Patents

Literature

64results about How to "Inhibition of rebound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anisotropically bonded magnet and fabricating method, magnetic path thereof

InactiveCN101814368AExcellent magnetic propertiesHigh mechanical strengthInductances/transformers/magnets manufactureMetallurgyNitrogen

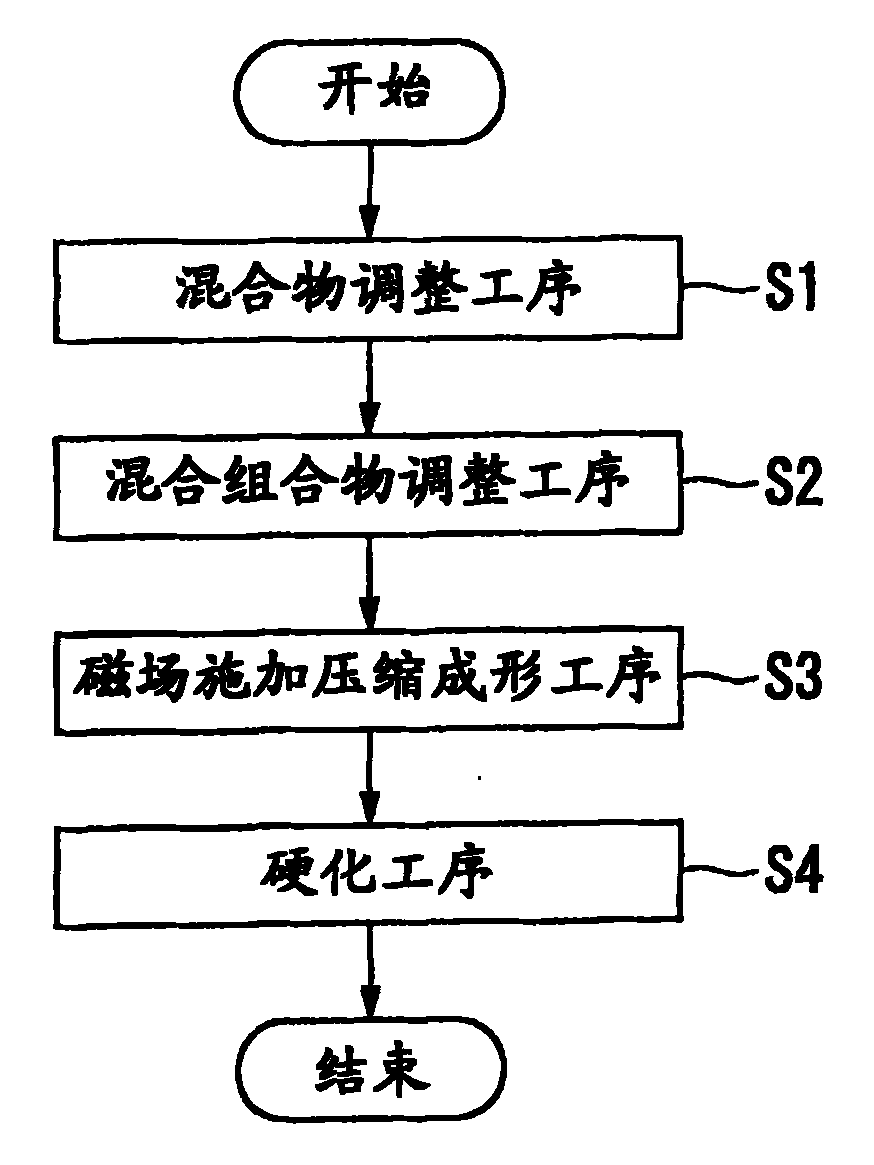

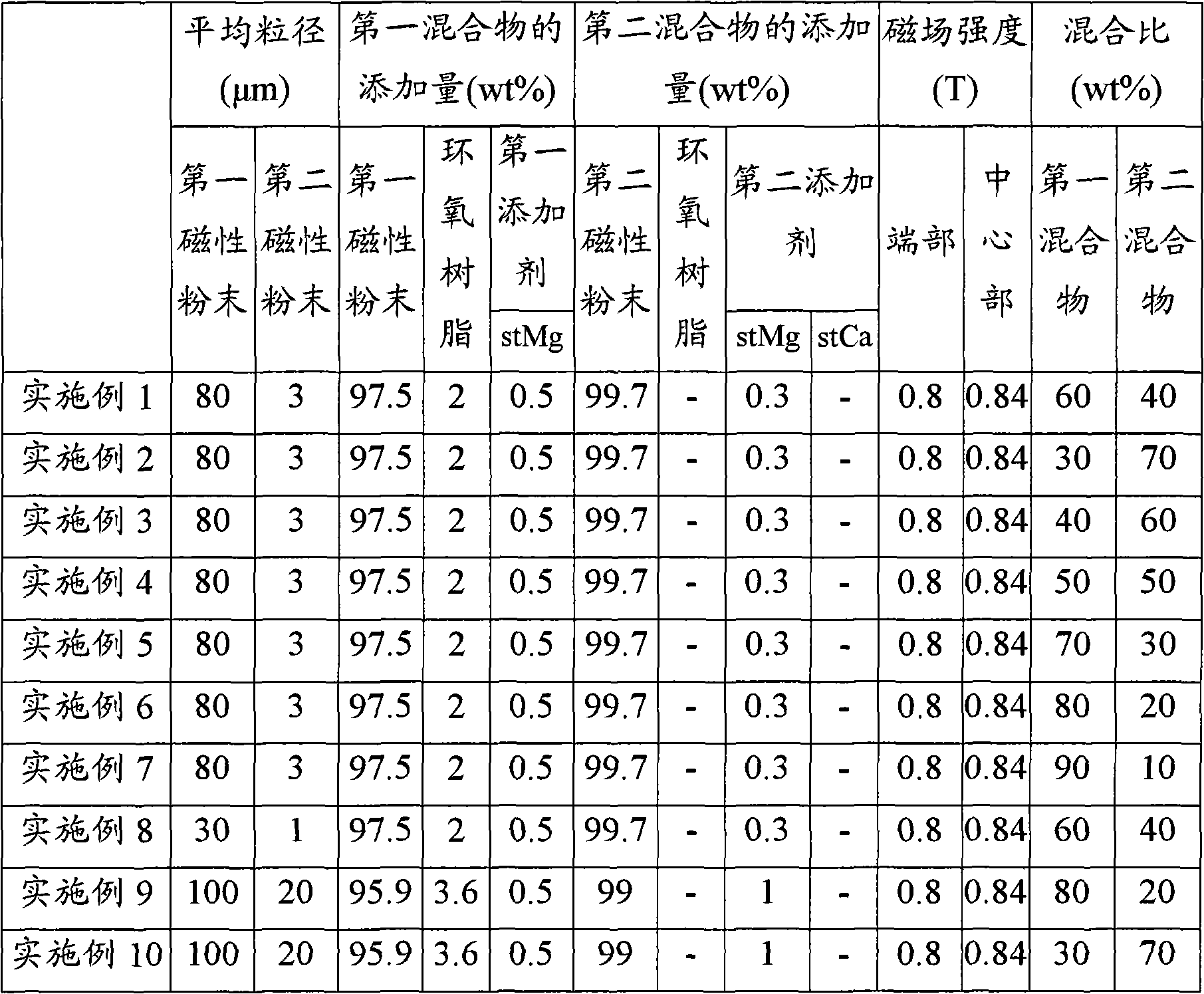

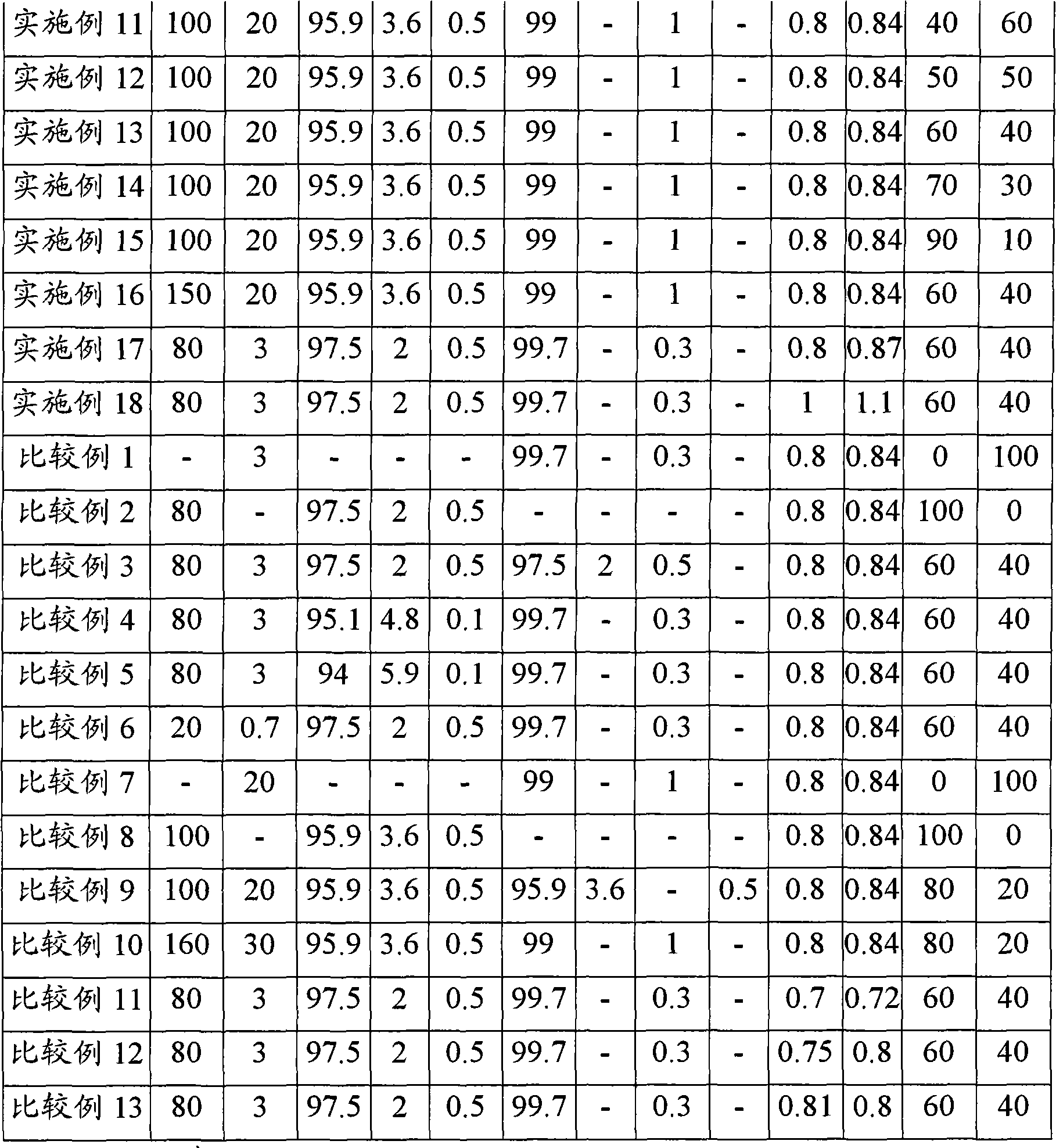

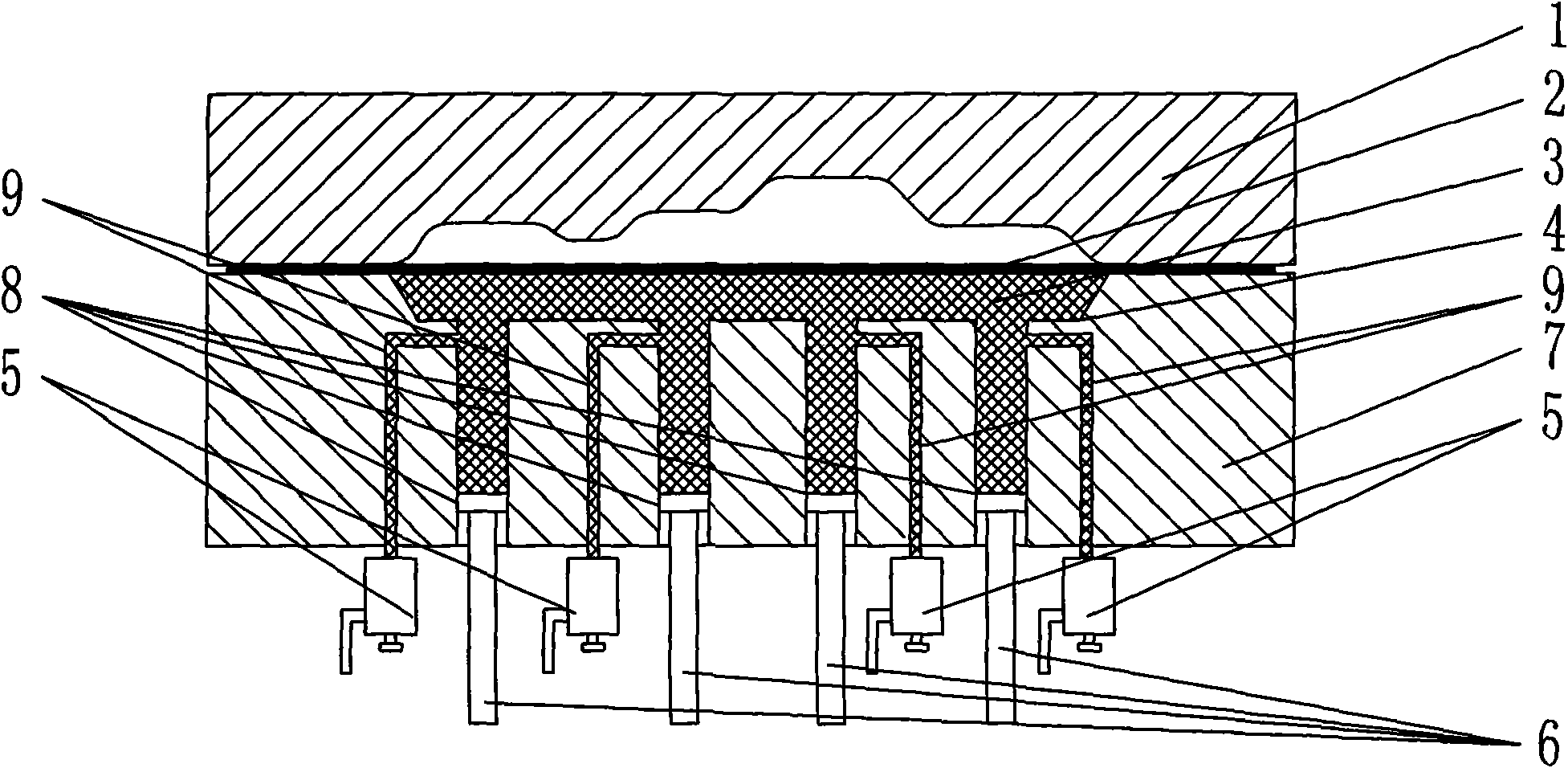

This invention relates to a fabricating method for anisotropically bonded magnet including: step S1 for adjusting the first mixture and the second mixture, where: the first mixture comprises the first magnetic powder, of which the grain size is in the range of 20-150mum, thermosetting resin of 2.0 wt%being added into the anisotropically bonded magnet, the first additive; the second mixture comprises the second magnetic powder, of which the grain size is in the range of 1-20mum, the second additive; step S2 for adjusting the first mixture and the second mixture; step S3 for making the magnetic intensity of the end part of the shaping metal die be under the 0.8T, the magnetic intensity of the central part of the shaping metal die is 5% higher than that of the said end part of the shaping metal die after said mixed compounds being filled into the metal die; step S4 for heating said mixed compounds at the atmosphere of inert gases or nitrogen gases so as to harden compounds.

