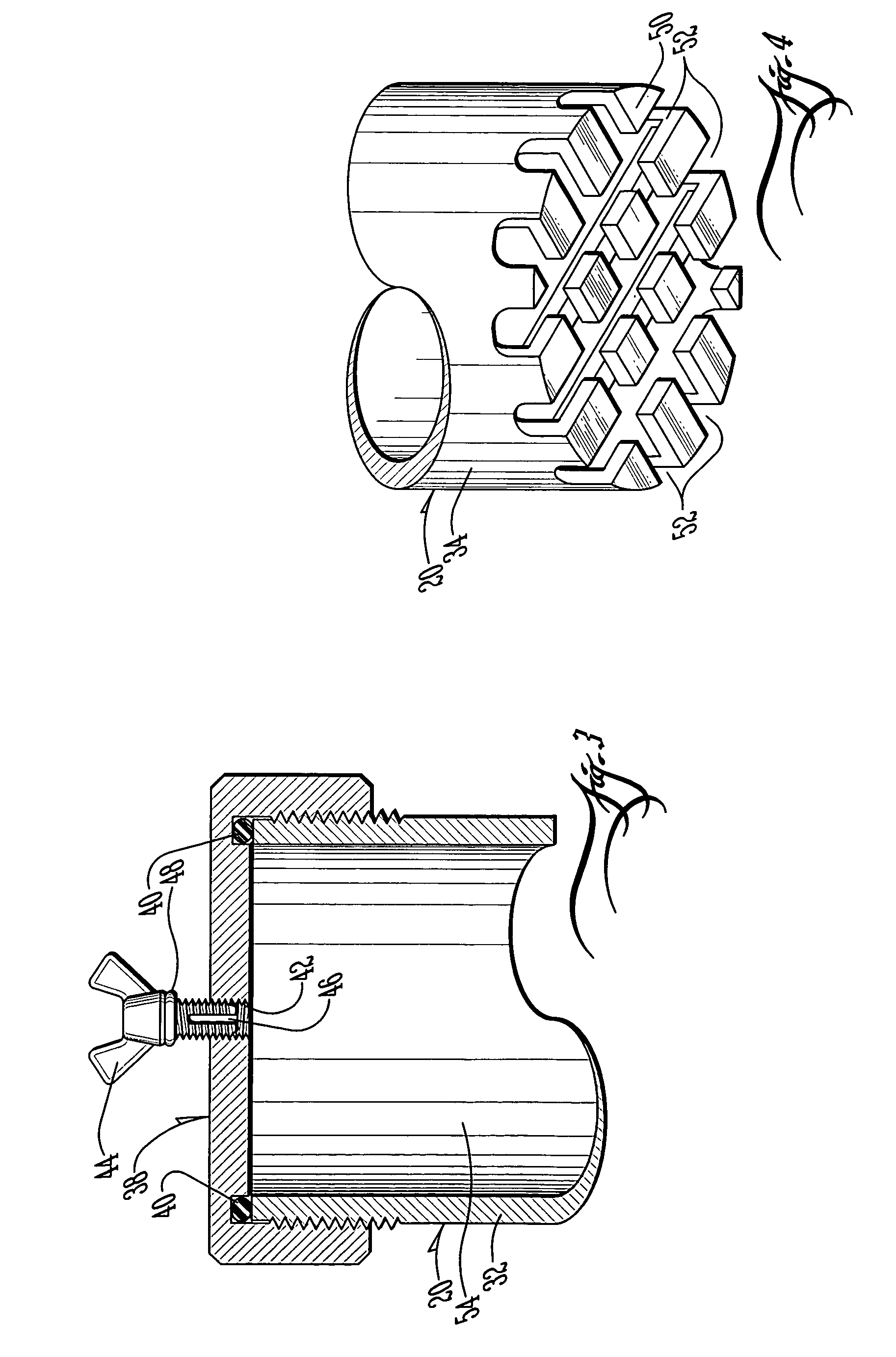

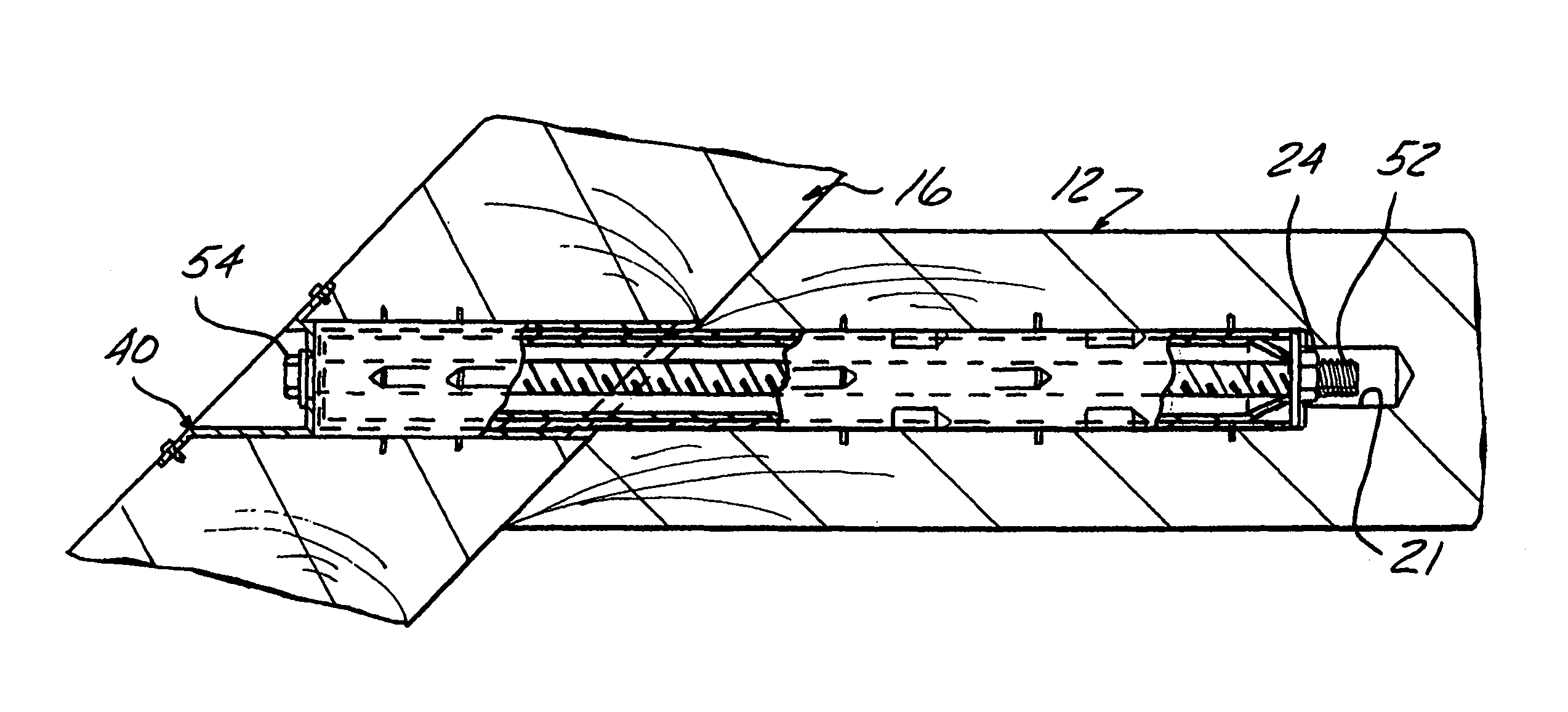

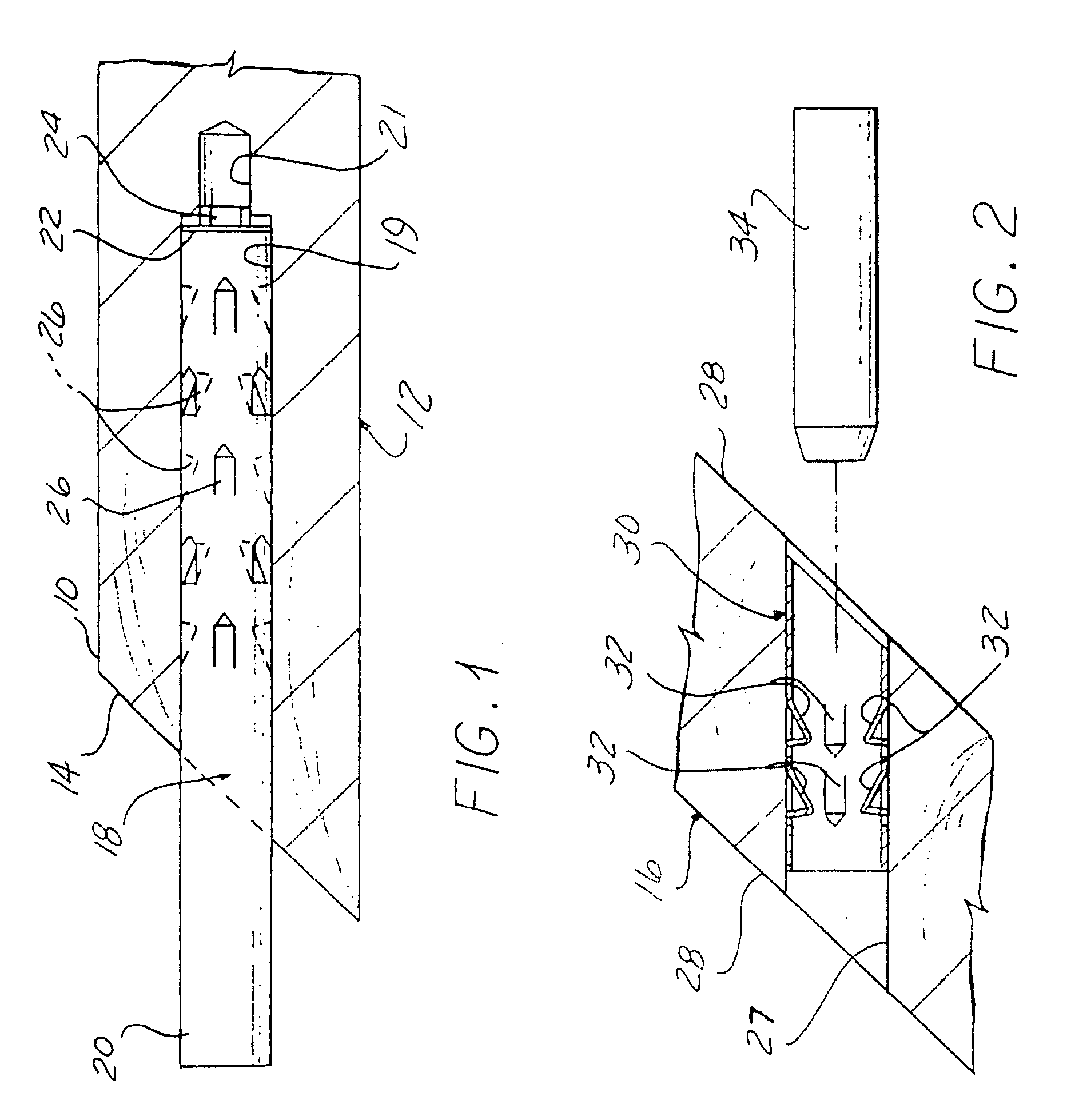

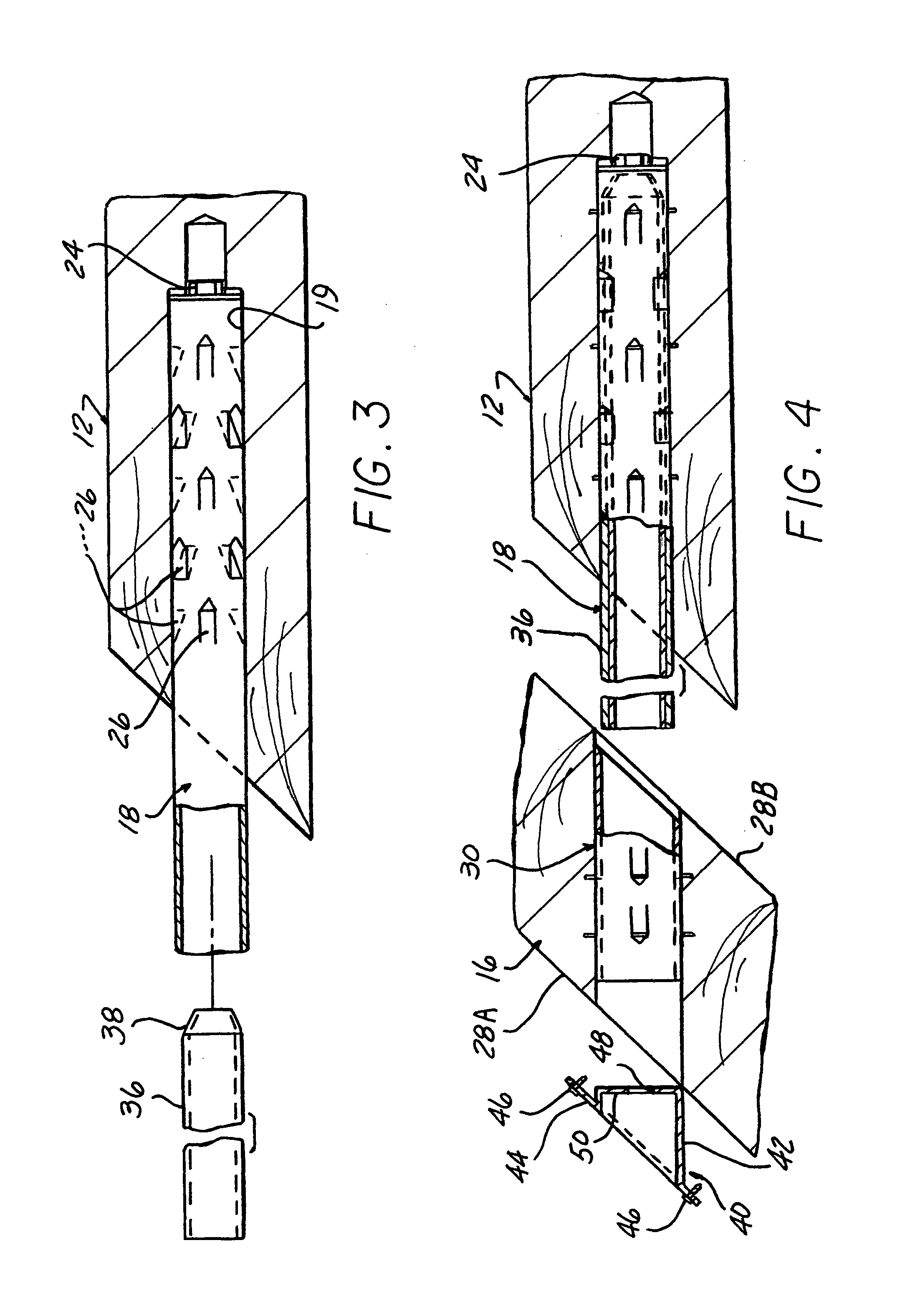

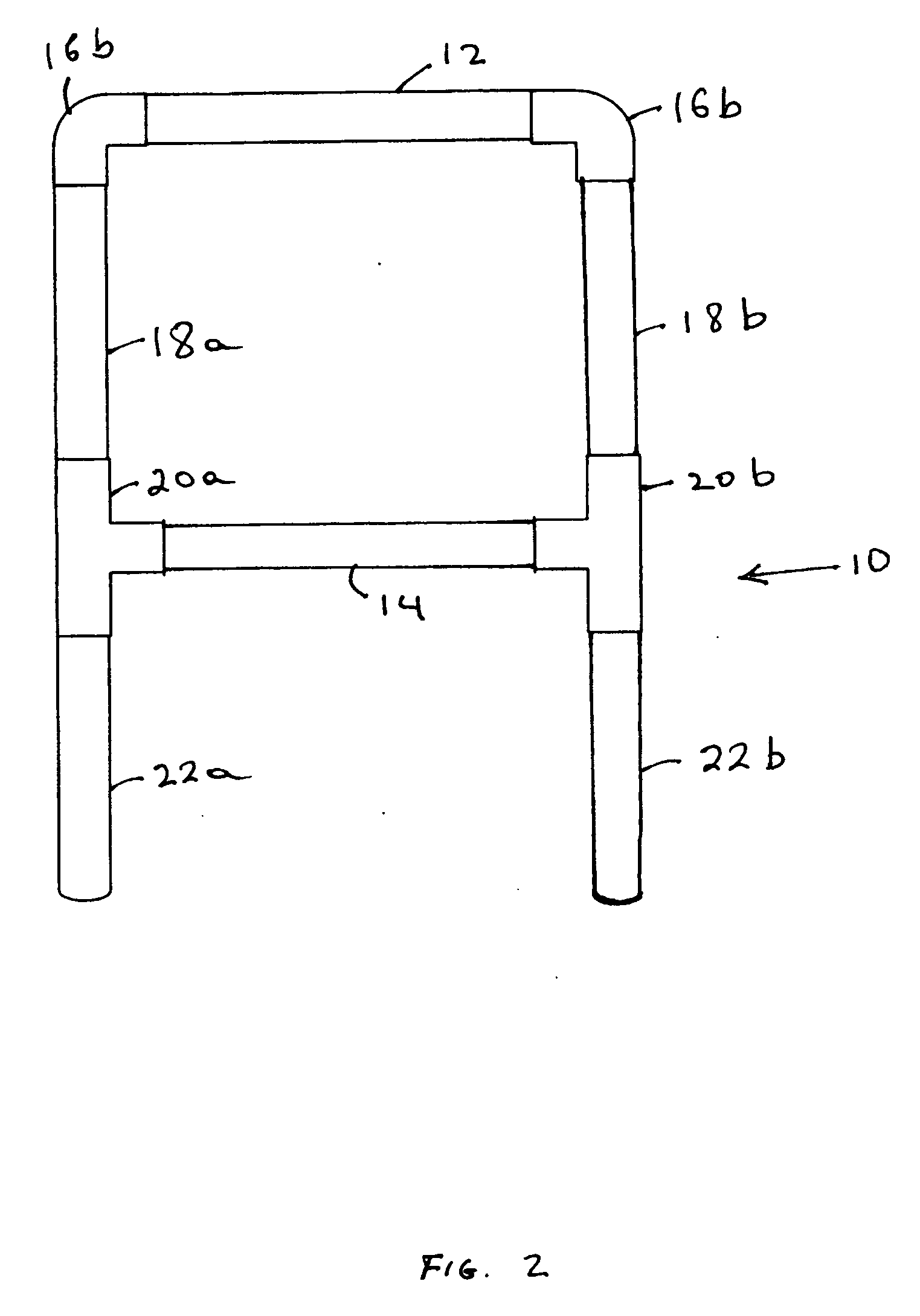

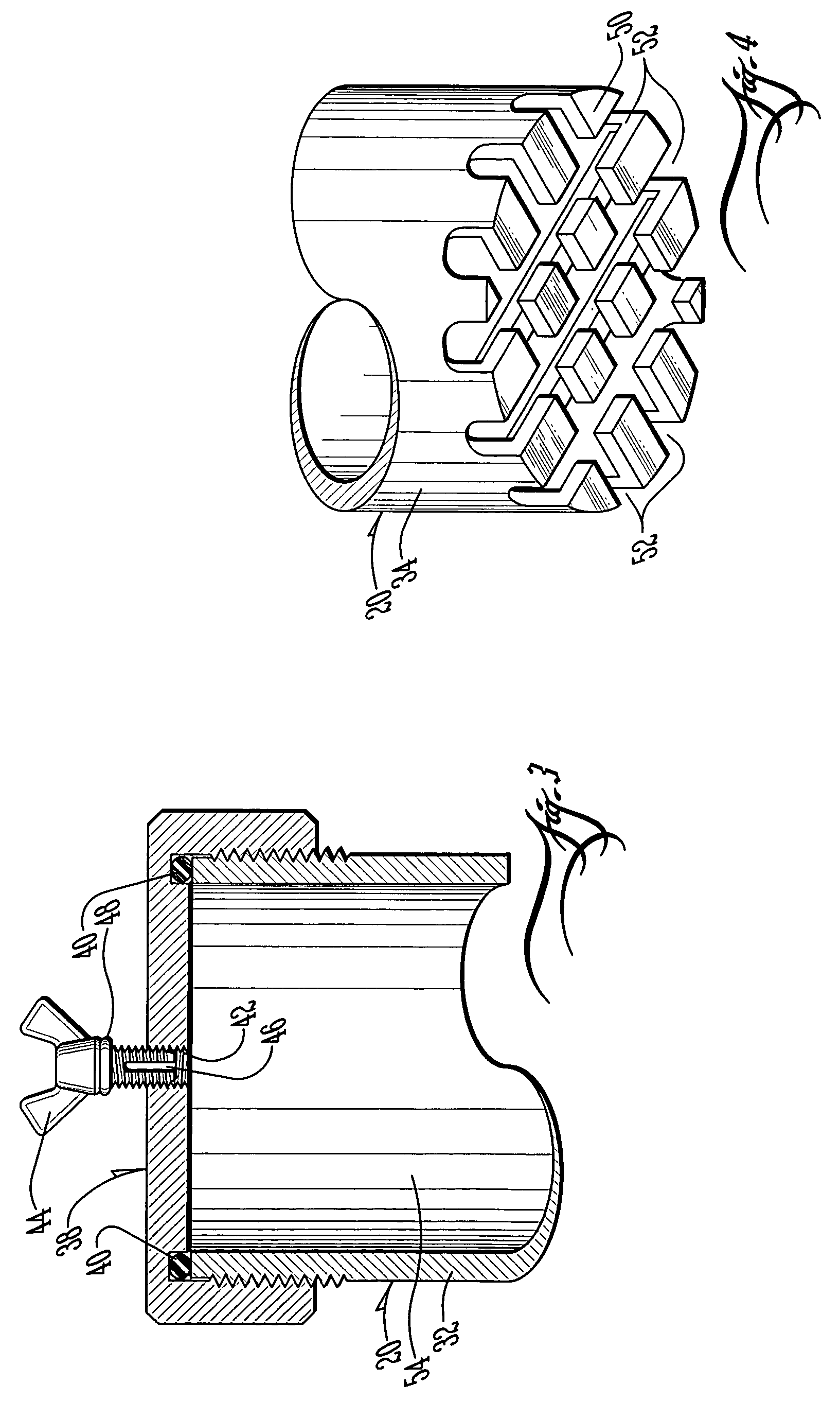

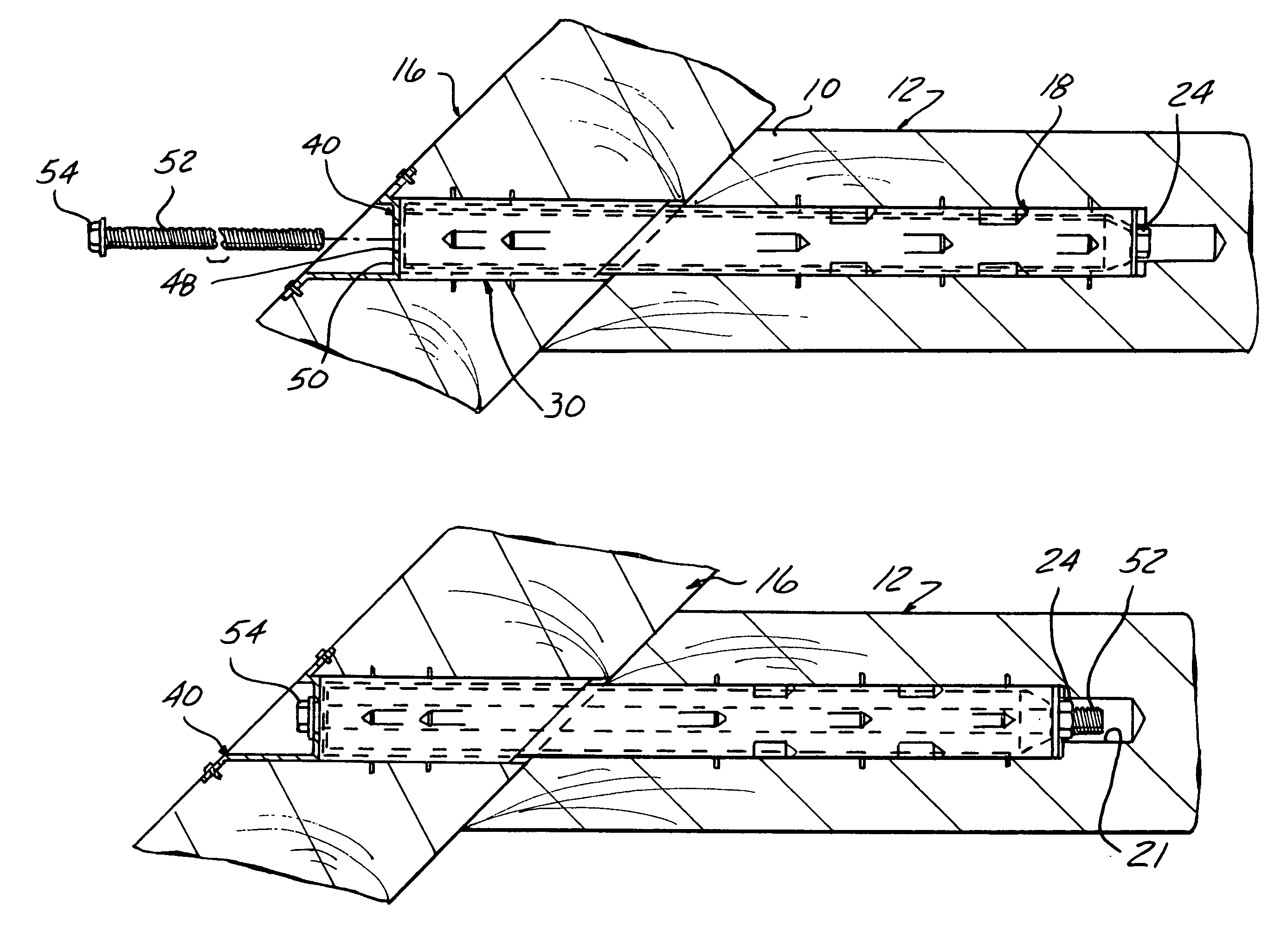

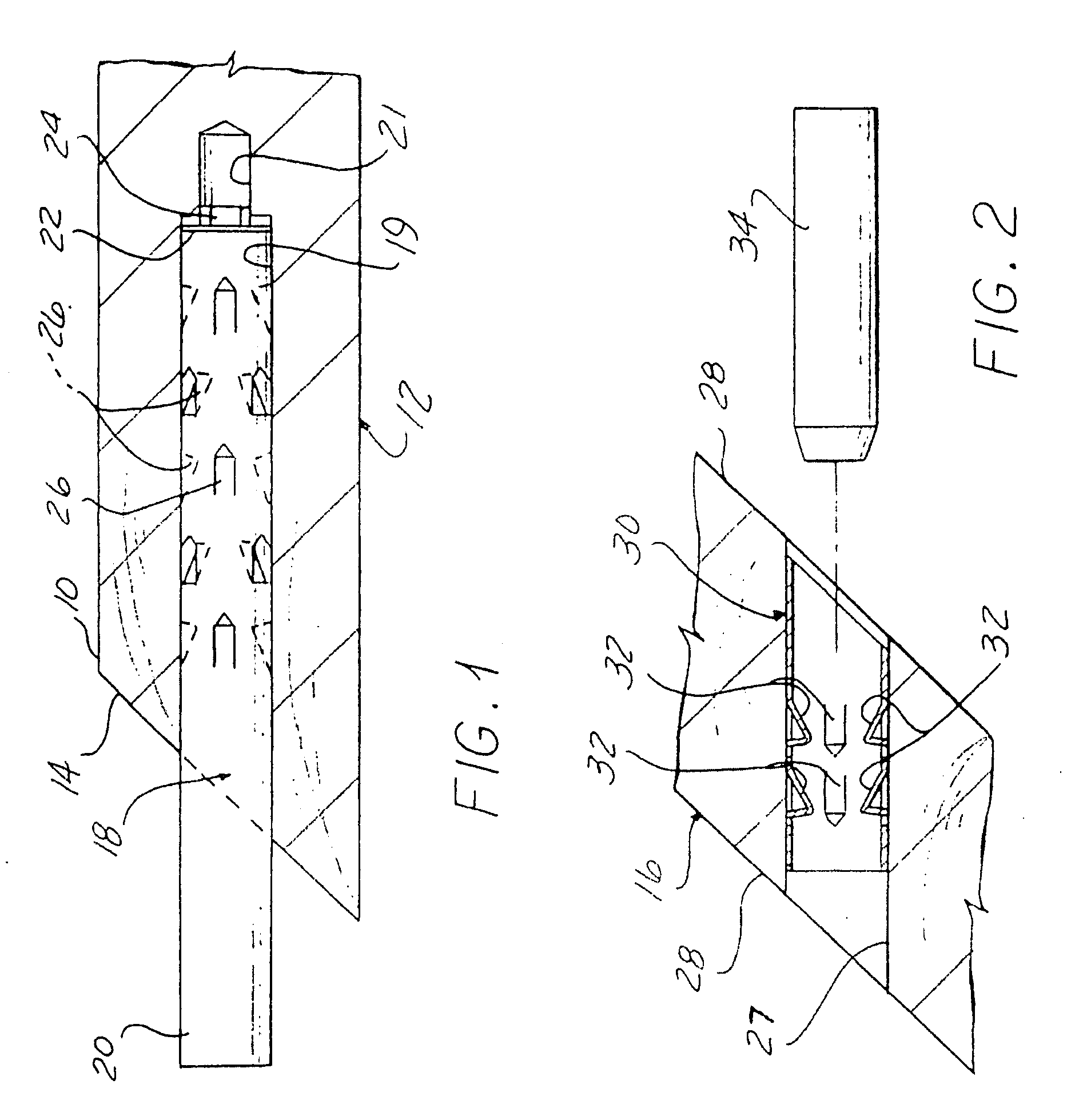

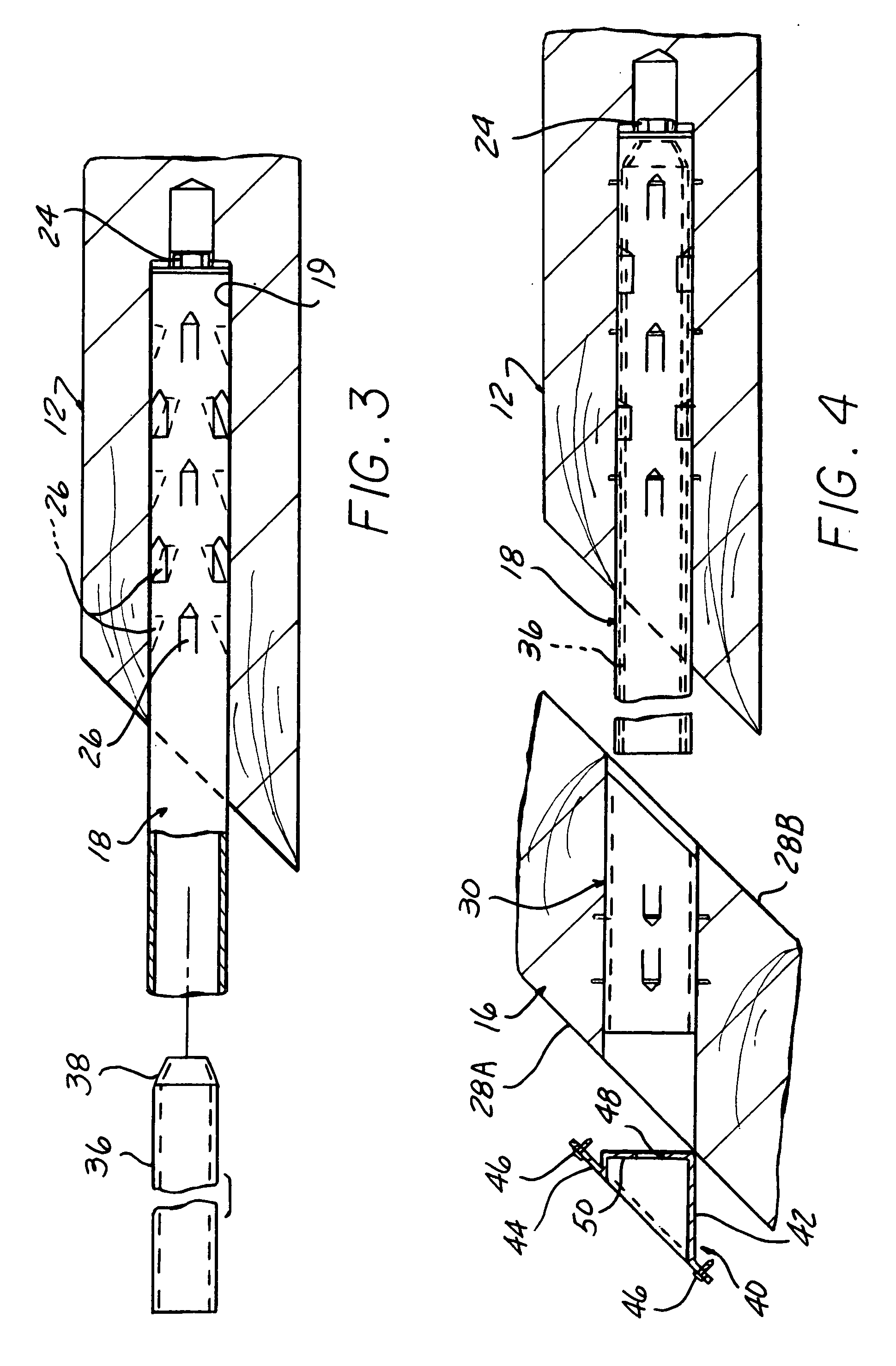

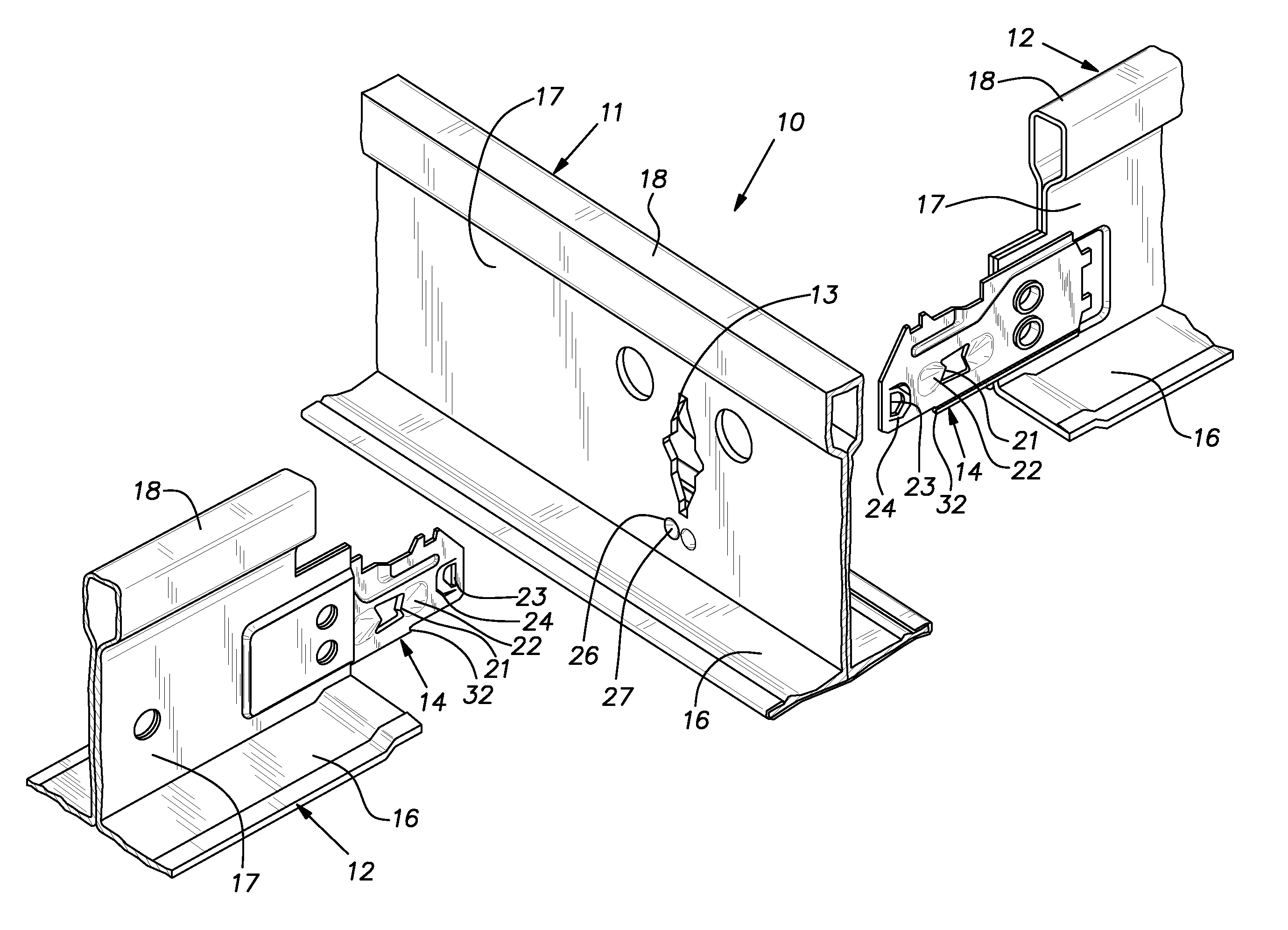

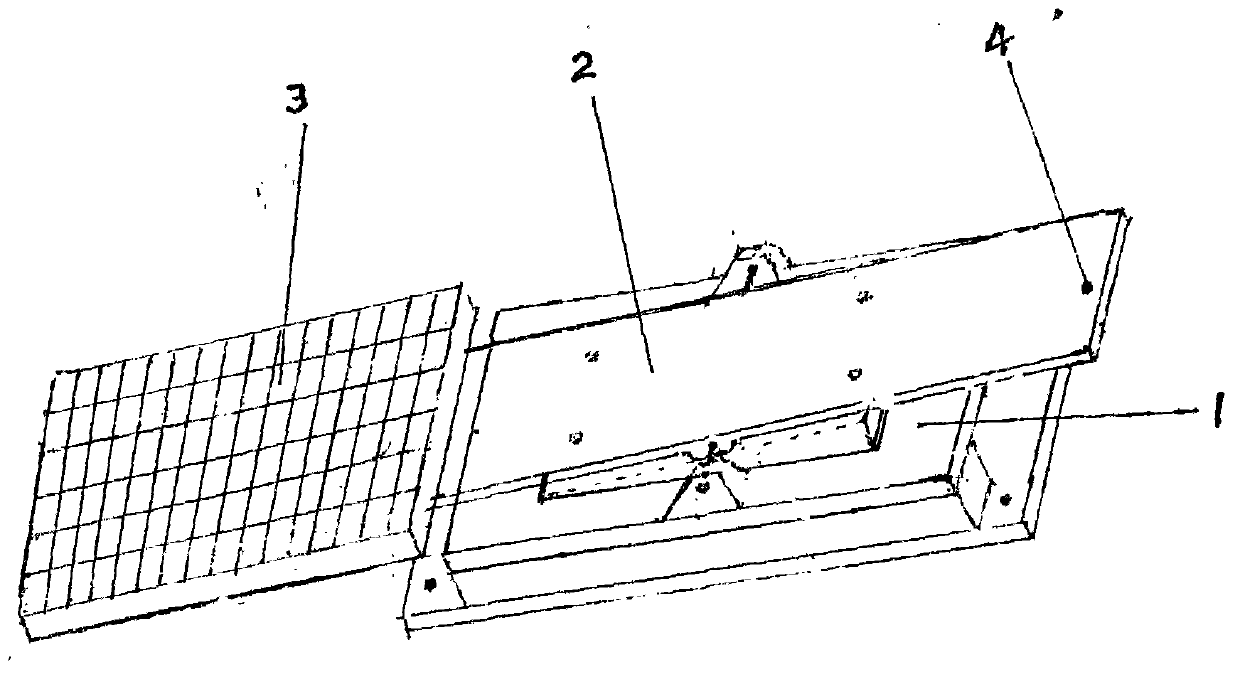

Structural member joints

A connector and method for joining one end of a first wood member such as a wood log or beam to a side of a second wood member involving metal sleeves secured in aligned holes in a respective member with a protruding one of the sleeve slidable into the other sleeve. A bolt is threaded into an internally threaded element on the inner end of the sleeve in the first member and advanced to pull the members together. The sleeves are secured in the holes with spike features driven out into the surrounding wood. Alternatively, a tee connector has a plate portion fitting into a slot extending through aligned holes in the plate and one end of the first member. A cross plate is held against the one side of the other member with thread fasteners.

Owner:KAUPPILA RICHARD W

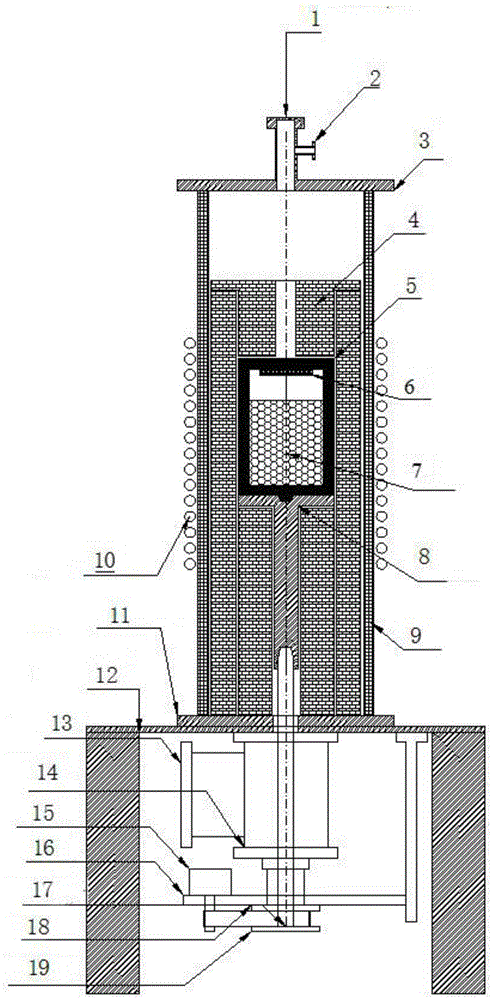

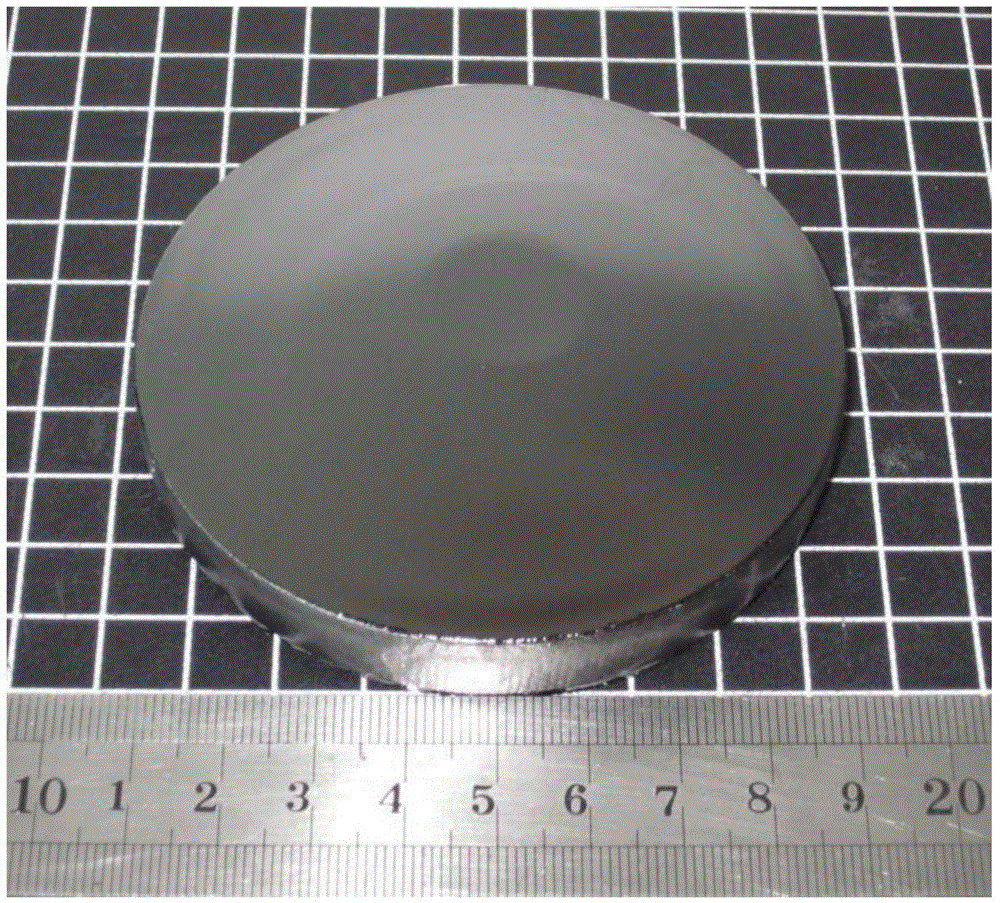

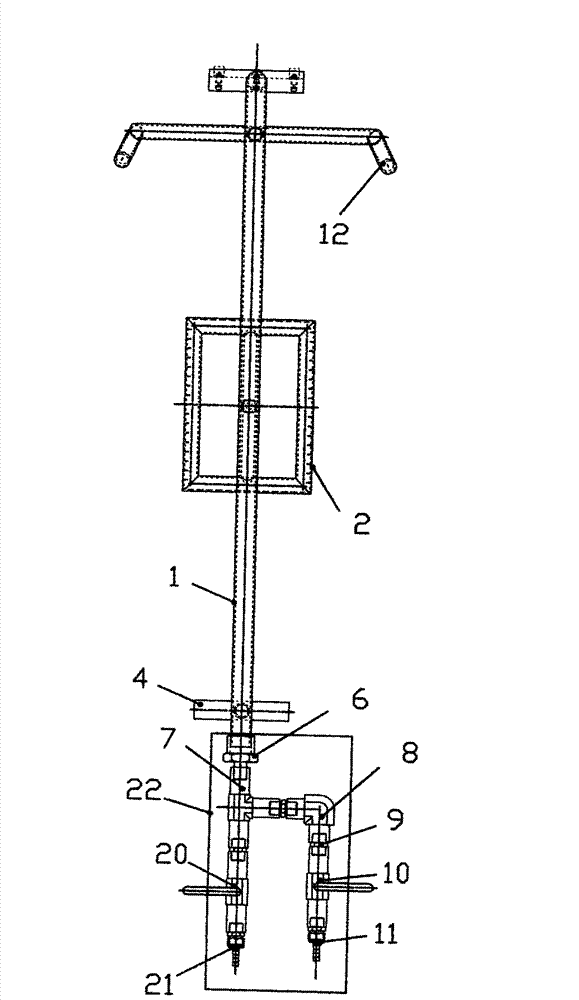

Centrally symmetric silicon carbide (SiC) single crystal growing device and method

InactiveCN105568370ACentral symmetryIncrease profitPolycrystalline material growthFrom condensed vaporsThermal insulationSingle crystal

The invention relates to a centrally symmetric silicon carbide (SiC) single crystal growing device. The growing device comprises a graphite crucible with a cover, wherein the bottom of the graphite crucible is connected with a rotating system which rotates the graphite crucible; the rotating system comprises a rotating tray, a center rotating rod and a driving device which drives the center rotating rod to move actively; the driving device is in sealing connection with a vacuum growth cavity by a tee connector; the center rotating rod passes through the tee connector to be connected with the driving device. According to the growing device disclosed by the invention, the bottom of the graphite crucible is connected with the rotating system which rotates the graphite crucible, when the rotating system is