Centrally symmetric silicon carbide (SiC) single crystal growing device and method

A growth device and a symmetrical technology, applied in the field of SiC single crystal growth devices, can solve the problems that the crystal does not have central symmetry, reduce the radial temperature gradient, and the shape does not have central axis symmetry, so as to save the source material and Growth time, increased effective thickness, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

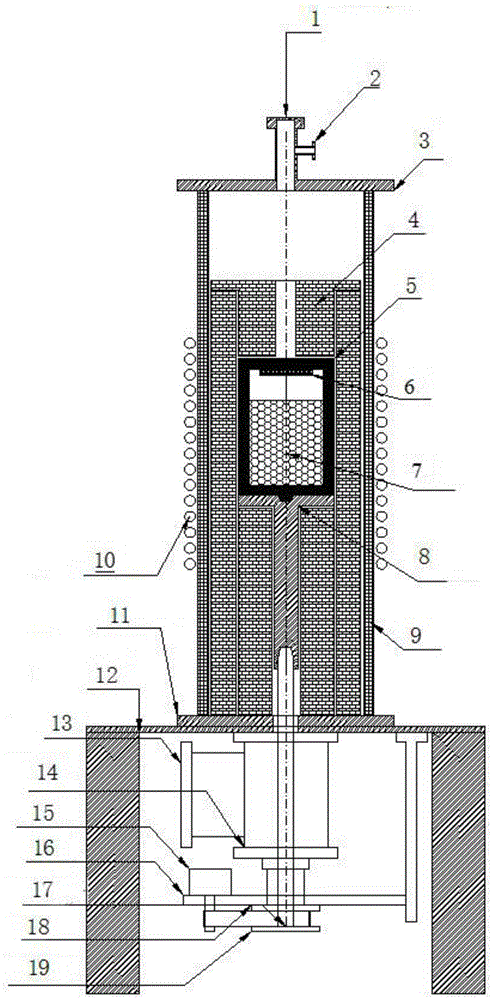

[0039] A SiC single crystal growth device with central symmetry, structure such as figure 1 As shown, it includes a heating device, a vacuum growth chamber 9, and a graphite crucible 5 with a cover. The bottom of the graphite crucible 5 is connected with a rotating system that rotates the graphite crucible. The rotating system includes a rotating tray 8, a center rotating rod 14 and a driving center rotating rod. Active driving device, the driving device is hermetically connected with the vacuum growth chamber 9 through the three-way connector 14, the central rotating rod 17 passes through the three-way connector 14 and is connected to the drive device. The drive device includes a stator 18 and a The rotor 19 and the rotating electric machine 15, one port of the three-way connector 14 is hermetically connected to the vacuum growth chamber 9, one port is connected to the exhaust port 13 through a molecular pump, the other port is magnetically sealed to the rotor 19, and the centra...

Embodiment 2

[0046] The same as the SiC single crystal growth device with central symmetry described in Example 1, except that:

[0047] The center of the bottom end of the rotating handle of the rotating tray 8 is provided with a positioning groove, and the top of the central rotating rod 17 is provided with a positioning end adapted to the positioning groove. After positioning, the central axis of symmetry of the tray coincides with the central axis of the central rotating rod. The positioning end is triangular.

[0048] The graphite crucible 5 has central symmetry. A positioning cone is provided at the center of the bottom of the graphite crucible 5, and a positioning hole matching the positioning cone is provided on the rotating disk of the rotating tray 8. The positioning cone is triangular. The graphite crucible 5 and the rotating tray 8 are connected and positioned by a positioning cone, so that the center symmetry line of the rotating tray and the center symmetry line of the graphite c...

Embodiment 3

[0050] Using the SiC single crystal growth device described in Example 1 to grow a SiC single crystal with central symmetry, the steps are as follows:

[0051] (1) Start the heating device to heat the temperature in the graphite crucible to 2273K~2773K;

[0052] (2) Turn on the rotating motor, the rotating motor drives the center rotating rod to rotate, and adjust the speed of the center rotating rod to 1-60 rpm. When the center rotating rod rotates, the position of the insulation material remains unchanged;

[0053] (3) Adjust the crystal growth pressure to 5-100mbar to grow the crystal. The crystal growth time is 20-120h, and the carrier gas is filled during the crystal growth process.

[0054] (4) After the crystal growth is over, the temperature is gradually reduced to room temperature, and the rotating motor is turned off to obtain a SiC single crystal with central symmetry.