Owner:SEIKO INSTR INC

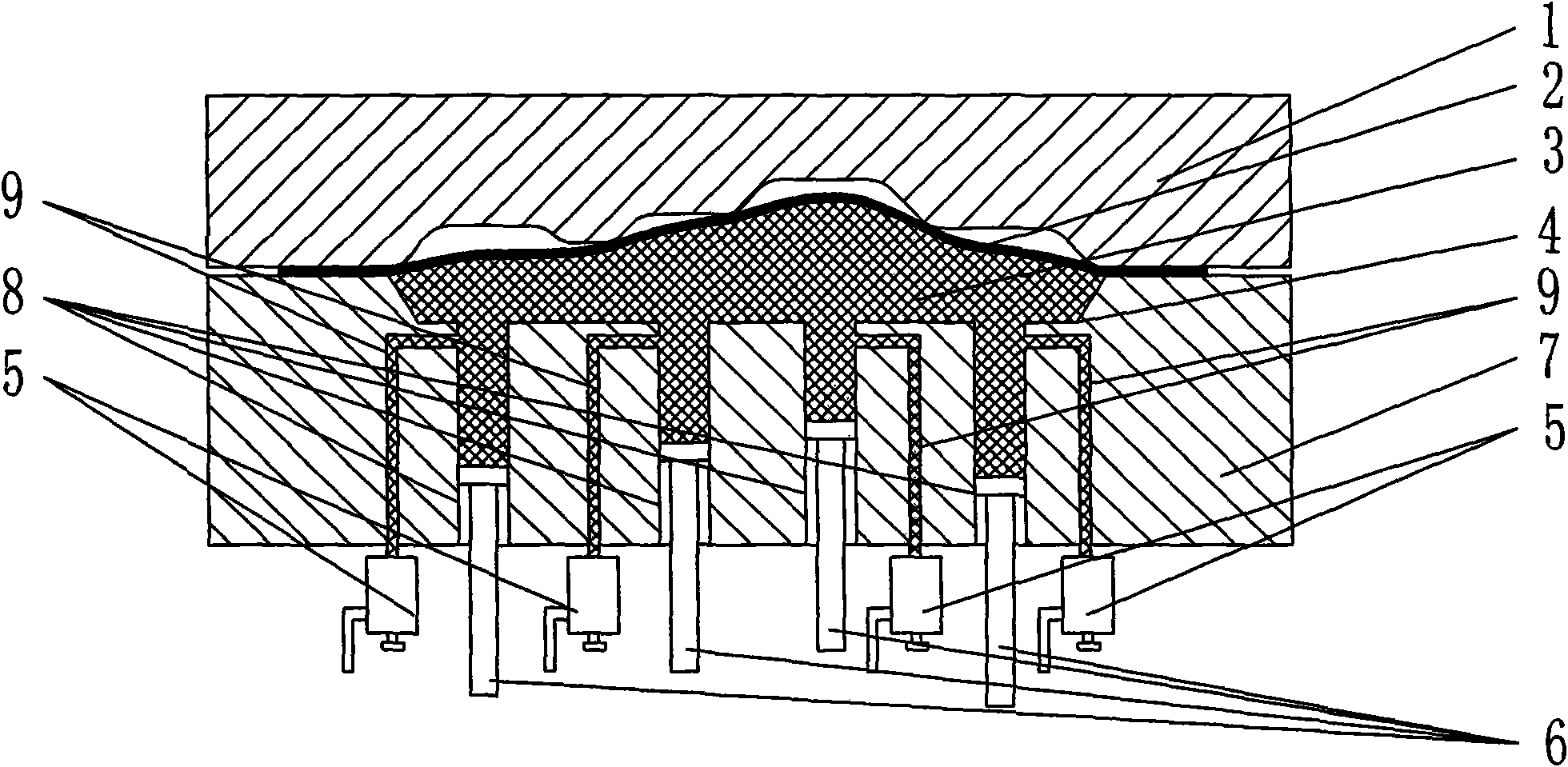

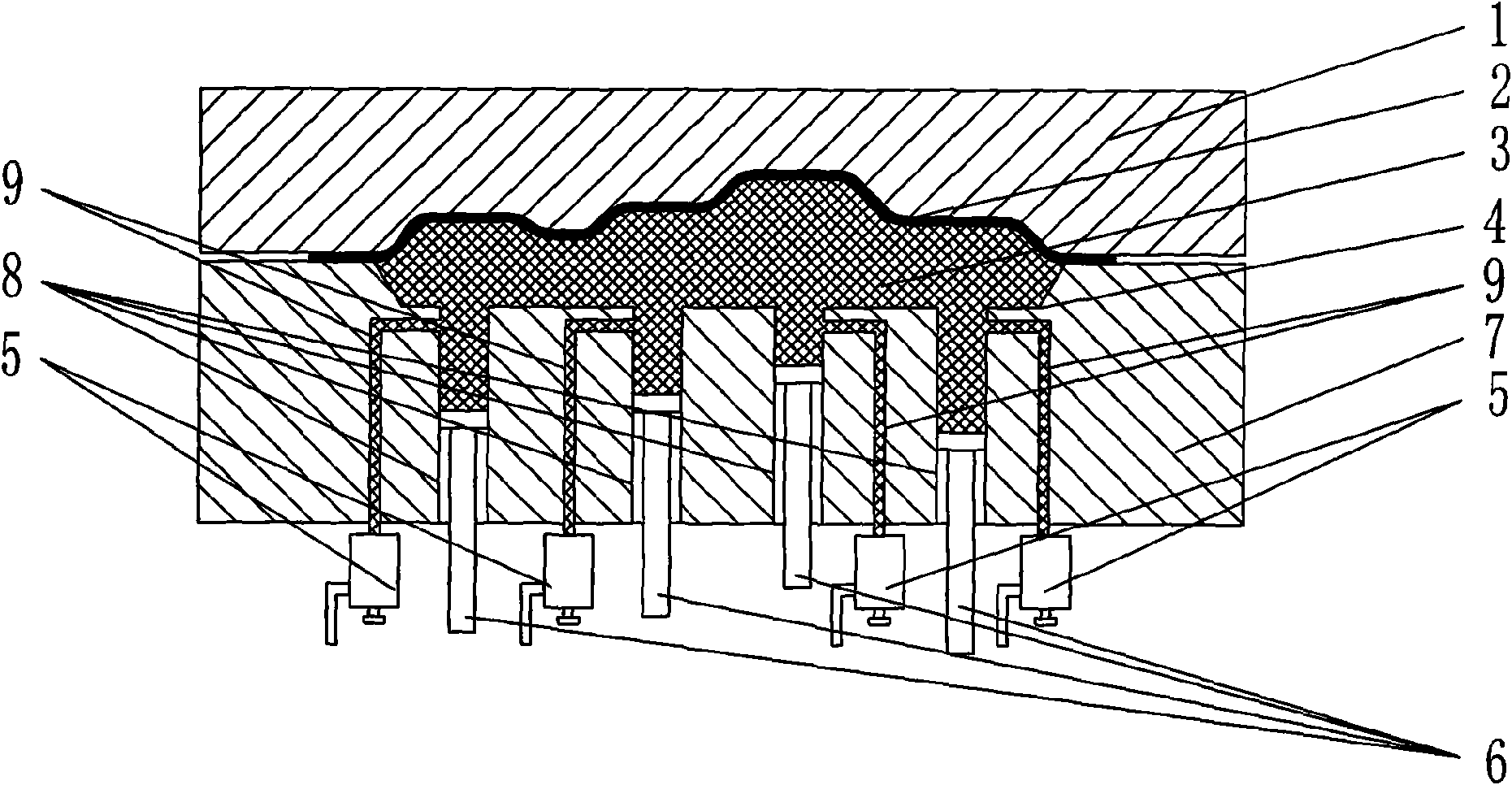

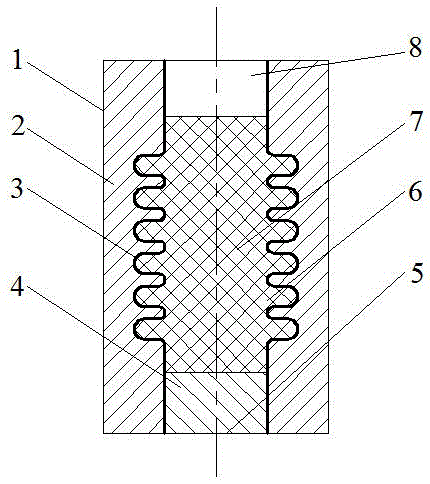

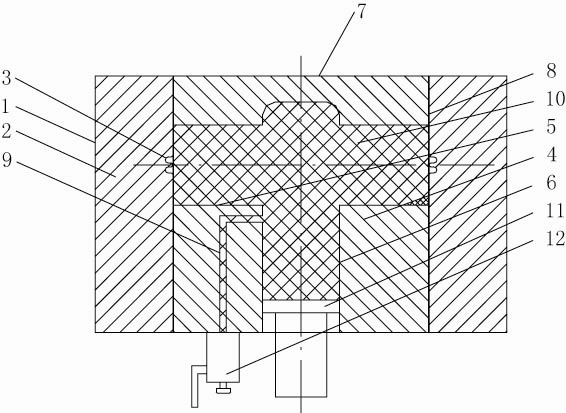

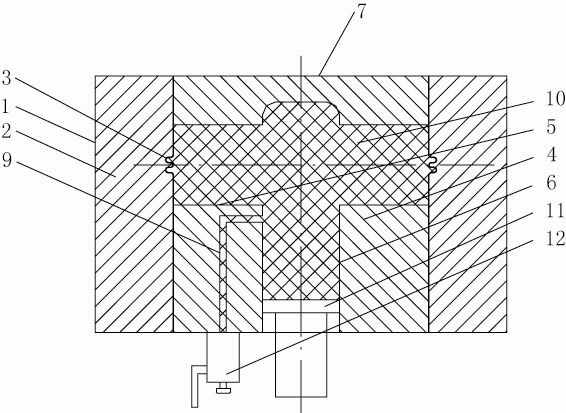

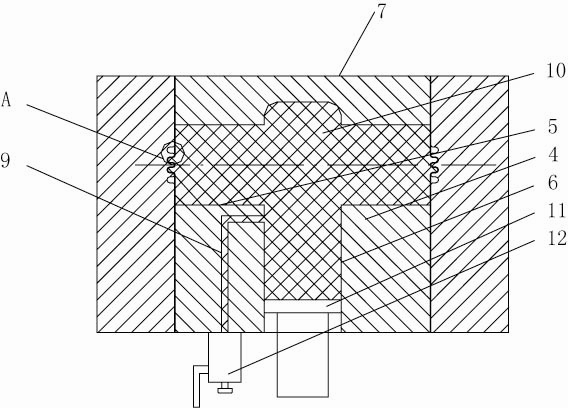

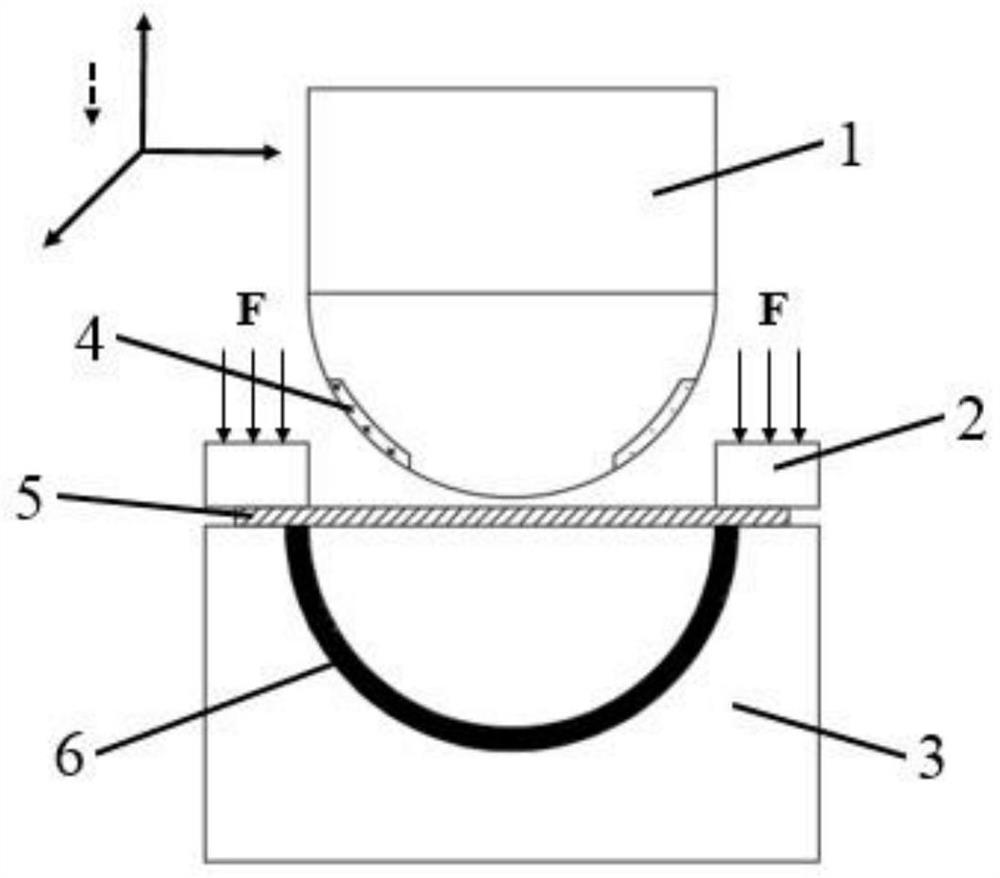

Pressure control method for forming aluminum alloy covering part viscoelastic-plastic soft mode

The invention discloses a pressure control method for forming an aluminum alloy covering part viscoelastic-plastic soft mode, relating to the pressure control method for forming an aluminum alloy covering part soft mode. The invention solves the problems of local tinning and cracking, larger rebound, bad surface quality and higher manufacture cost which are existed in the prior aluminum alloy covering part. The invention substantially comprises the following steps of: shaping a mould; installing a piston and an overflow valve; filling viscoelastic-plastic materials; matching a mould; adjusting the overflow valve to control the pressure value of the deformed region of the aluminum alloy plate blank material; tightly gluing the aluminum alloy plate blank material with the die cavity of a cavity die under the thrusting function of the viscoelastic-plastic materials to form the needed aluminum alloy covering part; opening the mould; taking out the formed aluminum alloy covering part; and removing the viscoelastic-plastic materials remained on the surface of the aluminum alloy covering part. The invention inhibits the rebound of the formed aluminum alloy covering part, prevents the local region from being cracked, improves the surface quality of the aluminum alloy covering part, and reduces the manufacture cost of the aluminum alloy covering part.

Owner:HARBIN INST OF TECH

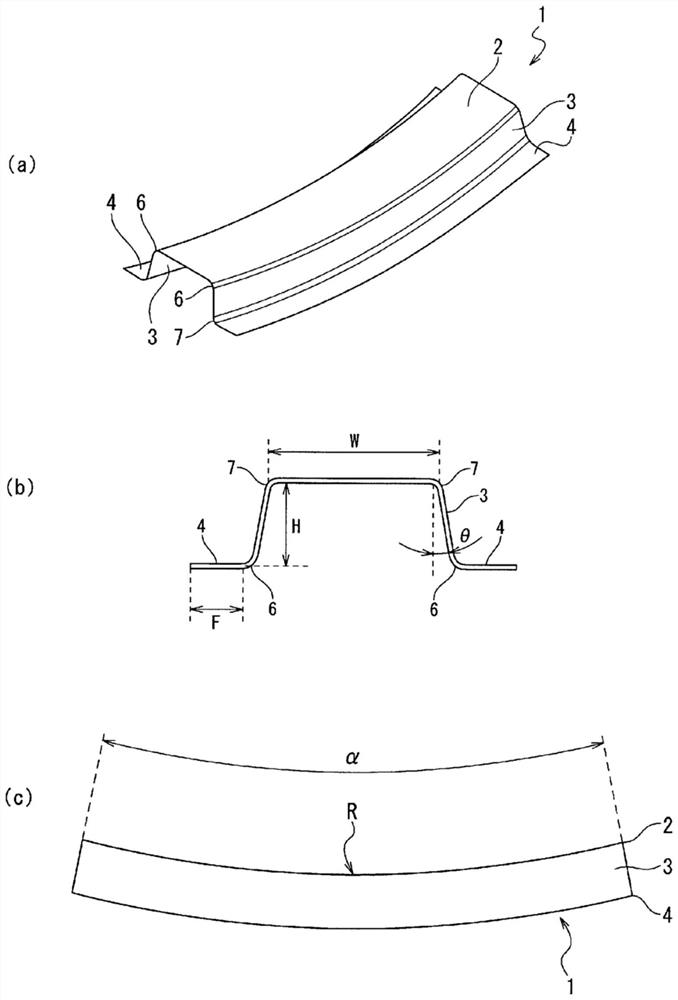

Press-formed product

ActiveCN104136142AInhibition of reboundImprove flatnessEngine componentsThin material handlingHardnessMechanical engineering

A press-formed product that enables inexpensively providing a shock-absorbing member having a high crashing load with respect to a three-point bending load is provided. The press-formed product is a press-formed product of a steel sheet 13, the press-formed product including a body 24 having a hat-shaped cross section and extending in a direction, the transverse cross section including a bottom portion 20a and a shoulder portion 20c that is contiguous to the bottom portion 20a through an R end 25. In the transverse cross section, a first region 27 from the R end 25 to a position a predetermined distance away in a direction in which the bottom portion 20a extends, and a second region 28 that is a part of the bottom portion 20a and is contiguous to the first region 27 have a work-hardening distribution introduced by press-forming of the body 24, the work-hardening distribution being one in which average hardness Hv1 of an area of the first region 27 from a surface of the steel sheet 13 to a position with a depth obtained by multiplying a thickness of the steel sheet 13 by 0.2 and average hardness Hv2 of an area of the second region 28 from the surface of the steel sheet 13 to the position obtained by multiplying the thickness of the steel sheet 13 by 0.2 satisfy a relationship of Hv1 > 1.05 x Hv2.

