Wideband single layer microstrip patch antenna

A technology of microstrip patch antenna and microstrip patch, which is applied in the direction of antenna, electrical components, radiation element structure, etc., can solve the problem of narrow impedance bandwidth and achieve the effect of small cross section and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

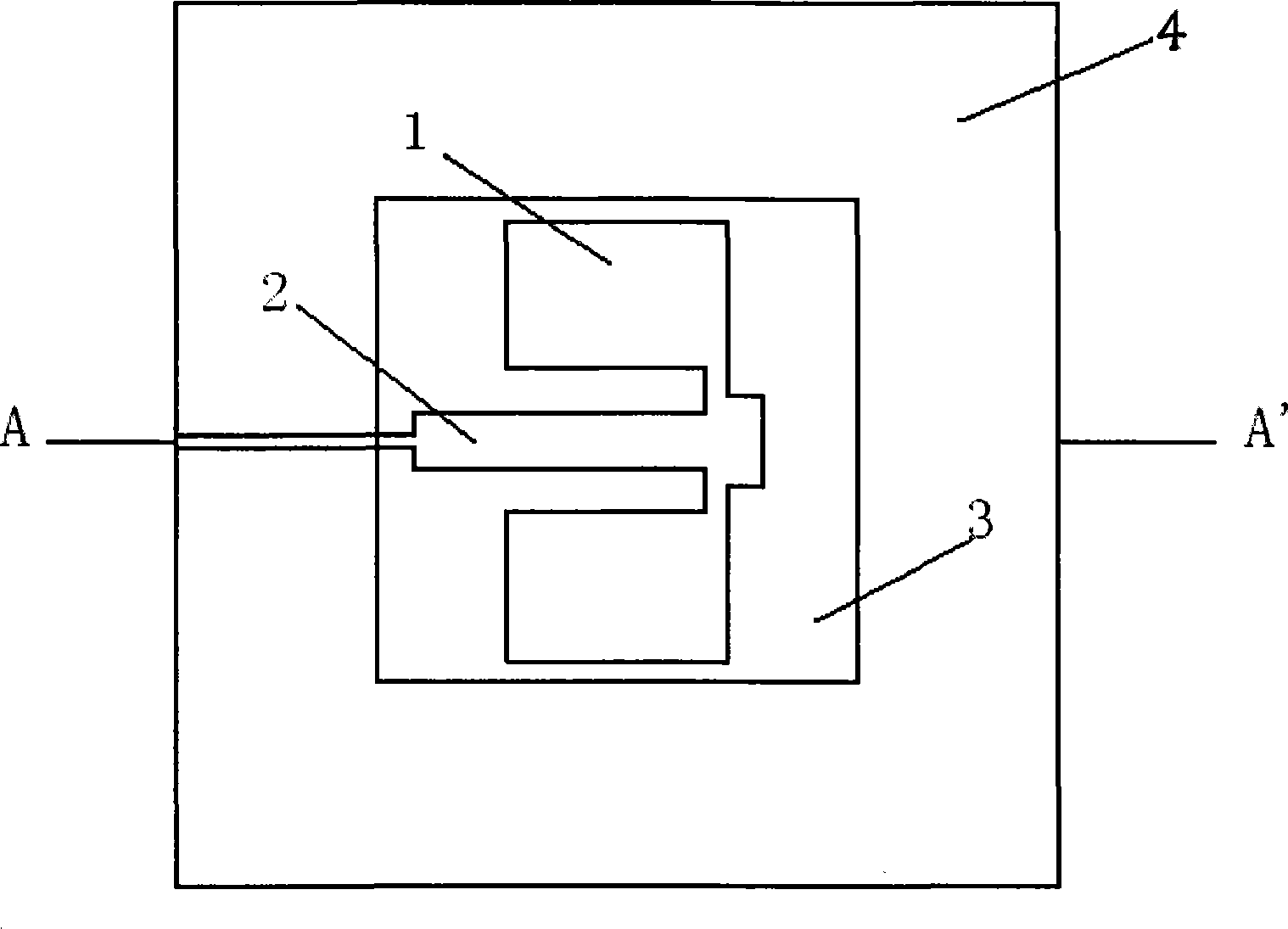

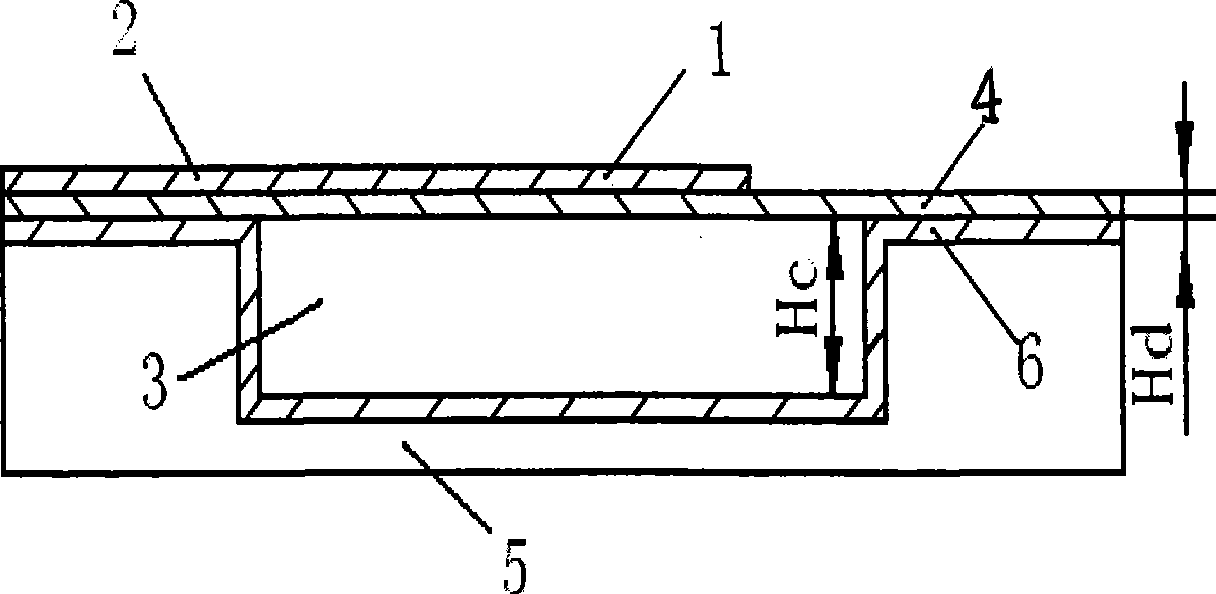

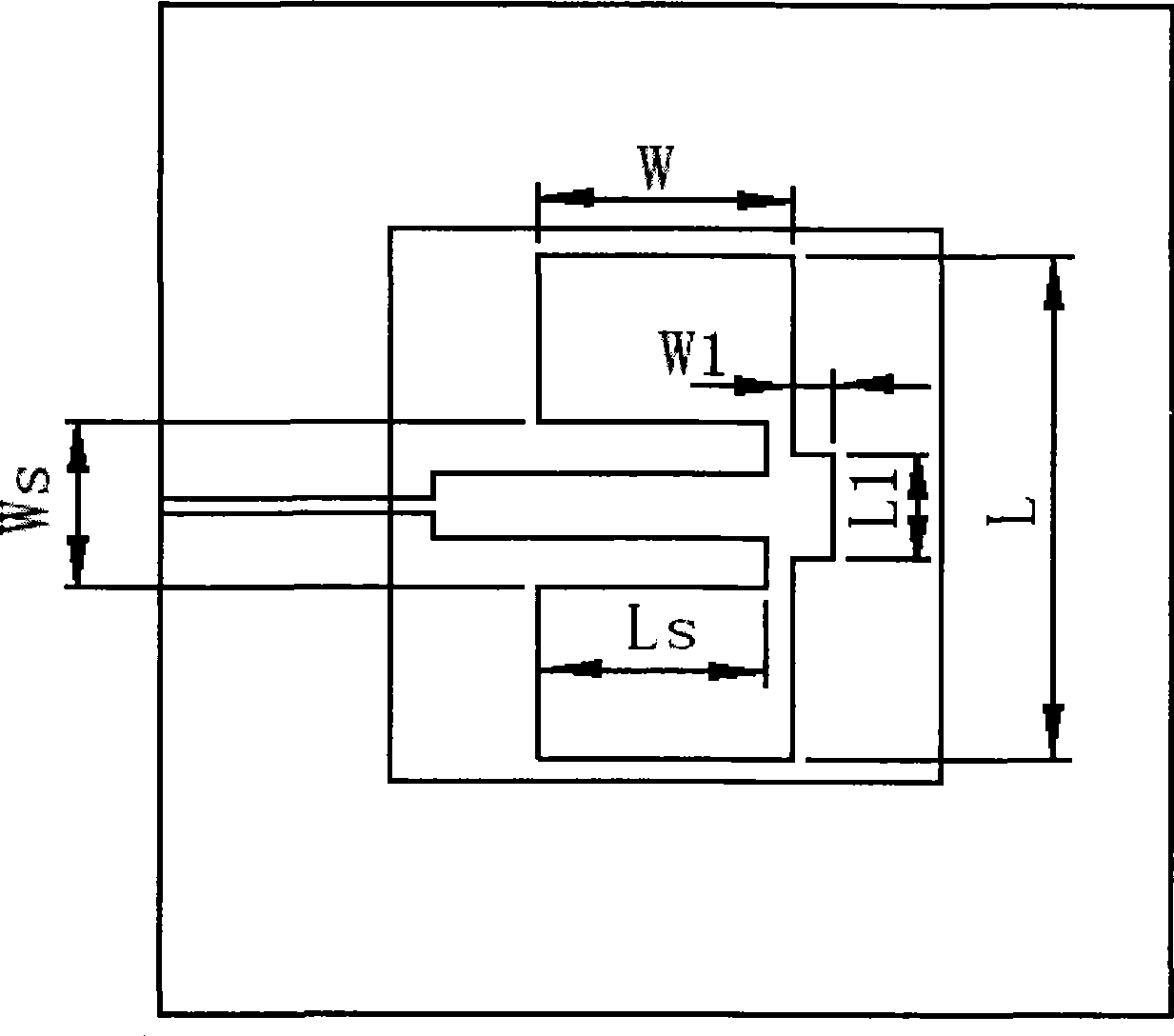

[0036] see figure 1 and figure 2 A broadband metal cavity-backed single-layer convex microstrip patch antenna includes a convex microstrip patch 1, a stepped coplanar microstrip line 2 with two widths, a back cavity 3, a microstrip dielectric plate 4, Structural support plate 5 and metal ground 6.

