Patents

Literature

54 results about "Soft mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

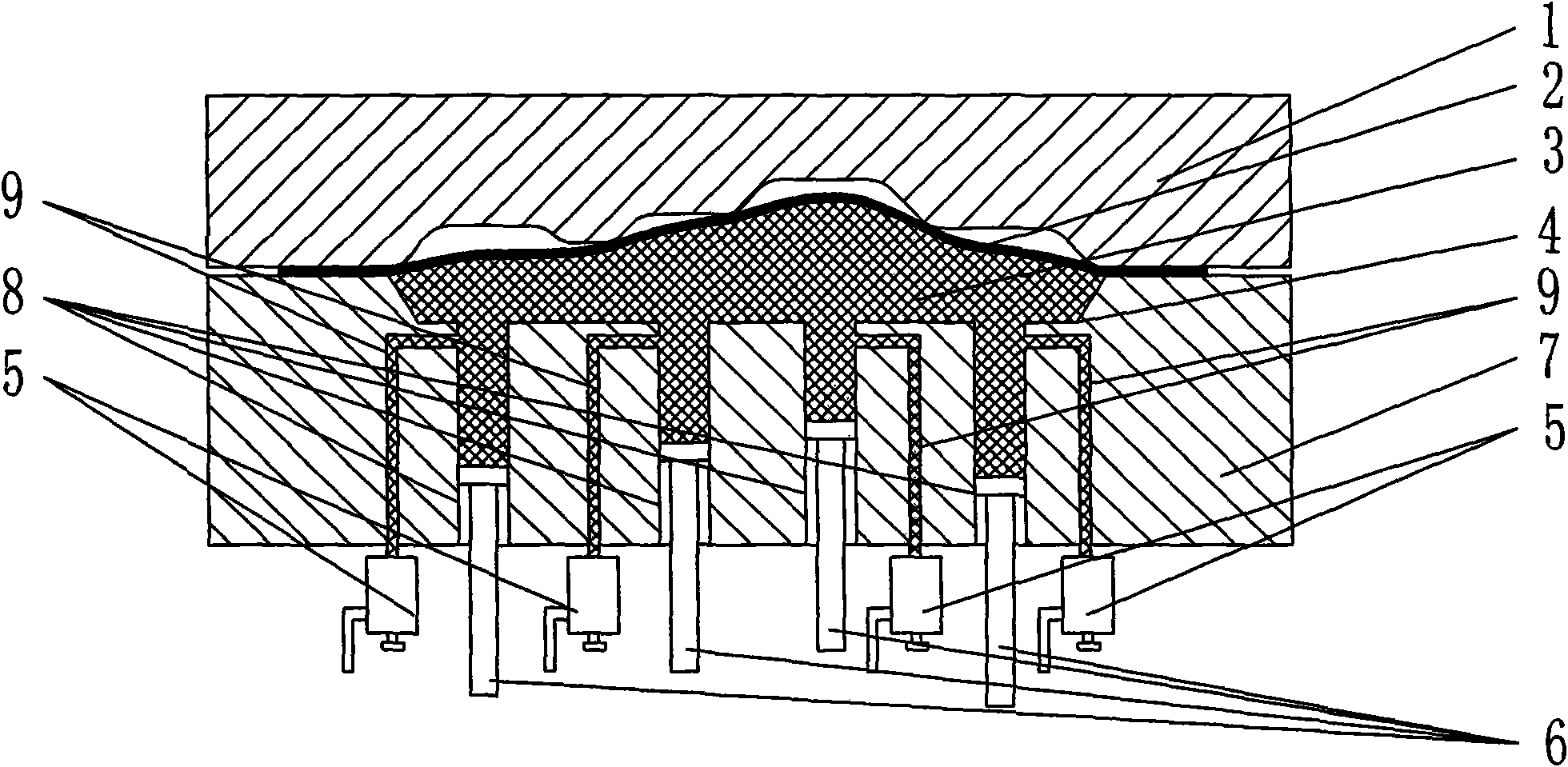

Method for manufacturing microlens array by soft mode impressing

InactiveCN101339364ASo as not to damageEasy to separatePhotomechanical apparatusLensHigh volume manufacturingHot melt

The invention discloses a method for manufacturing microlens array by soft mode imprinting, wherein, master microlens array is manufactured by utilizing a traditional photoresist hot melting method, poly-dimethyl-siloxane is taken as a microlens die, and the graph of the microlens array is transformed to a uv gel on a glass substrate by utilizing an imprinting method. The method of the invention has the advantages of simple process, low cost, and being capable of mass production.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

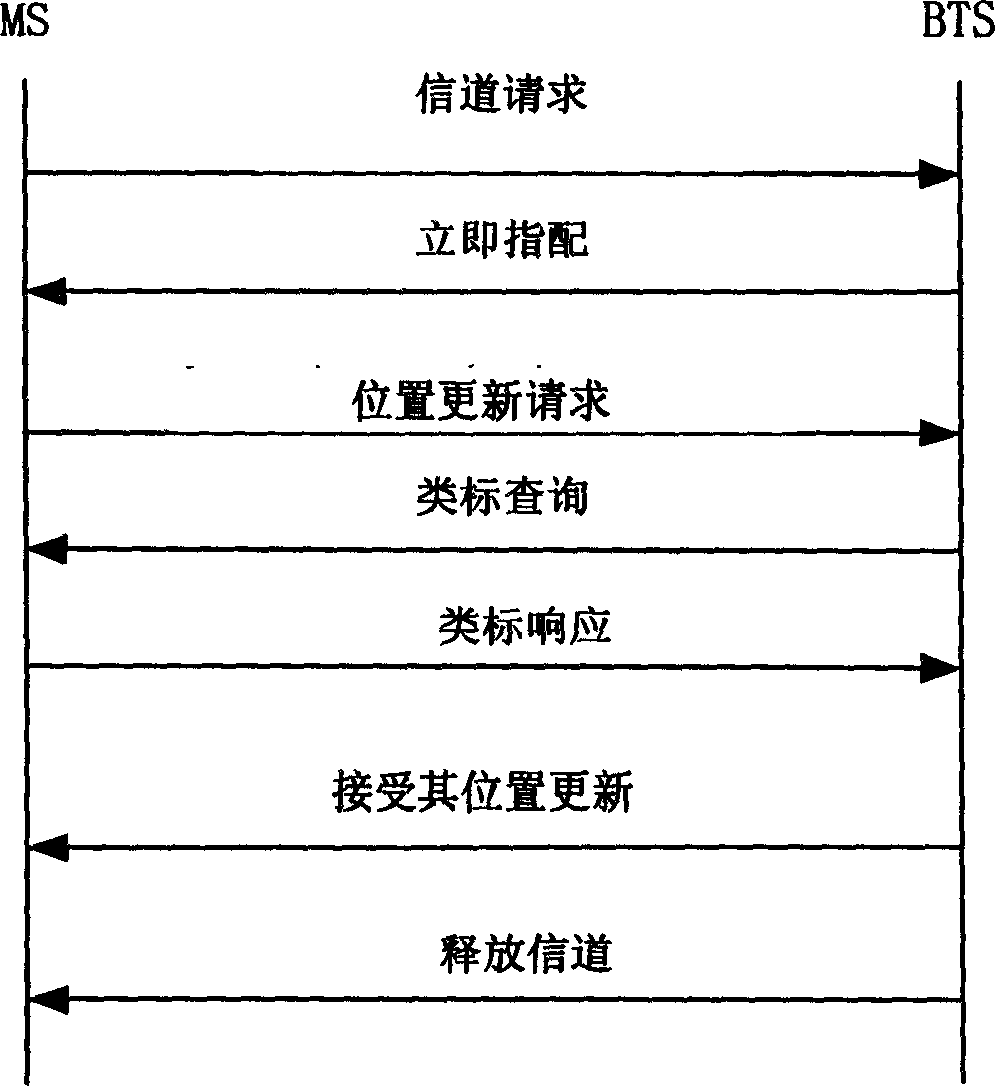

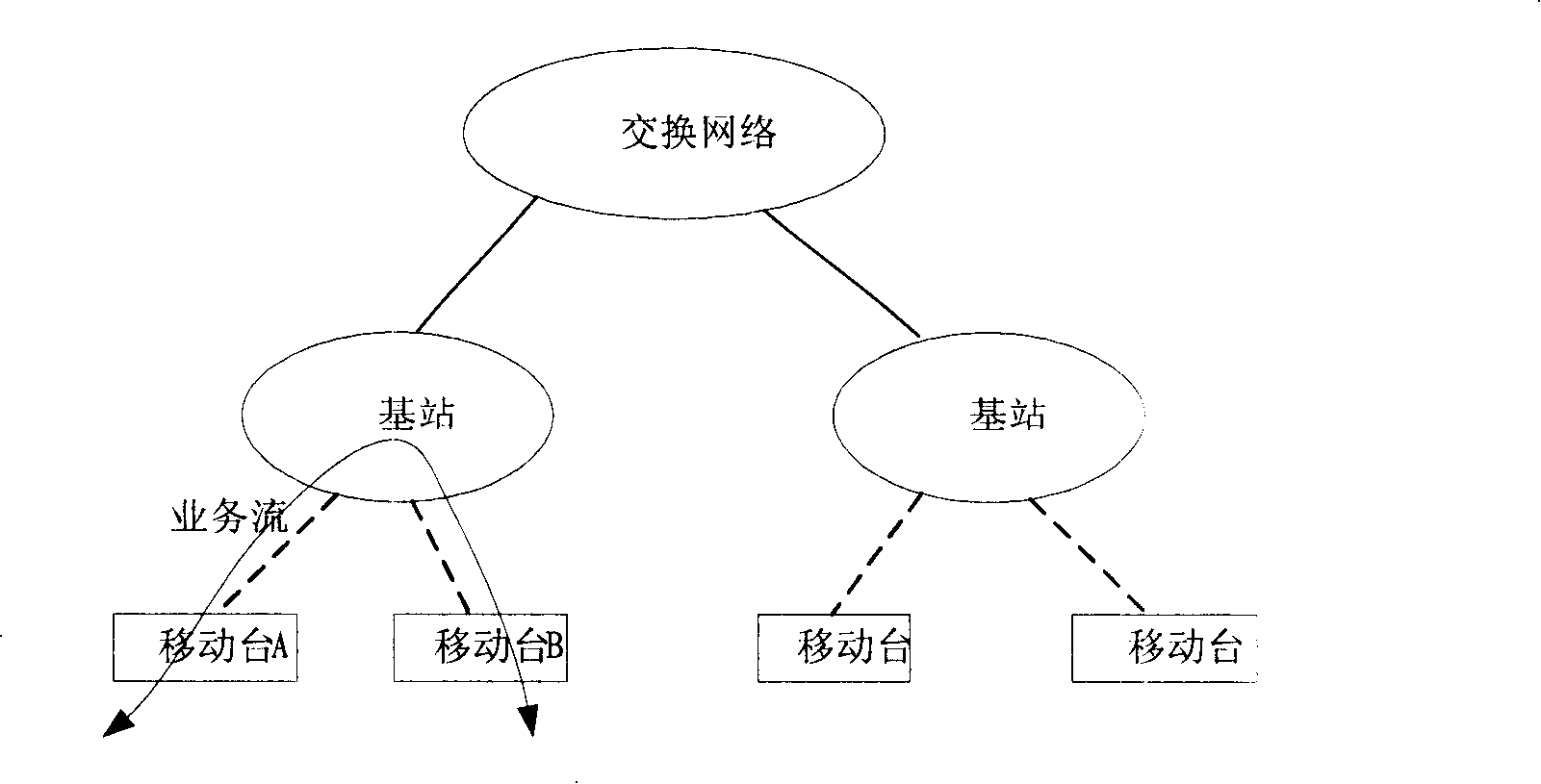

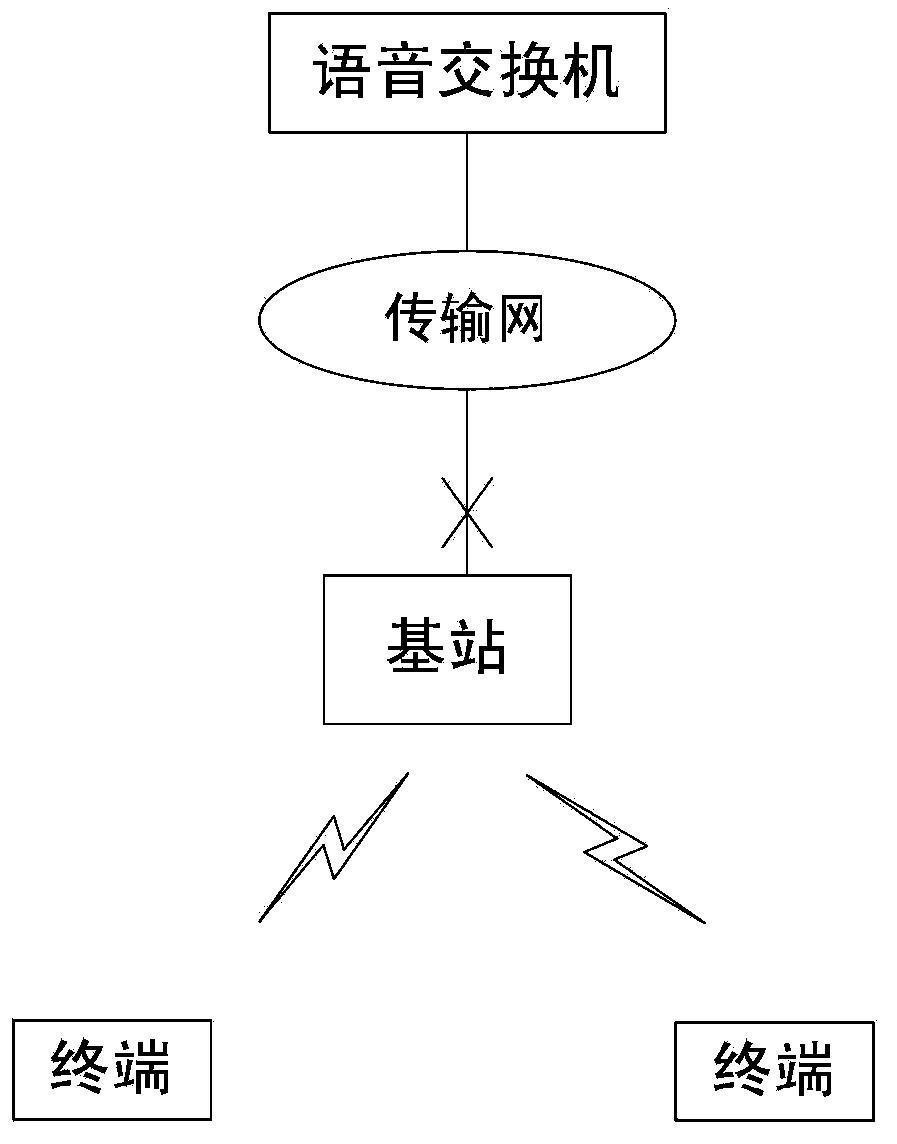

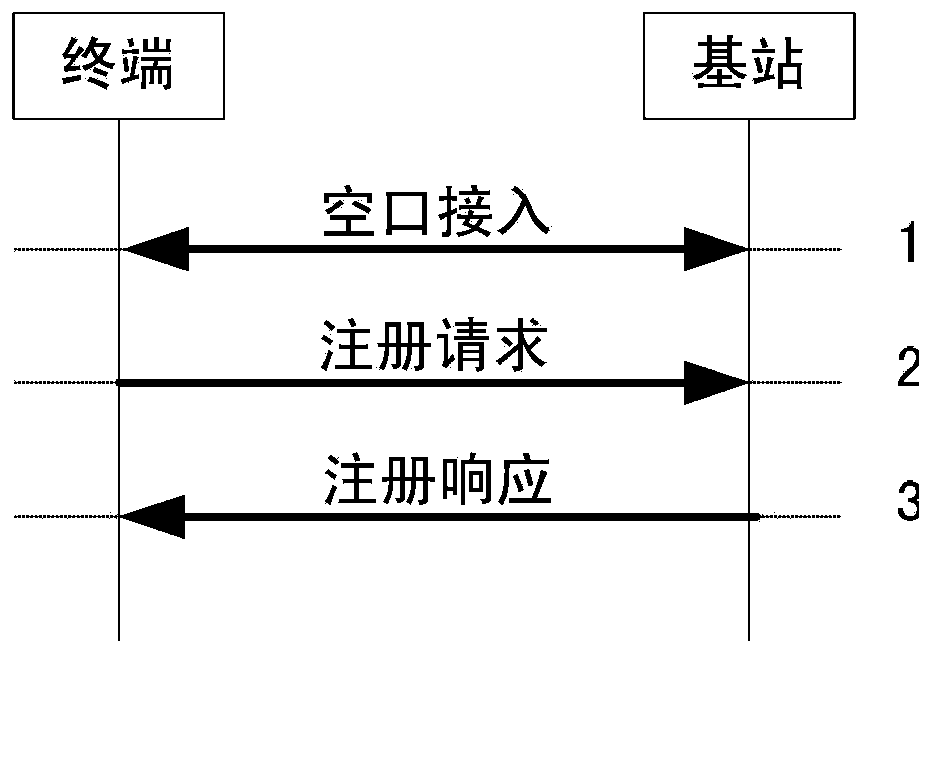

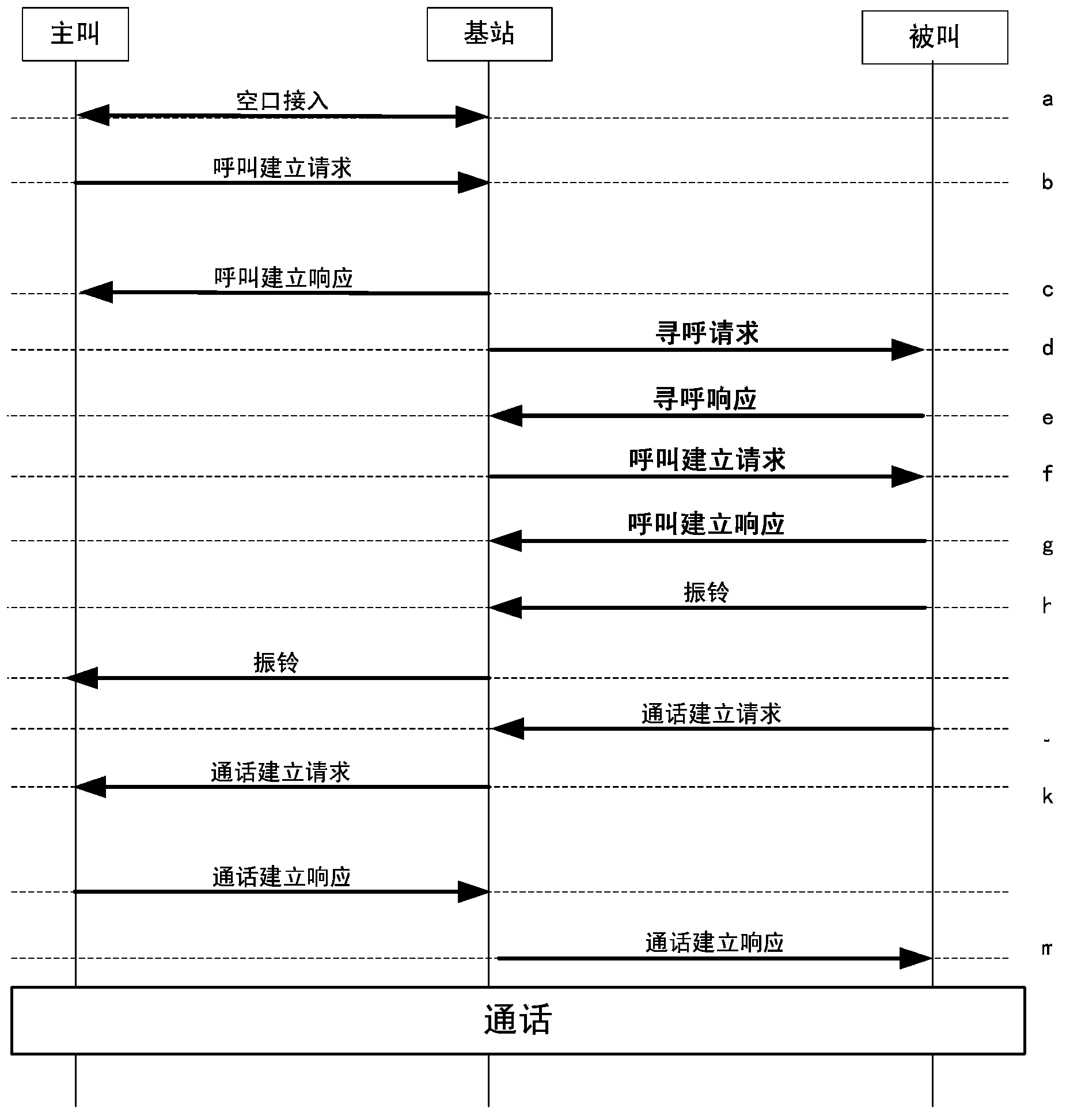

Fault reduction realizing method of cluster net communication

InactiveCN1835609AMeet the requirements of rapid emergencyEasy to implementRadio/inductive link selection arrangementsSignal processingMobile phone

The method for solving the problem not capable of making phone call after the base station disconnects to the base station controller and comprises: the control unit of base station detects the transmission link of base station; when deciding a transmission interruption happens, the working mode of base station is set as a fail-soft mode; the signaling processing unit configures the frequency carrier, it includes system information, channel configuration and notice message description; then, the signaling processing unit fills out the received system information into the system message field, and transmits the notice message description on NCH channel; after receiving the notice message description, the mobile phone stays in relevant time slot according to a failure-soft channel ID configured for it in order to initiate or receive the PTT calling.

Owner:HUAWEI TECH CO LTD

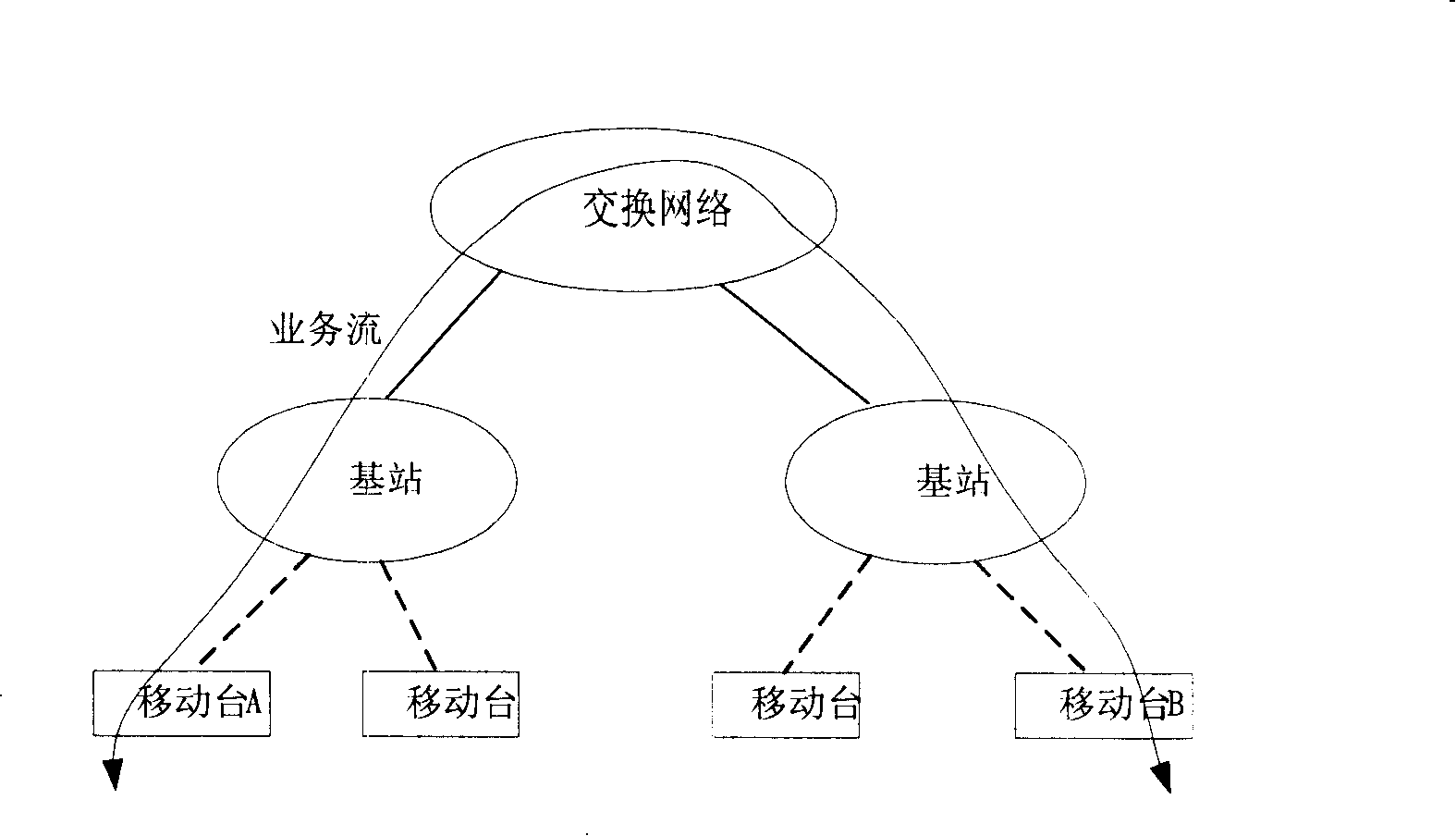

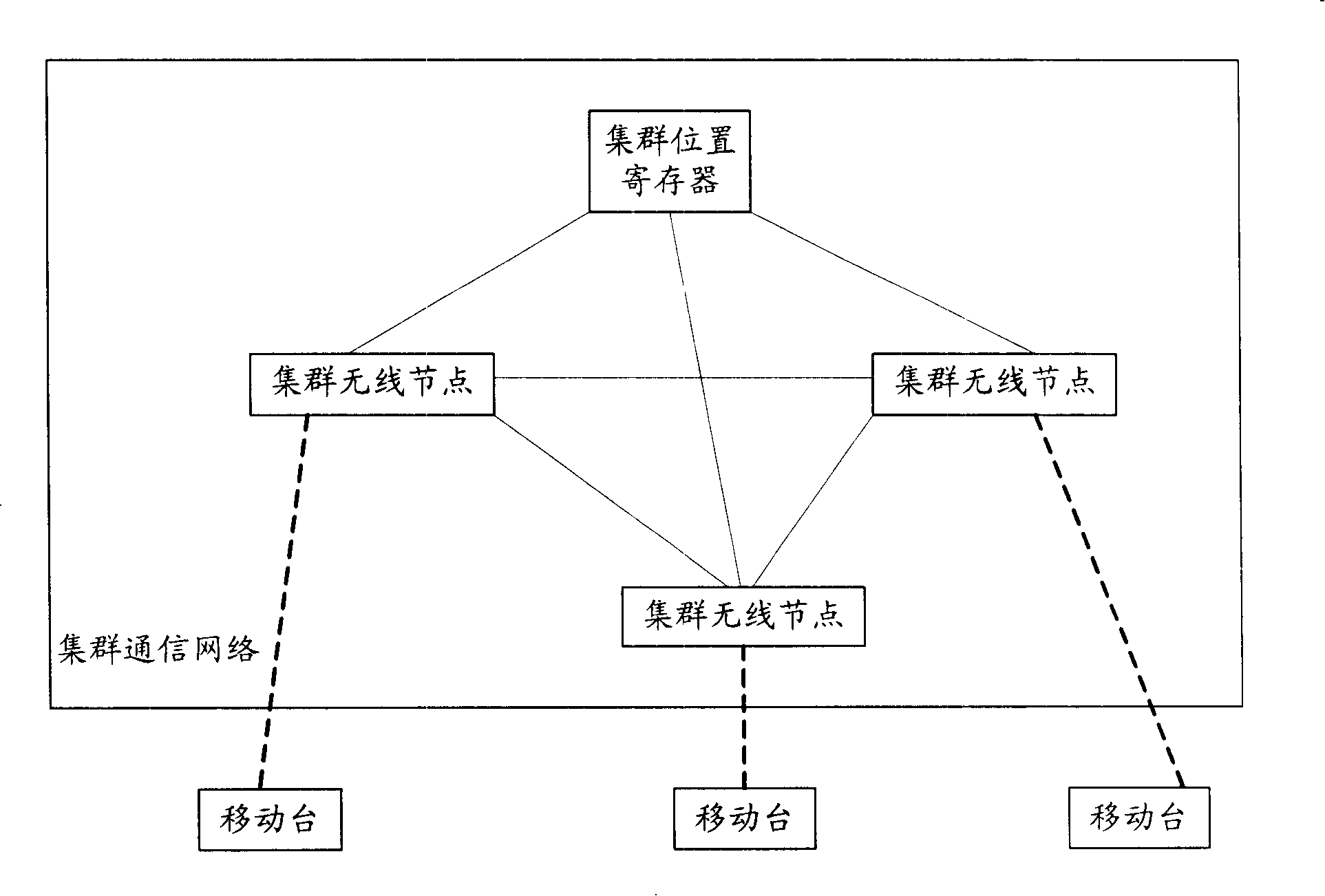

Cluster network system and failure attenuation method on the basis of the network system

ActiveCN101212723AEase of failure to weaken functionalityGuaranteed normal callsRadio/inductive link selection arrangementsProcessor registerMobile station

The invention provides a cluster network system which comprises cluster wireless nodes, a cluster location register which is connected with all cluster wireless nodes and a mobile station which belongs to the corresponding cluster wireless node; The cluster wireless nodes comprise a service processing unit and a wireless processing unit; the wireless processing unit comprises a service processing subunit which can deal with cluster call service the same as the service processing unit. Based on the system, a fail-soft working method comprises the following steps: the cluster wireless nodes are monitored, a fail-soft mode is stated by the system and a cluster terminal is informed when a fault of the service processing unit of the wireless nodes occurs, determines whether the mobile station is in a covering and overlapping area which is covered by wireless and among the cluster wireless nodes, if not, the cluster terminal of the service processing subunit of the wireless processing unit sponsors the cluster call service in the fail-soft mode. The invention is easy to realize the fail-soft working method of a base station and can guarantee that all wireless users can converse normally.

Owner:DATANG MOBILE COMM EQUIP CO LTD

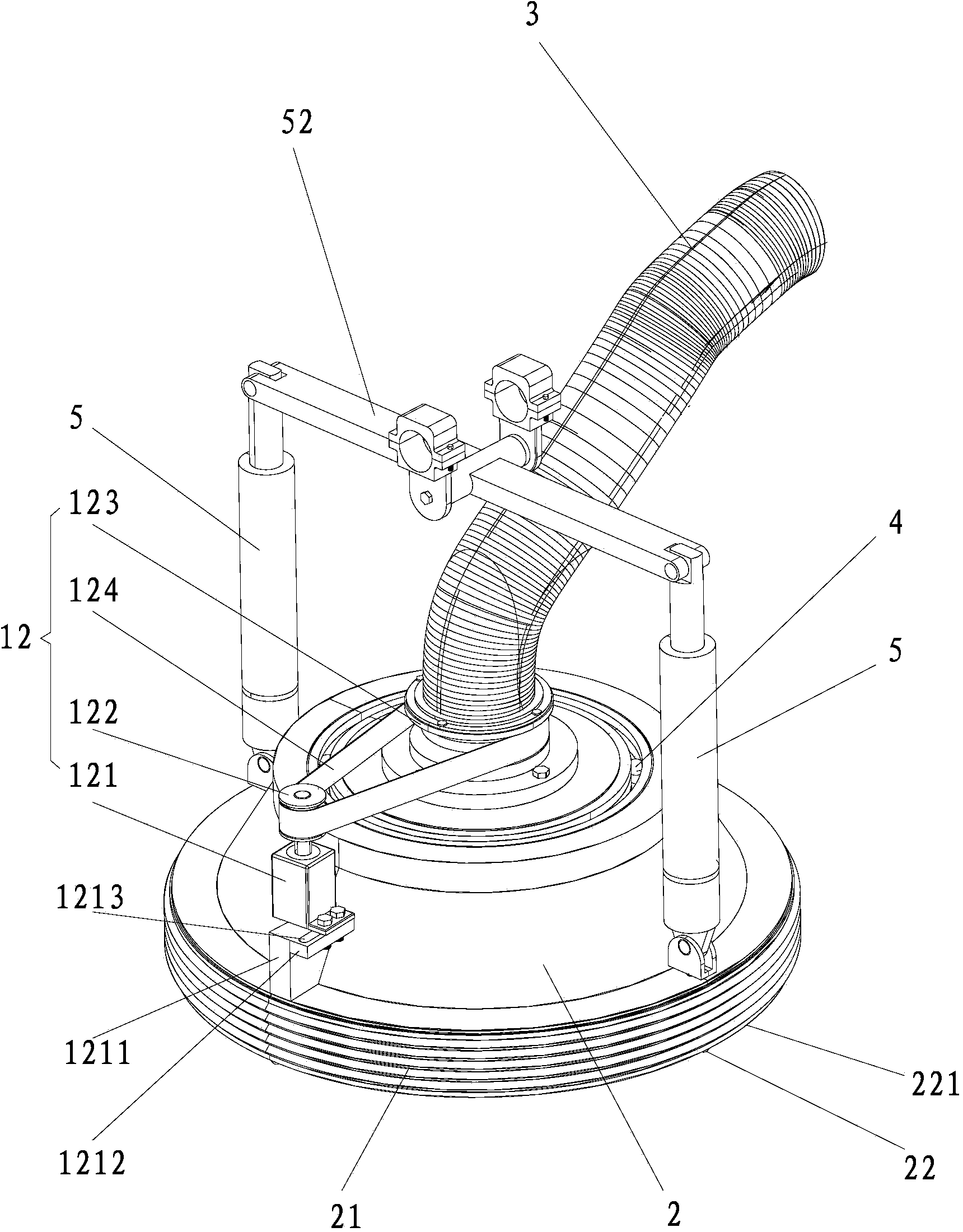

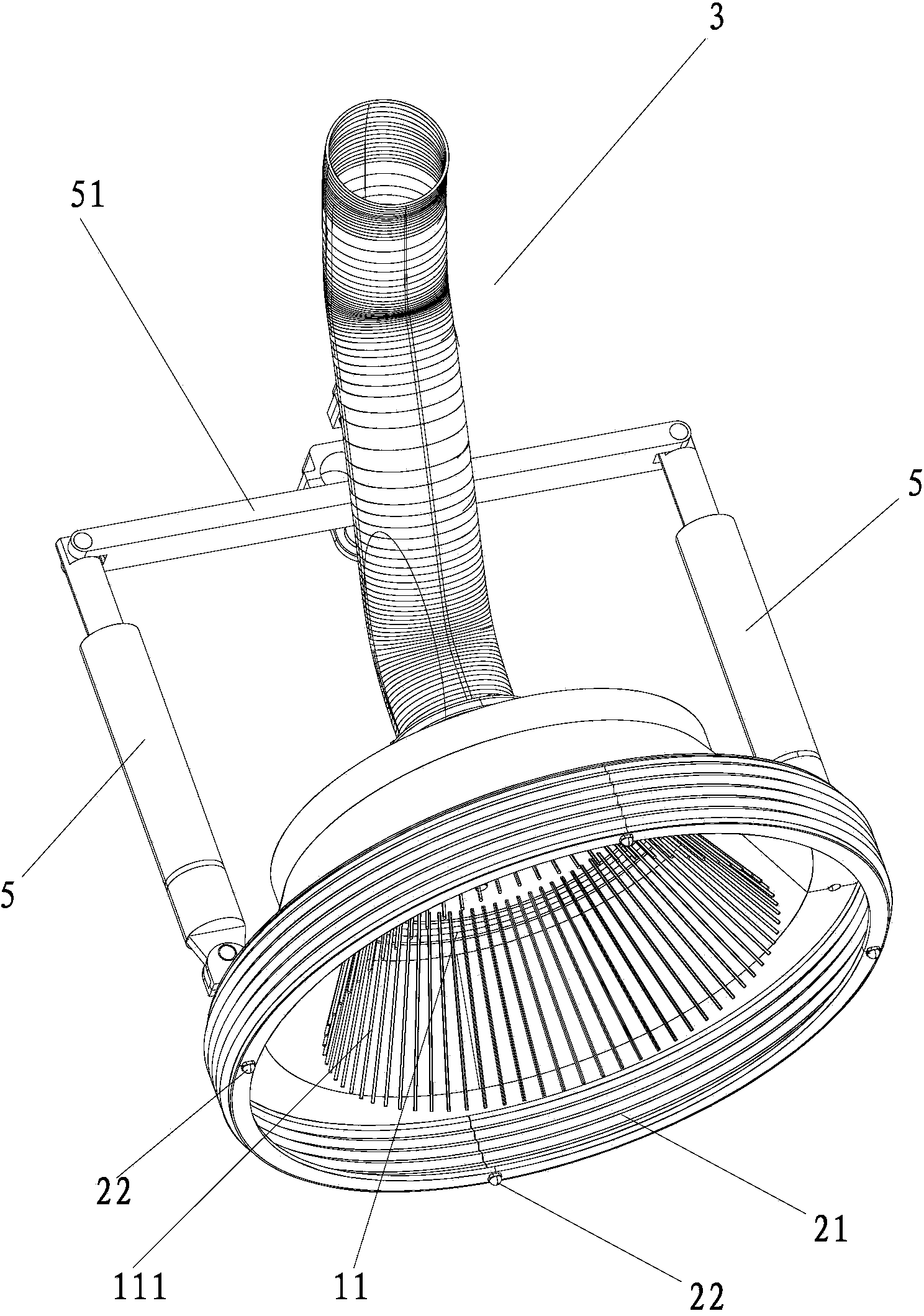

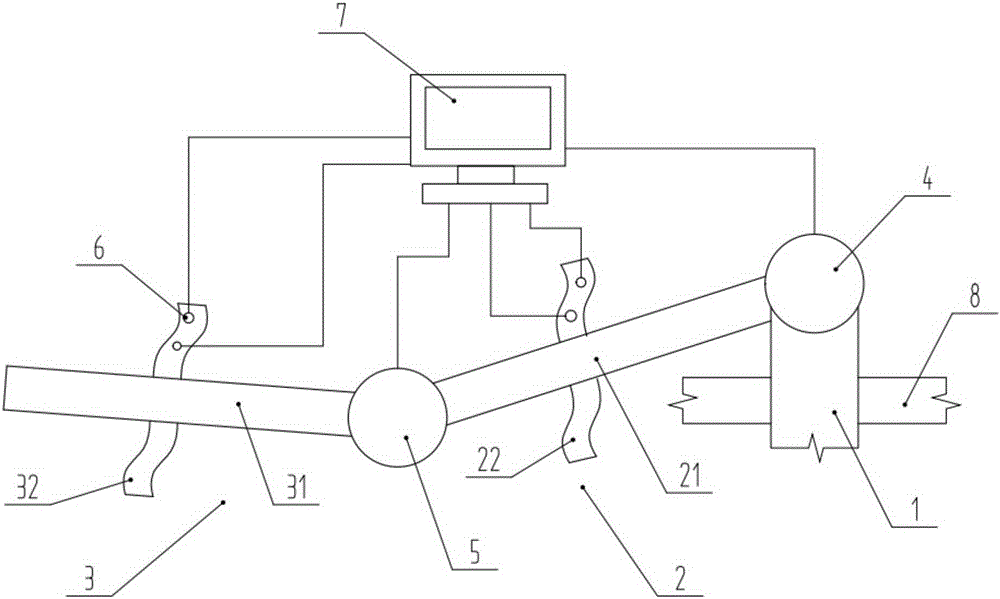

Novel sweeping and absorbing integrated cleaning mechanism

ActiveCN103510484AOvercome structureOvercome the defect of poor cleaning abilityRoad cleaningRoad surfaceEngineering

The invention provides a novel sweeping and absorbing integrated cleaning mechanism. The novel sweeping and absorbing integrated cleaning mechanism comprises a rotating cleaning brush carried by a sweeper. A shell making contact with the ground in a soft mode covers the rotating cleaning brush. A pumping pipeline is communicated with the upper portion of the shell. Due to the adoption of the technical scheme, the novel sweeping and absorbing integrated cleaning mechanism breaks through the structural form of traditional sweepers and integrates a rubbish brushing and sweeping mechanism and a rubbish pumping mechanism; the cleaning brush is rotated to brush and sweep rubbish in the shell in a rotating mode, is prevented from being absorbed on the ground and is in a free floating state. Negative pressure is formed in the shell through the pumping pipeline, the rubbish is pumped to a rubbish can of the sweeper through the pumping pipeline and is stored, and the cleaning brush is rotated to be matched with the shell and the pumping pipeline to form an Archimedes spiral type rubbish absorbing structure. The novel sweeping and absorbing integrated cleaning mechanism is strong in rubbish pumping and intake capacity and overcomes the defects that the traditional sweepers are single in structure and poor in cleaning ability. Compared with the prior art, the novel sweeping and absorbing integrated cleaning mechanism is thorough in road surface rubbish cleaning, efficient, novel and reasonable in structure and strong in practicability.