Owner:NIPPON STEEL CORP +1

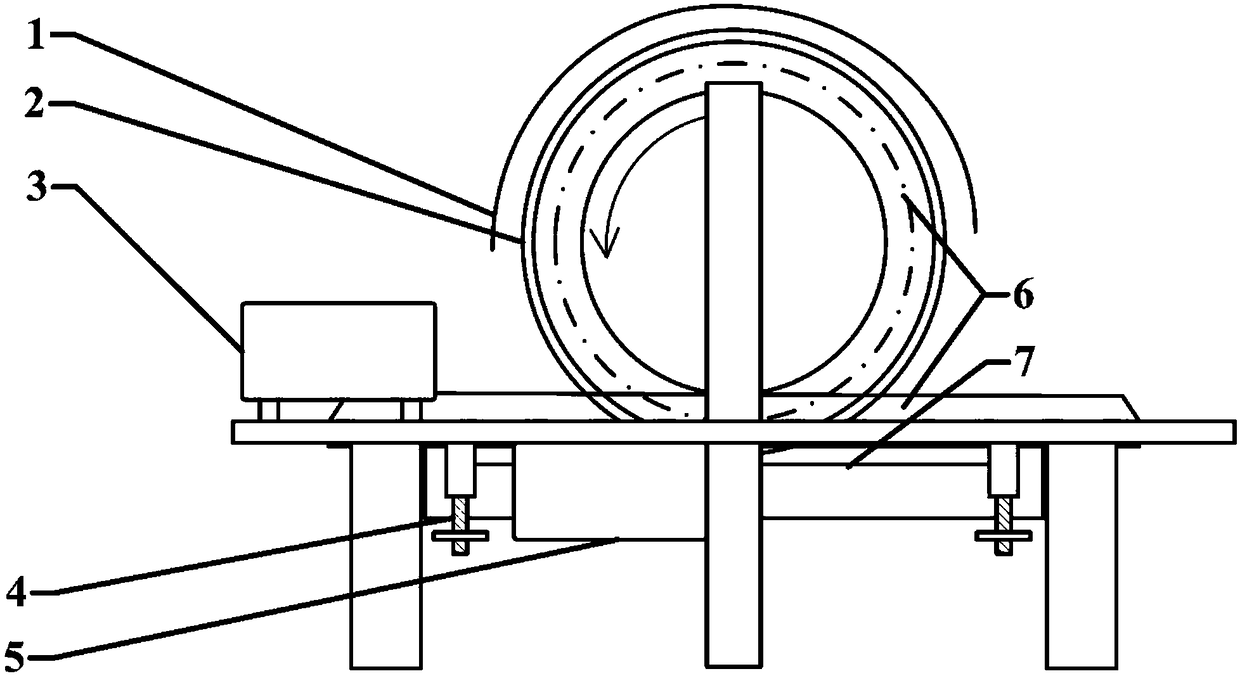

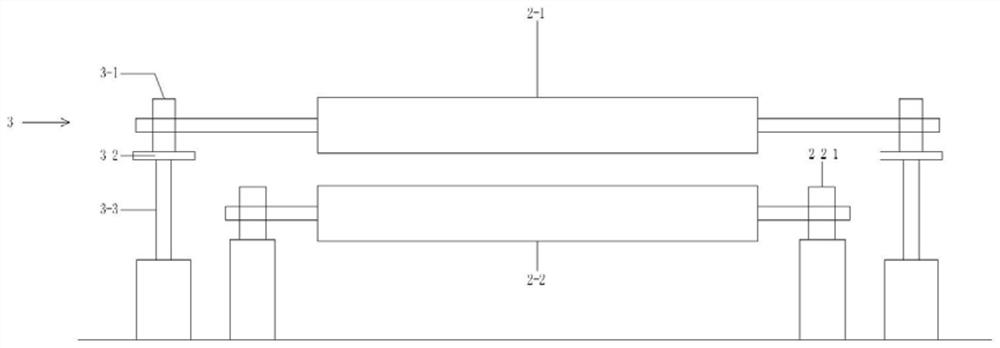

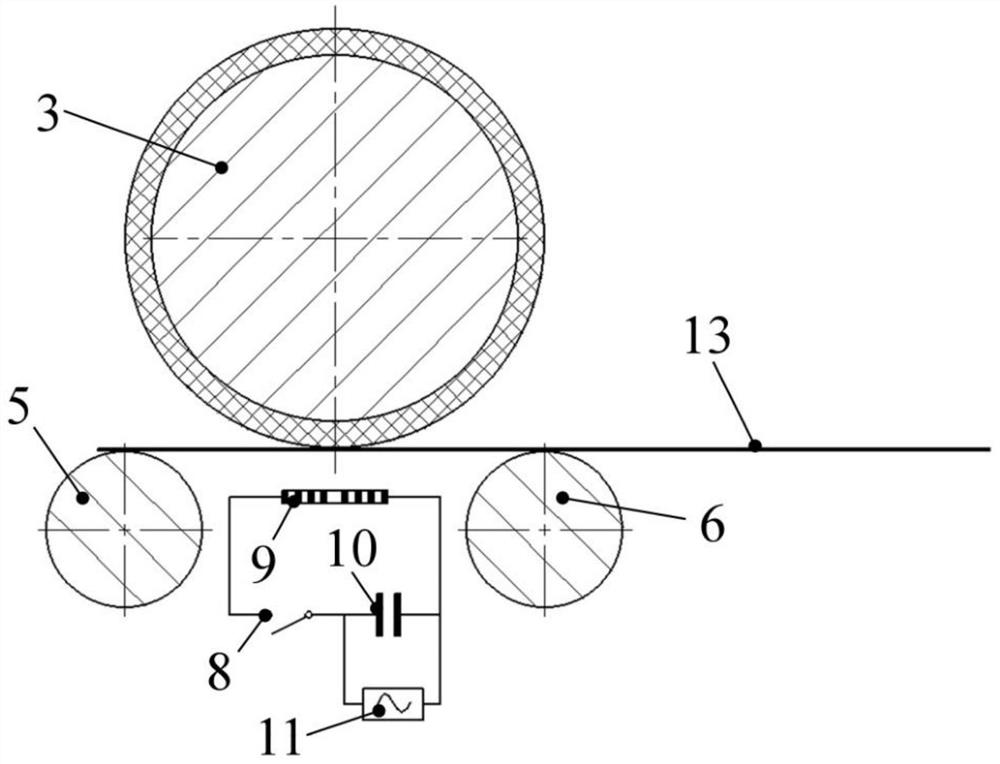

Flexible plate reeling machine with side roller

PendingCN107812807AInhibition of reboundIncrease flexibilityEjection devicesAutomatic controlManufacturing technology

The invention discloses a flexible plate reeling machine with a side roller and belongs to the technical field of plate reeling machine equipment manufacturing. Targeted to the phenomenon that large springback is generated when an existing plate reeling machine with two rollers reels a plate with a high yield ratio, a rigid roller is added in the discharging direction of the flexible plate reelingmachine to serve as the side roller; when a cylindrical workpiece is reeled, due to the effect of the side roller, reverse reloading is exerted on the plate so that springback of the parts can be effectively inhibited; movement of a side roller movement hydraulic cylinder is controlled through hydraulic servo, the distance between the side roller and the rigid roller is changed, roll-bending forming of the parts different in curvature is achieved within a certain range, and the problem that the parts different in curvature are formed by the traditional plate reeling machine with the two rollers in the manner of roller changing is solved. The universality of the plate reeling machine is improved, the production cost is lowered, and the plate reeling quality and the automated level are effectively improved supplemented by automated control.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

