Patents

Literature

97results about How to "Increase the effective thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

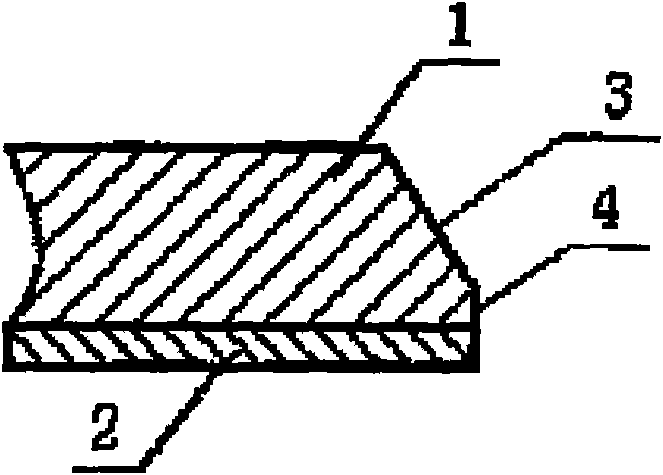

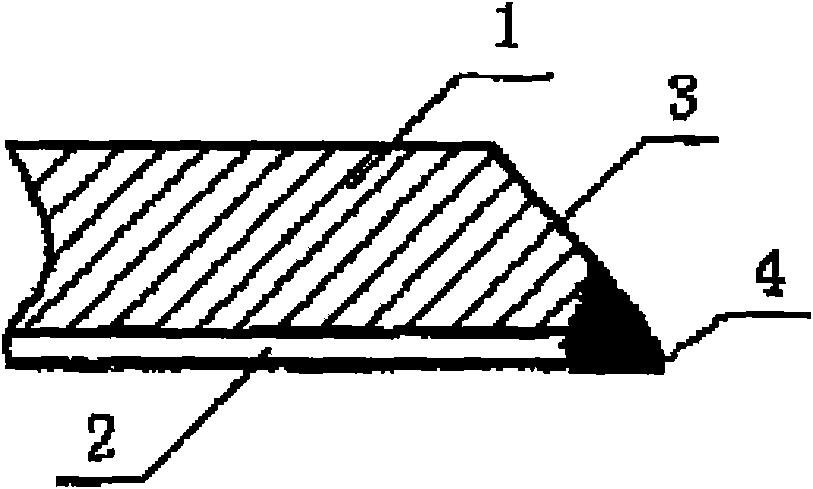

Thin-wall stainless steel double-layer and carbon steel base layer composite tube girth weld welding method

ActiveCN101100013AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsWeld seamMaterials science

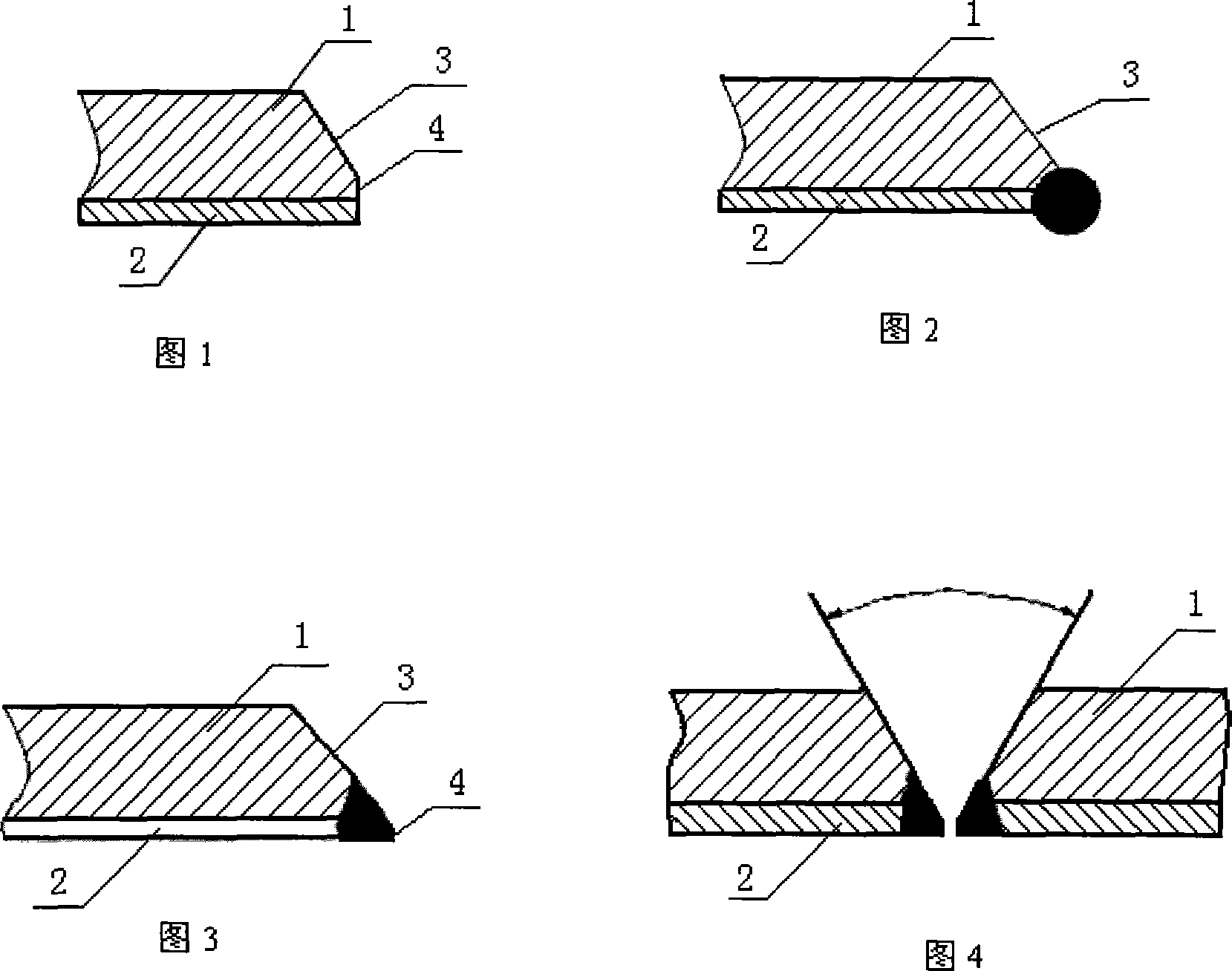

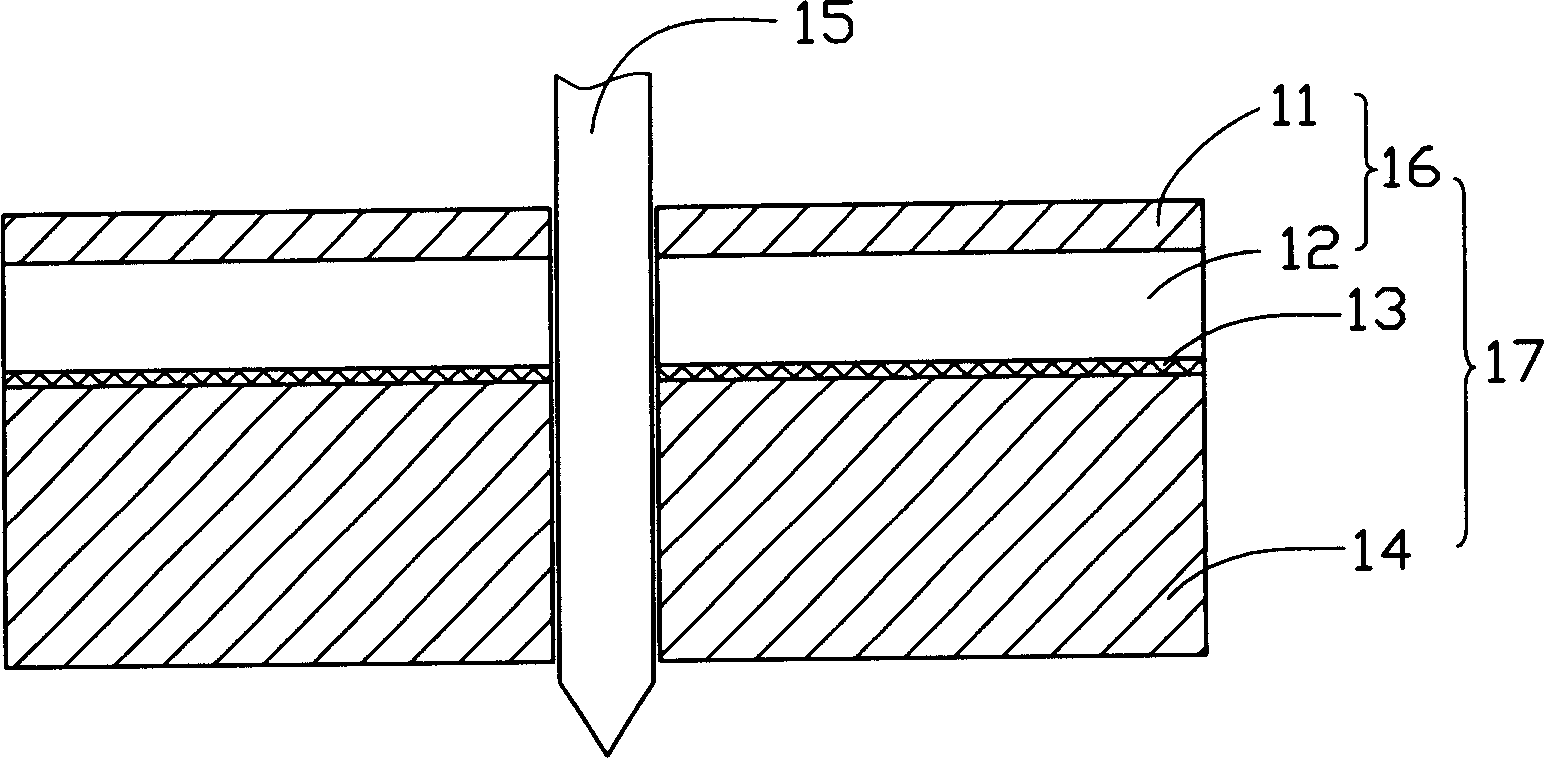

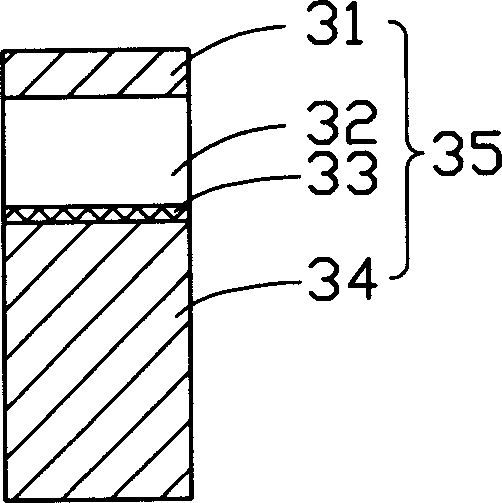

The process of ring welding composite pipe comprising one thin stainless steel layer and one carbon steel base layer includes the following steps: 1. chamfering and eliminating oil stain; 2. bead welding and trimming chamfer; 3. pairing bimetal composite pipe chamfers; 4. argon shielded tungsten arc welding in the bottom; 5. welding the second layer to weld the base layers of two composite pipes; and 6. filling welding and finishing welding. During the welding process, stainless steel electrode and 309 or 309Mo welding material are adopted for reaching high strength and high toughness of the weld seam, and the chamfers have increased effective thickness of stainless steel layer for high welding quality and high corrosion resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

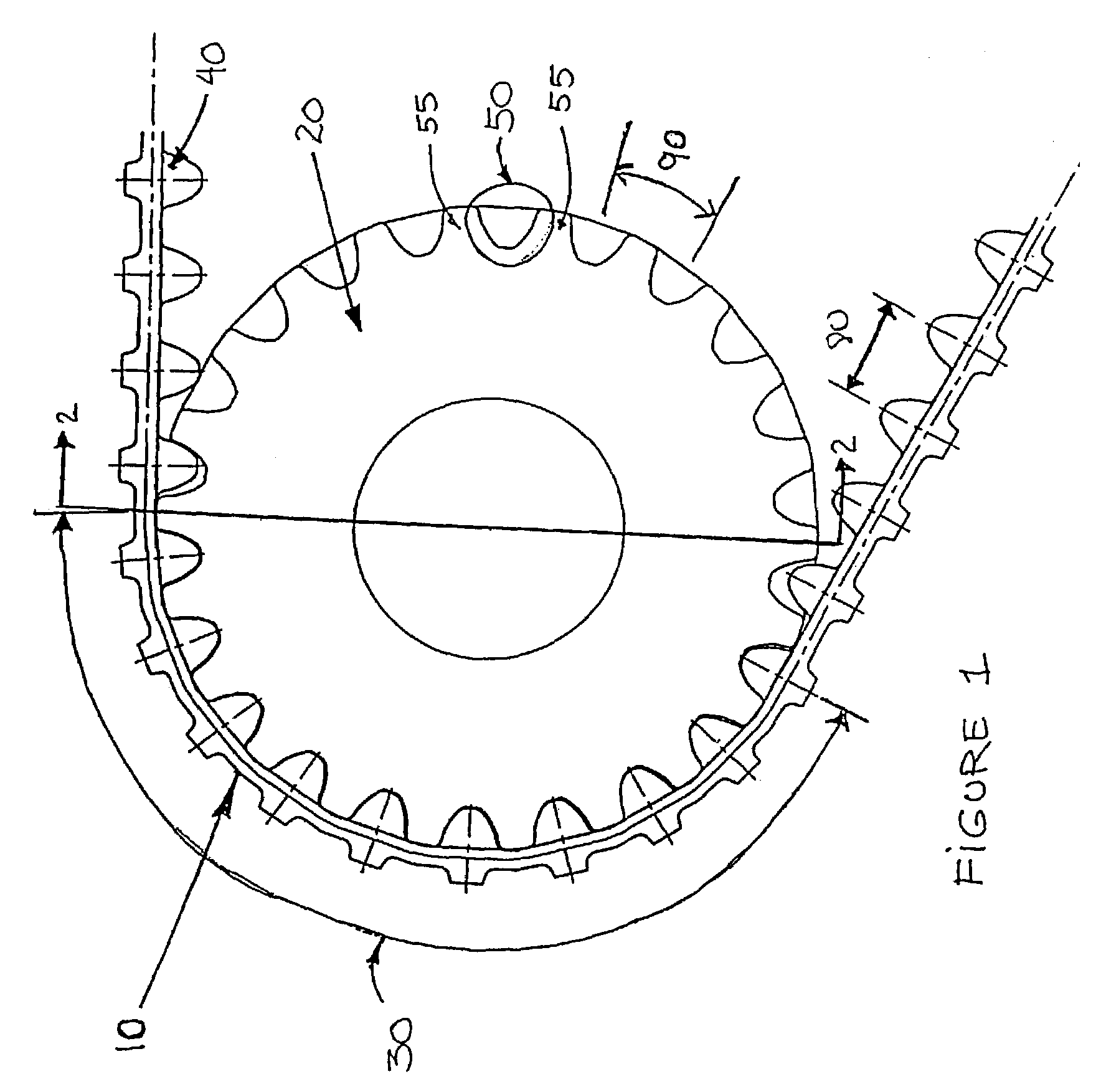

Angled traction lugs for endless band

This invention refers to the traction lugs of reinforced elastomeric endless traction bands, and more particularly to those which are used on heavy vehicles like defense vehicles or for skid steer vehicles. More specifically, the invention relates to traction lugs which are angled with respect to the transversal axis of the traction band and preferably disposed in chevrons, which optimize the band's traction while reducing the occurrences of teeth skipping and the level of vibrations and noise induced by the interaction of the traction band with the sprocket.

Owner:SOUCY INT

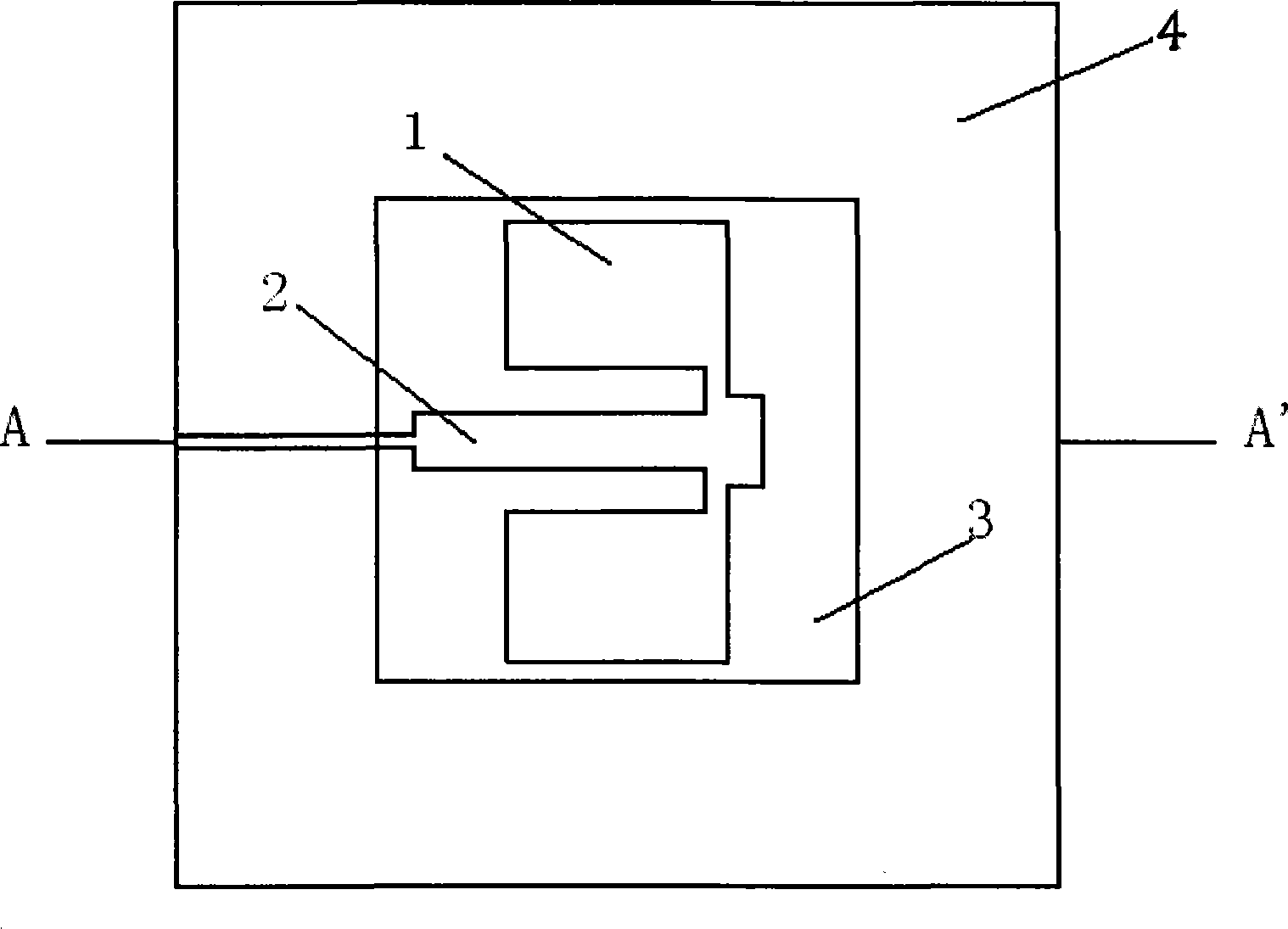

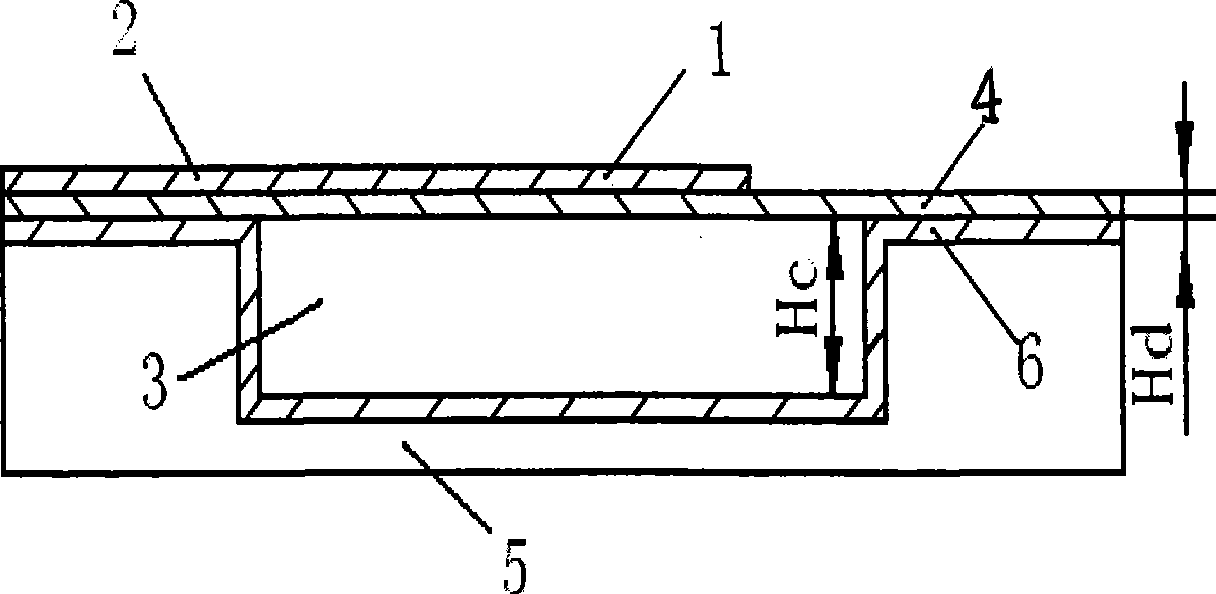

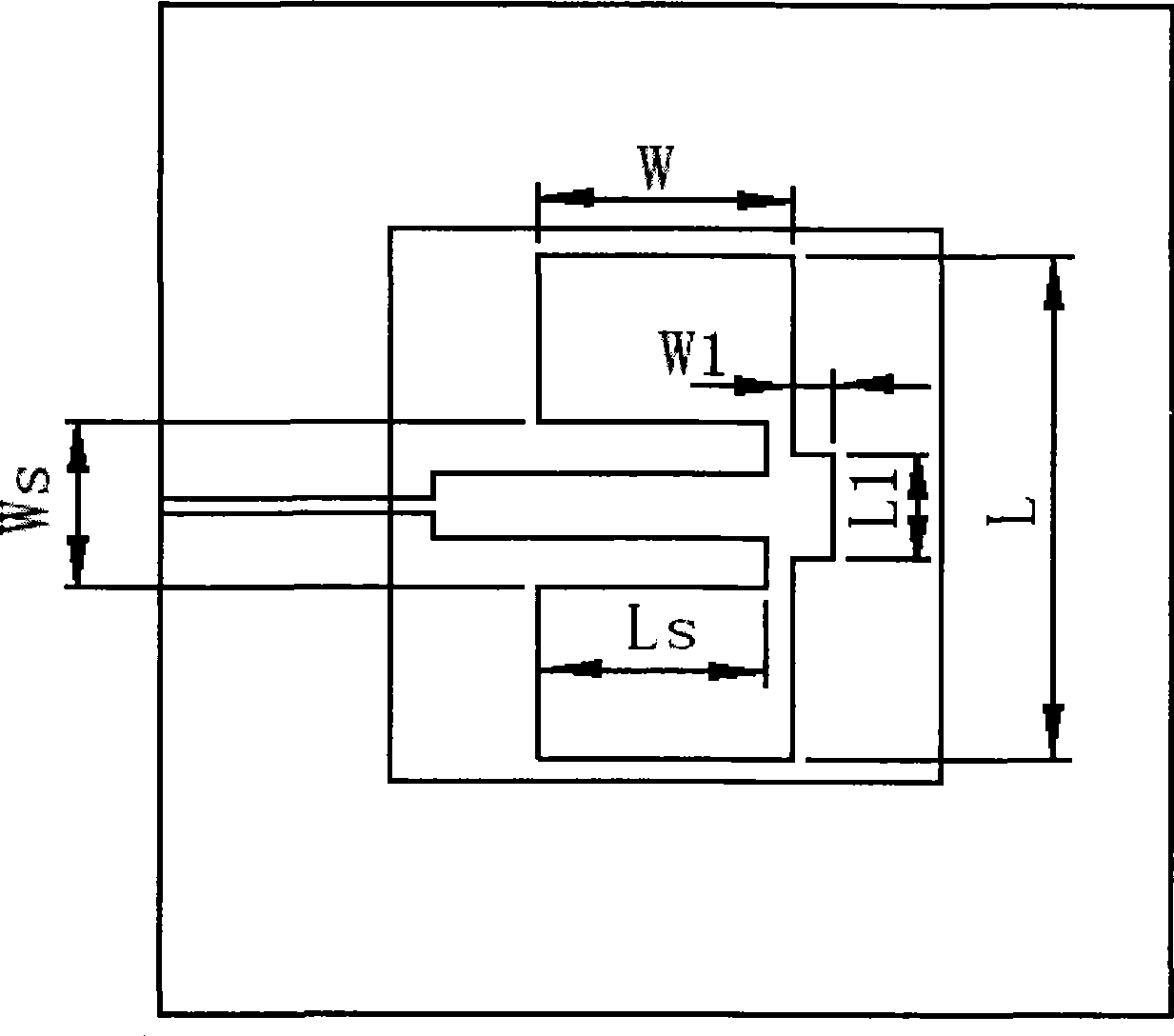

Wideband single layer microstrip patch antenna

ActiveCN101420066ASimple structureCompact structureRadiating elements structural formsMicrostrip patch antennaAntenna bandwidth

The invention relates to a wide band one-layer microstrip patch antenna, which solves the problem of narrow impedance width in the currently common microstrip antenna. The microstrip patch of the antenna is a one-layer microstrip patch; one end of a stair-stepping coplane microstrip line with two widths is inserted in the patch antenna by the open slot on a convex microstrip patch, and the other end of a feeding microstrip line is positioned at the edge of a microstrip dielectric-slab; a concave metal carinal cavity is arranged at the back surface of the microstrip dielectric-slab excluding the position corresponding to the microstrip patch and in the middle of structural mounting plate. The wide band one-layer microstrip patch antenna can form a large microstrip patch antenna array easily, which is in favor of impedance matching of the antenna, the subnetwork design for microstrip work, the weight reduction of the antenna and the bandwidth widening of the antenna; the wide band one-layer microstrip patch antenna of the invention has the advantages of simple and compact structure and small cross section, which improves the telecommunication performance and reduces the whole weightof the antenna array.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