used, the rotation speed of the center rotating rod is 1 to 60 revolutions per minute; a non-centrosymmetric thermal field caused by spiral induction coils and thermal insulation is avoided; a centrosymmetric thermal field is constructed, and the transmission of substances is in central axial symmetry, so that the obtained crystal is centrally symmetric; the thicknesses of all edges are identical, and the use ratio of crystal materials is improved.

Owner:SHANDONG UNIV

Even-flow septic tee arrangement

An even-flow tee arrangement for use with a septic system consists of a tee connector having top and bottom section cemented together. The bottom section includes a splitter plate extending from the tee-shaped exit end to two pairs of directional vanes proximate the entrance end of the tee connector.

Owner:BURROWS KENNETH +1

Metal die preheating device and metal die preheating technology thereof

The invention provides a metal die preheating device. A first split-flow branch pipe and a second split-flow branch pipe are respectively arranged at two ends of a heating main pipe, and an initial end of the heating main pipe is provided with a tee connector which is respectively provided with a first connector through a first valve and a second connector through a second valve. The metal die preheating technology of the metal die preheating device includes the steps of firstly opening dies at two sides of a metal die, then fixing the metal die preheating device on the metal die so that the first split-flow branch pipe is floated in a shape cavity of the metal die and the second split-flow branch pipe is floated in a pouring gate of the metal die, then connecting a fuel source on the first connector and connecting a pneumatic supply on the second connector, opening valve switches so that fuel gas flows into the two split-flow branch pipes through the heating main pipe to be ignited and burned after flowing out of nozzles, and adjusting size of flame by adjusting switches of two valves until the metal die is evenly heated to reach relevant technology parameters. The metal die preheating device and the metal die preheating technology of the metal die preheating device has the advantages of being capable of solving the problems that the existing die is low in service life, long in heating time, high in cost, large in labor intensity of workers and unstable in the technology parameters.