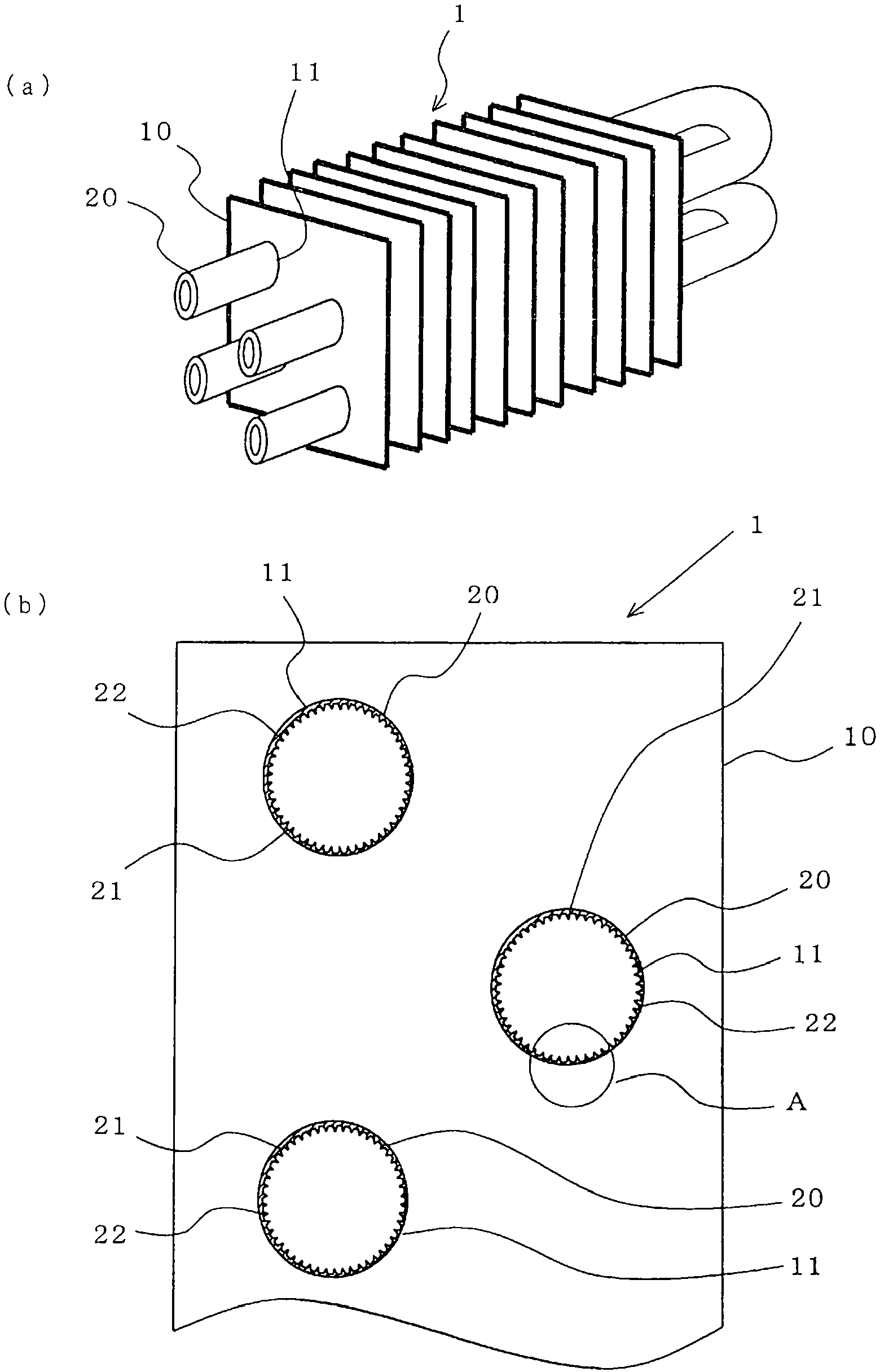

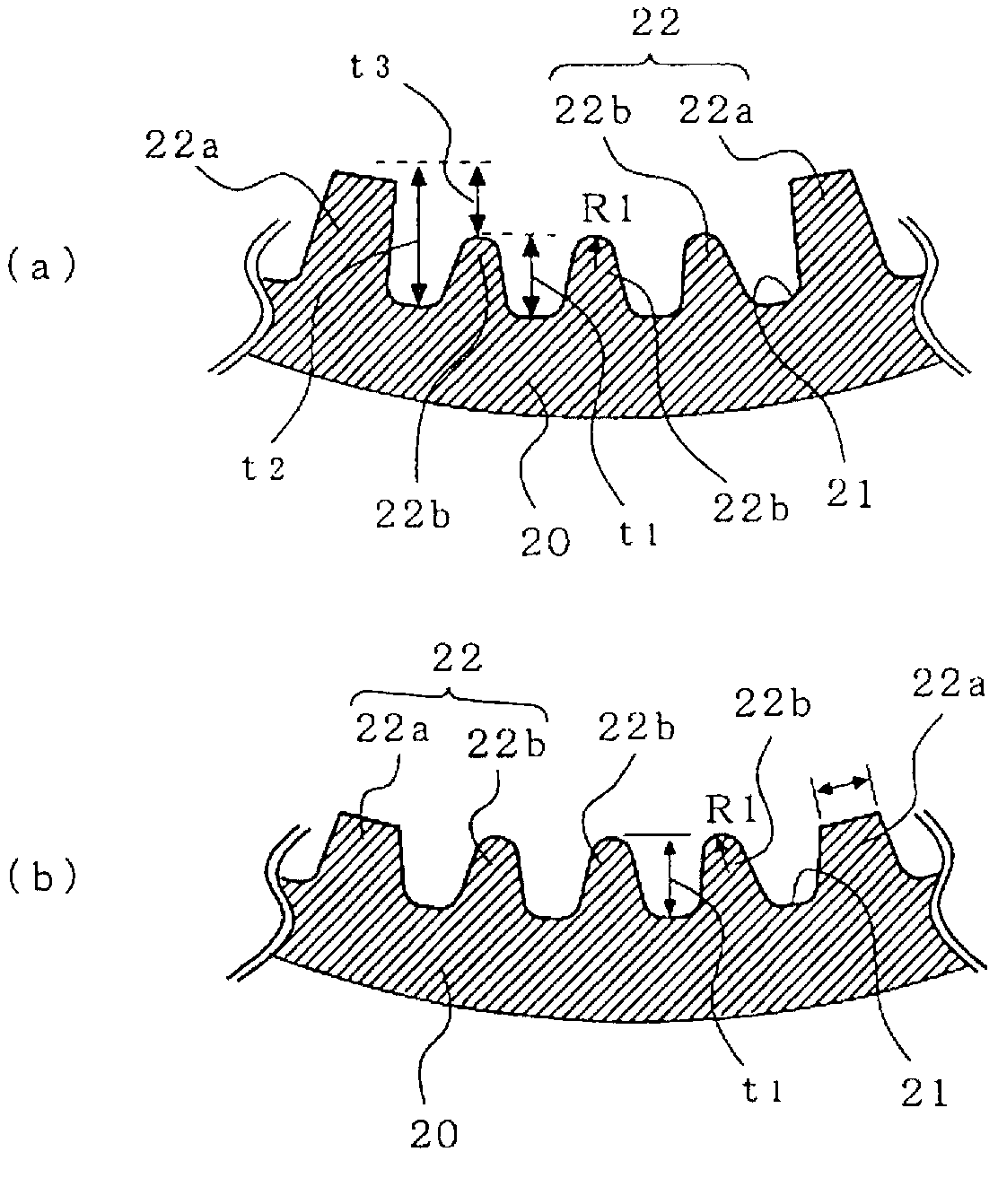

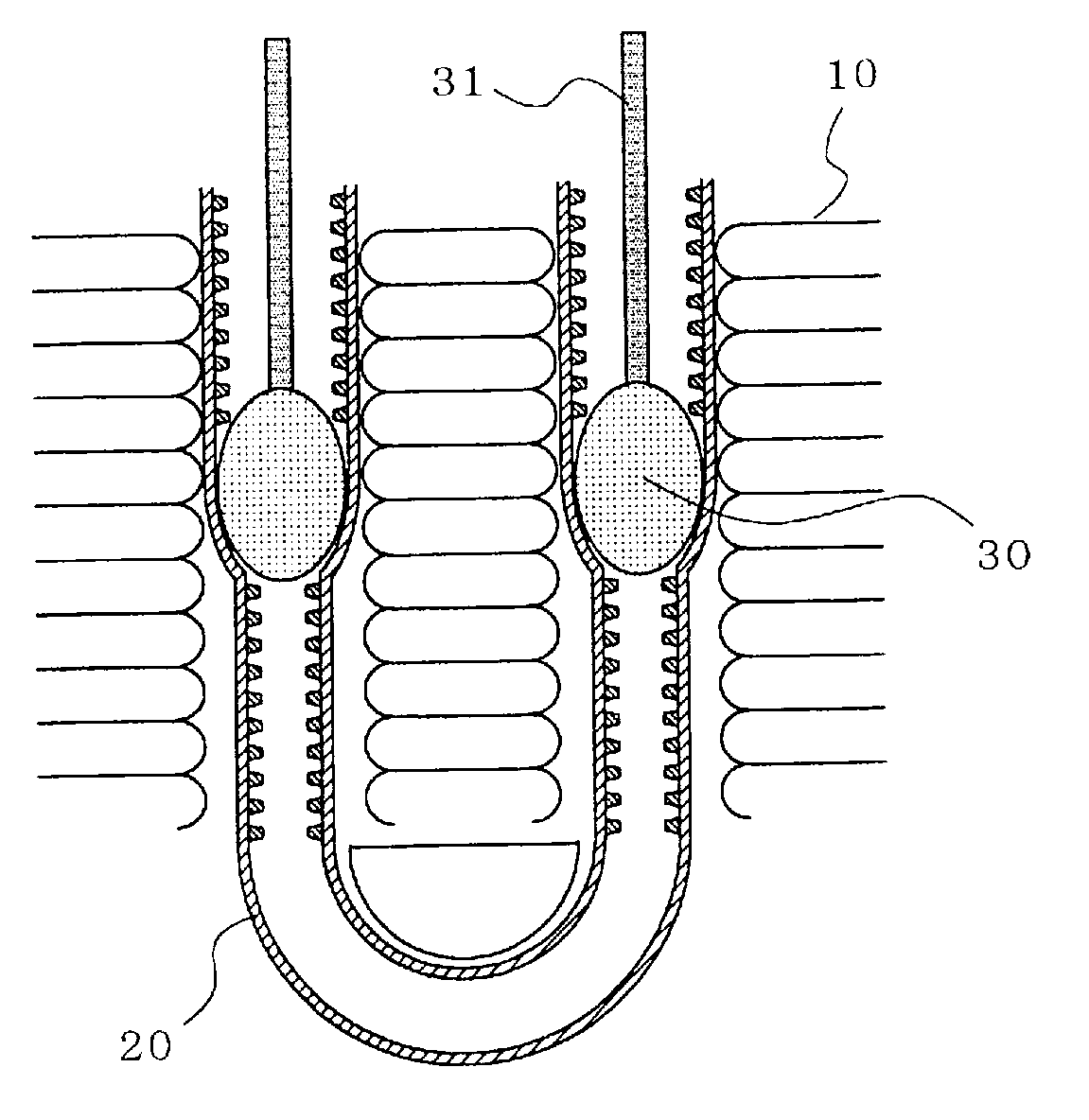

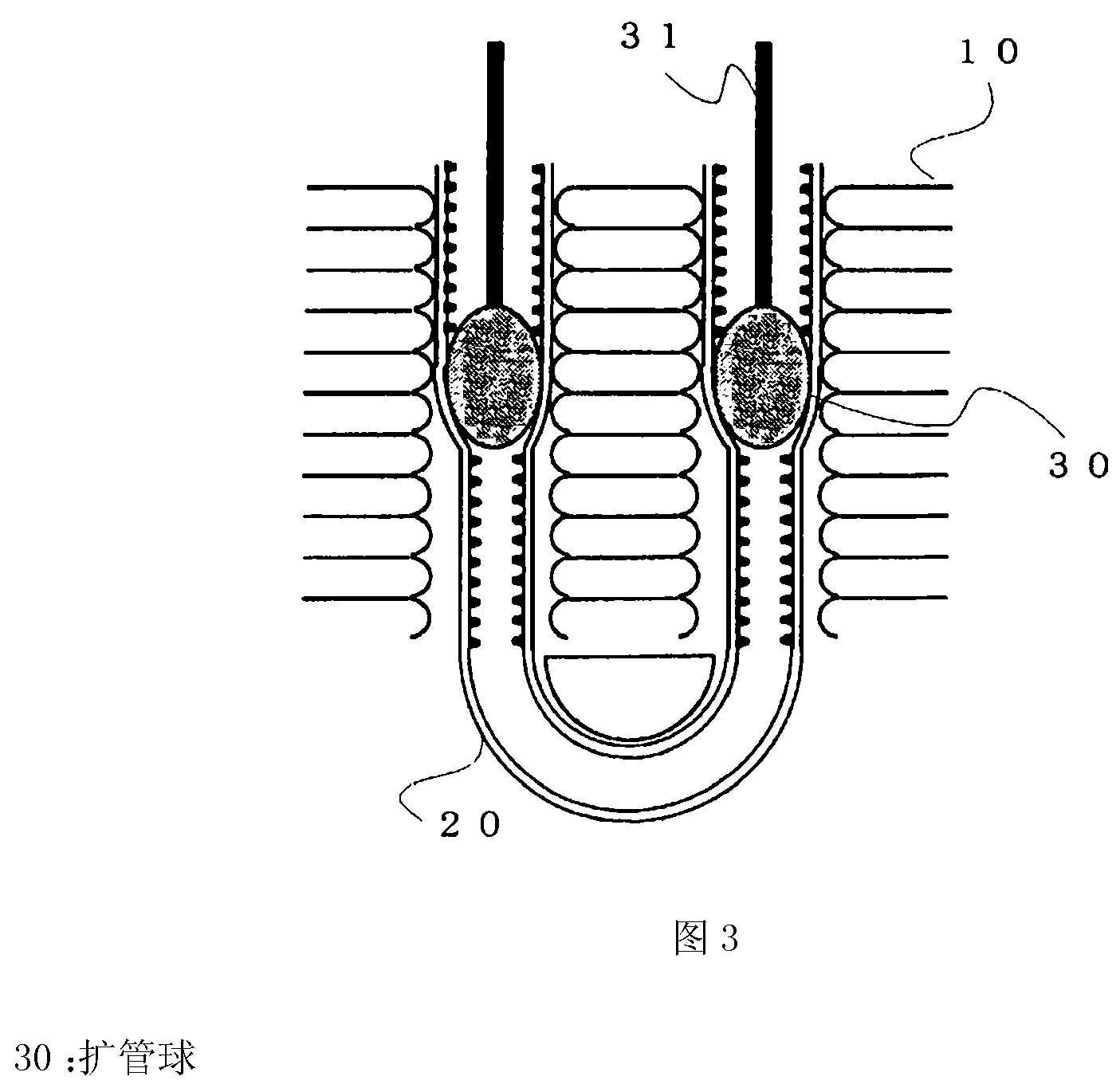

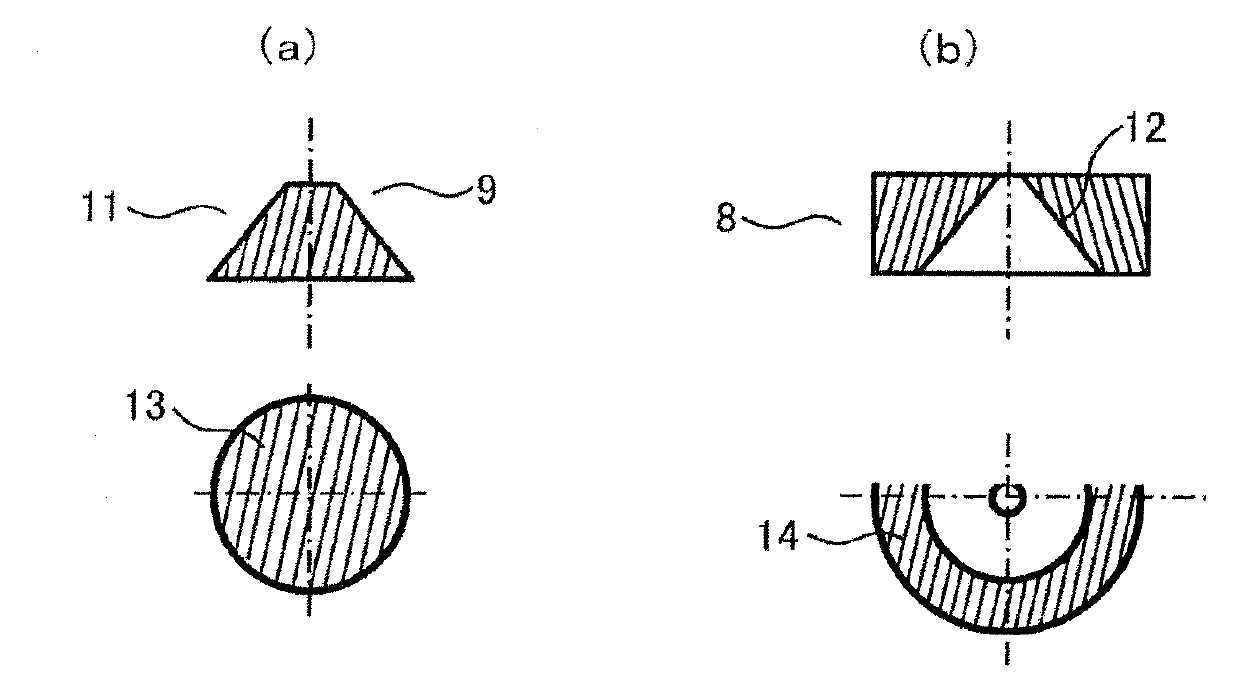

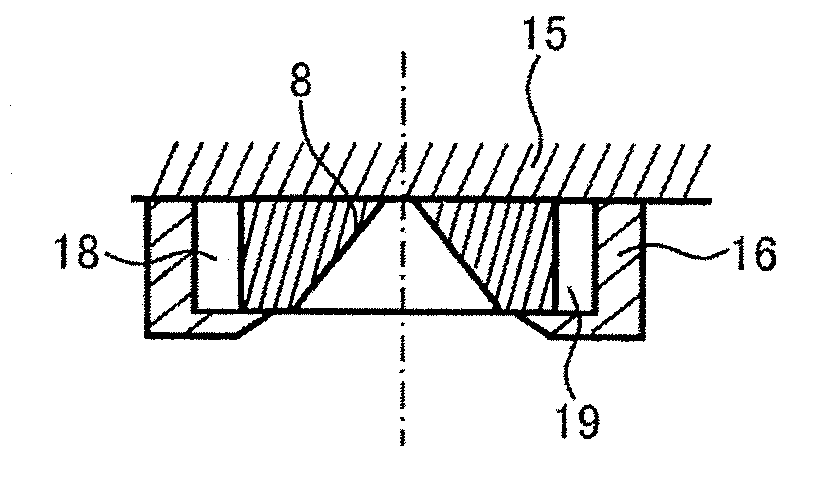

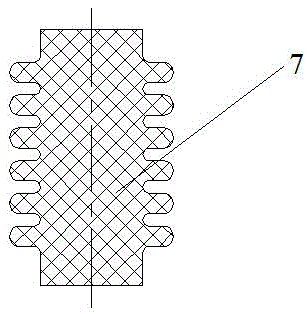

Heat transfer tube for heat exchanger, heat exchanger, refrigeration cycle device, and air conditioning device

InactiveCN102713487AInhibition of reboundImprove heat transfer performanceEvaporators/condensersStationary conduit assembliesAir conditioningRefrigeration

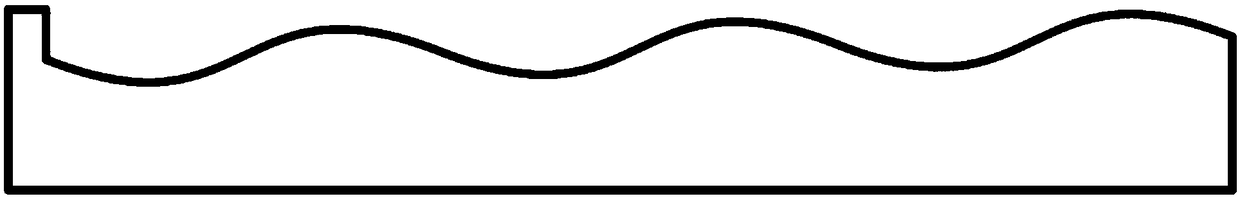

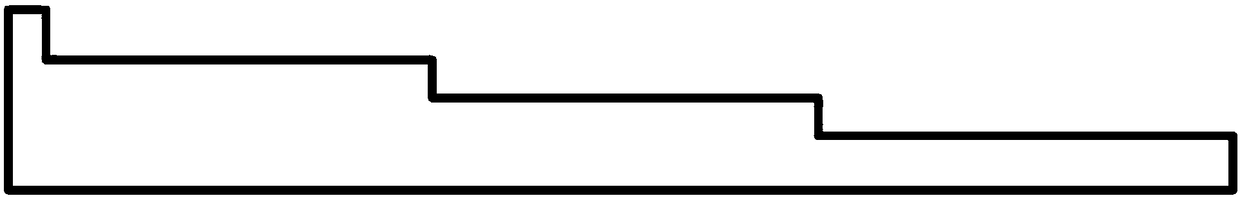

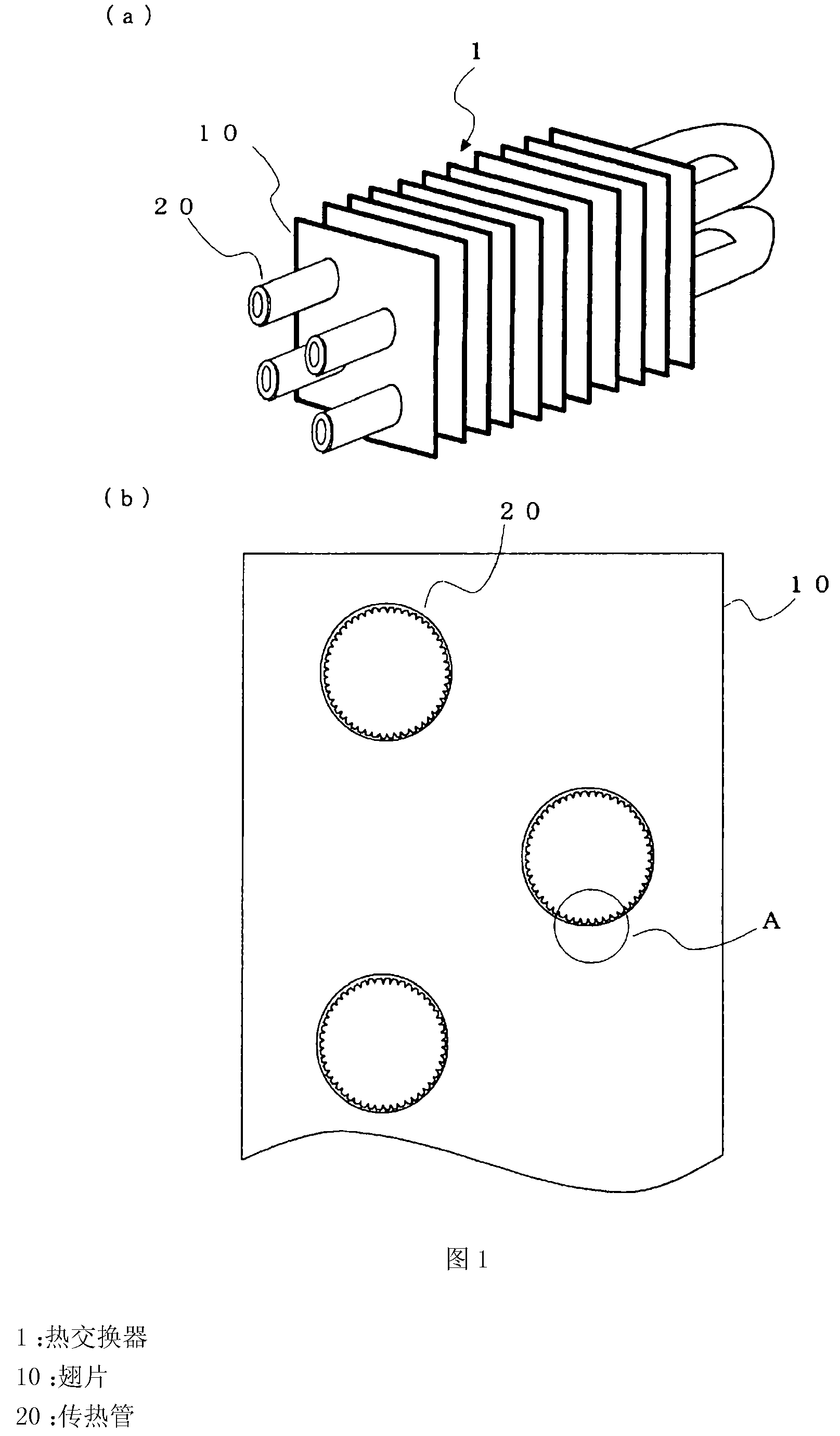

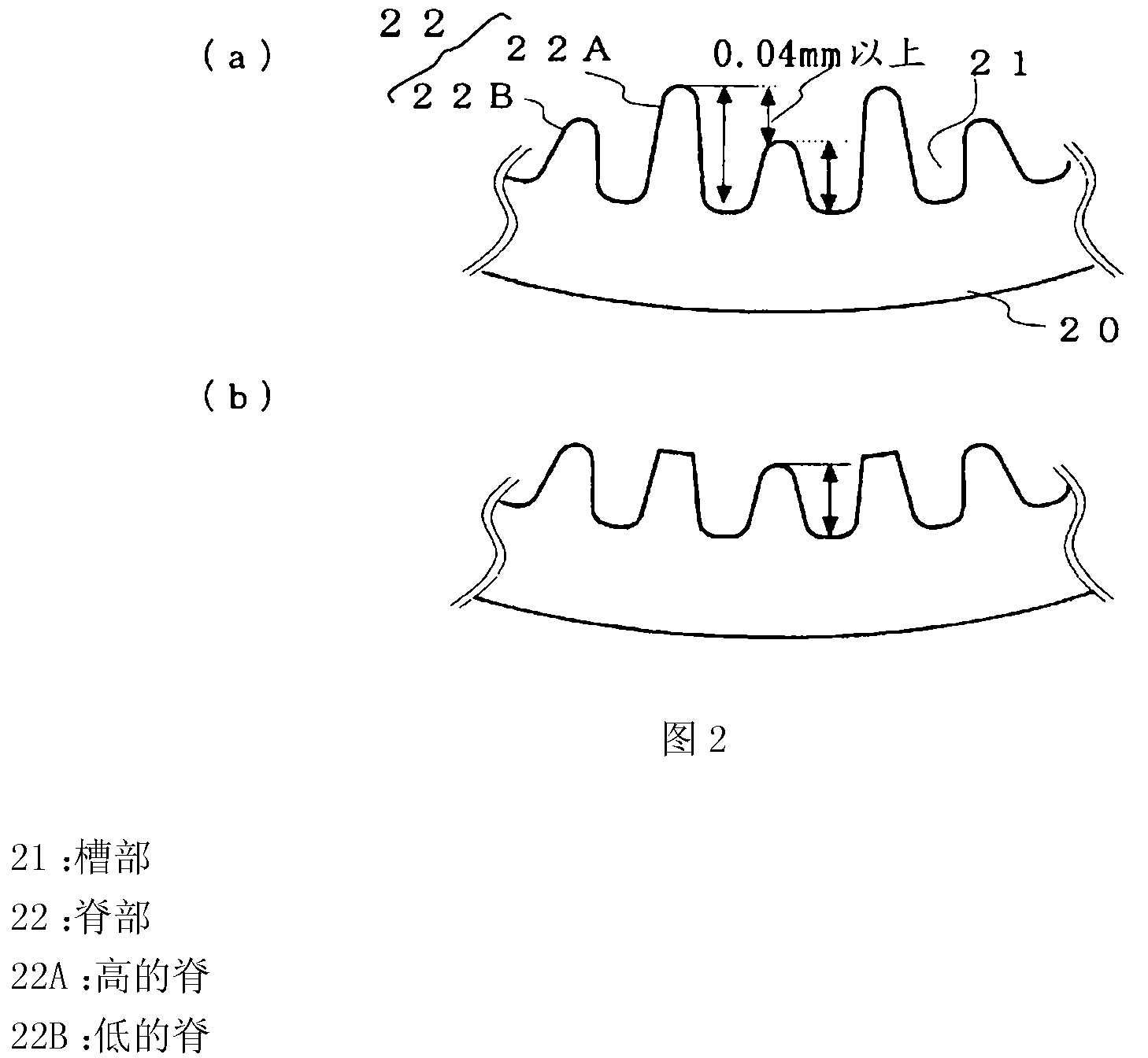

High ridges (22a) and low ridges (22b) lower than the high ridges are helically provided on the inner surface of a tube (20) so as to be arranged in the axis direction thereof, and the high ridges (22a) and the low ridges (22b) have predetermined heights. The number of the high ridges (22a) is from 11 to 19, and the number of the low ridges (22b) which are formed between adjacent high ridges (22a) is from 3 to 6. The crests of the high ridges (22a) have, before the diameter of the tube is expanded, a trapezoidal cross-sectional shape having a flat top, and the ratio (W1 / D) between the width (W1) of the tip of the top and the outer diameter (D) of the heat transfer tube (20) is from 0.011 to 0.040 after the diameter of the tube is expanded. Also, the height of the high ridges (22a) before the diameter of the tube is expanded is greater by 0.04 mm or more than the height of the low ridges (22b).