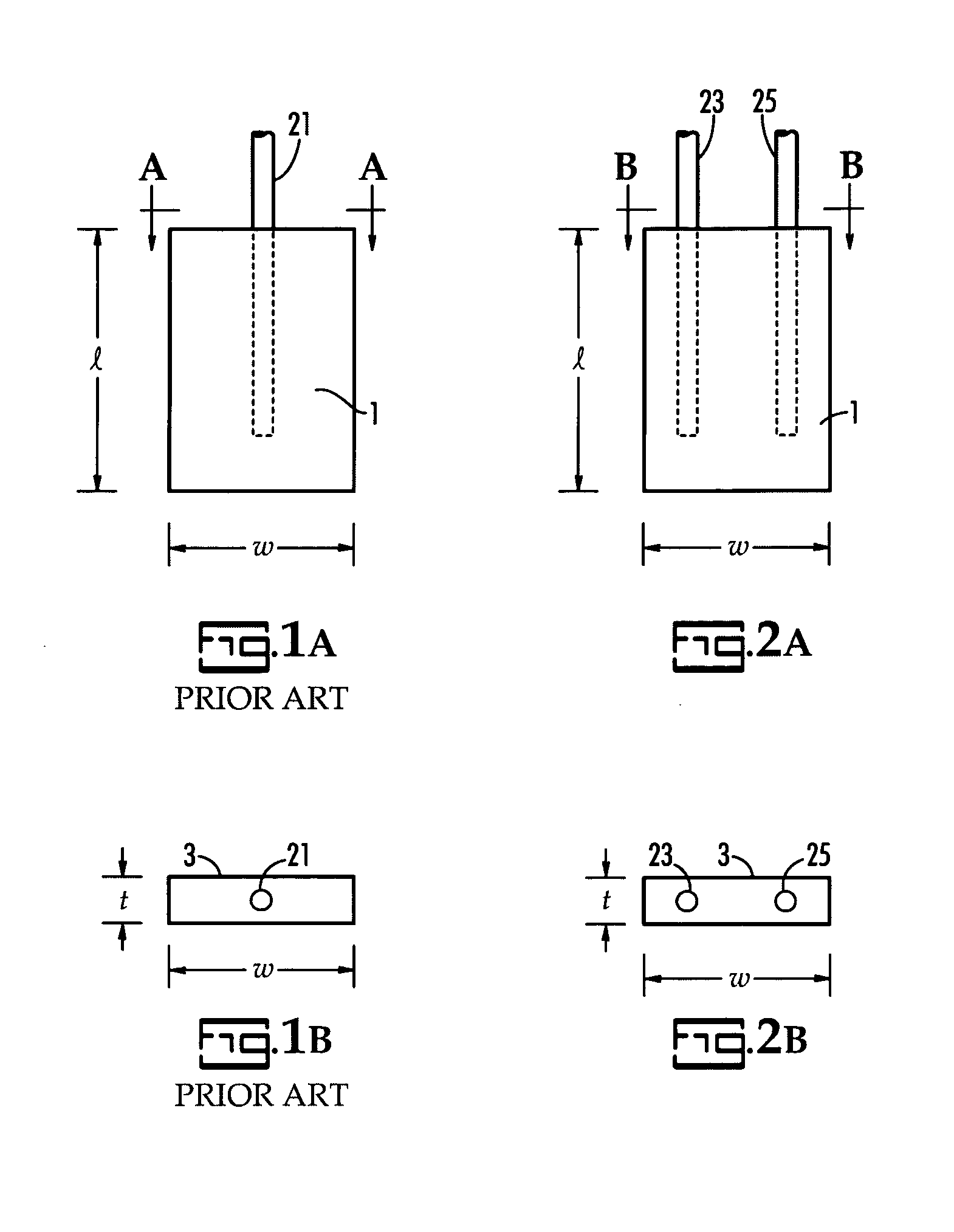

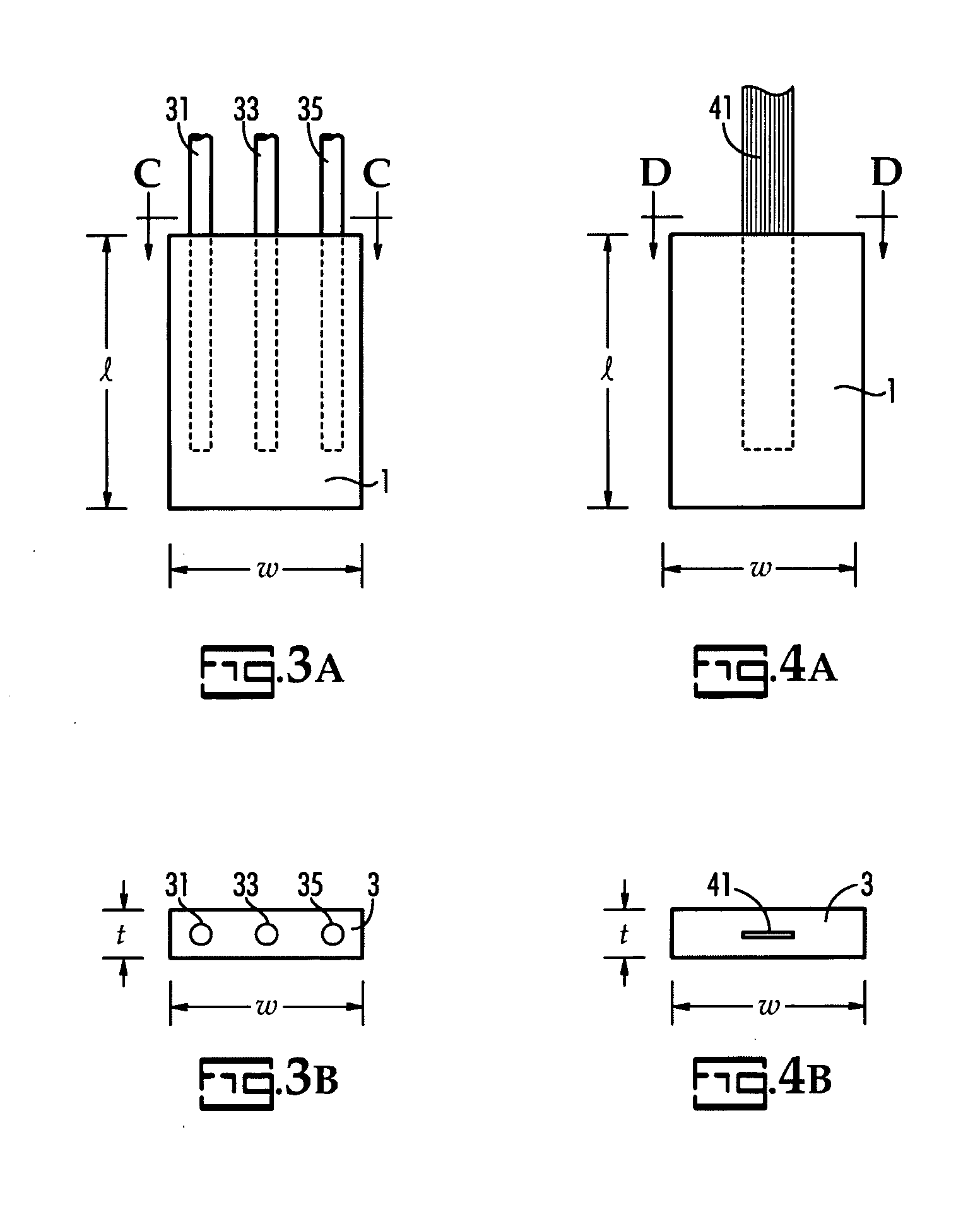

Reduced ESR through use of multiple wire anode

InactiveUS20050237698A1Drag minimizationLower resistance contactSolid electrolytic capacitorsFixed capacitor terminalsElectrolytic capacitorMetallic Lead

The ESR of a solid electrolytic capacitor can be decreased by using more than one anode lead or by using an anode lead with a cross-section which is oval or rectangular so as to increase contact area between anode lead and anode compact and reduce the resistance of the lead. The preferred anode is Ta and the preferred wire is Ta.

Owner:KEMET ELECTRONICS CORP

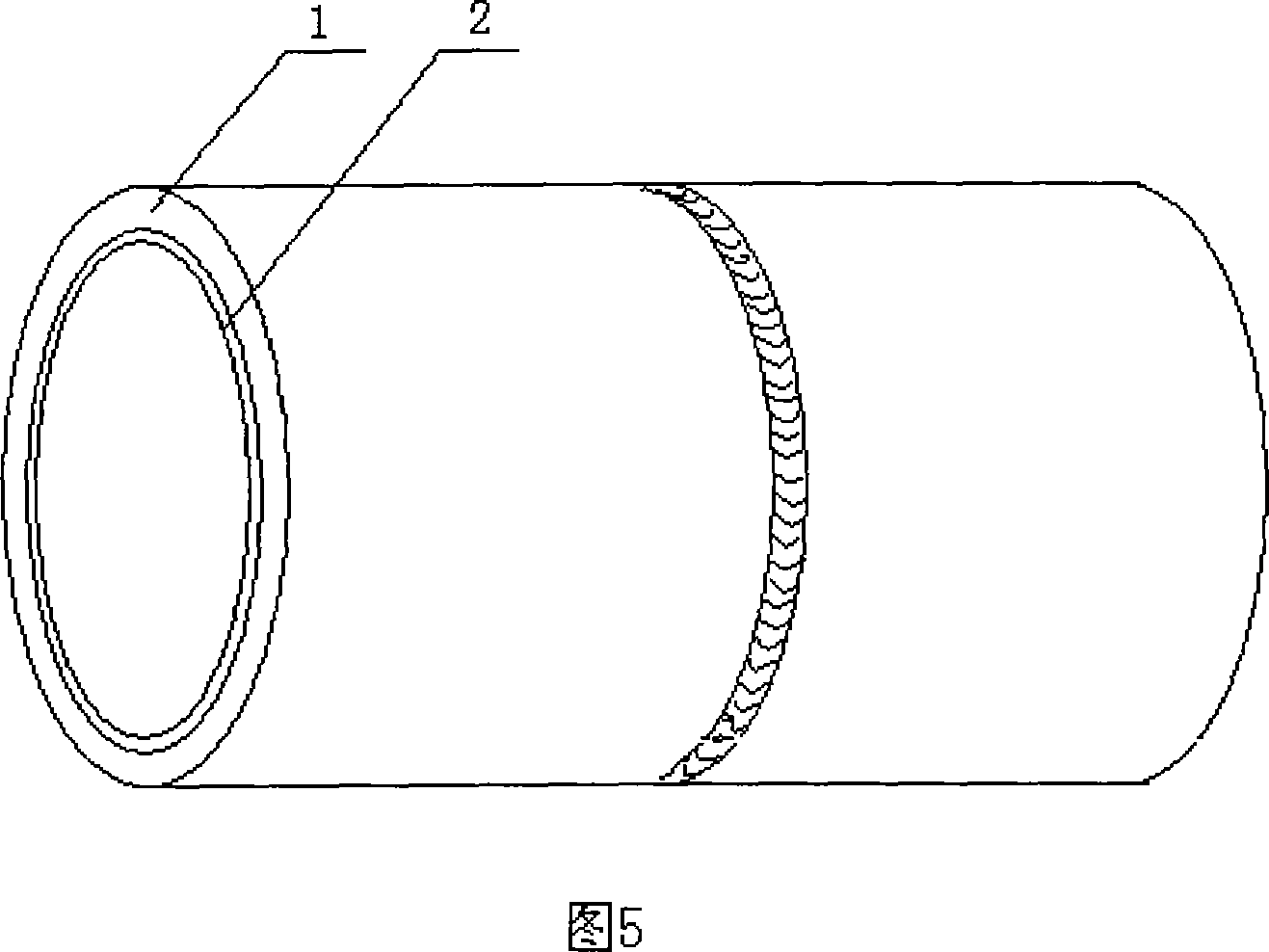

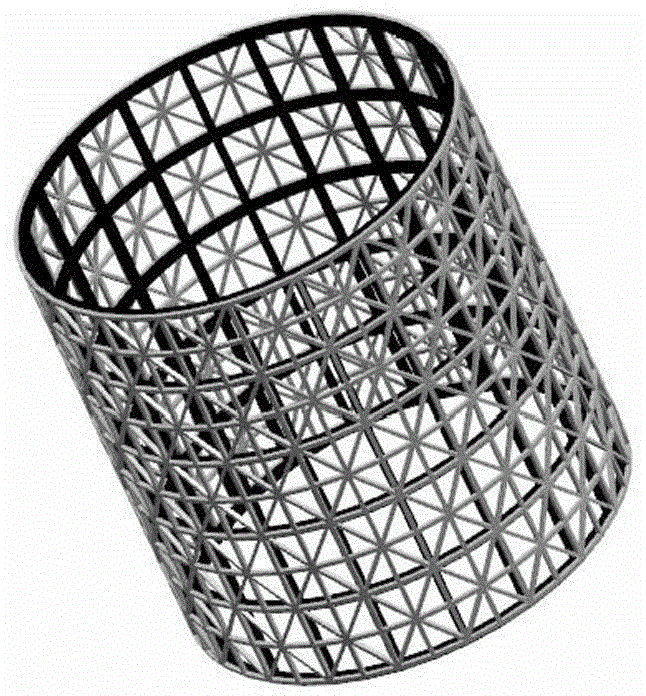

Multilayer grating bearing cylinder and preparation method thereof

ActiveCN104608915AImprove stabilityImproves buckling stabilityFuselage framesWeight reductionGratingEngineering plastic

The invention discloses a multilayer grating bearing cylinder and a preparation method thereof. The multilayer grating bearing cylinder is formed by nesting at least two single-layer grating cylinders, and the densities of the meshes of the adjacent single-layer grating cylinders are different. The preparation method for the multilayer grating bearing cylinder made from a composite material comprises the following steps: producing a wood pattern for casting a soft mode, producing a silicon rubber soft mode, assembling a mould, winding the soft mode in an assistance manner, carrying out vacuum bag moulding, demoulding and carrying out after-treatment, and integrally moulding the multilayer grating bearing cylinder; or preparing the single-layer grating cylinders according to the steps, and then assembling the single-layer grating cylinders into the multilayer grating bearing cylinder. The preparation method for the multilayer grating bearing cylinder made from metal or engineering plastic comprises the following steps: preparing a casting mould for the disassembly components of the single-layer grating cylinders, melting and casting, welding, and then assembling the single-layer grating cylinders into the multilayer grating bearing cylinder; or moulding in one step by a 3D printing technology. The multilayer grating bearing cylinder has the characteristics of good structural stability, light mass, high mechanical properties, difficulty of structural overall buckling instability, simple and practicable preparation method, and low cost.

Owner:NAT UNIV OF DEFENSE TECH

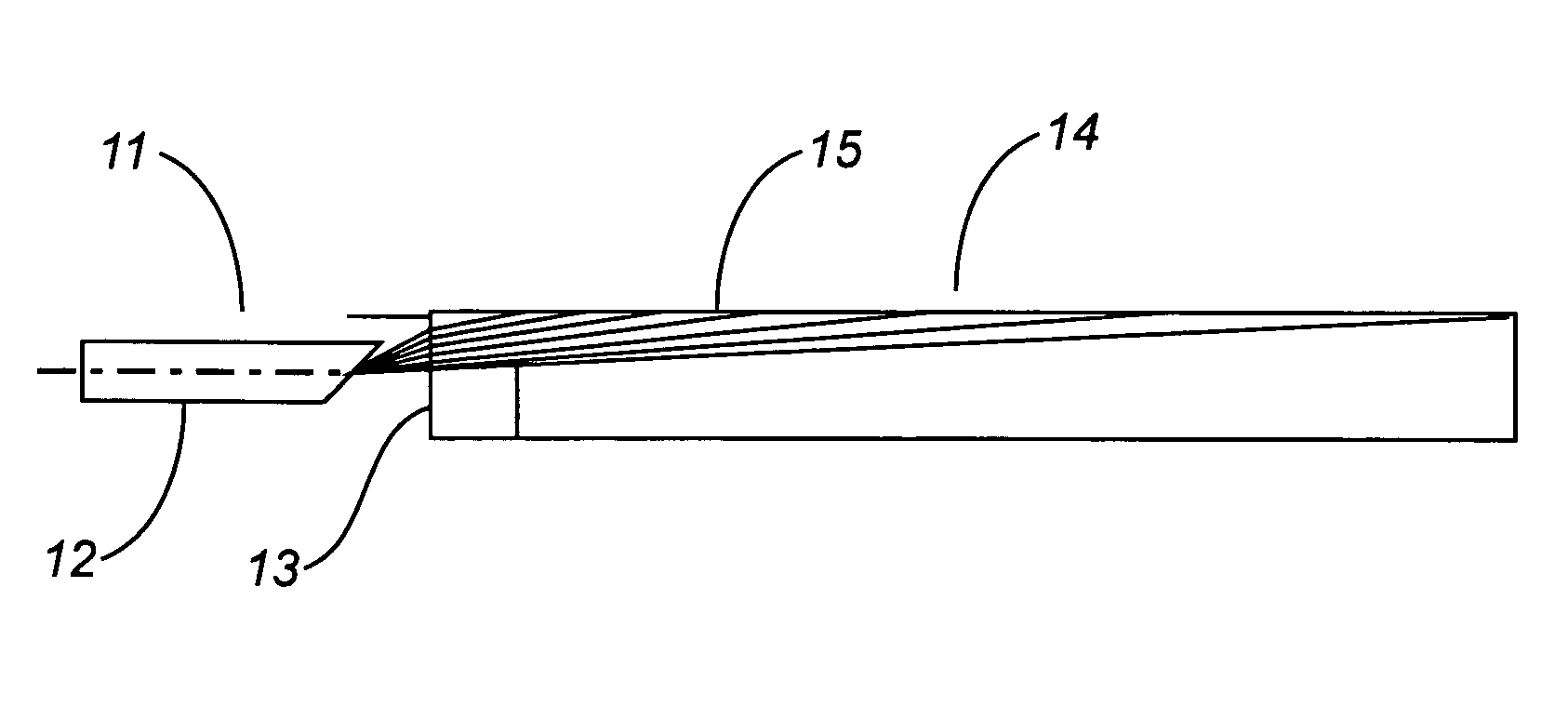

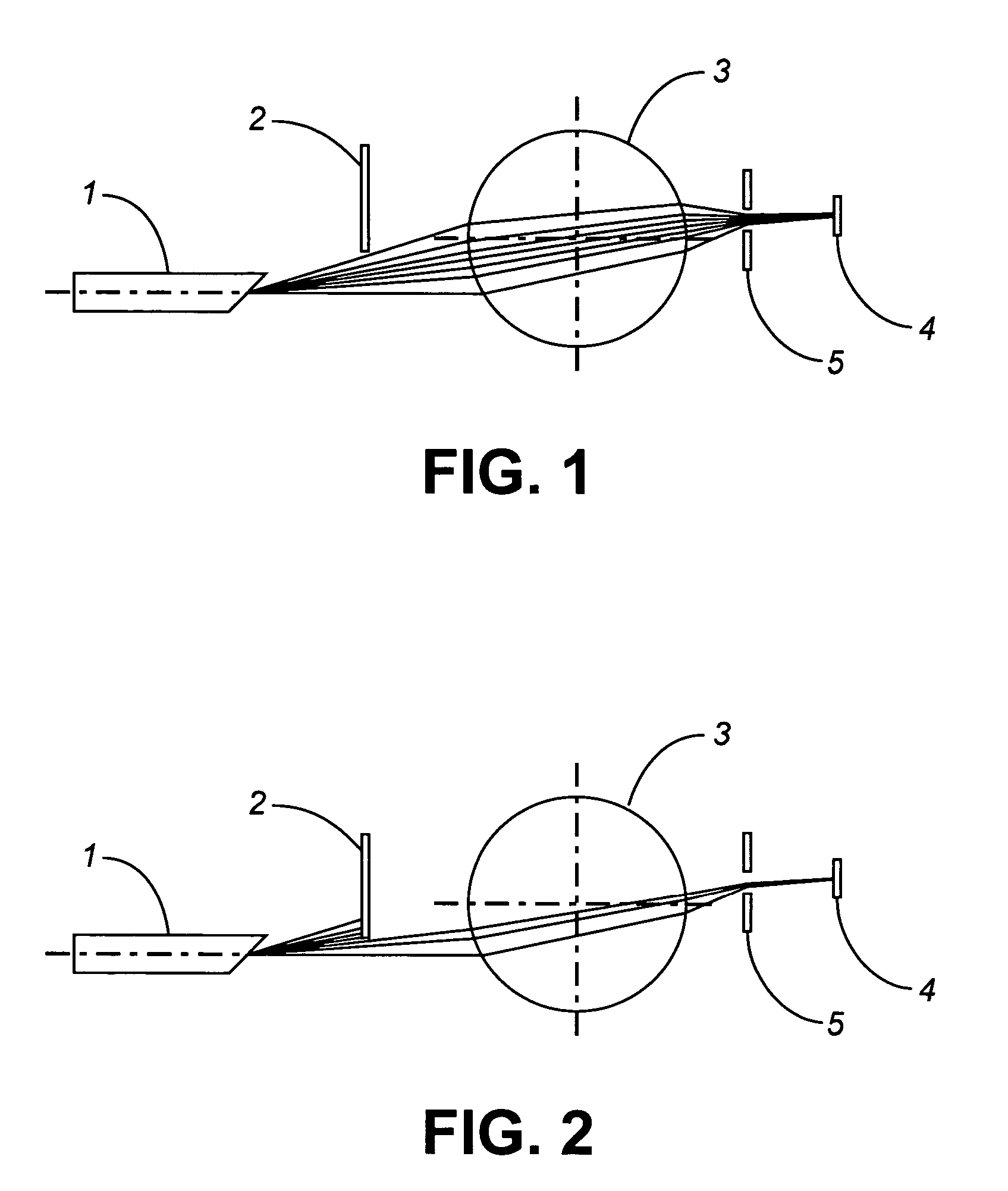

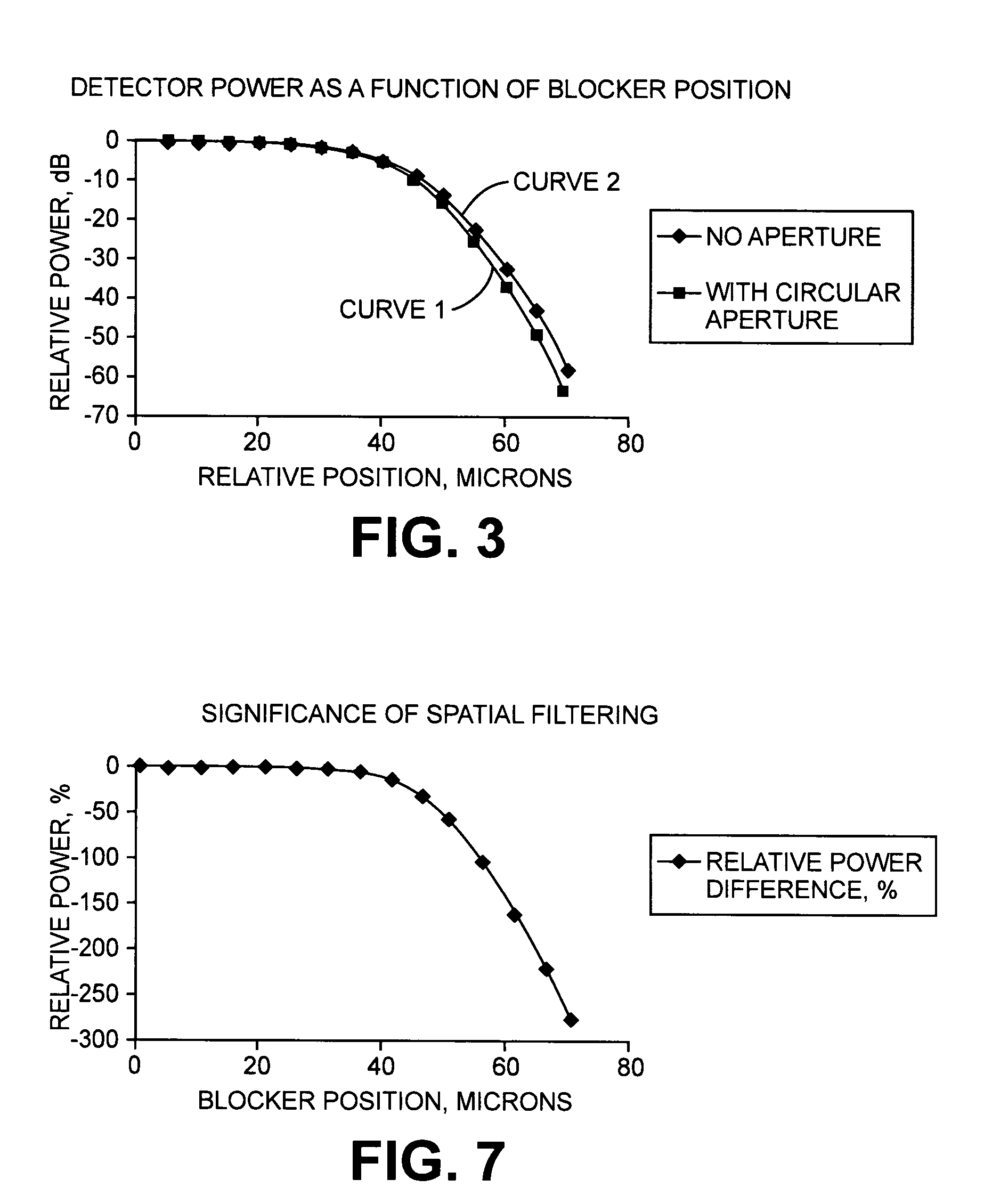

Optical receiver with high dynamic range

InactiveUS7068890B2Increase the effective thicknessImprove responseCoupling light guidesSemiconductor devicesOptical attenuatorOptical coupling

An optical coupling assembly having an optical receiver that exhibits extended dynamic range, and, more particularly, an optical receiver that is integrated with a Variable Optical Attenuator (VOA) to extend the dynamic range of the receiver.