Owner:HUAQIAO UNIVERSITY

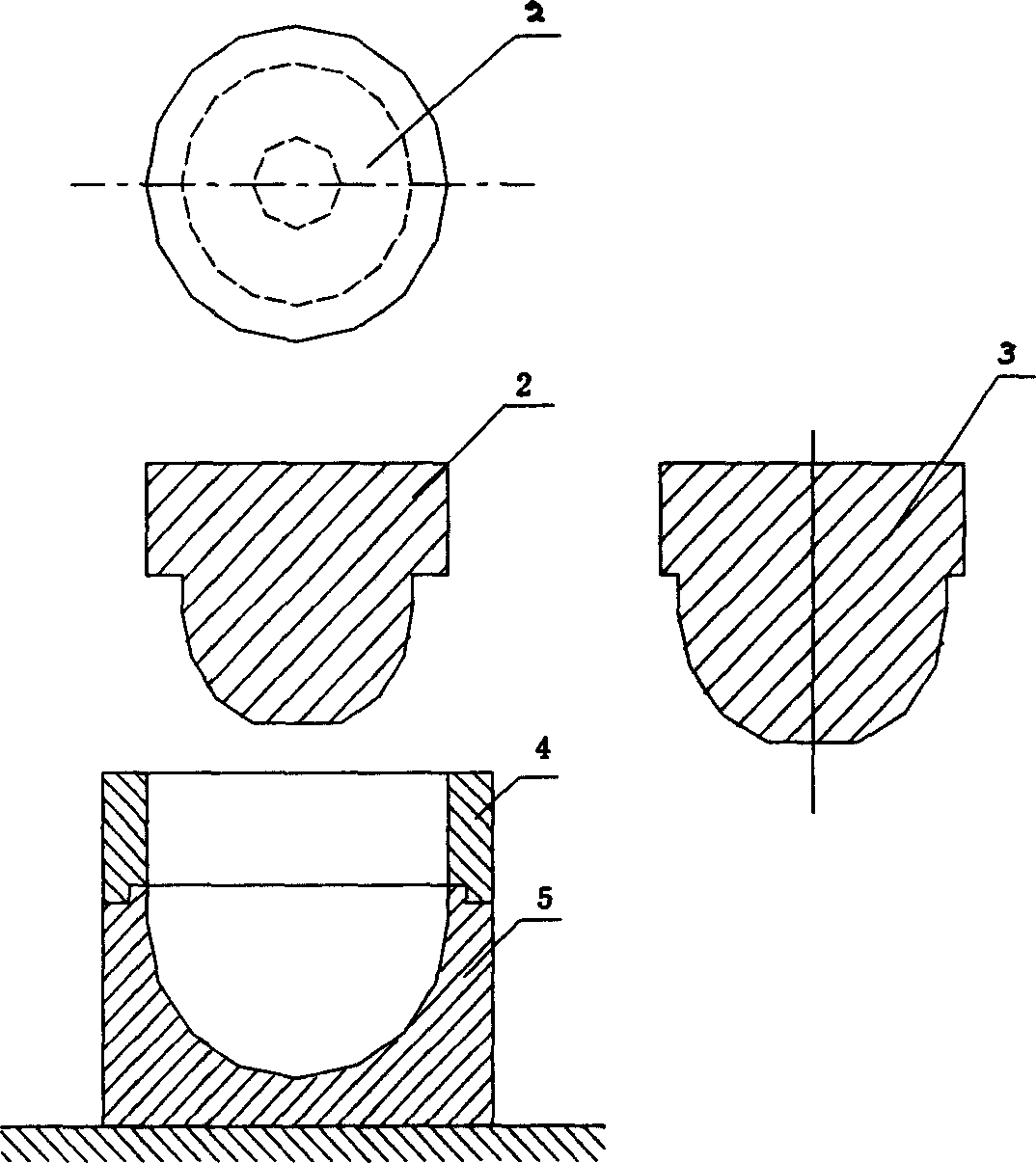

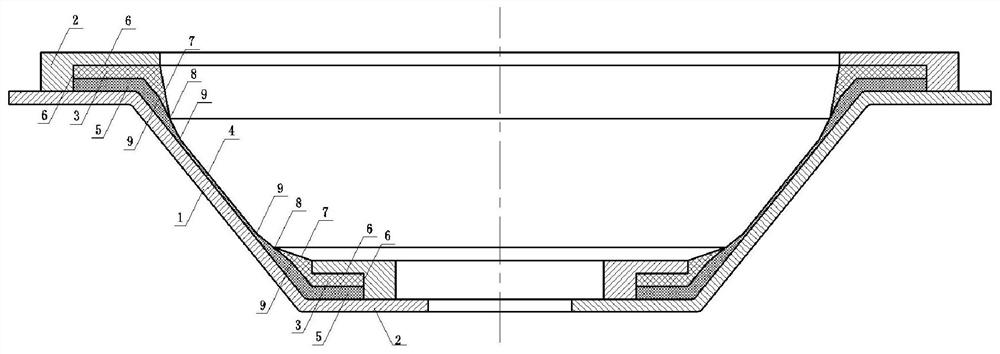

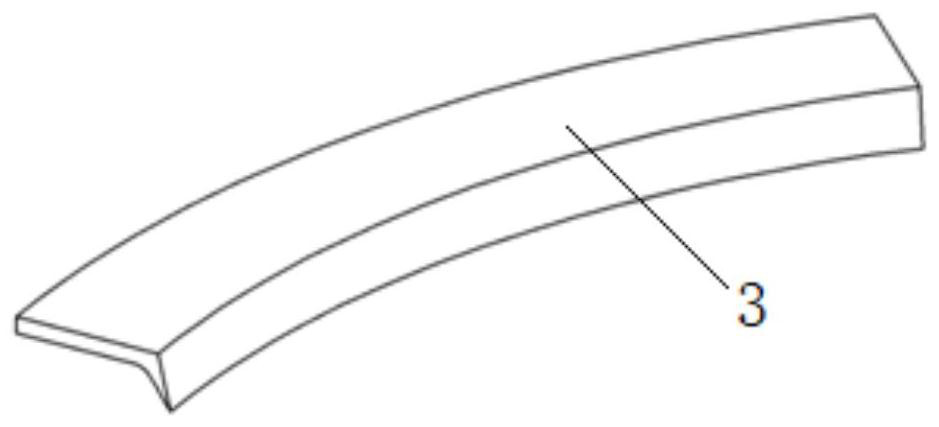

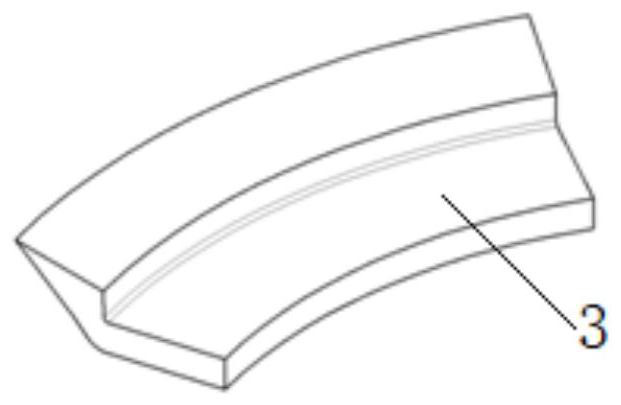

Die pressing and forming method for polytetrafluoroethylene thin wall crustose products flexible die

The invention is a soft mode die forming method of teflon thin-wall shell product, using a definitely elastic soft mode to regulate and transfer molding pressure between a rigid mould and teflon powder, thus able to primely remedy inevitable nonuniformity during charging materials of teflon special-shaped pieces, overcoming the defect in molding teflon thin-wall shell products, radically improving product quality and yield, and unnecessary to add any new devices, liquid mediums and sealing bags.

Owner:中国航天科技集团公司第一研究院第七〇三研究所

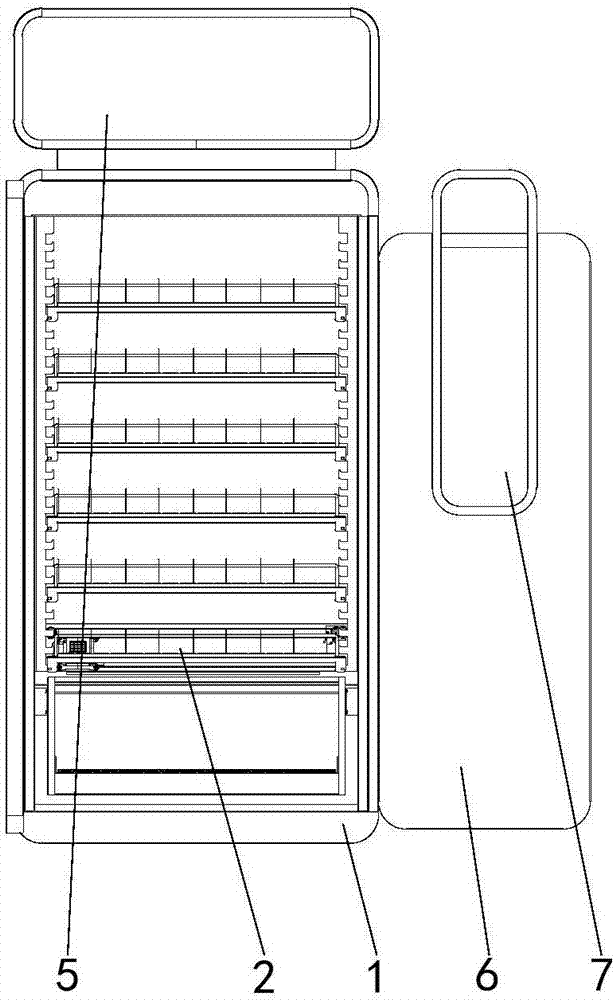

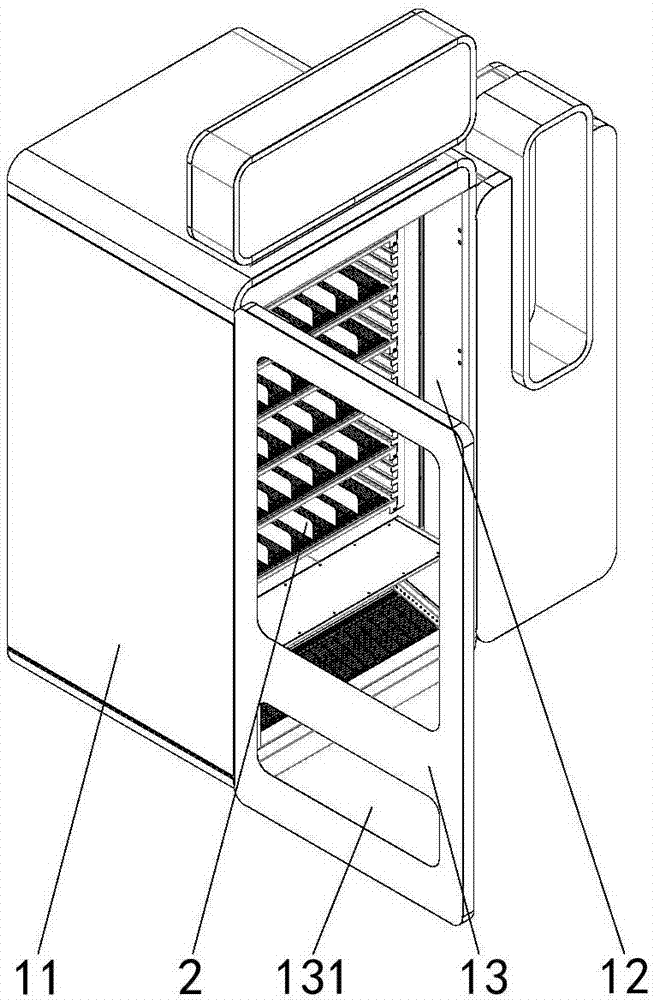

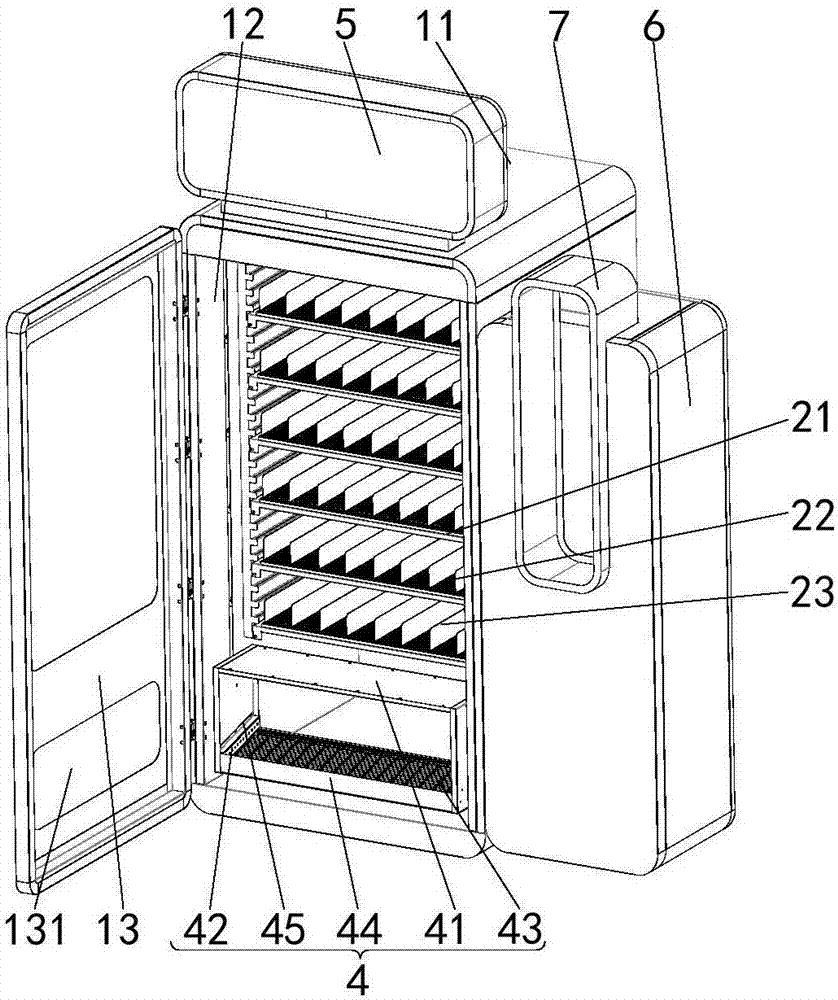

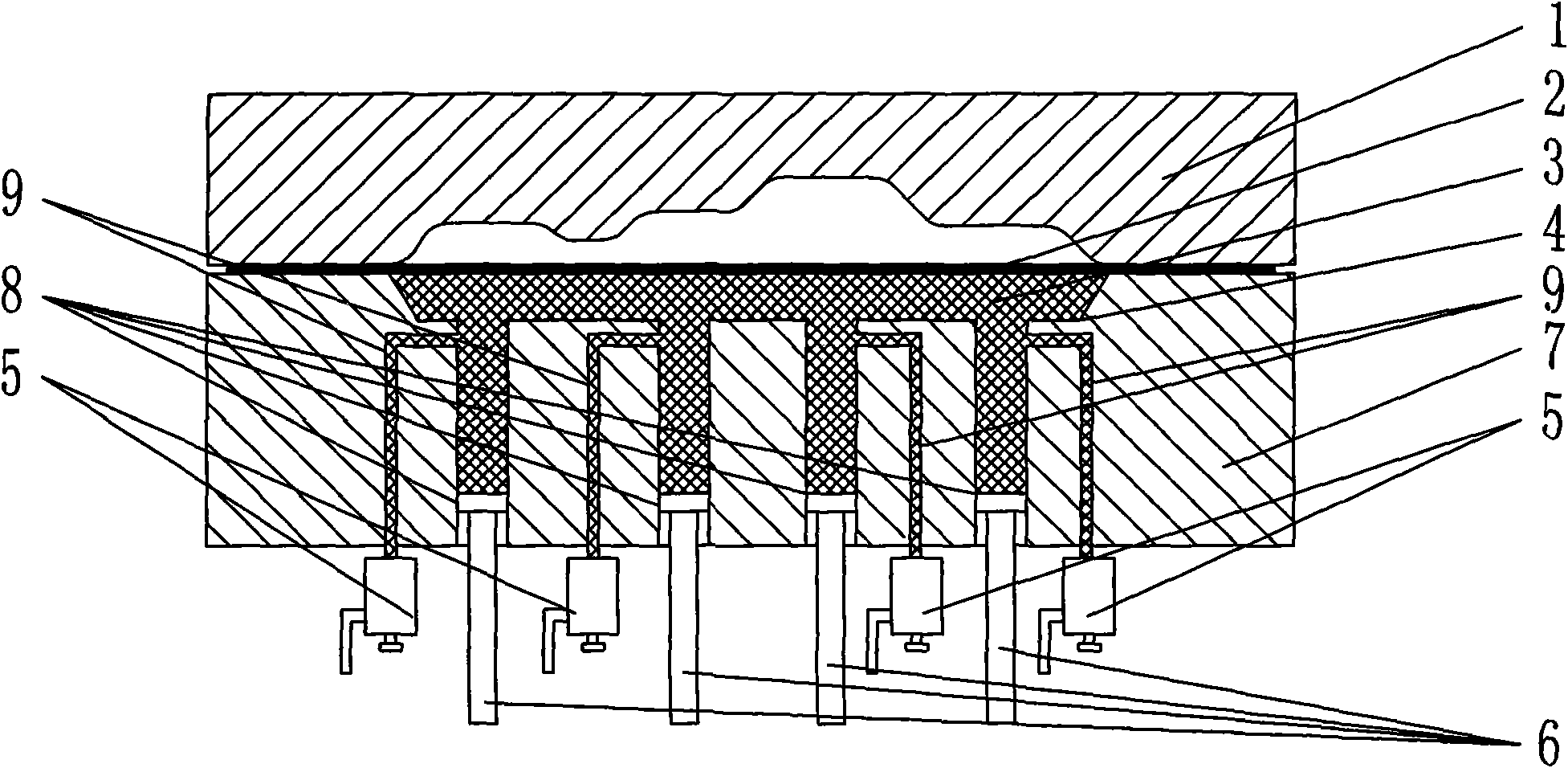

Vending machine

PendingCN107492197ACoin-freed apparatus detailsApparatus for dispensing discrete articlesAcute angleControl system

The invention provides a vending machine and relates to the technical field of vending machinery. The vending machine comprises a goods cabinet, a goods storage module, a control module, a goods taking module, a goods outlet module and a lifting module, wherein the goods taking module, the goods outlet module and the lifting module are respectively connected with the control module, the goods taking module comprises a box body, a sensor and a goods channel, the sensor is connected with a control system, the box body comprises a base plate, a first side plate, a top plate and a second side plate which are sequentially connected to form a goods taking channel, the lifting module is connected with the first side plate and the second side plate, the goods channel and the base plate are arranged at an acute angle mode, multiple second rolling shafts are arranged on the goods channel to make goods slip off, the lifting module drives the box body to reach designated height, the goods outlet module pushes goods into the goods taking channel, the sensor judges whether goods taking succeeds or not, and then the lifting module drives the box body to descend and reach a goods taking port. The vending machine delivers goods in a light-soft mode and avoids goods damage, and the varieties of commodities which can be sold are increased.

Owner:BEIJING YUNJING YUANPU INFORMATION TECH CO LTD

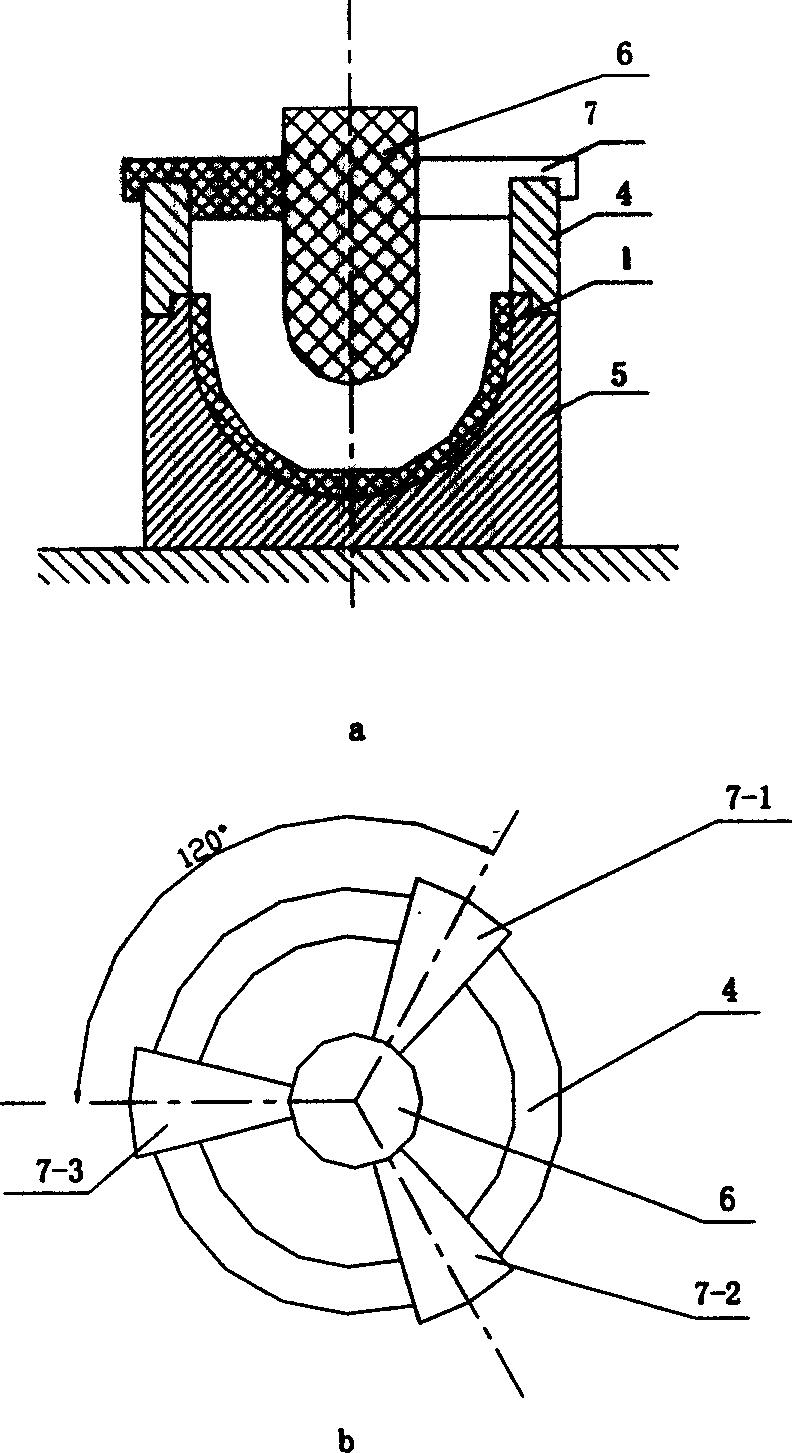

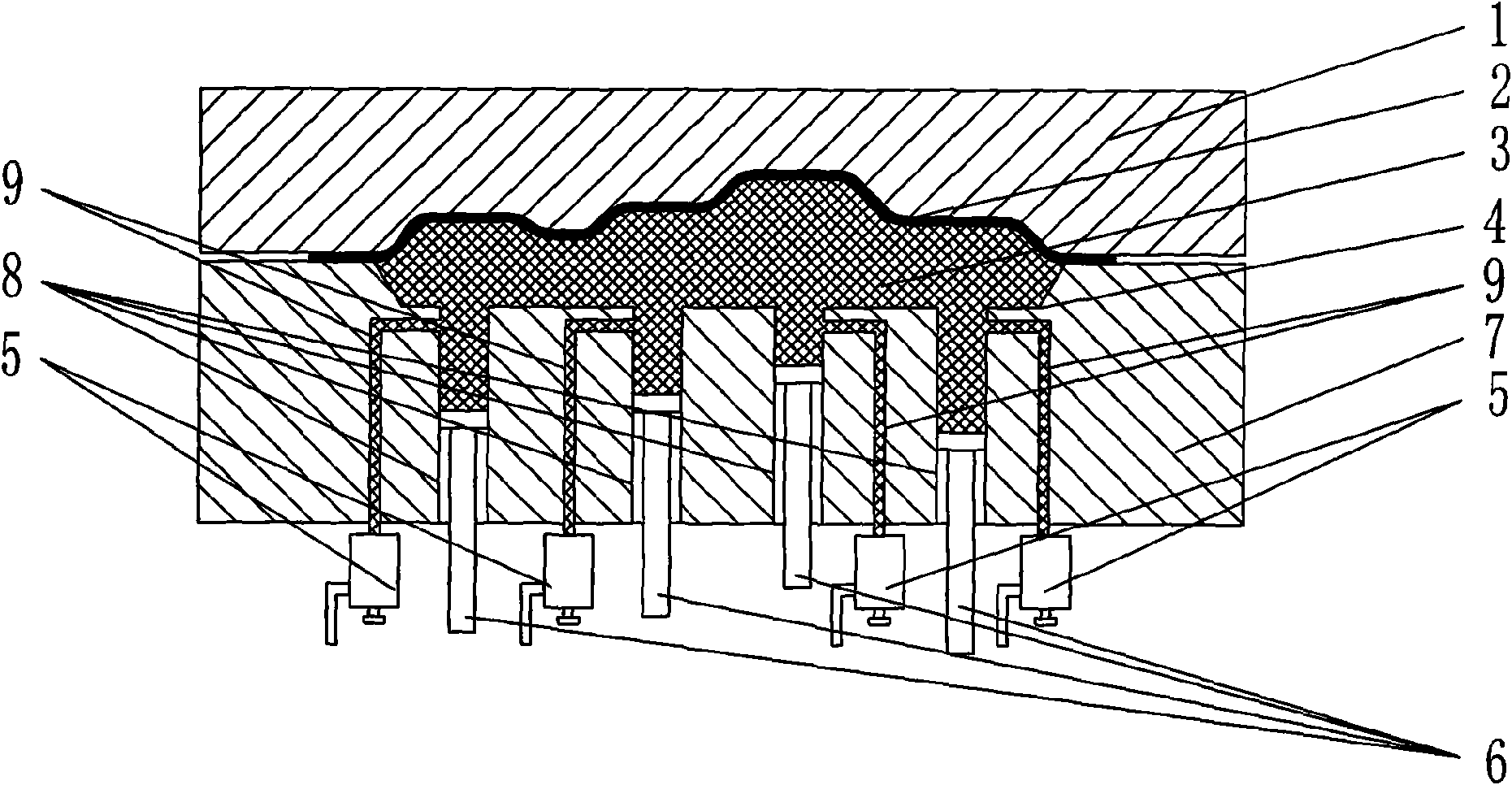

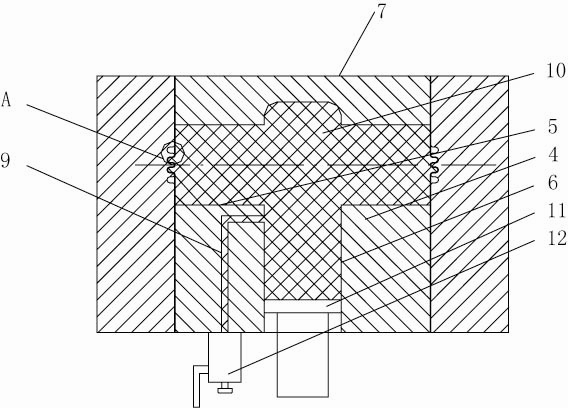

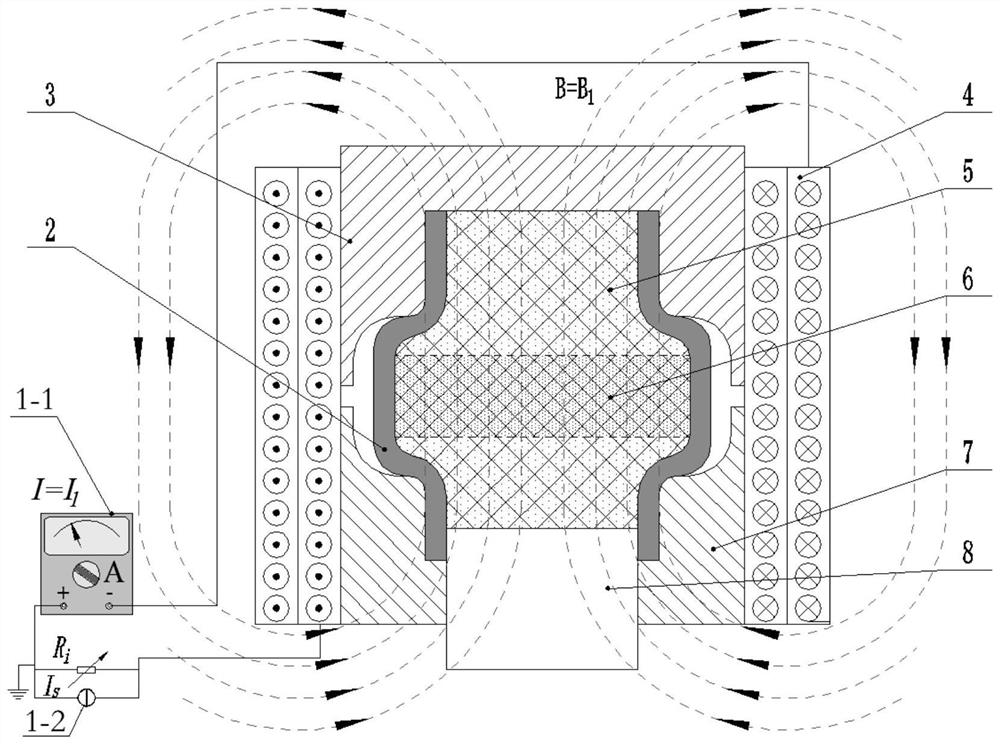

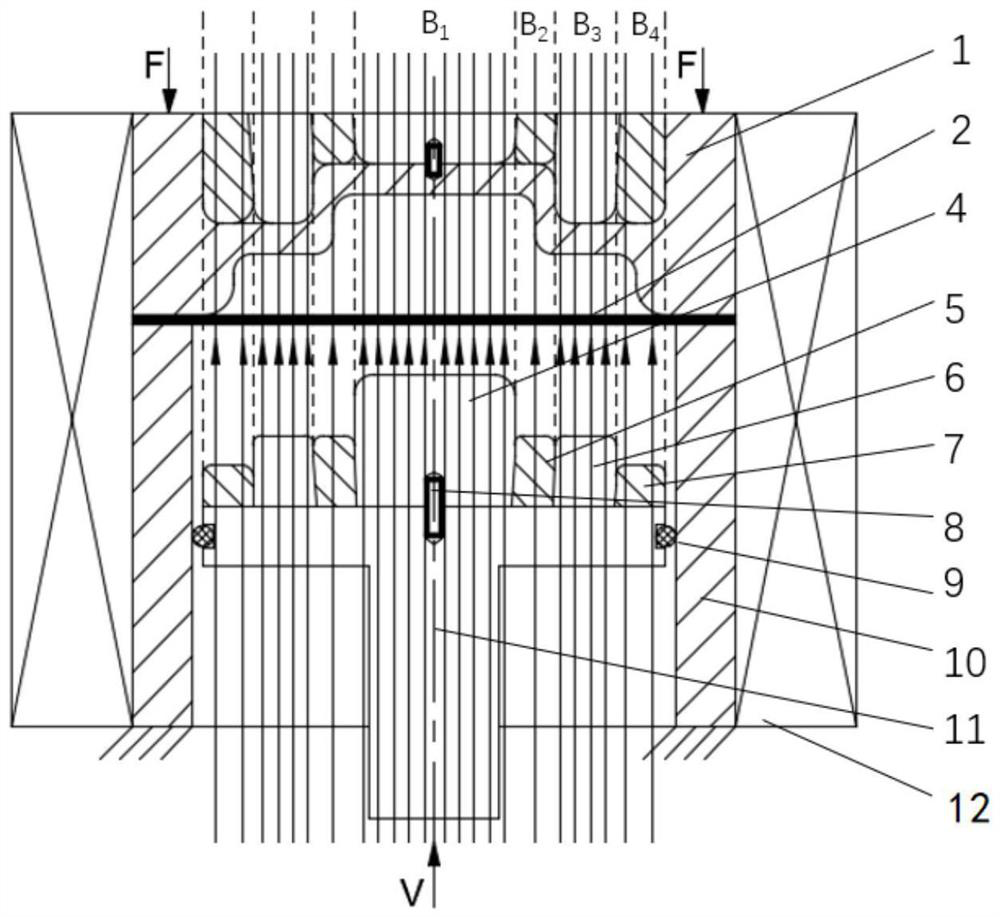

Pressure control method for forming aluminum alloy covering part viscoelastic-plastic soft mode

The invention discloses a pressure control method for forming an aluminum alloy covering part viscoelastic-plastic soft mode, relating to the pressure control method for forming an aluminum alloy covering part soft mode. The invention solves the problems of local tinning and cracking, larger rebound, bad surface quality and higher manufacture cost which are existed in the prior aluminum alloy covering part. The invention substantially comprises the following steps of: shaping a mould; installing a piston and an overflow valve; filling viscoelastic-plastic materials; matching a mould; adjusting the overflow valve to control the pressure value of the deformed region of the aluminum alloy plate blank material; tightly gluing the aluminum alloy plate blank material with the die cavity of a cavity die under the thrusting function of the viscoelastic-plastic materials to form the needed aluminum alloy covering part; opening the mould; taking out the formed aluminum alloy covering part; and removing the viscoelastic-plastic materials remained on the surface of the aluminum alloy covering part. The invention inhibits the rebound of the formed aluminum alloy covering part, prevents the local region from being cracked, improves the surface quality of the aluminum alloy covering part, and reduces the manufacture cost of the aluminum alloy covering part.