Owner:WENZHOU RUIMING IND

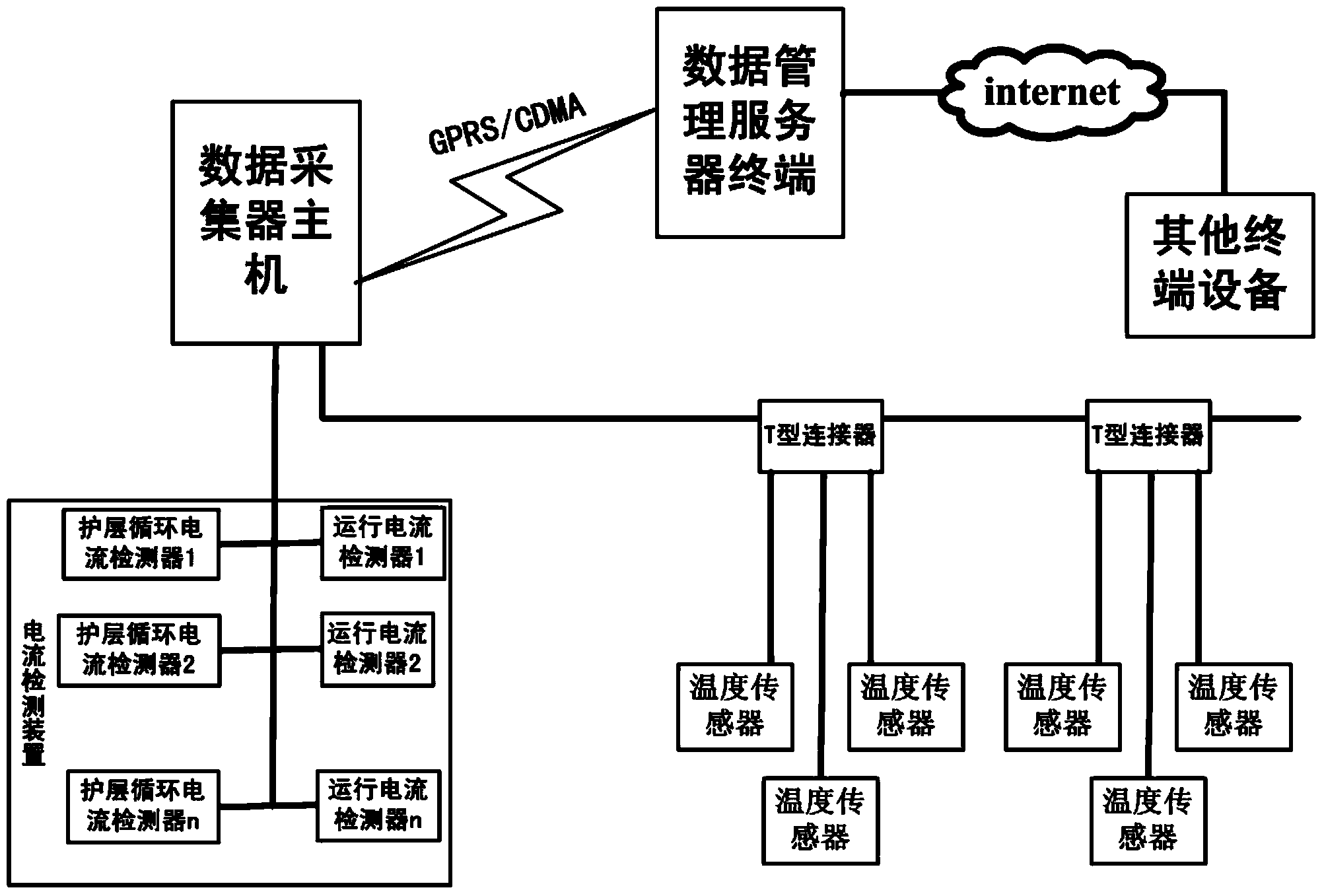

Online monitoring system for temperature and current carrying capacity of power cable

InactiveCN103528701AReliable assessmentSolve environmental adaptability problemsCurrent/voltage measurementThermometers using electric/magnetic elementsData acquisitionCirculating current

The invention discloses an online monitoring system for temperature and current carrying capacity of a power cable. The online monitoring system comprises a data acquisition device host, a current detection device, temperature sensors, T-shaped connectors and a data management server terminal, wherein the current detection device comprises a protection layer circulating current detector and an operating current detector; the current detection device and the T-shaped connectors are connected with the data acquisition device host and a plurality of temperature sensors are connected onto each T-shaped connector; and the data acquisition device host is connected with the data management server terminal through a communication network. The online monitoring system for the temperature and the current carrying capacity of the power cable disclosed by the invention has the advantages that the operating state of the high-voltage cable can be determined in real time, the working reliability of the power cable is improved and the like.

Owner:STATE GRID CORP OF CHINA +1

Decorative display assembly and method for displaying signs

A decorative display frame is formed by assembling and connecting pipe sections and fittings. In the assembled position, an upper frame member is connected to two side frame members via two elbows, a lower frame member is connected to the two side frame members via two tee connectors, a first support is connected to the first side frame member and the lower frame member via the first tee connector and a second support is connected to the second side frame member and the lower frame member via the second tee connector. The decorative display frame is supported in an upright position by the two supports which are inserted securely in the ground of a yard or other outdoor surface. A picture, an announcement or other sign is attached to the decorative display frame for display.

Owner:DU BOSE TAMMY LISA

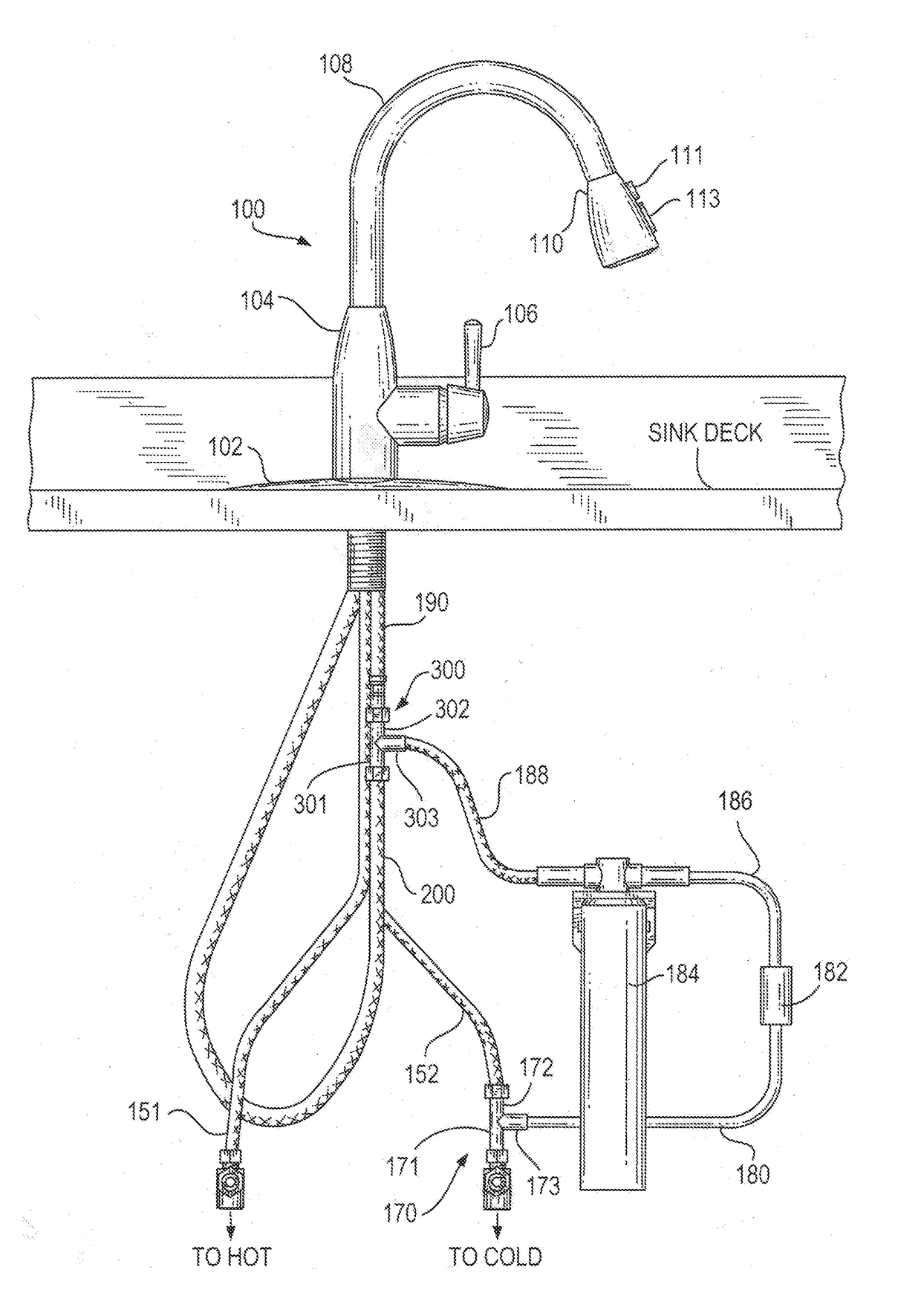

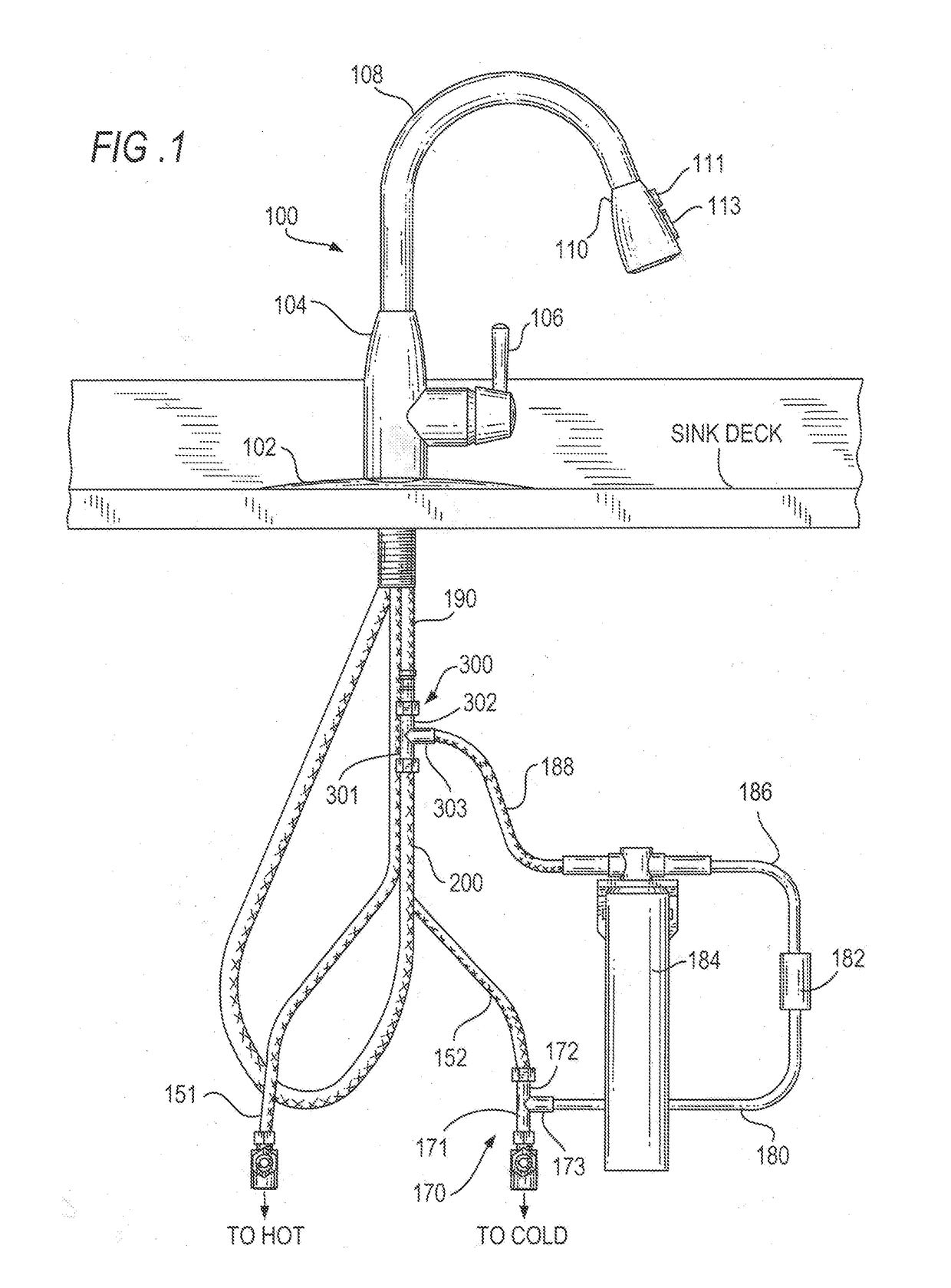

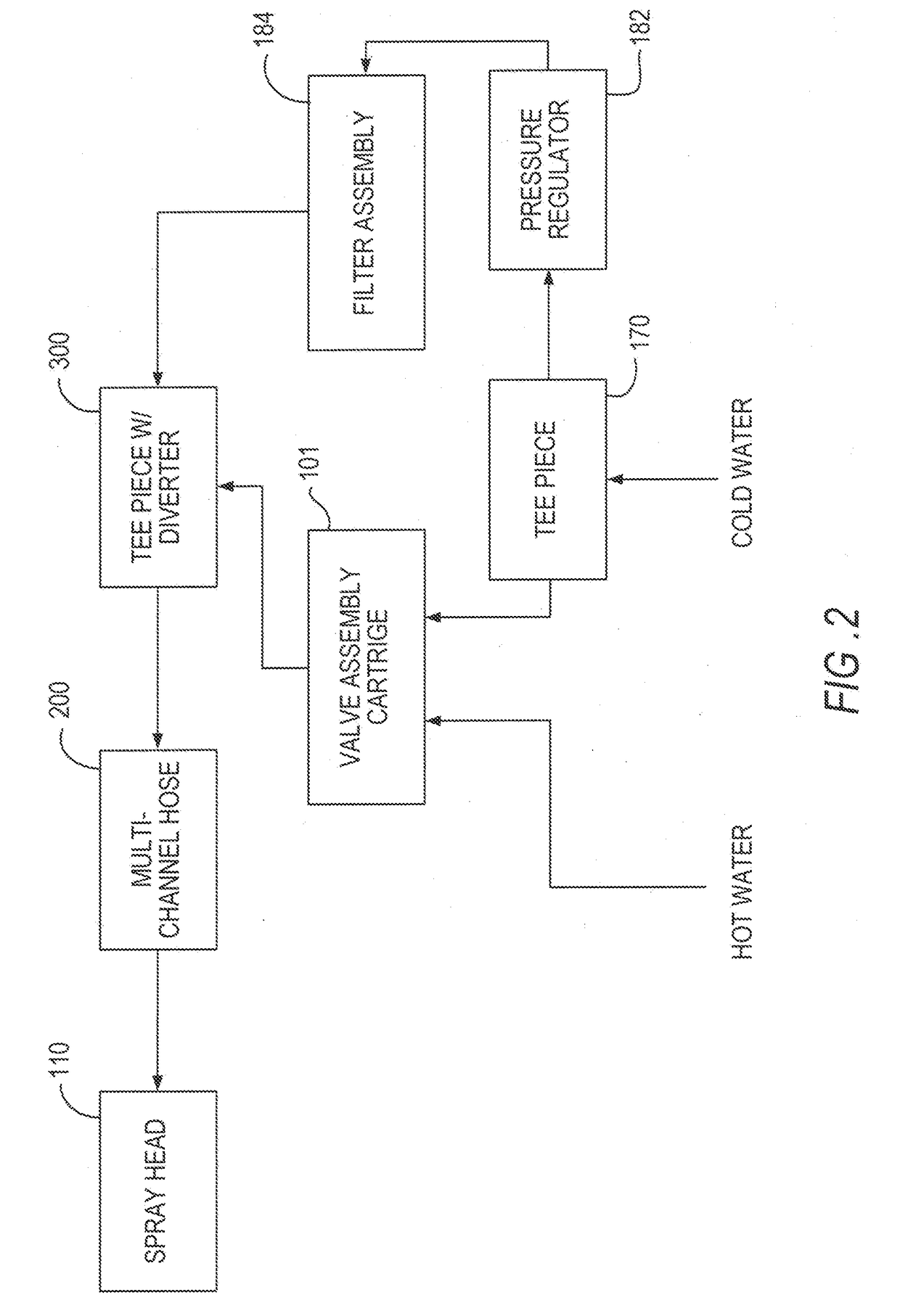

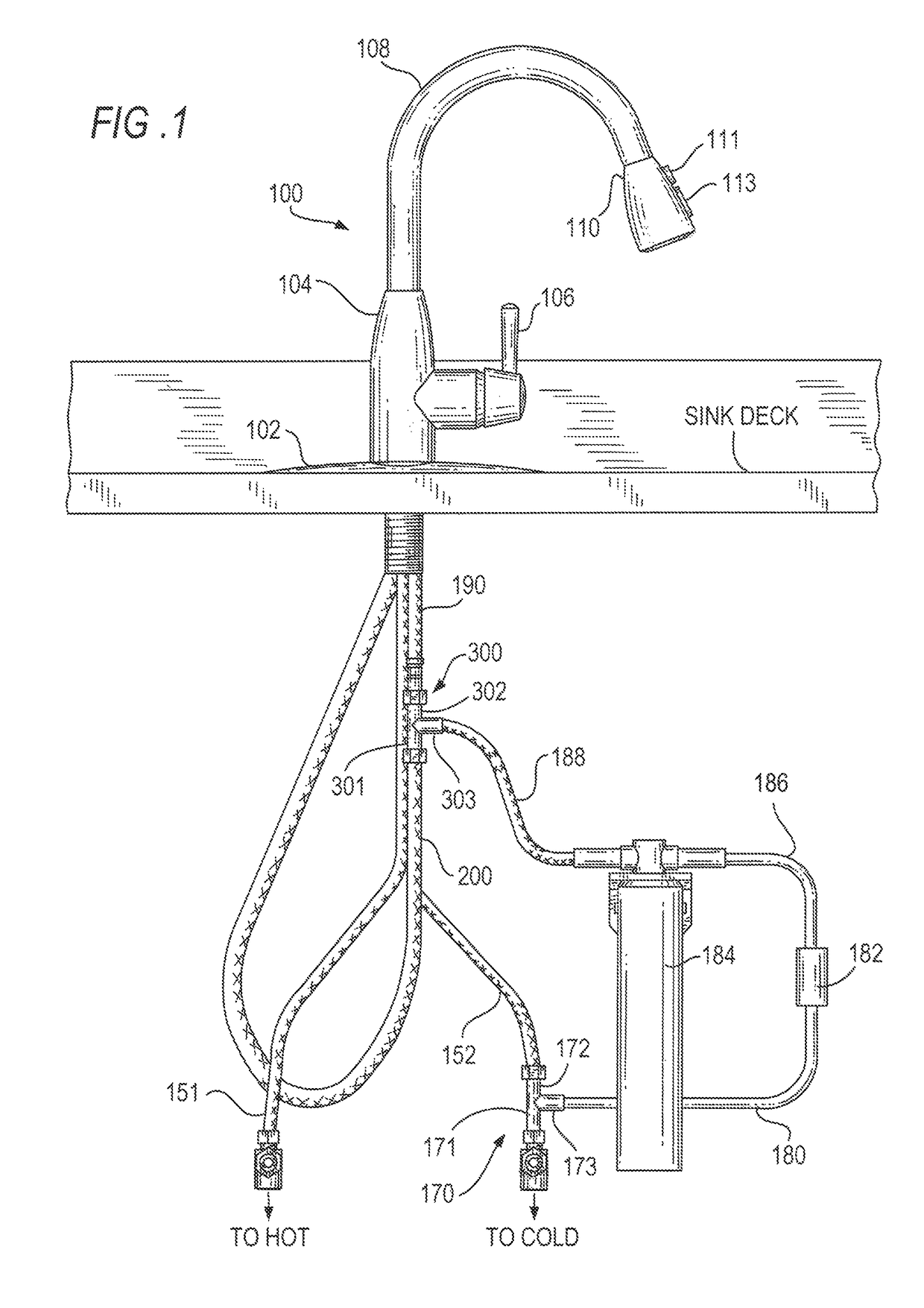

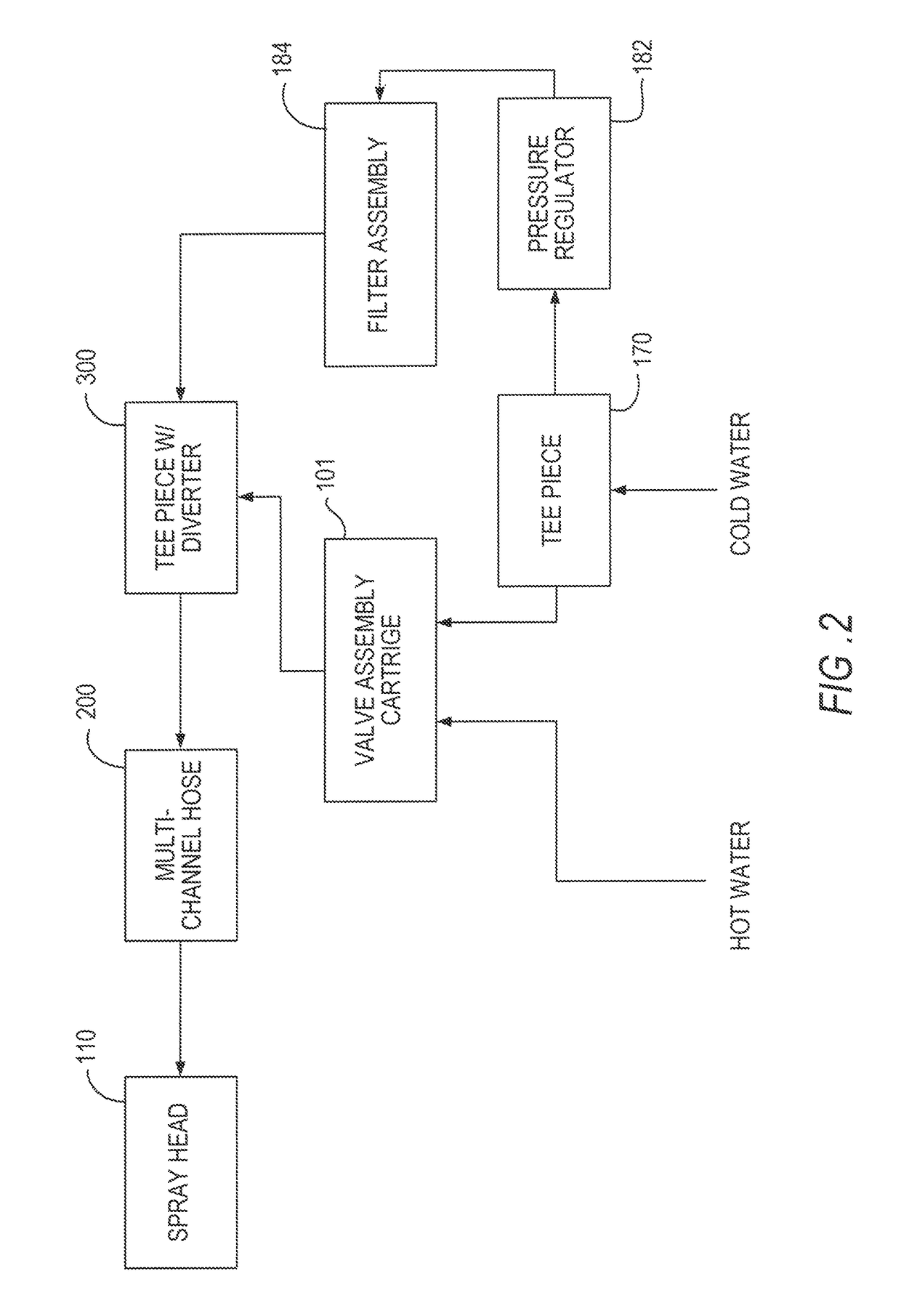

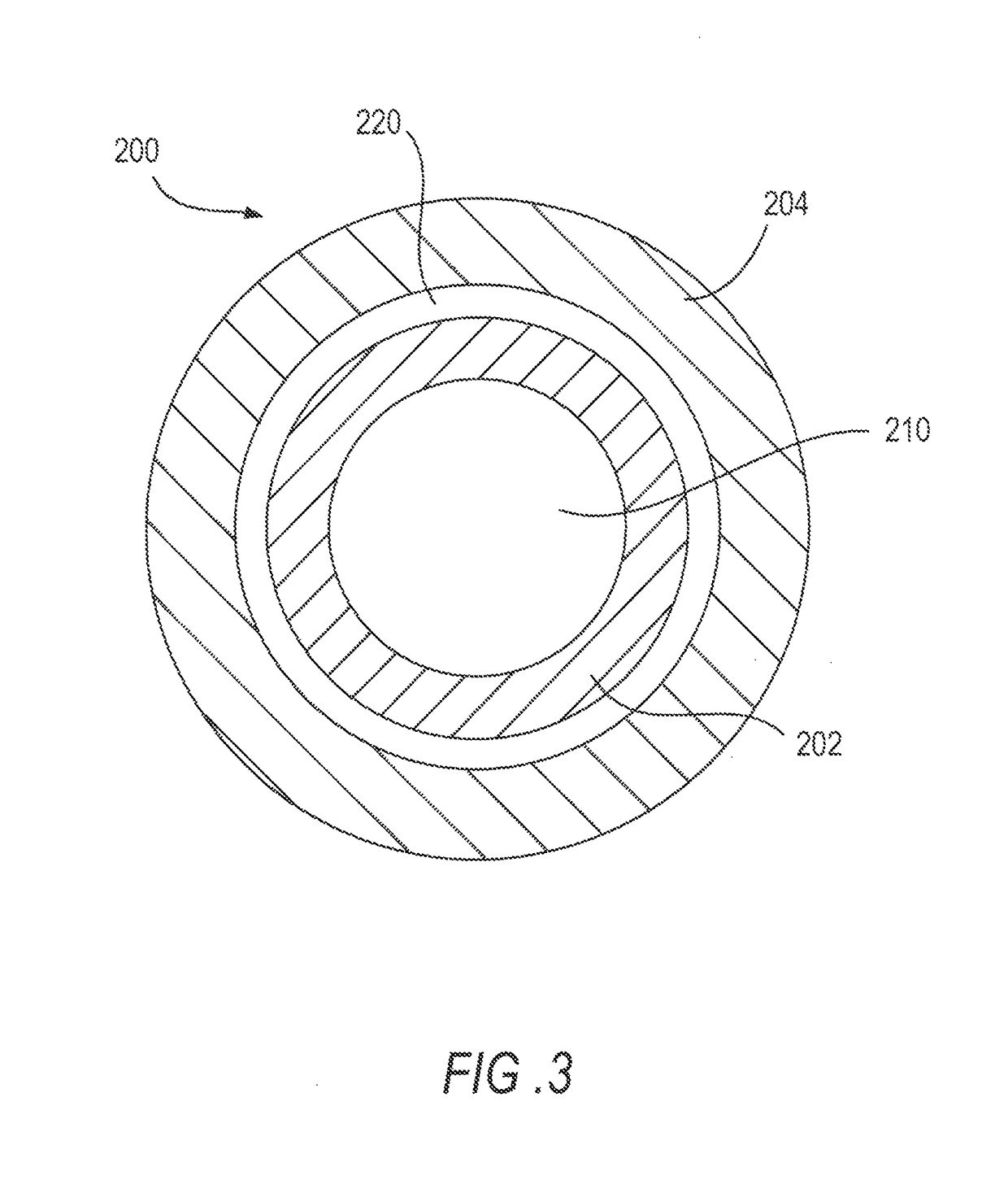

Integrated faucet filtration system

ActiveUS20170101325A1Overcome disadvantagesEasily exit and enterTreatment involving filtrationDomestic plumbingWater filterFiltration

A filtration system for a pull-down or pull-out faucet includes a multi-channel hose configured to fluidly couple to a spray head, a water filter configured to provide filtered water, and a diverter-equipped T-connector. The T-connector has a first branch configured to receive unfiltered water from a valve cartridge of the faucet, a second branch configured to receive filtered water from the water filter, and a third branch configured to deliver filtered and unfiltered water from the first and second branches to different channels of the multi-channel hose. The spray head also includes an activation switch configured to allow selective output of filtered and unfiltered water from the spray head.