Owner:LUMENTUM OPERATIONS LLC

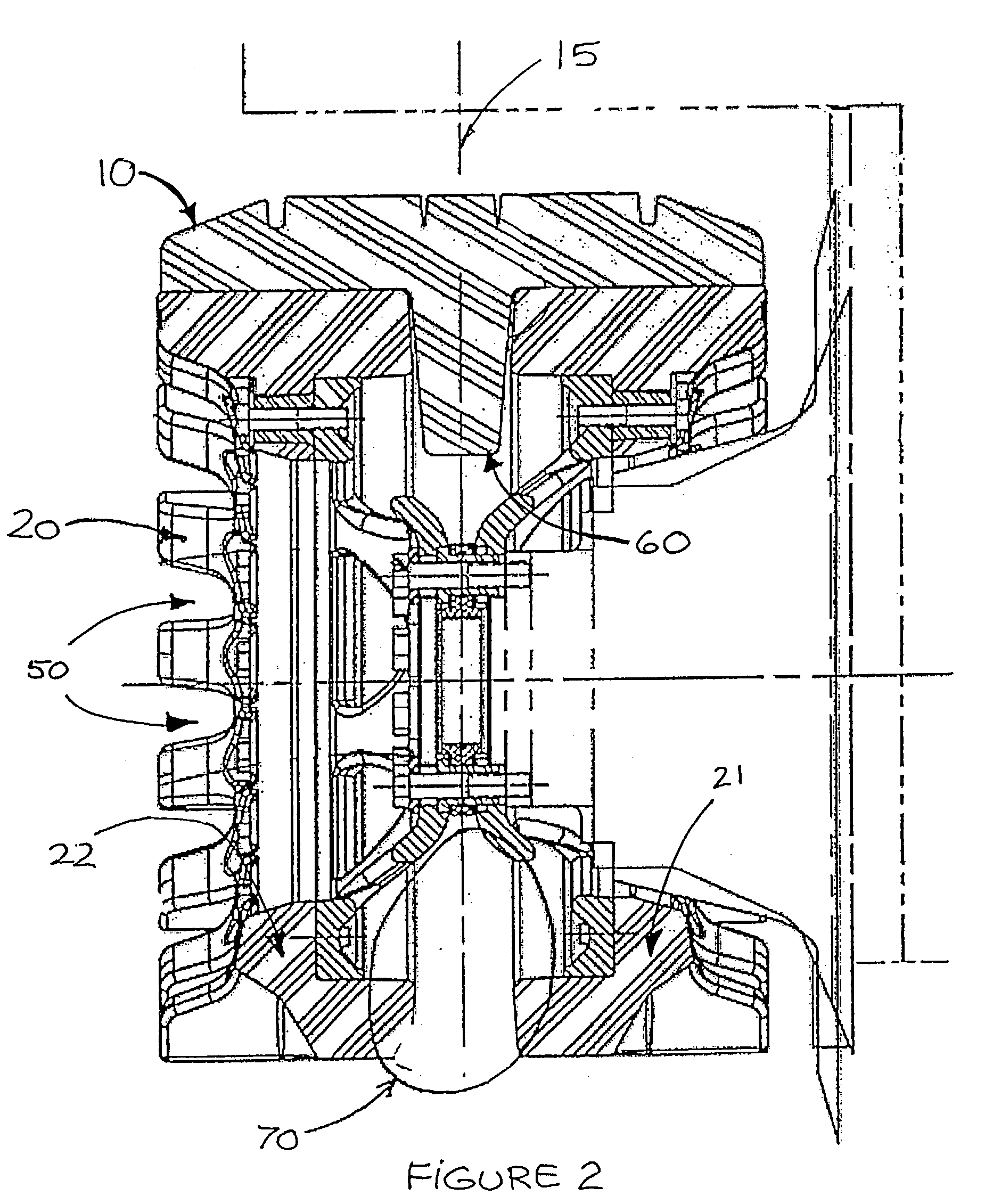

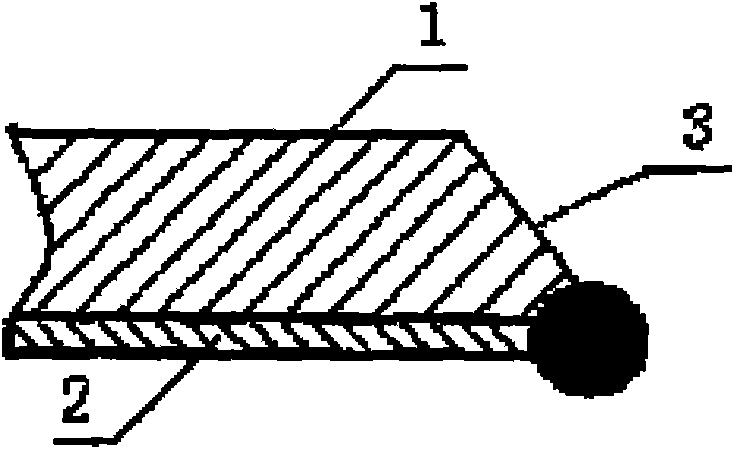

Method for welding circumferential weld between metal thin-wall clad layer and base layer of clad pipe

InactiveCN101927390AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsStainless steel electrodeUltimate tensile strength

The invention provides a method for welding circumferential weld between a metal thin-wall clad layer and a base layer of a clad pipe, which is used for welding circumferential weld of dual-metal clad steel pipes. The method is characterized by (A) groove processing: cleaning oil stains on the groove; (B) carrying out surfacing on the truncated edge, close to the clad layer, of the groove and coping the groove; (C) fitting up the groove of the dual-metal clad pipe; (D) root backing weld: adopting the gas tungsten arc welding method and carrying out welding along the groove of the dual-metal clad pipe under the state of argon-filled protection inside the pipe; (E) carrying out second layer welding on the root backing weld and welding the welding base layer of the dual-metal clad pipe; and (F) filled welding and cosmetic welding: wherein the welding materials are stainless steel electrodes. The method has the following effects: adopting 309 or 309Mo welding materials, thus ensuring the strength and good toughness of the weld; eliminating the gaps which probably exist between the clad layer and the base layer at the end of the groove; and increasing the effective thickness of the stainless steel layer at the groove root so that the quality of the welding joints are insensitive to misalignment, thus ensuring the corrosion resistance.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

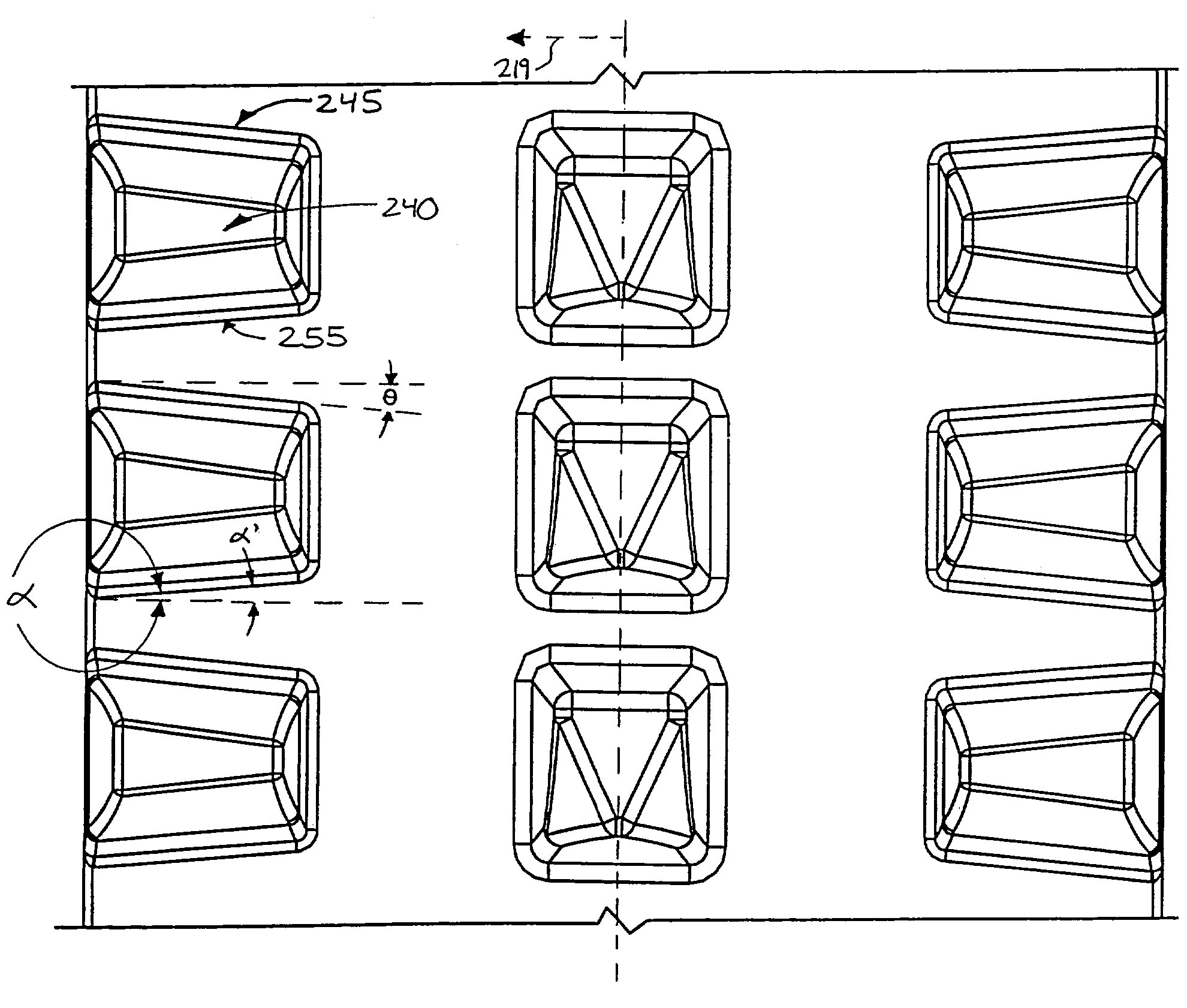

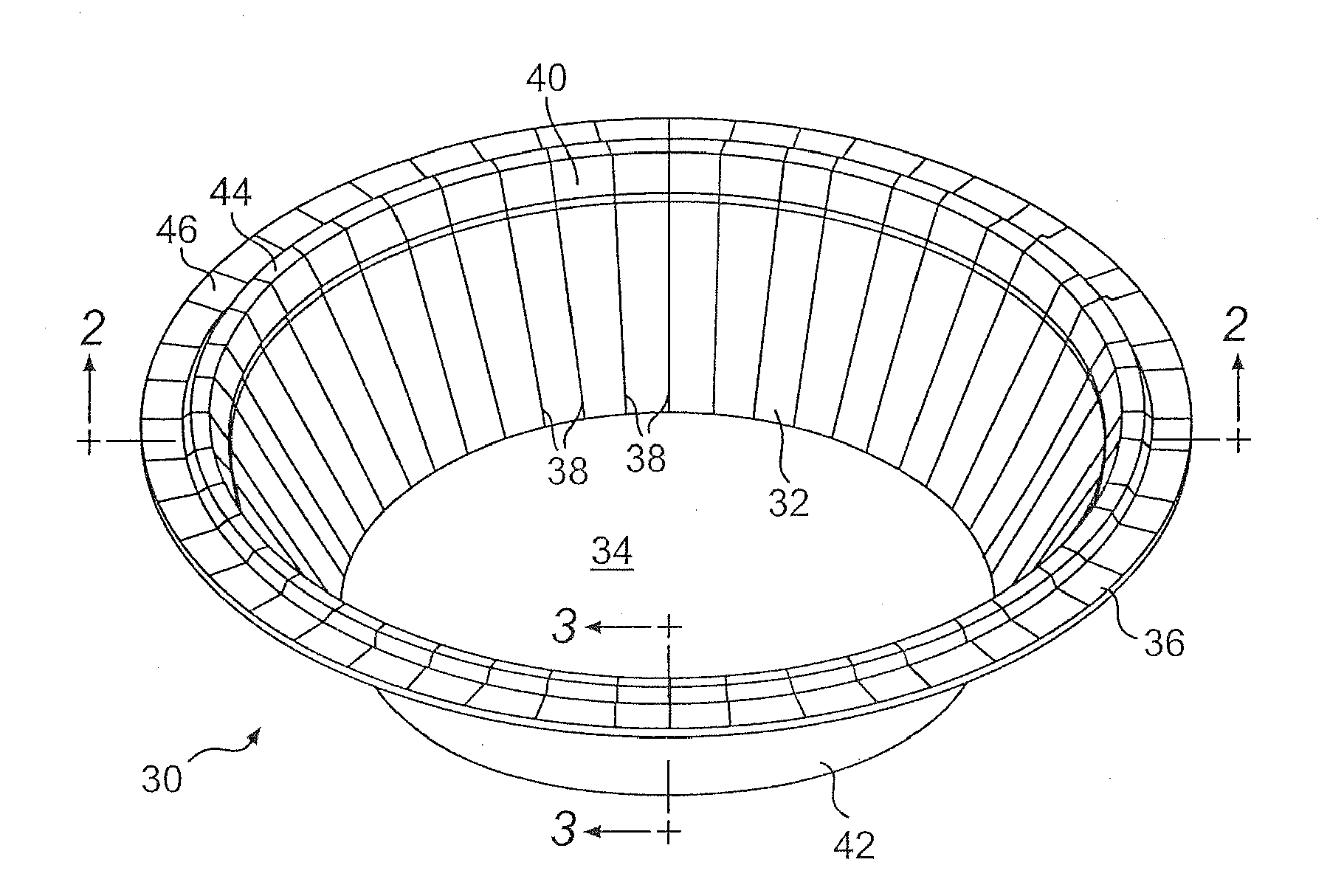

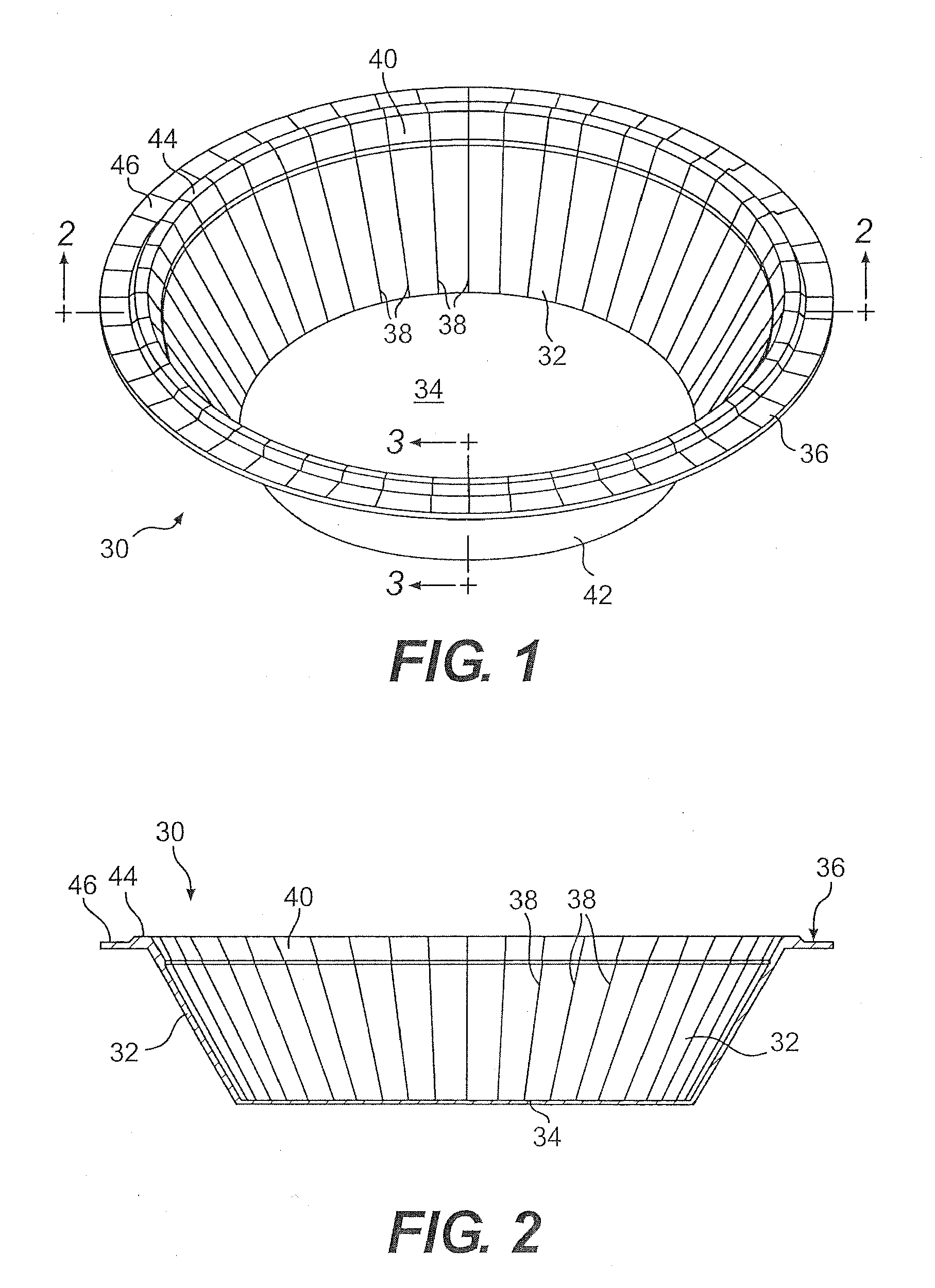

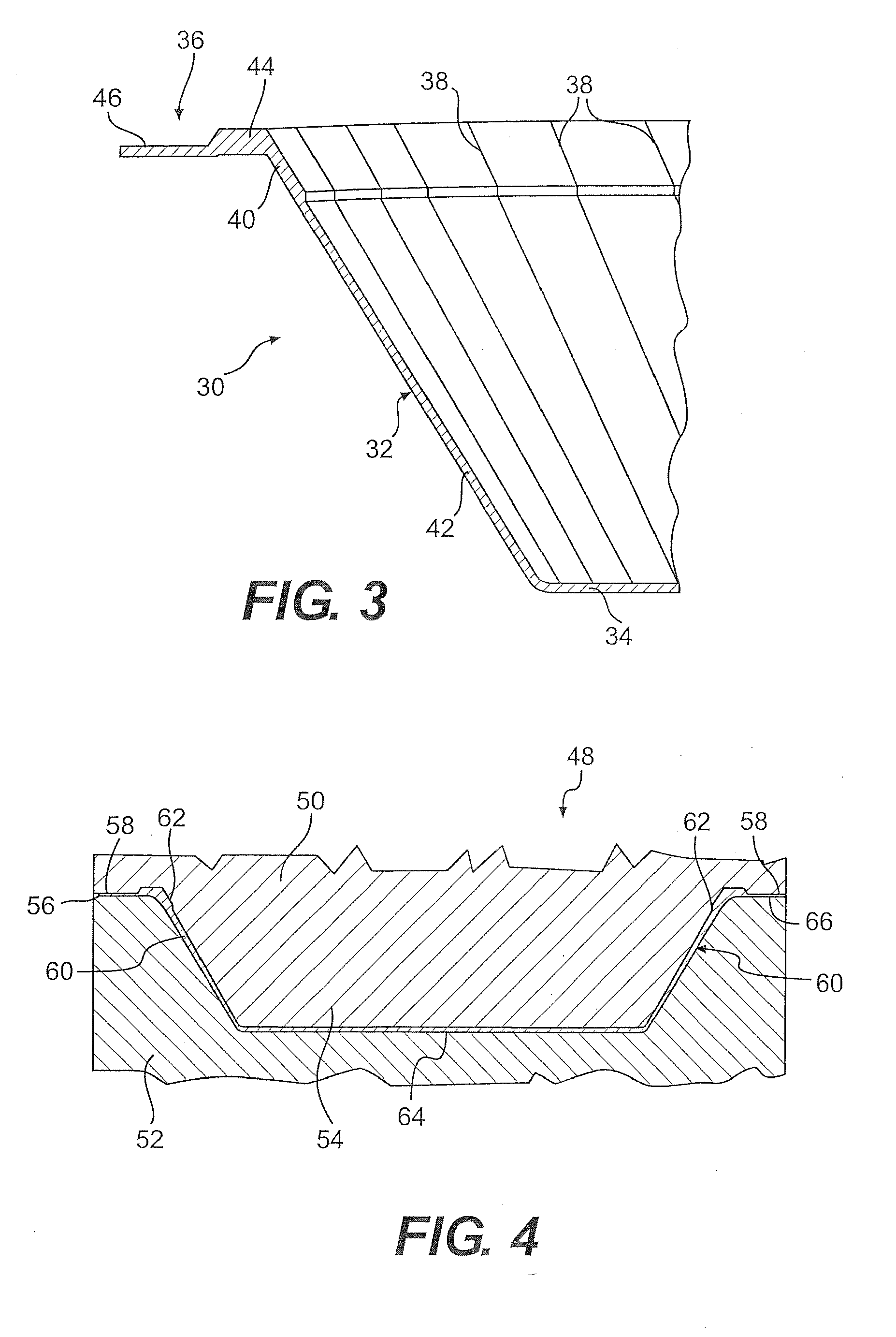

Nestable Container With Uniform Stacking Features

ActiveUS20110272317A1Facilitate reliable denestingIncrease the effective thicknessBox making operationsPaper-makingEngineeringFlange

Owner:GRAPHIC PACKAGING INT

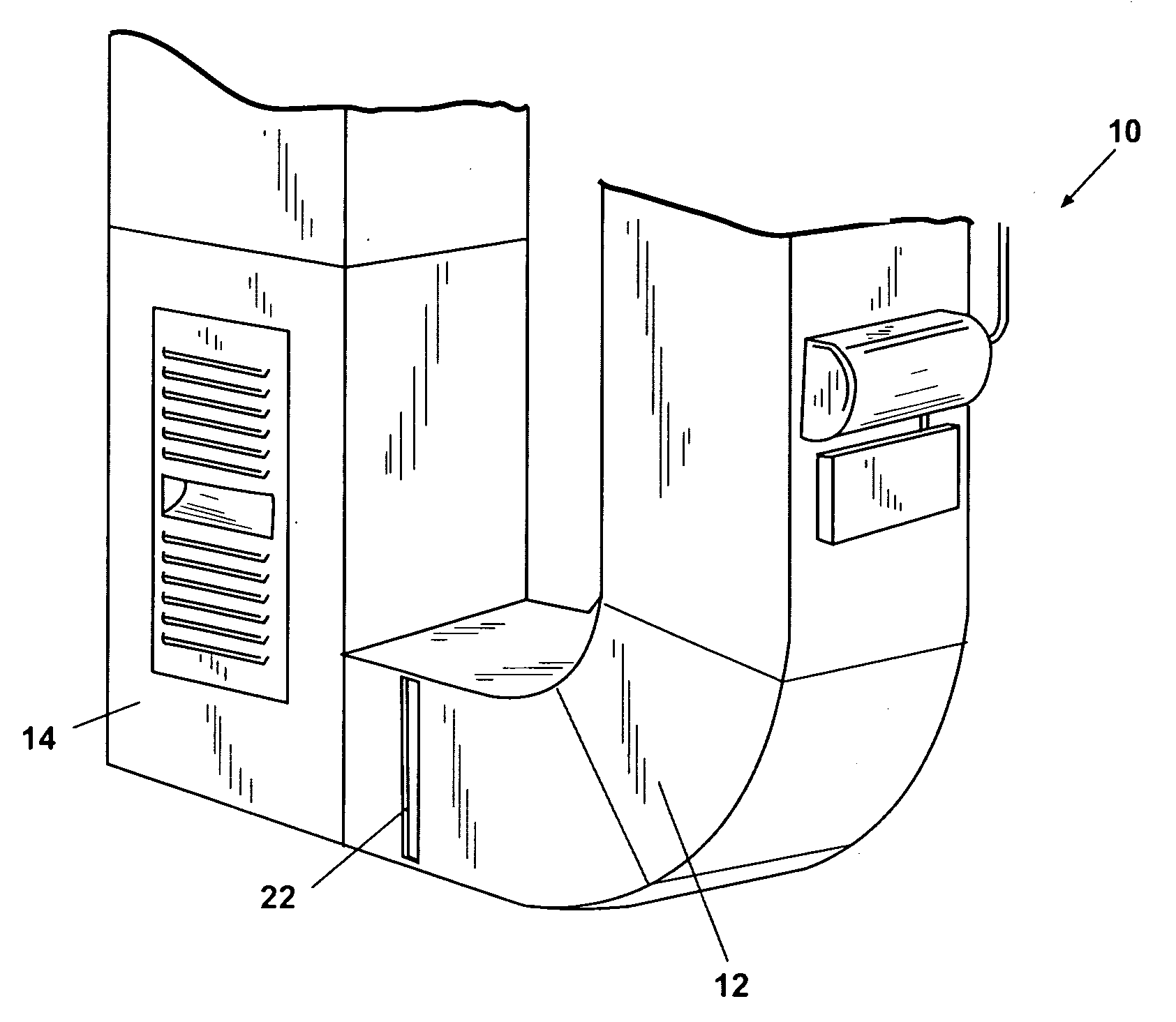

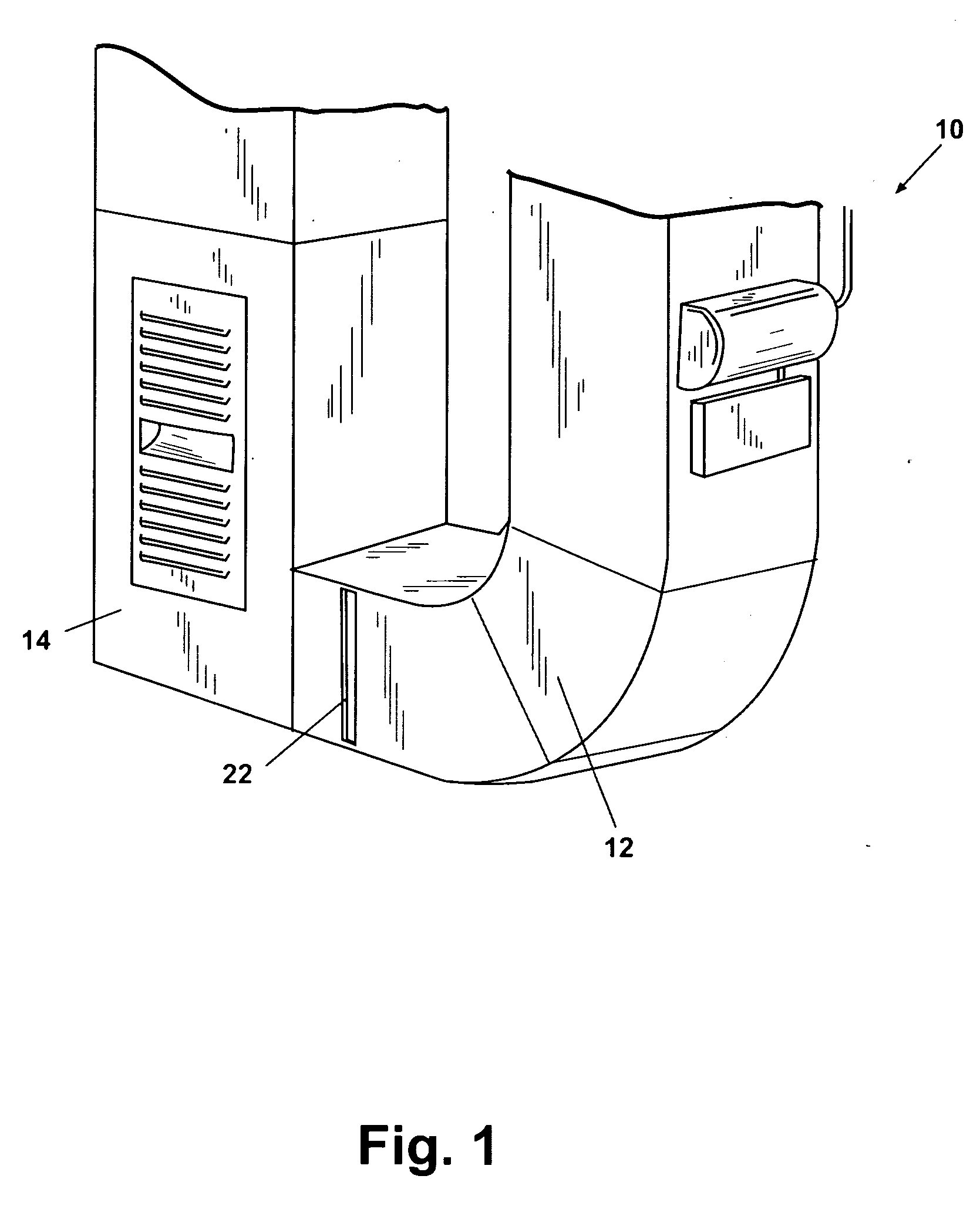

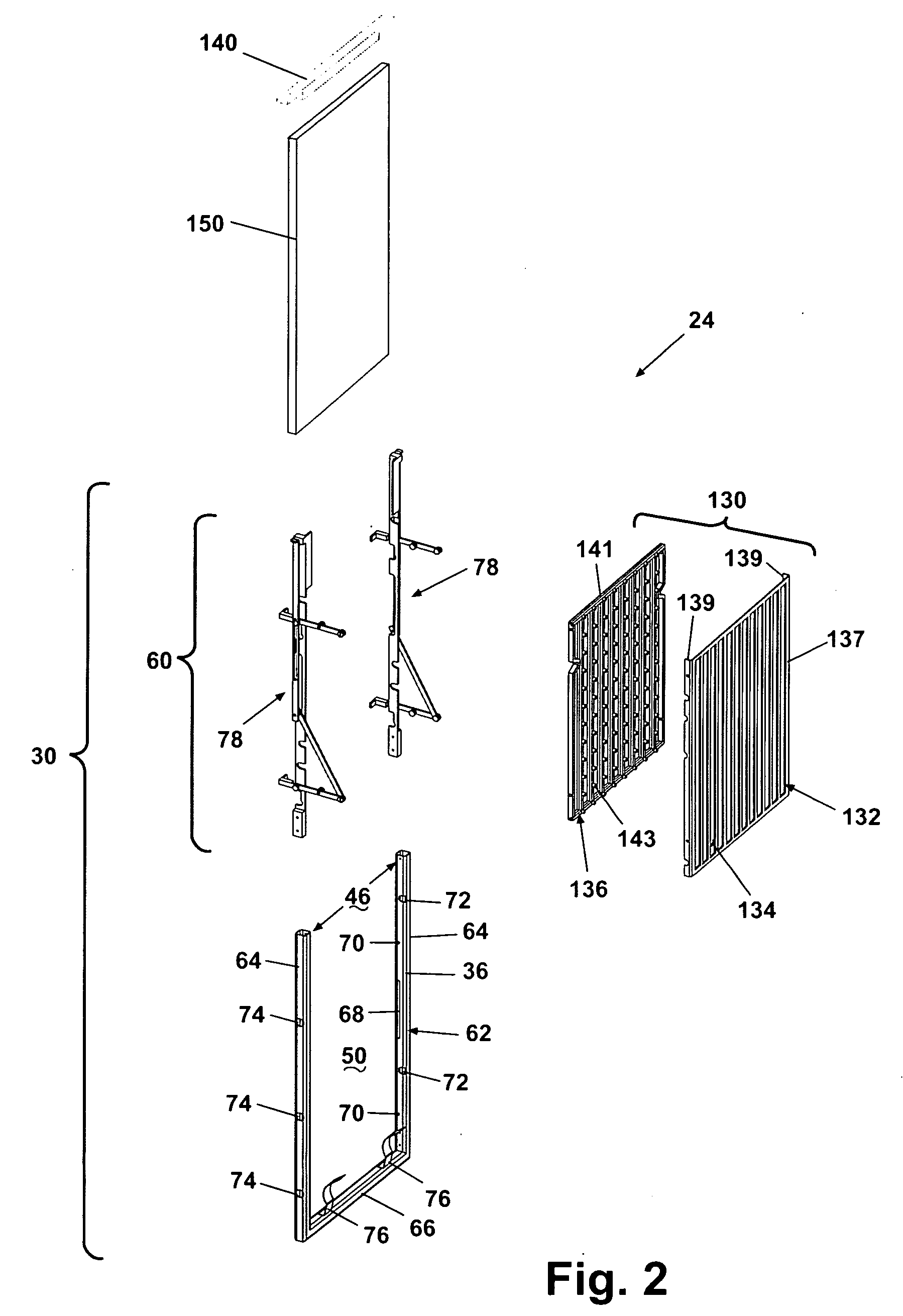

Air cleaner and expandable frame therefor

InactiveUS20050204922A1Filtering characteristicIncrease the effective thicknessDispersed particle filtrationLighting and heating apparatusAir cleanersElectrostatic precipitator

The invention relates to an air cleaner and an expandable frame for use with a conventional household air conditioning system with a return duct having an opening sized to receive a standard panel filter. The expandable air cleaner frame comprises a peripheral frame sized to be received within the opening in the return duct and a carrier coupled to the peripheral frame. The carrier supports an air conditioning element, such as a field charger or an electrostatic precipitator. The expandable air cleaner frame is movable between a collapsed position, wherein the effective thickness thereof is less than the opening, and an expanded position, wherein the effective thickness thereof is greater than the opening.