Owner:HARBIN INST OF TECH

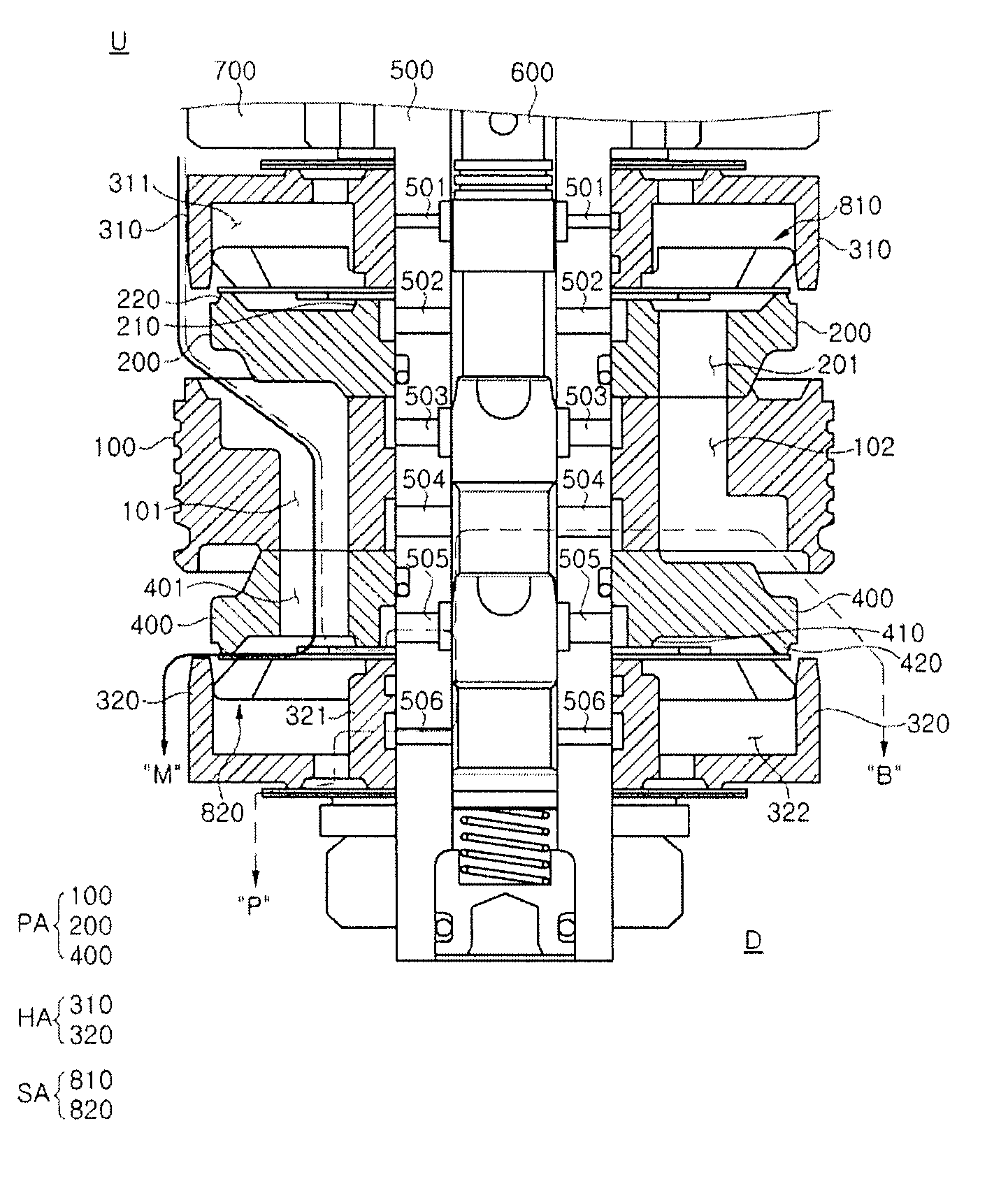

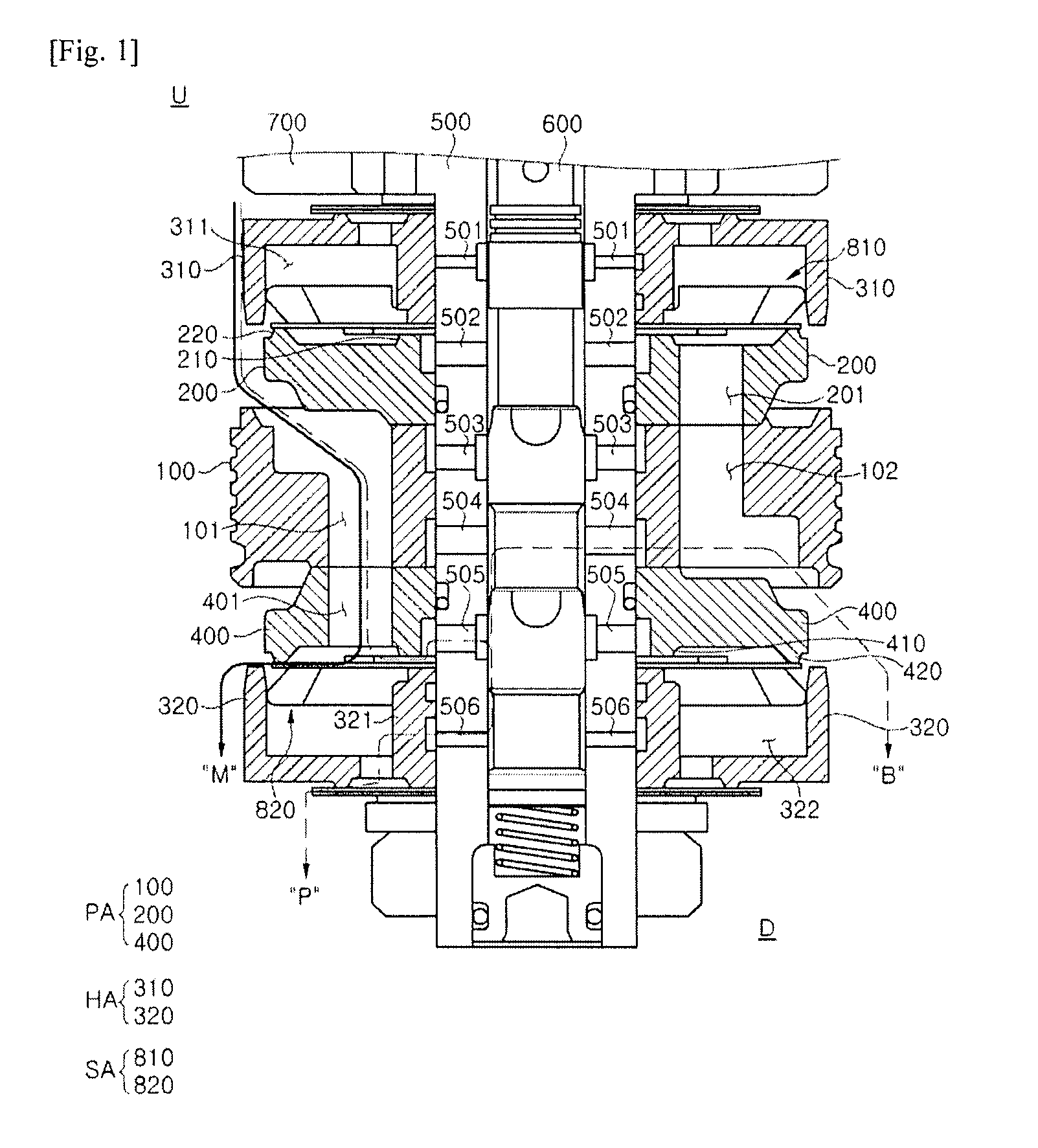

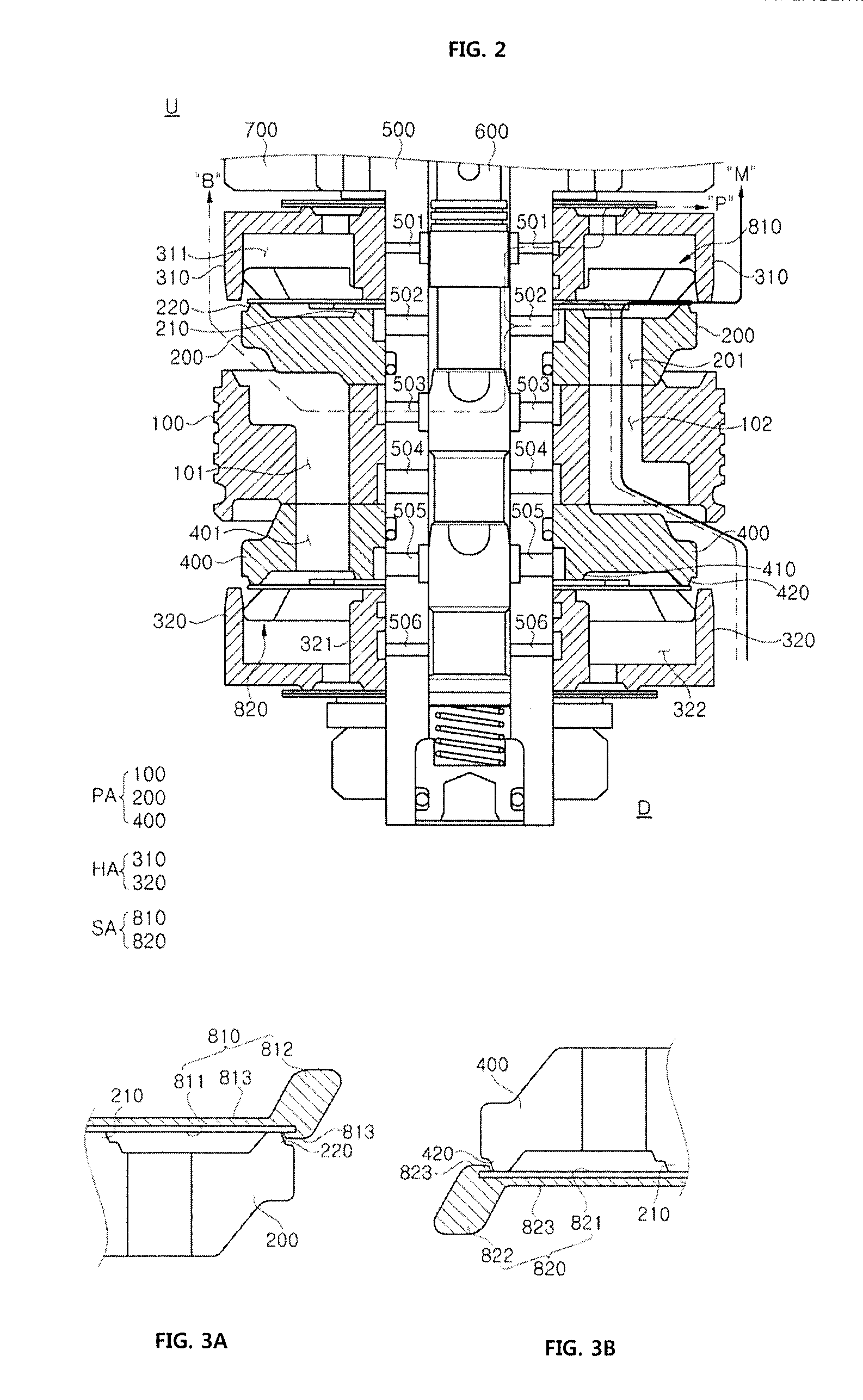

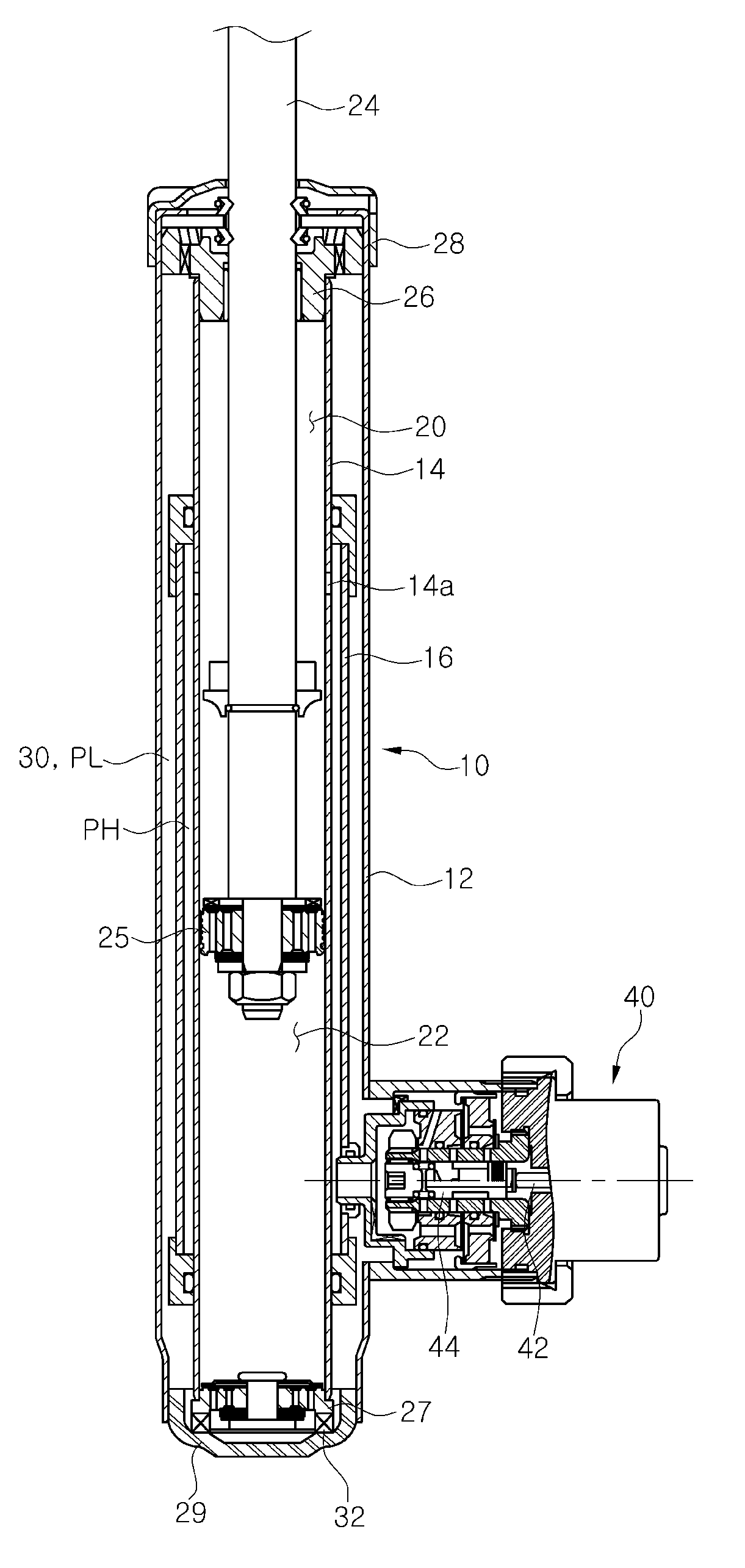

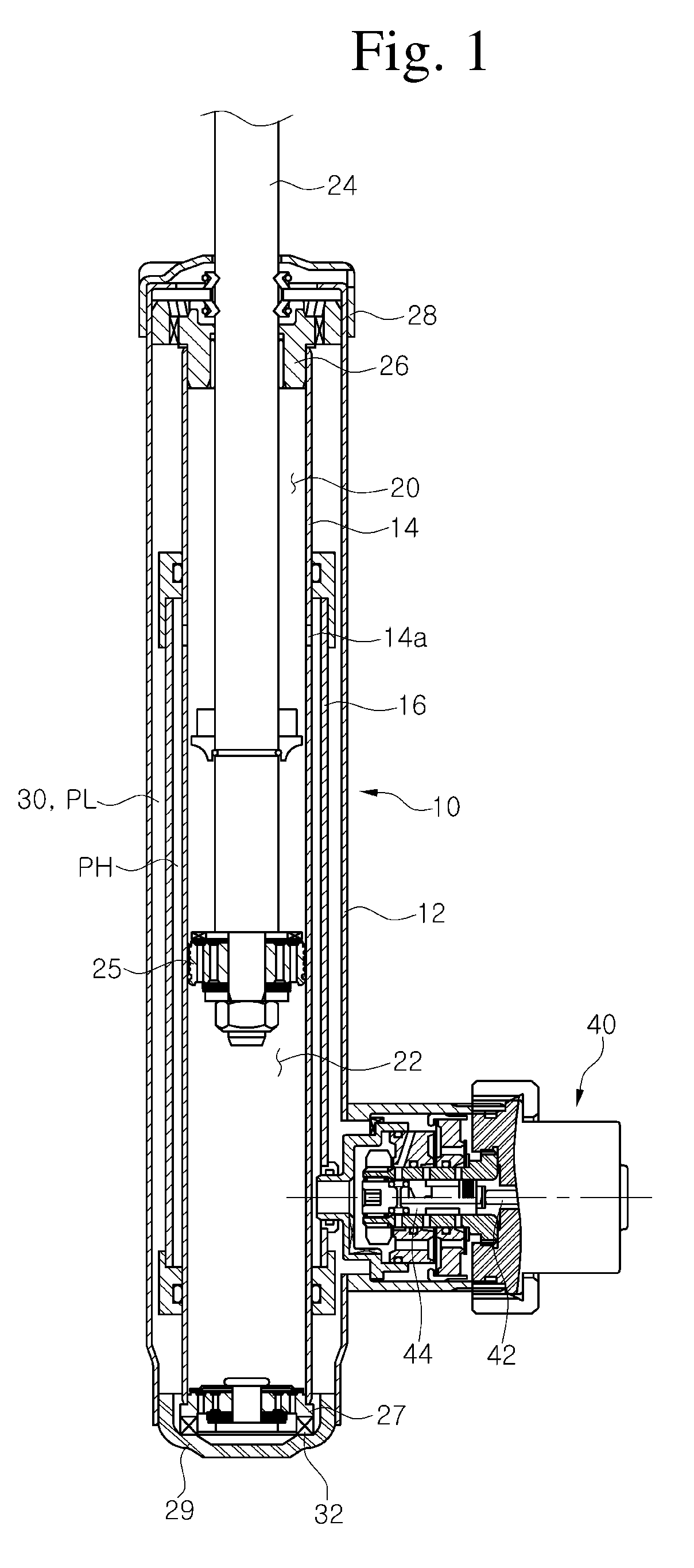

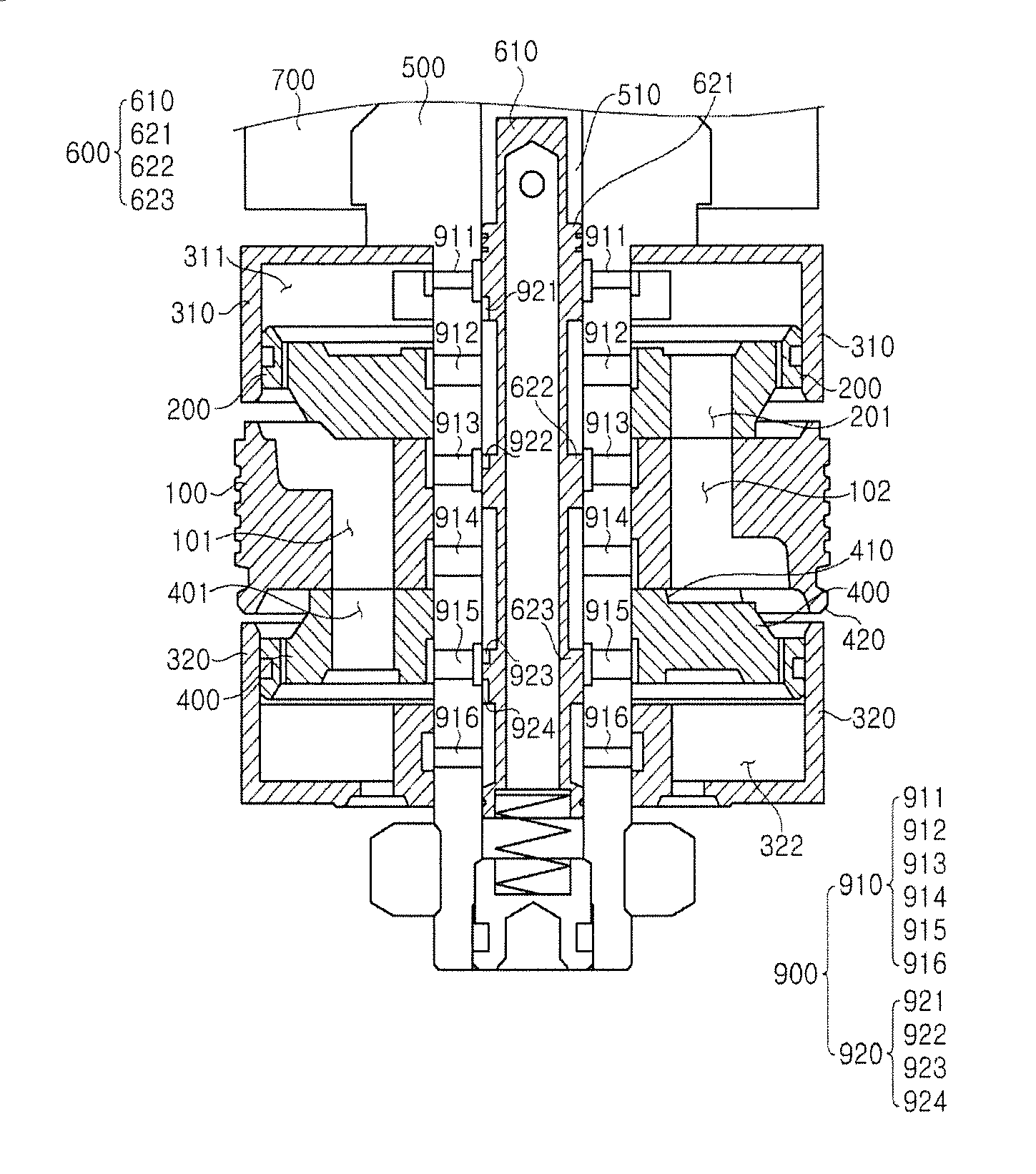

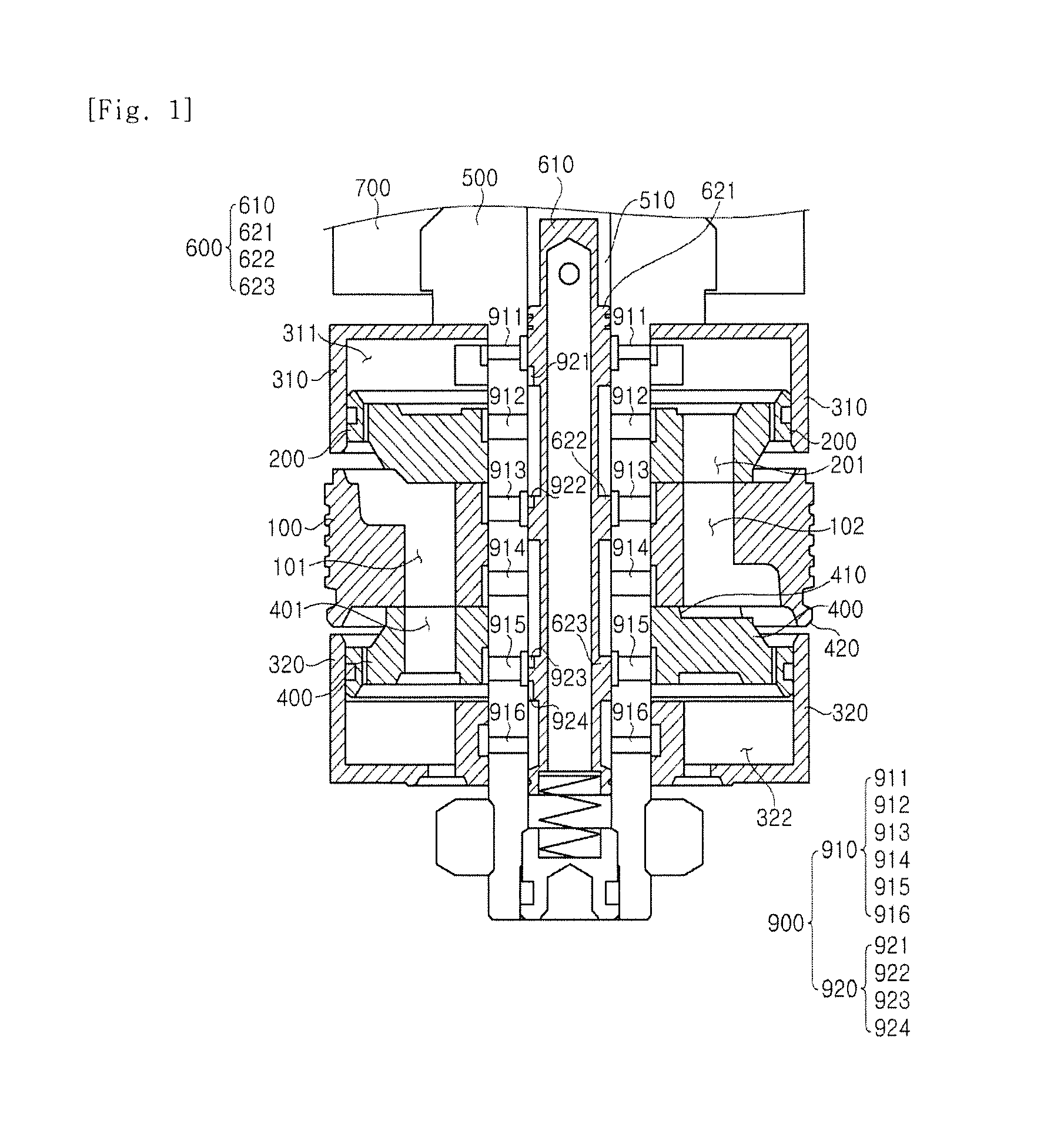

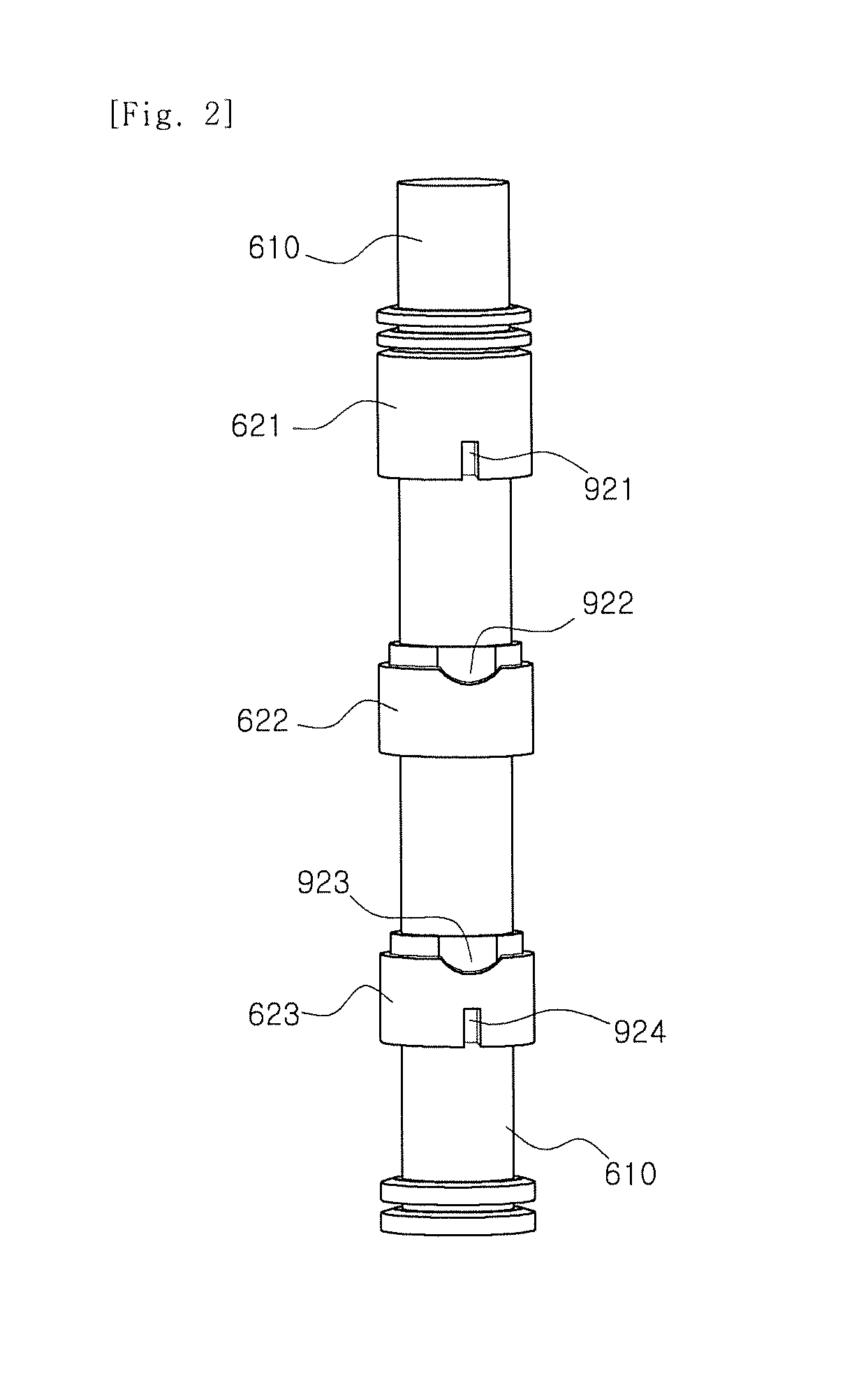

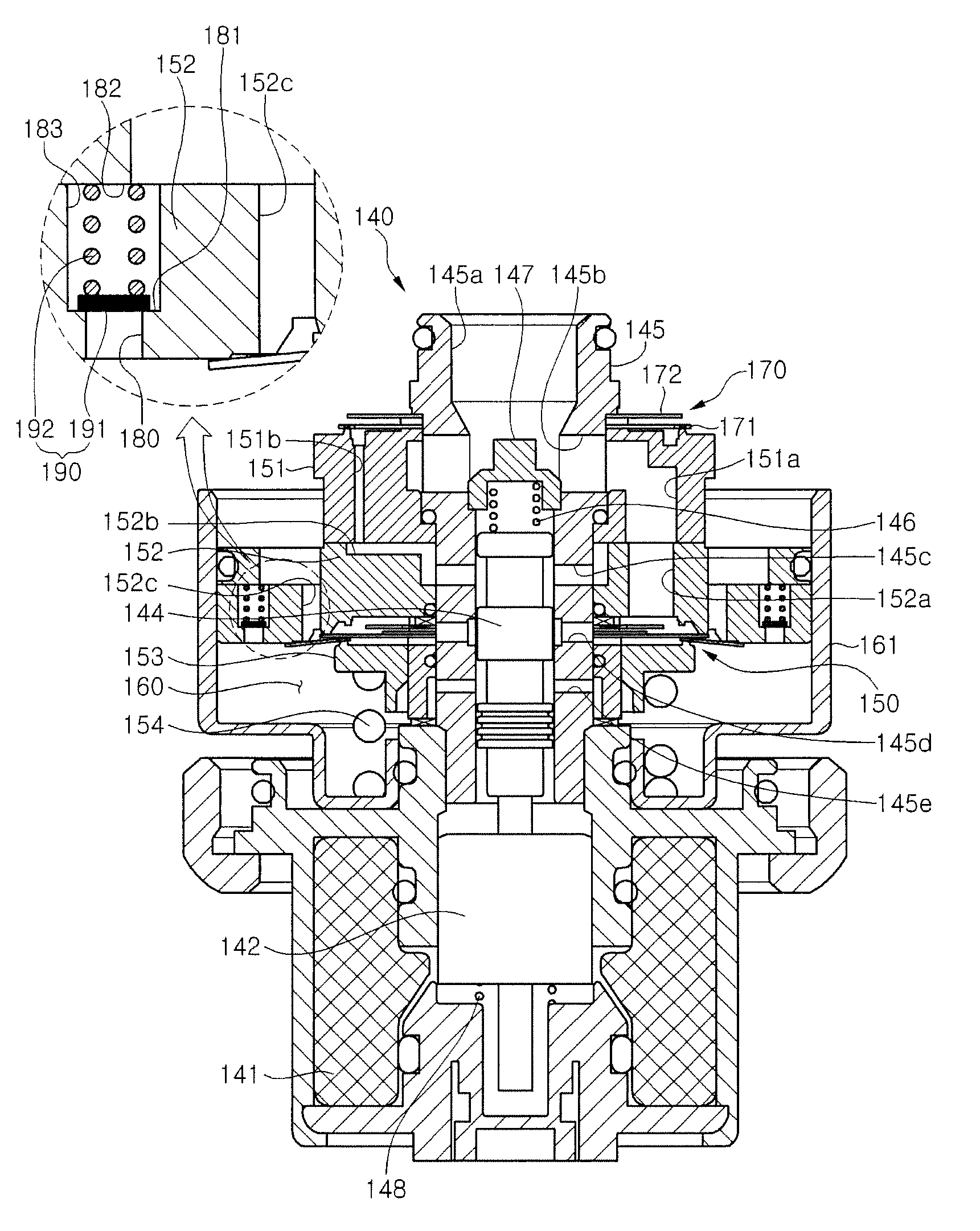

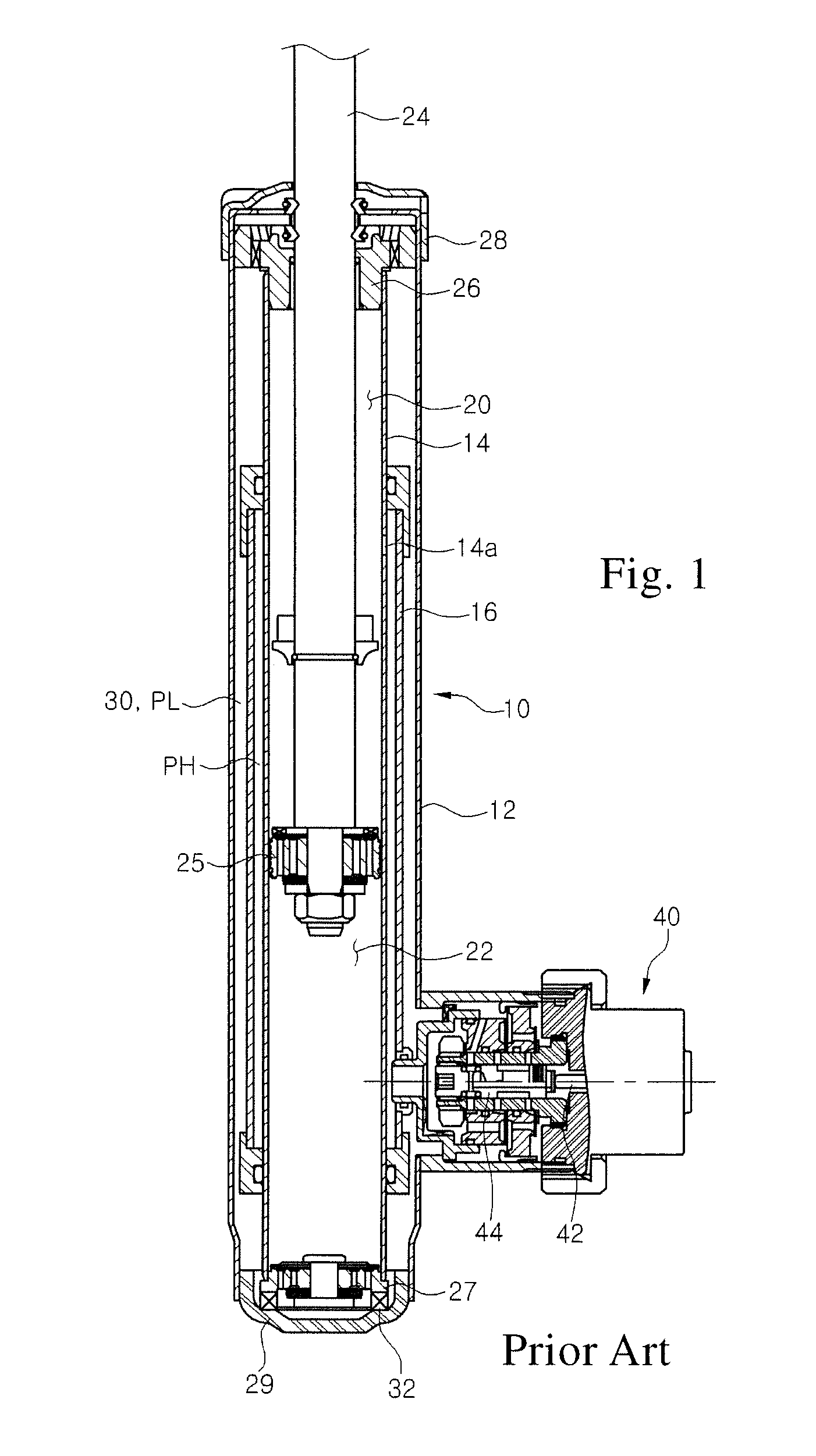

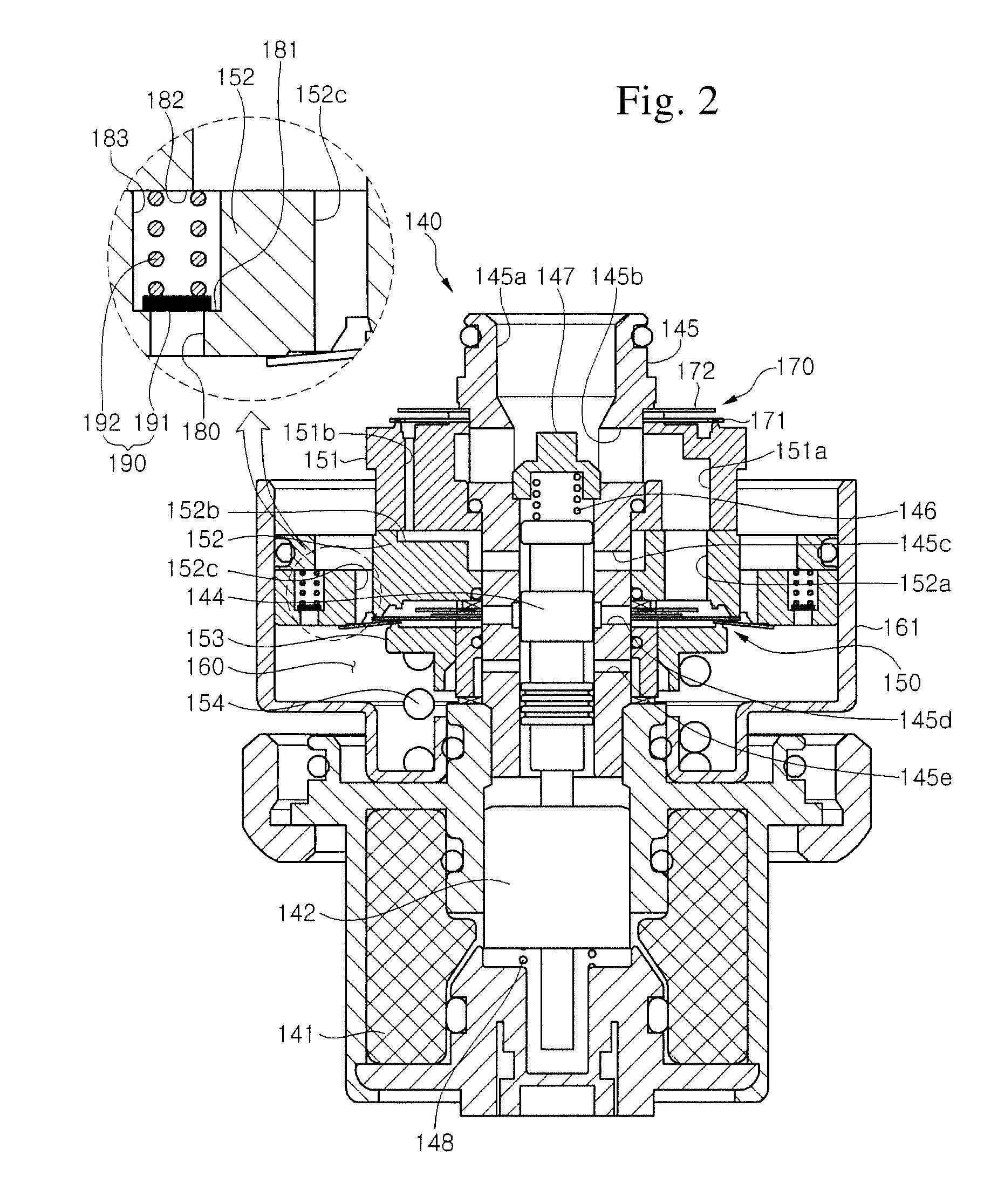

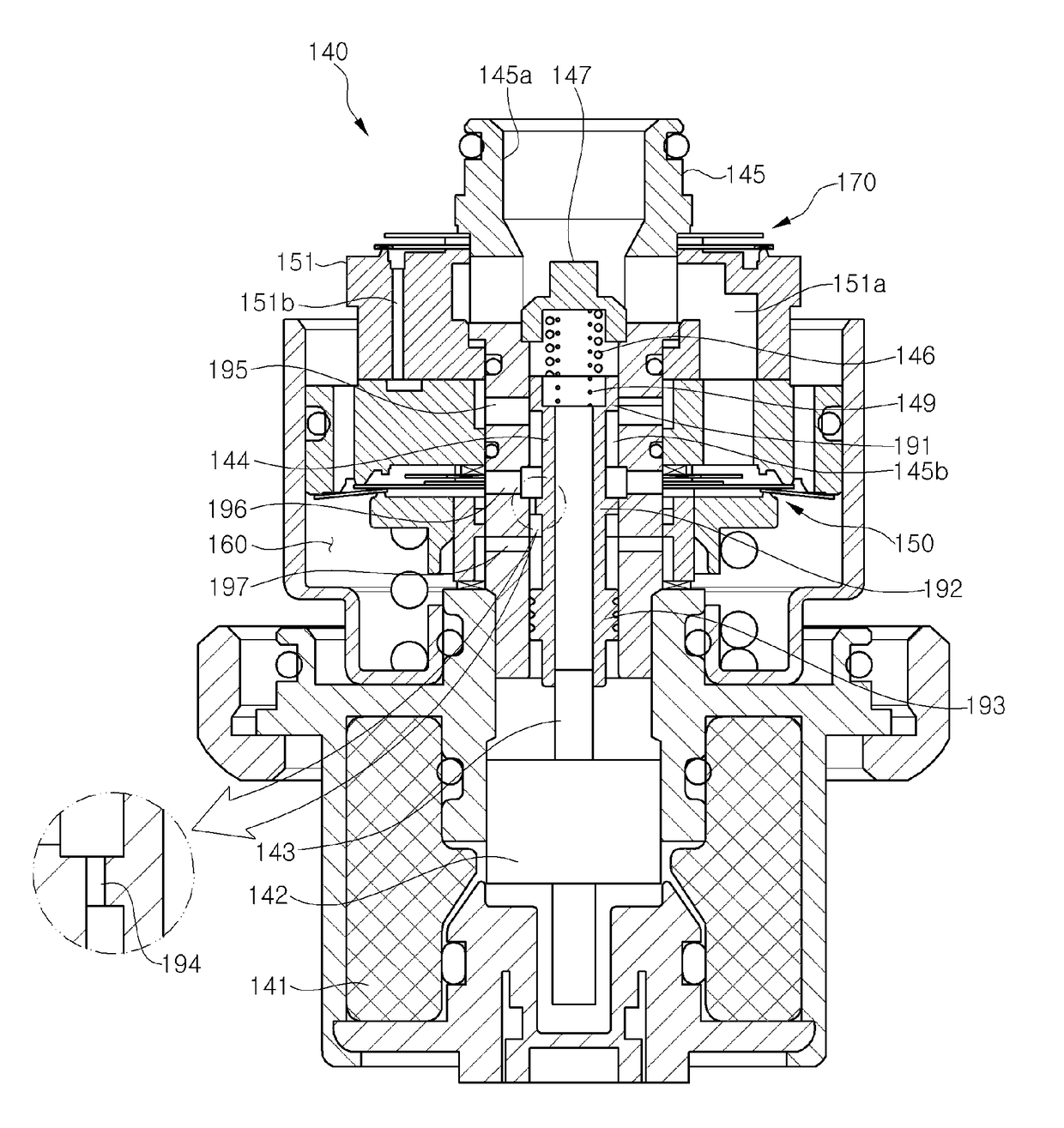

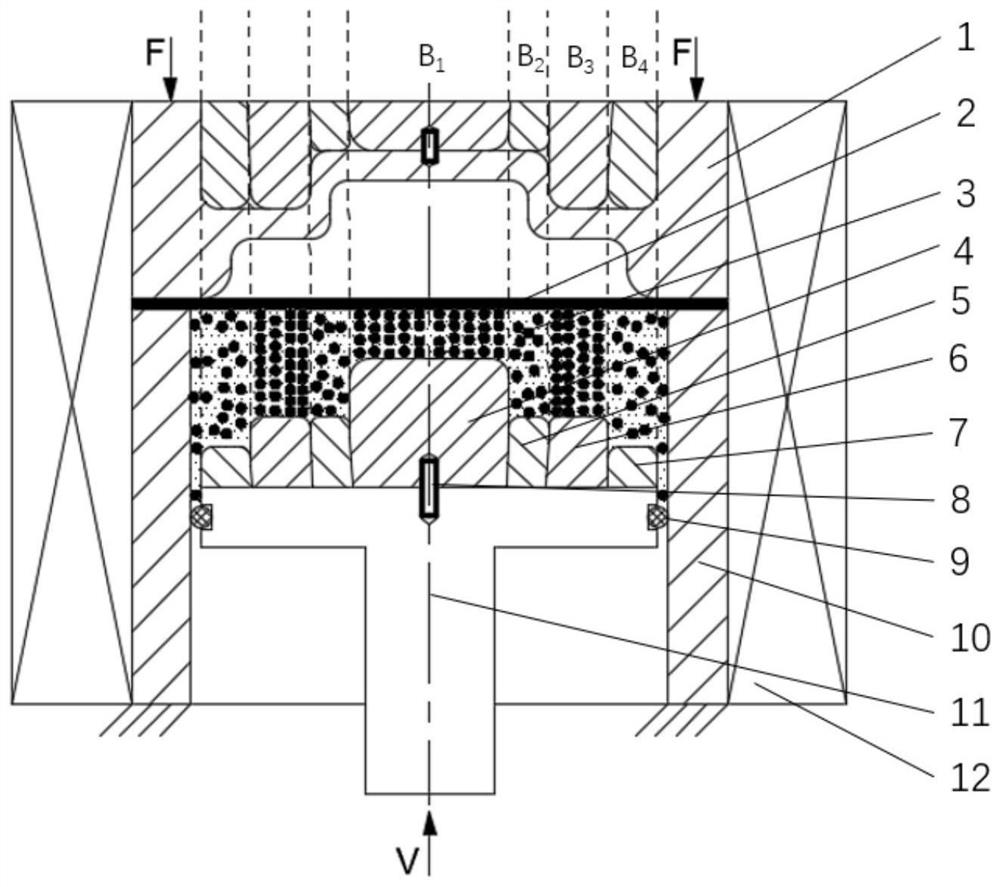

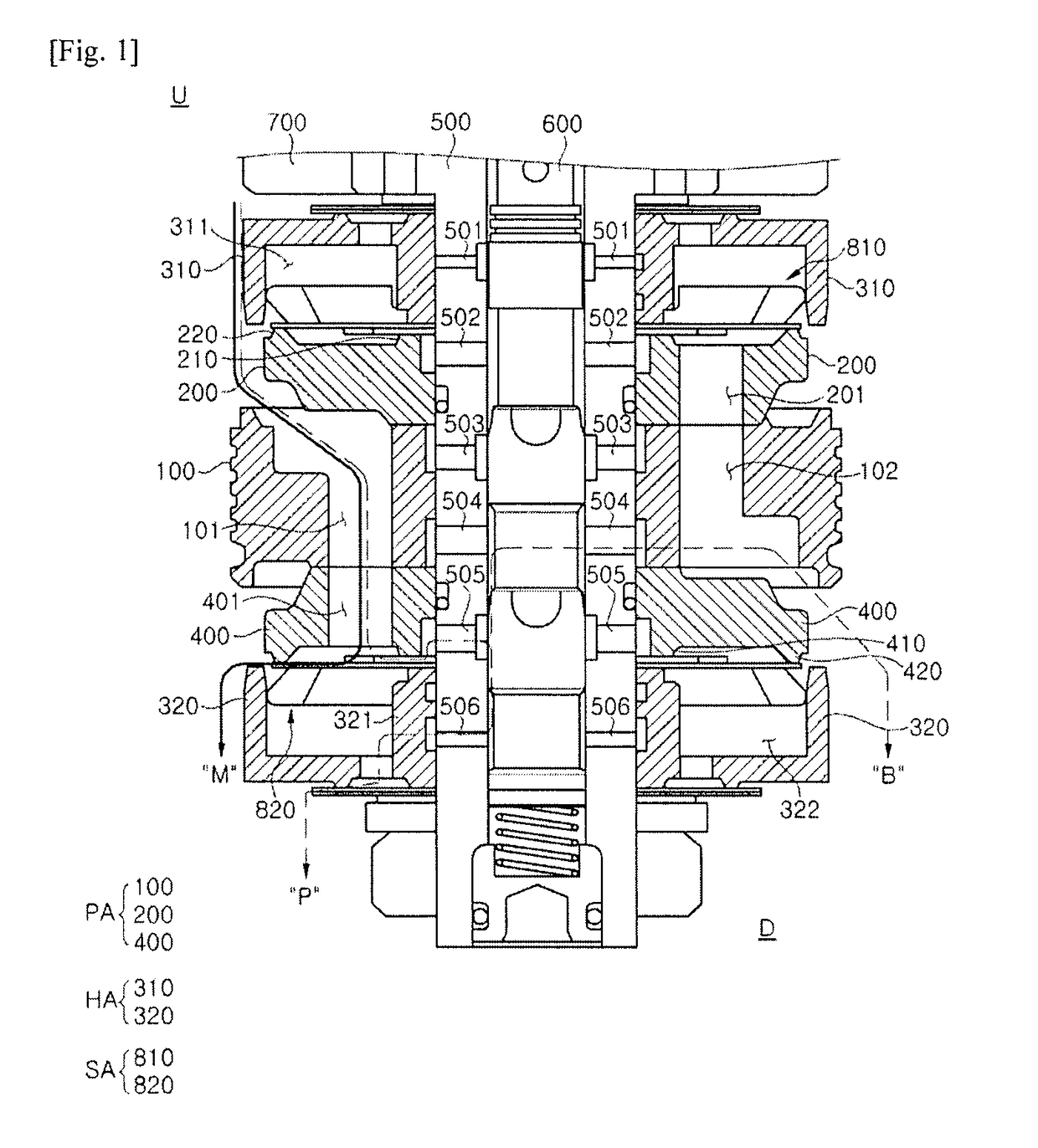

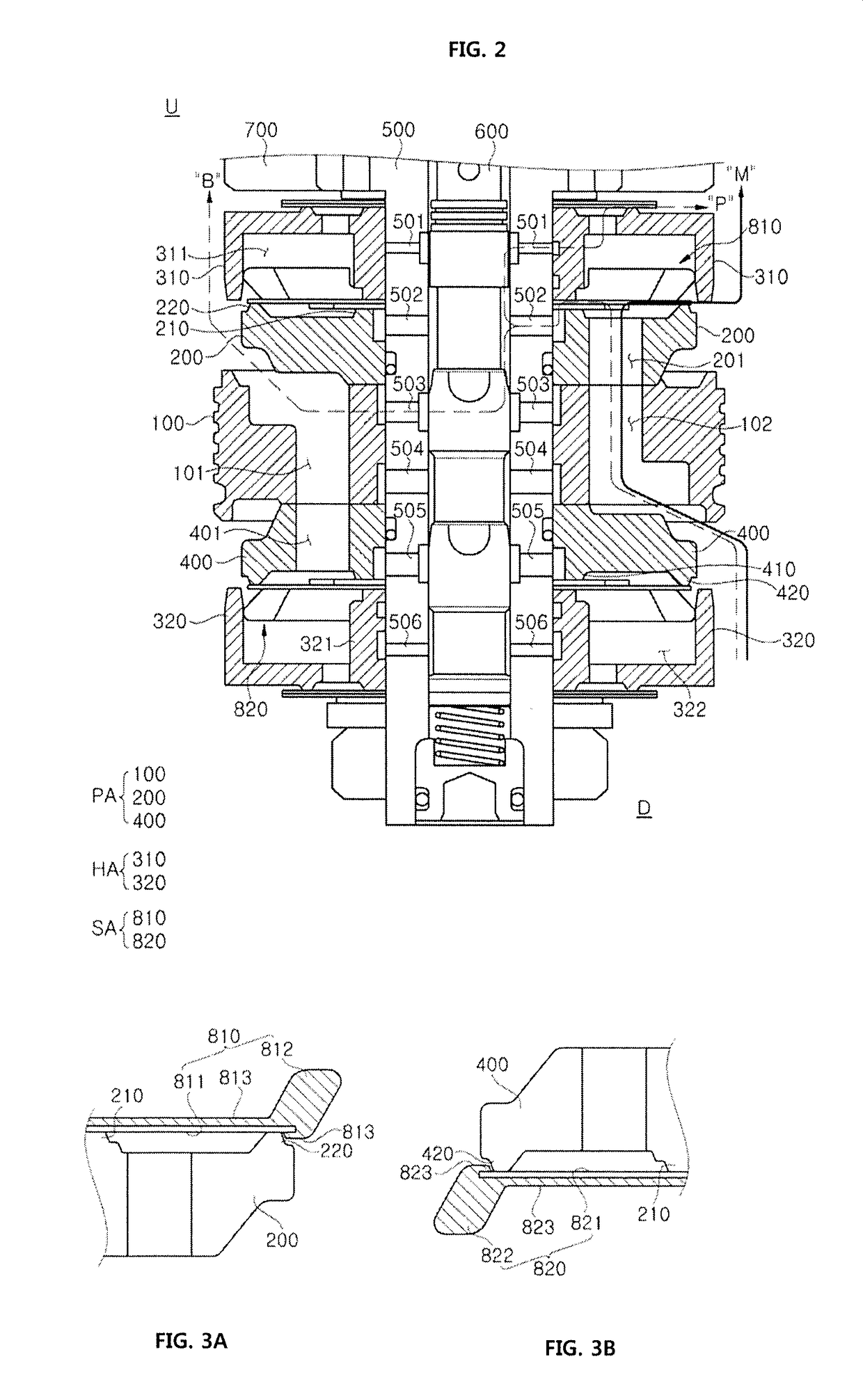

Damping force variable valve assembly and damping force variable shock absorber having the same

ActiveUS20140284156A1Reduce back pressureOperating means/releasing devices for valvesSpringsMagnetic tension forceLow speed

Provided are a damping force variable valve assembly with a low-speed control valve capable of controlling an ultra-low flow rate and a low flow rate when a damping force variable valve operates in a soft mode, and a damping force variable shock absorber including the damping force variable valve assembly. The damping force variable valve assembly, which is installed in a damping force variable shock absorber for adjustment of a damping force of the shock absorber, includes: a solenoid; a spool which is movable by the magnetic force of the solenoid; a spool guide which surrounds the spool; a main valve which is installed in a main passage formed in a valve body installed in the spool guide; a back pressure chamber which is provided in the rear of the main valve; a chamber forming body which forms the back pressure chamber.