Owner:AS AMERICA

Lawn chemical application system

InactiveUS7011254B2Easy and inexpensive to manufactureEasy and inexpensive to and installSelf-acting watering devicesWatering devicesClosed chamberWater flow

Owner:THORNTON BRIAN

Integrated faucet filtration system

ActiveUS10183871B2Overcome disadvantagesEasily exit and enterTreatment involving filtrationDomestic plumbingWater filterFiltration

A filtration system for a pull-down or pull-out faucet includes a multi-channel hose configured to fluidly couple to a spray head, a water filter configured to provide filtered water, and a diverter-equipped T-connector. The T-connector has a first branch configured to receive unfiltered water from a valve cartridge of the faucet, a second branch configured to receive filtered water from the water filter, and a third branch configured to deliver filtered and unfiltered water from the first and second branches to different channels of the multi-channel hose. The spray head also includes an activation switch configured to allow selective output of filtered and unfiltered water from the spray head.

Owner:AS AMERICA

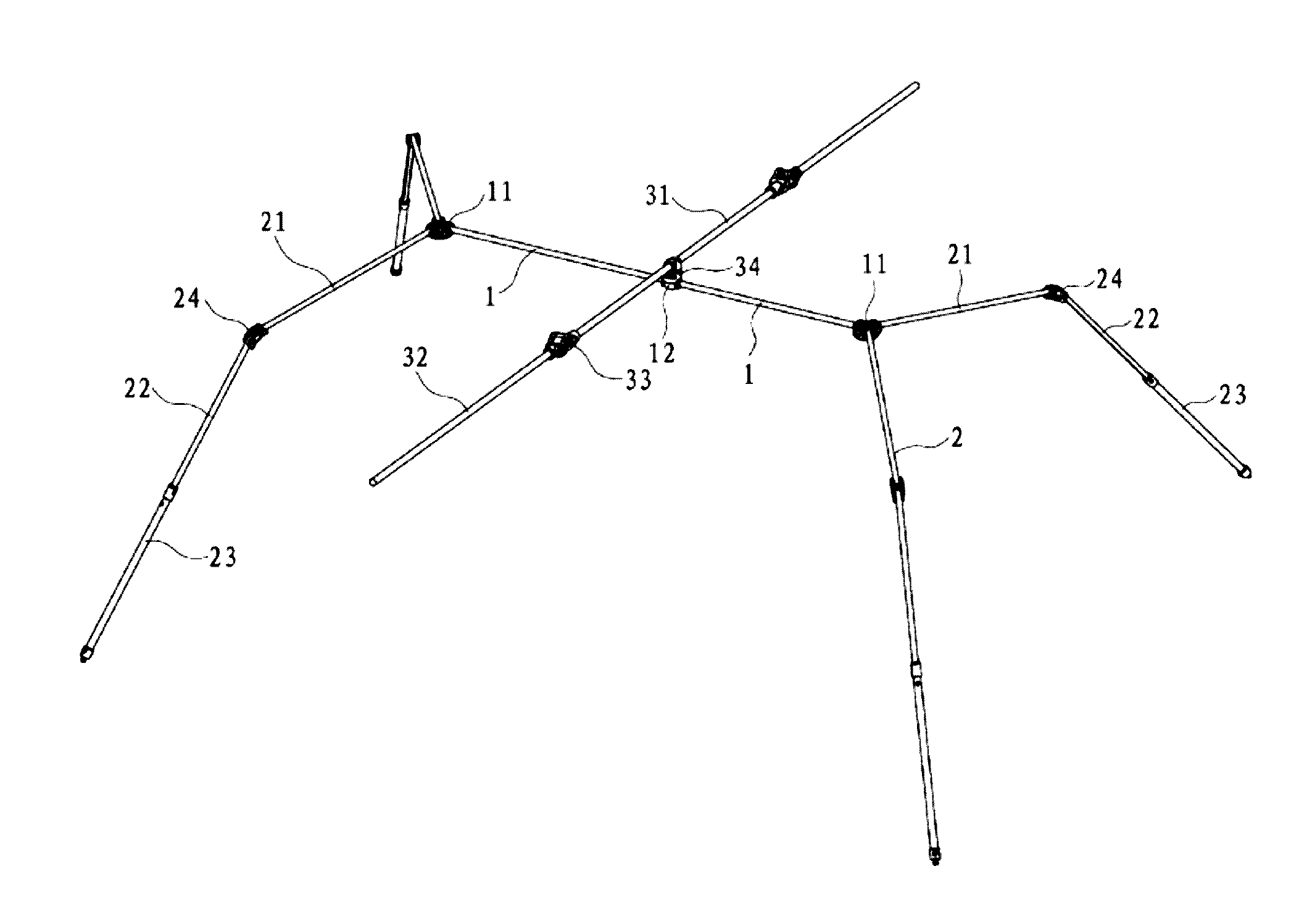

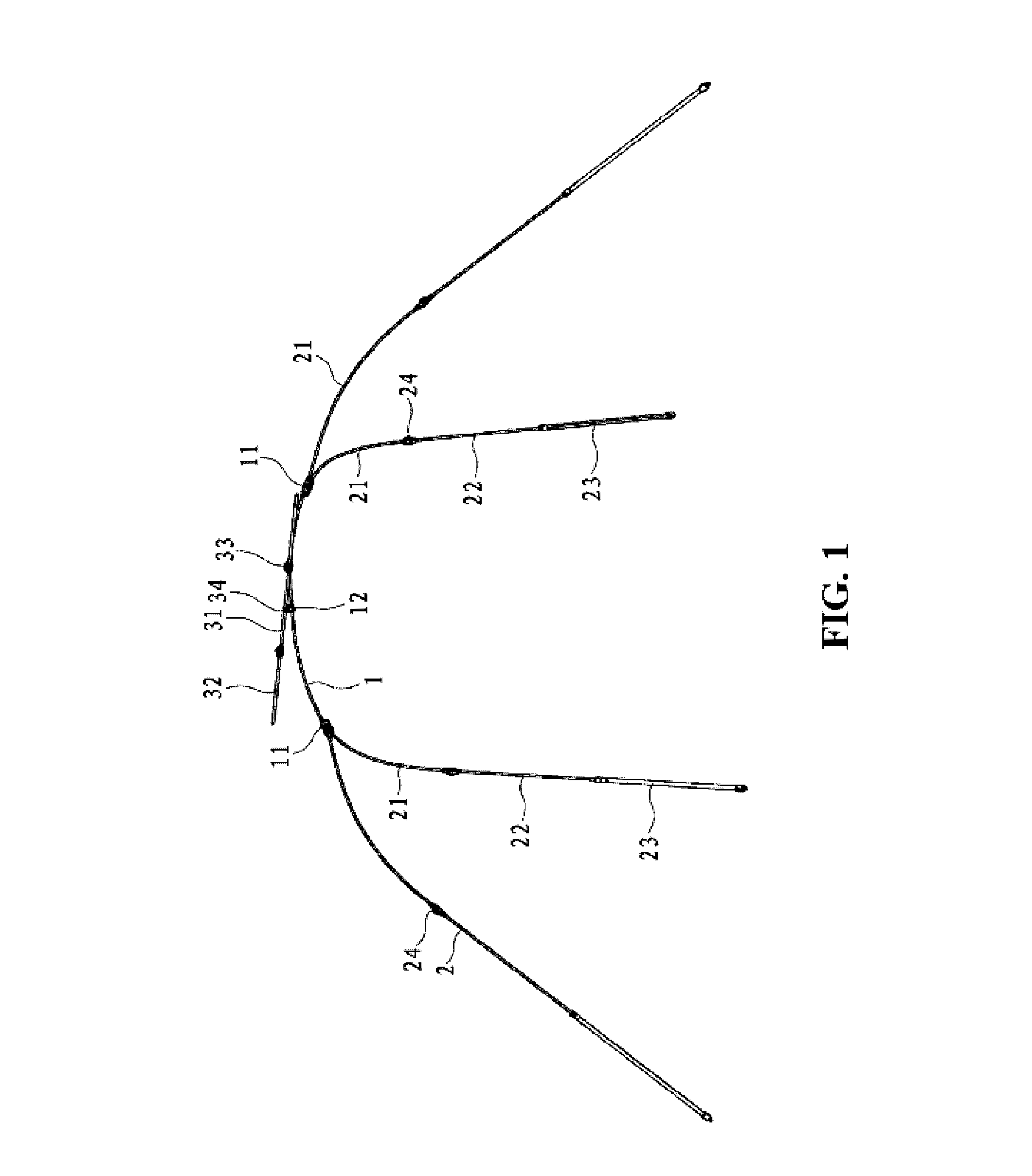

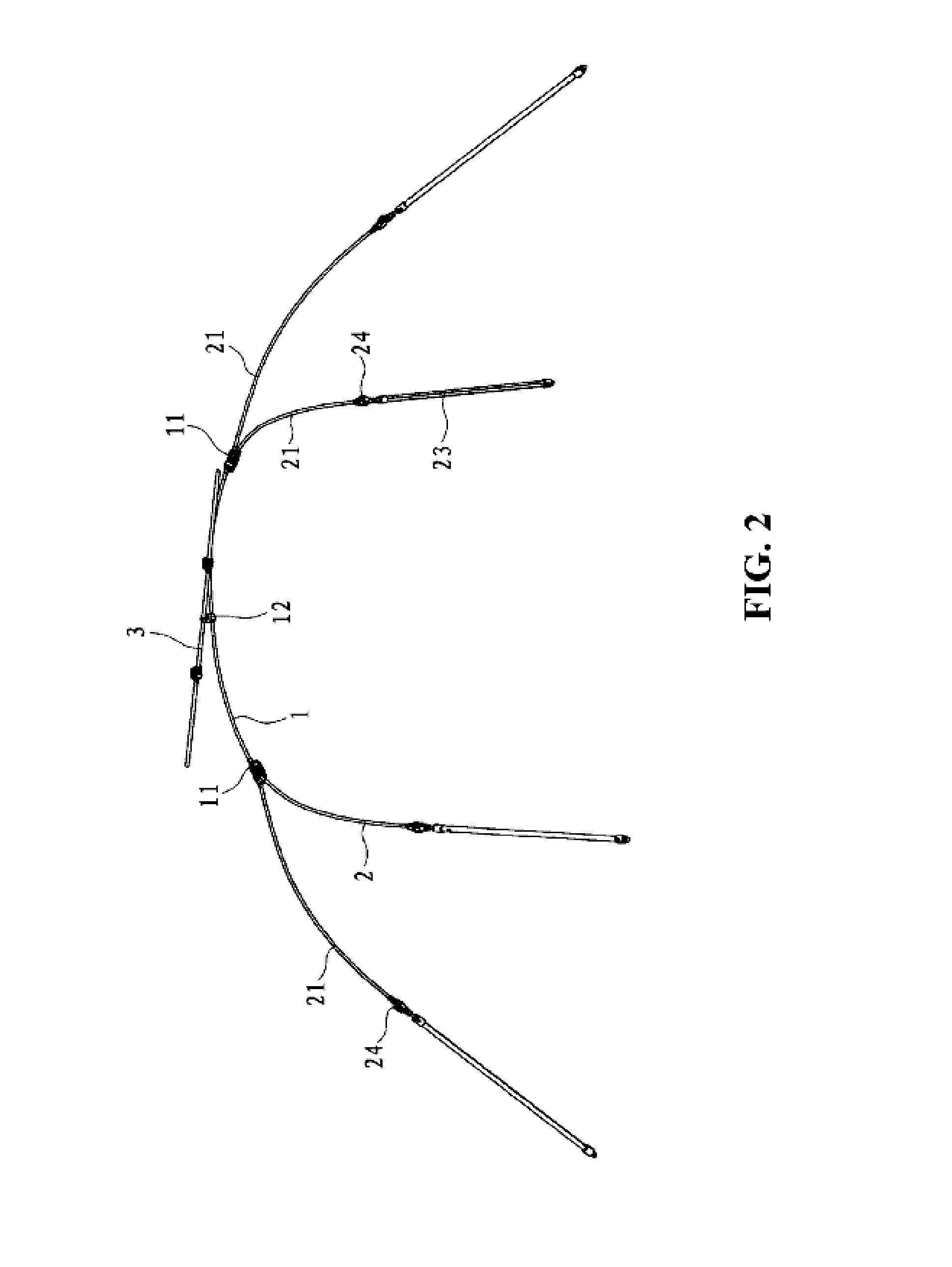

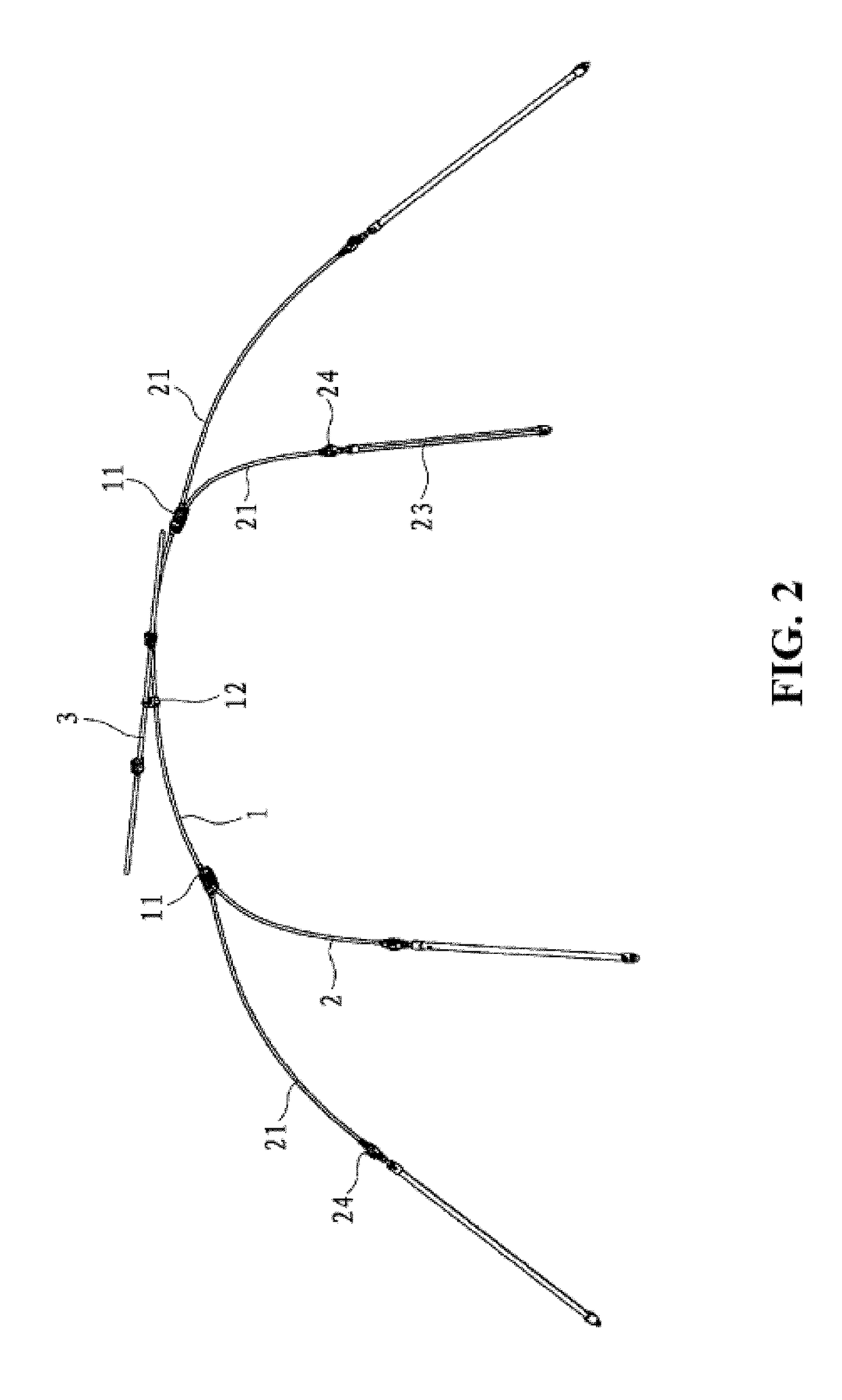

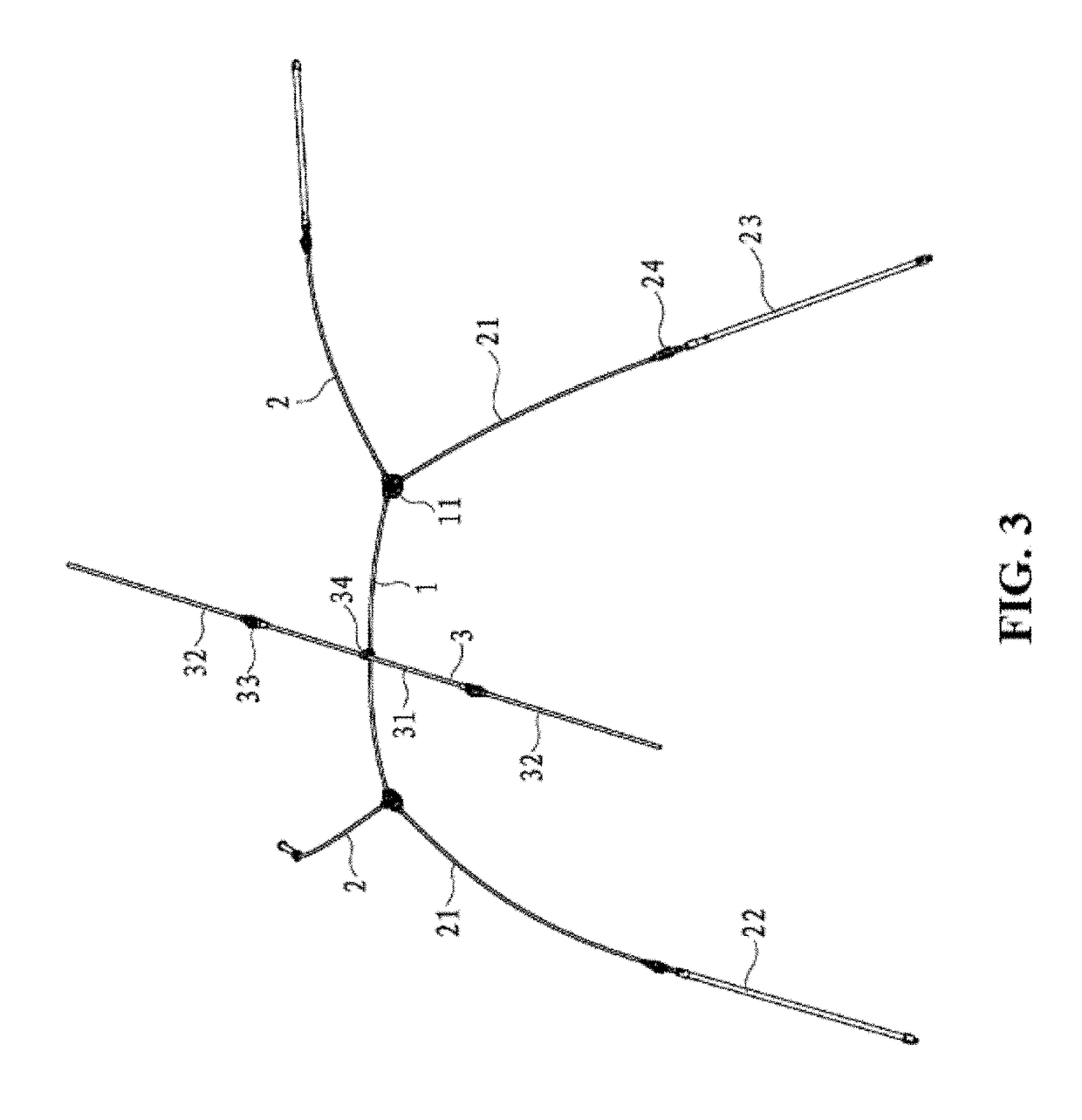

Tent having enhanced tent top

A tent with an enhanced tent top includes a top transverse rod, four upright rods, two tee connectors, and a cantilever rod. The top transverse rod has two ends. Each tee connector is pivotally connected to one end of the top transverse rod and two upright rods. The cantilever rod is movably or rotatably connected to the top transverse rod. The cantilever rod includes two free ends, which extend to two sides of the top transverse rod when the tent is unfolded.