Owner:WHIRLPOOL CORP

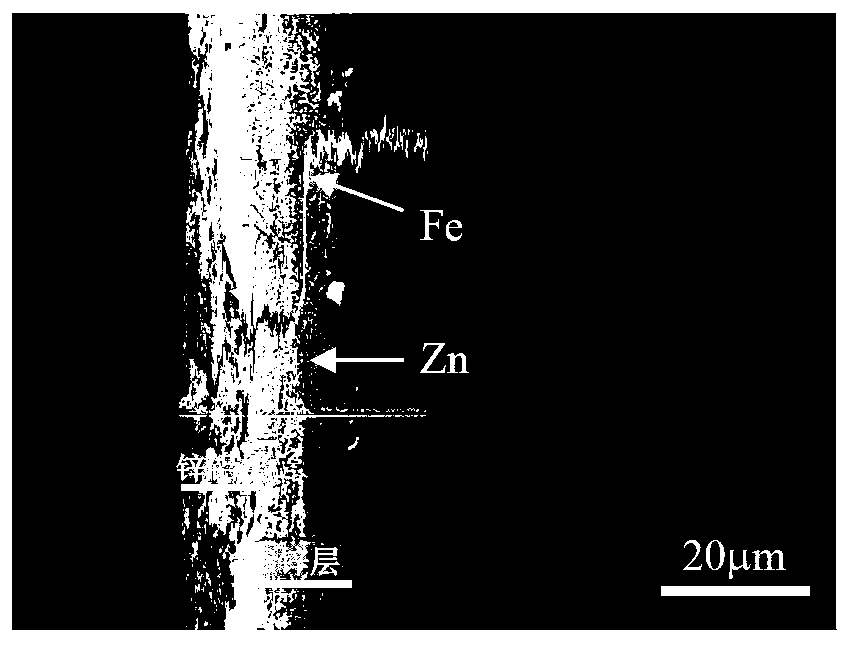

Production method for ship fastener complex coating

ActiveCN103316828AIncrease the effective thicknessSmall effective thicknessPretreated surfacesSpecial surfacesMetallic materialsDip-coating

The invention belongs to the technical field of metal material surface processing and relates to a production method for a ship fastener complex coating. A zinc impregnation coating, a zinc-aluminum coating and an epoxy coating are arranged on the fastener surface from internal to external and zinc impregnation, washing, zinc-aluminum coating liquid dip-coating, zinc-aluminum coating solidification, epoxy coating liquid dip-coating and epoxy coating solidification are performed on the faster after sequentially being performed on oil removing and rust removing to form into a protective layer. The production method for the ship fastener complex coating has the advantages of being simple in production technology and reasonable in principle. The complex coating has the advantages of being good in corrosion resistance, being capable of effectively solving the problem that the faster is corroded in the seawater environment and being environmentally friendly.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

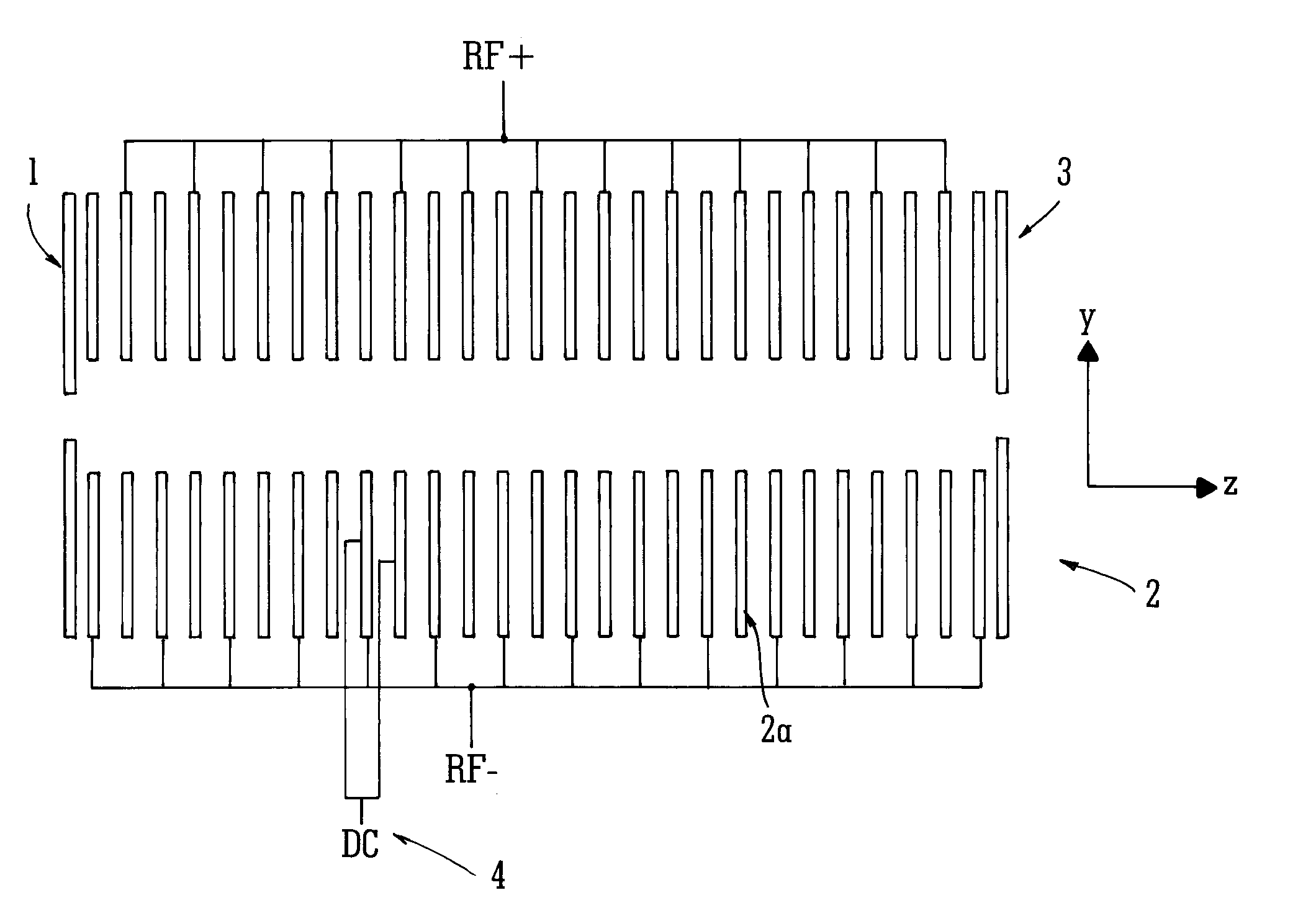

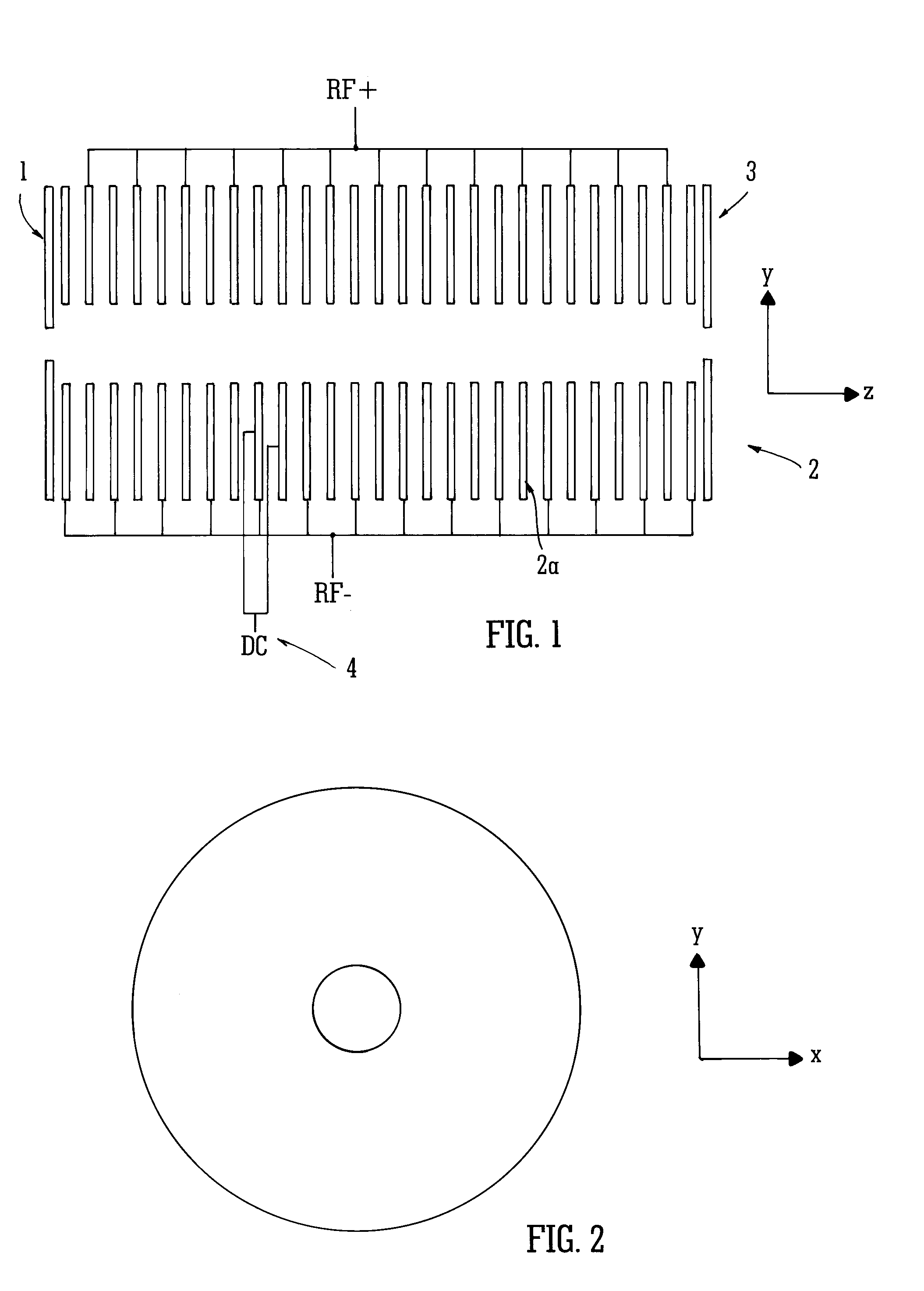

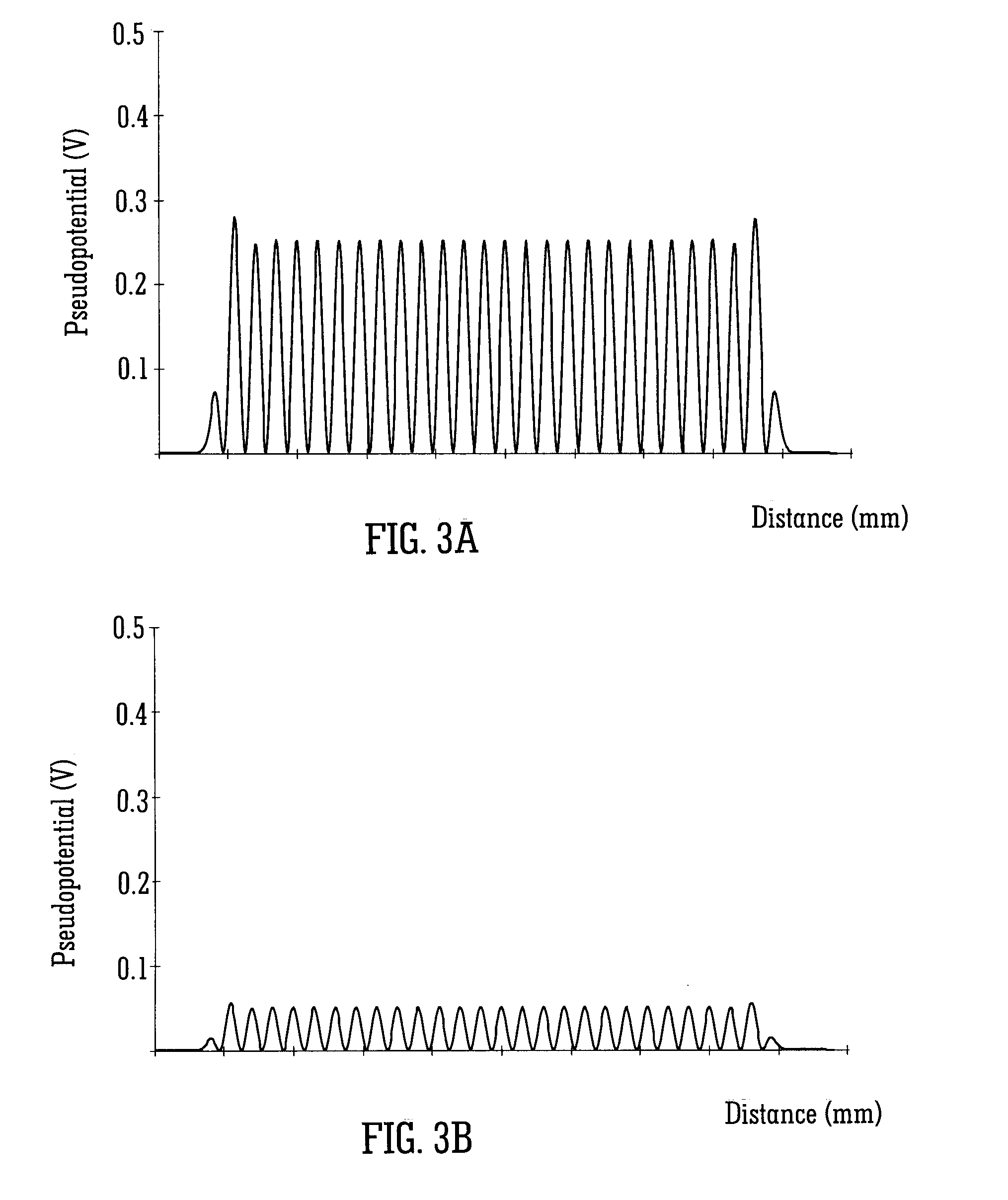

Mass Spectrometer

ActiveUS20110180704A1Increase amplitudeEffective amplitudeStability-of-path spectrometersSpectrometer circuit arrangementsReverse orderMass-to-charge ratio

An ion guide or mass analyser is disclosed comprising a plurality of electrodes having apertures through which ions are transmitted in use. A pseudo-potential barrier is created at the exit of the ion guide or mass analyser. The amplitude or depth of the pseudo-potential barrier is inversely proportional to the mass to charge ratio of an ion. One or more transient DC voltages are applied to the electrodes of the ion guide or mass analyser in order to urge ions along the length of the ion guides or mass analyser. The amplitude of the transient DC voltage applied to the electrode may be increased with time so that ions are caused to be emitted from the ion guide or mass analyser in reverse order of their mass to charge ratio.

Owner:MICROMASS UK LTD

Flexible electric conductive fabric and its producing method

InactiveCN1715473AImprove shielding effectIncrease bite forceMagnetic/electric field screeningFibre treatmentMetal alloyCotton fibre

The present invention features that the flexible electrically conductive fabric has base fabric woven with metal fiber in 35-45 % and cotton fiber in 55-65 %, surface metal or alloy coating including one priming layer and one outer layer. The present invention can shield high strength electromagnetic field effectively and has resistance of as low as 1 micro-ohm / cm, shield effect up to 90-120 dB on electromagnetic wave in the frequency range of 0.15 MHz to 20 GHz and magnetic field shielding effect up to 40-50 dB. The present invention has the advantages of being light, ventilating, transparent, non-toxic, fireproof, etc. and is especially suitable for use in fields needing shield on strong electromagnetic wave.

Owner:上海利昂高科技有限公司

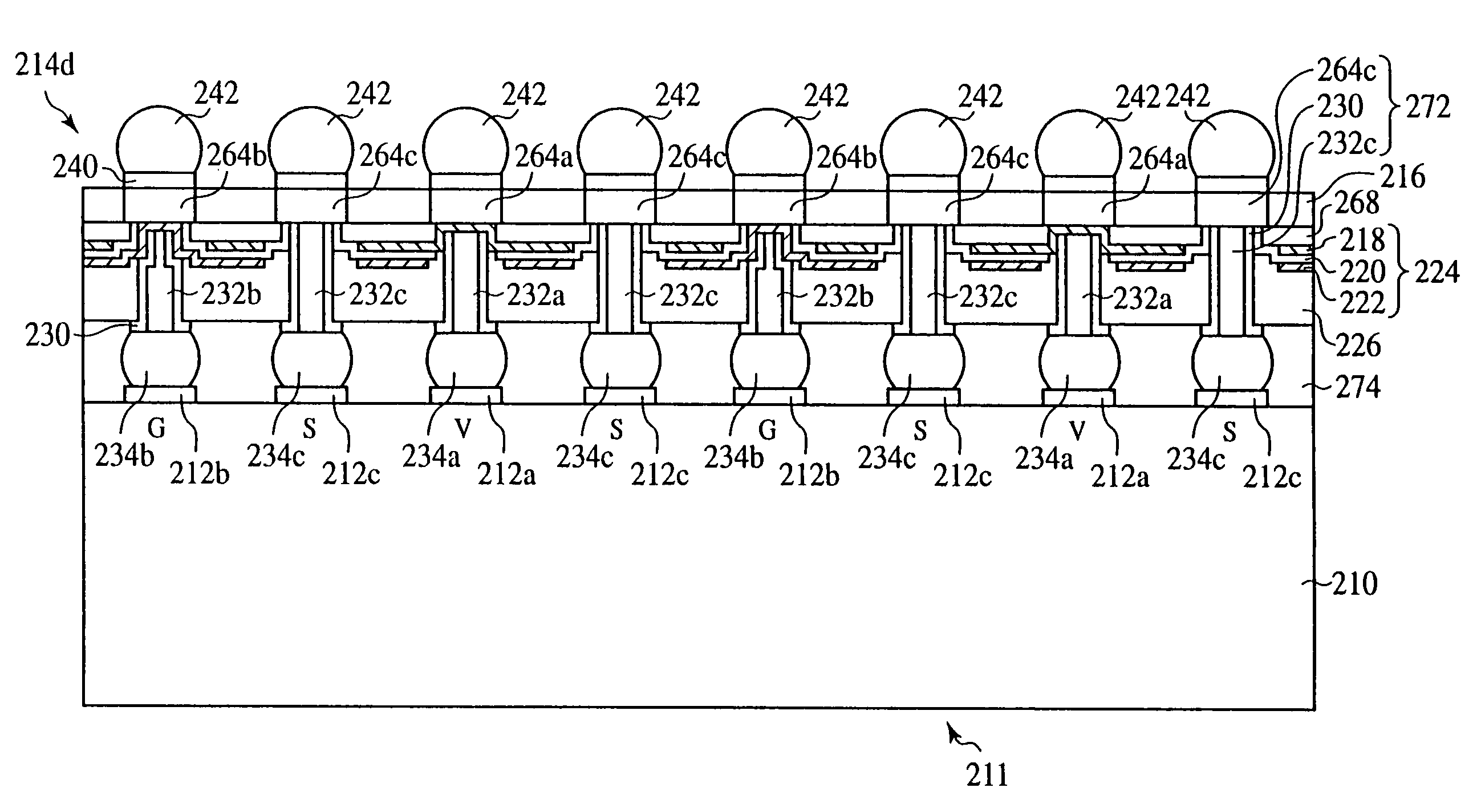

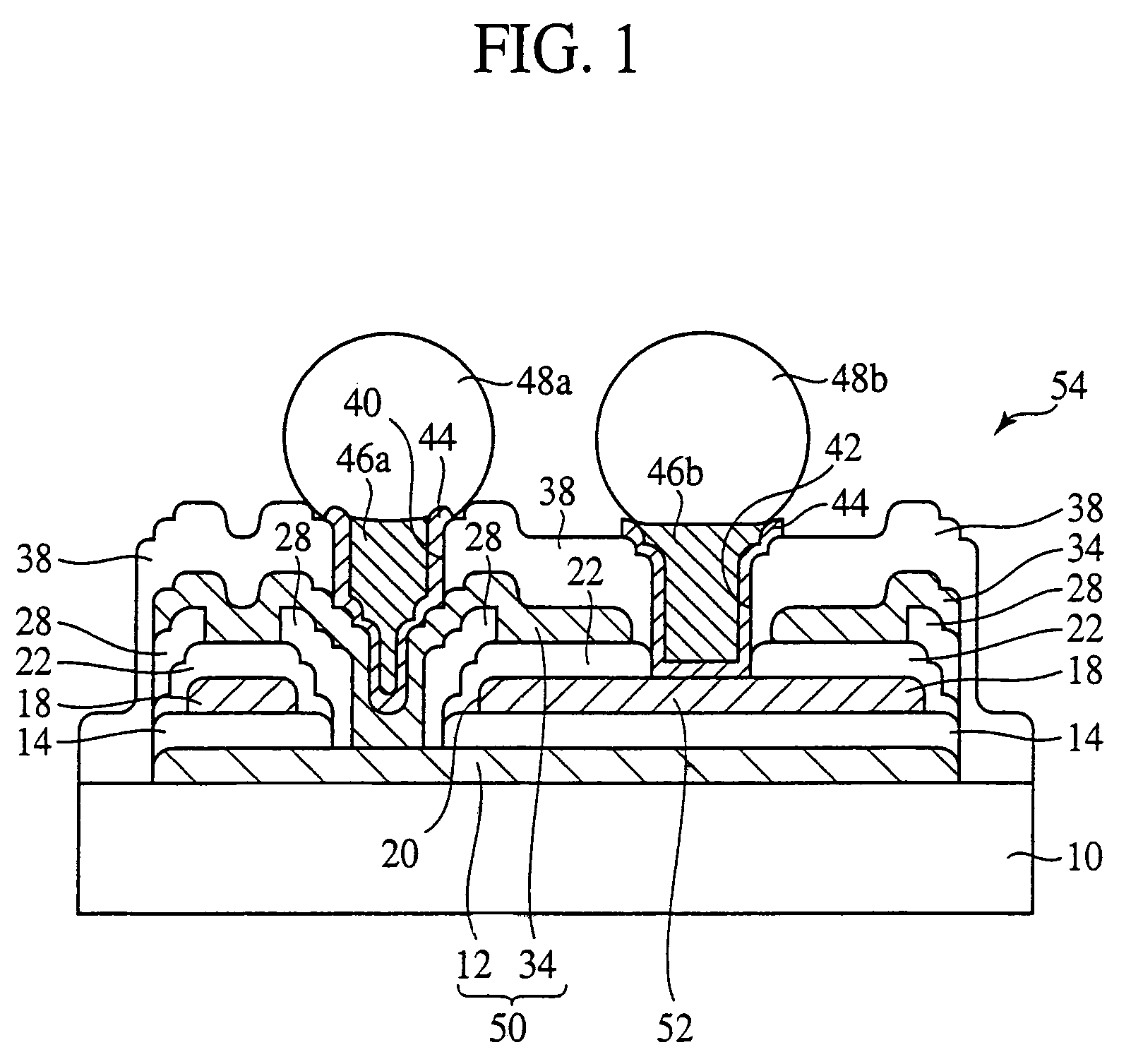

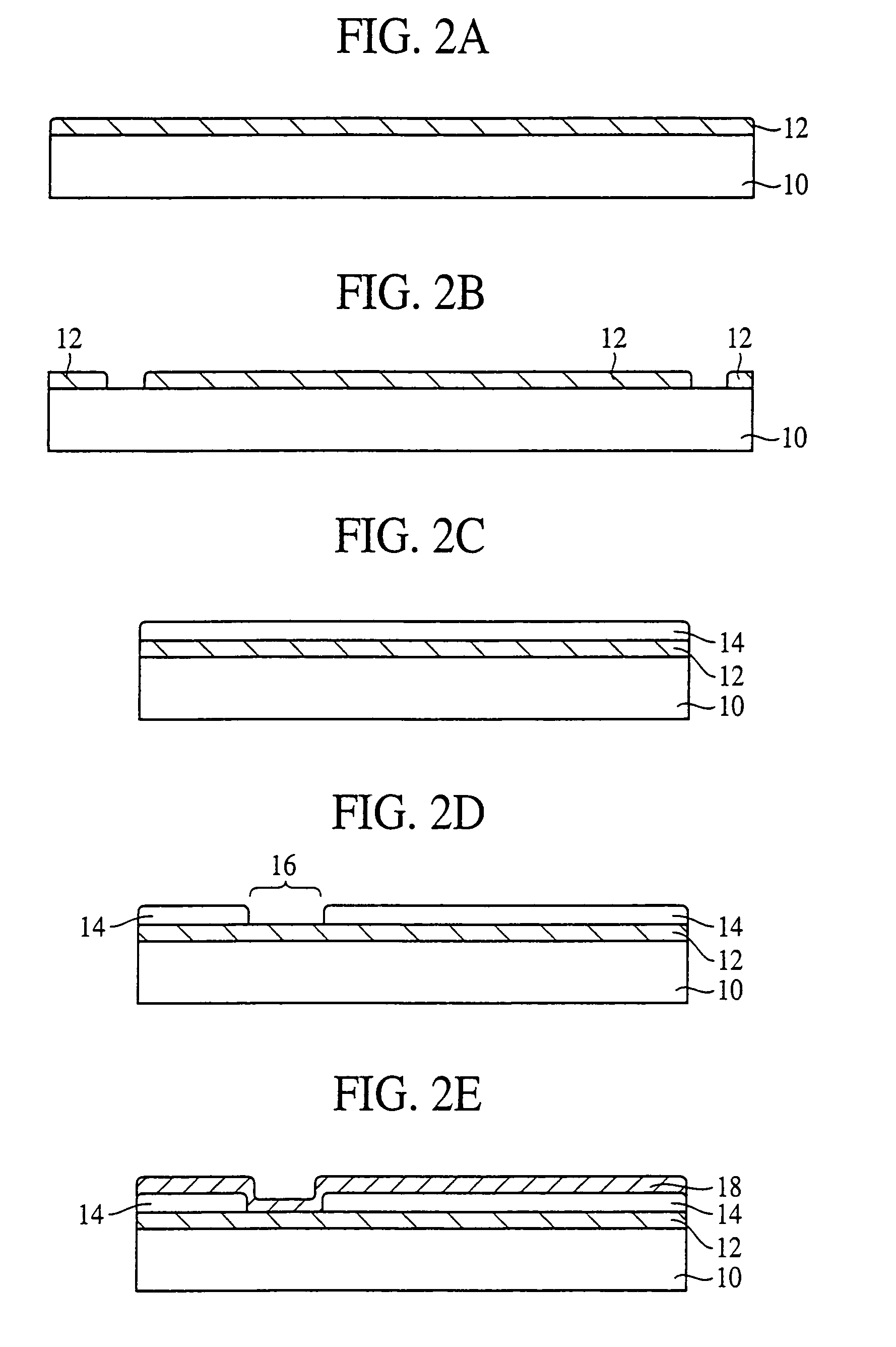

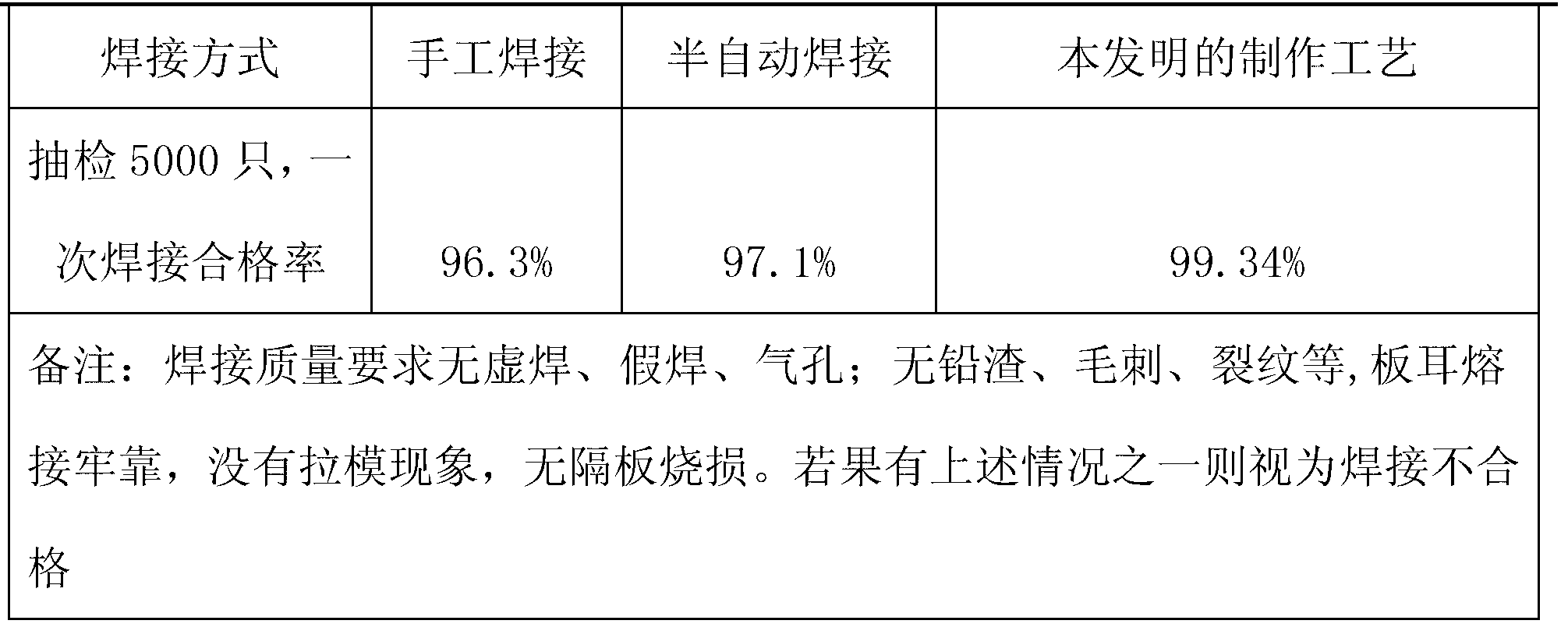

Capacitor and semiconductor device and method for fabricating the semiconductor device