Owner:HL MANDO CORP

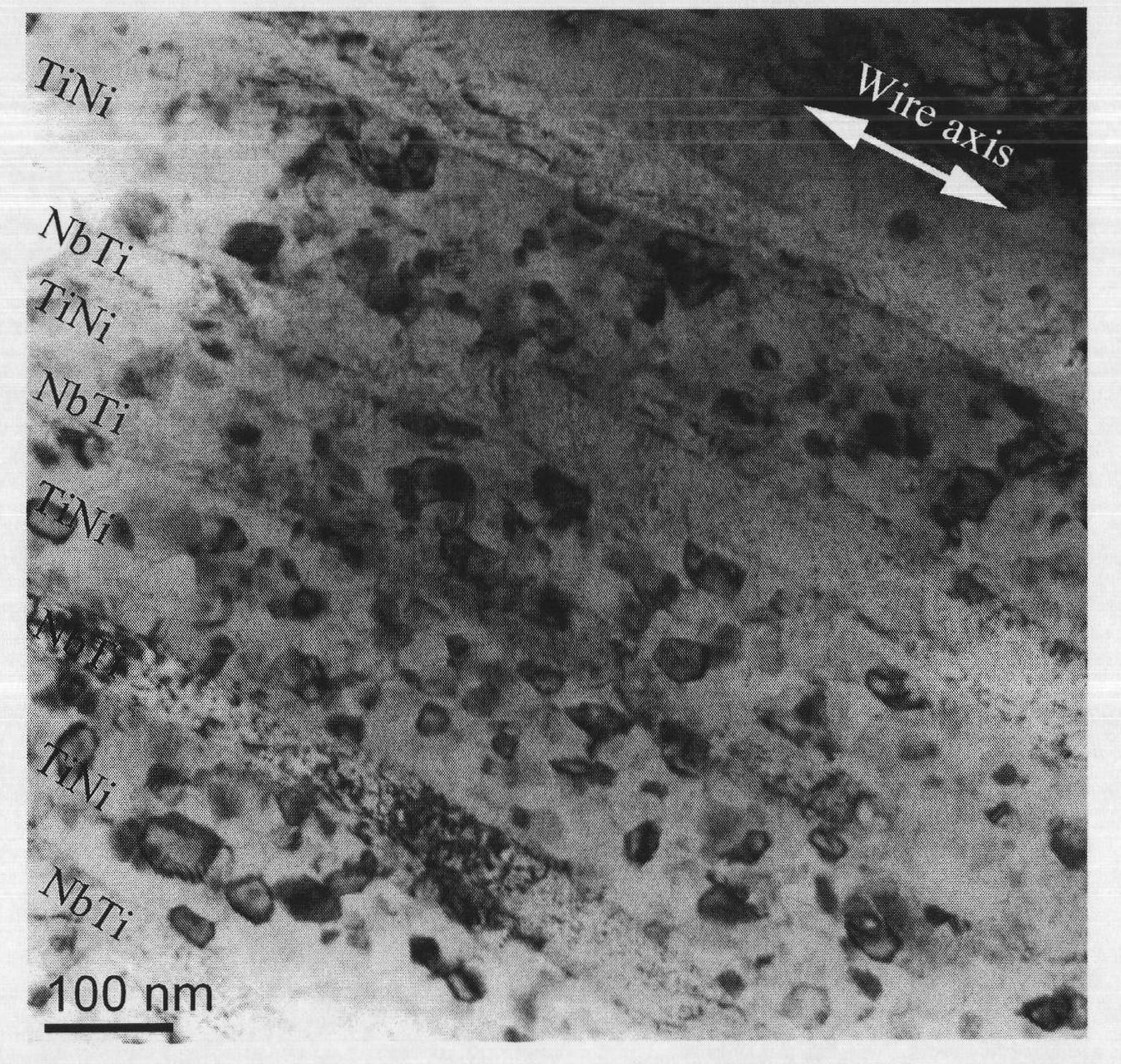

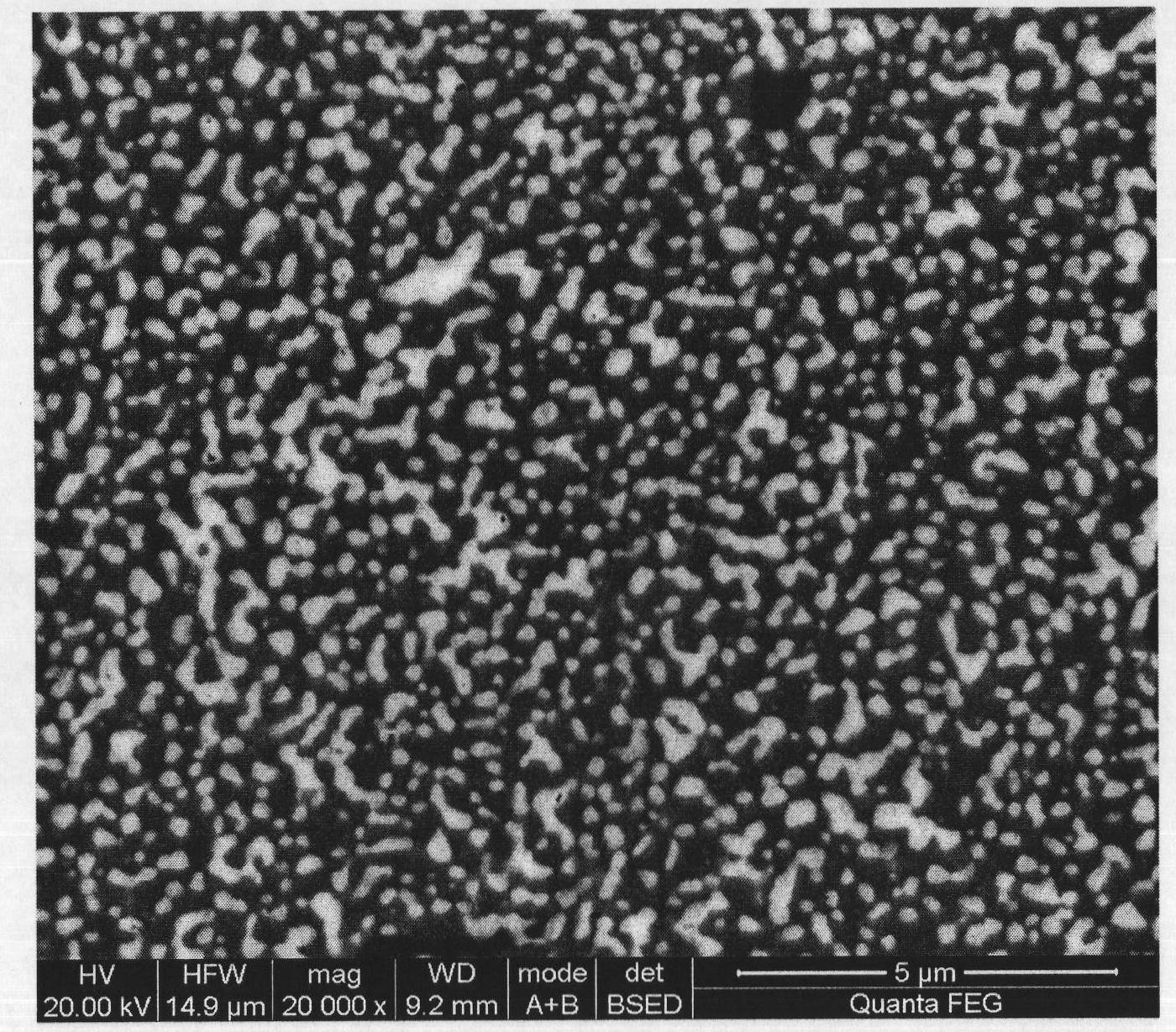

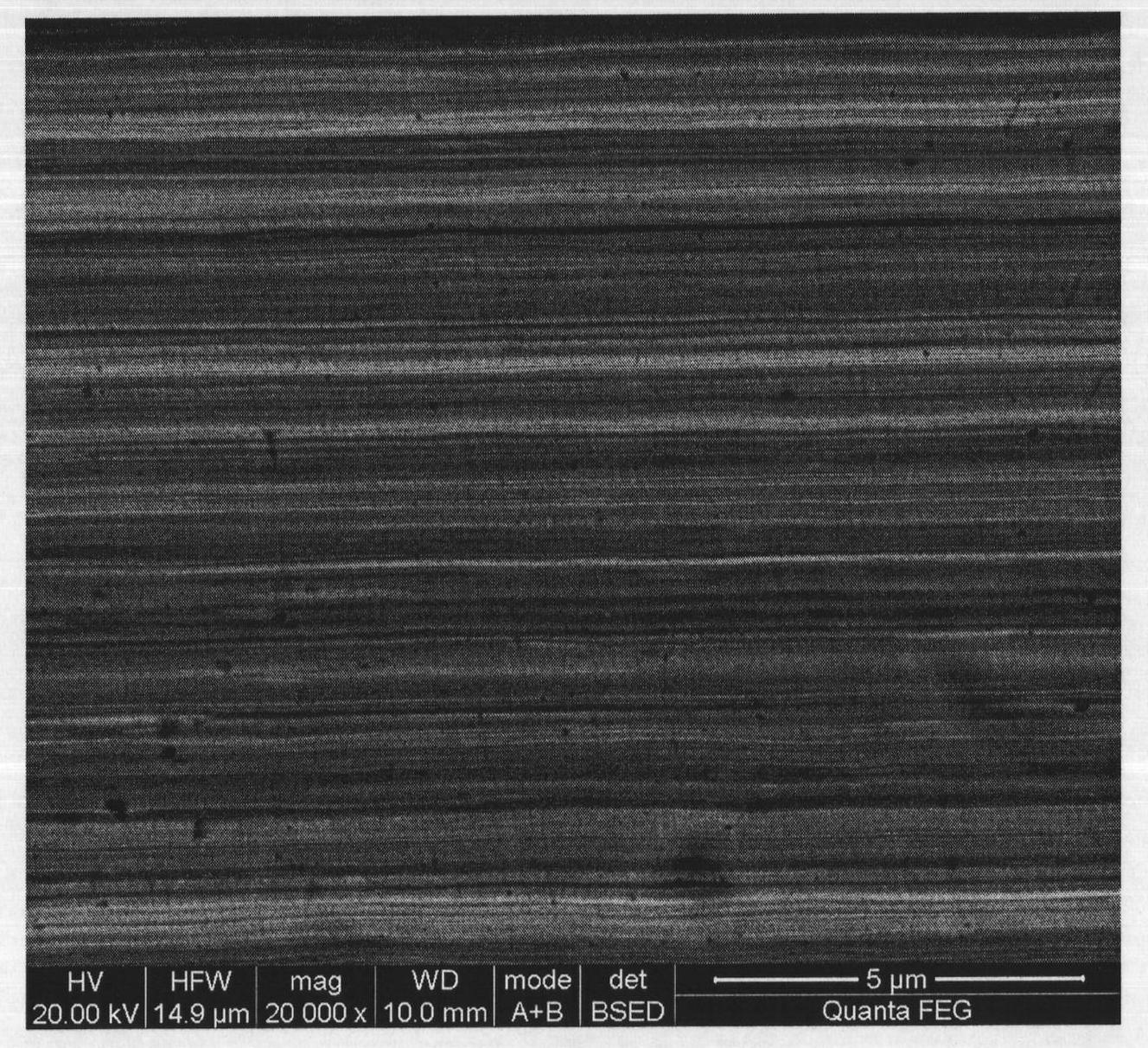

NbTi/TiNi memory alloy composite material and preparation method thereof

InactiveCN101805843AEnhanced interface bindingImprove the bonding strength of the interfaceNiobiumAlloy composite

The invention relates to an NbTi / TiNi memory alloy composite material and a preparation method thereof. The memory alloy composite material comprises the following components calculated by the total weight of the memory alloy composite material: Nb element with the atomic percentage of 18-22%, and Ti element and Ni element with the atomic rate of 0.3: 1-1.5: 1, wherein the sum of the atomic percentage of the three elements of Ti, Ni and Nb is 100%. The memory alloy composite material has the special functional features of high yield strength, strain soft mode, linear super-elasticity, double-stress platform and the like. The invention further relates to the preparation method of the NbTi / TiNi memory alloy composite material, which comprises the following steps: selecting elementary substances of niobium, titanium and nickel with the purity of above 99.0% by weight according to the mixture ratio of the components of the NbTi / TiNi memory alloy composite material, placing the elementary substances of niobium, titanium and nickel into a smelting furnace with the vacuum degree of being higher than 10-1Pa or inert gas protection, and smelting for forming the NbTi / TiNi memory alloy composite material.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