Owner:MITSUBISHI ELECTRIC CORP

Large-deformation rolling technology based on asymmetric rolling equipment

ActiveCN108126981AMeet different shape forming requirementsWeakened textureMetal rolling arrangementsGear wheelThree-phase

The invention relates to a large-deformation rolling technology based on asymmetric rolling equipment. According to the large-deformation rolling technology based on the asymmetric rolling equipment,a detachable bottom plate is replaced with a shaping demand bottom plate, a hydraulic adjustment device is adopted to adjust spacing between a roller and the bottom plate, the rolling temperature is adjusted through a roller heating plate and a bottom plate heating device, before rolling, a sample is placed into a sample heating device to be preheated to reach a preset deformation temperature, thesample is pushed into a feeding opening, a transmission unit is driven by a three-phase motor to make the roller rotate, and a gear-rack transmission device makes the roller and the bottom plate linked to complete rolling. By the adoption of the large-deformation rolling technology based on the asymmetric rolling equipment, after rolling, recrystallization and annealing treatment are combined tocarry out synergistic regulation to obtain fine-grain superplastic structure, multi-grade structure structure in which large and small crystal particles are mixed can also be obtained, and the strength and the plasticity are greatly improved at the same time; the grain size of plates is reduced, the texture of rolled plates is weakened, the performance of the rolled plates is improved, through cooperation of the roller and the work bottom plate, different kinds of plates can be prepared, technological processes are reduced, the machining cost is reduced, and the production efficiency is improved.

Owner:JILIN UNIV

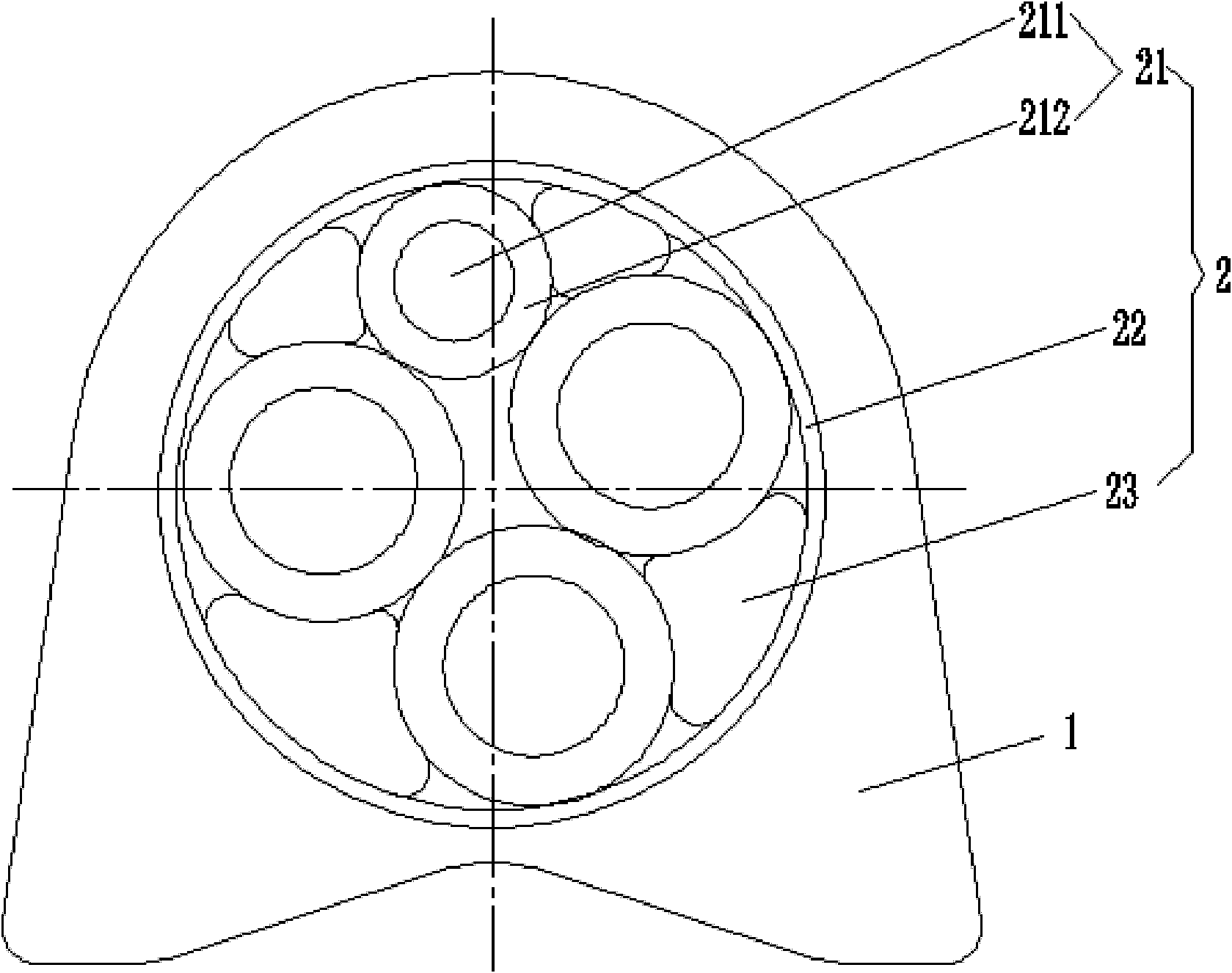

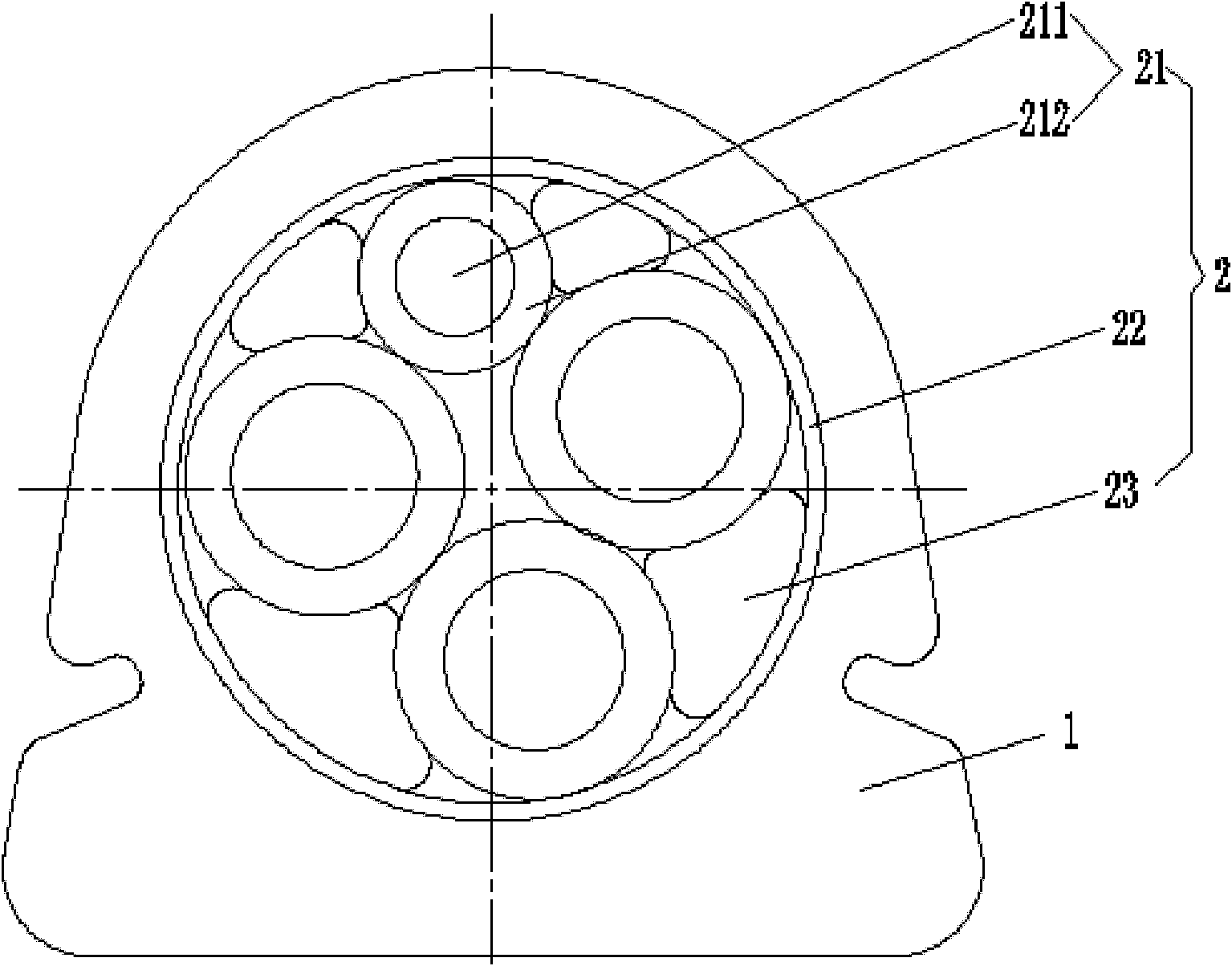

Heat transfer tube for heat exchanger, heat exchanger, refrigerating cycle apparatus, and air conditioning apparatus

ActiveCN102112838AInhibition of reboundExcellent adhesionCompression machines with non-reversible cycleEvaporators/condensersInternal pressureEngineering

Provided is a heat transfer tube for a heat exchanger or the like, which can acquire a predetermined heat transfer performance without increasing any internal pressure loss. The heat transfer tube comprises higher crests (22A) and lower crests (22B) helically with respect to a tubular axis direction. The higher crests (22A) are formed of ten to twenty ridges to have a predetermined height, and the lower crests (22B) are formed of two to six ridges between the higher crests (22A) to have a lower height than that of the higher crests (22A).

Owner:MITSUBISHI ELECTRIC CORP

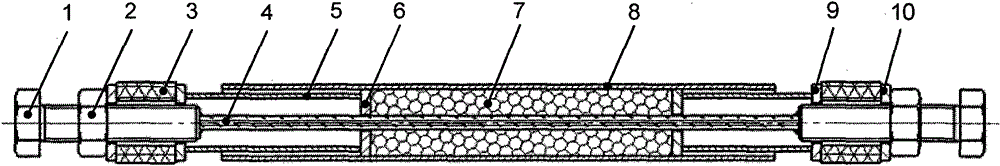

Spring cable

InactiveCN102737766AExtended service lifeReduce concentrationExtensible conductorsExtensible conductor cablesEngineeringAsymmetry

The invention discloses a spring cable which comprises a cable core and a sheath which is wrapped around an outside surface of the cable core. A cross section of the sheath is not circular, and two parts of the sheath are not asymmetry in shape and have different thicknesses with an axial plane of the spring cable as a boundary. When the cable is bended, the cable always extends or retracts along a position with a weakest stress, thus one end with thicker sheath is always arranged at the inner side during cable bending, when the cable is coiled or loaded to a disk, the end with the thicker sheath retracts at the inner side of the cable automatically, coils and retracts directionally and automatically, a bending stress and a torsional stress generated by the cable can be uniformly distributed on the entire length of the cable, the concentration of the bending stress is reduced, partial damage of the cable is avoided, and a service life of the cable is greatly raised.

Owner:FAR EAST CABLE +2

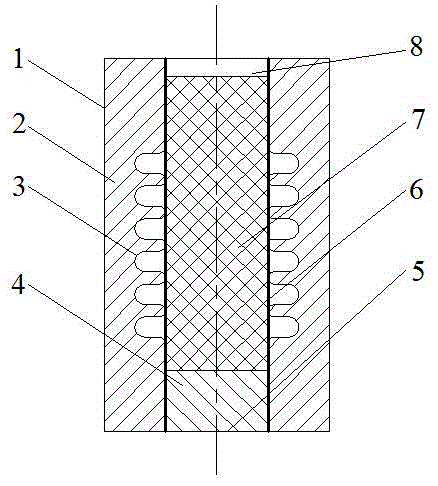

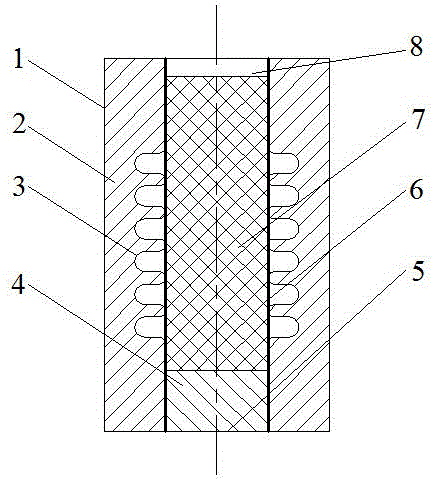

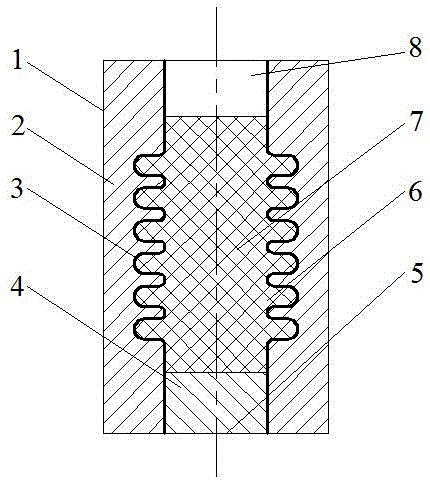

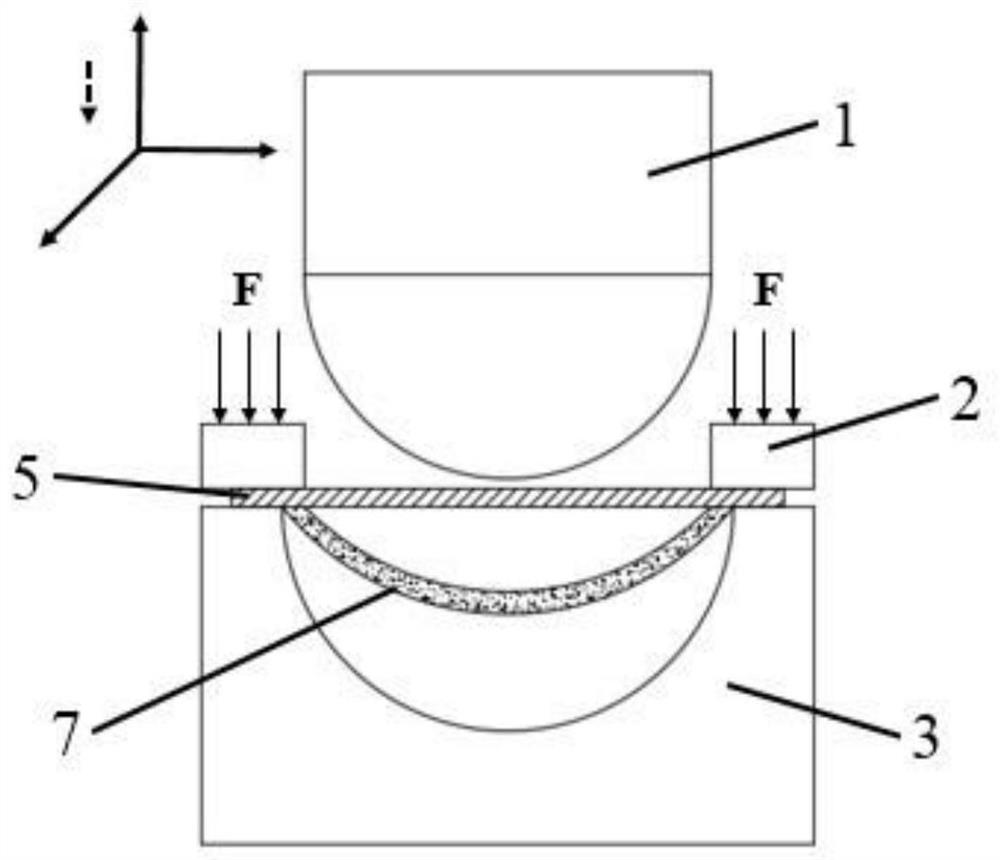

Method for forming thin-wall metal bellows based on shape memory polymer

ActiveCN105562493AImprove surface qualityImprove uniformityRoom temperatureUltimate tensile strength

The invention provides a method for forming a thin-wall metal bellows based on a shape memory polymer and relates to a thin-wall metal bellows forming method. The invention aims at solving the problems that wall thickness distribution of a formed part is uneven, a local region can be easily cracked, a forming device is complex and cost is relatively high when a steel die is used for carrying out stamping forming of a thin-wall metal bellows with relatively high material strength at room temperature. According to key points of the technical scheme, the method provided by the invention comprises the following steps: preparing a ripple shape memory polymer, making a forming die, making a core die to be assembled with the forming die, filling a medium bin with rubbery state shape memory polymer material, naturally cooling the shape memory polymer to room temperature, opening the die, and taking out the formed part. The method provided by the invention is applied to thin-wall metal bellows forming.