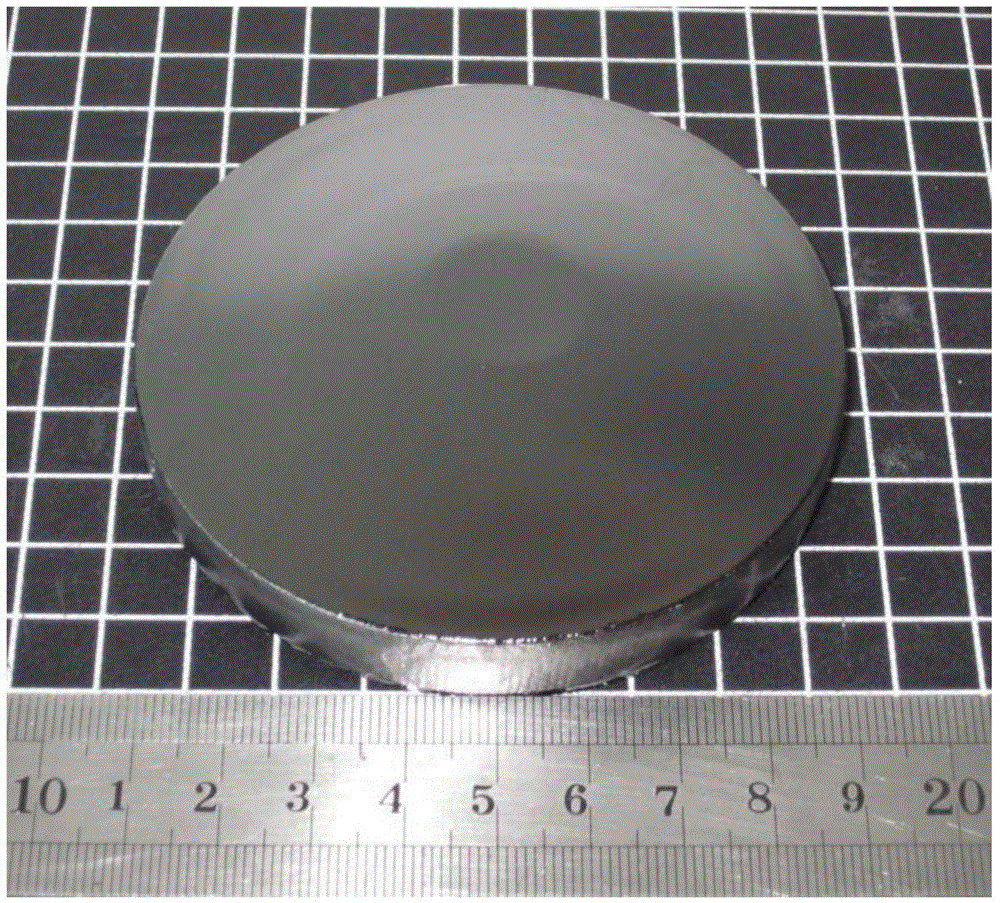

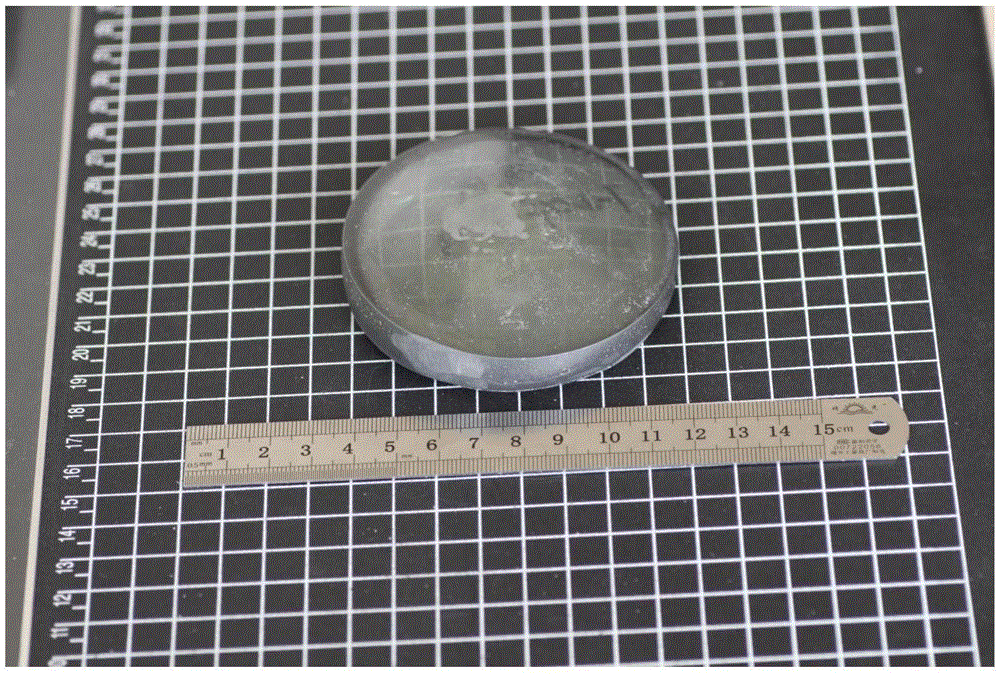

[0055] figure 2 The 3-inch SiC crystal obtained by using the invented device has central symmetry. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com