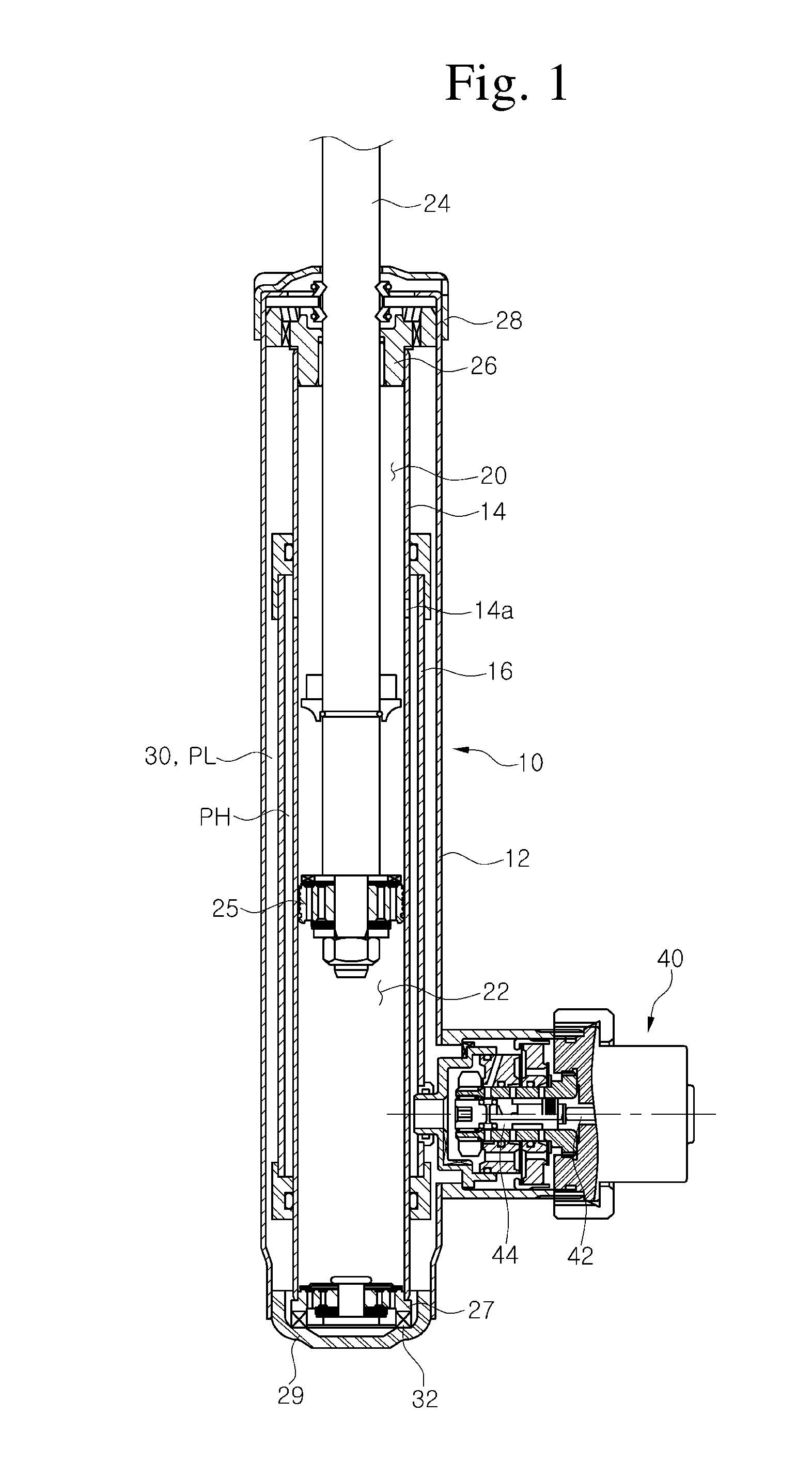

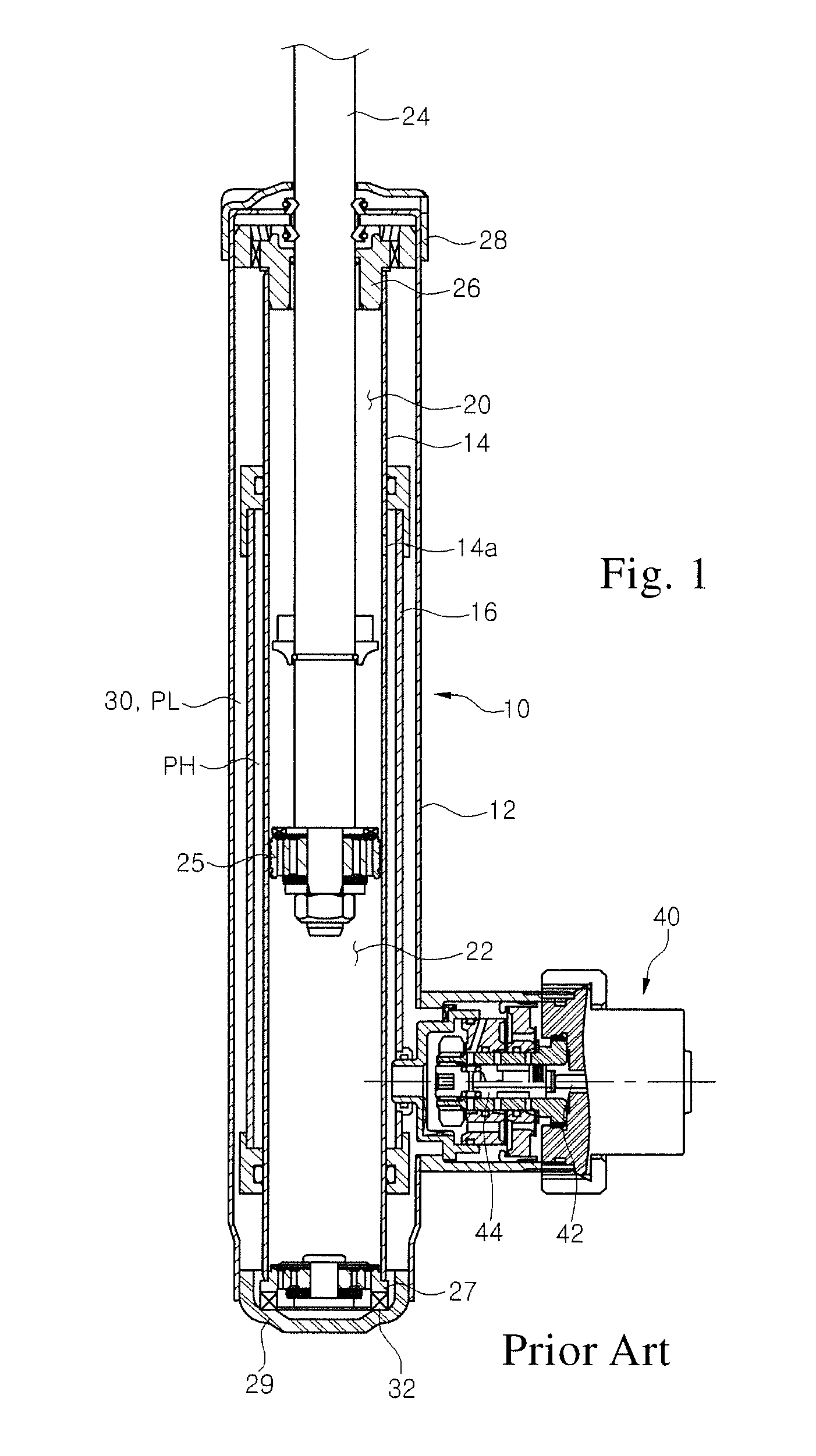

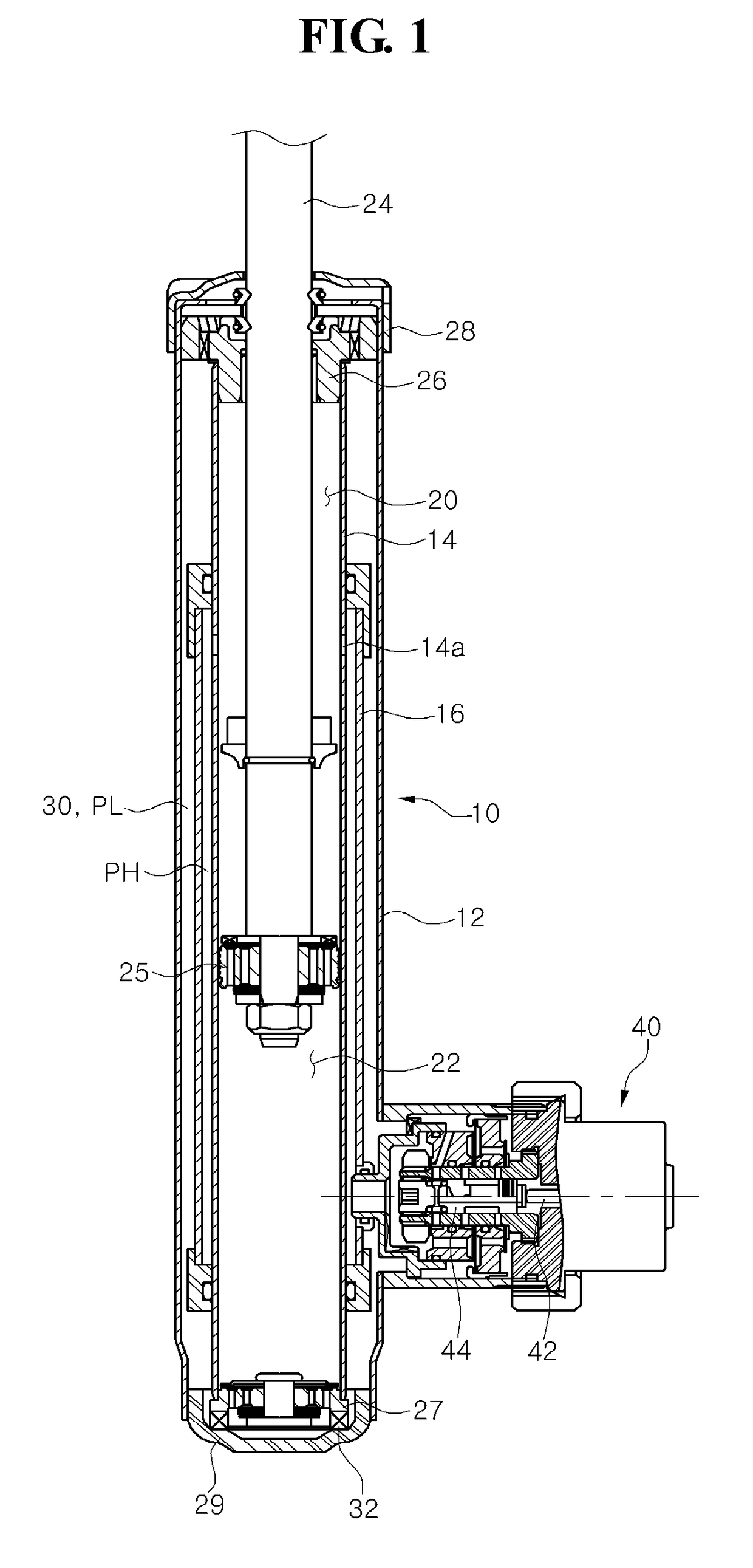

Electronically controlled internal damper

ActiveUS20160223047A1Improve sealingReduce stiffnessSpringsLiquid based dampersInternal pressureWorking fluid

An electronically controlled internal damper includes: a main passage formed by a working fluid flowing through a main piston; a pilot passage formed by a working fluid as much as a predetermined amount discharged from a first pilot chamber and a second pilot chamber so as to maintain internal pressures of the first pilot chamber and the second pilot chamber to a predetermined level when pressures of the first pilot chamber and the second pilot chamber are increased beyond the predetermined level; and a bypass passage formed by a working fluid passing through the compression retainer and the rebound retainer symmetrically disposed above and under the main piston and a plurality of holes formed transversely to a vertical length direction of a spool rod. Accordingly, the electronically controlled internal damper is capable of implementing damping performance in both a soft mode and a hard mode with a relatively simple structure and increasing sealing performance while reducing rigidity.

Owner:HL MANDO CORP

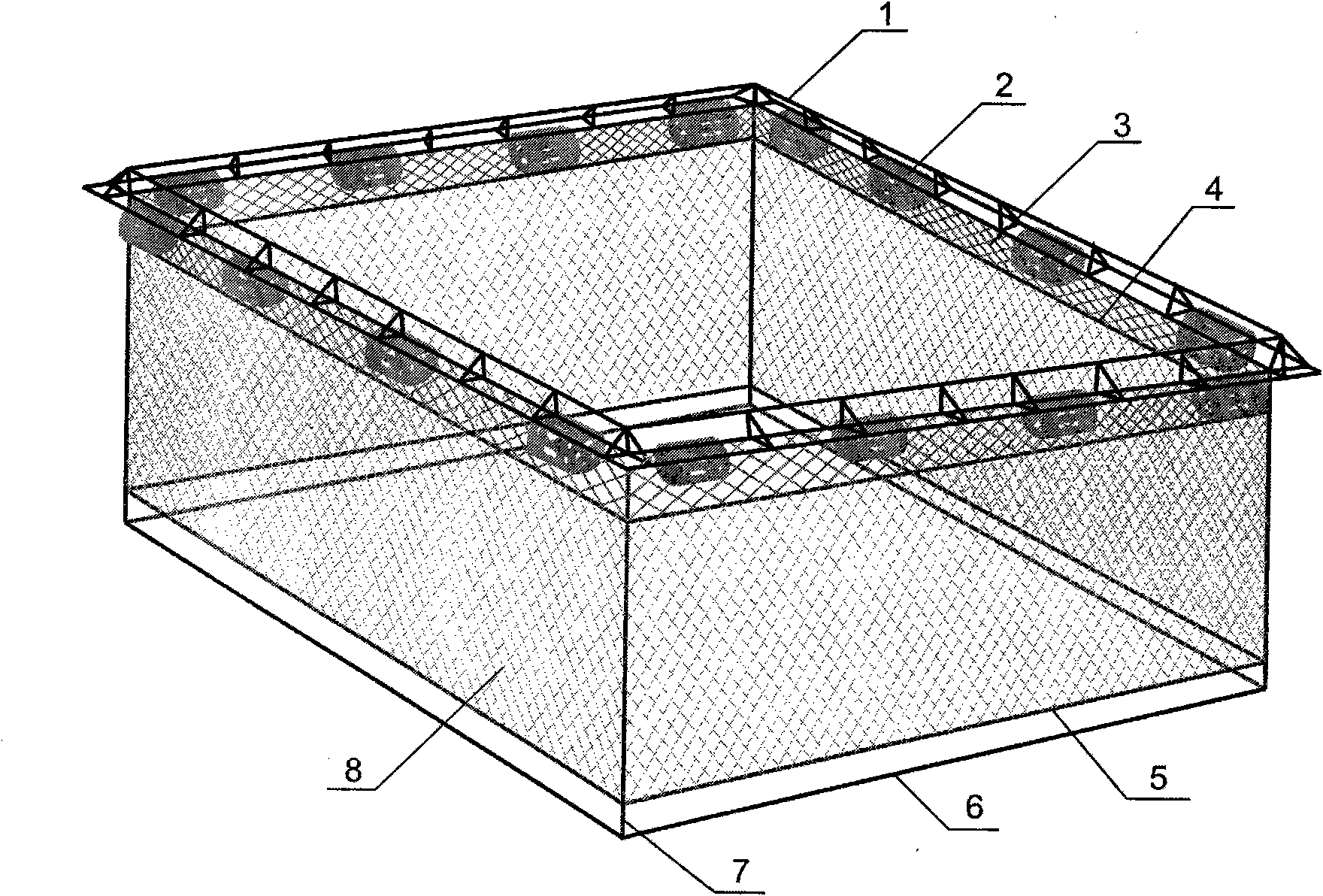

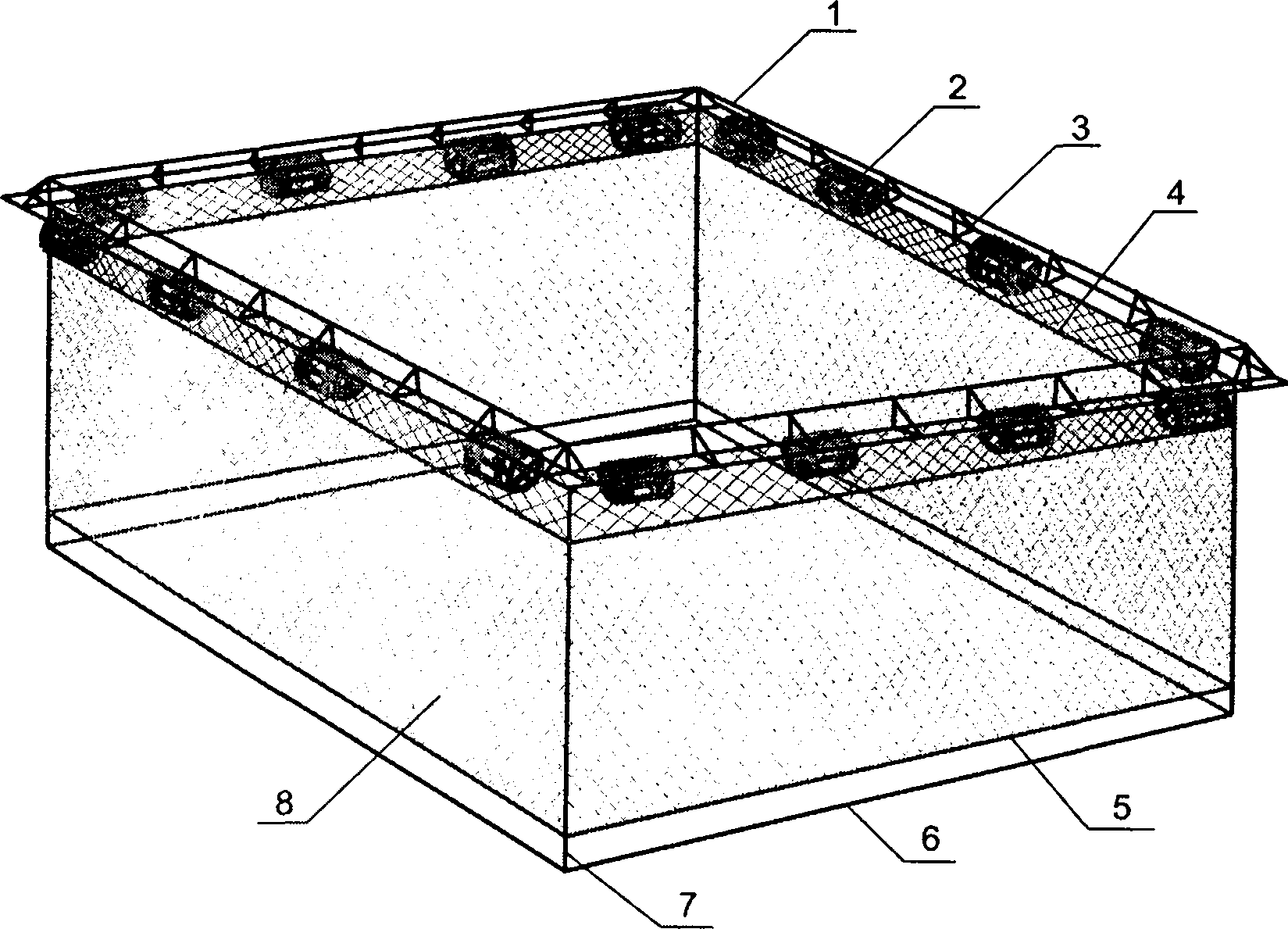

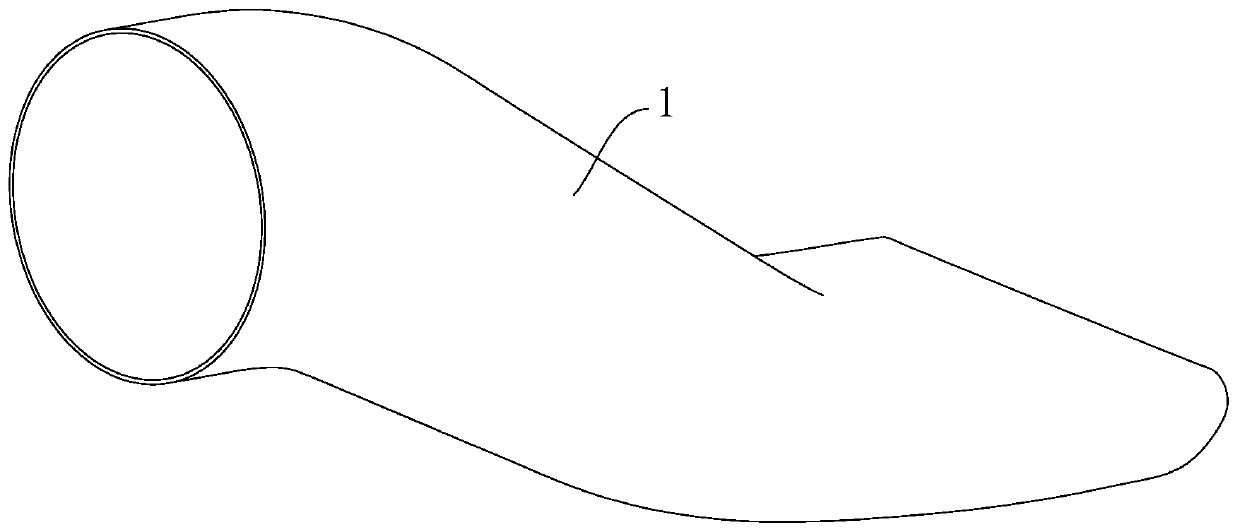

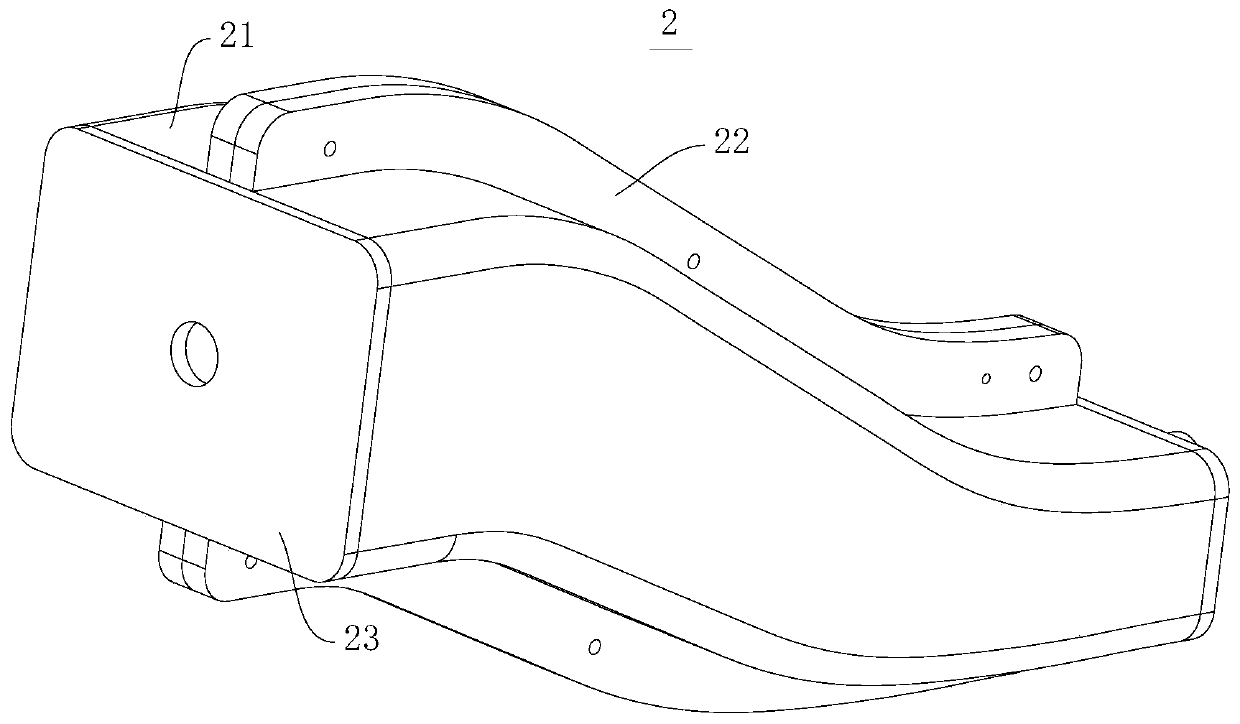

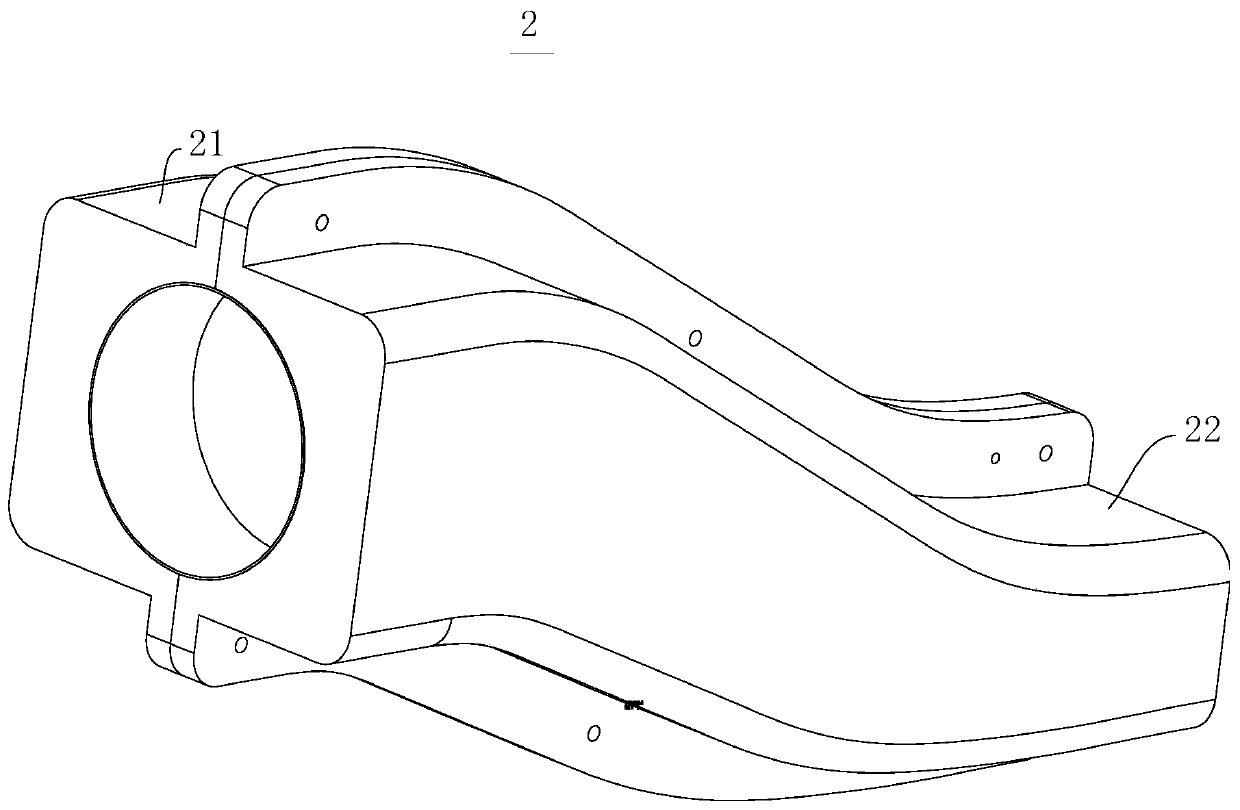

Turbot cultivation net cage having anti-pollution function

InactiveCN102308763ASolve the rustExtended service lifeClimate change adaptationPisciculture and aquariaPollutionMaterials science

The invention discloses a turbot cultivation net cage having an anti-pollution function, and relates to a turbot cultivation net cage. The turbot cultivation net cage uses a hot-dip galvanized iron pipe, a cylindrical plastic foam floating ball, a high-strength single fast knot polyethylene net, a high-strength nylon warp knitting net, an anti-pollution copper alloy rhombus net, a high-strength fishing polyethylene rope, an ultrahigh-strength rope and high-strength fishing lines and is characterized in that: a net cage floating support is welded into a top frame and a bottom frame by using the hot-dip galvanized iron pipe; the cylinder plastic foam floating ball under the lower surface of the bottom frame of the floating support is coated with waterproof cloth and a small-mesh waste netting; a netting system for the net cage consists of a double-layer synthetic fiber netting serving as a first netting and the anti-pollution copper alloy rhombus net serving as a second netting; the first netting and the second netting are connected in a vertical half-soft mode; the net bottom of the net cage is hung with a square galvanized iron pipe framework with edges of 5.0 meters; and the net cage floating support is connected with a floating rope frame through a cable and tied on a berth fixing system.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Machining method of special-shaped hollow structure composite part molding mandrel

The invention relates to the technical field of resin base fiber reinforced composite prepreg hot pressing tank molding, in particular to a machining method of a special-shaped hollow structure composite part molding mandrel. The machining method adopts a mandrel molding mold; molding space is formed in the mandrel molding mold, and is used for molding the molding mandrel; and the wall surface ofthe molding space is a molding surface. The machining method comprises the following steps: soft mode blanks are folded on the molding surface; the soft mold blanks and the mandrel molding mold are pressed for tight contacting; the soft mold blanks are cured to form a soft mold; a water soluble material is cast in the soft mold until an inner cavity of the soft mold is totally filled; the water soluble material is cured; and the demolding is performed. The molding core mold obtained through the machining method has the advantages of simple machining, convenience to demold and lower cost.

Owner:成都联科航空技术有限公司

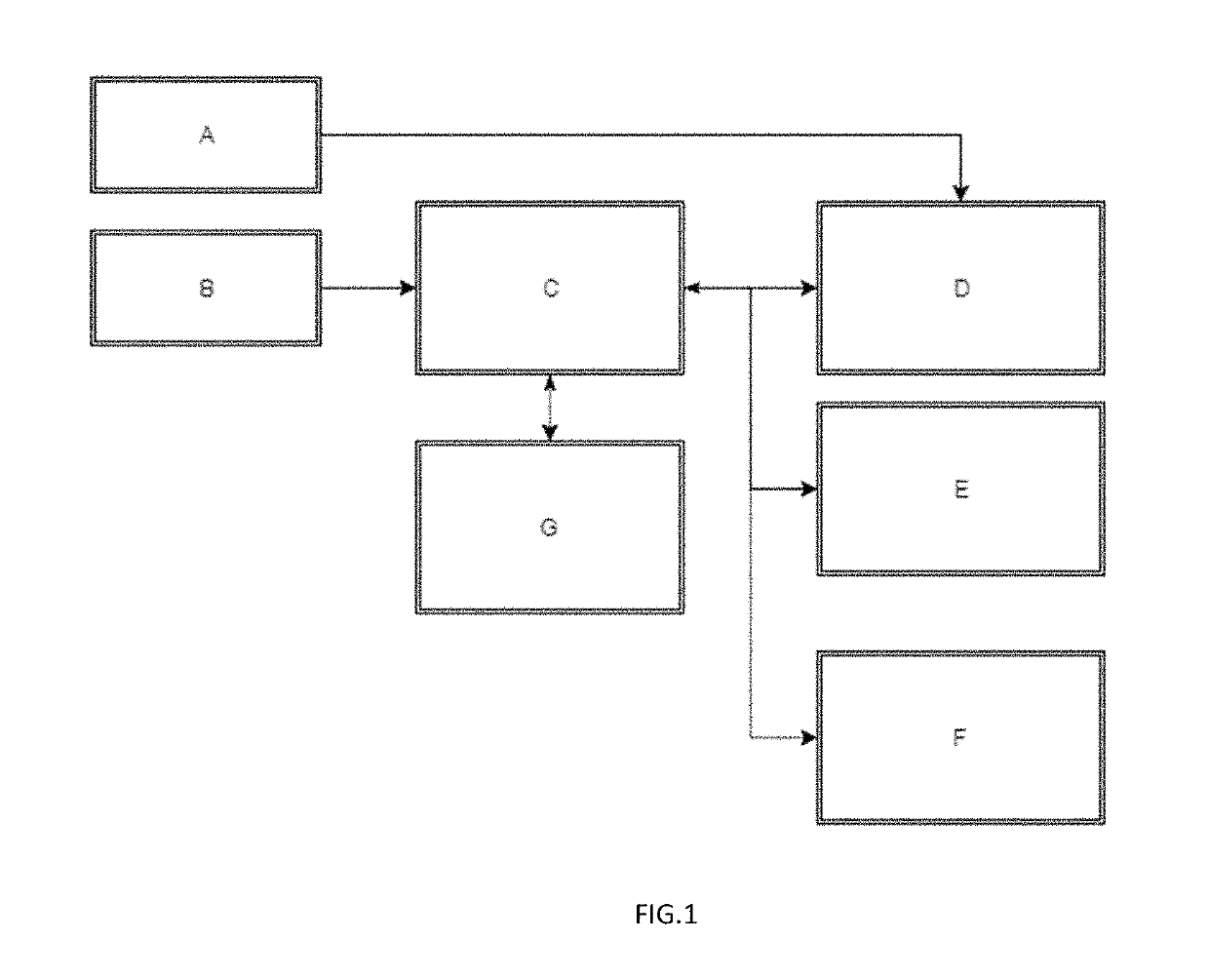

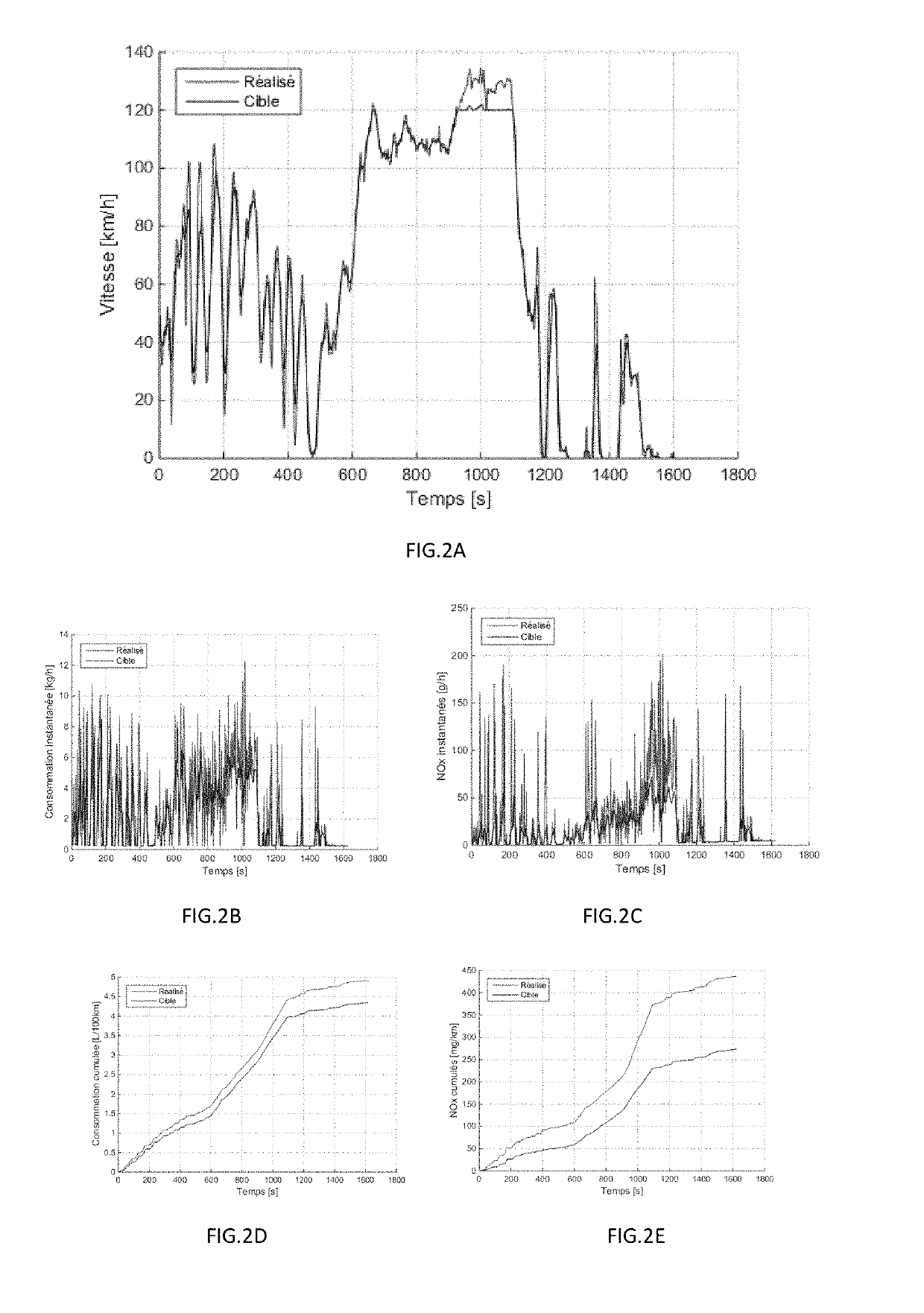

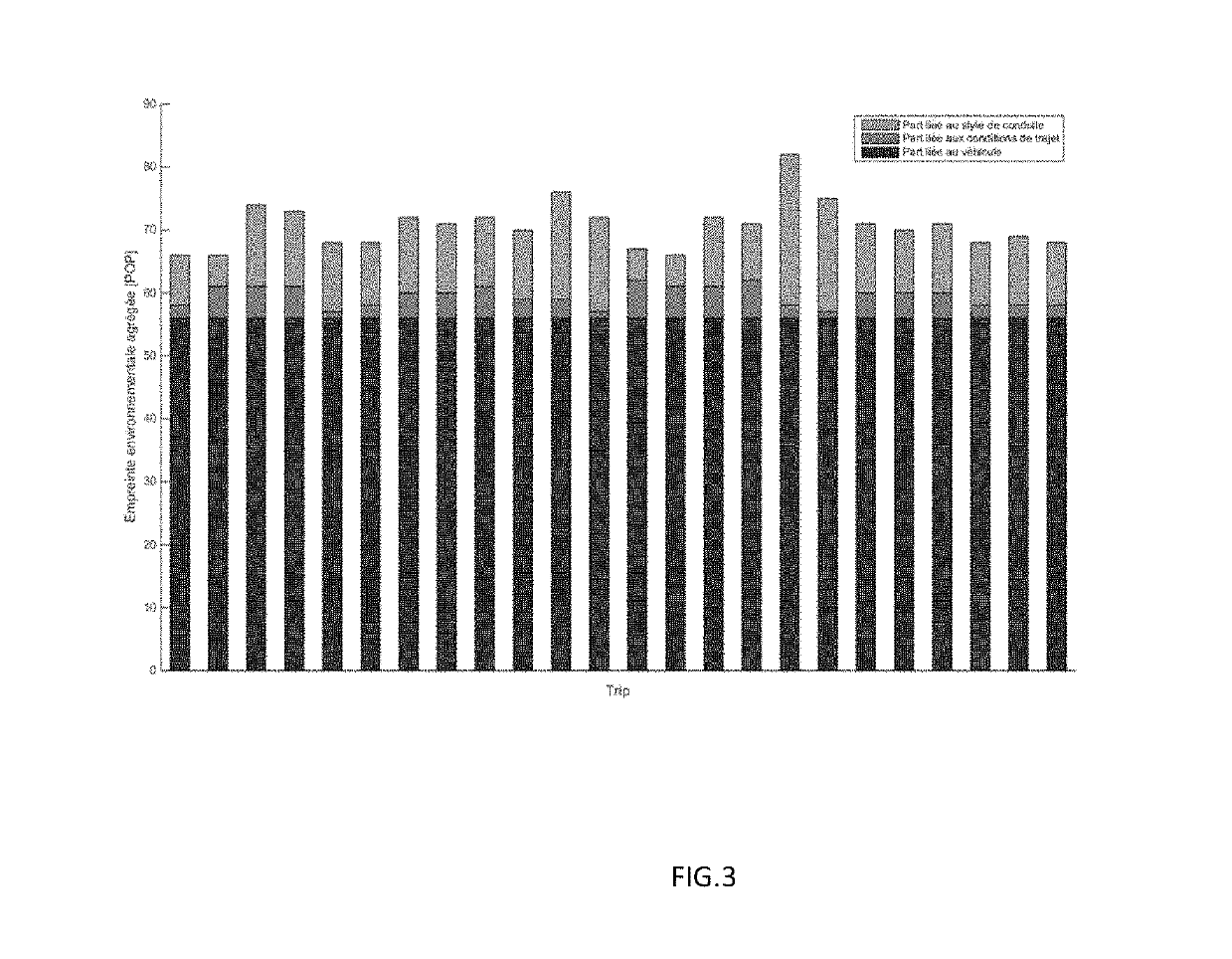

Method for determining indicators regarding the polluting nature of mobility taking real usage into account

ActiveUS20190102960A1Instruments for road network navigationElectrical controlMobile vehicleEnvironmental effect

The invention is a method for determining indicators of pollution from overall mobility of a user, comprising detecting trips in soft modes of transport and trips in motorized vehicles by use of a smart phone; determining a real environmental footprint linked to pollution emissions for each trip in a motorized vehicle by use of a model which estimates pollution emissions by accounting for macroscopic characteristics of the vehicle and a real speed profile representing the style of driving of the user; determining a target environmental footprint from each of the motorized vehicle trips by accounting for a target speed profile representing an optimal style of driving in the model for estimating pollution emissions; and breaking down the environmental footprint for each of the motorized vehicle trips into a footprint linked to the vehicle, and to a style of driving to a type of route and; determining an overall environmental footprint for the mobility of the user by accounting for all trips in soft modes of transport and trips in motorized vehicles over a given time interval, and determining at least one of driving indicators and environmental impact indicators for the user's overall mobility.