InactiveUS20050156279A1Increase capacitanceGuaranteed uptimeSemiconductor/solid-state device detailsSolid-state devicesDielectricCapacitance

Owner:FUJITSU LTD

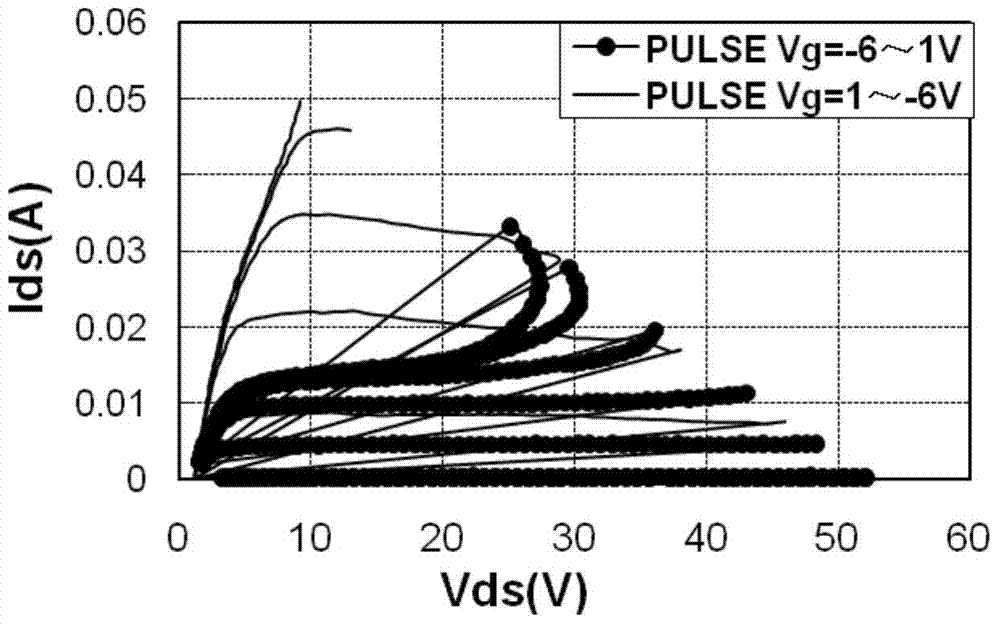

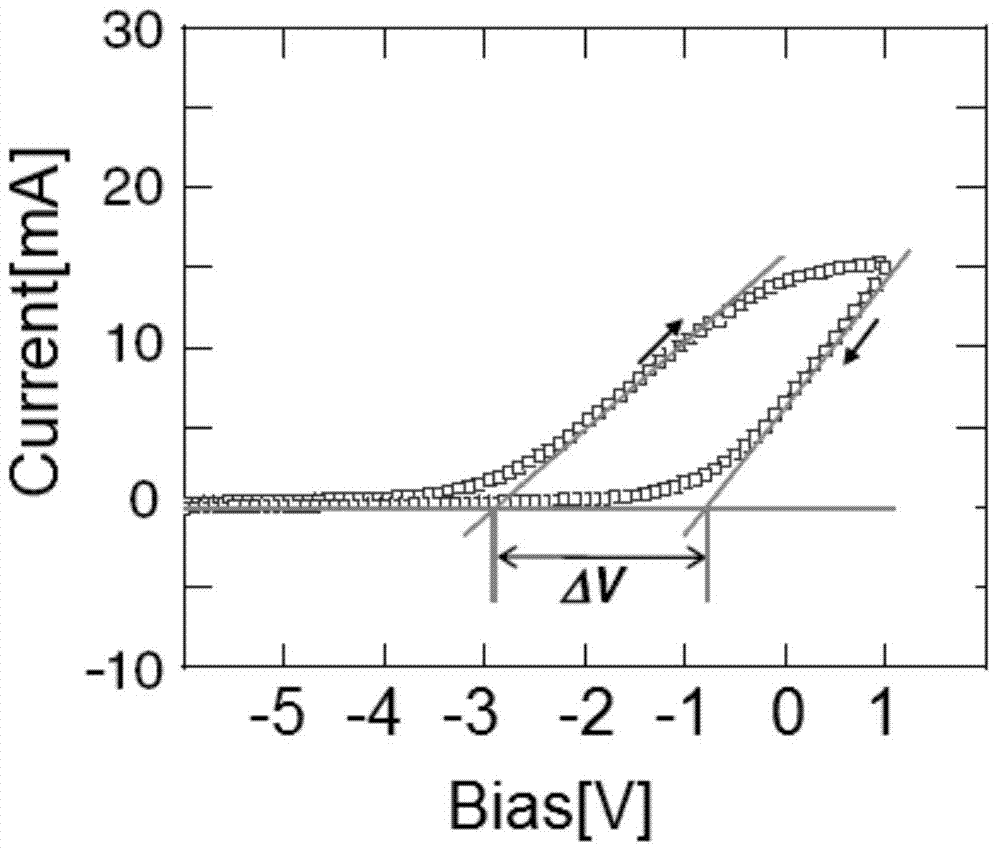

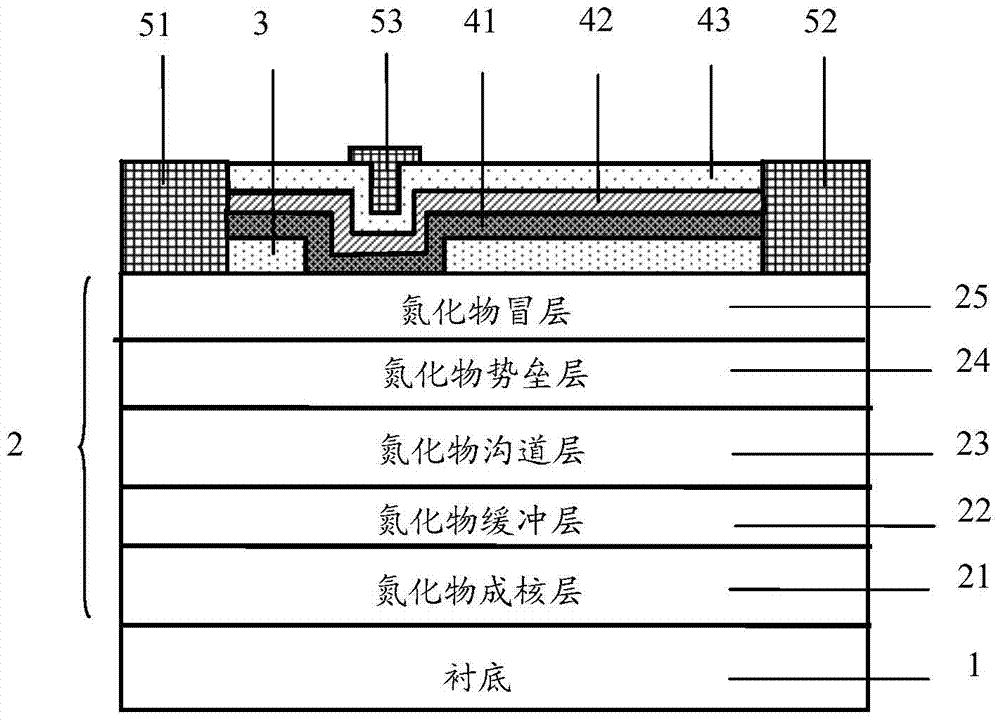

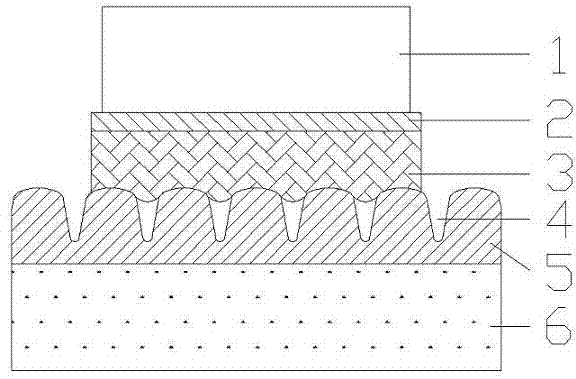

III-nitride semiconductor device and manufacturing method for same

ActiveCN103500763AReduce gate leakage currentHigh gate withstand voltageSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingPower semiconductor deviceState density

The invention discloses an III-nitride semiconductor device and a manufacturing method for the same. The III-nitride semiconductor device comprises a nitride semiconductor layer, a passivation layer, a source, a drain and a gate, wherein the nitride semiconductor layer and the passivation layer are grown on a substrate; the gate is positioned between the source and the drain; the nitride semiconductor layer comprises a nitride nucleating layer, a nitride buffer layer, a nitride trench layer and a nitride potential barrier layer; the passivation layer is etched in a gate area until the nitride potential barrier layer is exposed, and a groove is formed in the gate. According to the device and the method, a combined structure of a composite dielectric layer is adopted between the nitride potential barrier layer and a gate metal layer, and the composite dielectric layer comprises a nitride dielectric layer, an oxynitride dielectric layer and an oxide dielectric layer, which are sequentially formed from the substrate, so that the increase of interface state density is avoided; compared with a conventional III-nitride semiconductor device with a single oxide dielectric layer, the III-nitride semiconductor device with the composite dielectric layer has the advantage that the electric leakage and current collapse effects of the semiconductor device can be simultaneously reduced.

Owner:ENKRIS SEMICON

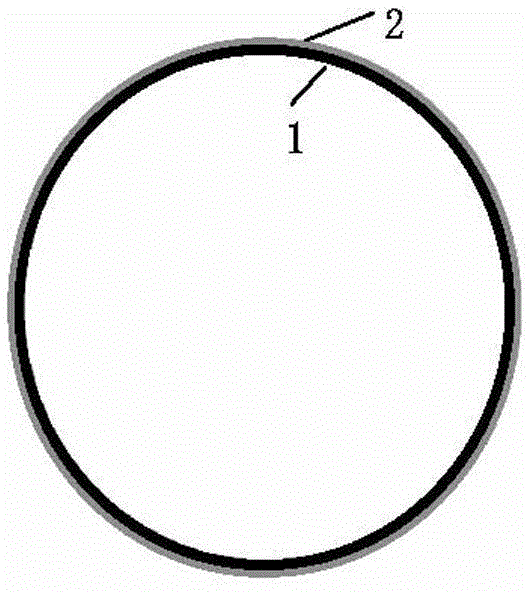

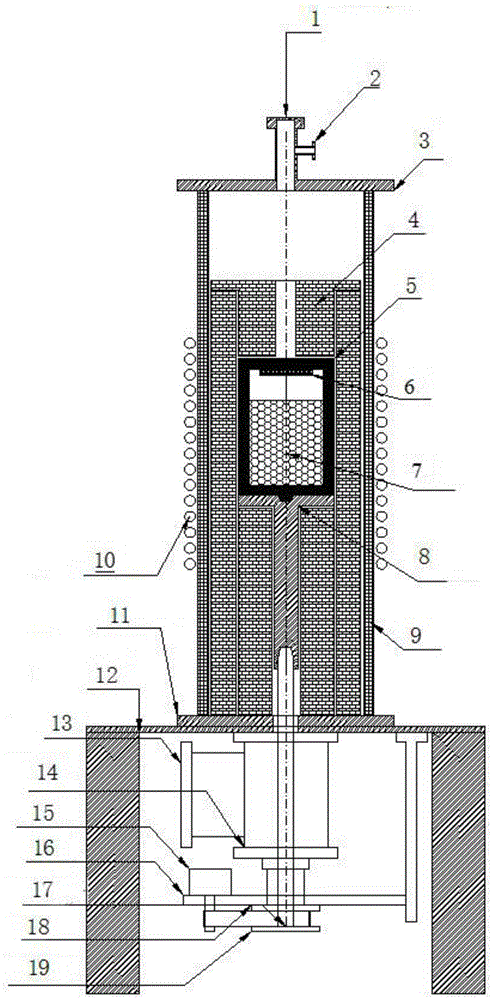

Centrally symmetric silicon carbide (SiC) single crystal growing device and method

InactiveCN105568370ACentral symmetryIncrease profitPolycrystalline material growthFrom condensed vaporsThermal insulationSingle crystal

The invention relates to a centrally symmetric silicon carbide (SiC) single crystal growing device. The growing device comprises a graphite crucible with a cover, wherein the bottom of the graphite crucible is connected with a rotating system which rotates the graphite crucible; the rotating system comprises a rotating tray, a center rotating rod and a driving device which drives the center rotating rod to move actively; the driving device is in sealing connection with a vacuum growth cavity by a tee connector; the center rotating rod passes through the tee connector to be connected with the driving device. According to the growing device disclosed by the invention, the bottom of the graphite crucible is connected with the rotating system which rotates the graphite crucible, when the rotating system is used, the rotation speed of the center rotating rod is 1 to 60 revolutions per minute; a non-centrosymmetric thermal field caused by spiral induction coils and thermal insulation is avoided; a centrosymmetric thermal field is constructed, and the transmission of substances is in central axial symmetry, so that the obtained crystal is centrally symmetric; the thicknesses of all edges are identical, and the use ratio of crystal materials is improved.

Owner:SHANDONG UNIV

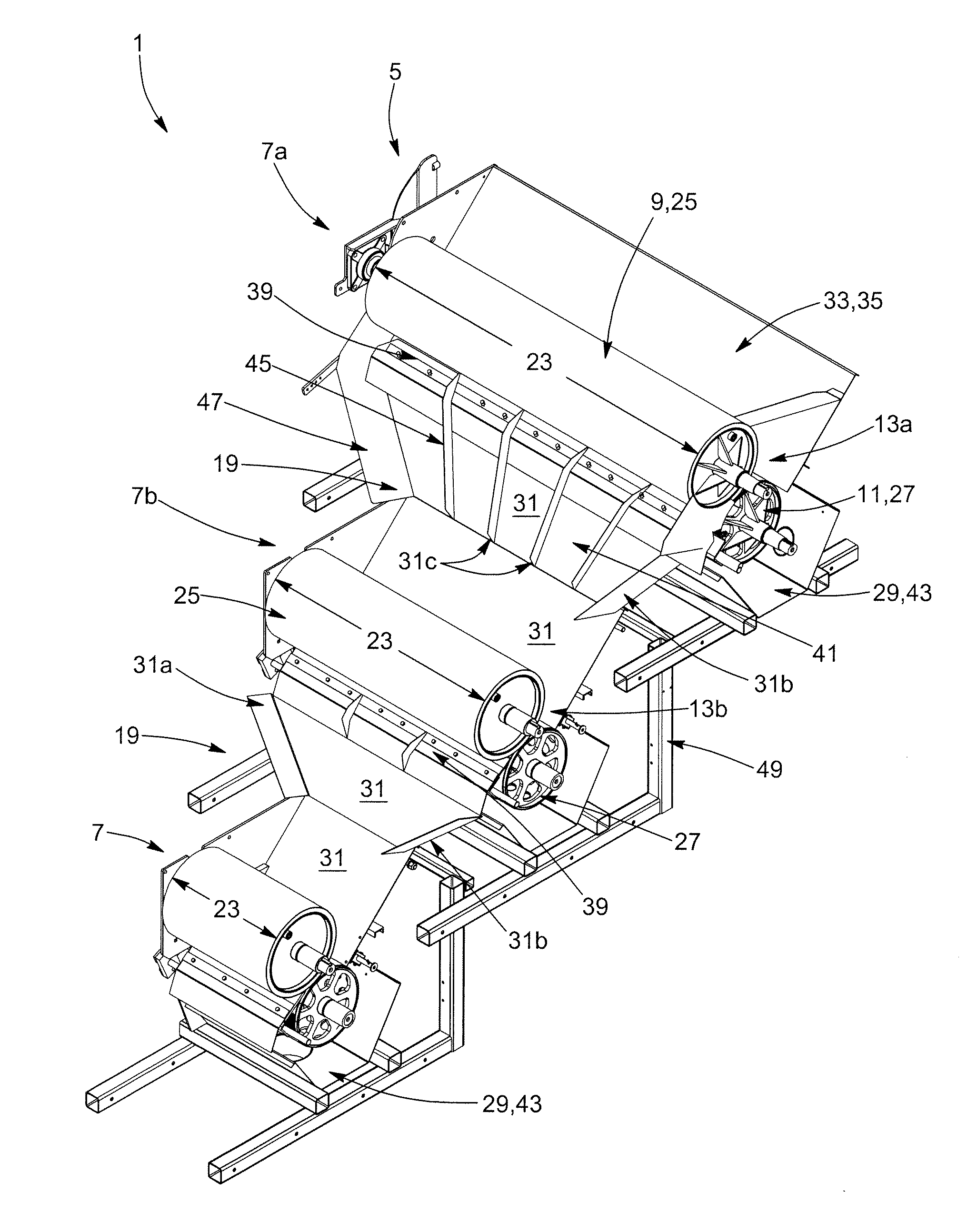

Liquid separation device

ActiveUS20120031856A1Improve drying rateImprove the level ofManure treatmentDrying solid materials without heatEngineeringSolid material

A liquid separating device (1) for processing a mixture material (3) containing both solid and liquid materials (3a,3b), in order to separate liquid material (3b) from the solid material (3a), the liquid separating device (1) includes a support frame (5), a series of liquid separation assemblies (7a,7b) and a corresponding guiding assembly (19) between each pair of liquid separation assemblies (7). The liquid separation assemblies (7) are disposed about the support frame (5) in a cascading configuration, and the passage (13) of each liquid separation assembly (7) is narrower in width than the passage of a preceding liquid separation assembly (7) so that each subsequent liquid separation assembly (7b) is enabled to extract more liquid material via an increased wringing pressure resulting from a thickening of the remaining mixture material (3) to be processed and the narrower subsequent passage (13b) through which it is channeled and pressed.

Owner:GEA FARM TECH CANADA

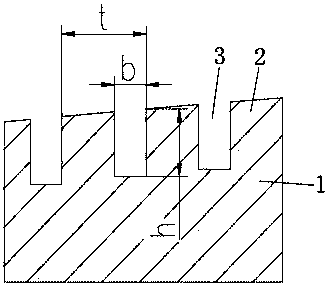

Method of cutting workpiece of film filter

InactiveCN1455271AIncrease the effective thicknessReduce residual stressOptical filtersWavelength-division multiplex systemsEngineeringTransition layer

The method includes two implementing modes. In the first mode, before cutting the work piece, the transition layer connects the assistant substrate to the glass substrate. In the second mode, an other work piece comprises one glass substrate with the thickness being thicker than the final expected thickness. Then, the unwanted part of the glass substrate is removed. The method of the two implementing modes increases the effective thickness of the work piece so as to reduce residual stress of the film filter plate finished product. Moreover, the risk of the film stack peeled off from the glass substrate is reduced when the work piece is cut.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Welding process of boss of hydrogenation reactor

ActiveCN103170815AAvoid the hassle of surfacingAvoid levelingArc welding apparatusEngineeringWelding process

The invention relates to a welding process of a boss of a hydrogenation reactor. A port in one end of a cylindrical shell section is processed flatly after coiling, circle checking and flaw detection of the cylindrical shell section are qualified; and then a surfacing position of the boss is marked, and thus the trouble that a cylinder body is firstly leveled and then overturned for surfacing the boss when the boss is surfaced is avoided, the leveling procedure during processing of the boss is avoided, therefore the production time is saved, the levelness of the boss is ensured, and the purpose of ensuring the welding quality of the boss is achieved.

Owner:青岛兰石重型机械设备有限公司

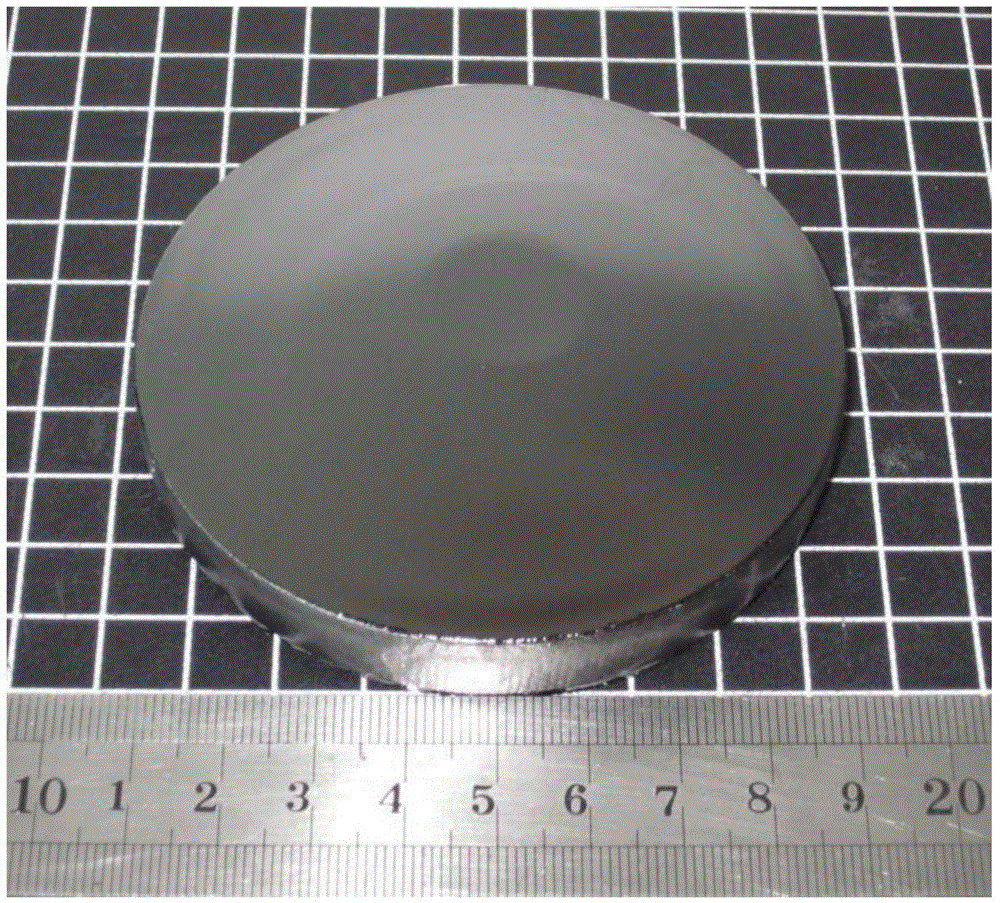

Perforation ejecting head and surface treatment method thereof

ActiveCN104213069APlay a supporting roleInhibit sheddingMandrelsSolid state diffusion coatingRoom temperatureEngineering

The invention discloses a surface treatment method of a perforation ejecting head. The surface treatment method comprises the following steps: (1) spiral or annular matrixes integrated with an ejecting head main body are processed on the peripheral surface and the head end surface of the ejecting head main body; and spiral grooves or annular grooves are formed between the matrixes; and (2) the ejecting head main body obtained in the step (1) is put in a heating furnace for heating up to the temperature of 900-1100 DEG C; an oxidant is fed for keeping the temperature for 5-10 hours; then the temperature is reduced to 800-900 DEG C; the ejecting head main body is slowly cooled to the normal temperature after being discharged from the furnace; and oxide layers are continuously generated at the bottoms of the spiral grooves or the annular grooves, on the side wall surfaces of the grooves and on the surfaces of the matrixes. The surface treatment method of the perforation ejecting head increases the effective thickness of the oxide layers so as to prolong the service life of the ejecting head.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