Owner:CAMPVALLEY XIAMEN LEISURE PRODS

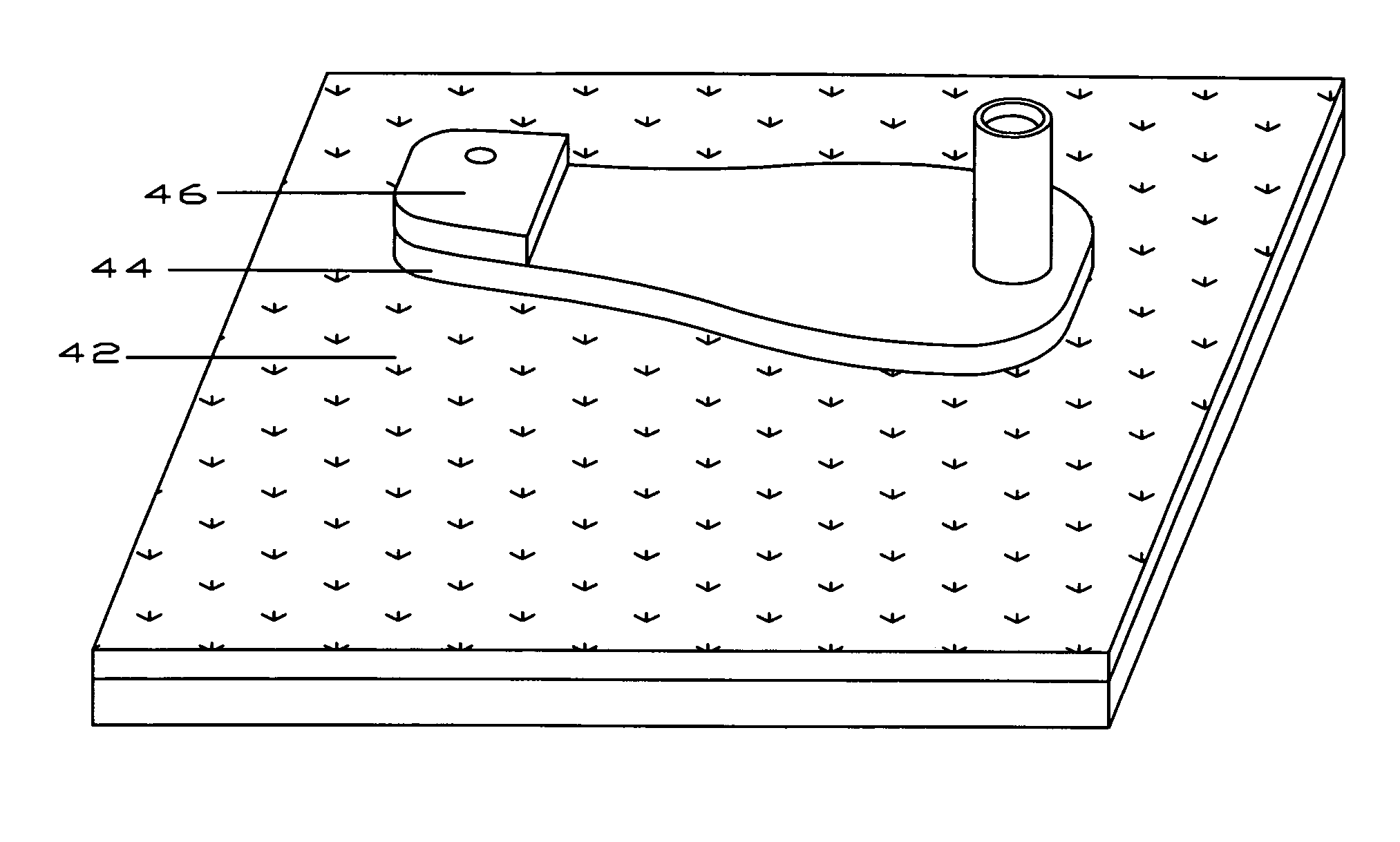

Golf tee connector

A golf tee connector (46) designed for golf practice. Said connector allows a Range Pro™ golf tee application Ser. No. 11 / 199,540-(44) to connect to a mat, creating a connection that helps save time and money on the costly replacement of golf tees that come up from the bottom of the mat and by allowing the Range Pro™ golf tee application Ser. No. 11 / 199,540-(44) to connect to a mat brings that state of the art flexibility that Range Pro™ golf tee application Ser. No. 11 / 199,540-(44) is known for with no resistance from the mat, making a long life tee useable on a driving range mat.

Owner:LIPIDAROV PETER

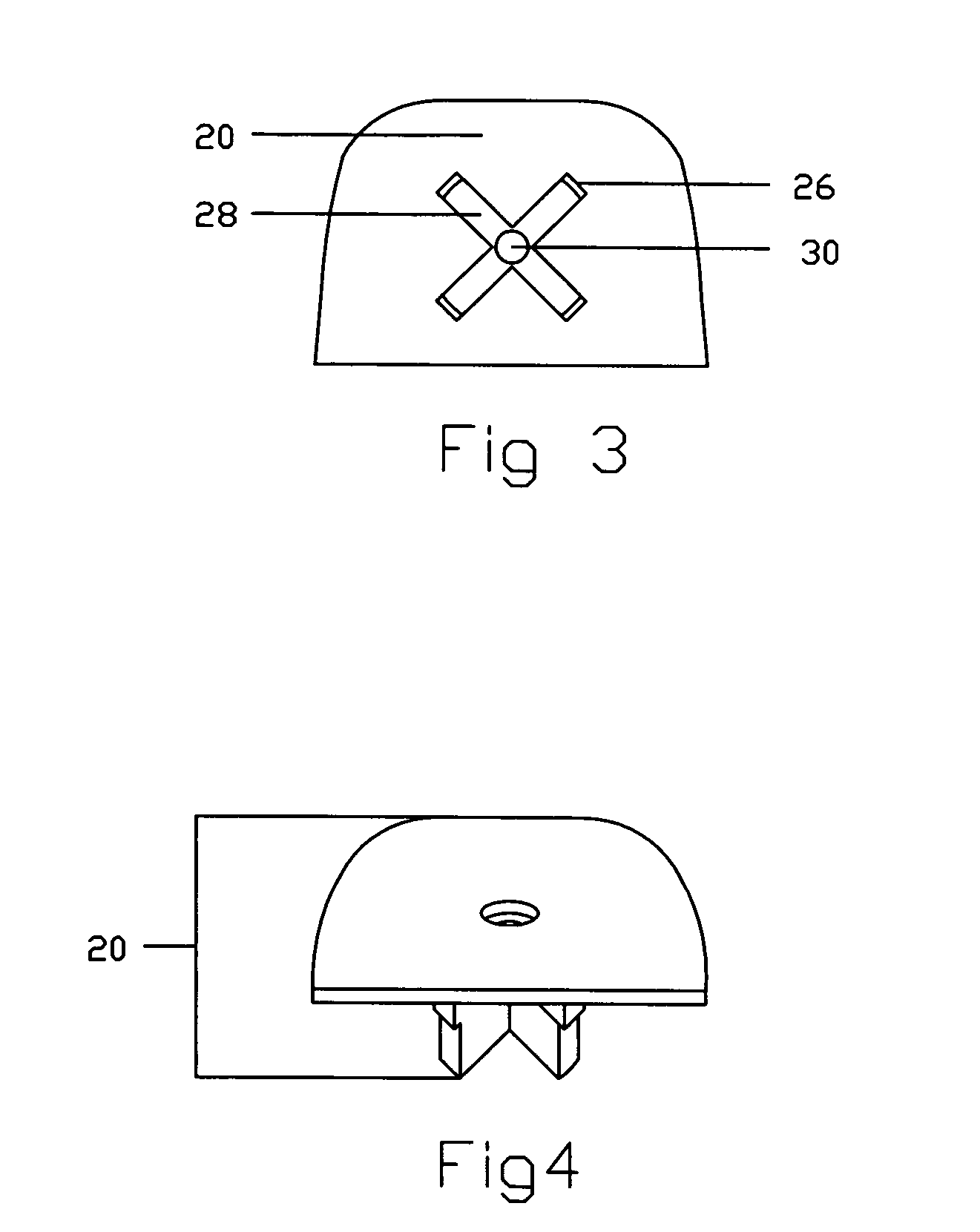

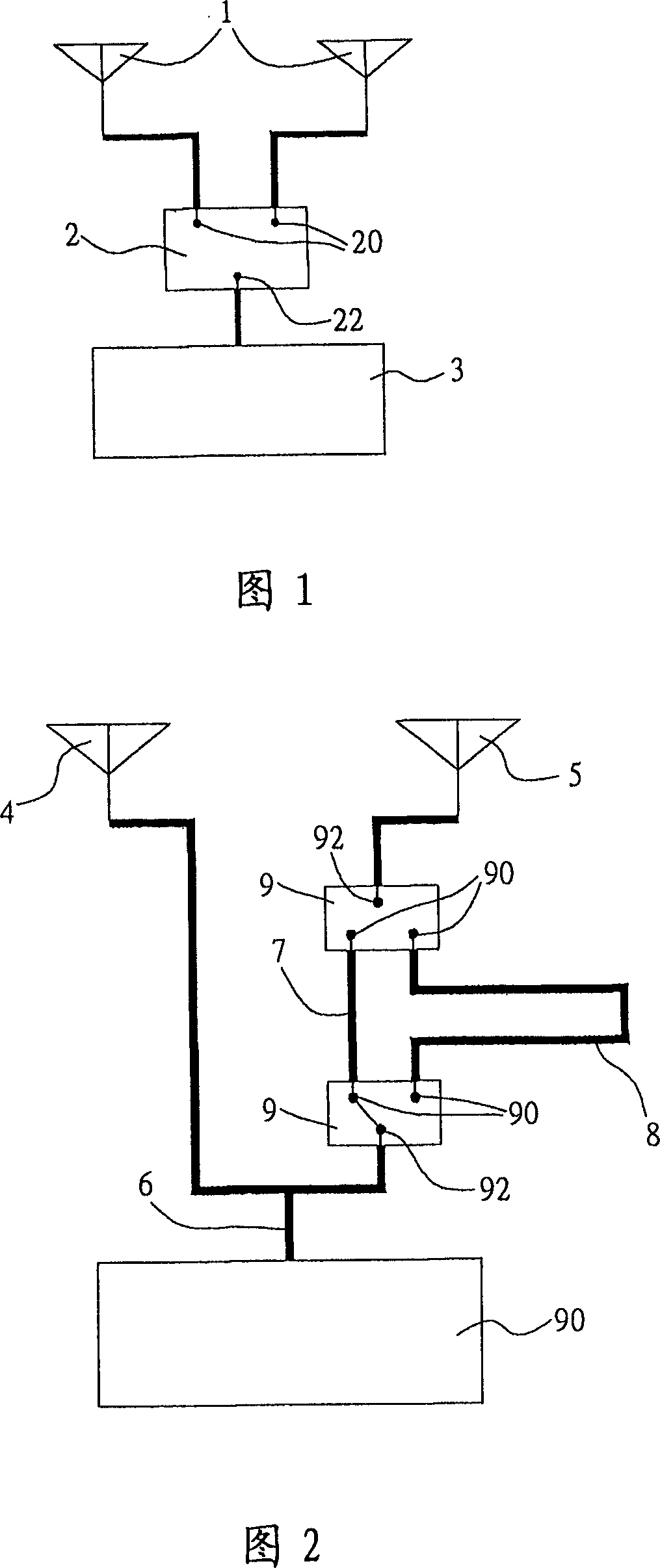

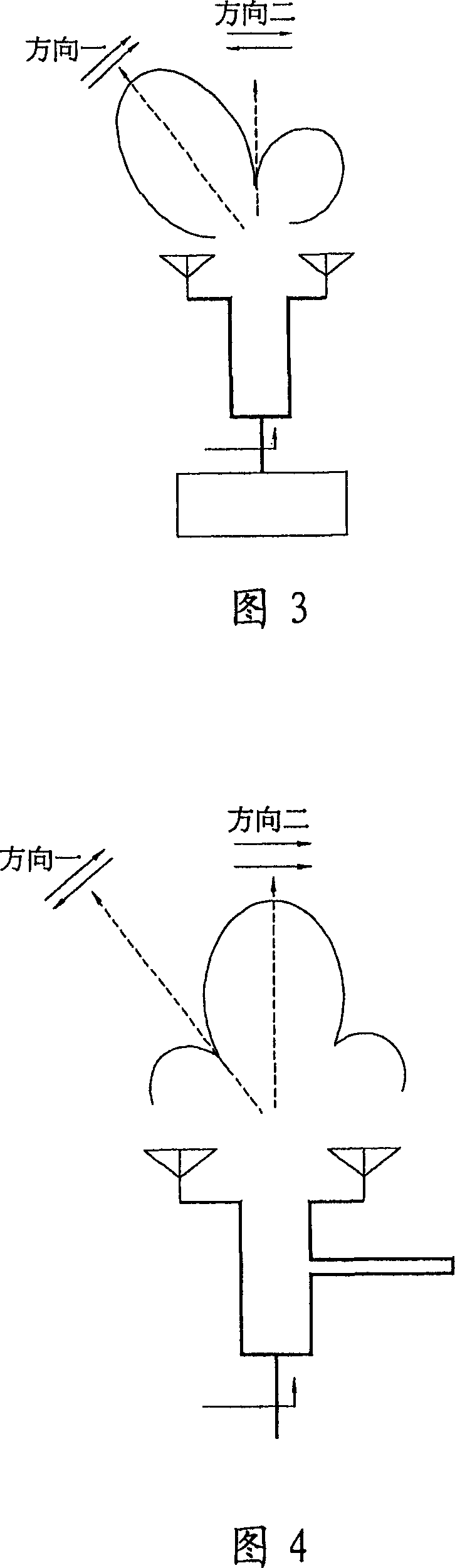

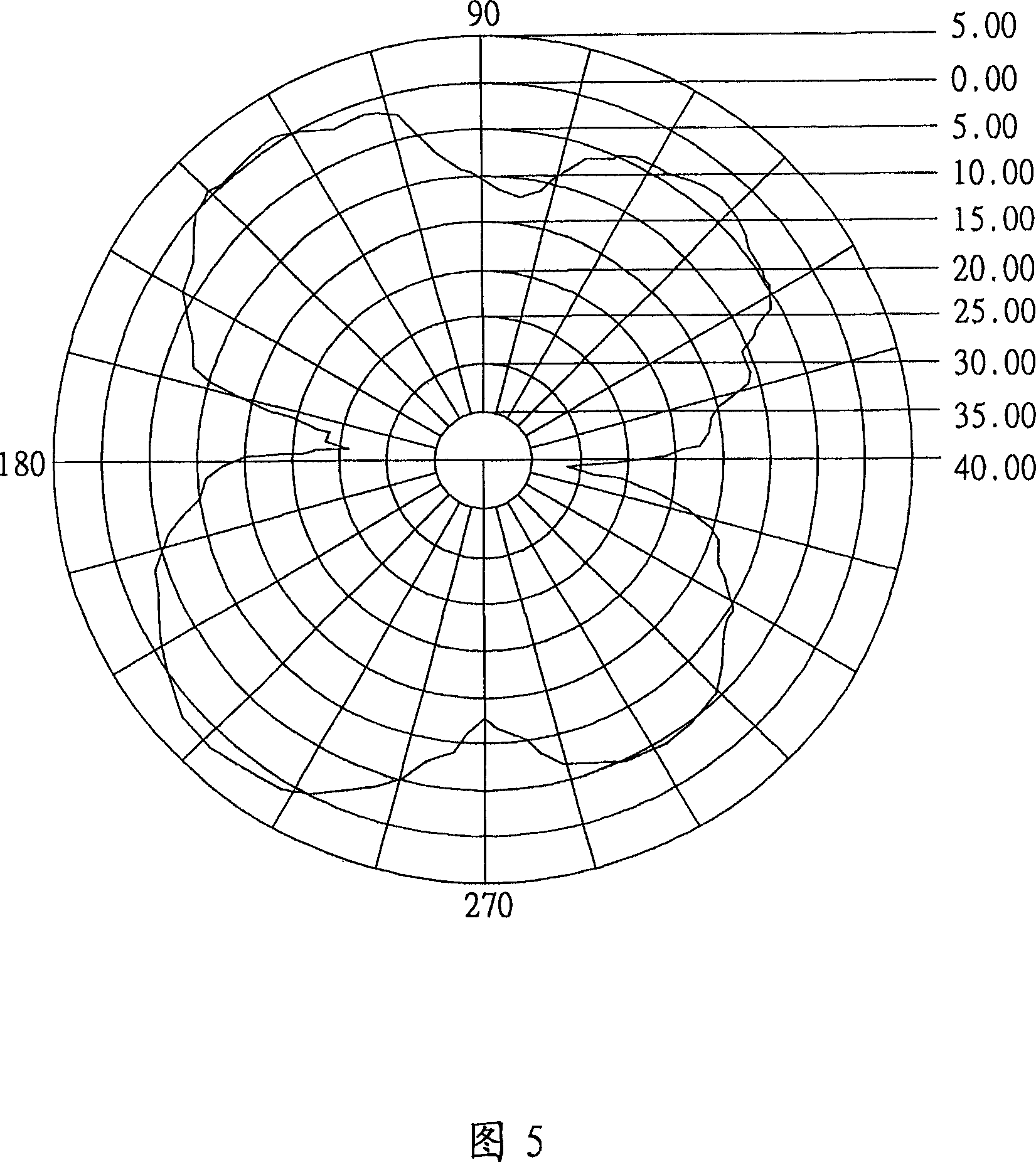

Smart antenna

The intelligence type antenna is an antenna array composed of two antenna units and T type connector. Two radio frequency switchers are setup between one antenna unit and T type connector. There are two transmission lines between two radio frequency switchers. After two radio frequency switchers are switched, through first transmission line or second transmission line, the antenna units connected to the radio frequency switcher are connected to the T type connector so as to make information fed to the two antenna units generate difference between in-phase or out-of-phase. Thus, two antenna units are utilized at same time. Comparing with traditional antenna diversity multitasking, the invention solves disadvantages that only one antenna is utilized at same time. The invention can receive information in optimal quality.

Owner:ALPHA NETWORKS INC

Tent having enhanced tent top

A tent with an enhanced tent top includes a top transverse rod, four upright rods, two tee connectors, and a cantilever rod. The top transverse rod has two ends. Each tee connector is pivotally connected to one end of the top transverse rod and two upright rods. The cantilever rod is movably or rotatably connected to the top transverse rod. The cantilever rod includes two free ends, which extend to two sides of the top transverse rod when the tent is unfolded.