Owner:INST FR DU PETROLE

Damping force variable valve assembly and damping force variable shock absorber having the same

ActiveUS9447835B2Reduce back pressureOperating means/releasing devices for valvesSpringsMagnetic tension forceLow speed

Provided are a damping force variable valve assembly with a low-speed control valve capable of controlling an ultra-low flow rate and a low flow rate when a damping force variable valve operates in a soft mode, and a damping force variable shock absorber including the damping force variable valve assembly. The damping force variable valve assembly, which is installed in a damping force variable shock absorber for adjustment of a damping force of the shock absorber, includes: a solenoid; a spool which is movable by the magnetic force of the solenoid; a spool guide which surrounds the spool; a main valve which is installed in a main passage formed in a valve body installed in the spool guide; a back pressure chamber which is provided in the rear of the main valve; a chamber forming body which forms the back pressure chamber.

Owner:HL MANDO CORP

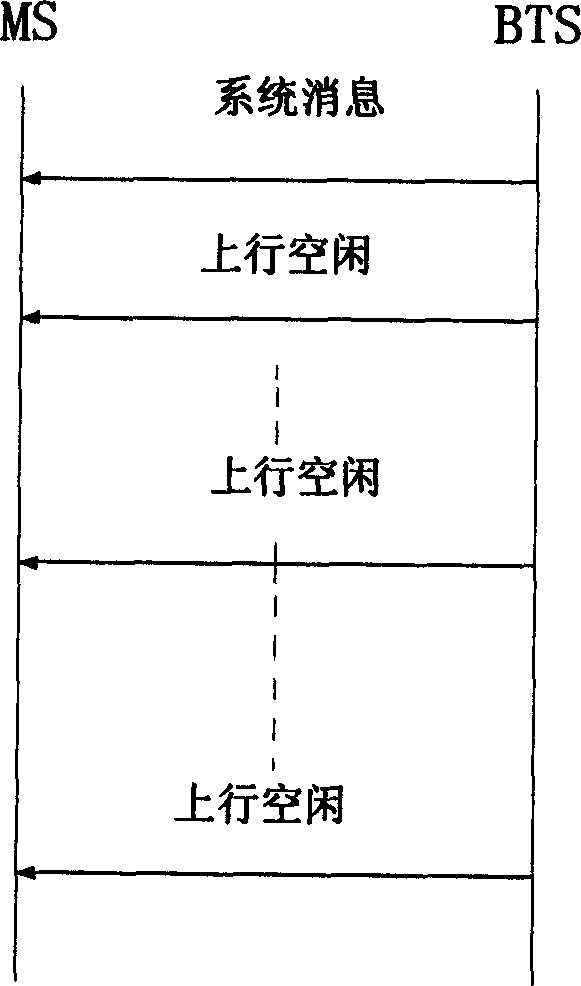

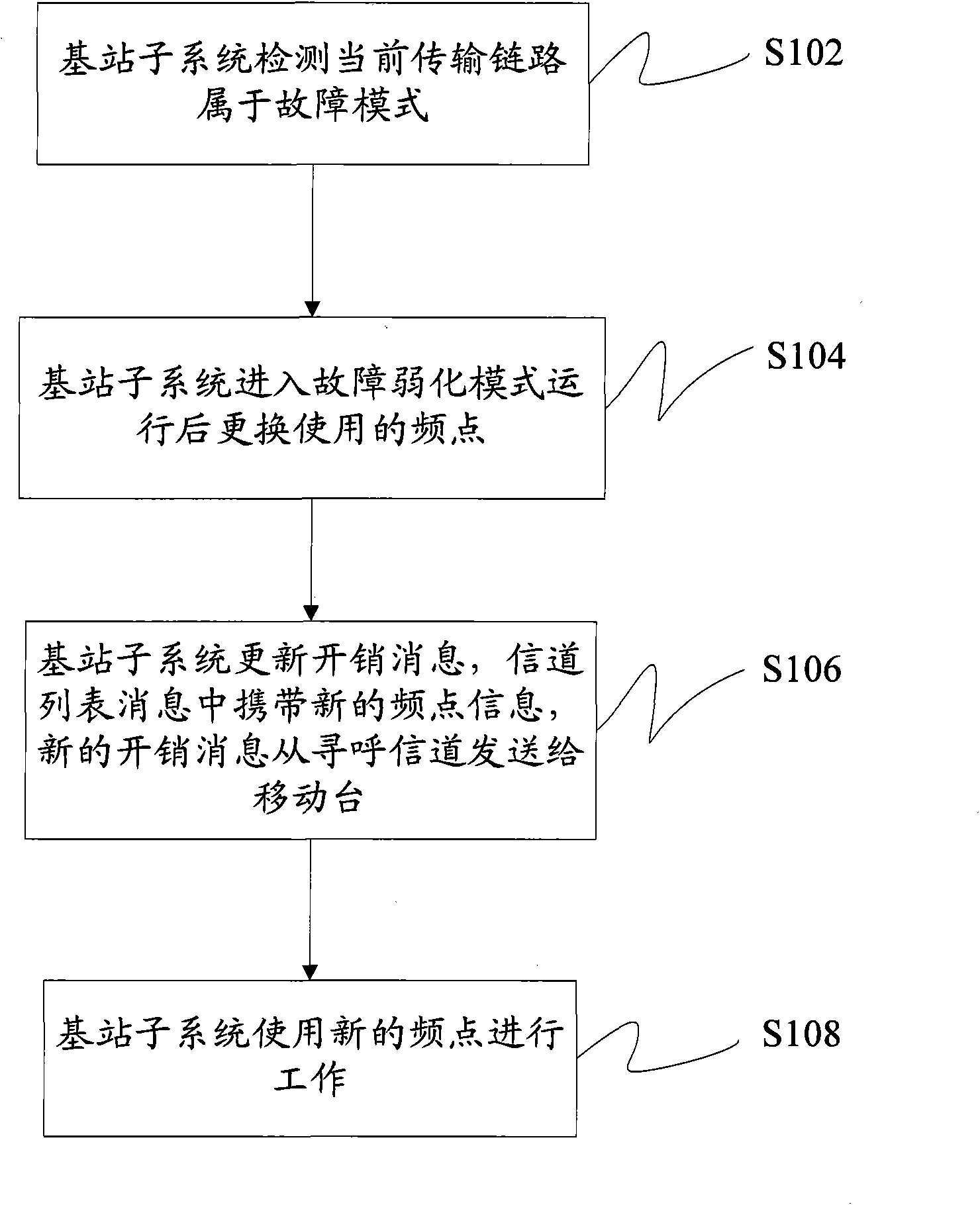

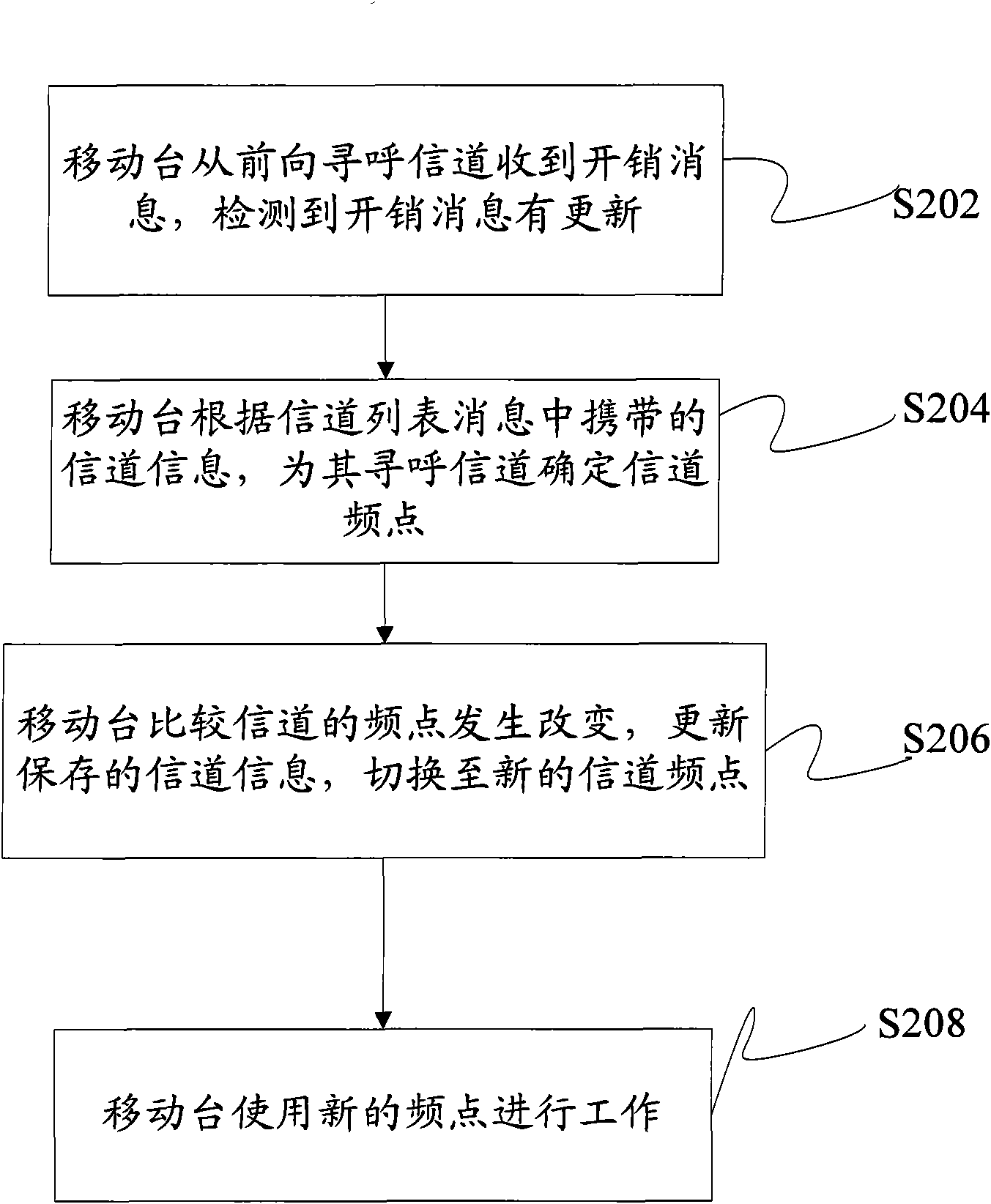

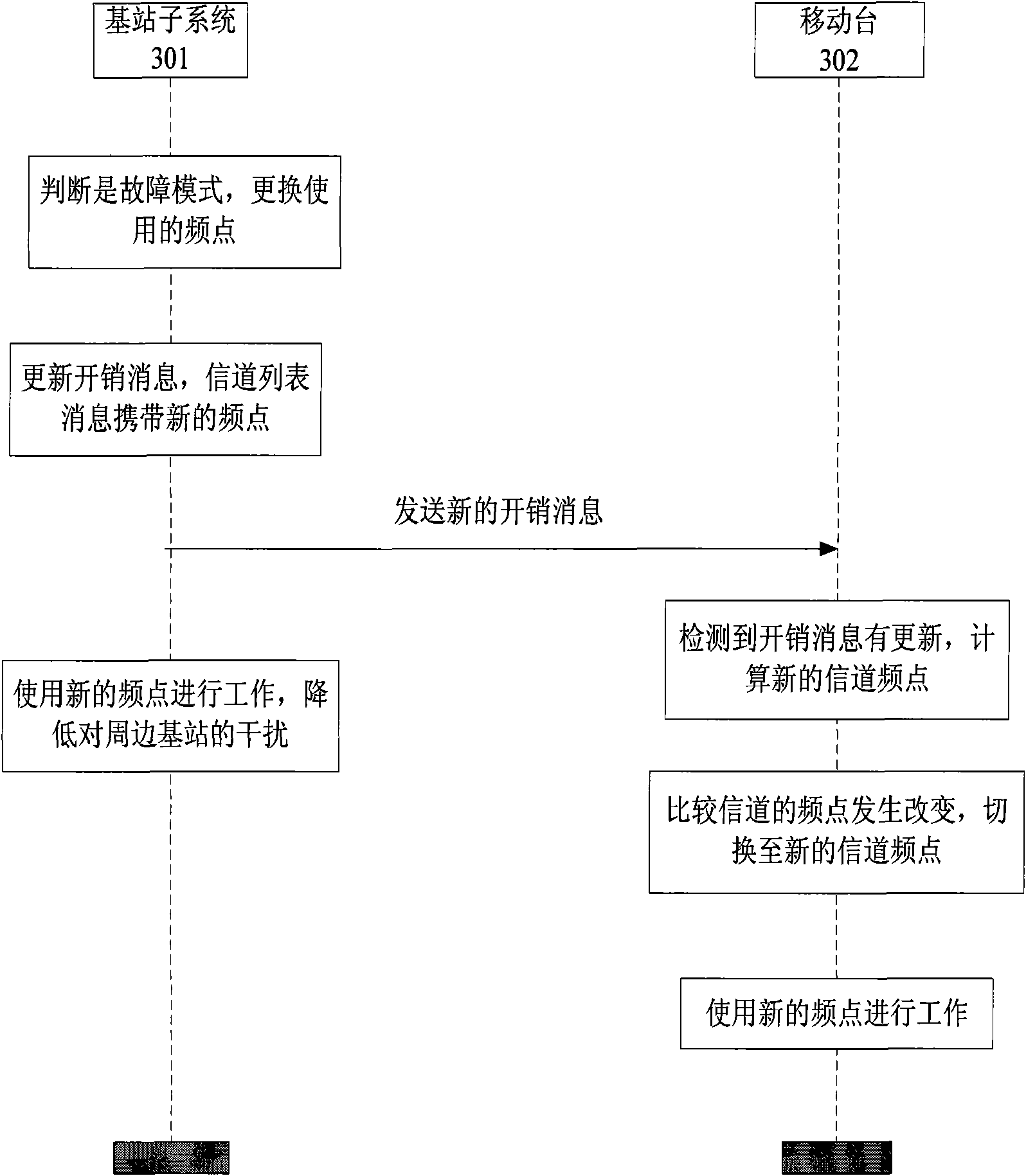

Method and system for reducing interference between base stations in fail-soft mode

InactiveCN102104925AReduce distractionsQuality improvementAssess restrictionCode division multiple accessBase station subsystem

The present invention discloses a method for reducing interference between base stations in a fail-soft mode, wherein the method is implemented in such a way that: a base station subsystem comes into running in the fail-soft mode when detecting that transmission link is in the fail-soft mode; the base station subsystem changes frequency point automatically after coming into the fail-soft mode; the base station updates and sends an overhead message; and a mobile station re-calculates a locked frequency point and locks to the new frequency point carried in a CDMA (Code Division Multiple Access) channel list message when detecting that the overhead message is updated. The invention also discloses a system for reducing interference between base stations in the fail-soft mode. The method and the system for reducing interference between base stations in the fail-soft mode can effectively reduce the interference between base stations in the fail-soft mode without influence on conversation quality of circumjacent base stations.

Owner:ZTE CORP

Intelligent upper limb rehabilitation training device

InactiveCN105287167ASimple structureAppropriate amount of rehabilitation trainingDiagnosticsChiropractic devicesHuman bodyMotion parameter

The invention discloses an intelligent upper limb rehabilitation training device. The device comprises a rack, a big arm unit, a small arm unit, a big arm driving motor, a small arm driving motor, a physical sign monitoring sensor and a controller. The intelligent upper limb rehabilitation training device is simple in structure and can perform rehabilitation training on the upper limbs of a human body, human body real-time health data collected by the physical sign monitoring sensor are transmitted to the controller, and the controller adjusts movement parameters of the upper limb rehabilitation training device based on current control parameters and the real-time health data, collected by the physical sign monitoring sensor, of the human body, so a patient makes rehabilitation training at an appropriate amount in a soft mode to achieve rehabilitation.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

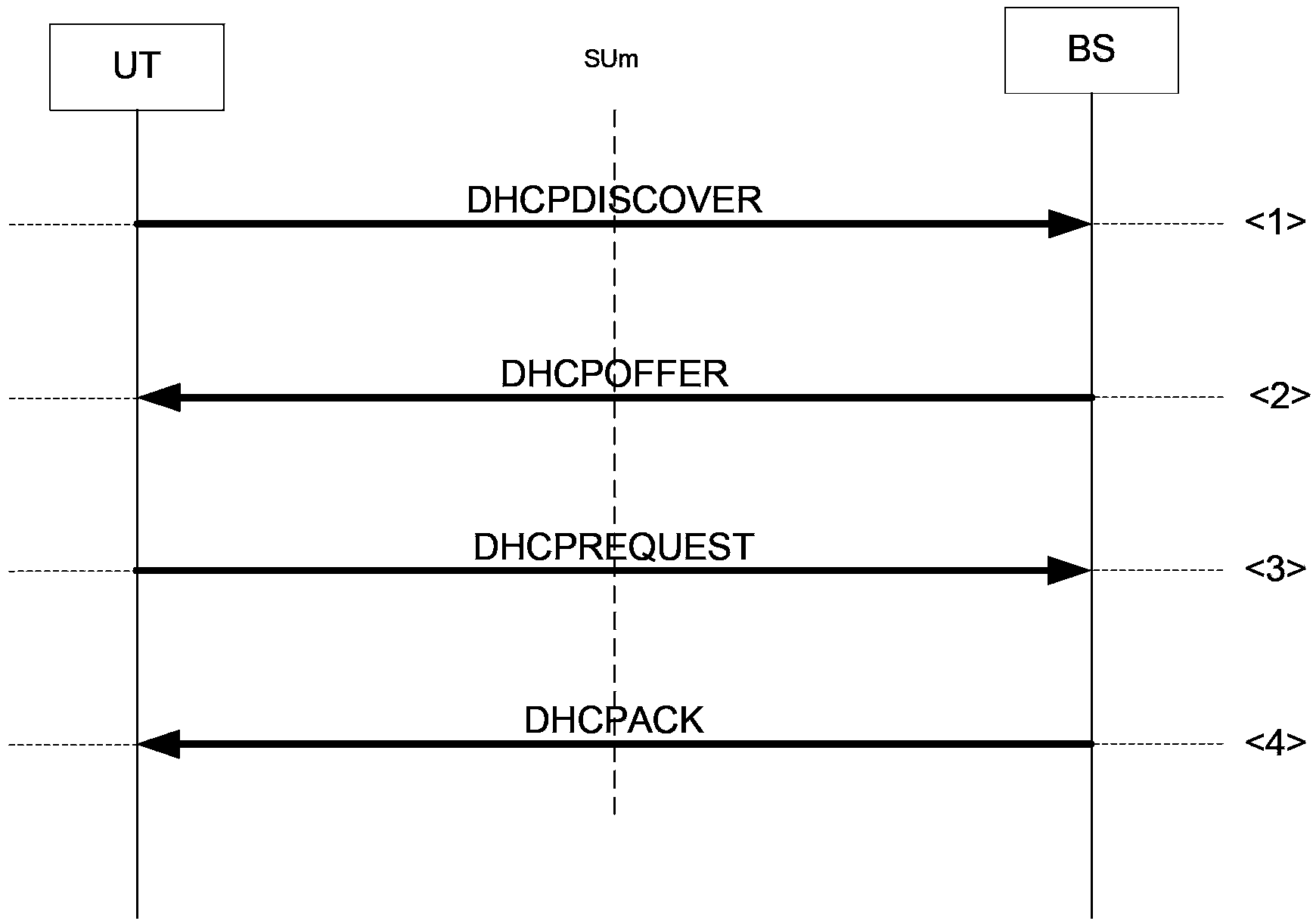

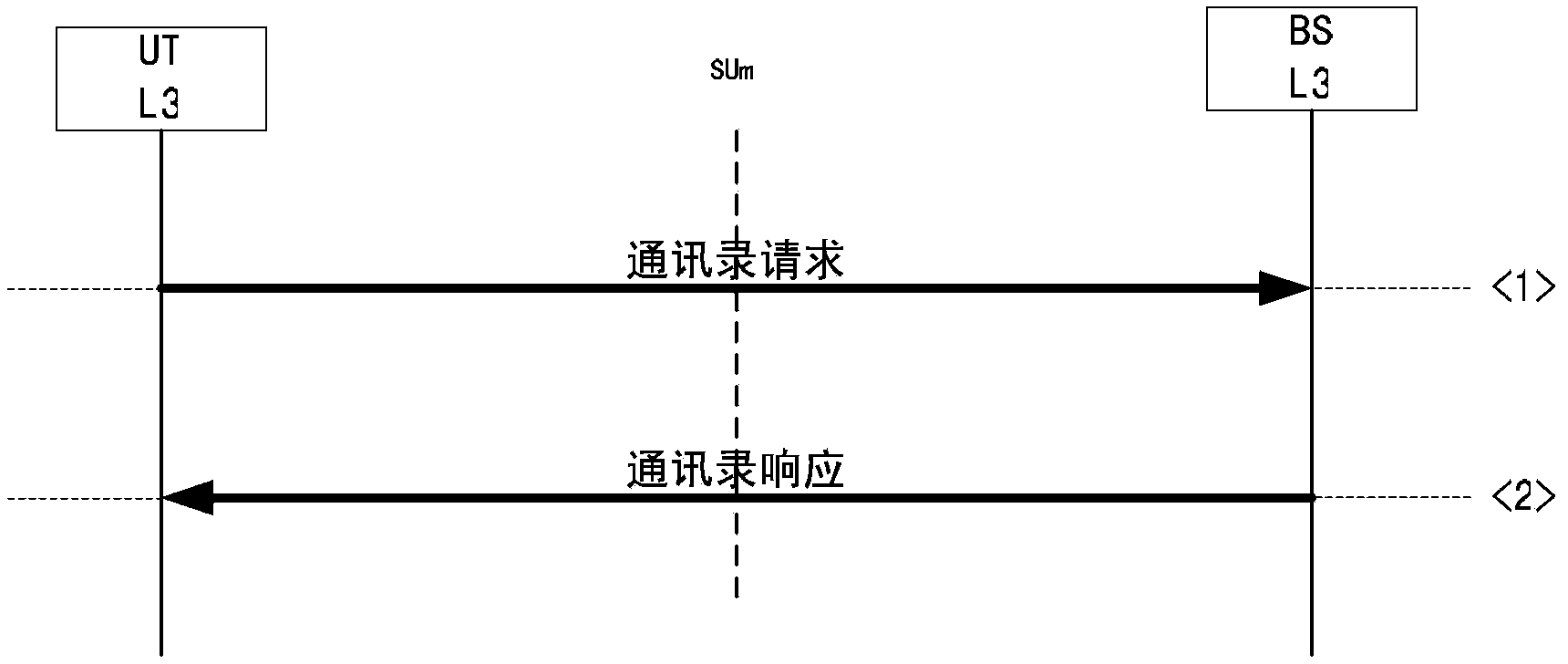

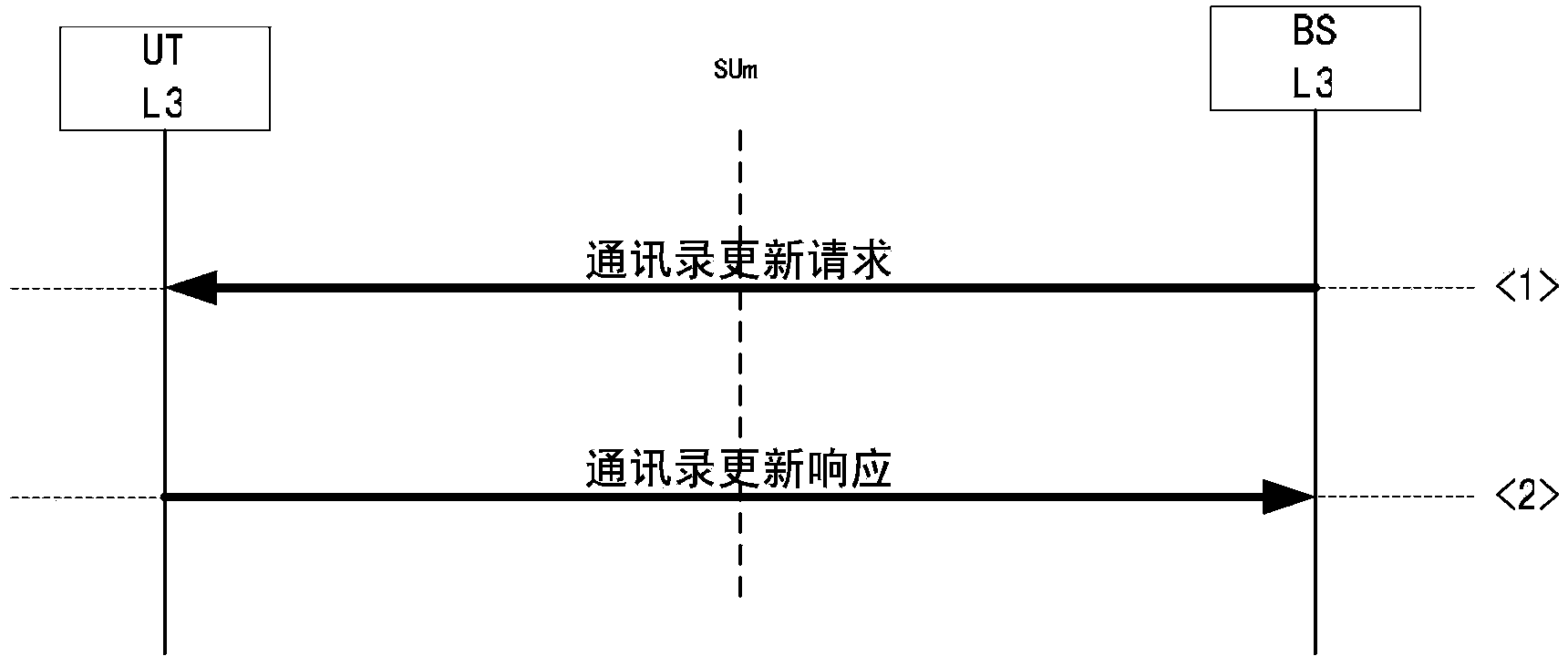

Method for achieving data services in base station fail soft mode

The invention provides a method for achieving data services in a base station fail soft mode. The method includes the following steps: (a) information of address books of all terminals under a base station is stored in the base station, wherein the information includes phone numbers, device identification and IP addresses, and the IP addresses of the newly-registered terminals are distributed by the base station; (b) after learning that the base station gets into the fail soft mode, the terminals initiatively obtain an address book list from the base station; (c) the calling terminals select the phone numbers of the called terminals in the address books and directly initiate the data services to the IP addresses corresponding to the phone numbers in the address books; (d) the base station transfers data packages of the data services to the corresponding terminals. By means of the method, the base station can distribute the IP addresses to the terminals in the fail soft mode, and the terminals can clearly obtain the information of all users within the coverage area of the base station and can carry out the data services according to the IP addresses of the users.

Owner:BEIJING XINWEI TELECOM TECH

Electronically controlled internal damper

ActiveUS20160221411A1Ride-comfort can be improvedReduce damping forceSpringsResilient suspensionsLow speedReciprocating motion

An electronically controlled internal damper is provided. Due to a structure in which a valve unit is mounted on a spool rod along which a driven spool reciprocates and a damping unit is provided in an outer peripheral surface of the driven spool and the spool rod, it is possible to improve ride comfort by reducing a low-speed damping force of a soft mode in the driven spool and the spool rod without increasing their sizes.