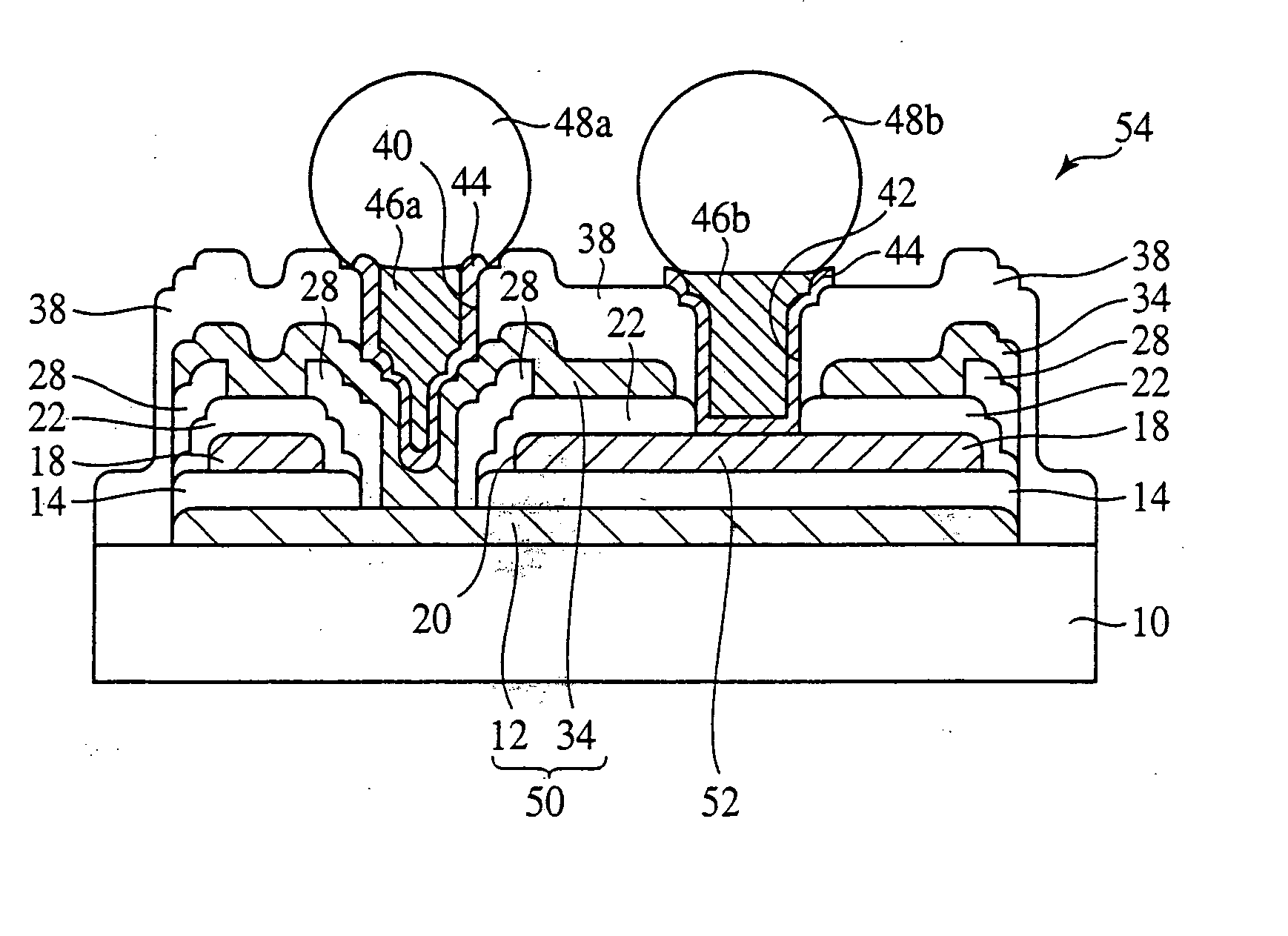

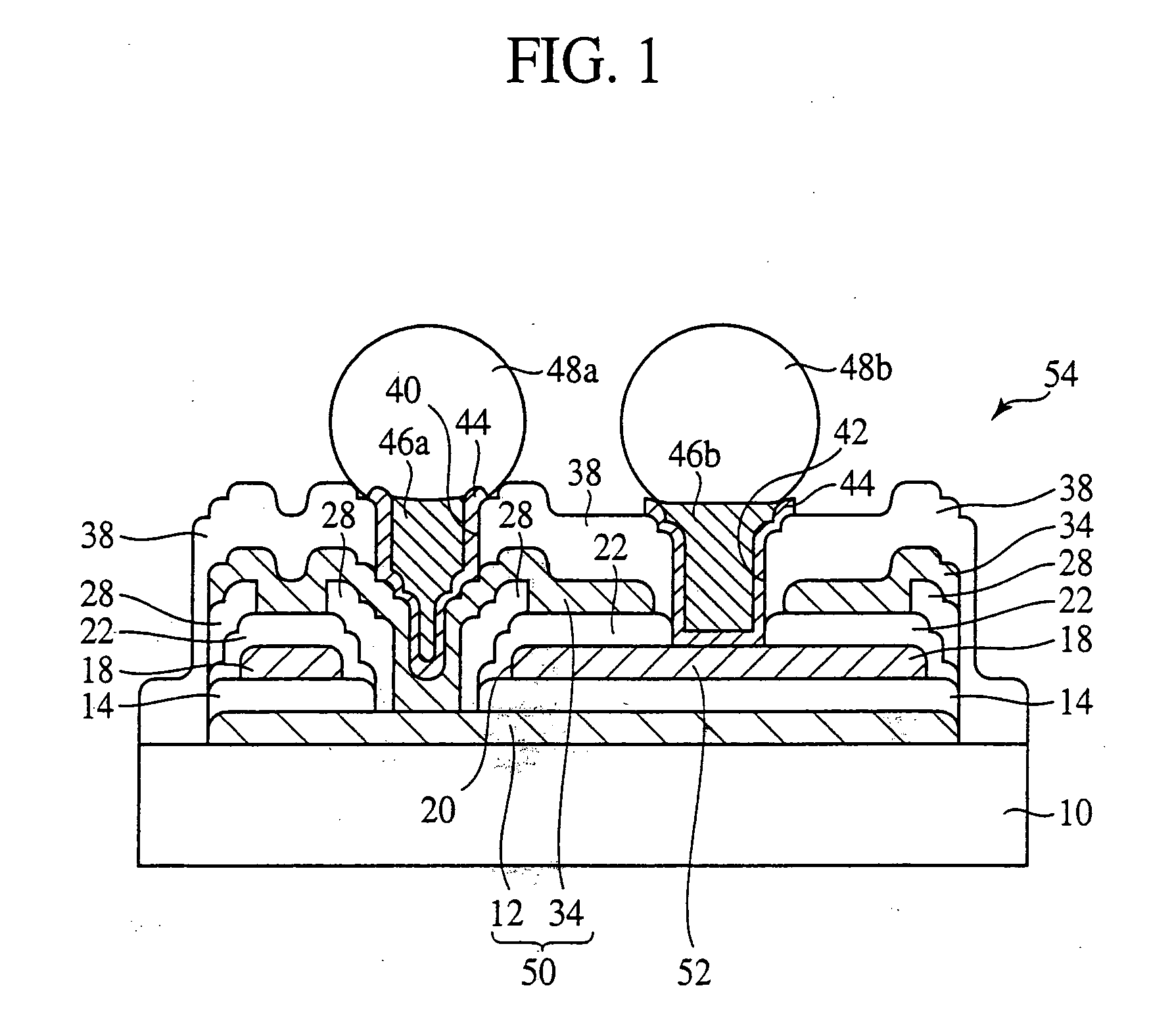

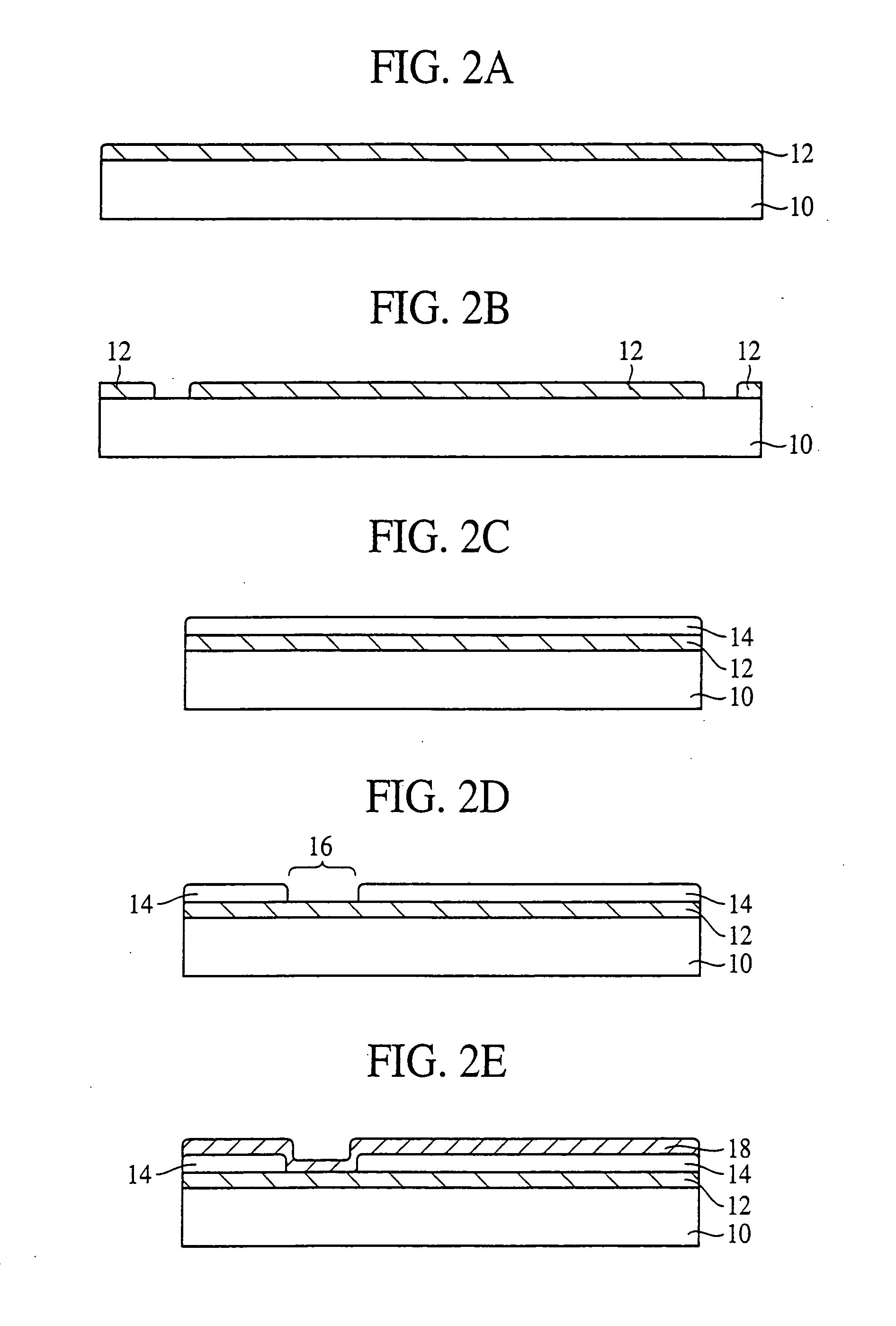

Semiconductor device having passive component and support substrate with electrodes and through electrodes passing through support substrate

InactiveUS7339277B2Increase capacitanceGuaranteed uptimeSemiconductor/solid-state device detailsPrinted electric component incorporationCapacitanceSemiconductor

A capacitor comprises a first conducting film 12 formed on a substrate 10, a first dielectric film 14 formed on the first conducting film, a second conducting film 18 formed on the first dielectric film, a second dielectric film 22 formed above the second conducting film, covering the edge of the second conducting film, a third conducting film 34 formed above the second dielectric film, covering a part of the second dielectric film covering the edge of the second conducting film. The capacitor further comprises an insulation film 28 covering the edge of the second conducing film or the part of the second dielectric film. An effective thickness of the insulation film between the second conducting film and the third conducing film in the region near the edge of the second conducting film can be increased, whereby concentration of electric fields in the region near the edge of the second conducting film. Consequently, the capacitor can have large capacitance without lowering voltage resistance.

Owner:FUJITSU LTD

Metal-based circuit board with ultrahigh heat-conducting property and preparation method thereof

ActiveCN103118487AImprove adhesionHigh peel strengthConductive pattern formationCircuit susbtrate materialsHeat conductingEngineering

The invention discloses a metal-based circuit board with ultrahigh heat-conducting property. The circuit board comprises a base material layer, a composite heat-conducting insulating layer attached to the surface of the base material layer, and a conducting circuit layer printed by a printed electronics technology, wherein the composite heat-conducting insulating layer comprises a substrate layer and an insulating layer; the upper surface of the substrate layer is attached to the insulating layer; and the lower surface of the substrate layer is attached to the surface of the base material layer. The invention also discloses a preparation method for the metal-based circuit board with the ultrahigh heat-conducting property. By the metal-based circuit board with the ultrahigh heat-conducting property, the defects of low breakdown voltage resistance and peel strength, non-uniform thickness of a conducting circuit, and the like are overcome while the heat transfer requirement is met.

Owner:南京安迪工业科技有限公司

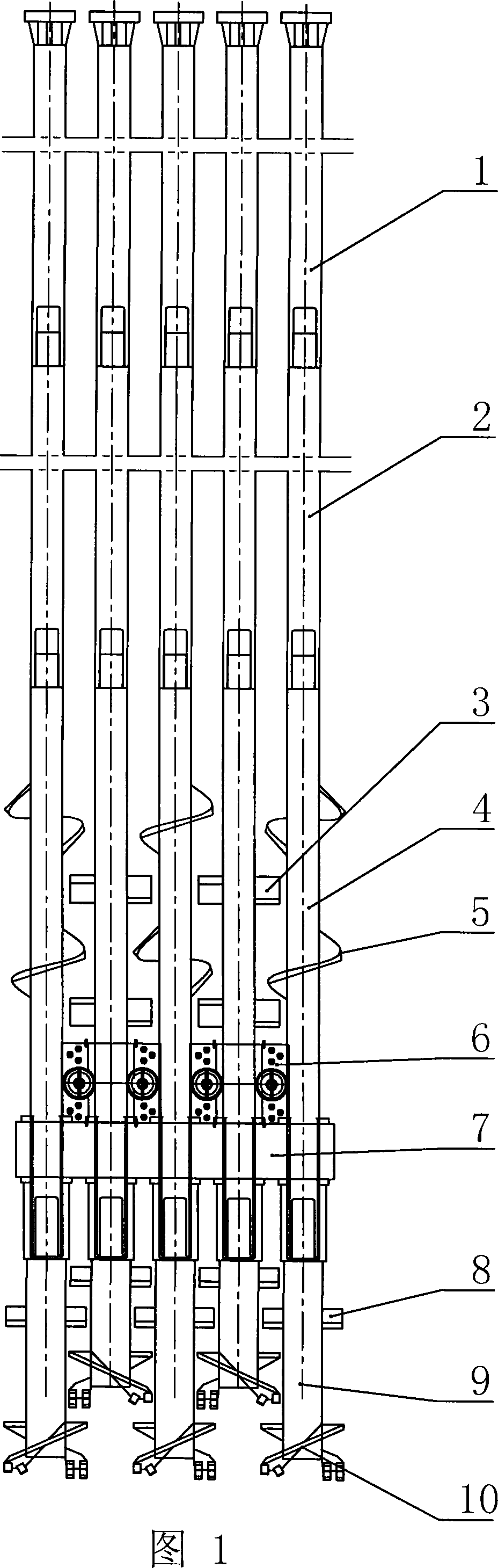

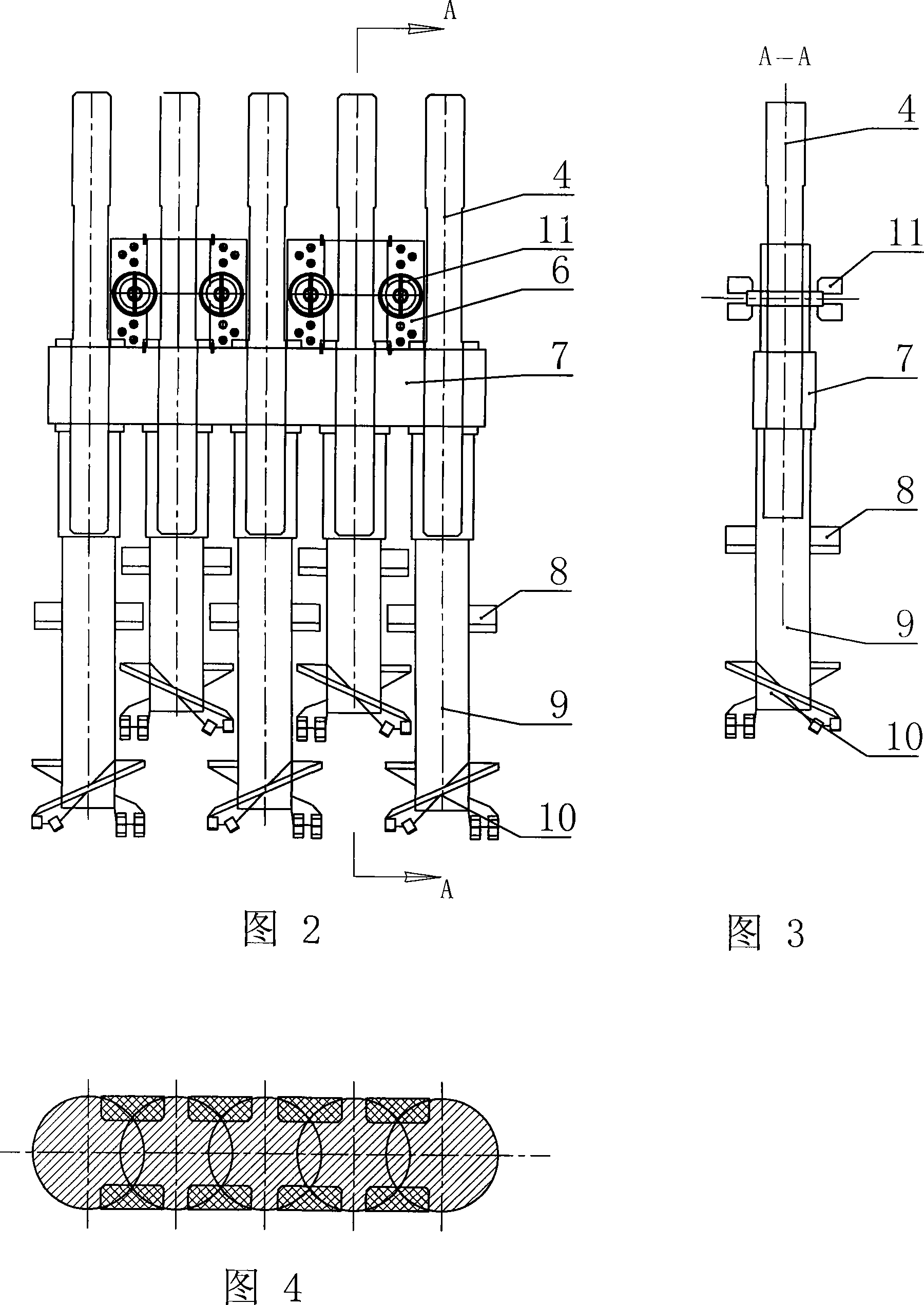

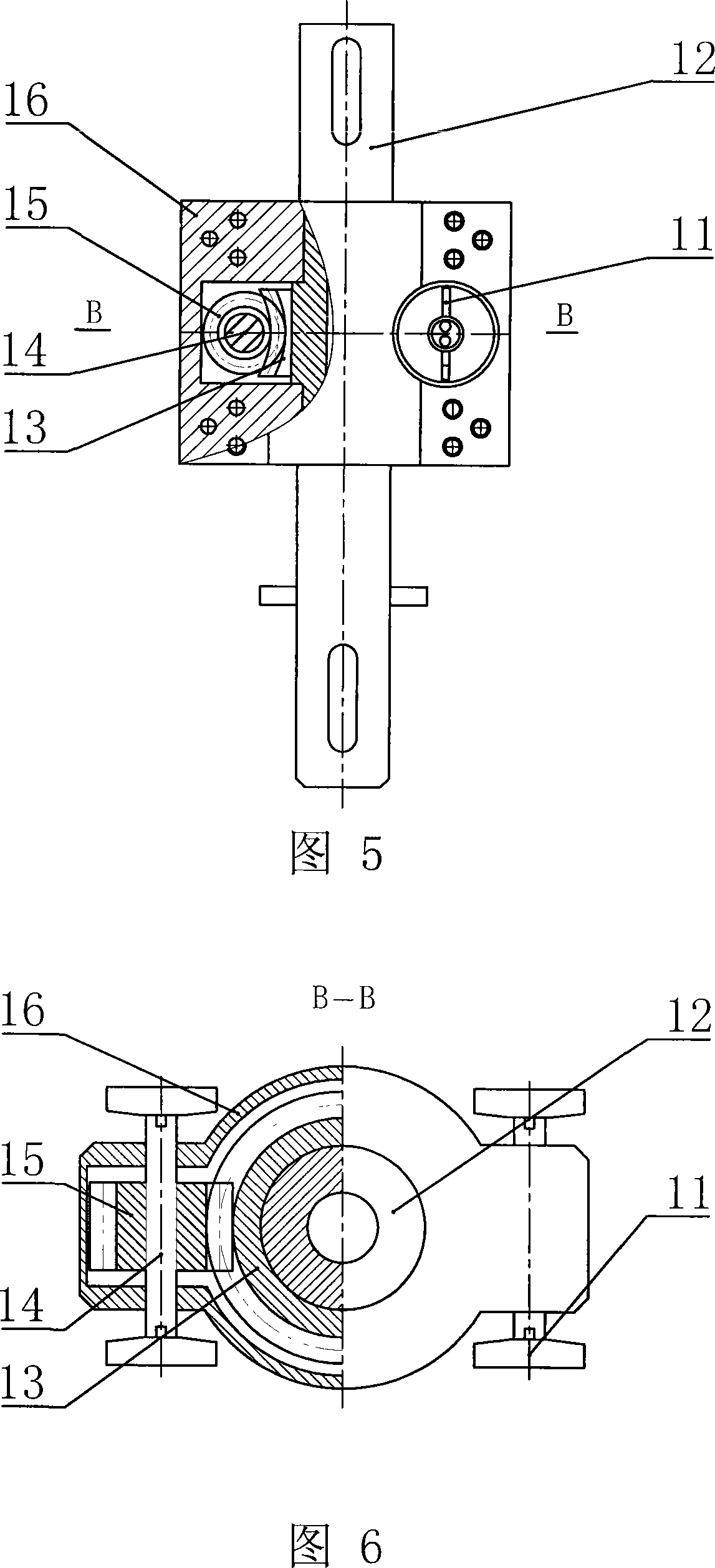

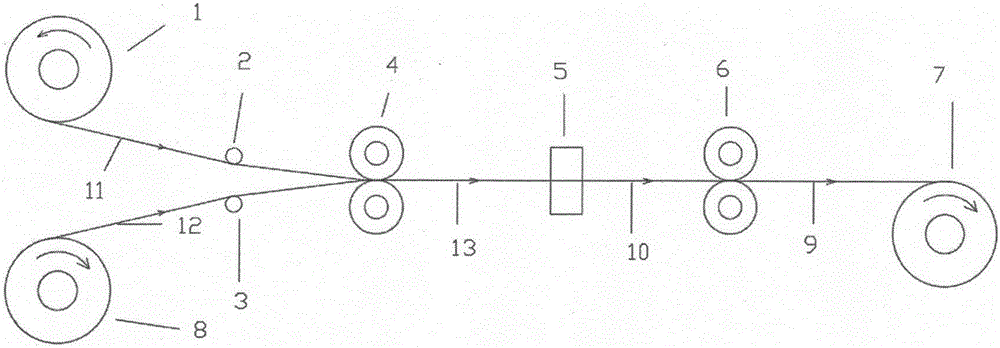

Multi-headed isopach deep agitation driller

InactiveCN101082264AReduce dosageGuaranteed integrityConstructionsRotary drillingSlurry wallStructural engineering

The invention discloses a multithread equal-thickness deep mixing drill which belongs to the technology field of engineering drill. It is composed of more than two groups of upper and lower drill rocker parallel setting on the retainer. The retainer contains a wall cutter which contains a case hinging the retainer. A hollow turboshaft is coaxial fixed corresponding to the lower drill rocker on the case passing through it. A turbine is packaged outside the turboshaft. The worm meshing the turbine is set on its one or two sides. The worm shaft supports on the case against to the lower drill rocker and its two ends extending out of the case are equipped with wall cutting-tool. The longitudinal projection of the cutting-tool locates on the public chord extension line of the external turning trace of the two adjacent twist drills. The wall cutting-tool rotates to cut the border with the smallest separation between the adjacent round digging pores. The thicknesses of the digging pores are unified to get the equal-thickness underground serial wall. With the fewer materials and the greater strength, it is applied for the supporting water-seal of the foundation ditch and the levee antiseep.

Owner:JIANGSU HONGSHENG CONSTR ENG GROUP

Microwave electromagnet shielding fabric and manufacturing method thereof

ActiveCN104514141AImprove shielding effectIncrease the effective thicknessFibre treatmentSuperimposed coating processAviationElectromagnetic radiation

The invention discloses a microwave electromagnet shielding fabric. The fabric comprises a basic layer and a metal composite coating. The basic layer is made of terylene network silk fabrics and is characterized in that a metal composite coating is arranged on the basic layer, wherein the bottom layer of the metal composite coating is a silver coating with a silver content of 4 to 10 grams per square meter, and the surface layer of the metal composite coating is an aurous coating, and the gold (I) content is 13 to 20 grams per square meter. The shielding performance on electromagnet field is improved, the synergetic effect between metal layers is enhanced, and the effective thickness of fabrics is also taken into account, so the provided fabric can be used in a wide frequency range of 300 MHz-300 GHz, the shielding effectiveness is 60-90 dB, and the reflectivity can reach 98%. The provided fabric has high shielding effectiveness and a strong reflecting performance on microwave electromagnetic radiation, and thus is especially suitable for being applied to industries such as aviation, aerospace, military research, medical industry, mine industry, and the like.

Owner:合肥爱家防辐射科技有限公司 +1

Method for molding micro-profiled composite joint strips

ActiveCN106807750AEfficient productionStable productionRollsMetal rolling arrangementsStress pointRoll forming

The invention discloses a method for molding micro-profiled composite joint strips. The method is characterized by comprising the following steps: performing wire drawing or roller drawing on square composite wires for pre-forming the needed double-peak appearance wires; and performing final forming on the pre-formed composite wires through a precision-rolling mill with a welding rib limited concave-convex molding roller, thereby obtaining the needed product with a special profile shape. The stress point of the composite strip in the rolling process is changed in a manner of pre-forming the double-peak appearance, so that the interface of the micro-profiled composite wire can be straightened, the precious metal cladding phenomenon is reduced, the utilization rate of precious metals is greatly improved, and the needed micro-profiled composite product is easily formed; and moreover, rolling forming is performed by utilizing the welding rib limited roller, the welding rib position does not need to be adjusted in the production process, the process wastes can be reduced, the production efficiency is improved, and the production cost of the whole product is reduced.

Owner:SHANGHAI TOUCH METALS TECH

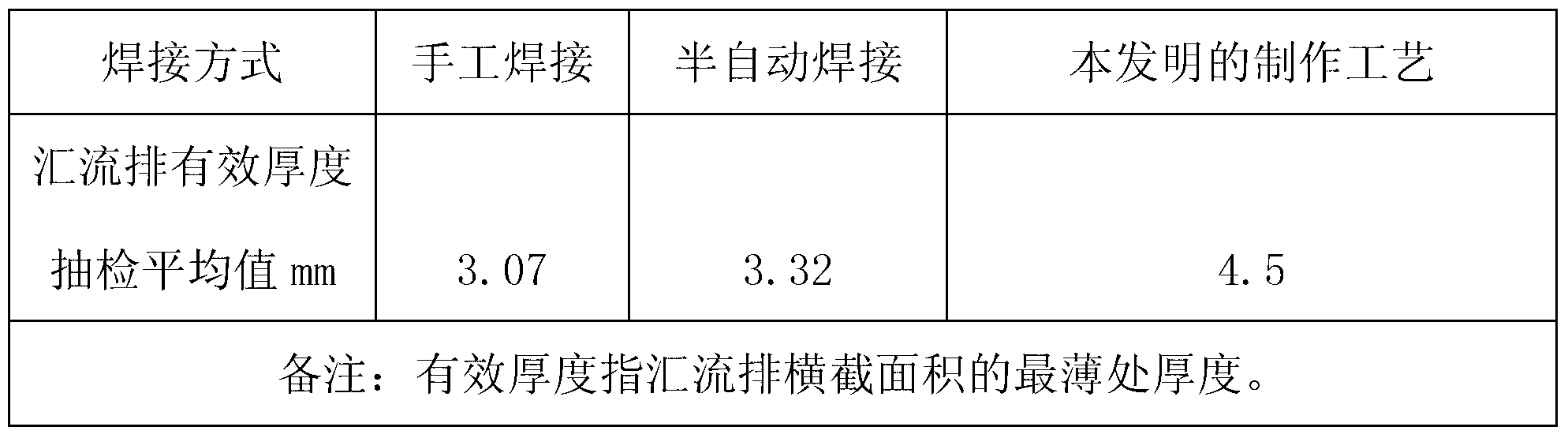

Tank formation manufacturing technology for storage batteries

ActiveCN103264154AIncrease the effective thicknessImprove welding qualityManufacturing technologyWater vapor

The invention discloses a tank formation manufacturing technology for storage batteries,relates to the field of lead-acid storage battery production and solves the problem of the poor welding quality between bus-bars and electrode tabs. The manufacturing technology comprises the technological processes of feeding of plate packs in an assembly box, electrode tab arrangement, cutting and brushing of electrode tabs, dipping of flux, cast-welding, inspection and discharging after qualification. The cast-welding process is performed through a cast-welding machine and comprises the following steps: 1) heating of a lead pan; 2) preheating of a lower die; 3) scrapping of molten lead; 4) electrode tab cast-welding; 5) water cooling; 6) water vapor mixing cooling; 7) gas cooling; 8) secondary preheating of the lower die; and 9) feeding of the electrode tabs in battery containers. The manufacturing technology is used for cast-welding of lead-acid storage battery grids.