Owner:CAMPVALLEY XIAMEN LEISURE PRODS

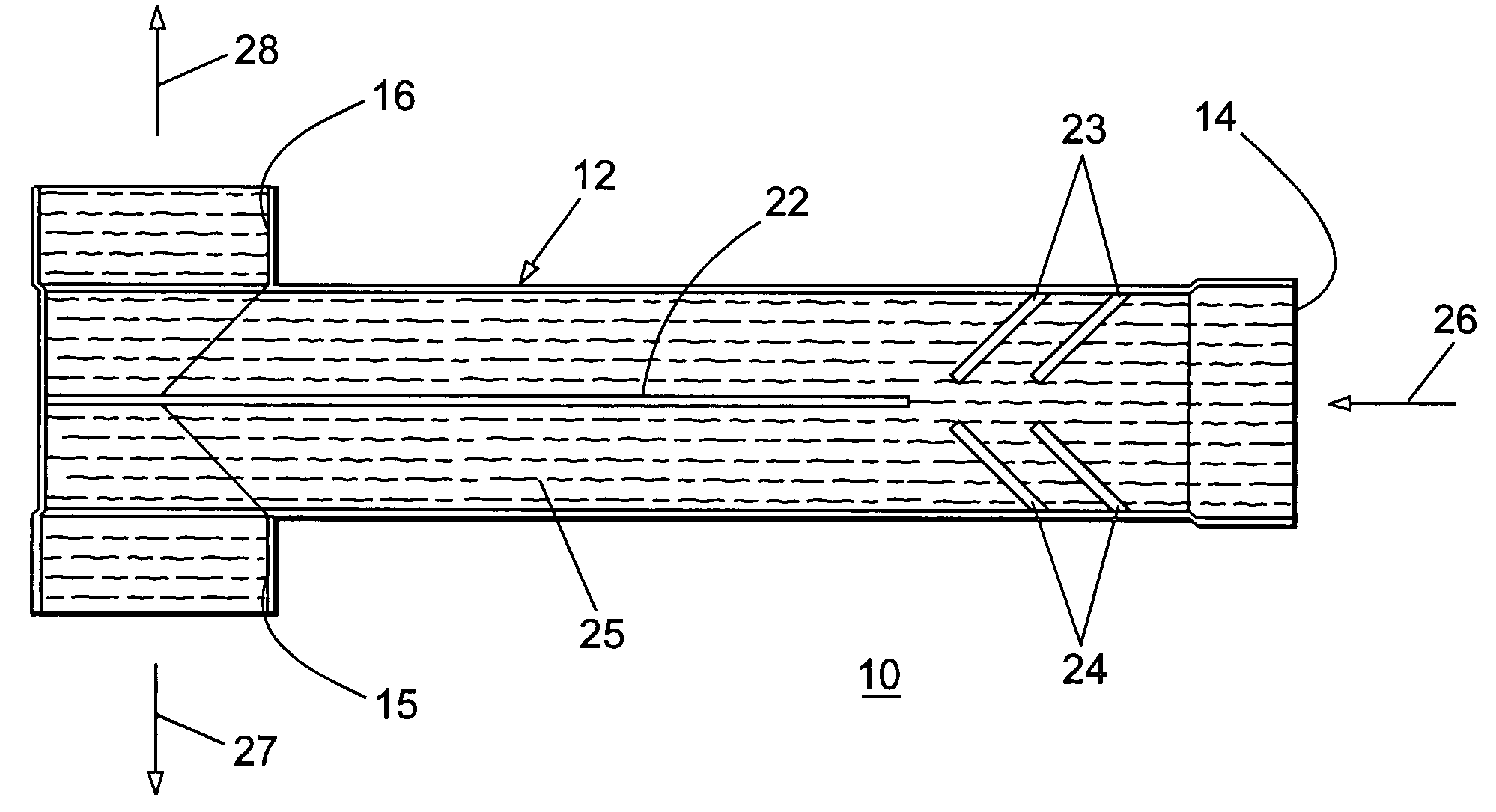

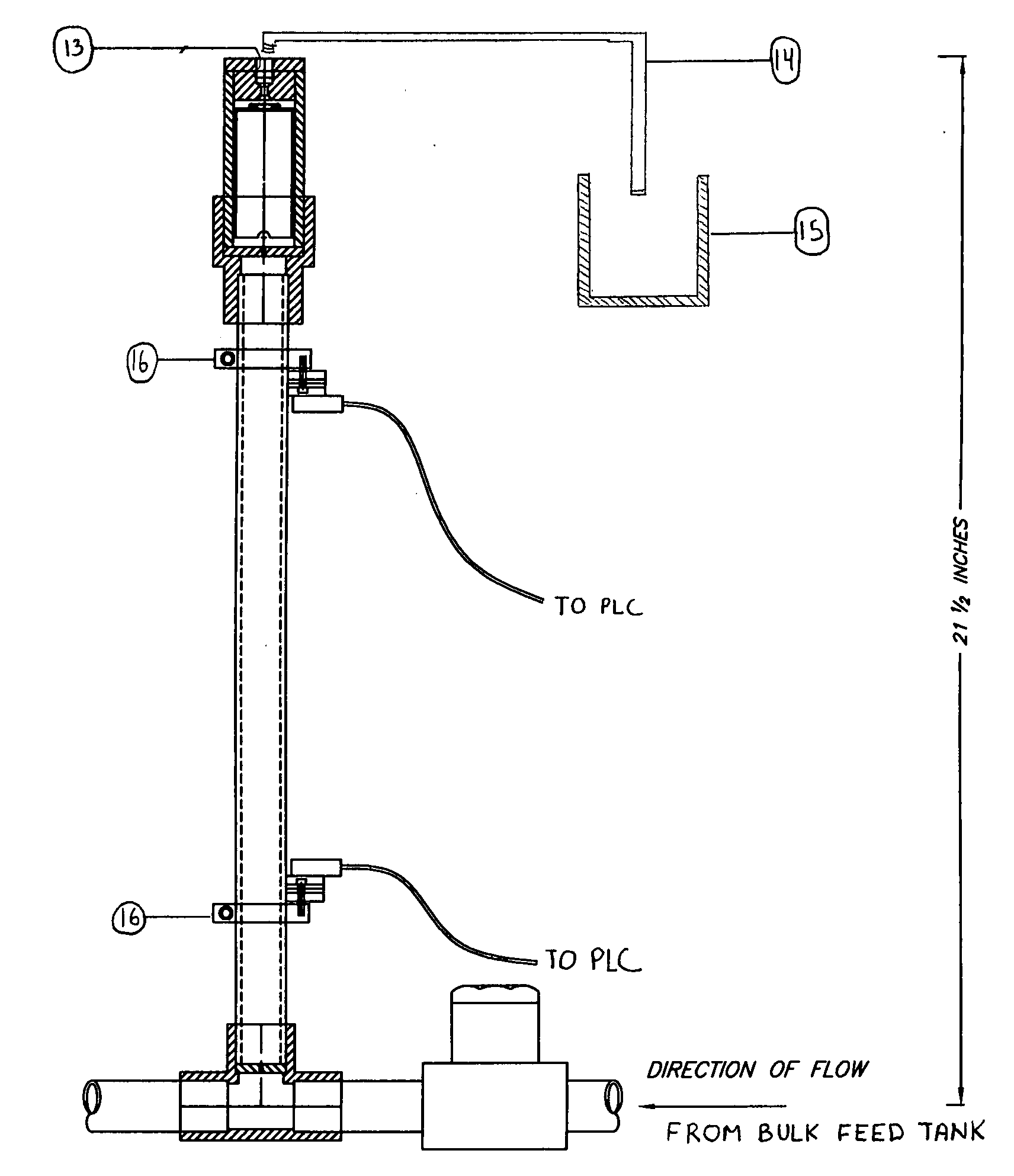

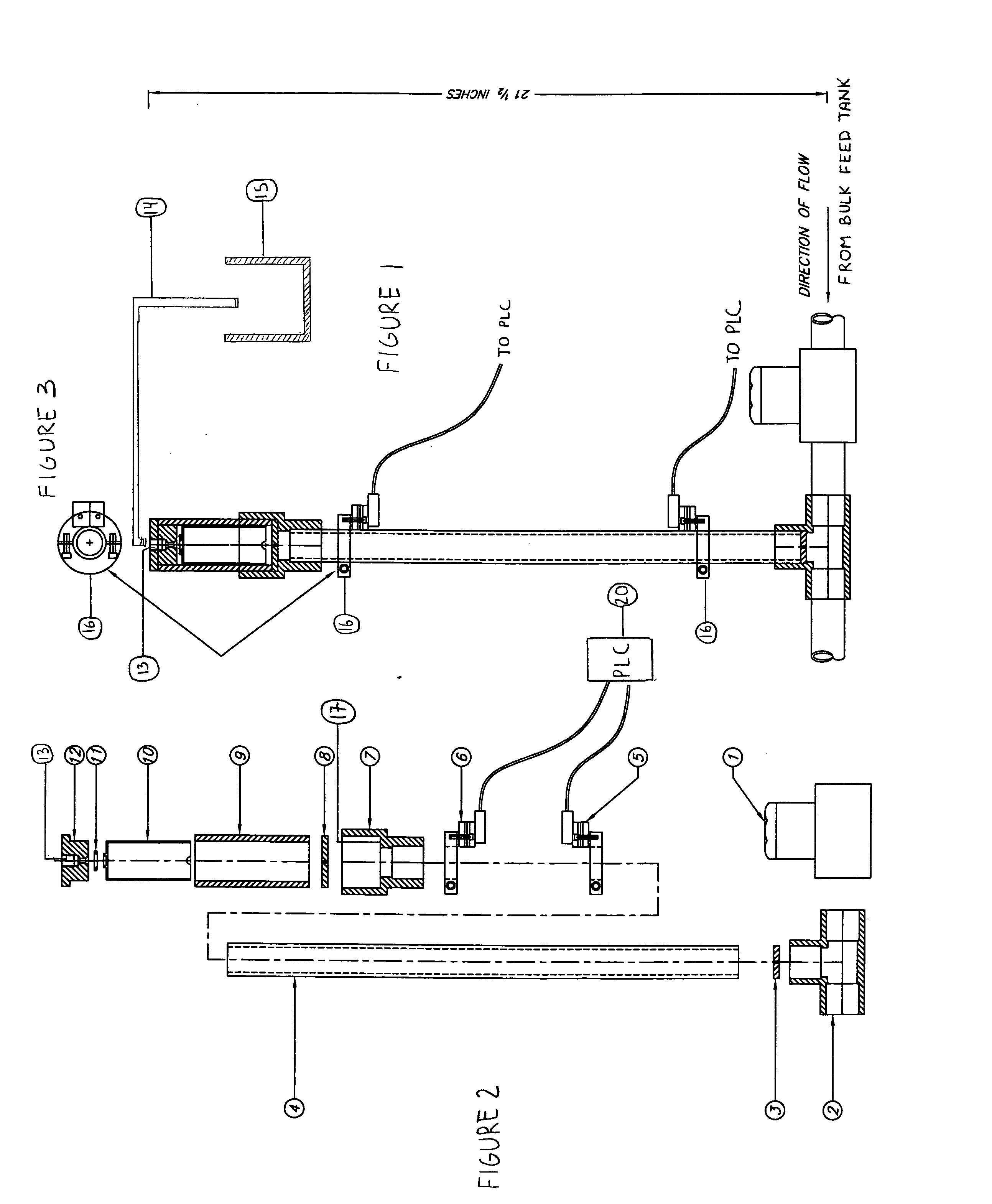

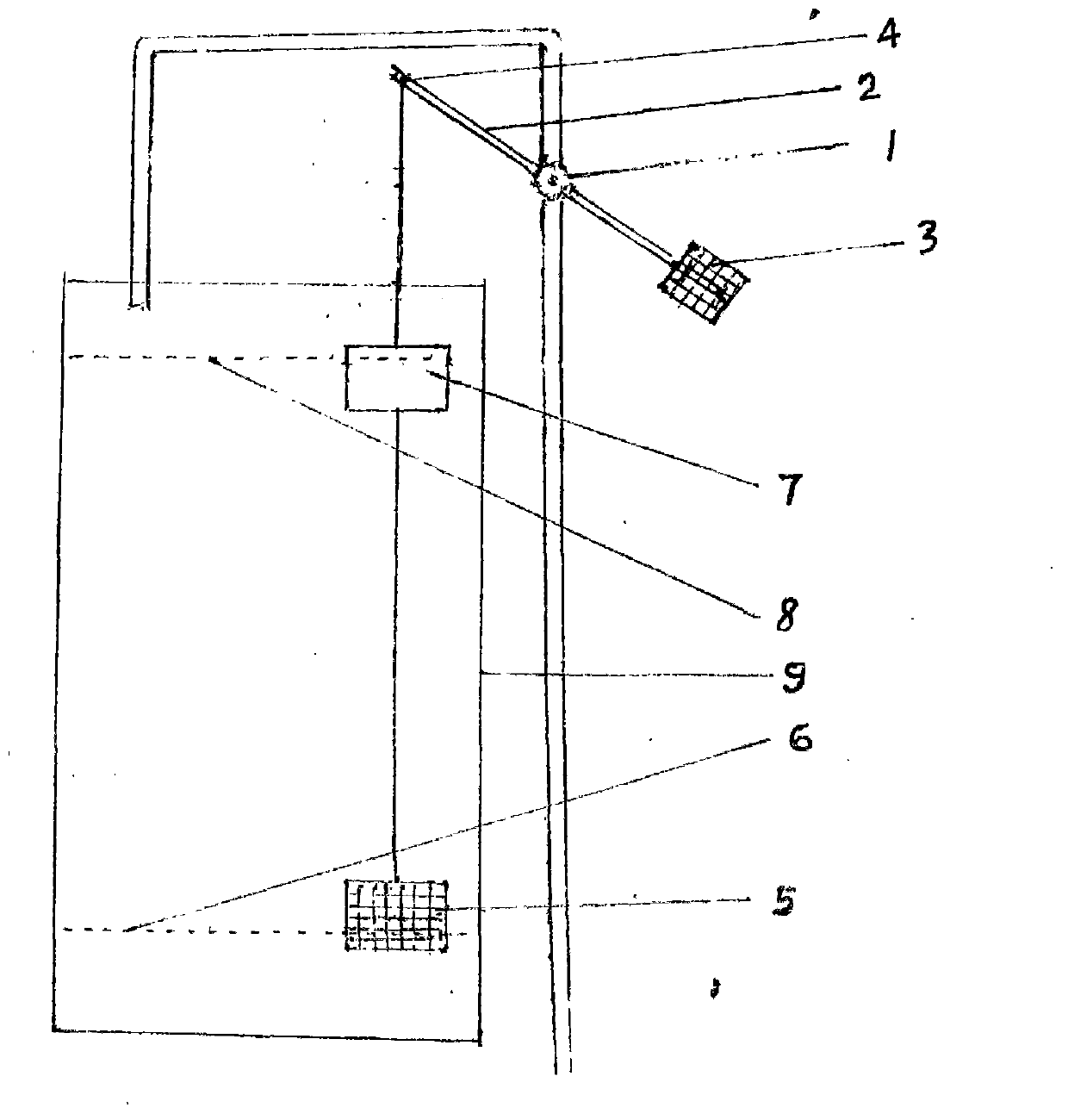

Automatic flow measuring device

InactiveUS20070169546A1Fully automatedVolume/mass flow measurementVolume flow proportion measurementProgrammable logic controllerFully automatic

An automatic flow measuring device is used in an industry where accuracy in dispensing of liquid is necessary. It is fully automatic in nature and is used with a PLC (programmable logic controller) to give the system intelligence and reporting capability. The automatic flow measuring device for measuring fluid flow includes an automatically operated valve, a tee connector operatively coupled to the automatically operated valve, an elongated member defining a measuring chamber coupled to the tee connector, at least a first fluid level sensor mounted on the elongated member at a first position thereon and a second fluid level sensor mounted on the elongated member at a second position thereon. The first and second sensors are preferably electronic and send signals to the PLC which opens and closes the automatically operated valve.