Owner:HL MANDO CORP

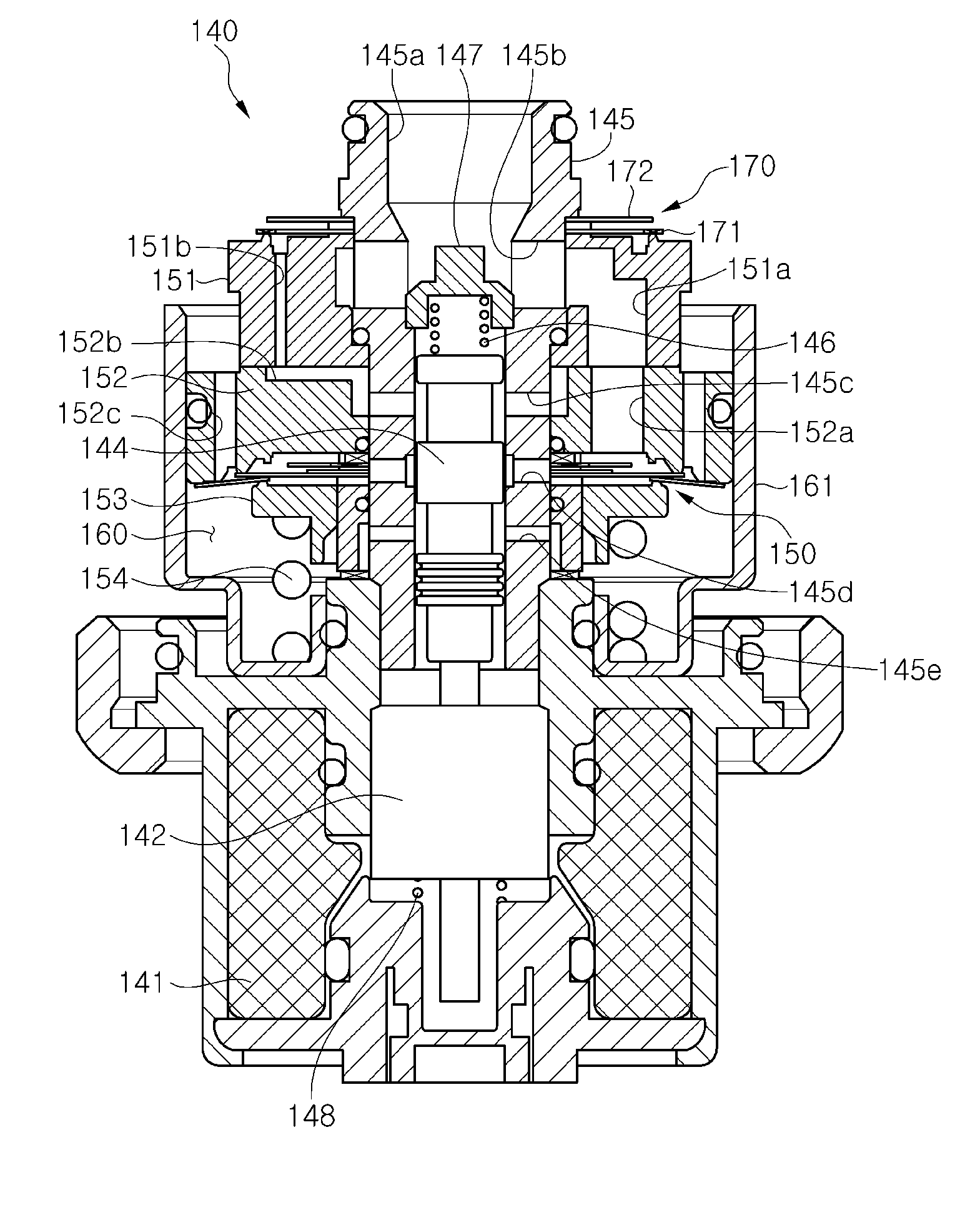

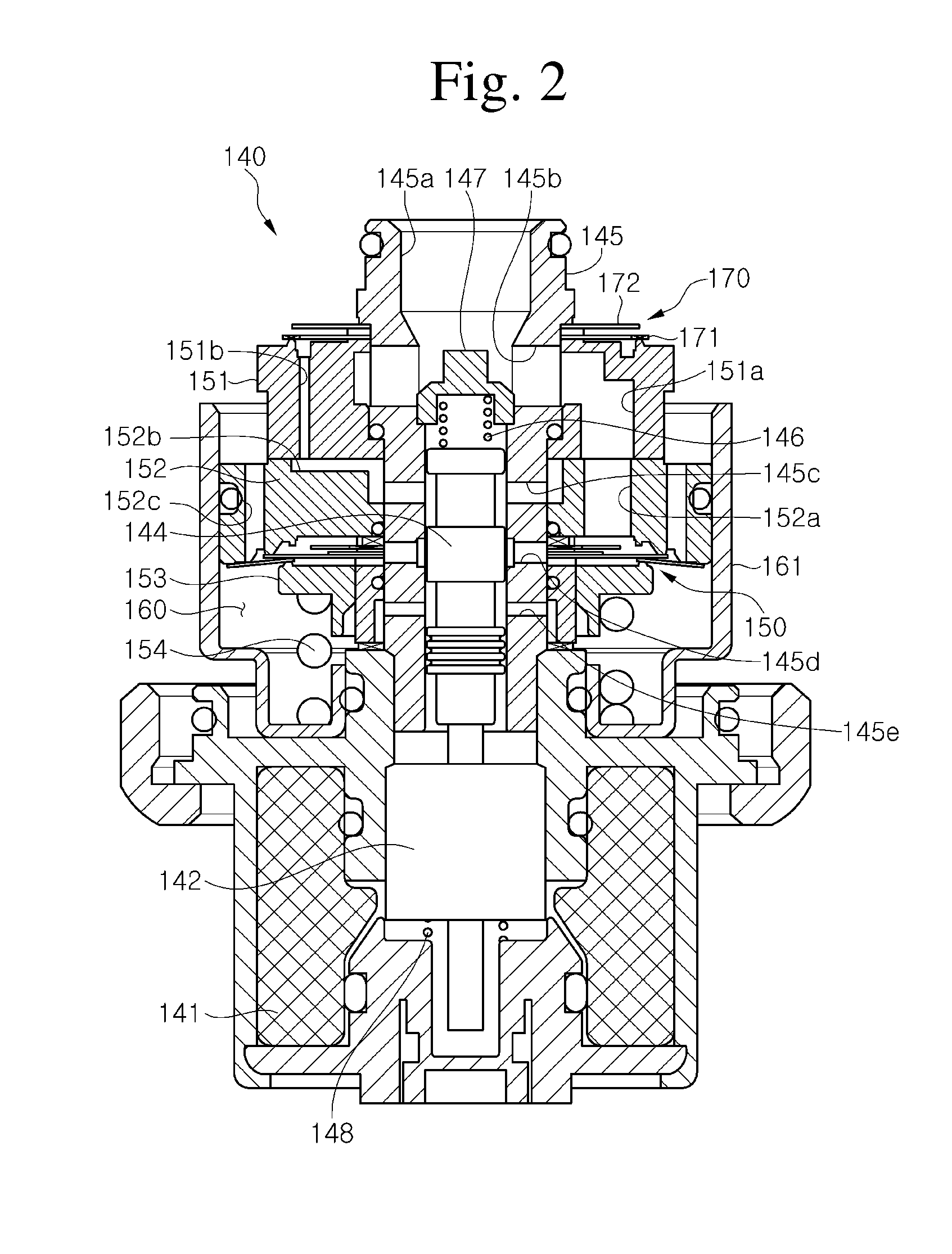

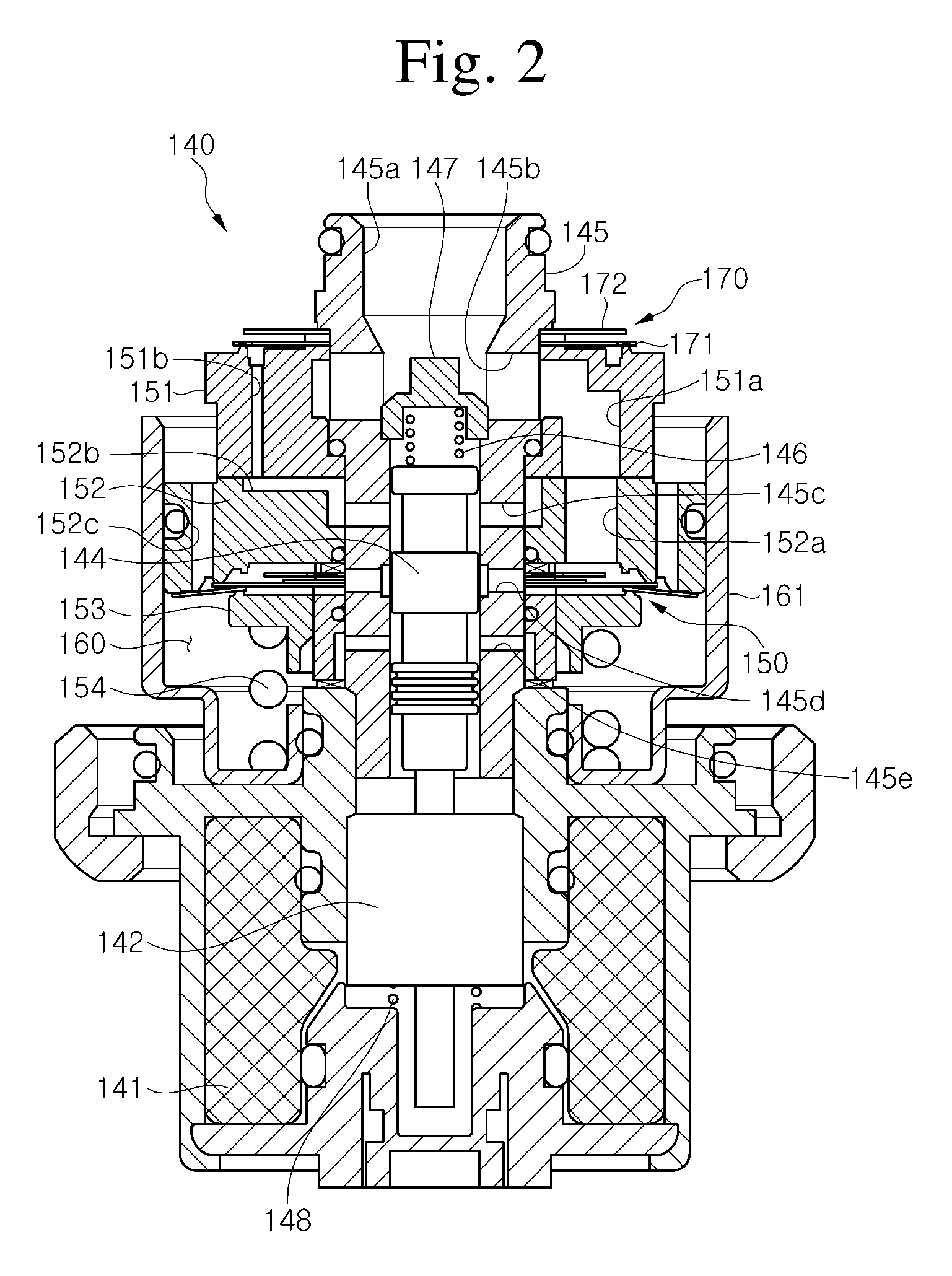

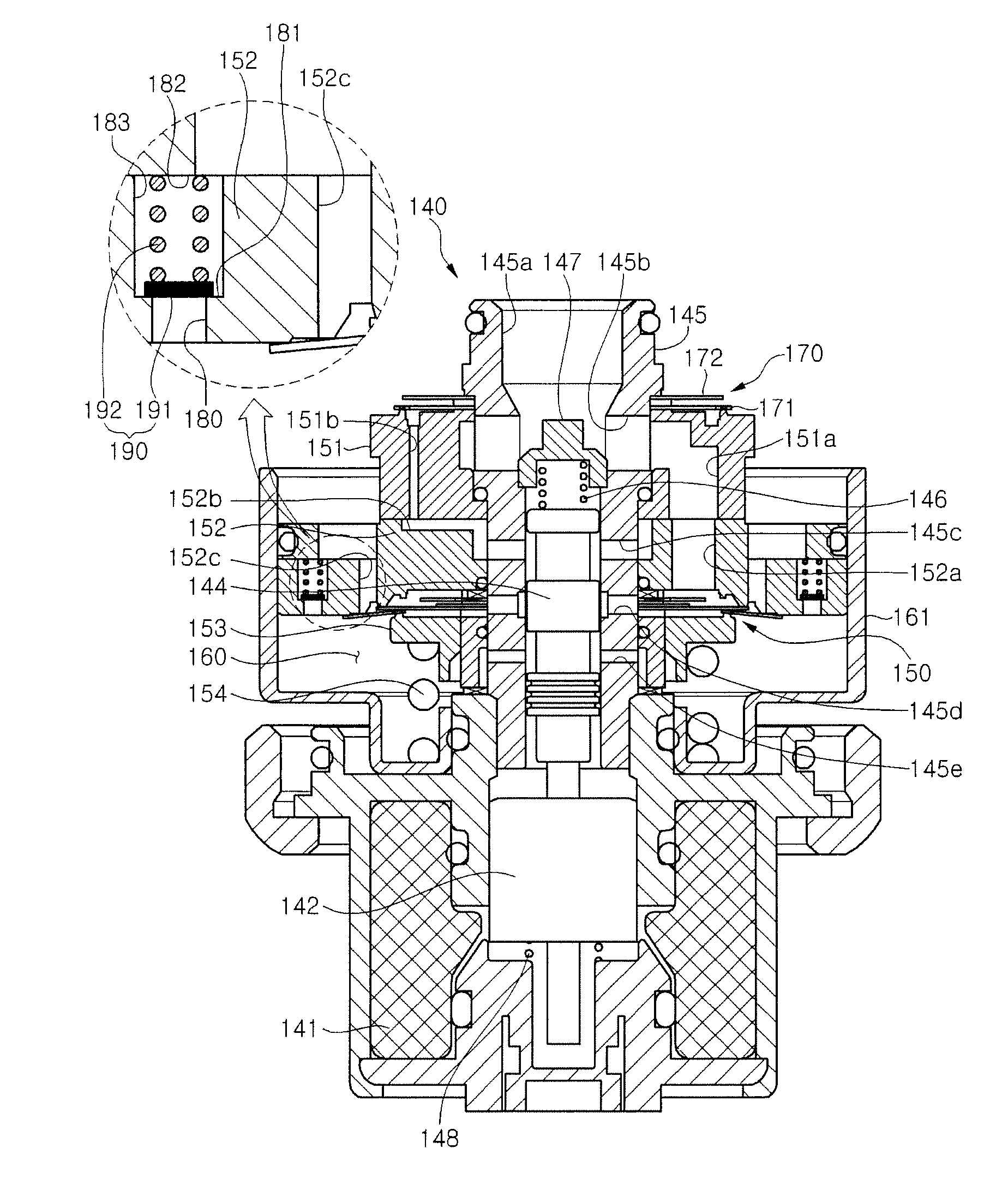

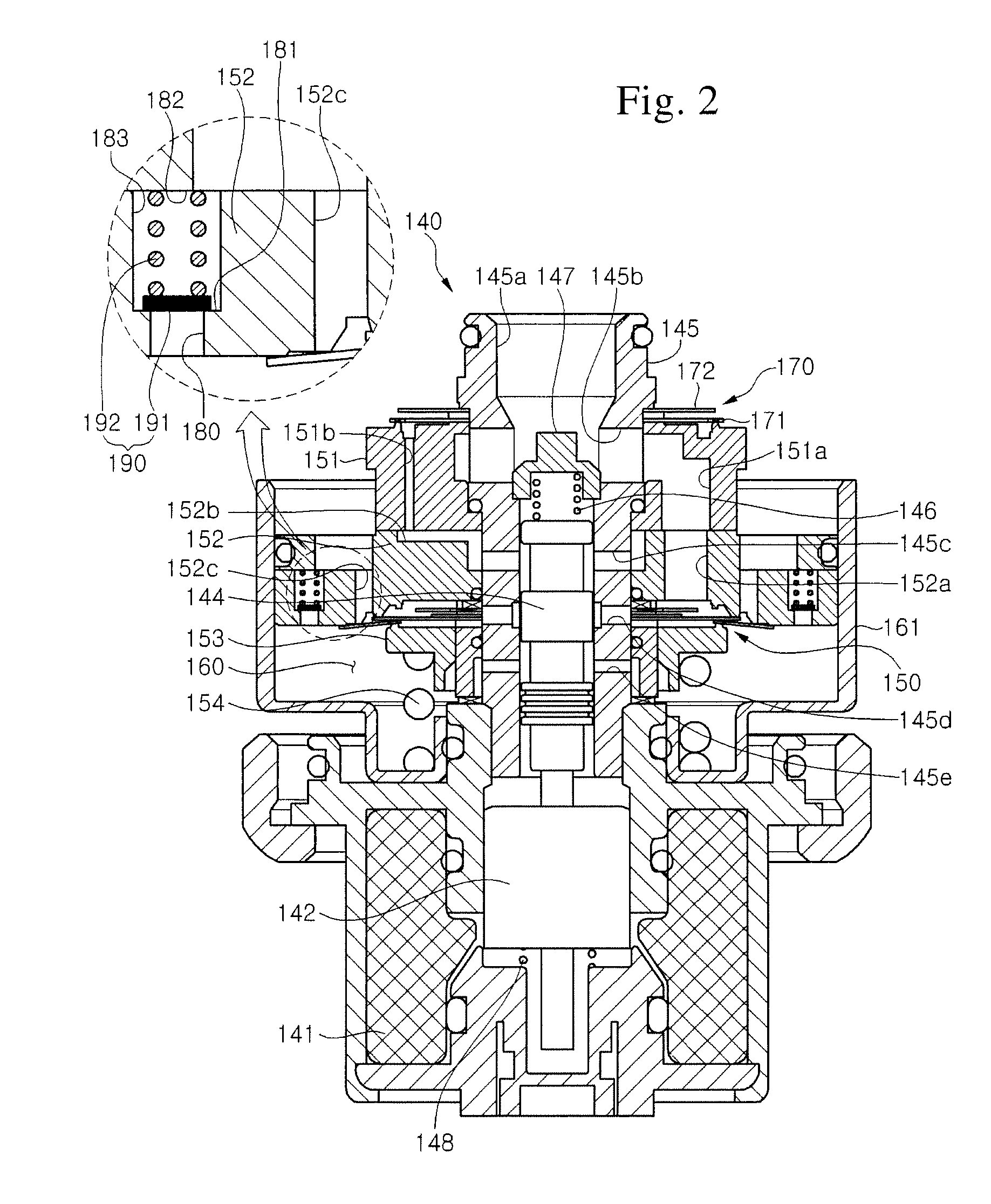

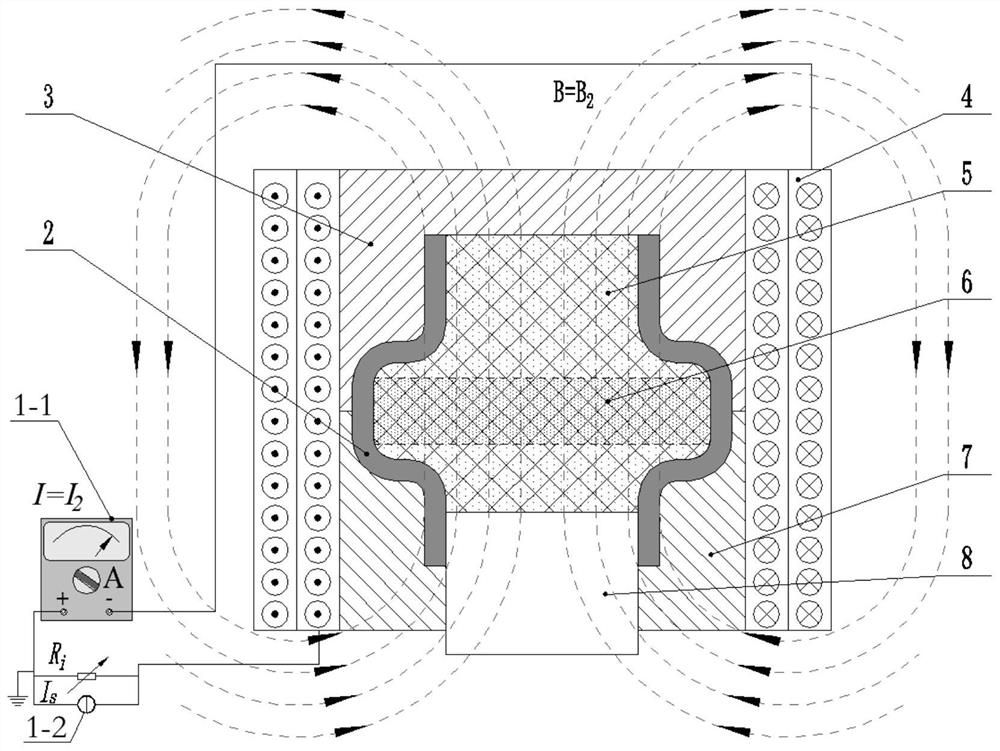

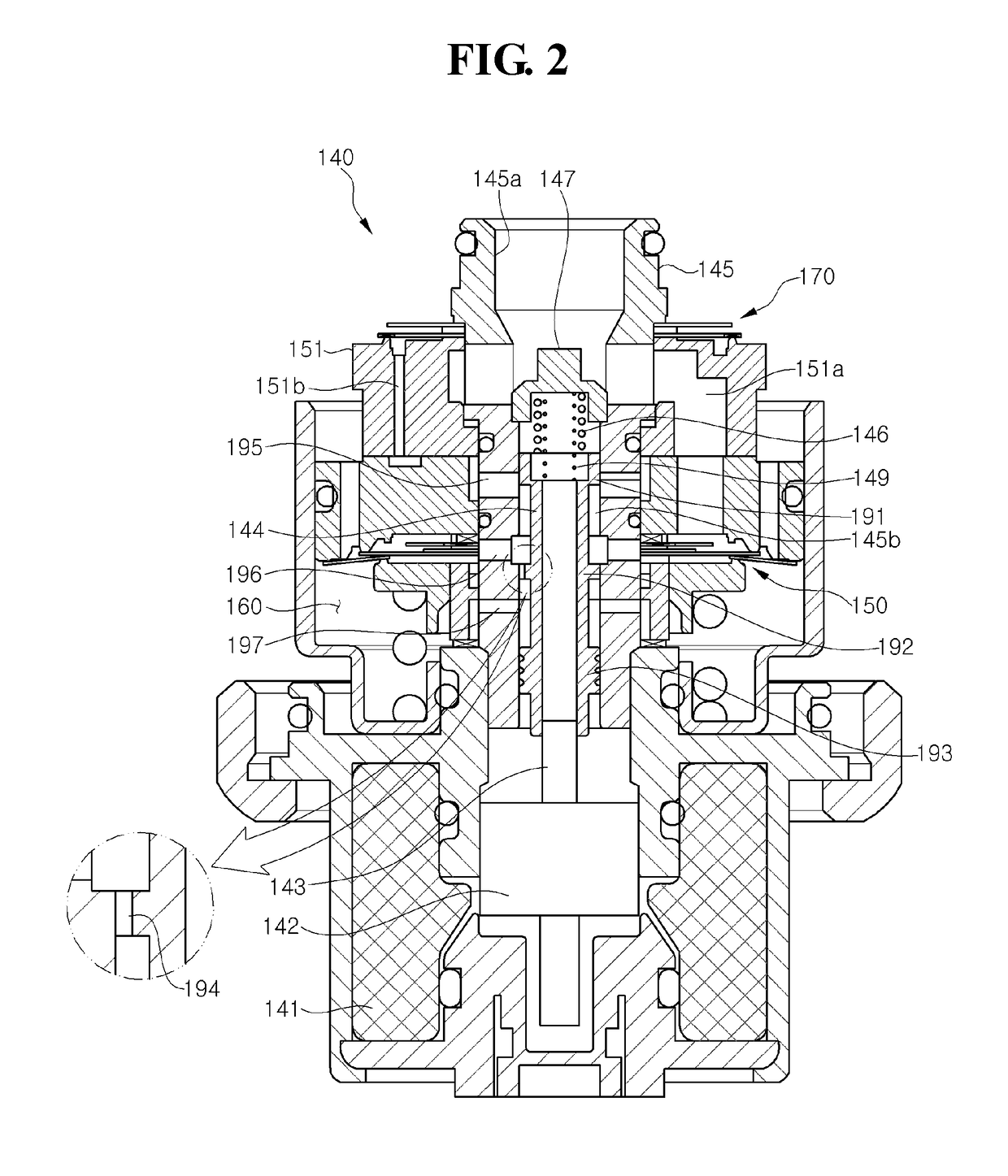

Damping force variable valve assembly

A damping force variable valve assembly includes a spool (144) which is moved by a magnetic force, a spool guide (145) which surrounds the spool (144), valve bodies (151, 152), a main valve (150), a back pressure chamber (160) which is formed at the back of the main valve (150), and an elastic opening / closing portion which is installed in the valve body to open and close a pressure adjustment passage (180) communicating the inside of the back pressure chamber (160) with the outside of the back pressure chamber (160). Due to the interaction between the spool (144) and the spool guide (145), the damping force of the shock absorber is variable between a hard mode in which the back pressure of the back pressure chamber (160) is increased and a soft mode in which the back pressure of the back pressure chamber (160) is decreased. In a case where a flow velocity of a working fluid is low in the hard mode, the elastic opening / closing portion opens the pressure adjustment passage (180) when an internal pressure of the back pressure chamber (160) exceeds a preset pressure.

Owner:HL MANDO CORP

Damping force variable valve assembly

ActiveUS20150316117A1SpringsSprings/dampers functional characteristicsInternal pressureWorking fluid

A damping force variable valve assembly includes a spool (144) which is moved by a magnetic force, a spool guide (145) which surrounds the spool (144), valve bodies (151, 152), a main valve (150), a back pressure chamber (160) which is formed at the back of the main valve (150), and an elastic opening / closing portion which is installed in the valve body to open and close a pressure adjustment passage (180) communicating the inside of the back pressure chamber (160) with the outside of the back pressure chamber (160). Due to the interaction between the spool (144) and the spool guide (145), the damping force of the shock absorber is variable between a hard mode in which the back pressure of the back pressure chamber (160) is increased and a soft mode in which the back pressure of the back pressure chamber (160) is decreased. In a case where a flow velocity of a working fluid is low in the hard mode, the elastic opening / closing portion opens the pressure adjustment passage (180) when an internal pressure of the back pressure chamber (160) exceeds a preset pressure.

Owner:HL MANDO CORP

Viscoelasto-plastic soft mode forming method of minor-radius corrugated surface thin-wall metal barrel part

ActiveCN101885018AInhibition of reboundImprove surface qualityHollow articlesPlastic materialsRoom temperature

The invention discloses a viscoelasto-plastic soft mode forming method of a minor-radius corrugated surface thin-wall metal barrel part, relating to a forming method of a minor-radius corrugated surface thin-wall metal barrel part. The invention is designed aiming at the problems that the metal corrugation barrel with smaller corrugation radius and higher material strength, which has thin wall thickness or with ultrathin wall thickness formed by steel mould stamping forming or hot-forming at room temperature, has even distribution of pressure acting on blank and can not adapt to stress variation in the deformation process, the wall thickness of the forming part is unevenly distributed, and the local area is easy to break. The method comprises the following key points of steps: forming an initial-level minor-radius corrugated surface thin-wall metal barrel blank, and comprises the following steps: manufacturing an initial-level forming die, coating release agent, manufacturing the mandrel, assembling the initial-level forming die and the mandrel, filling viscoelasto-plastic material, installing a piston and an overflow valve, adjusting pressure value, opening the die to take out the formed part, removing the viscoelasto-plastic material remained on the surface of the part, and replacing the forming die. The invention is used for forming the minor-radius corrugated surface thin-wall metal barrel part.

Owner:HARBIN INST OF TECH

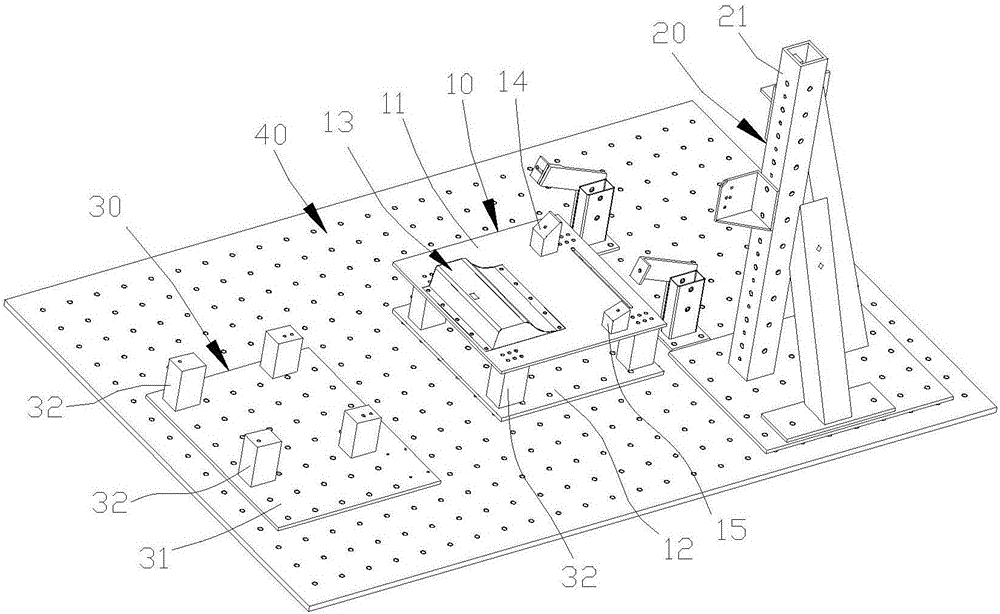

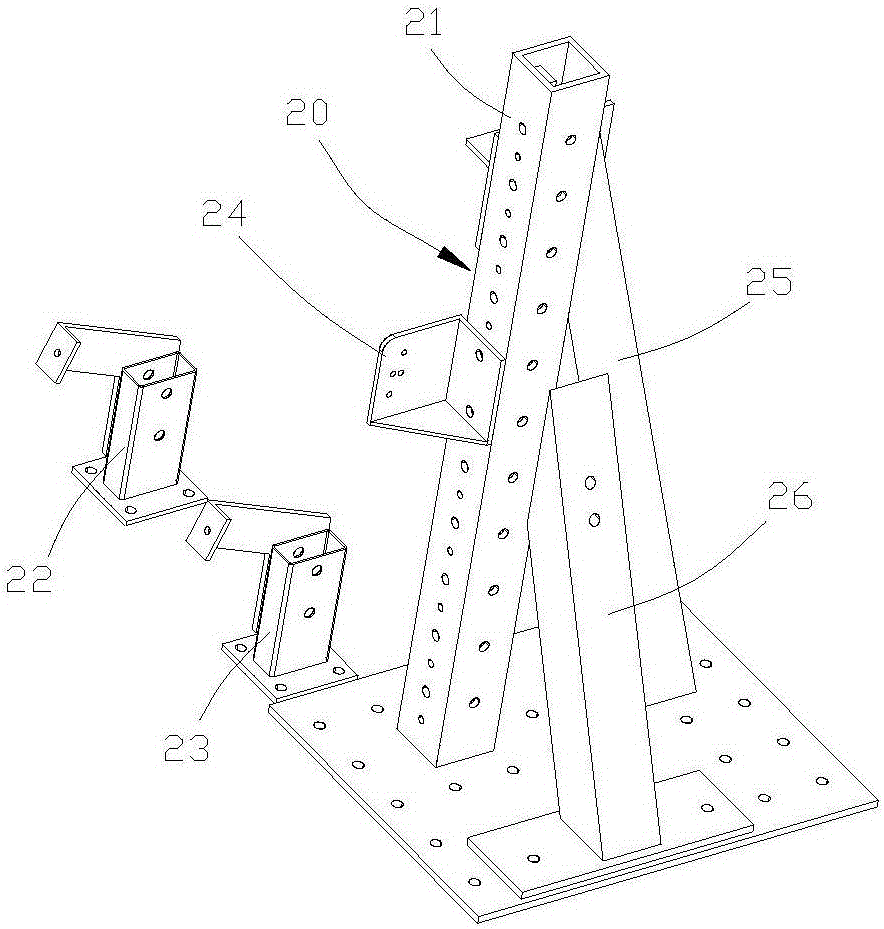

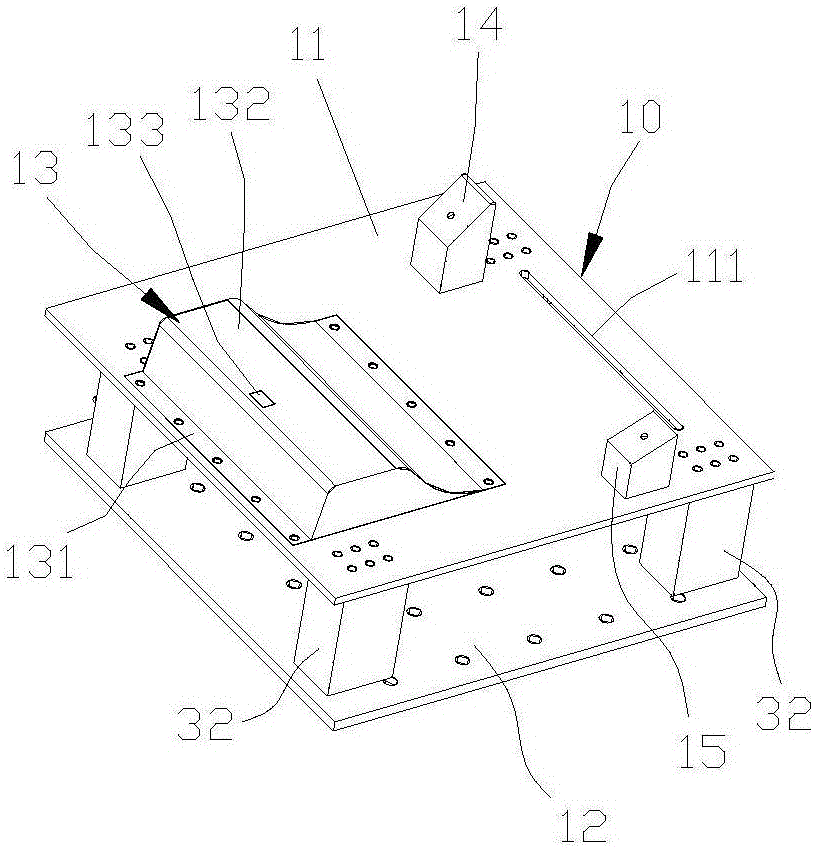

Automotive back seat restraint system test bed

InactiveCN106441931AReduce the risk of rectificationReduce development costsVehicle testingBack seat passengerSoftware engineering

The invention discloses an automotive back seat restraint system test bed, comprising a sliding table as well as a front seat fixing unit and a back seat fixing unit arranged on the sliding table, wherein a support assembly is arranged beside the back seat fixing unit, the back seat fixing unit comprises an upper bottom plate and a lower bottom plate fixed with the upper bottom plate, and an anti-dive plate, a lock catch installing rack and a safety belt fixing block are fixed on the surface of the upper bottom plate. By adopting the technical solution, the front and back seat fixing units and supporting assemblies are arranged on the sliding table, the position of a test dummy is adjusted to the relative state of a real automobile, the relative position of a back seat passenger space is guaranteed to be consistent with the design state, a passenger restraint system can be verified before a soft mode is started in the body, the matching problem of the restraint system and the design problem of parts are discovered in time at the early stage of automotive model development, the rectification risk of the soft mode body is reduced, and thus the development period is shortened and the development cost is reduced.