Owner:CHAOWEI POWER CO LTD

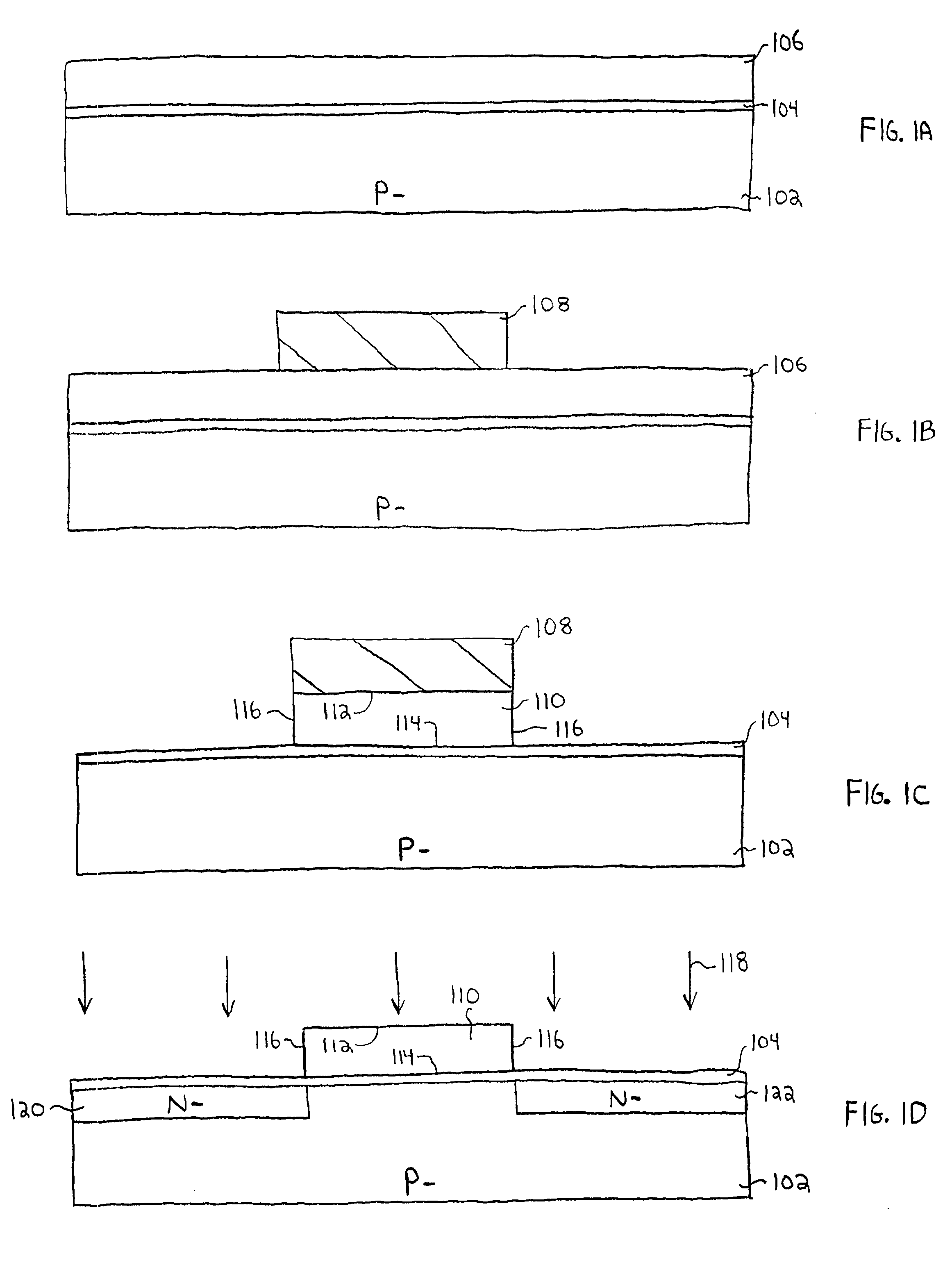

Igfet with silicide contact on ultra-thin gate

InactiveUS20020003273A1Conducive to lightweightWell-controlled doping profileTransistorSemiconductor/solid-state device manufacturingDopantSalicide

An IGFET with a silicide contact on an ultra-thin gate is disclosed. A method of forming the IGFET includes forming a gate over a semiconductor substrate, forming a source and a drain in the substrate, depositing a contact material over the gate, and reacting the contact material with the gate to form a silicide contact on the gate and consume at least one-half of the gate. By consuming such a large amount of the gate, a relatively thin gate can be converted into an ultra-thin gate with a thickness on the order of 100 to 200 angstroms. Preferably, the bottom surface of the gate is essentially undoped before reacting the contact material with the gate, and reacting the contact material with the gate pushes a peak concentration of a dopant in the gate towards the substrate so that a heavy concentration of the dopant is pushed to the bottom surface of the gate without being pushed into the substrate. As exemplary materials, the contact material is a refractory metal such as titanium, the gate is polysilicon, and the dopant is arsenic.

Owner:DAWSON ROBERT +6

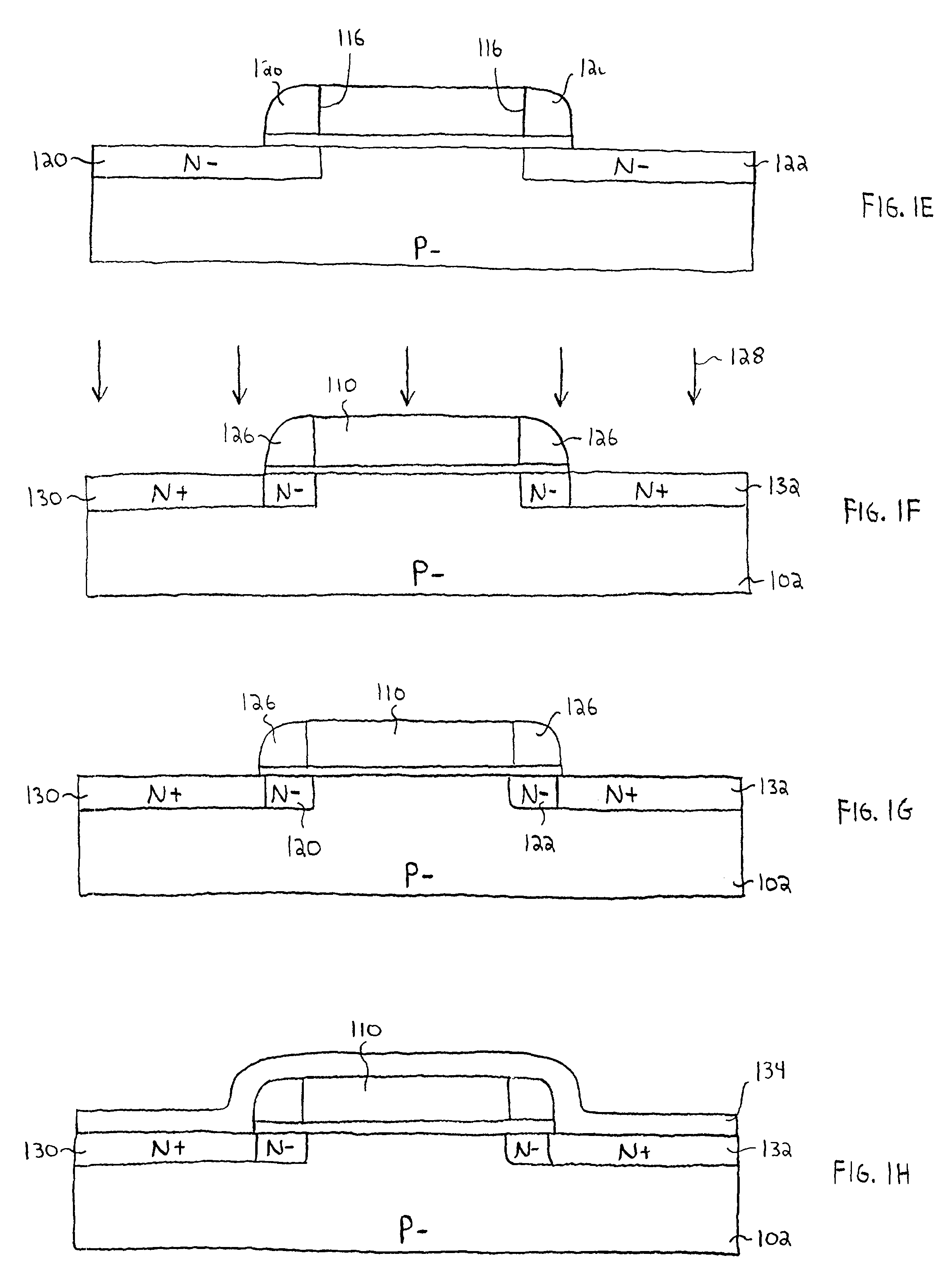

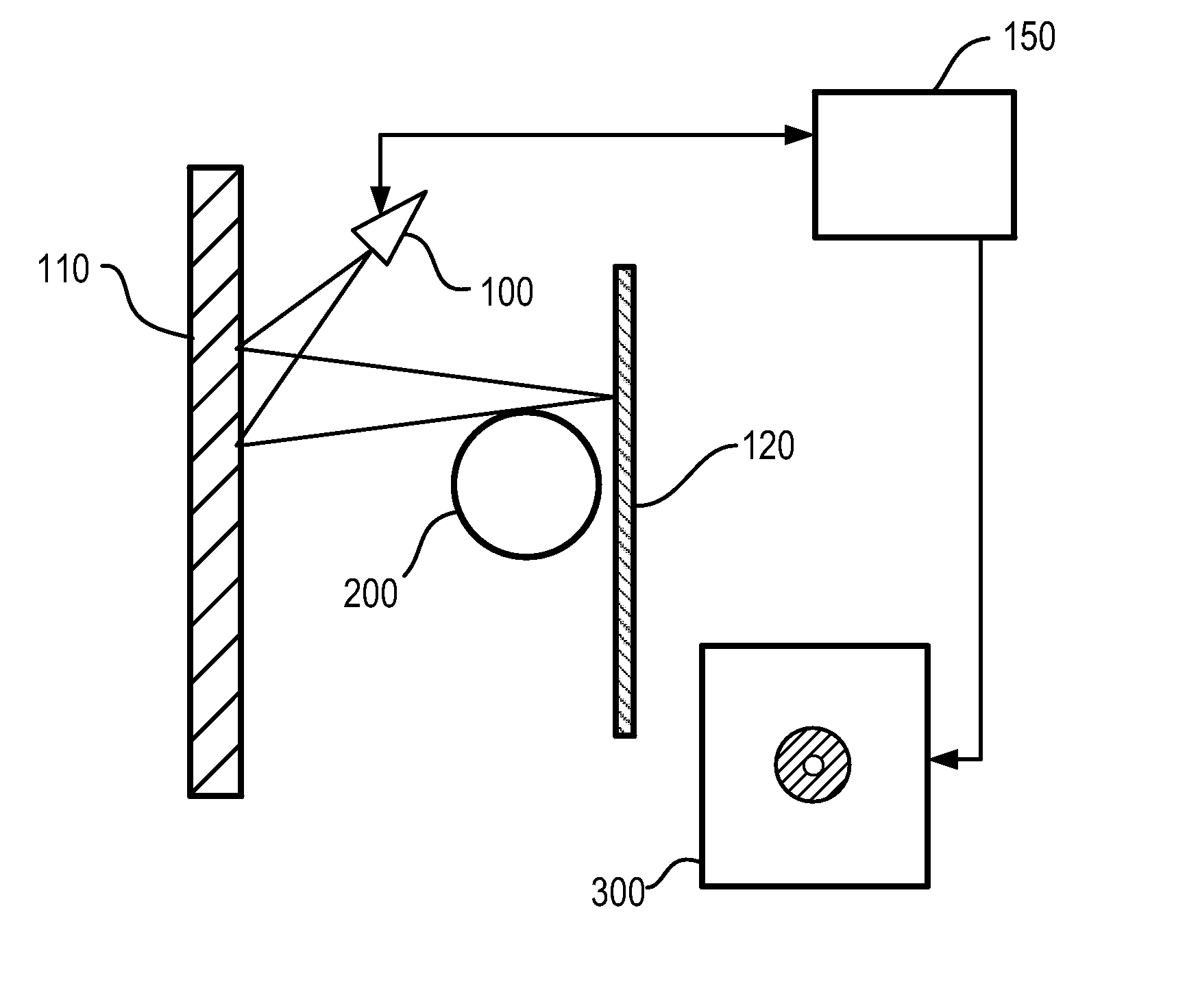

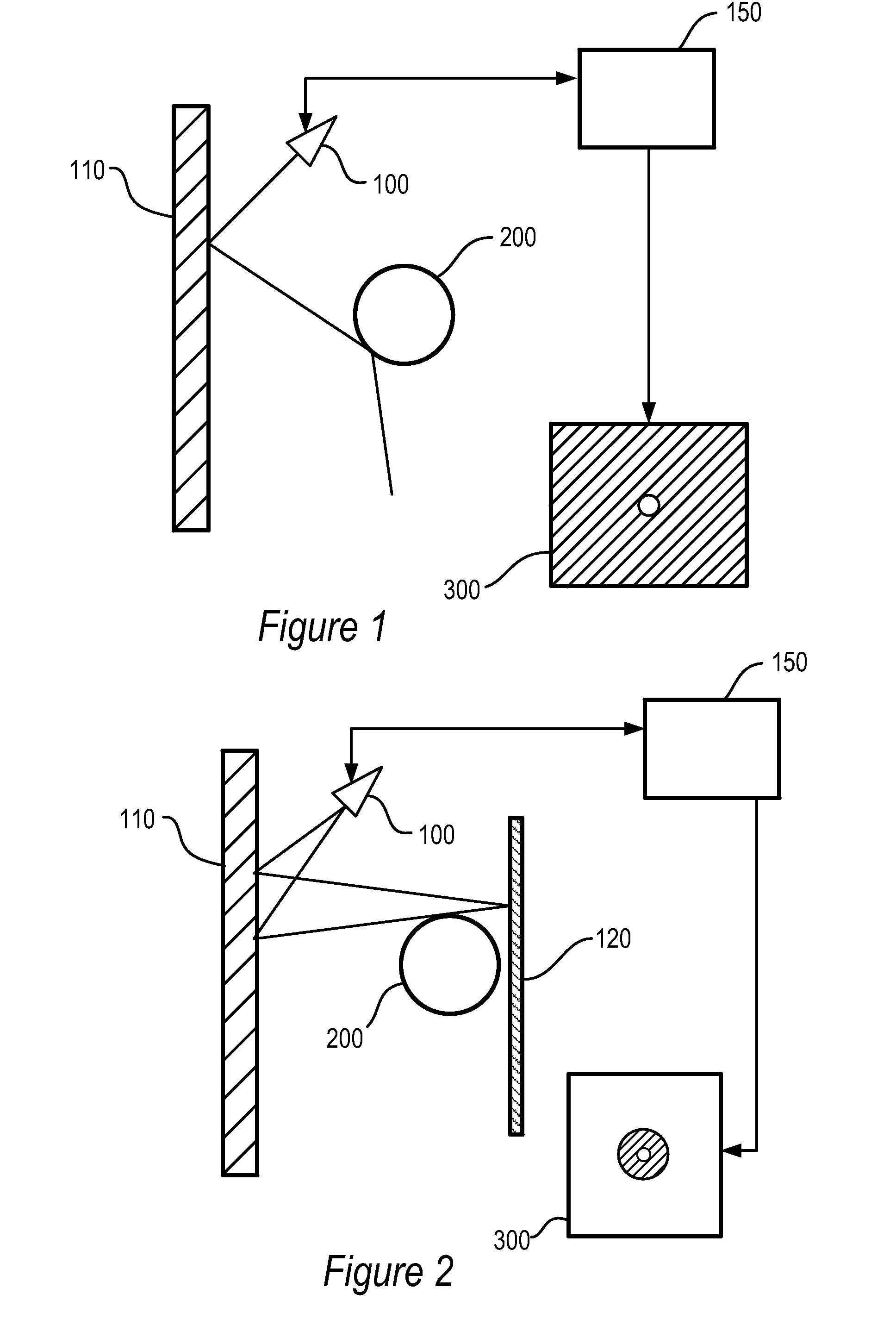

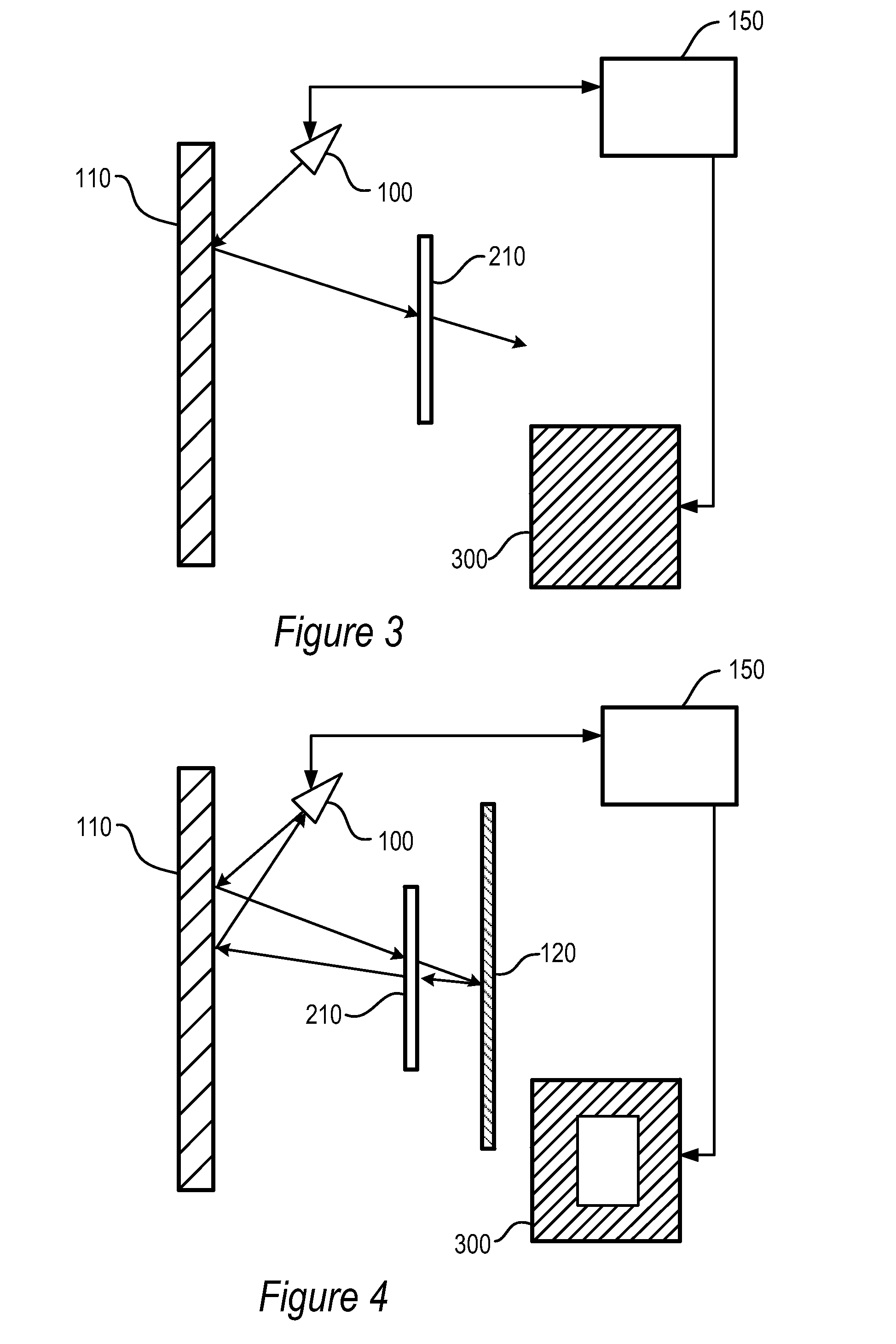

Imaging Through Silhouetting

ActiveUS20080161685A1Increase the effective thicknessEasy to useDiagnostic recording/measuringSensorsComputer scienceMicrowave imaging

Improved microwave imaging using a reflector. By providing a reflective surface in the range of the imaging system, additional information is available for imaging objects. The relative surface provides silhouette information on the object, and increases the effective thickness of the object to aid analysis.