Owner:CONTROL & POWER SYST

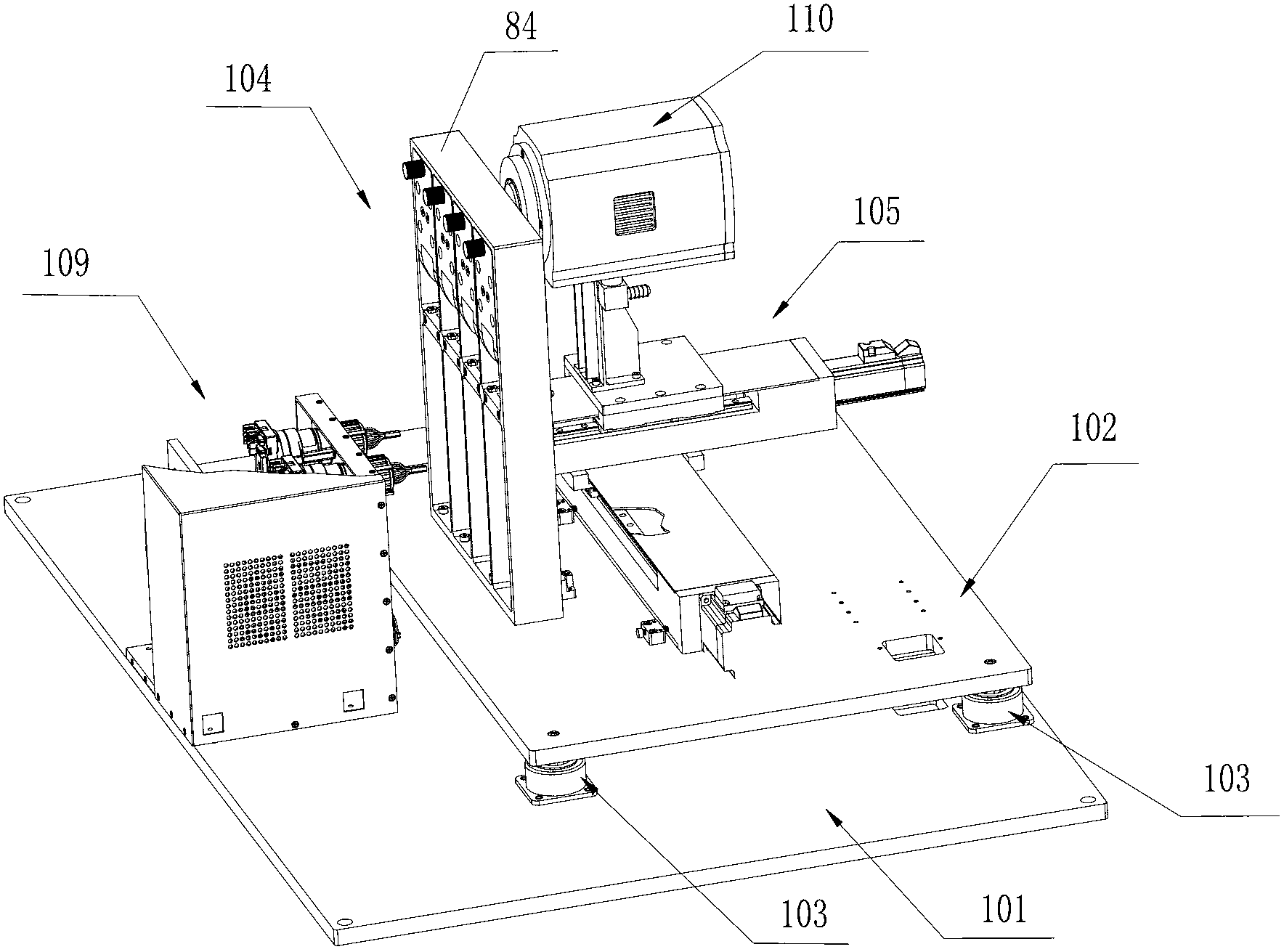

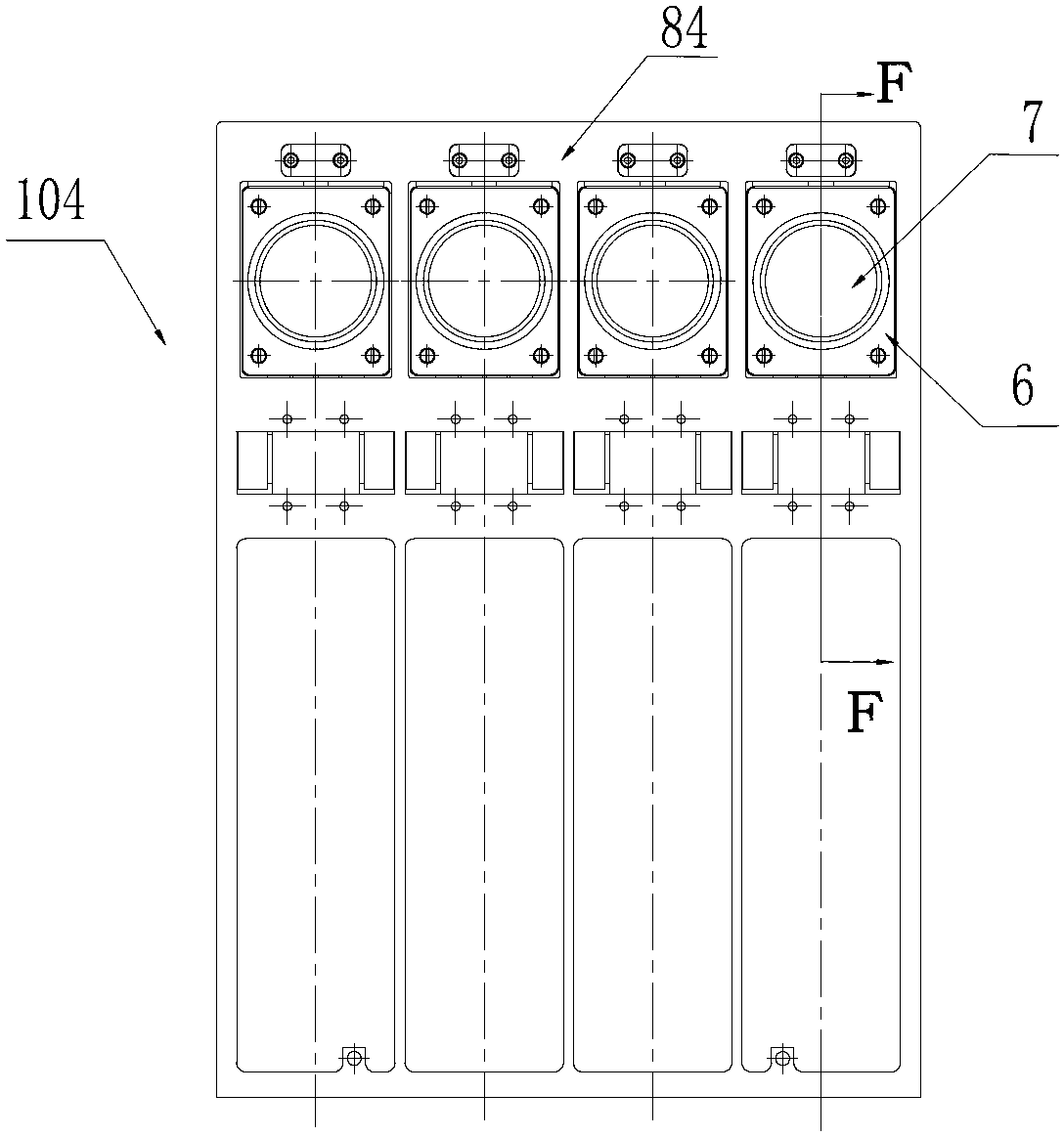

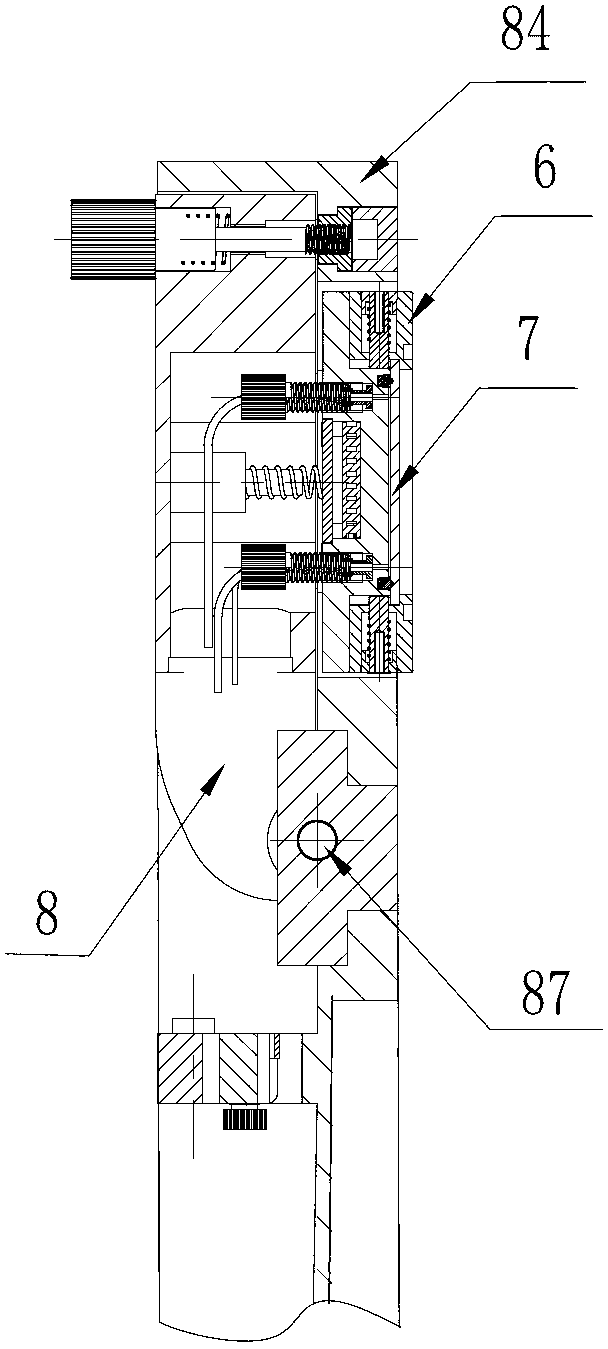

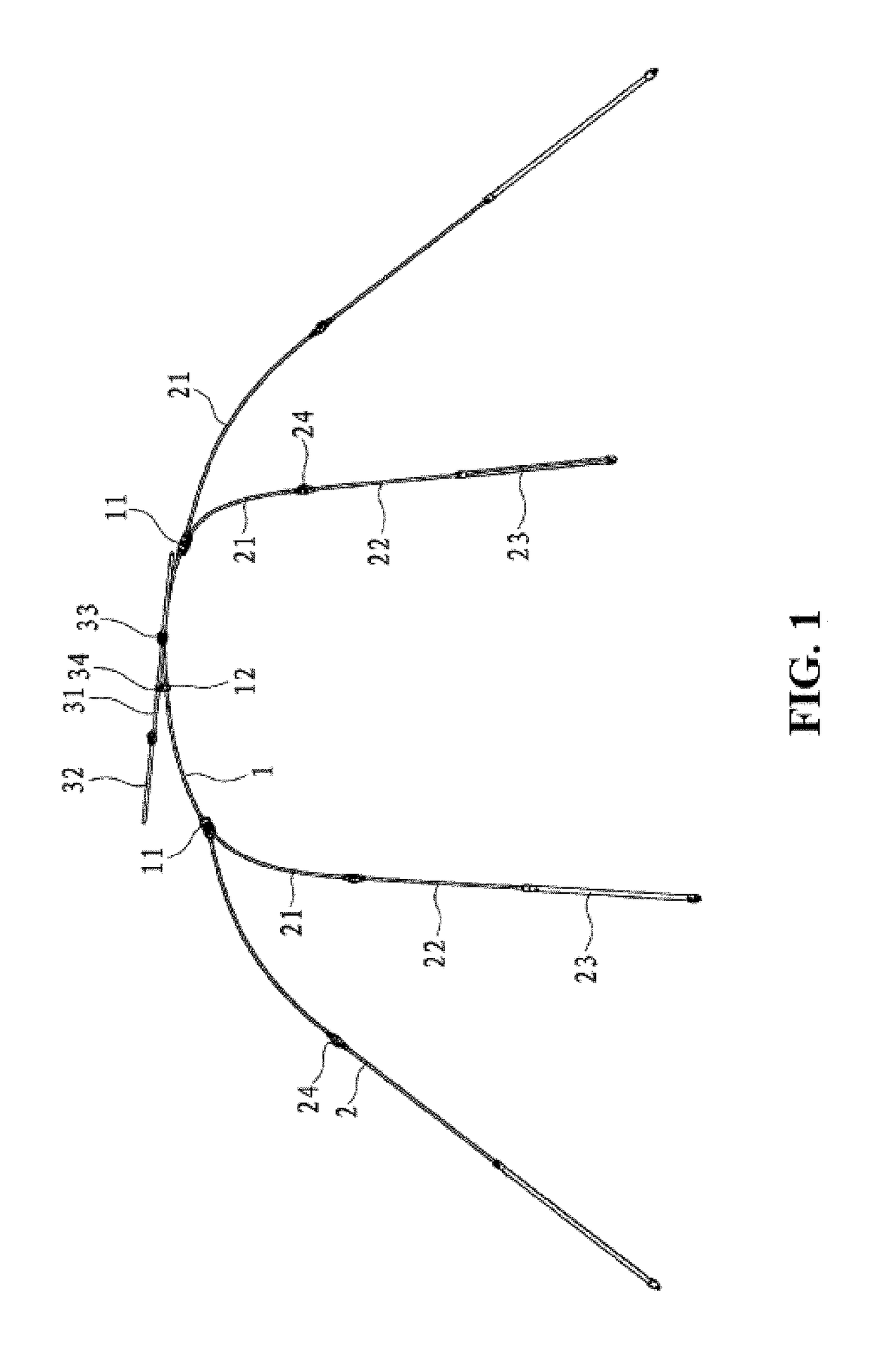

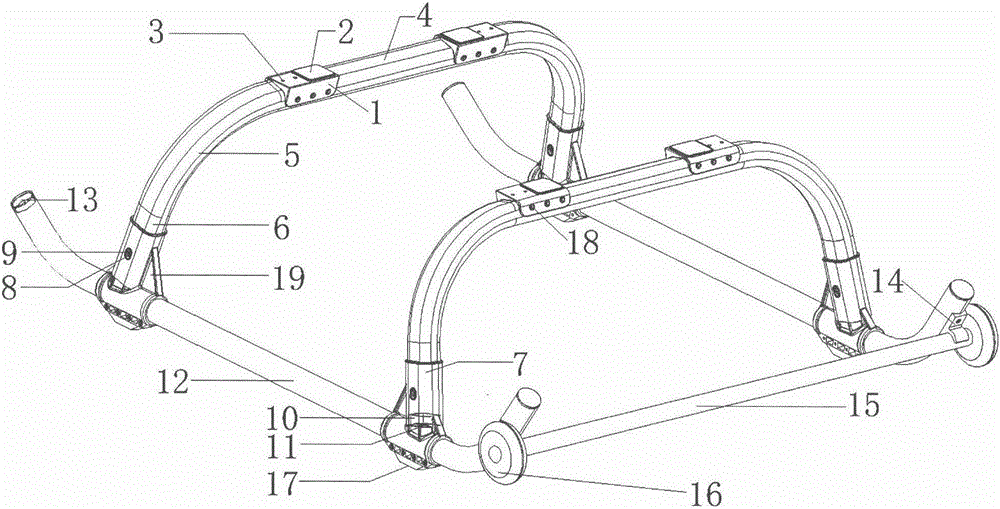

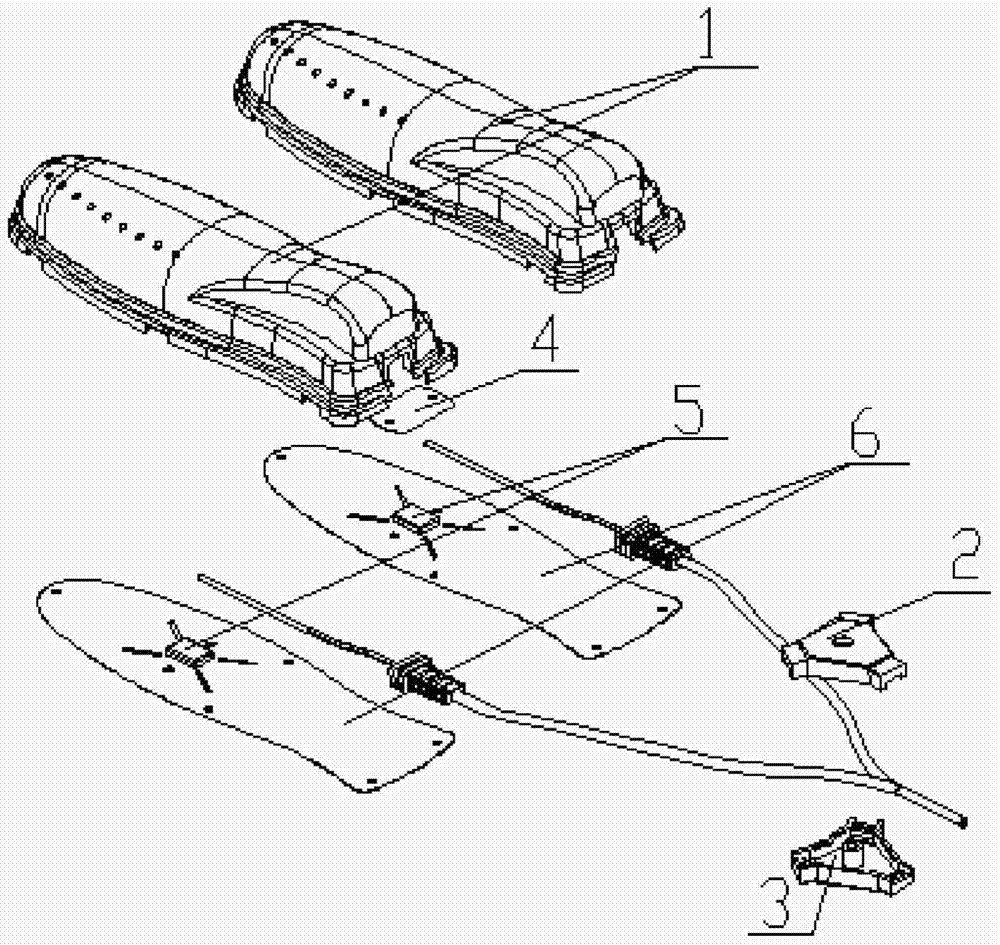

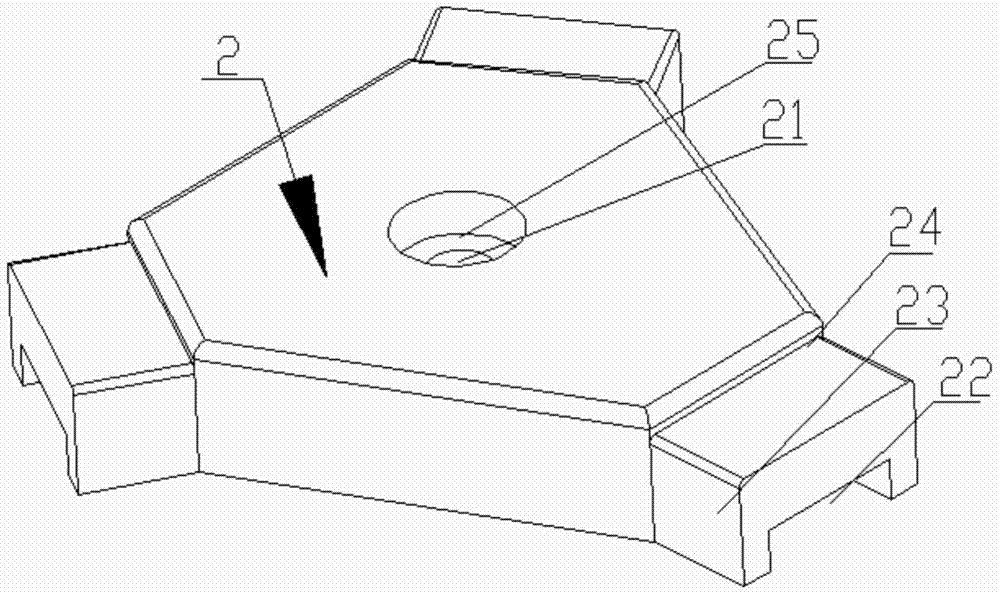

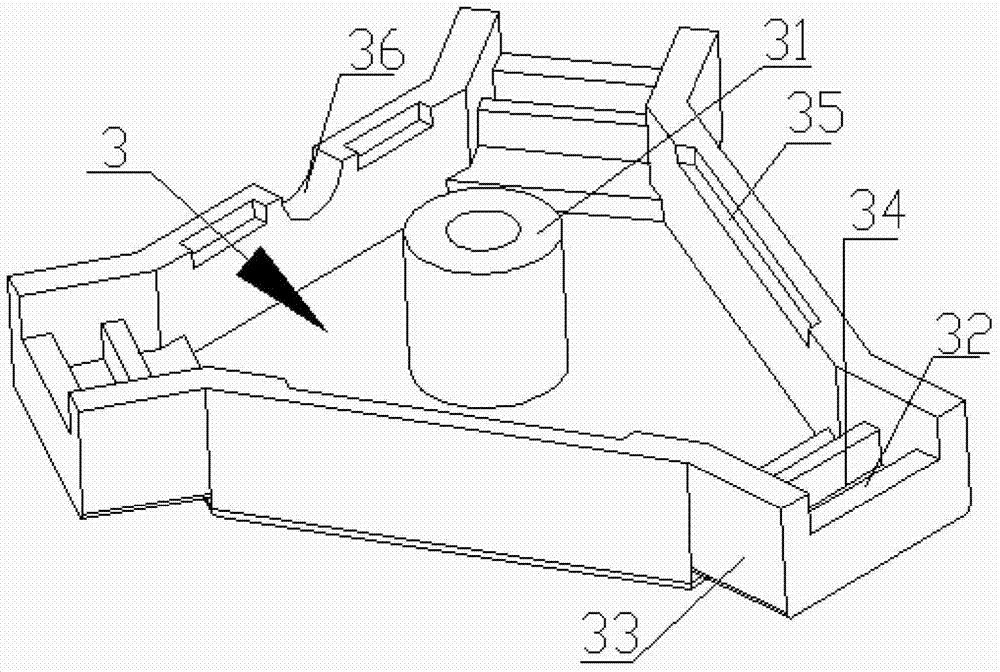

Unmanned helicopter carbon fiber undercarriage apparatus

InactiveCN106240805ADetection performance data is goodWeight increaseAlighting gearFiberCarbon fibers

The invention belongs to the technical field of unmanned helicopters and particularly relates to an unmanned helicopter carbon fiber undercarriage apparatus, comprising an unmanned helicopter base, a mounting platform, cushions A and carbon fiber cross beams fixedly through mounting holes; the carbon fiber cross beams, carbon fiber cross beams R and carbon fiber support posts are integrated rectangular tubes; carbon fiber tee connectors are fitted in lower rectangular tubes of the carbon fiber support posts, and rectangular pads and buffer rings B are fitted in upper rectangular tubes of the carbon fiber support posts that are then fixed through buffer shafts; carbon fiber slides are fitted into lower slotted round tubes of the carbon fiber connectors and are fixed to bottom platform buffer pads C through rivets; the unmanned helicopter carbon fiber undercarriage apparatus has the advantages that the carbon fiber undercarriage is 50% lighter than an aluminum alloy undercarriage, 0.8 kg of stainless steel buffer assembly is omitted for the aluminum alloy undercarriage, and the unmanned helicopter can bear more weight and travel longer; the buffer devices A, B and C for the carbon fiber undercarriage protect instruments and devices; the carbon fiber undercarriage apparatus is light, strong and tough and enables prolonged maintenance time of the unmanned helicopter and decreased potential hazards and operation cost.

Owner:李雪锋 +2

Structural member joints

A connector and method for joining one end of a first wood member such as a wood log or beam to a side of a second wood member involving metal sleeves secured in aligned holes in a respective member with a protruding one of the sleeve slidable into the other sleeve. A bolt is threaded into an internally threaded element on the inner end of the sleeve in the first member and advanced to pull the members together. The sleeves are secured in the holes with spike features driven out into the surrounding wood. Alternatively, a tee connector has a plate portion fitting into a slot extending through aligned holes in the plate and one end of the first member. A cross plate is held against the one side of the other member with thread fasteners.

Owner:KAUPPILA RICHARD W

Shoe dryer

The invention discloses a shoe dryer. The shoe dryer comprises two bodies arranged suitable for structures of a pair of shoes, heating pieces used for heating and two wires connected with the heating pieces respectively, the two wires are fixed to a tee connector, and the two wires are connected with a plug at the position of the tee connector through another wire, wherein the plug is used for being in inserting connection with a socket. The shoe dryer comprises the tee connector, the two wires connected with the heating pieces in the bodies are connected and fixed together through the tee connector, through the tee connector, the two fixed wires are connected with the wire connected with the plug, the wire connected with the plug is also fixed into the tee connector, and therefore the wires of the two bodies are firmly fixed into the tee connector, and the wires are closely connected and not prone to damage.

Owner:启东茂财源鞋业有限公司

Lawn chemical application system

InactiveUS20060108455A1Easy and inexpensive to manufactureEasy and inexpensive to and installWatering devicesSpray nozzlesWater flowClosed chamber

A lawn chemical application system is disclosed. The system comprises a dispenser having a lower chamber, an upper chamber, an upstream opening, and a downstream opening. The dispenser may be formed by a tee connector and a cylinder secured to an upper opening of the tee connector. Powered valves are operably connected to the upstream and downstream openings of the dispenser. The powered valves may be wired to open and close simultaneously. A lower portion of the upper chamber may be disposed below an upper portion of the lower chamber and above a lower portion of the lower chamber, leaving the lower portion of the lower chamber unobstructed over substantially its entire length. The lower portion of the upper chamber may have a plurality of openings to provide for adequate mixing of water with the chemicals stored in the upper chamber. In operation, soluble matter or other chemicals are placed in the upper chamber of the dispenser, and the two valves are opened simultaneously. Water flows through the first powered valve and into the dispenser, where the water is mixed with soluble matter or other chemicals stored in the upper chamber of the tee. The solution or mixture then passes from the dispenser, through the second powered valve, to one or more sprinkler heads of the irrigation system. When the application is finished, the valves are closed simultaneously.

Owner:THORNTON BRIAN

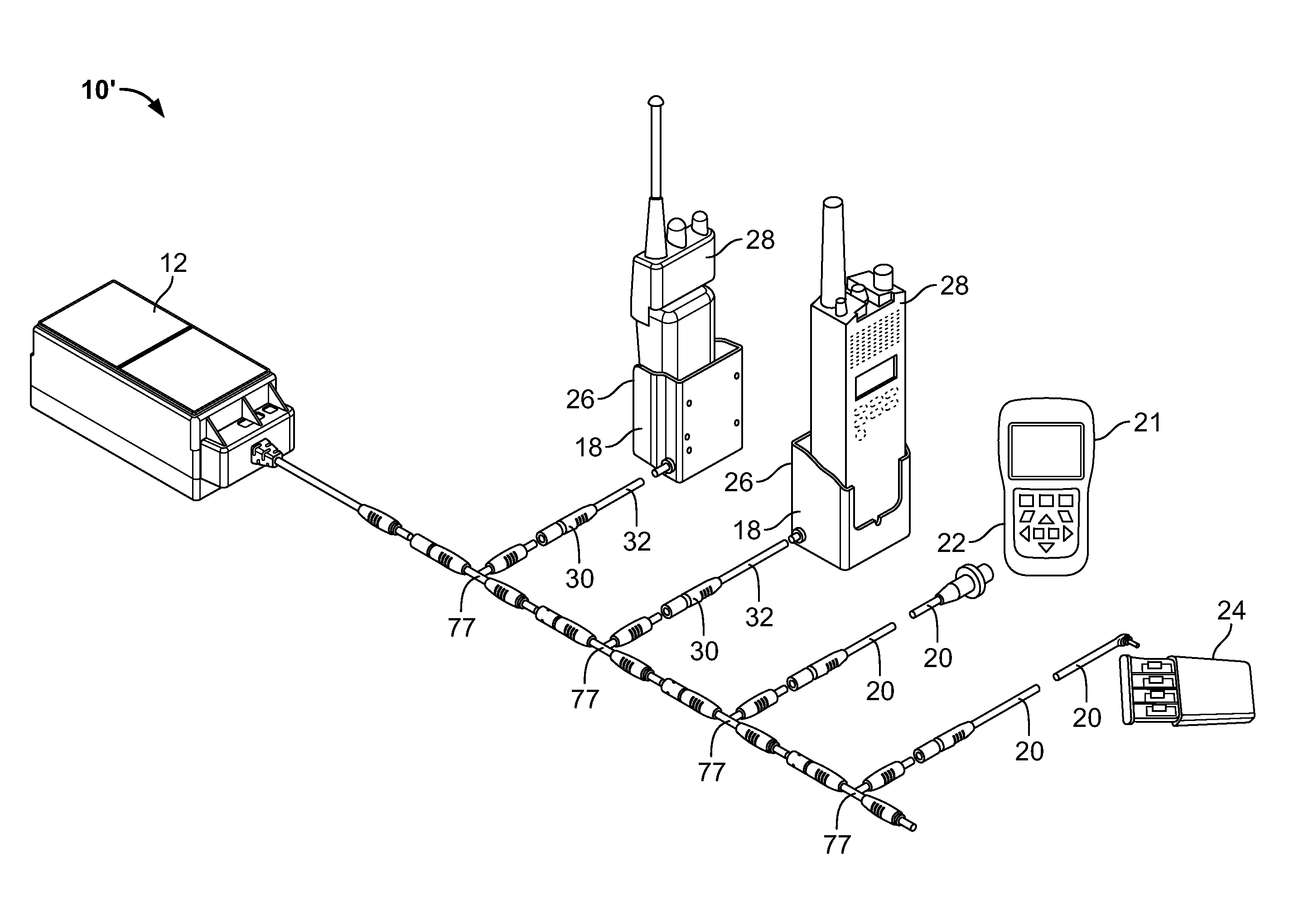

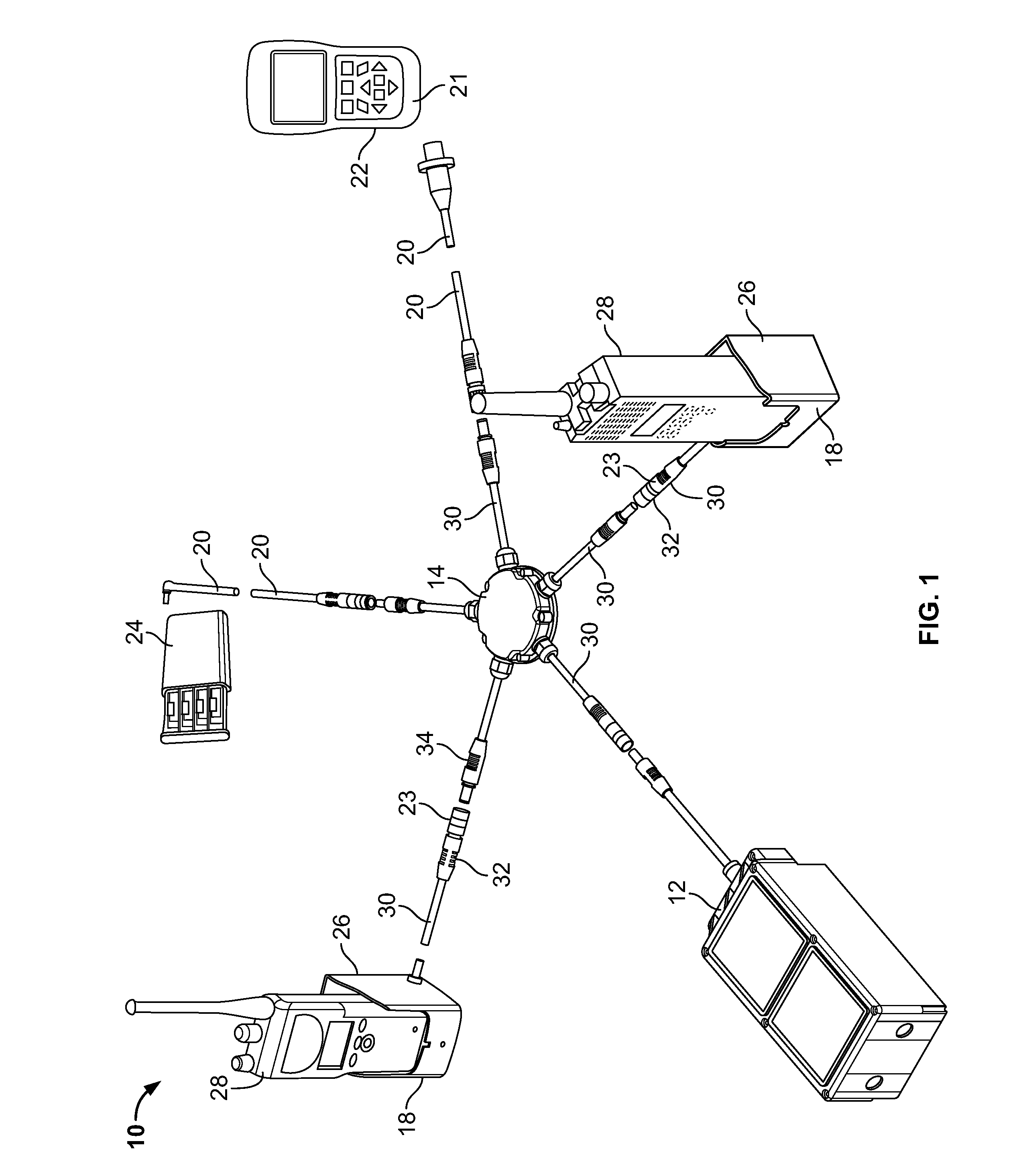

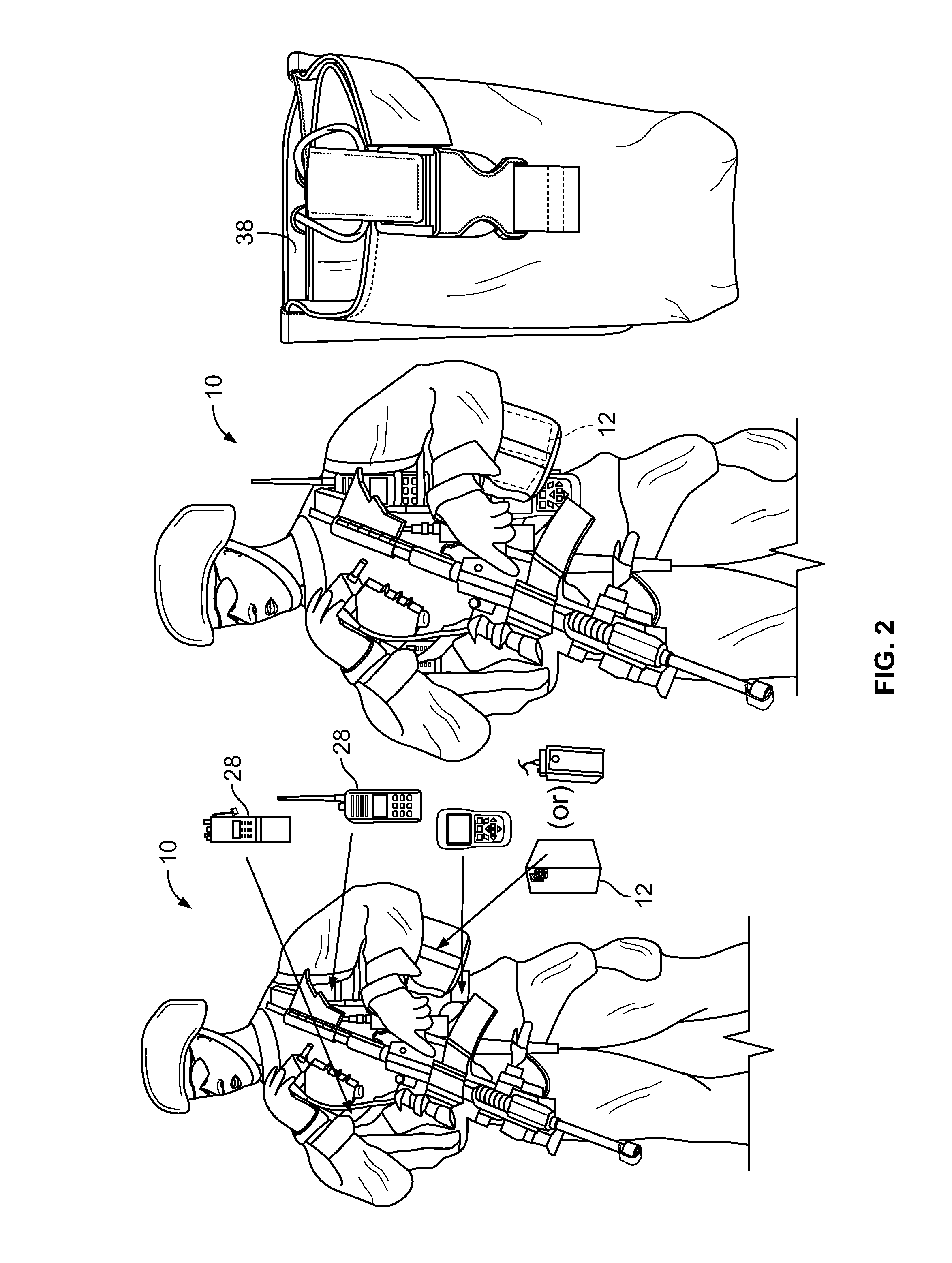

Lightweight power system for continuously charging multiple battery powered devices carried by a dismounted soldier

ActiveUS8587261B2Electric powerArrangements for several simultaneous batteriesEngineeringZinc–air battery

An apparatus for charging multiple rechargeable devices is disclosed. The apparatus includes a hub or multiple T-connectors connected between a power source, preferably a Zinc-air battery, and several chargers, the hub / T-connectors configured to provide electrical and mechanical connectivity between the power source and the chargers. The apparatus includes housings configured to encase the chargers and to conformally receive each of the corresponding devices containing rechargeable batteries. The apparatus further includes pouches configured to removably receive chargers, devices, and the power source. When the power source voltage falls below a certain threshold, then a charger associated with a device having the smallest difference between its rated voltage and its measured voltage discontinues charging before other chargers. The apparatus is wearable by a user.

Owner:ELECTRIC FUEL BATTERY

Valsalva Maneuver visualizing and quantifying device

PendingCN108186005AEasy to useConvenient and quick outpatient screeningGymnastic exercisingIntracranial pressure measurementEngineeringValsalva maneuver

The invention relates to the technical field of medical devices and discloses a Valsalva maneuver visualizing and quantifying device, comprising a first connection tube, a filter nozzle, a breath filter, a gas pressure meter, a tee connector, a second connection tube and a balloon; the filter nozzle and the breath filter are releasably and hermetically mounted at a left port of the first connection tube; a right port of the first connection tube is hermetically connected to a left port of the tee connector; an upper port of the tee connector is hermetically connected with the gas pressure meter; a right port of the tee connector is hermetically connected with a left port of the second connection tube; a right port of the second connection tube is hermetically connected with the balloon. The Valsalva maneuver visualizing and quantifying device can help a patient to finish Valsalva maneuver, allows for standard, quantified and visualized Valsalva maneuver, is simple in structure, easy tomanufacture, low in cost, convenient to use and high in popularization performance.