Owner:南京柔科航空设备科技有限公司

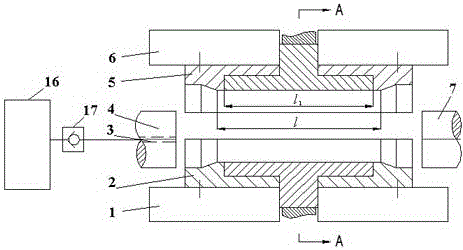

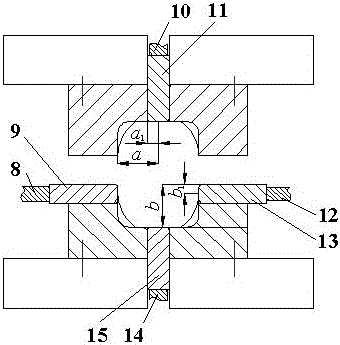

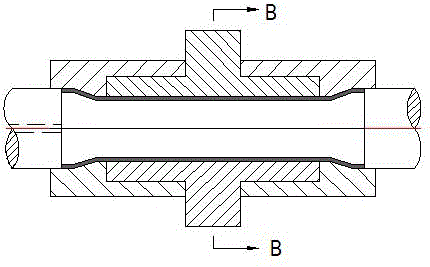

Forming method of hollow component

The invention relates to a forming method of a hollow component. According to the technical scheme, the forming method of the hollow component comprises the following steps: step one, preparing a die, adding four anti-deformation structures on the die, and mounting a one-way valve on a punch; step two, placing an initial tube blank in a cavity of the die, closing the die and sealing ends; step three, filling a fluid medium inside the tube blank; step four, enabling the anti-deformation structures to move oppositely; and step five, retracting the anti-deformation structures to initial positions, repeating the step four and the step five to form a component in the required shape, relieving internal fluid pressure, opening the die, and taking out a part. The anti-deformation structures are arranged in the die, so that a petal shape is repeatedly and accumulatively used, while the rolling effect of friction is eliminated, forming pressure is reduced, the breakage defect is avoided, and uniformity of the wall thickness is improved.

Owner:李明

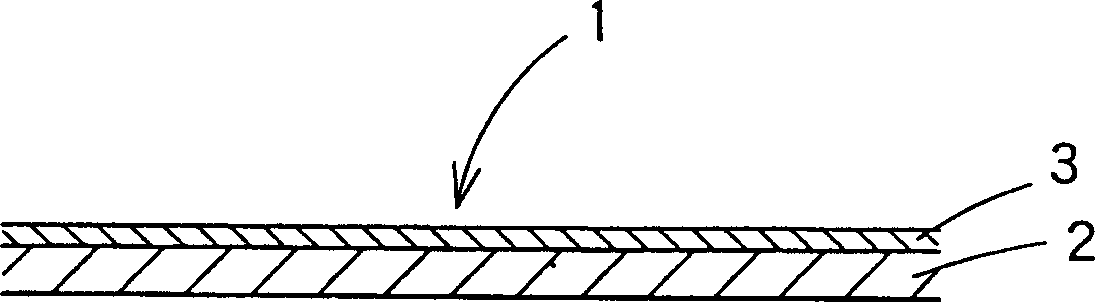

Aluminum/nickel clad material and method for manufacture thereof, and exterior terminal for electric cell

InactiveCN1556751AEasy to manufactureStable Weld JoinabilitySmall-sized cells cases/jacketsWelding/cutting media/materialsUltrasonic weldingHardness

An aluminum / nickel clad material (1) which comprises an aluminum layer (3) formed with pure aluminum and a nickel layer (2) formed with pure nickel being joined with each other by diffusion joining, wherein the nickel layer (2) has a hardness of Hv = 130 to 170; and the aluminum / nickel clad material (1), wherein the aluminum layer (3) and the nickel layer (2) are joined by diffusion joining via an Al - Ni based intermetallic compound layer having a thickness of 0.4 to 10.0 mum, preferably 1.0 to 6.0 mum. The latter clad material exhibits excellent peel strength. The aluminum / nickel clad material exhibits stable welding joinability towards an aluminum material even when ultrasonic welding is applied to it and is less prone to occurrence of failures in shape even when it is subjected to bending working, and thus is suitably used as a material for an exterior terminal for an electric cell.

Owner:NEOMAX MATERIALS

Viscoelasto-plastic soft mode forming method of minor-radius corrugated surface thin-wall metal barrel part

ActiveCN101885018AInhibition of reboundImprove surface qualityHollow articlesPlastic materialsRoom temperature

The invention discloses a viscoelasto-plastic soft mode forming method of a minor-radius corrugated surface thin-wall metal barrel part, relating to a forming method of a minor-radius corrugated surface thin-wall metal barrel part. The invention is designed aiming at the problems that the metal corrugation barrel with smaller corrugation radius and higher material strength, which has thin wall thickness or with ultrathin wall thickness formed by steel mould stamping forming or hot-forming at room temperature, has even distribution of pressure acting on blank and can not adapt to stress variation in the deformation process, the wall thickness of the forming part is unevenly distributed, and the local area is easy to break. The method comprises the following key points of steps: forming an initial-level minor-radius corrugated surface thin-wall metal barrel blank, and comprises the following steps: manufacturing an initial-level forming die, coating release agent, manufacturing the mandrel, assembling the initial-level forming die and the mandrel, filling viscoelasto-plastic material, installing a piston and an overflow valve, adjusting pressure value, opening the die to take out the formed part, removing the viscoelasto-plastic material remained on the surface of the part, and replacing the forming die. The invention is used for forming the minor-radius corrugated surface thin-wall metal barrel part.

Owner:HARBIN INST OF TECH

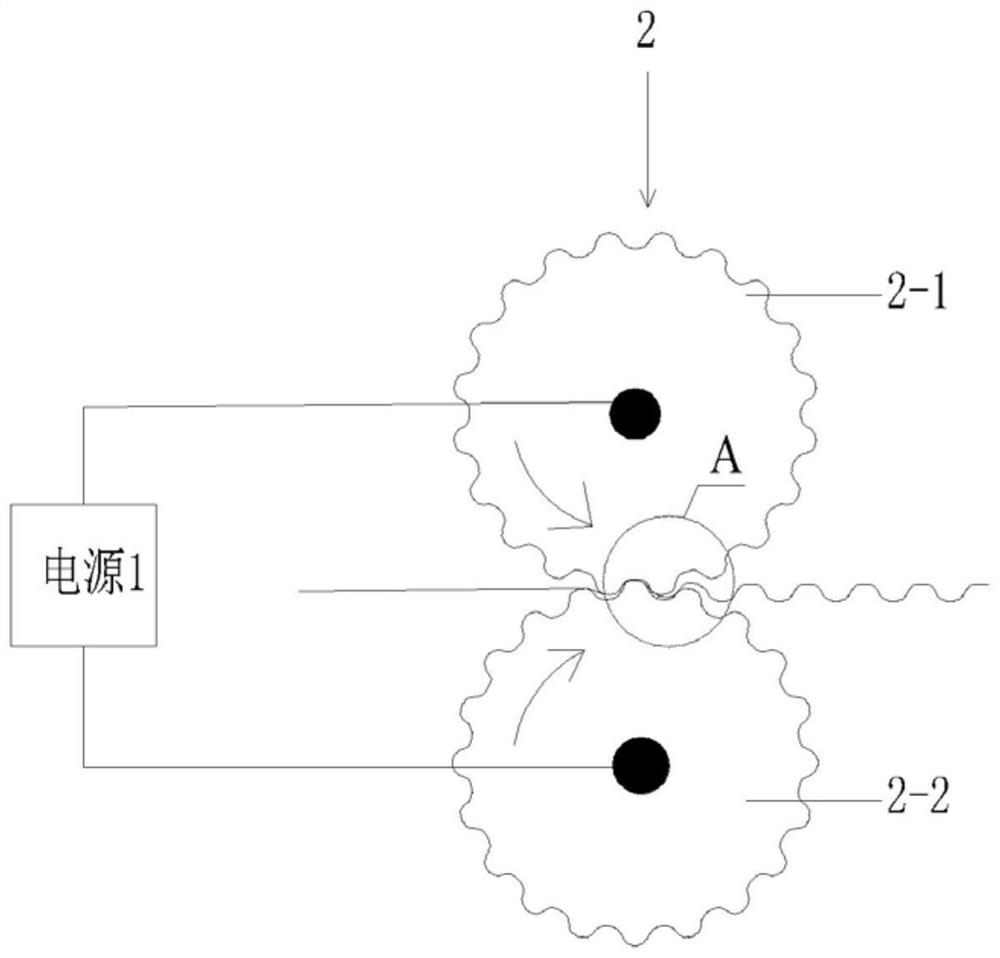

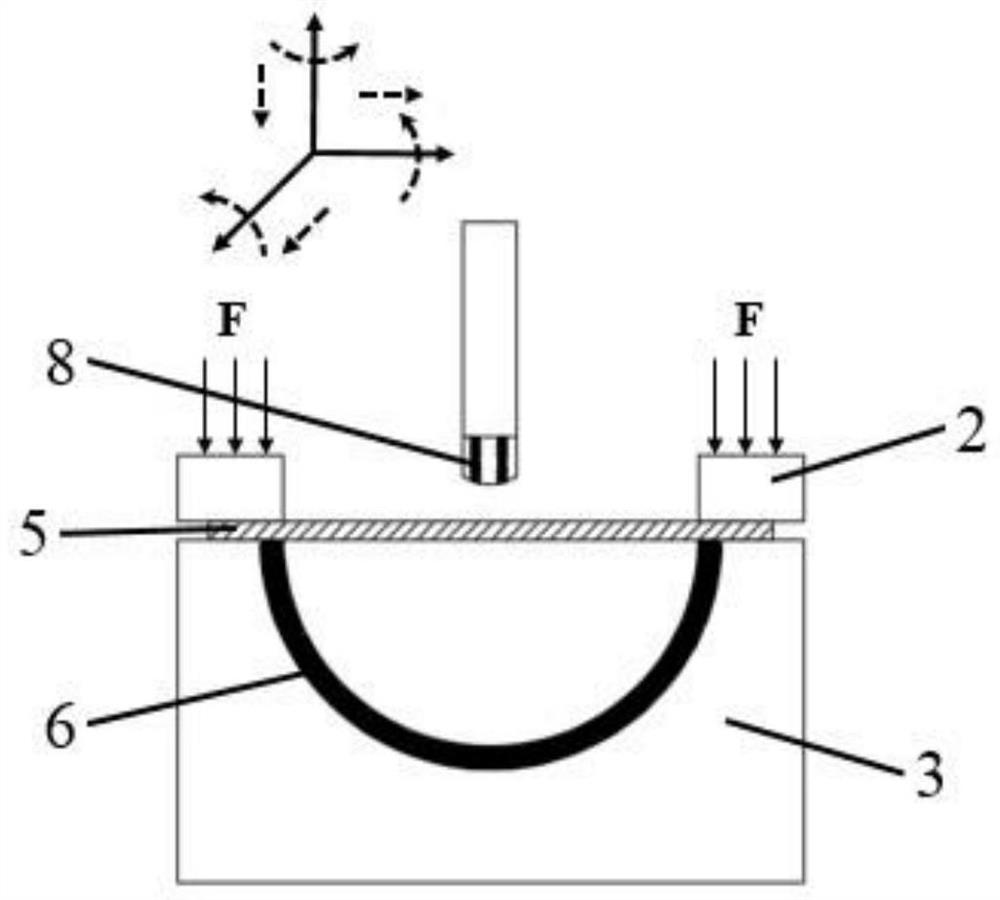

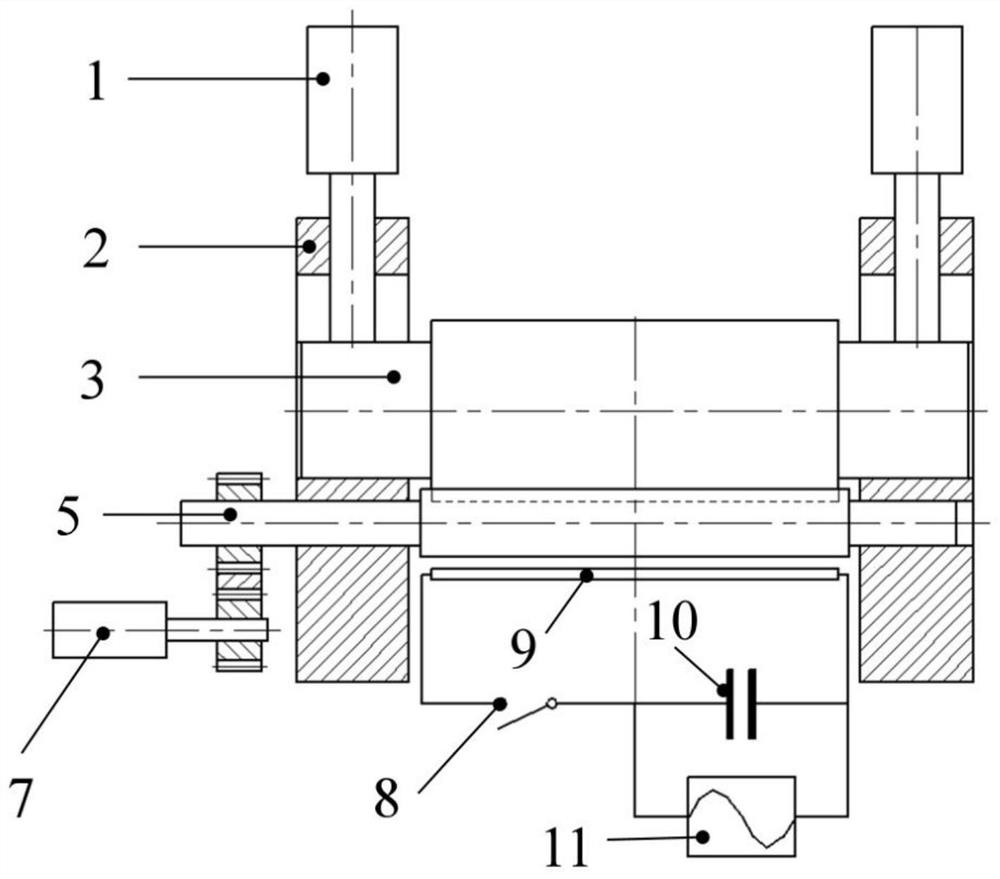

Current-aided flexible pressing roll stretch-forming method for titanium alloy and pressing roll stretch-forming device

The invention discloses a current-aided flexible pressing roll stretch-forming method for titanium alloy and a pressing roll stretch-forming device, and relates to a pressing roll stretch-forming method for titanium alloy and a pressing roll stretch-forming device. The problems that the whole production process has low efficiency and is not suitable for batch production because of low heating efficiency of the conventional pressing roll stretch-forming titanium alloy. The pressing roll stretch-forming method comprises the following steps of: selecting current of 1,000 to 20,000 A; placing the outer edge of a blank to be formed between an electrode and an insulating plate, pressing and electrifying for heating, wherein the heating speed is 5 to 20 DEG C per second; measuring the temperature of the blank to be formed through an infrared temperature measuring instrument; after the temperature of the blank to be formed reaches 700 to 930 DEG C, compacting the edge of the blank to be formed by an edge compaction device; and applying pressure to the blank to be formed by a pressing roll device, and finally finishing a plastic forming process. A lift cylinder of the pressing roll stretch-forming device is vertically arranged on the ground, the insulating plate is fixedly arranged at the upper end of the lift cylinder, and the electrode ends of two electrodes are connected with a power supply through leads. The method and the device are used for pressing roll stretch-forming of the titanium alloy.

Owner:HARBIN INST OF TECH

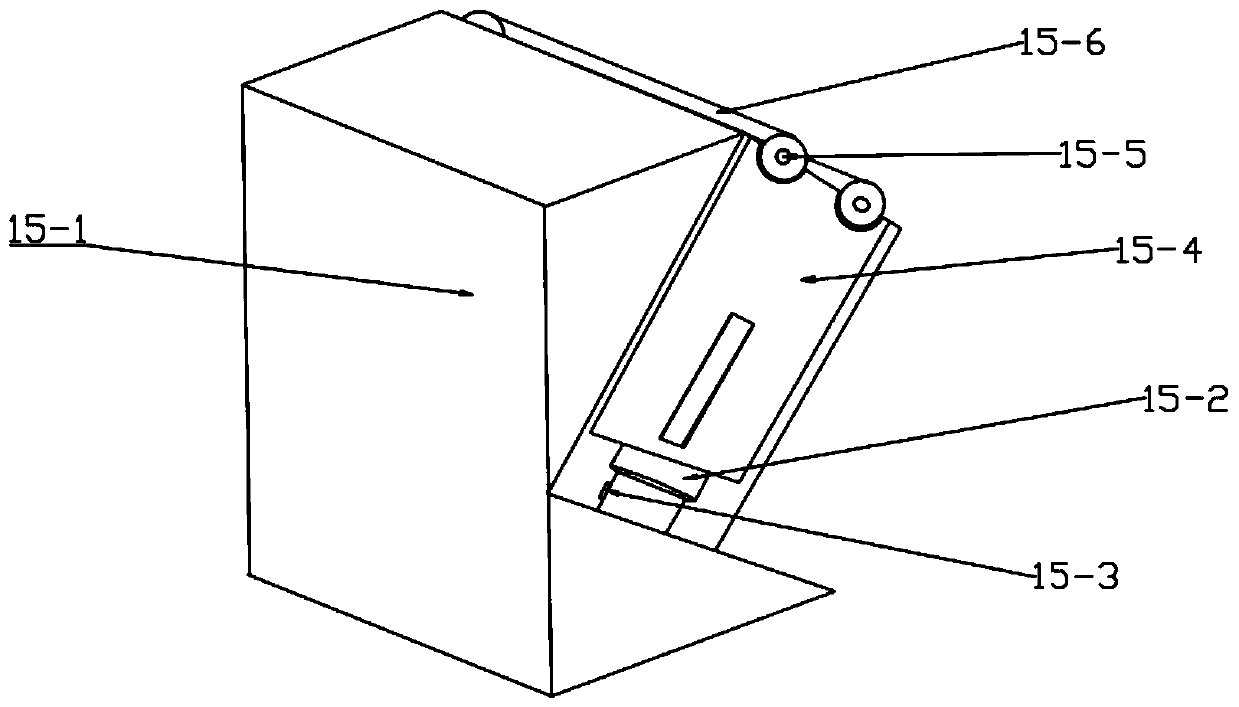

Device for storing yacht and using method of device

PendingCN108045422AAchieve stabilityRealize handlingHand carts with multiple axesElectrical and Electronics engineering