Owner:AGILENT TECH INC

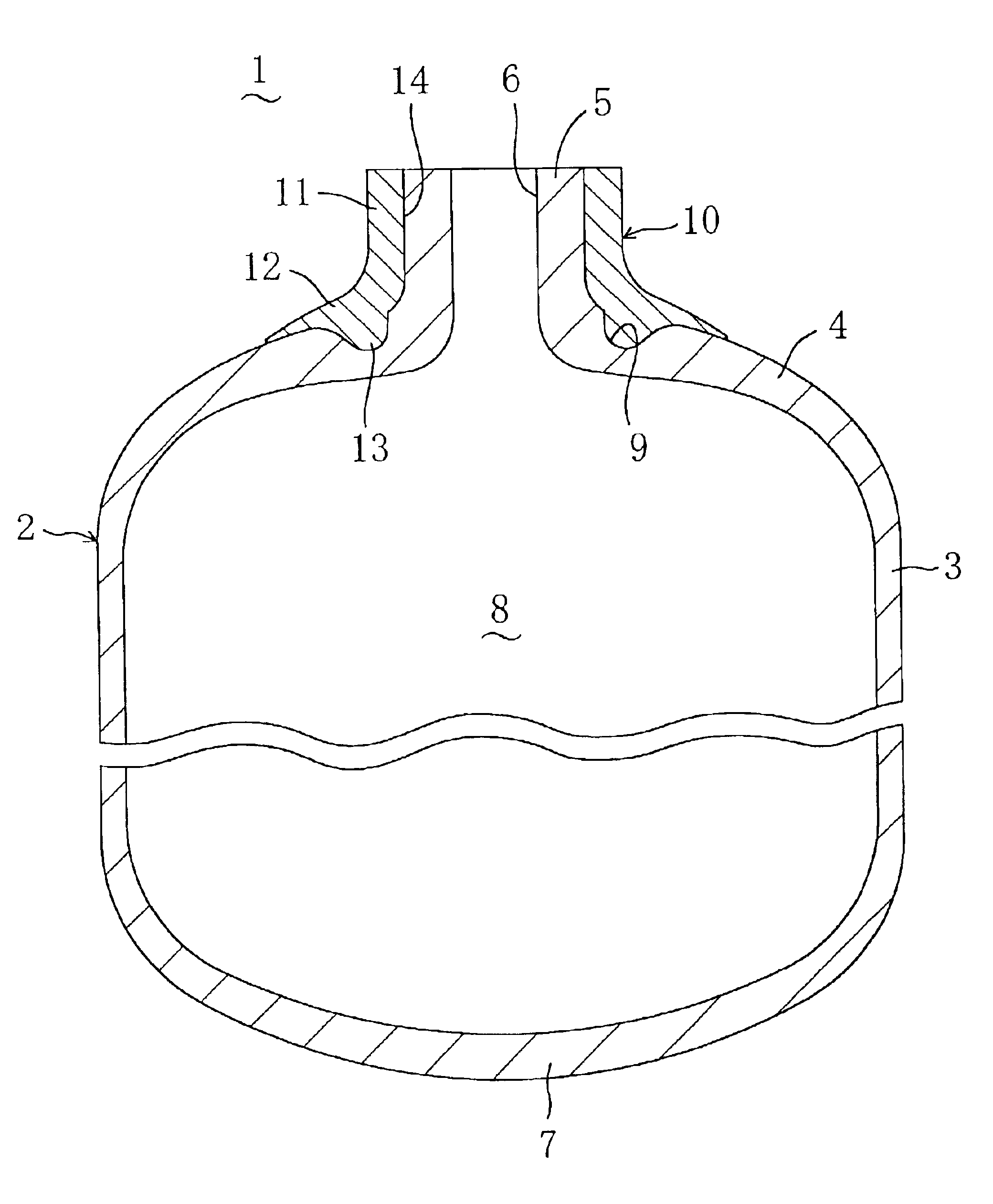

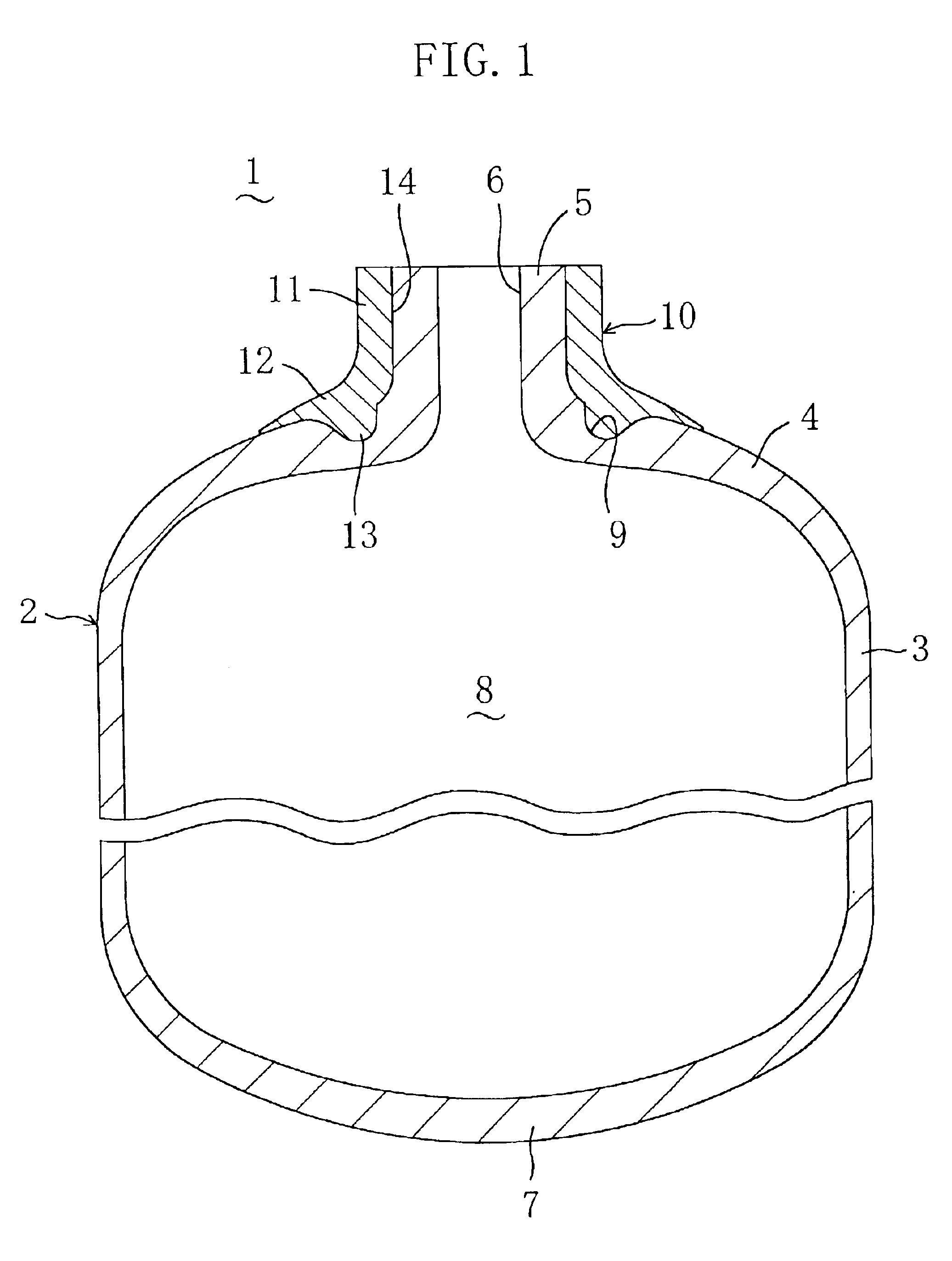

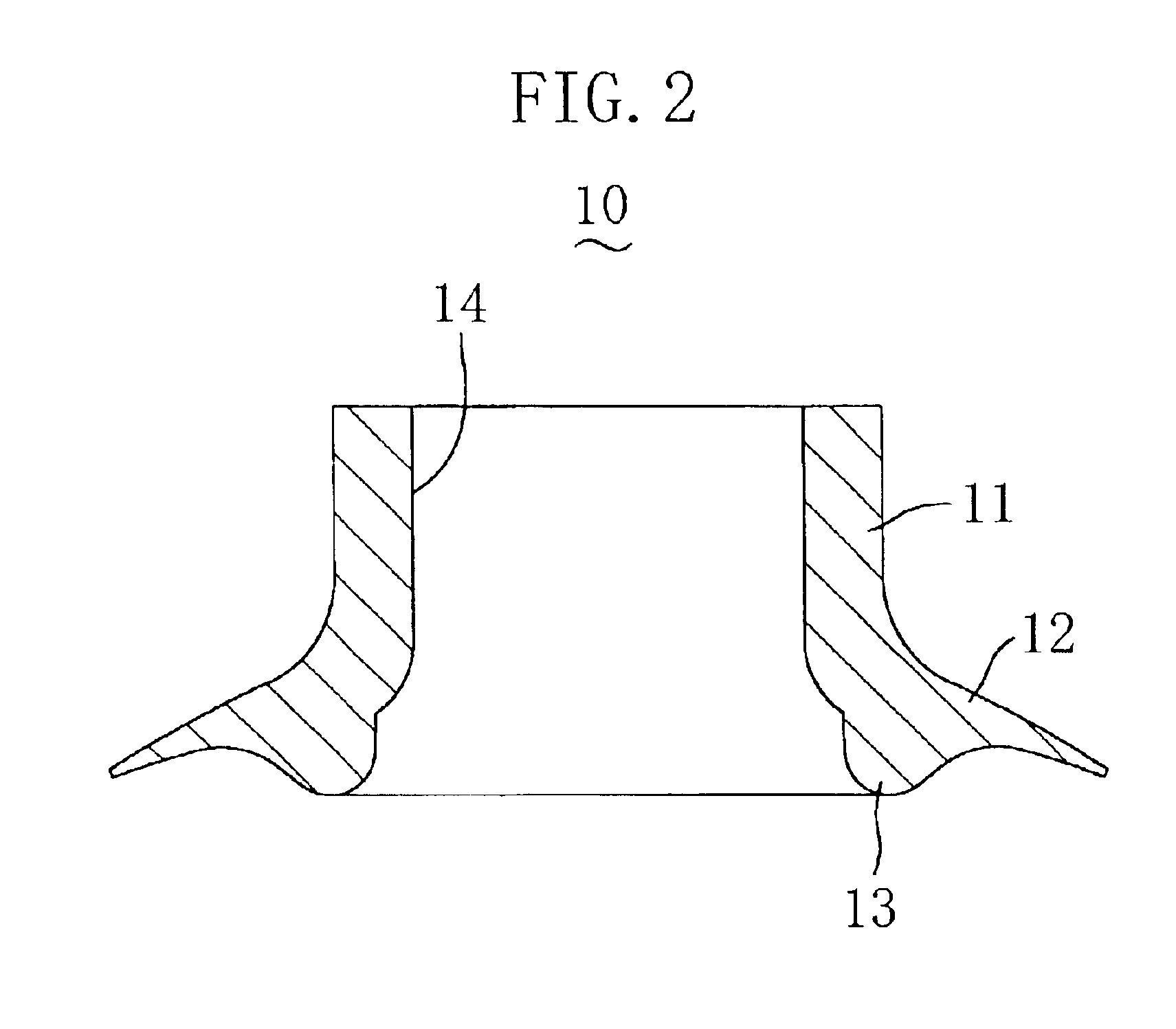

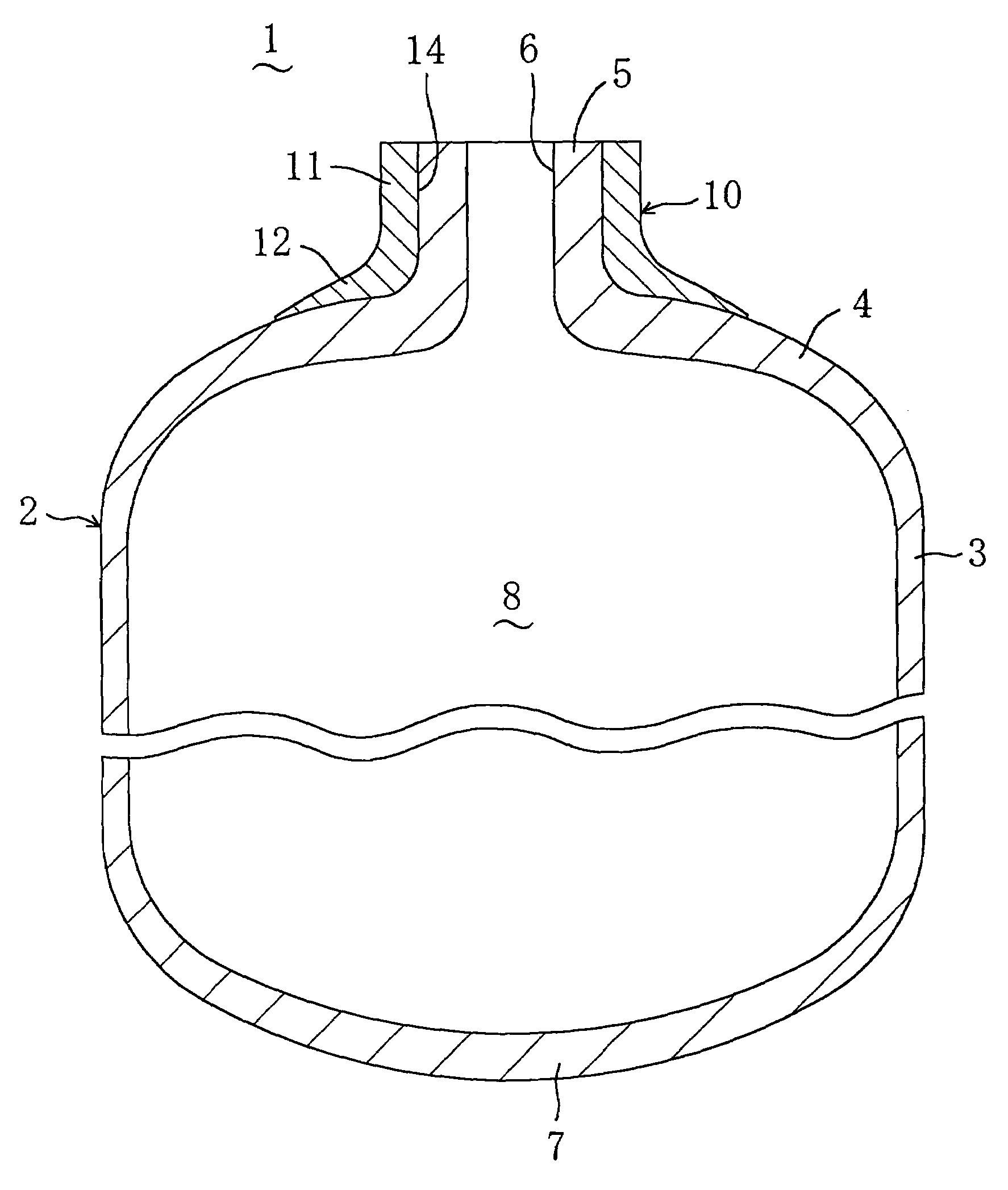

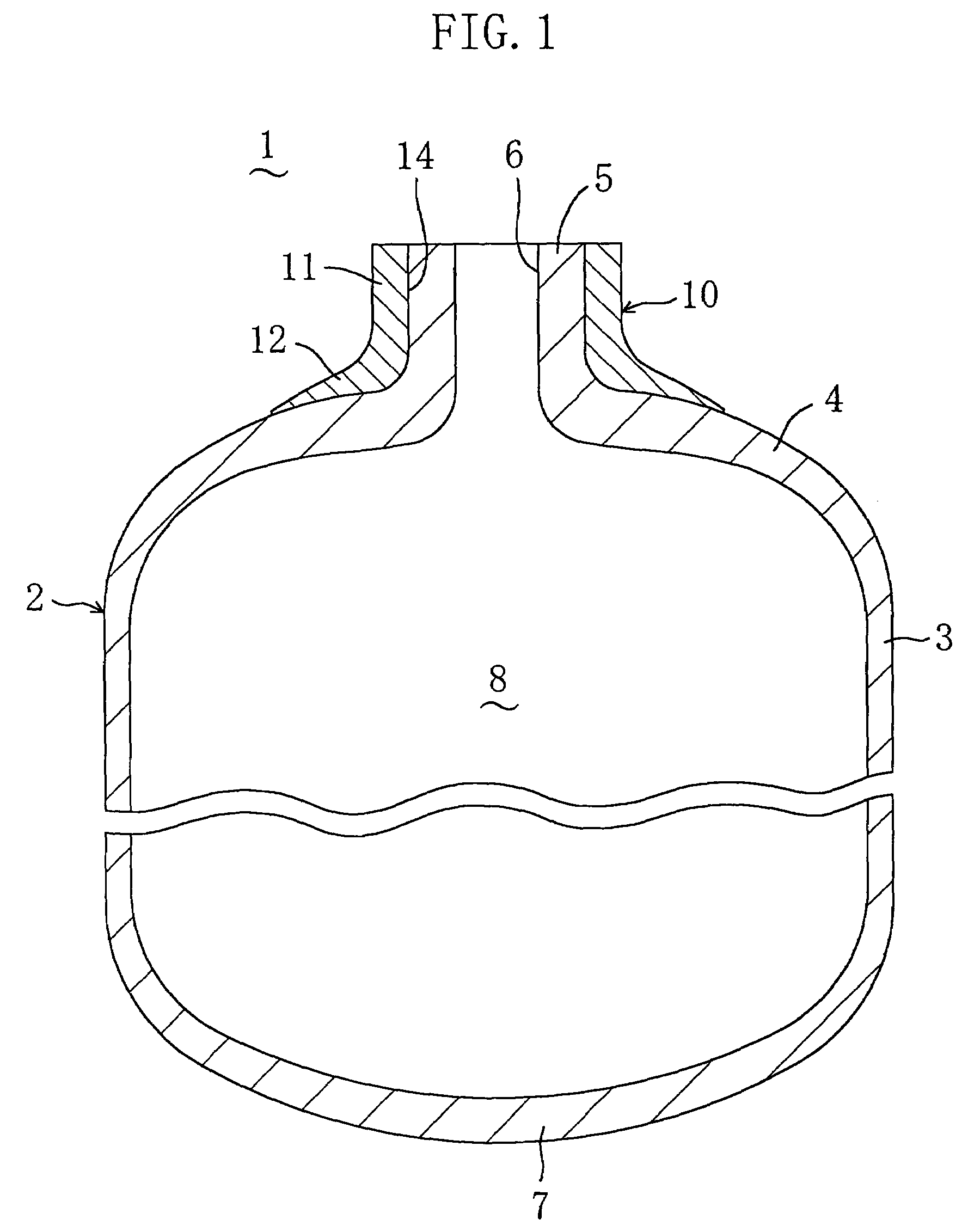

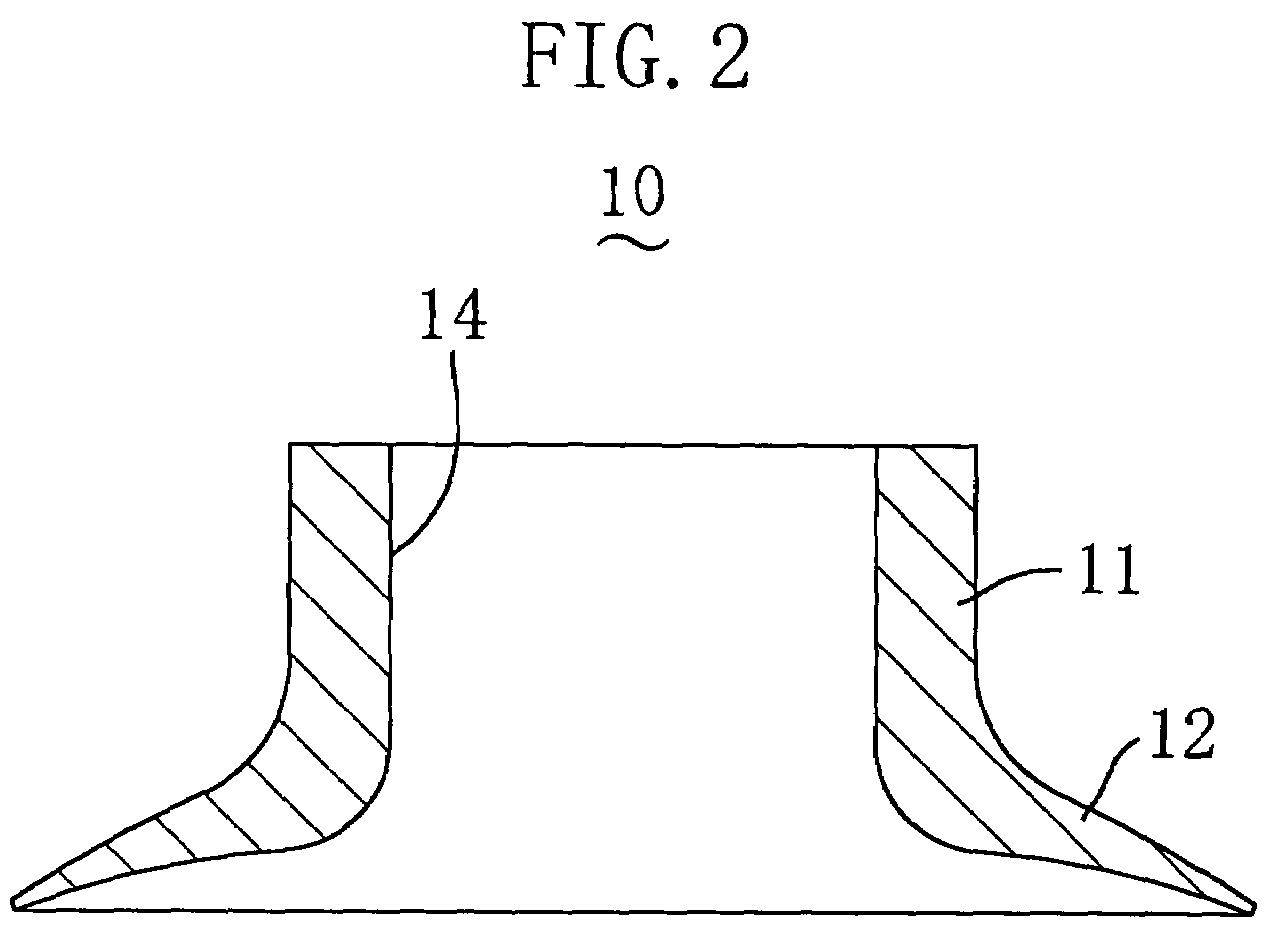

High-pressure tank and method for fabricating the same

InactiveUS6908006B2Reduce weightEasy and inexpensiveVessel mounting detailsVessel wallsHigh pressureWaste management

An annular fitting recess is formed circumferentially in the exterior of a tank body in the vicinity of the boundary between a dome section and a cylindrical gas discharge section of the tank body. A cylindrical reinforcing collar is fitted onto the cylindrical gas discharge section of the tank body to fit an annular boss of the reinforcing collar in the fitting recess of the tank body and then engaged integrally on the exterior of the tank body between the cylindrical gas discharge section and the dome section by shrinkage. This provides easily and inexpensively a high-pressure tank capable of withstanding high pressures of 35 to 75 MPa while keeping its lightness in weight.

Owner:SAM TECHOLOGY +2

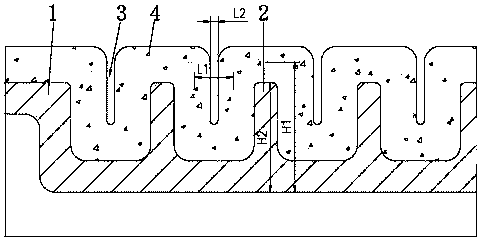

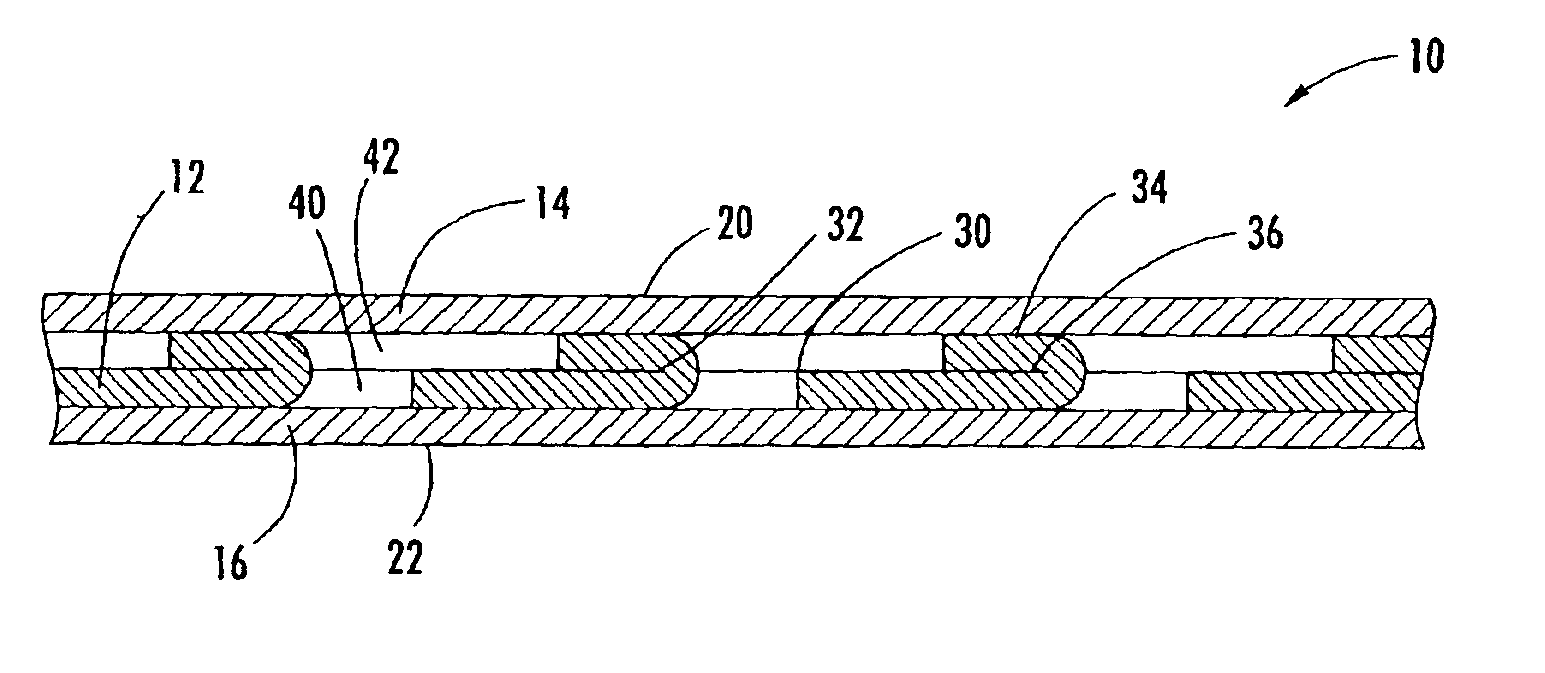

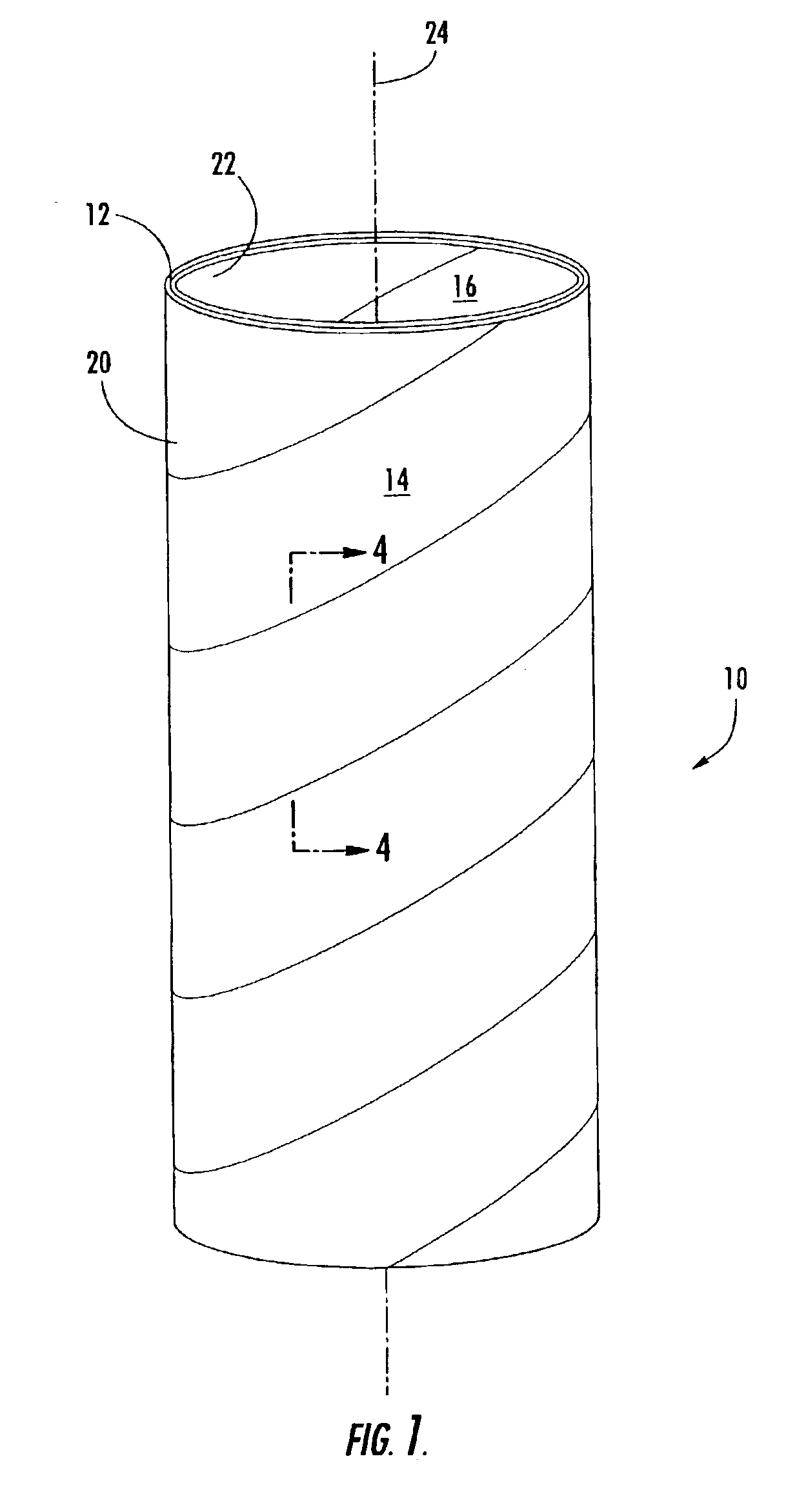

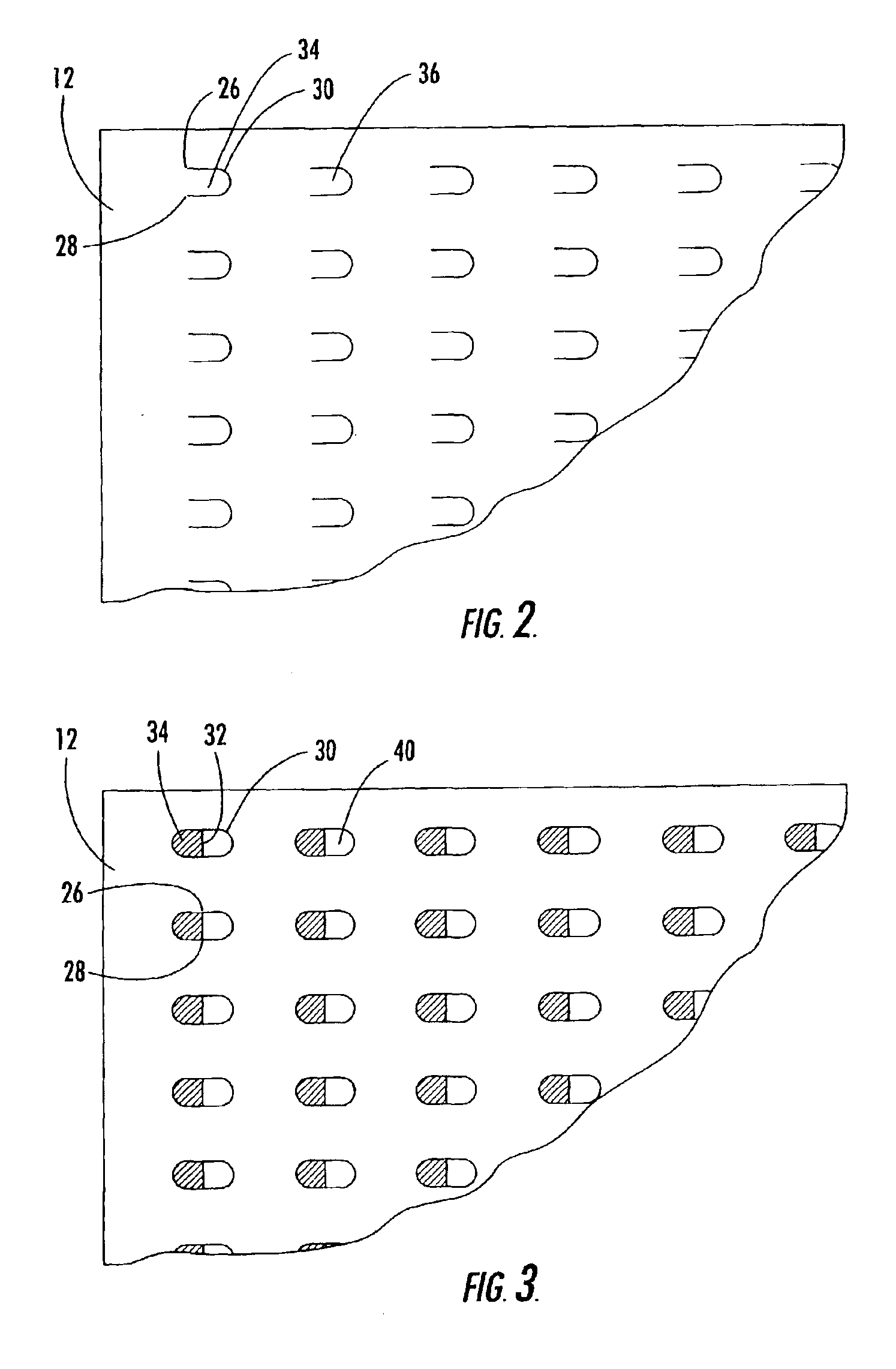

Paperboard tube structures with one or more cut-and-folded plies

InactiveUS6939590B2Increasing moment inertiaIncrease the effective thicknessMechanical working/deformationPaper/cardboard wound articlesPaperboardEngineering

There is provided a paperboard tube structure with an intermediate ply having cut-and-folded tabs to increase the effective thickness of the intermediate ply. The paperboard tube includes a plurality of paperboard plies wrapped one atop another about an axis with the intermediate ply positioned between an interior paperboard ply and an exterior paperboard ply. A plurality of cut-and-folded tabs are each created by a nonlinear incision in the intermediate ply that extends from a first endpoint to a second endpoint thereby creating a folding axis along a line from the first endpoint to the second endpoint. The tab is folded about the folding axis to overlie a region of the intermediate ply adjacent the folding axis. The tabs increase the effective thickness of the wall of the paperboard tube. Therefore, the bending stiffness of the paperboard tube is increased compared to a tube without cut-and-folded tabs or the tube requires less paperboard ply material to maintain an approximately equal bending stiffness as a tube without cut-and-folded tabs.

Owner:SONOCO DEV INC

High-pressure tank and method for fabricating the same

InactiveUS7137526B2Reduce weightEasy and inexpensiveVessel mounting detailsVessel manufacturingShrink-fittingHigh pressure

Owner:SAM TECHOLOGY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com