[0037] One end of the coplanar microstrip line 2 with two widths is inserted into the patch antenna through the slot on the convex microstrip patch, and the other end of the feeding microstrip line 2 is located at the edge of the microstrip dielectric plate 4;

[0038] The back of the microstrip dielectric plate 4 other than the corresponding part of the microstrip patch 1 is provided with a metal formation 6, and the back of the entire microstrip dielectric plate 4 is also provided with a structural support plate 5, and the structural support corresponding to the microstrip patch 1 The middle part of the plate 5 is a concave back cavity 3, and the inner surface of the concave b...

Embodiment 2

[0049] A preferred embodiment of the present invention is shown in Figure 7, which is an 8-element microstrip antenna line array applied to the X-band. This line array is formed by four 2-element arrays that are translated along a straight line, and the reverse phase feeding method is used between the 2 elements. , 8 convex microstrip patches 1 are connected with a coplanar 1:8 microstrip power dividing network 7 to form a line array, and finally are vertically welded with a coaxial connector 8 .

Embodiment 3

[0051] Another preferred embodiment of the present invention is shown in Fig. 8, and this 8 * 8 microstrip antenna sub-array is formed by the 8-element linear array shown in Fig. 7 and is translated along the same direction, and this sub-array is connected with T / R assembly, supplemented by The power supply, wave control and installation structural parts can be expanded into large sub-array active phased array antennas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com