Owner:川北医学院附属医院

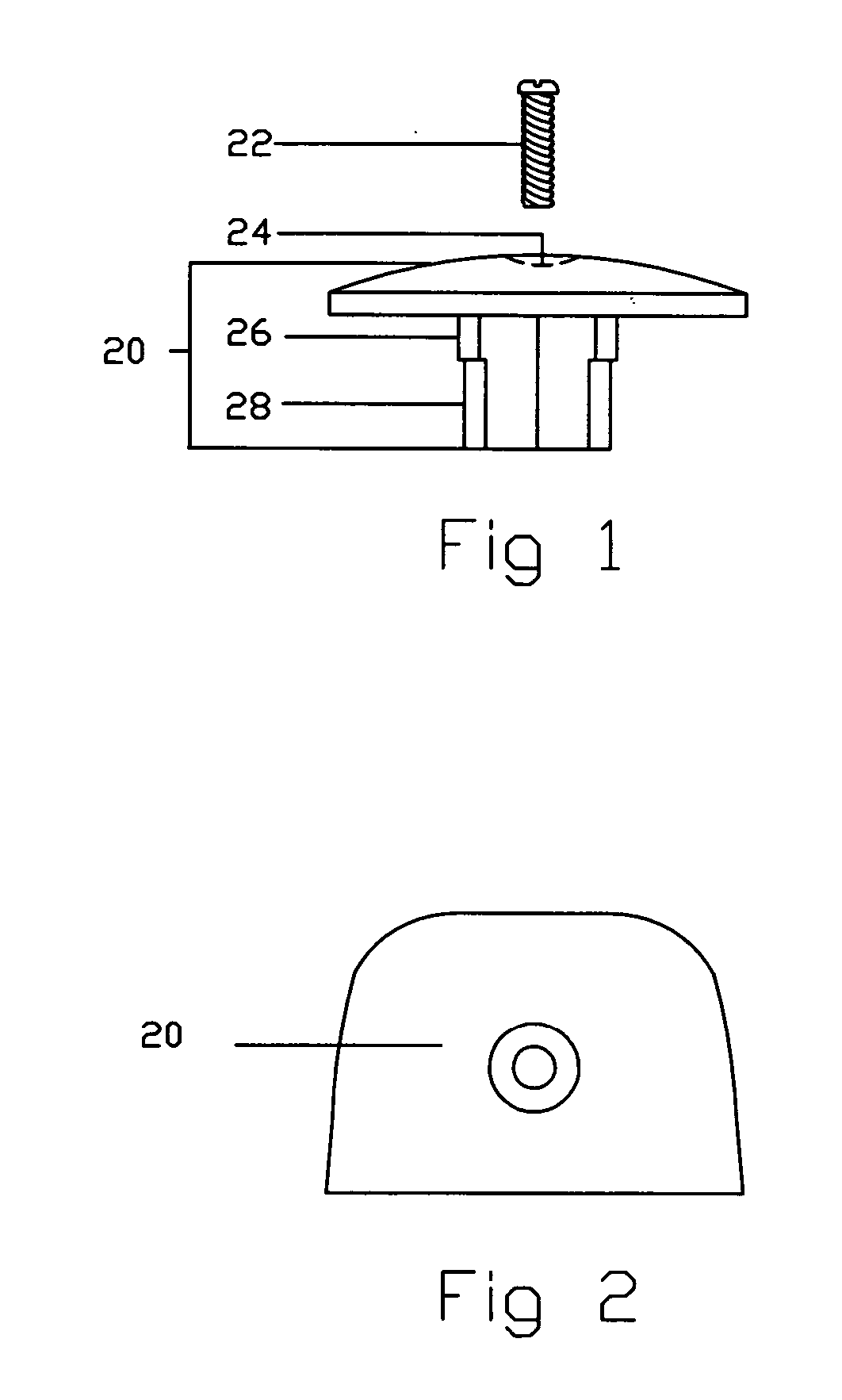

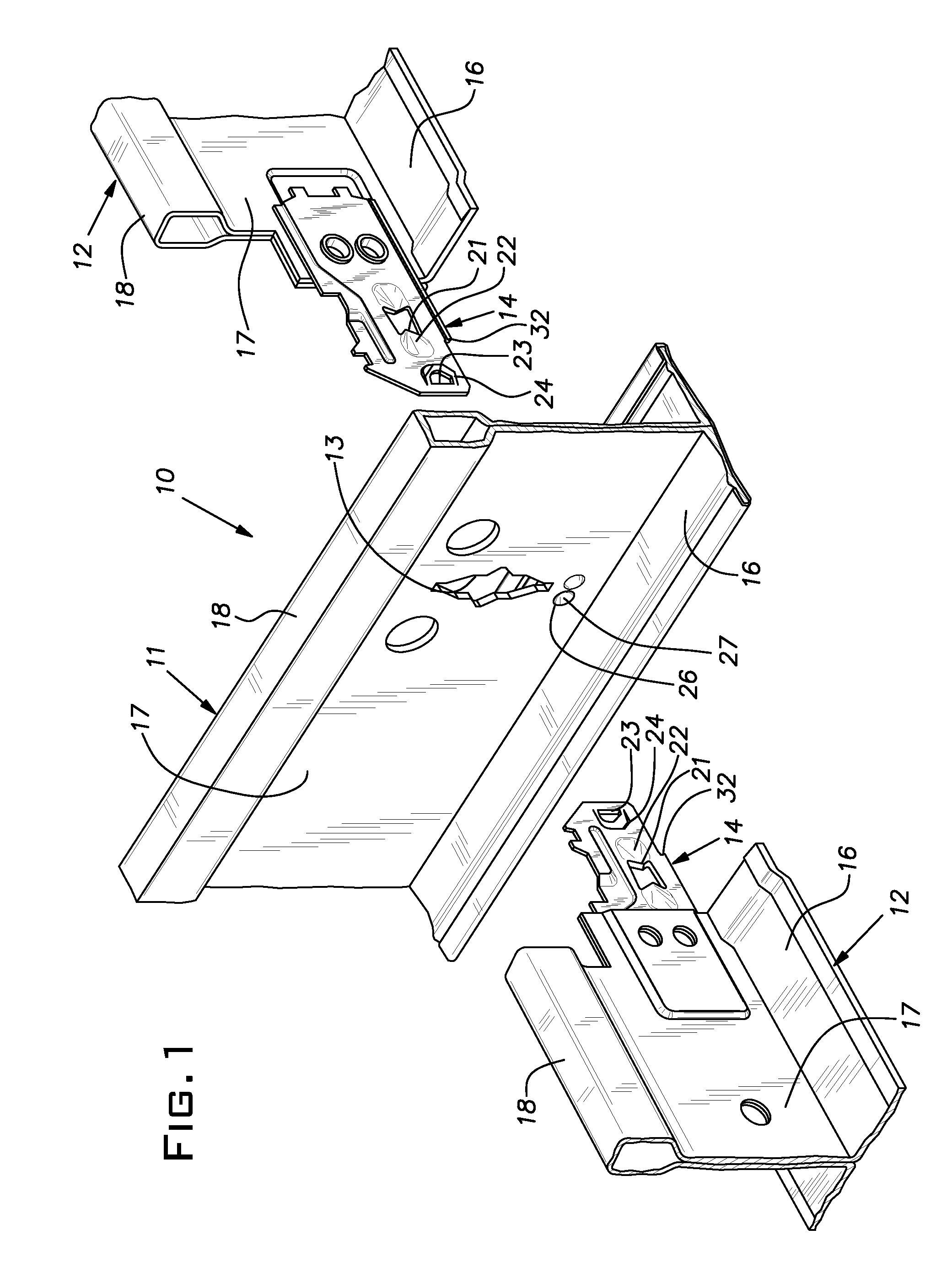

Clip connection

InactiveUS8511028B2Improve fitUniform effective thicknessCeilingsFurnace componentsLeading edgeEngineering

Owner:USG INTERIORS INC

Weight-pressing lever automatically controlling switch

InactiveCN103137379AAchieve foolproof technical resultsAvoid the hidden danger of failureElectric switchesAutomatic controlWater flow

A weight-pressing lever automatically controlling switch capable of automatically controlling water supplying and water pumping is successfully assembled and successfully used. An interior structure of the prior high-quality switch is adopted by the weight-pressing lever automatically controlling switch. A manual operation surface of the high-quality switch is directly or indirectly provided a weight-pressing lever by the same force. The weight-pressing lever automatically controlling switch capable closing and pressing weight and being made into a self-closing state is allocated, wherein a self-opening state is allocated if water flows out. The other opening end of the lever is connected with variation gravity and is automatically opened, wherein the force of the variation gravity is twice of the force of force capable of opening. The variation gravity comes from a floater and variation gravity ballast. The ballast is regulated to be in an underwater level to expose outside, lose flotage, be added in weight and automatically open. Through the flotage of the floater, the variation gravity ballast is driven to move upwards and ensures that a switch on an automatically closed mode automatically closes. Disturbance is overcome through tightness of the switch or compression set force of a spring, and accordingly the technical scheme which is of no risk at all is achieved. When an alarming device is connected in series, all hidden danger is eliminated and a novel satisfying produce is made, wherein the alarm device is made by the matching switch, a matching suspending light bottle with water accommodated on the upper water level and a matching tee connector.

Owner:付小林

Cool vest

InactiveUS20120151951A1Limit traumaTherapy is also rapidLighting and heating apparatusOvergarmentsAdhesiveEngineering

A method and apparatus for adjusting the body temperature of a patient comprises a vest receiving at least a portion of the body and head. The vest comprises a frontal opening with adjustable Velcro adhesive for accommodating different patients and two openings for the arms with rubber-tubing coiled between two layers of fabric, one being thermal insulated. The rubber-tubing from the vest will be connected to a pump then connected to a copper-tubing coil inside a cooler to form a closed circuit loop between the rubber-tubing, copper-tubing coil and pump. Water or other liquids will be circulated via pump into vest from copper-tubing coil inside a cooler filled with ice. The vest, pump and copper coil will be portable and there will be two union connectors, two tee connectors, and a manual diverter to enable unit to also be powered via a stationary cooling motor if so desired.

Owner:TERRY DENNIS T

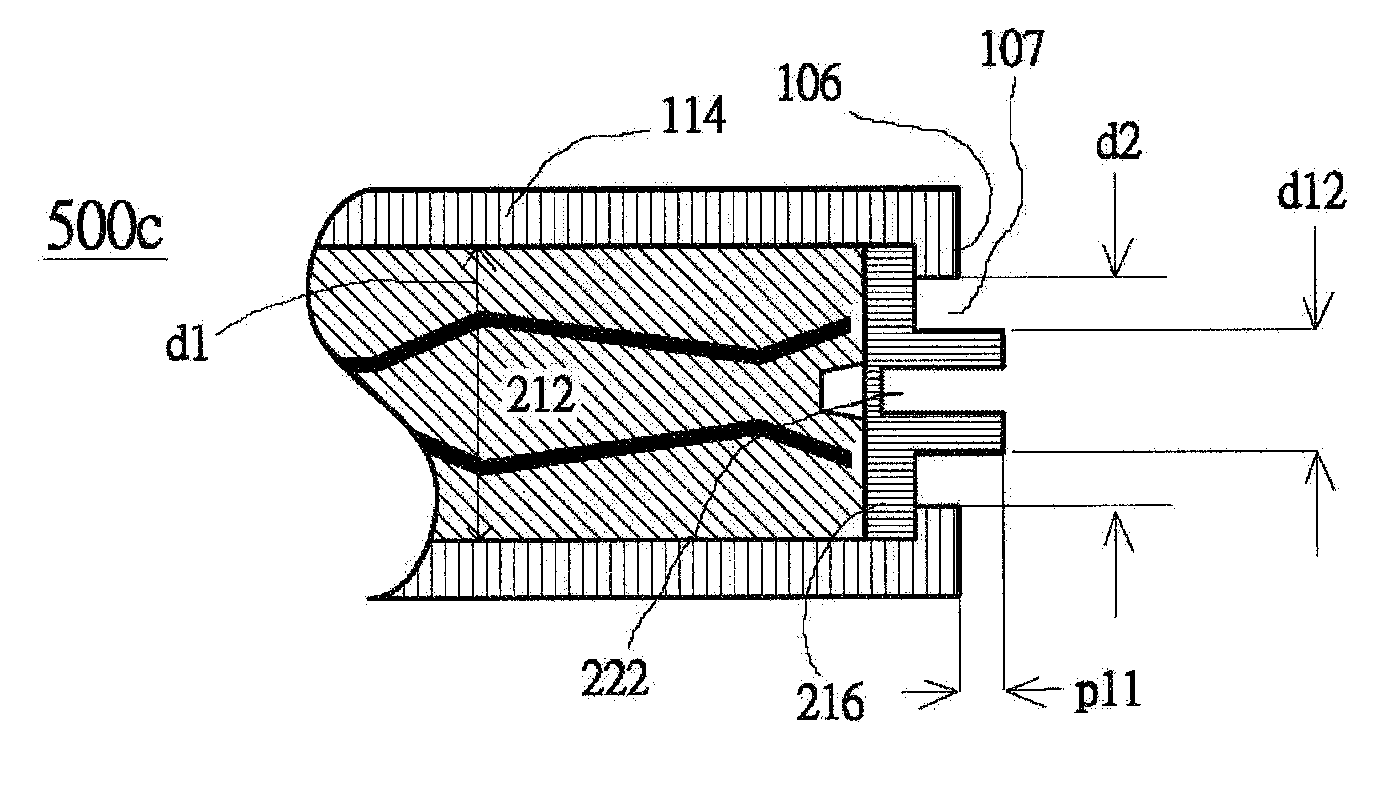

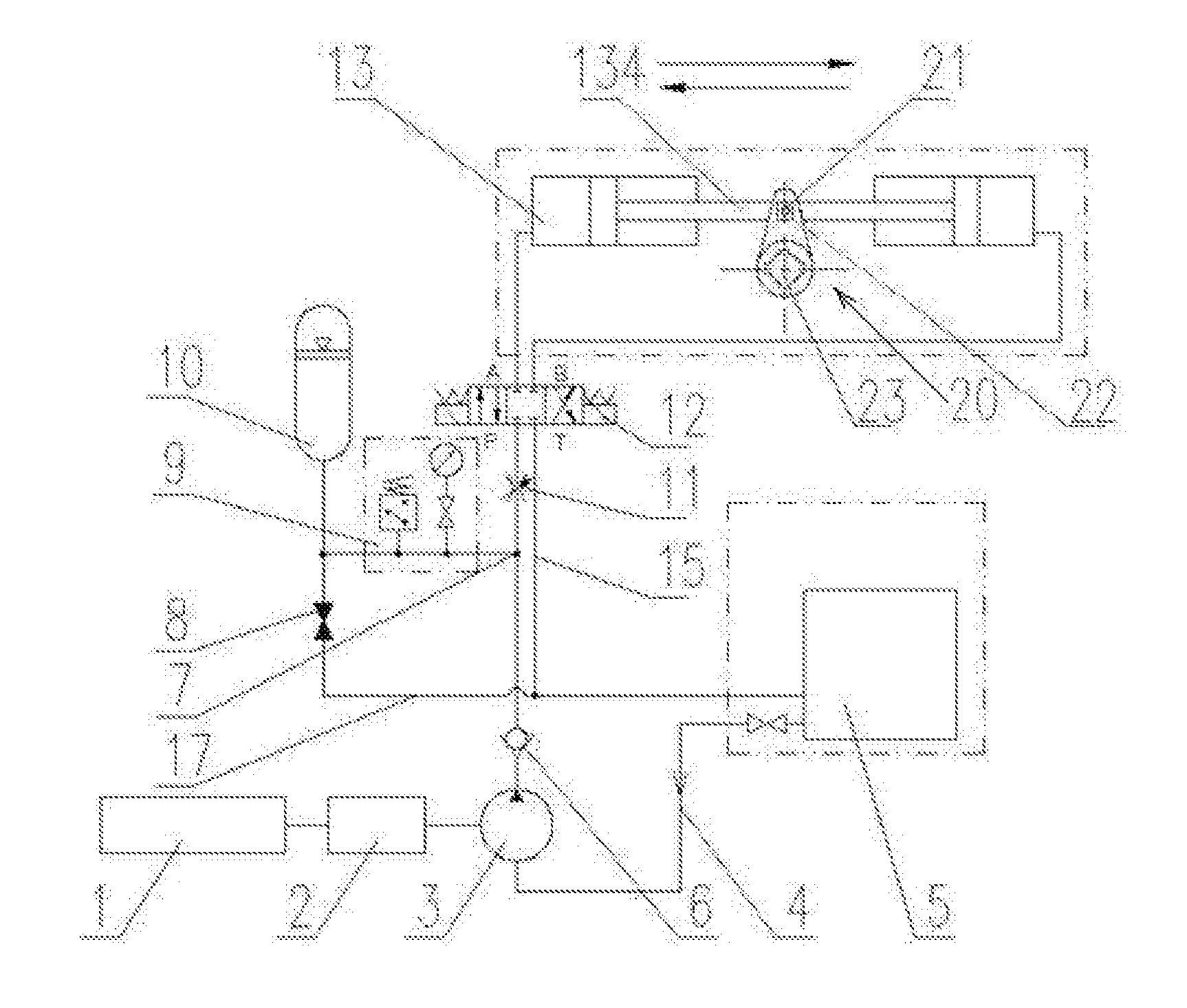

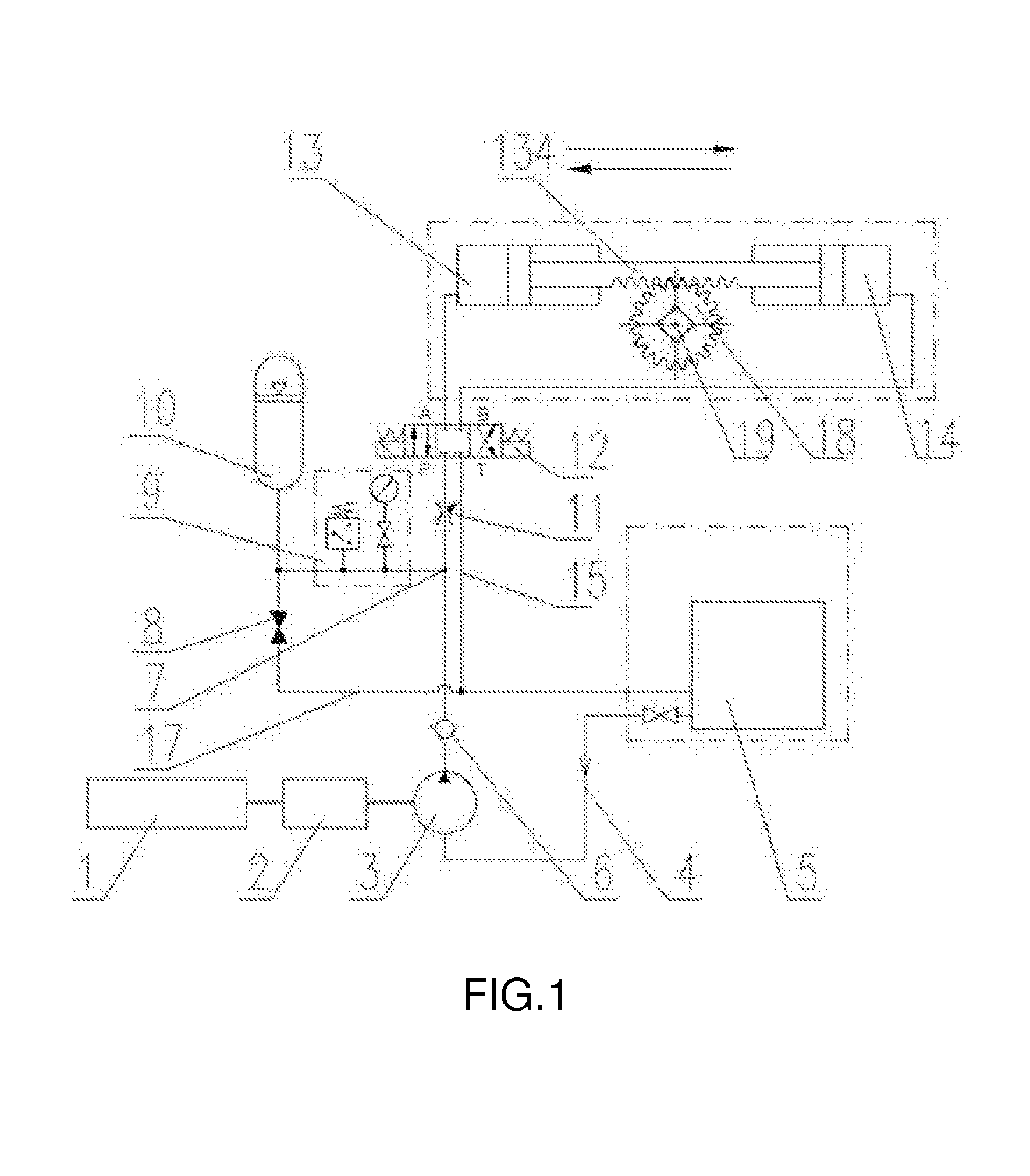

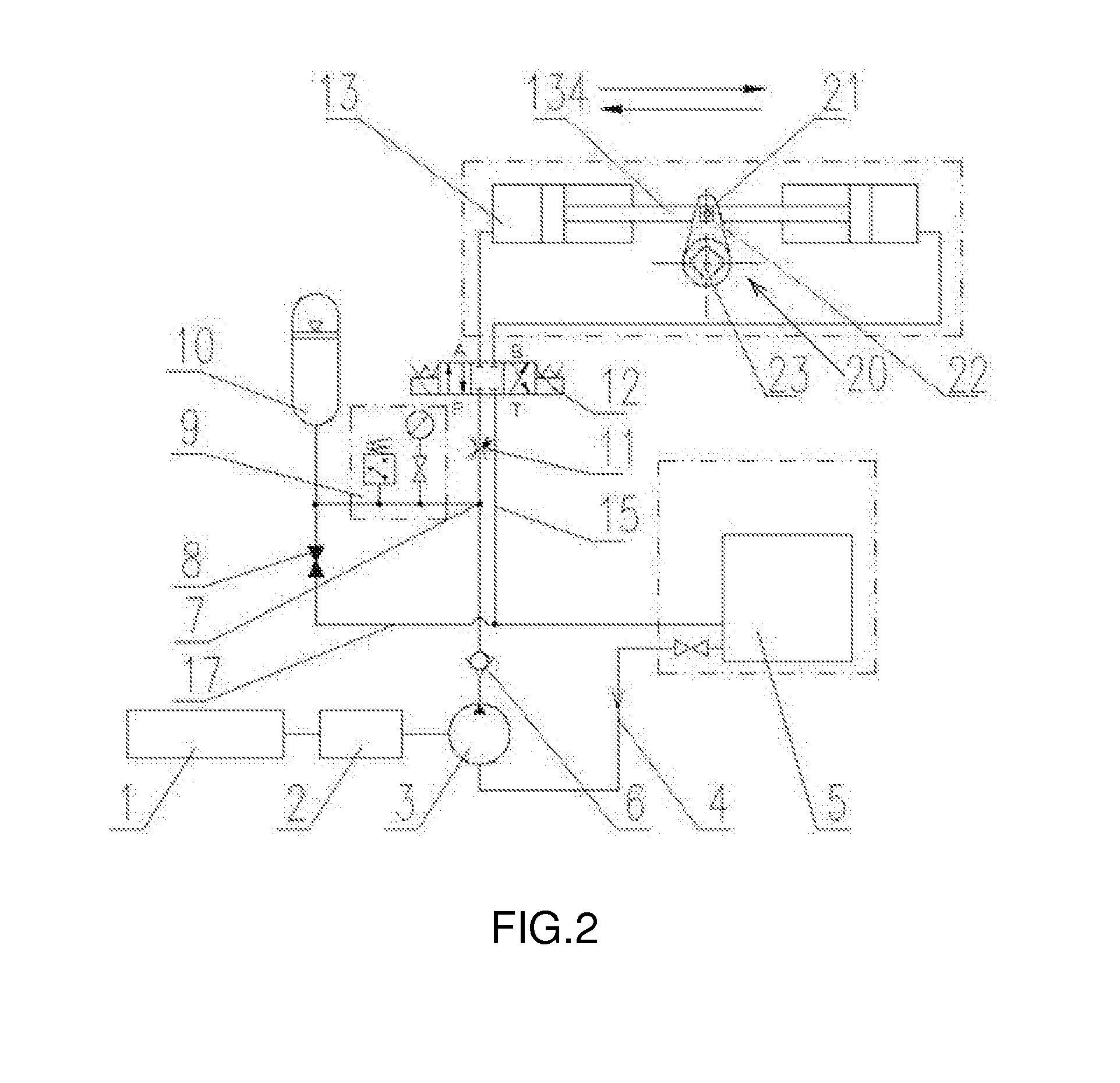

Electro-hydraulic system for driving large-scale rotary motion valve supplied by solar low-capacity power

InactiveUS20150041688A1Improves system input-output ratioReduce equipmentSolar heating energyOperating means/releasing devices for valvesSolenoid valveFuel tank

An electro-hydraulic system for driving a large-scale rotary motion valve supplied by a solar low-capacity power. A step motor (2) and an oil pump (3) are in turn driven by a low-capacity solar power supply (1). An oil tank (5), the oil pump, a check valve (6), a T-connector (7) and a liquid accumulator (10) are in turn arranged on an oil storage pipeline (4). An oil inlet pipeline (16) is connected to the rest of the ports of the T-connector. An oil inlet of a three-position four-way reversing solenoid valve (12) is connected to the oil inlet pipeline. Two ends of an oil return pipeline are connected to an oil return port of the reversing valve and an oil return port of the oil tank, respectively. Each of two oil outlets of the reversing valve is respectively connected to an oil port of a single-chamber cylinder via a pipeline. The outer ends of the piston rods of cylinders A and B are rigidly connected together to form one piston rod (134). A linear-to-rotary transition mechanism is provided between the piston rod (134) and a spool (19) of the rotary motion valve. Since the low-capacity solar power supply is adopted in the system, the equipment cost, the operation cost and the maintenance cost of the system are reduced, and the input-output ratio of the system is increased.

Owner:LIU BAOJUN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com