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

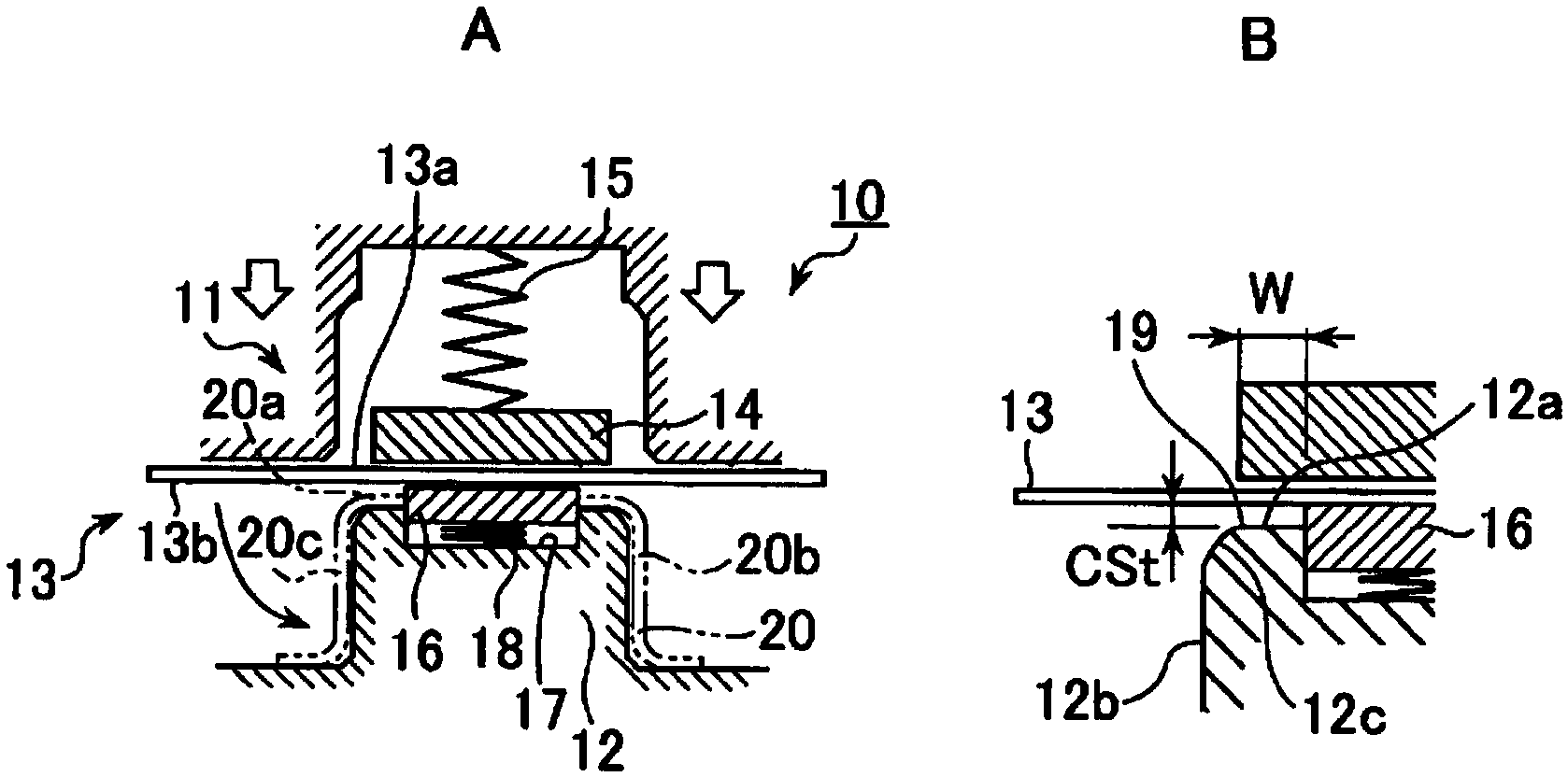

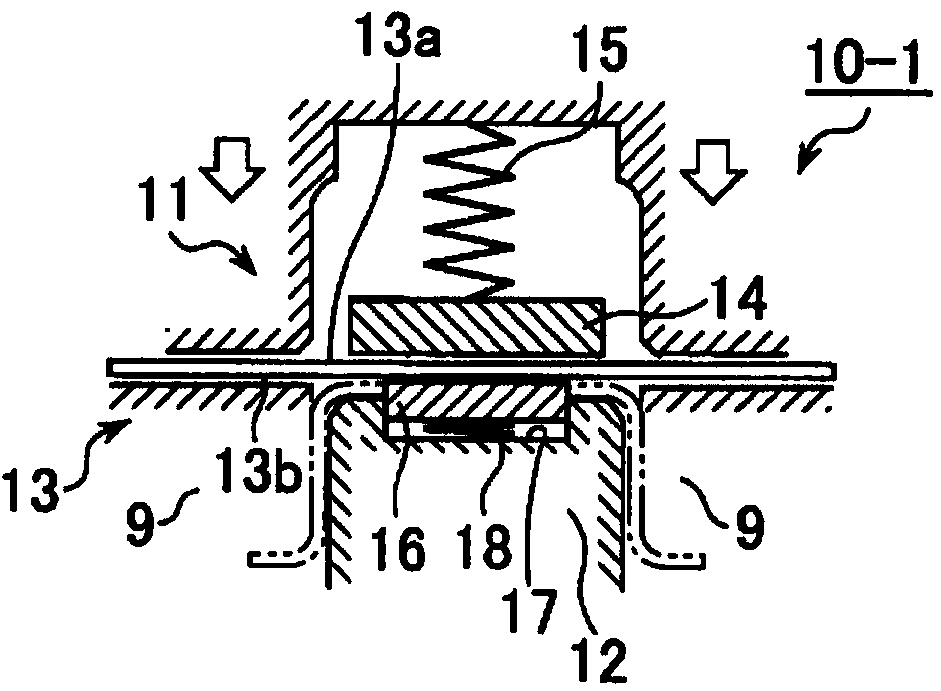

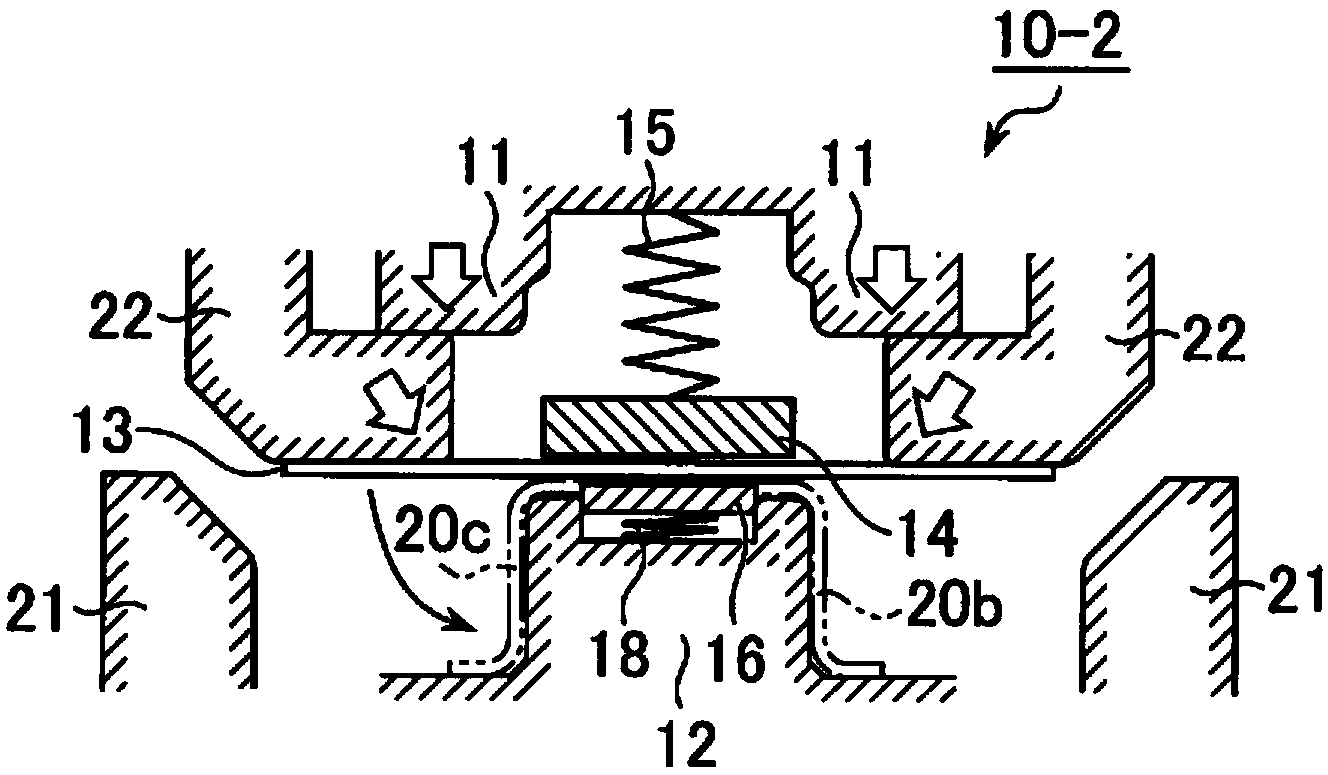

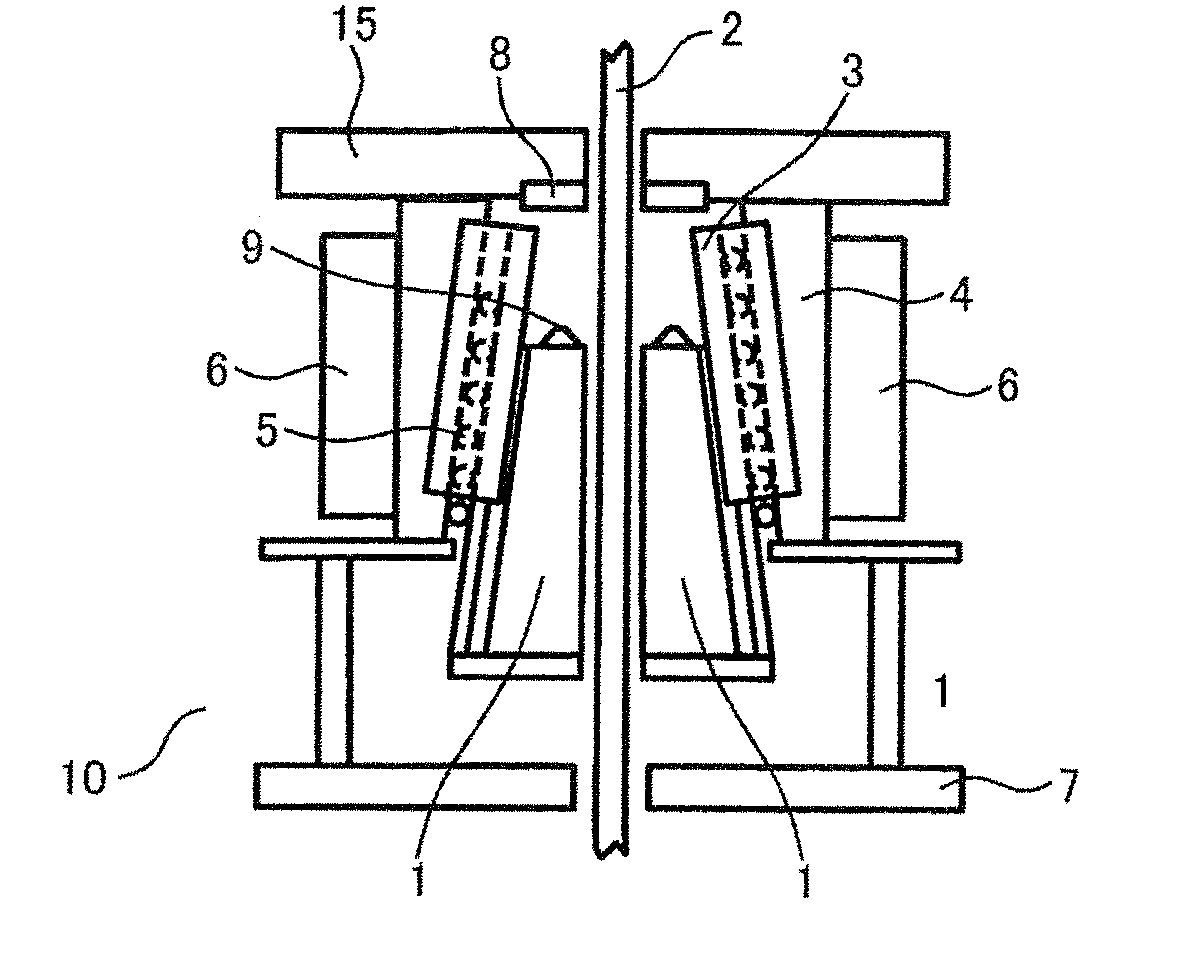

Elevator provided with emergency braking device

In order to prevent the bounce of a brake shoe during the initial braking, produce the braking force stably, and stop at the predetermined speed, the invention provides an elevator provided with an emergency braking device. In order to stop the cabin of the elevator, the brake shoe is slidably disposed on a guide rail in an elevating channel in a pressed manner by using the emergency brake device, and therefore the brake force can be generated. The elevator provided with the emergency brake device is further provided with a collision force direction converting part, which can be used to convert the collision force generated by the collision between the brake shoe being lifted upward and a top plate of the emergency braking device into the movement resistance in the horizontal direction. The collision force direction converting part is constituted by a pin used as a protruding member and a gap filling sheet used as a concave member. The pin is disposed on an upper part of the brake shoe, and the gap filling sheet is disposed on the top plate of the emergency braking device by the housing part in a supported manner, and can be embedded with the pin. The movement of the gap filling sheet in the horizontal direction can be used to prevent the bounce of the brake shoe.

Owner:HITACHI LTD

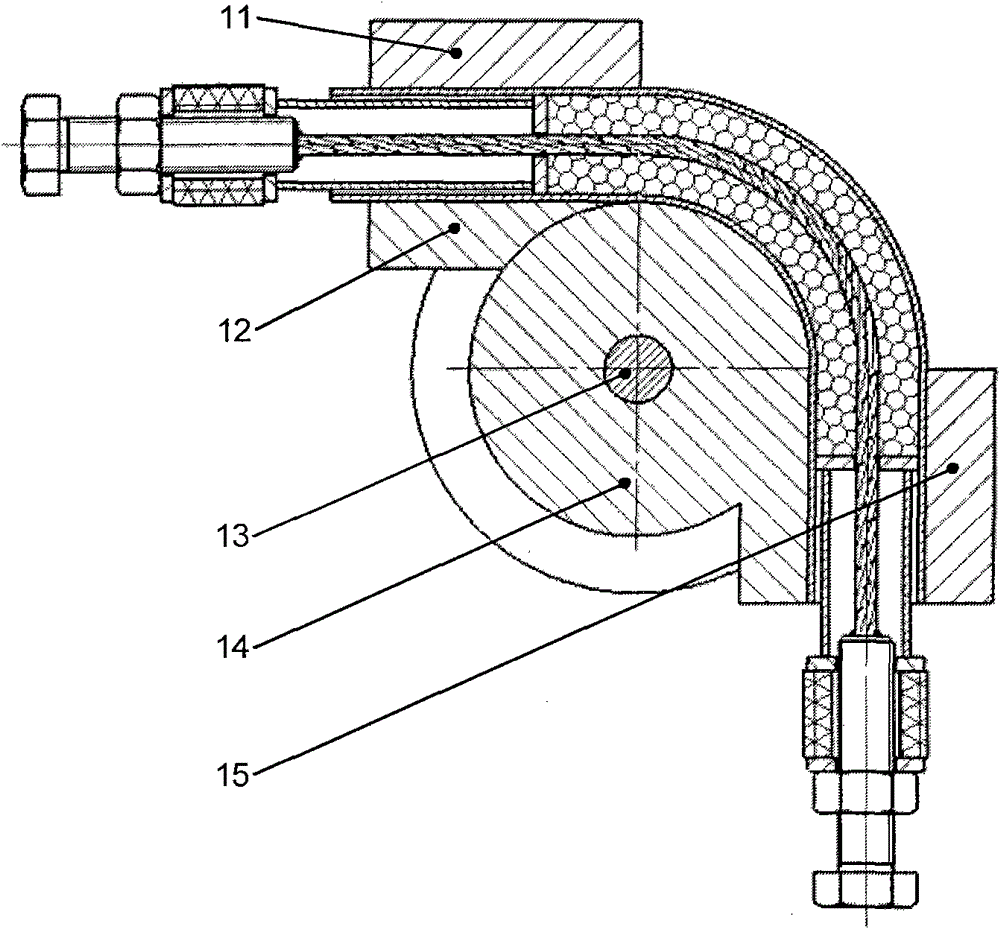

Method for bending and forming metal pipe by placing steel balls inside

The invention discloses a method for bending and forming a metal pipe by placing steel balls inside. The method is characterized by comprising the following steps of: (1) filling small steel balls of different numbers and different sizes serving as a pressure transmitting medium into a pipe forming section; (2) applying pressure to retainer rings at two ends of the steel balls by using closed pressure transmitting structures, wherein the pressure is always parallel to the axis of the pipe; (3) putting the closed and pressed metal pipe on a pipe bending die or pipe bending equipment, applying pressure to one end of the metal pipe, and clamping the other end of the metal pipe for bending and forming; and (4) opening the closed pressure transmitting structures at the two ends of the steel balls after bending is finished, and pouring and recycling the steel balls. The method has the advantages that: the steel balls are used as the pressure transmitting medium for bending and forming of the pipe, so forming defects of pipe bending parts can be effectively inhibited, and compared with the conventional other pressure transmitting medium, the steel balls are placed, sealed and taken out conveniently, the supporting force is large, and the problems of environmental pollution and the like are not produced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