Owner:CHERY AUTOMOBILE CO LTD

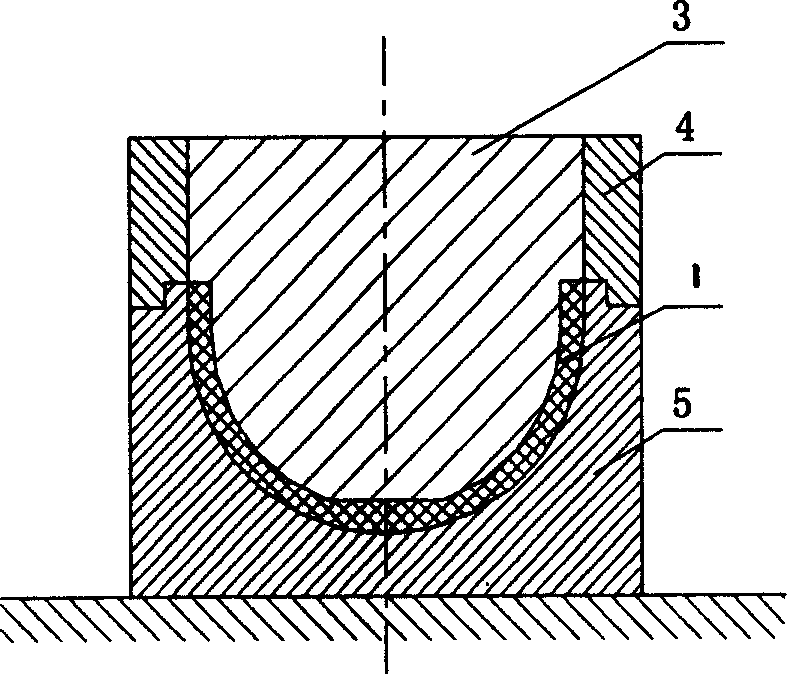

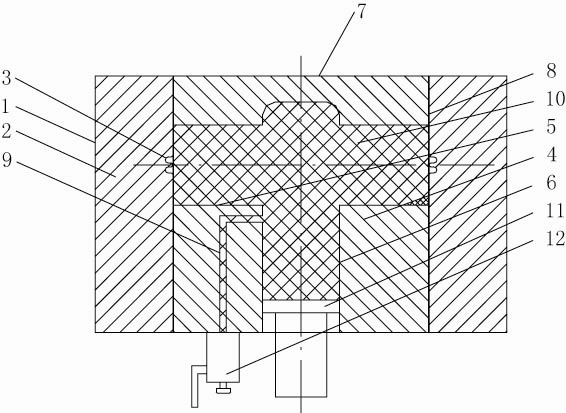

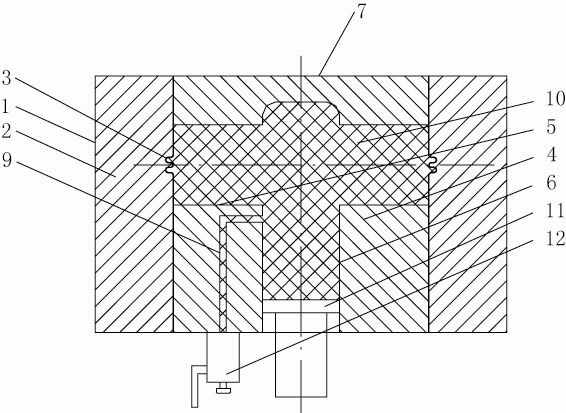

Composite conical section forming die pressurized by using soft die

ActiveCN112536946AConsistent dilatation pressureEliminate molding pressure lossDomestic articlesFiberForming processes

The invention discloses a composite conical section forming die pressurized by using a soft die. The forming die comprises a rubber soft die arranged between a die main body and a rigid outer die, andthe rubber soft die is used for pressurizing a composite prepreg section which corresponds to a flange thickening area and is laid on the die main body in the forming process. The rigid outer die isarranged at the exterior of the rubber soft die for limitation, and the inner side of the rubber soft die is a pressure relief surface, so that the expansion pressure of the soft die is consistent with the internal pressure of an autoclave; furthermore, the rubber soft die is formed by splicing circumferential sections, and forming pressure loss caused by internal tension of rubber in the pressingprocess is eliminated; and moreover, the inner side edge of the rubber soft die is located in the center of a wall thickness gradient area, so that a process boundary and a design boundary are staggered, and edge fiber buckling of the thickening area is avoided. In conclusion, the solid rubber soft die is designed for pressurization, and the problem that a large-wall-thickness corner position ofthe composite conical section is hard to compact is solved.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

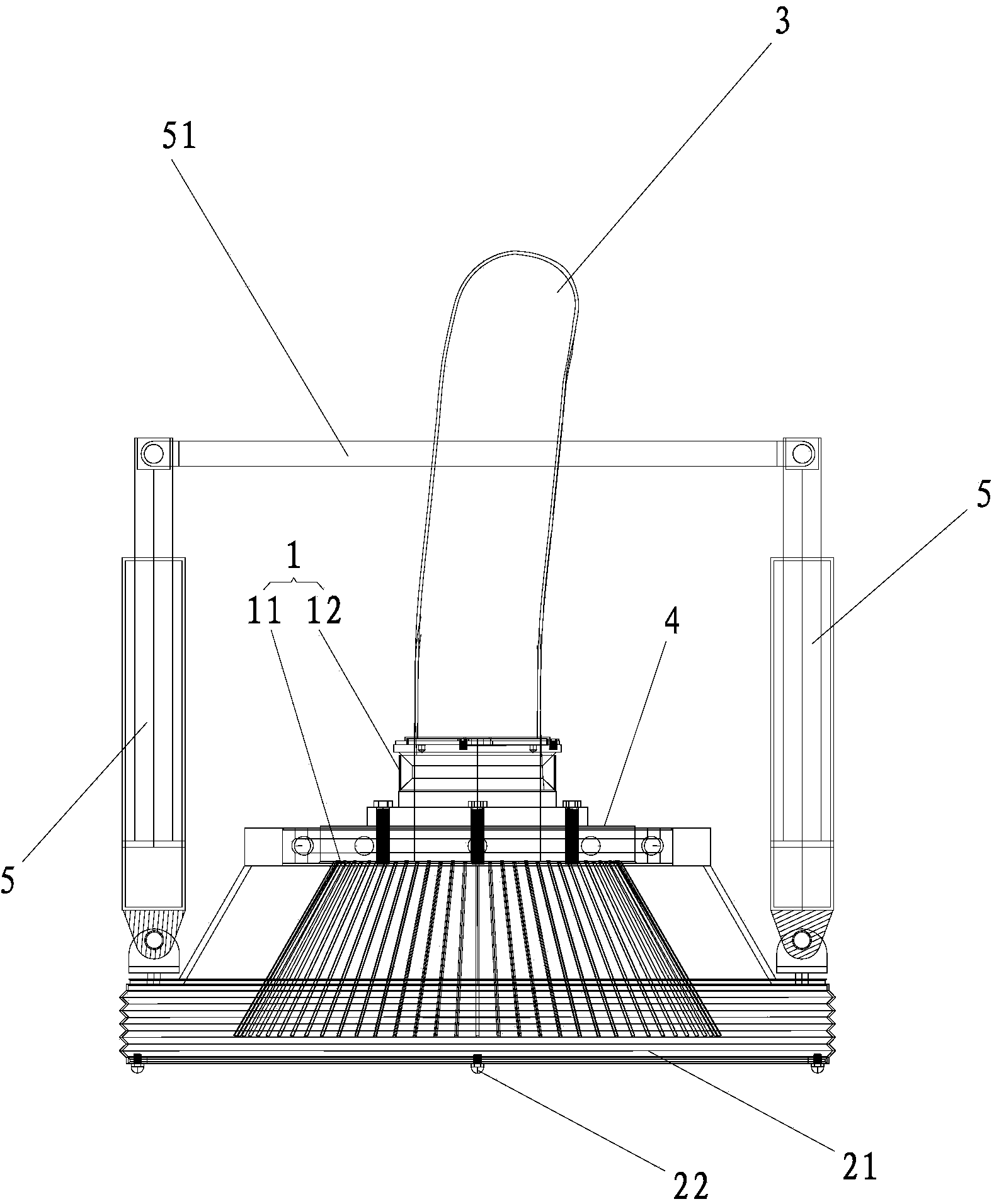

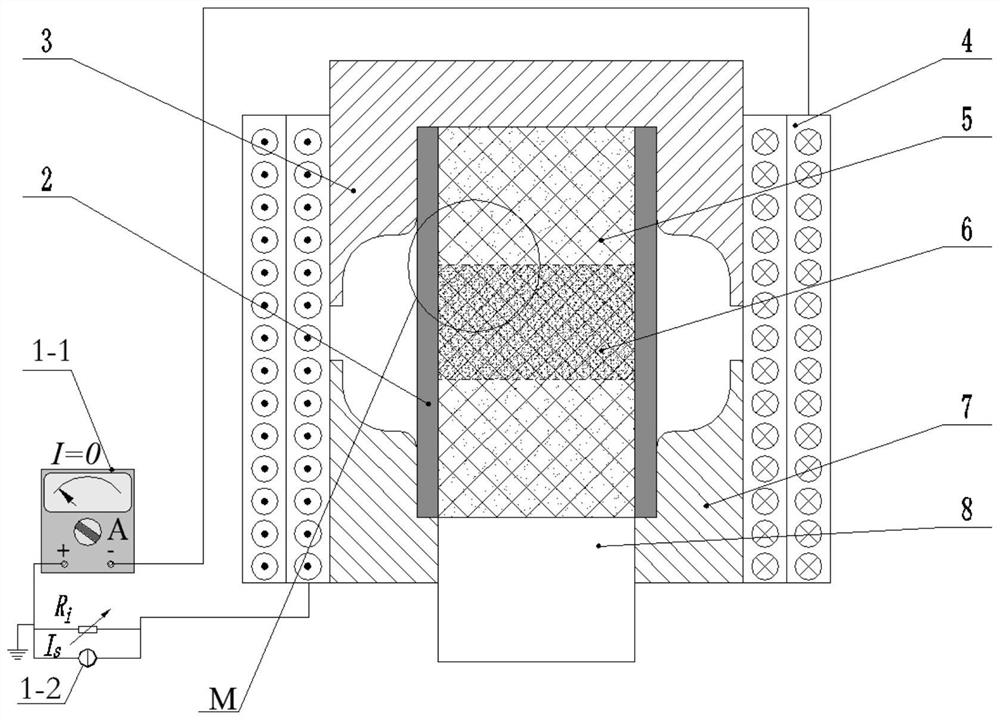

Reducing pipe fitting magneto-rheological elastic material soft die forming device and method

ActiveCN112547898AMeet different requirements of stiffnessImprove filling capacityPipe fittingEngineering

The invention provides a reducing pipe fitting magneto-rheological elastic material soft die forming device and method, and belongs to the field of pipe forming. The device comprises an upper die (3),a coil (4), a lower die (7) and a plunger (8), the coil (4) is arranged on the outer side of the upper die (3) and the outer side of the lower die (7), a cavity is formed between the upper die (3) and the lower die (7) and used for placing a pipe blank (2), the pipe blank (2) is filled with a heterogeneous magneto-rheological soft die which is divided into an upper portion, a middle portion and alower portion, the middle portion corresponds to a reducing portion of the pipe blank (2), the upper portion and the lower portion are made of an I-type magneto-rheological elastic material (5), themiddle portion is made of an II-type magneto-rheological elastic material (6), and the flow stress of the I-type magneto-rheological elastic material (5) is smaller than that of the II-type magneto-rheological elastic material (6) under the action of an external magnetic field. The method solves the problems that when a reducing pipe fitting is formed, the wall thickness of the vertex position ofthe reducing area of the pipe blank is reduced too much, and the reducing degree is limited.

Owner:HENAN UNIV OF SCI & TECH

Damping force variable valve assembly and damping force variable shock absorber including the same

ActiveUS20170211651A1Satisfactory steering performanceSatisfactory ride comfortOperating means/releasing devices for valvesSpringsSolenoid valveEngineering

The present disclosure relates to a damping force variable valve assembly, which is installed in a damping force variable shock absorber for adjustment of a damping force of the shock absorber, includes at least: a solenoid that generates a magnetic force when an electric current is supplied thereto; a plunger configured to be moved by the magnetic force of the solenoid; a spool that is moved together with the plunger and change a damping force between a hard mode and a soft mode by changing an inner passage of the damping force variable valve assembly; and a spool position determination member that locates the spool at a fail position, which does not correspond to the hard mode and the soft mode, so as to maintain the damping force of the shock absorber at a medium level between the hard mode and the soft mode upon fail of the solenoid.

Owner:HL MANDO CORP

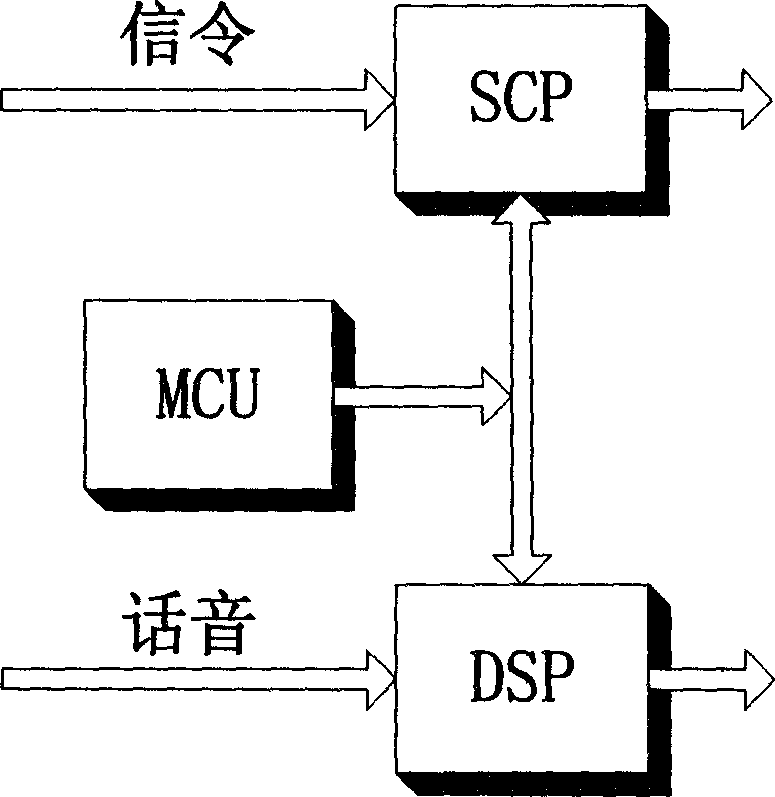

Voice service implementation method in fail soft mode of base station

InactiveCN104080037AReduce complexityReduce implementation complexityCommmunication supplementary servicesMessaging/mailboxes/announcementsComputer moduleService implementation

The invention provides a voice service implementation method in a fail soft mode of a base station. The method includes the steps that a voice service module is additionally arranged in the base station to be used for processing the voice service of a terminal after the base station enters into the fail soft mode, and processing includes terminal register and logout and voice calling service signaling processing. By the adoption of the method, terminal calling under the base station can be received continuously in the fail soft mode of the base station, the terminal voice service process is simplified according to the fail soft characteristic, and the implementation complexity of the voice service module is lowered.

Owner:BEIJING XINWEI TELECOM TECH

Magnetorheological fluid soft die forming method and device for deep-cavity thin-wall component

The invention discloses a magnetorheological fluid soft die forming method and device for a deep-cavity thin-wall component, and belongs to the technical field of plate forming. According to the geometrical characteristics of a component needing to be formed, a plurality of iron core pieces and non-magnetic steel pieces are combined into an upper shape-following forming assembly and a lower shape-following forming assembly which are matched with configuration of the component, regional magnetic fields are divided according to the deformation characteristics of different positions of the deep-cavity thin-wall component, and magnetorheological fluid is endowed with the most suitable performance at the positions of different geometrical characteristics, and therefore, a stress state and a friction state required by the plate are provided, material flow is promoted, and forming of the deep-cavity thin-wall component is achieved. According to the method, the problems of complex regionalized magnetic field regulation and control procedures and high difficulty in regionalized soft die forming of the deep-cavity thin-wall component at present are solved, excessive reduction of the wall thickness in the forming process is relieved, the forming quality of the deep-cavity thin-wall component is improved. The method and the device are suitable for large-scale and large-batch continuous production and have a good application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Electronically controlled internal damper

ActiveUS9732819B2Improve sealingReduce stiffnessSpringsLiquid based dampersInternal pressureWorking fluid

An electronically controlled internal damper includes: a main passage formed by a working fluid flowing through a main piston; a pilot passage formed by a working fluid as much as a predetermined amount discharged from a first pilot chamber and a second pilot chamber so as to maintain internal pressures of the first pilot chamber and the second pilot chamber to a predetermined level when pressures of the first pilot chamber and the second pilot chamber are increased beyond the predetermined level; and a bypass passage formed by a working fluid passing through the compression retainer and the rebound retainer symmetrically disposed above and under the main piston and a plurality of holes formed transversely to a vertical length direction of a spool rod. Accordingly, the electronically controlled internal damper is capable of implementing damping performance in both a soft mode and a hard mode with a relatively simple structure and increasing sealing performance while reducing rigidity.

Owner:HL MANDO CORP

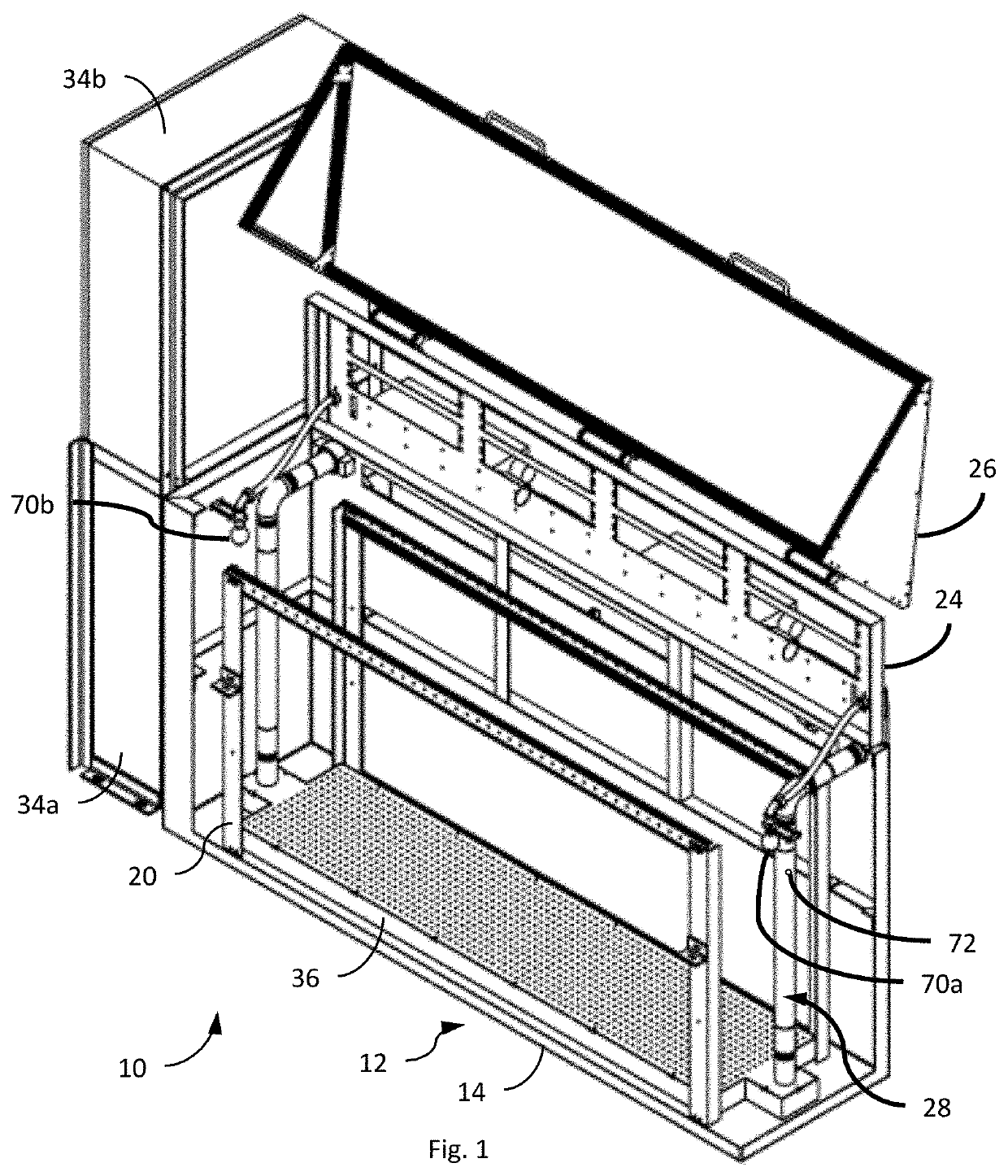

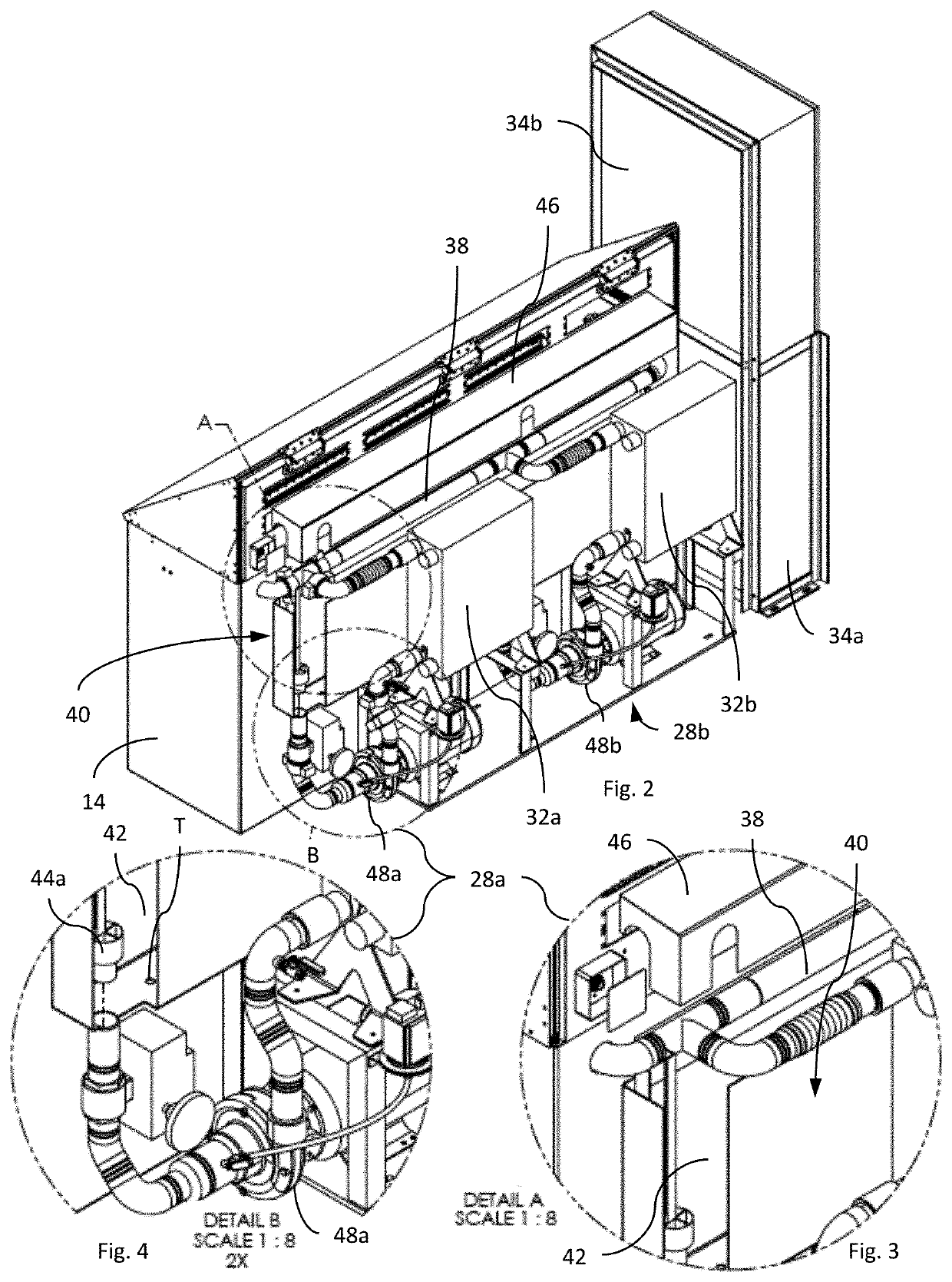

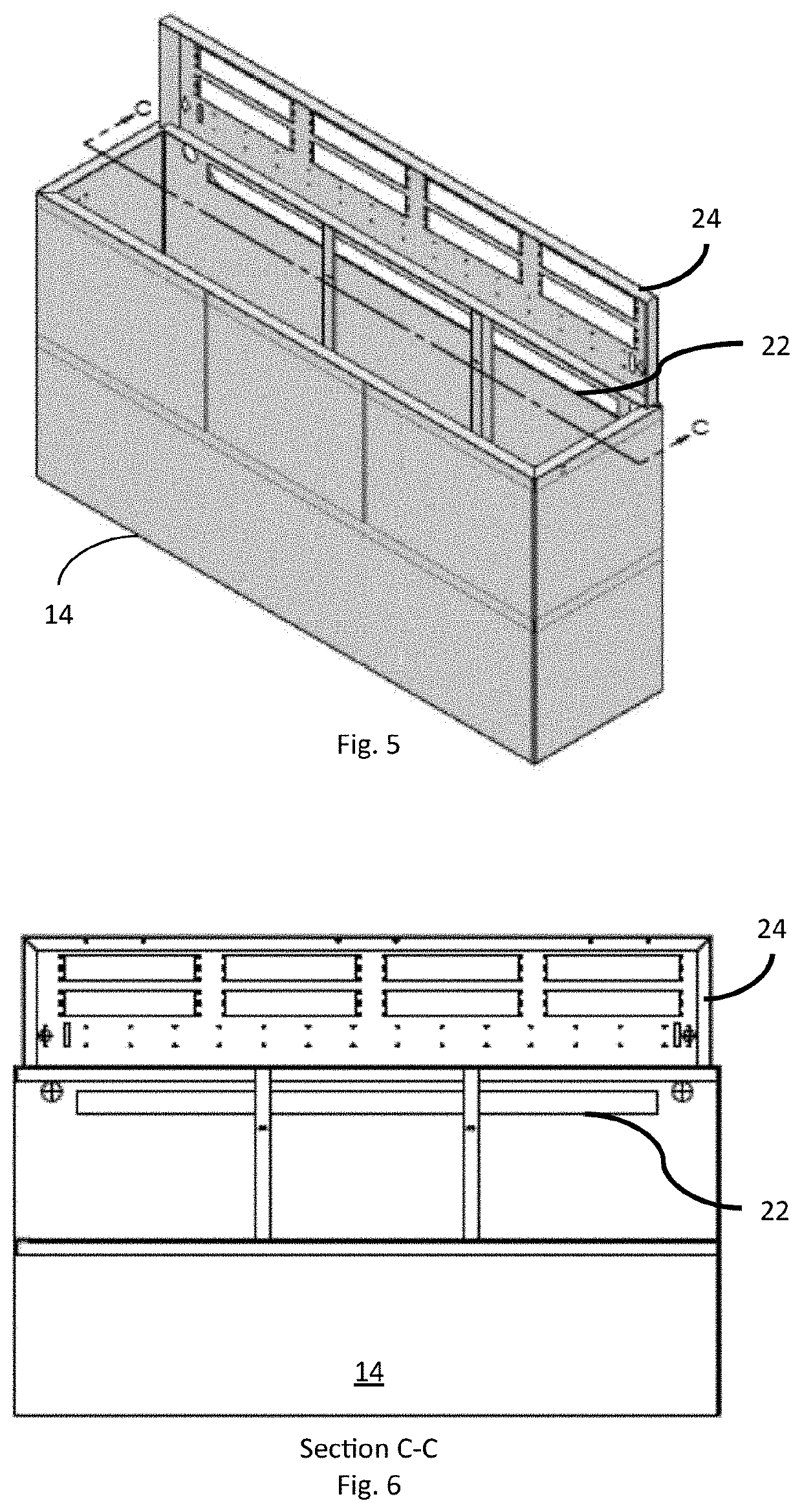

Appliance Immersion Cooling System

PendingUS20220104394A1Preventing numberCooling/ventilation/heating modificationsDielectricEngineering

A appliance immersion tank system comprising: a generally rectangular tank adapted to immerse in a dielectric fluid a plurality of appliances, each in a respective appliance slot distributed vertically along, and extending transverse to, the long axis of the tank; a primary circulation facility adapted to circulate the dielectric fluid through the tank; a secondary fluid circulation facility adapted to extract heat from the dielectric fluid circulating in the primary circulation facility, and to dissipate to the environment the heat so extracted; and a control facility adapted to coordinate the operation of the primary and secondary fluid circulation facilities as a function of the temperature of the dielectric fluid in the tank. A plenum, positioned adjacent the bottom of the tank, is adapted to dispense the dielectric fluid substantially uniformly upwardly through each appliance slot. A weir, integrated horizontally into a long wall of the tank, is adapted to facilitate substantially uniform recovery of the dielectric fluid flowing through each appliance slot. All active and most passive components of both the primary and secondary fluid circulation facilities, and the control facility are fully redundant, and are adapted automatically to operate in a fail-soft mode.

Owner:BOYD CHRISTOPHER L +6

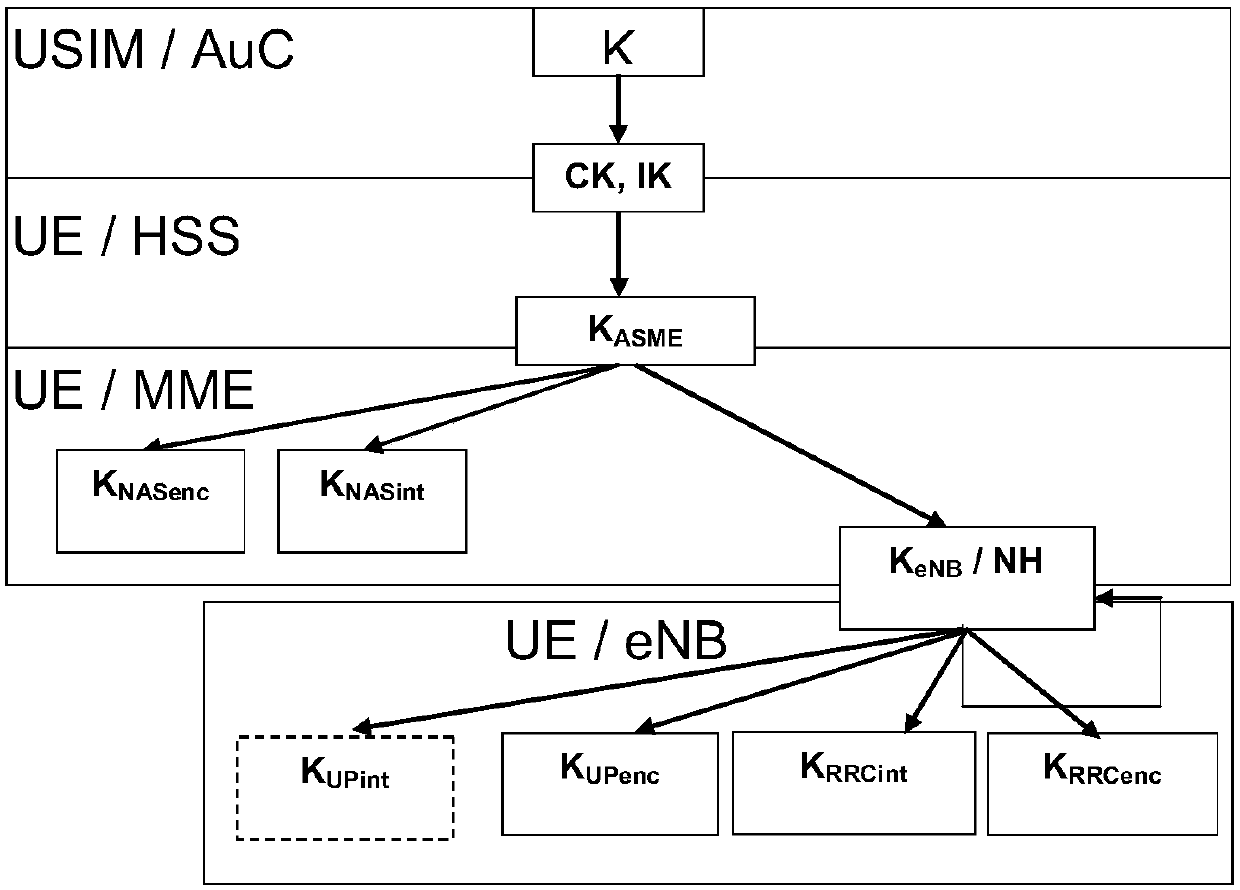

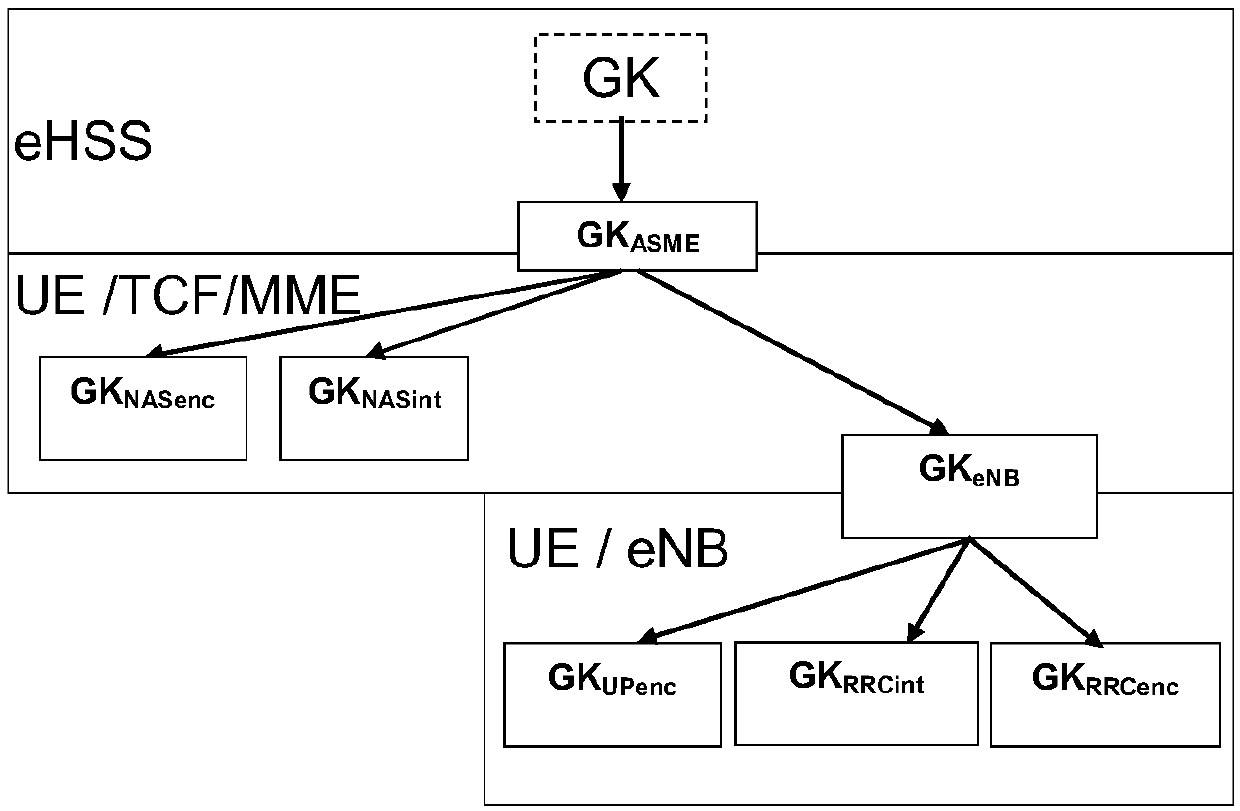

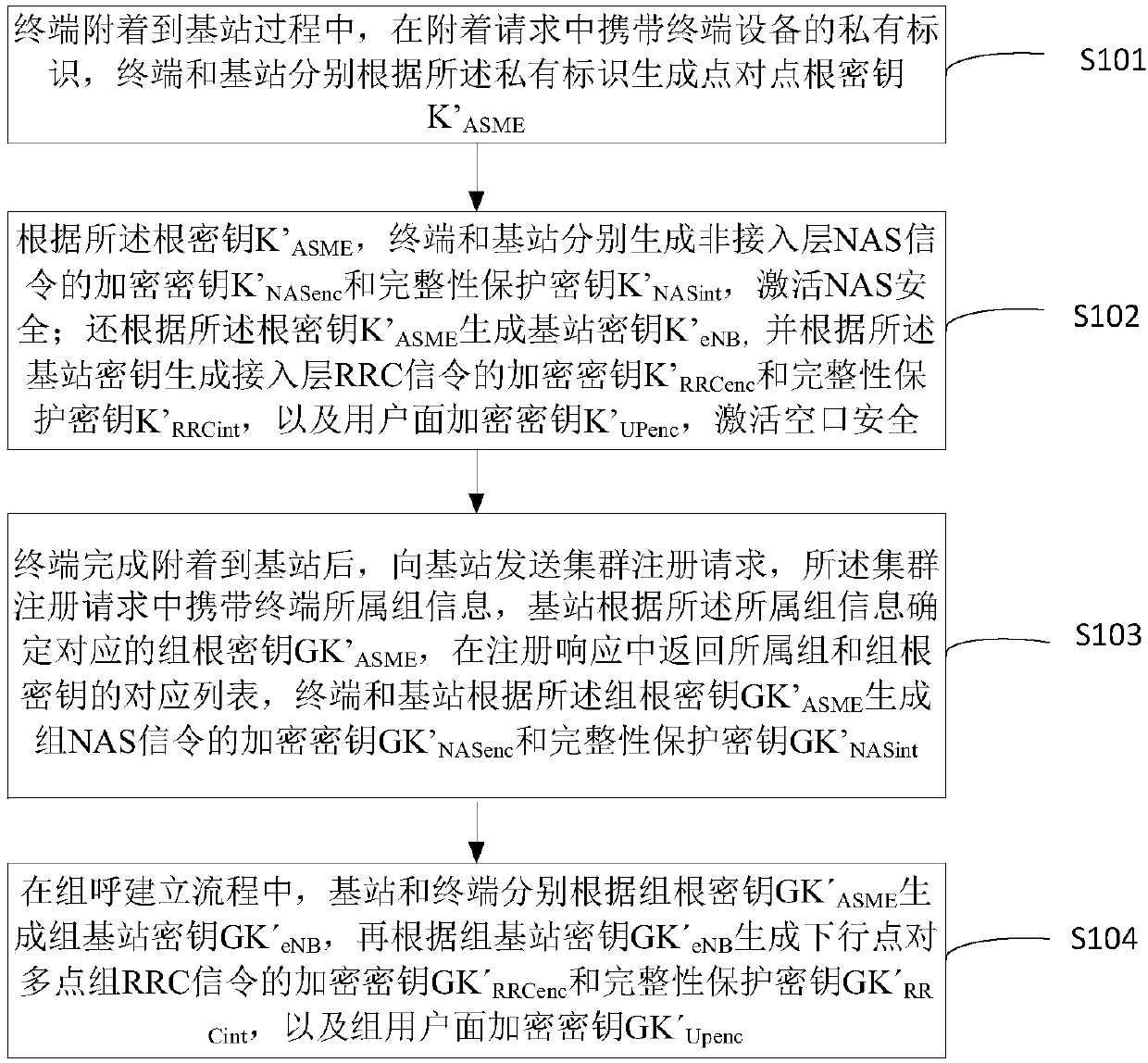

An air interface encryption method and device in a fail soft mode

InactiveCN109729522AData transmission securityConfiguration impactSecurity arrangementAir interfaceComputer terminal

The embodiment of the invention provides an air interface encryption method and device in a fail soft mode. In the method, a base station can determine a point-to-point root key according to a privateidentifier reported by UE; a terminal and the base station can carry out key derivation according to the root key; after point-to-point security is activated, a group root key is generated for a group according to group information carried in a cluster registration request sent by the terminal, then the terminal and the base station respectively carry out key derivation according to the group root key, and encryption and decryption are carried out by using the key in point-to-point and point-to-multipoint signaling and data transmission processes. Therefore, a point-to-point and point-to-multipoint key derivation and distribution mechanism can be executed in a fail-soft mode, and point-to-point and point-to-multipoint signaling and data transmission security in the mode is ensured. And the security mechanism in the existing normal working mode is slightly changed, so that the method provided by the embodiment of the invention is simple and easy to implement, and the configuration of the existing network is not greatly influenced.

Owner:POTEVIO INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com