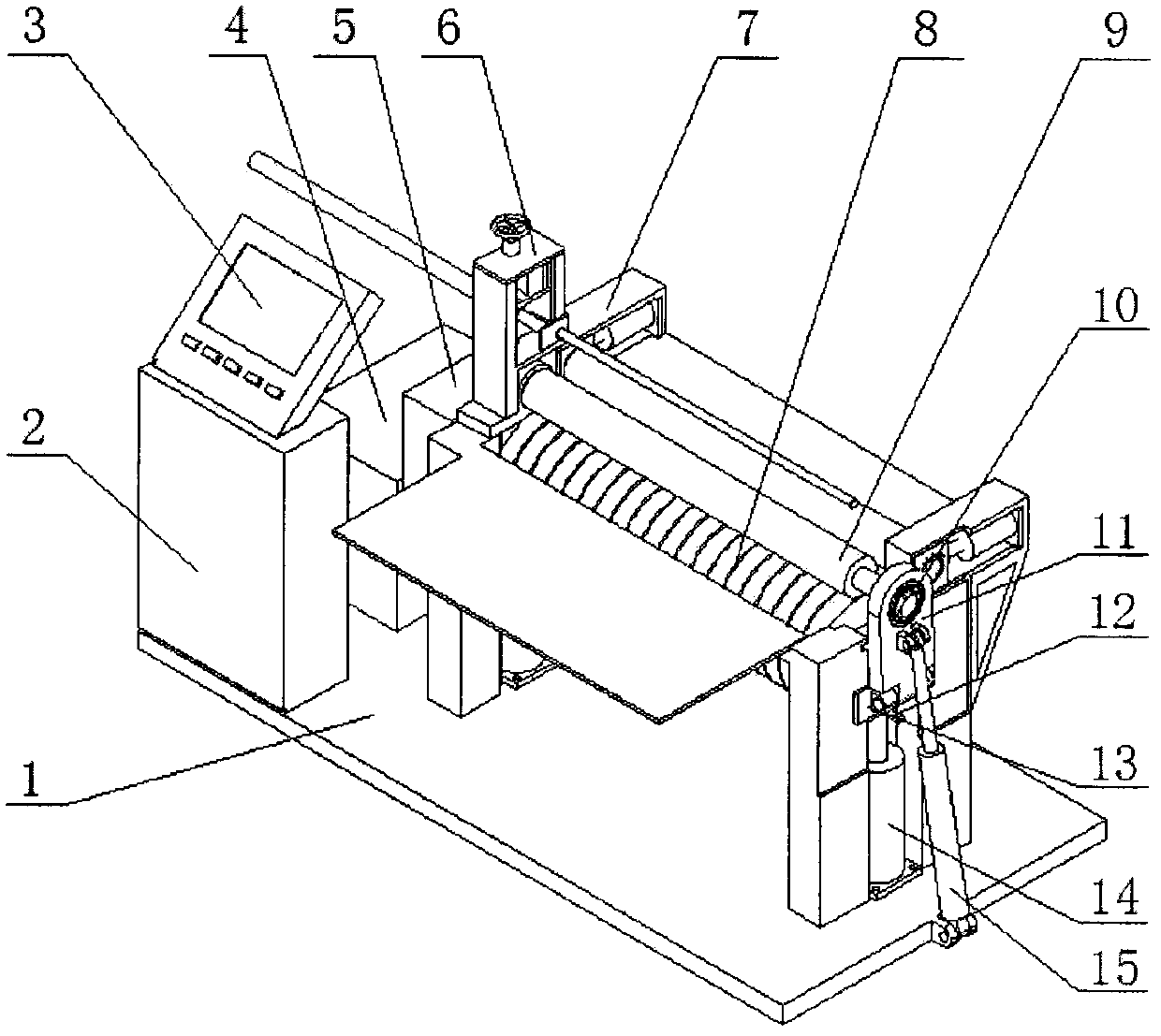

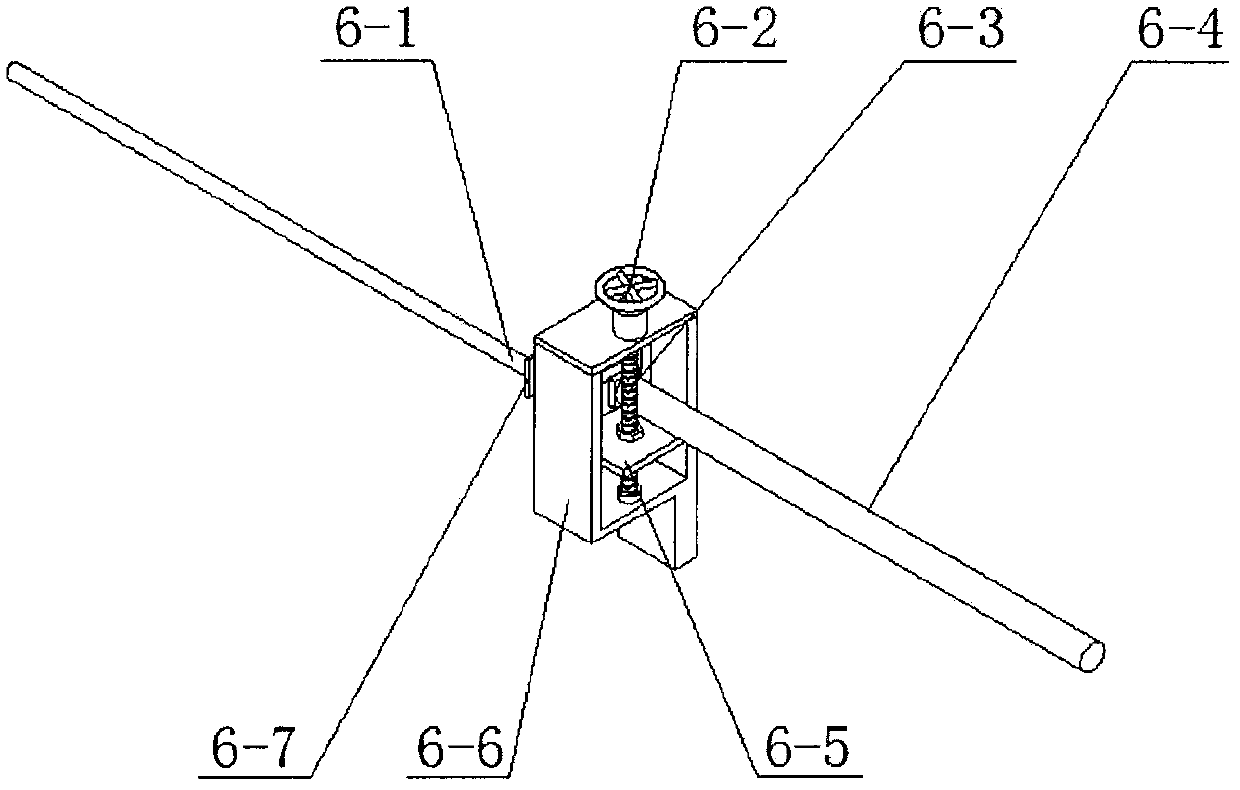

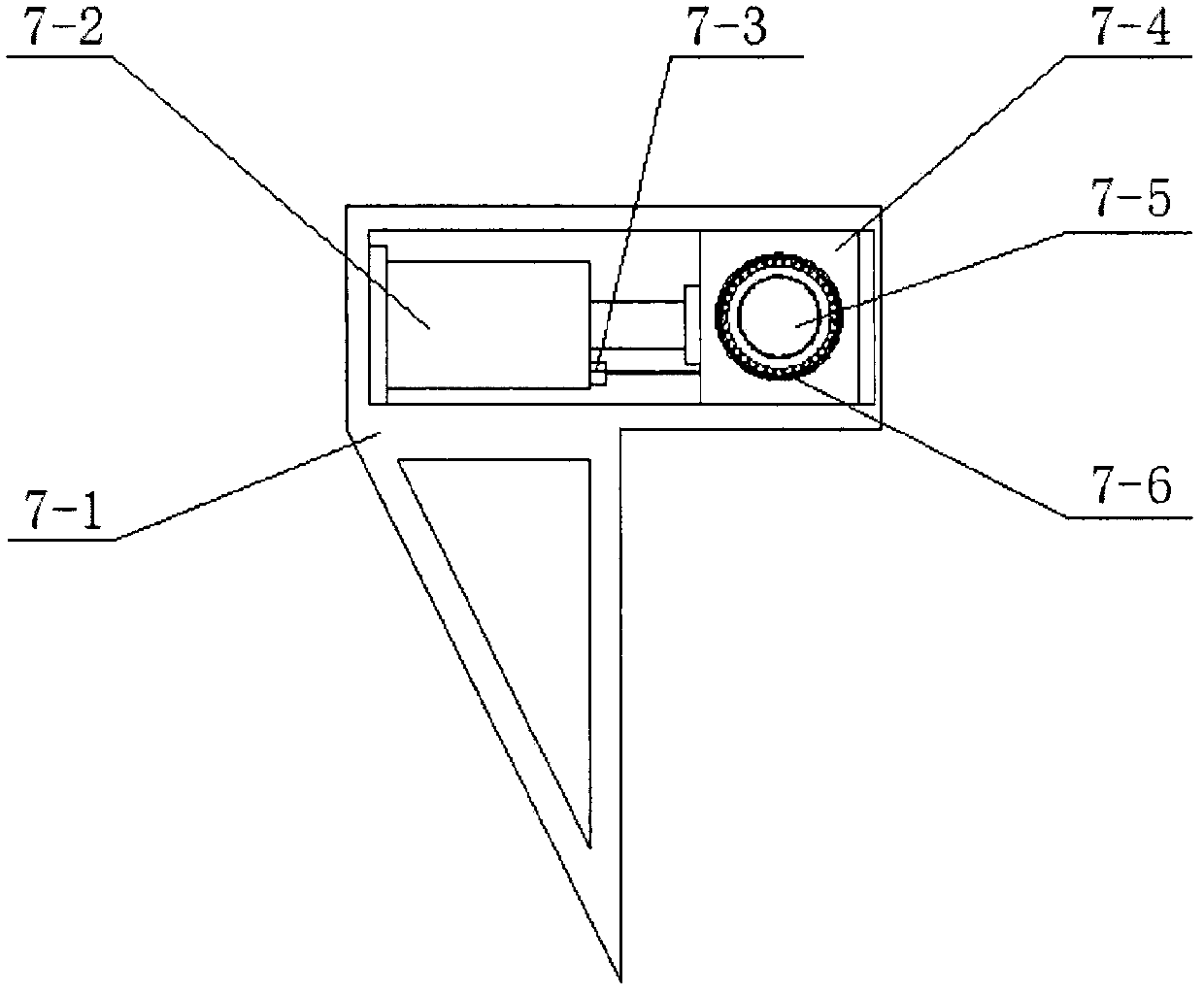

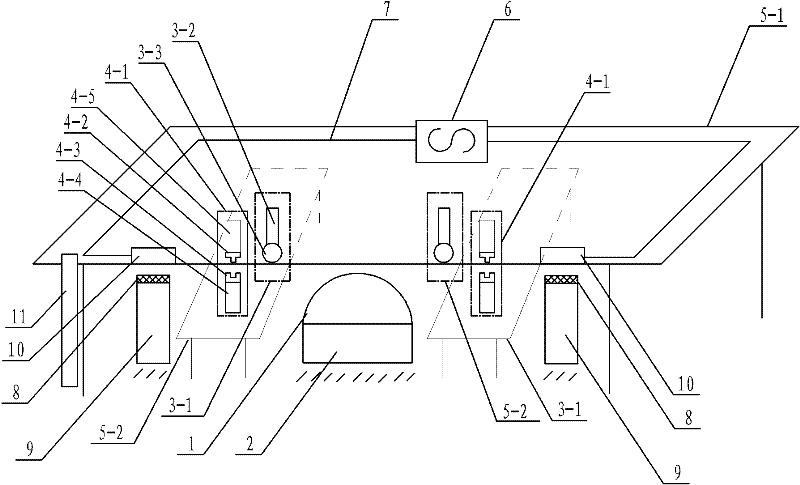

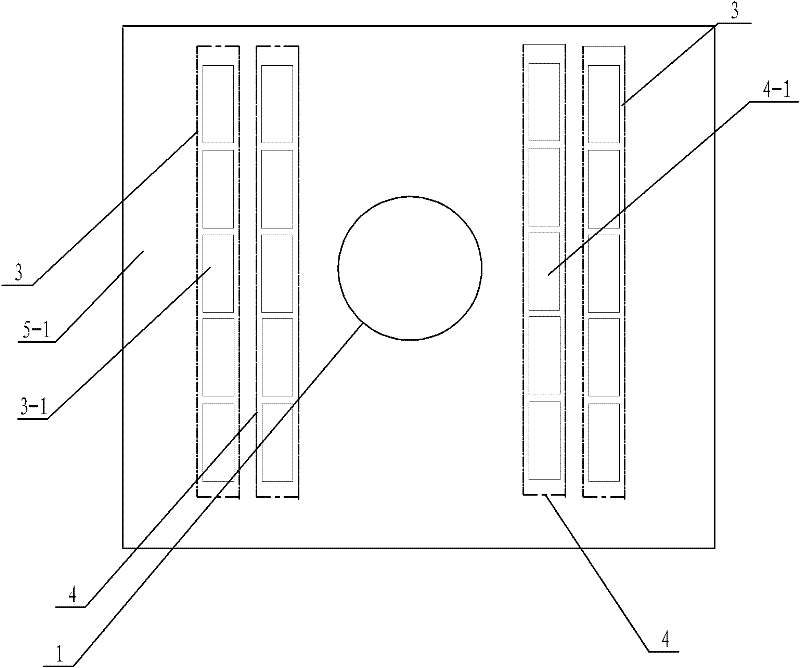

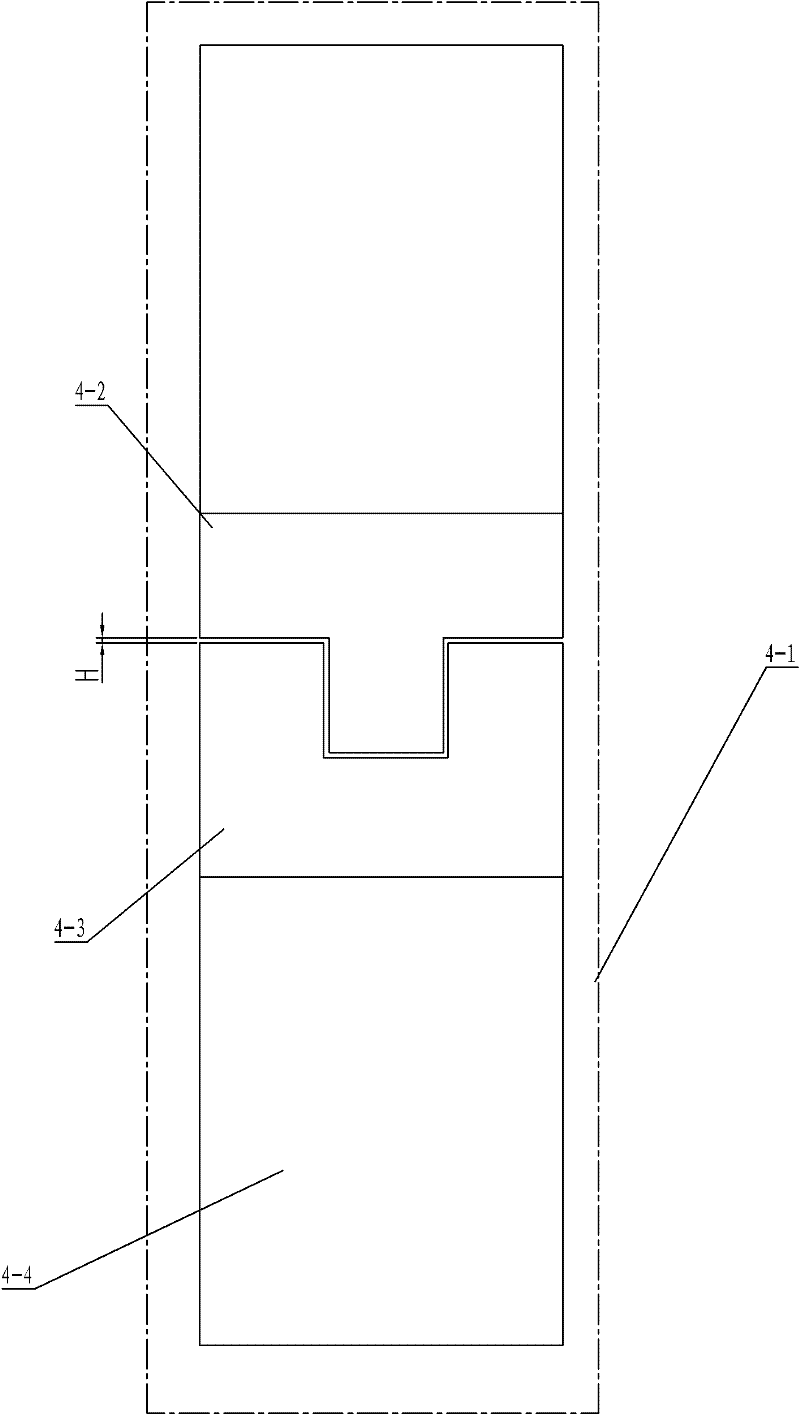

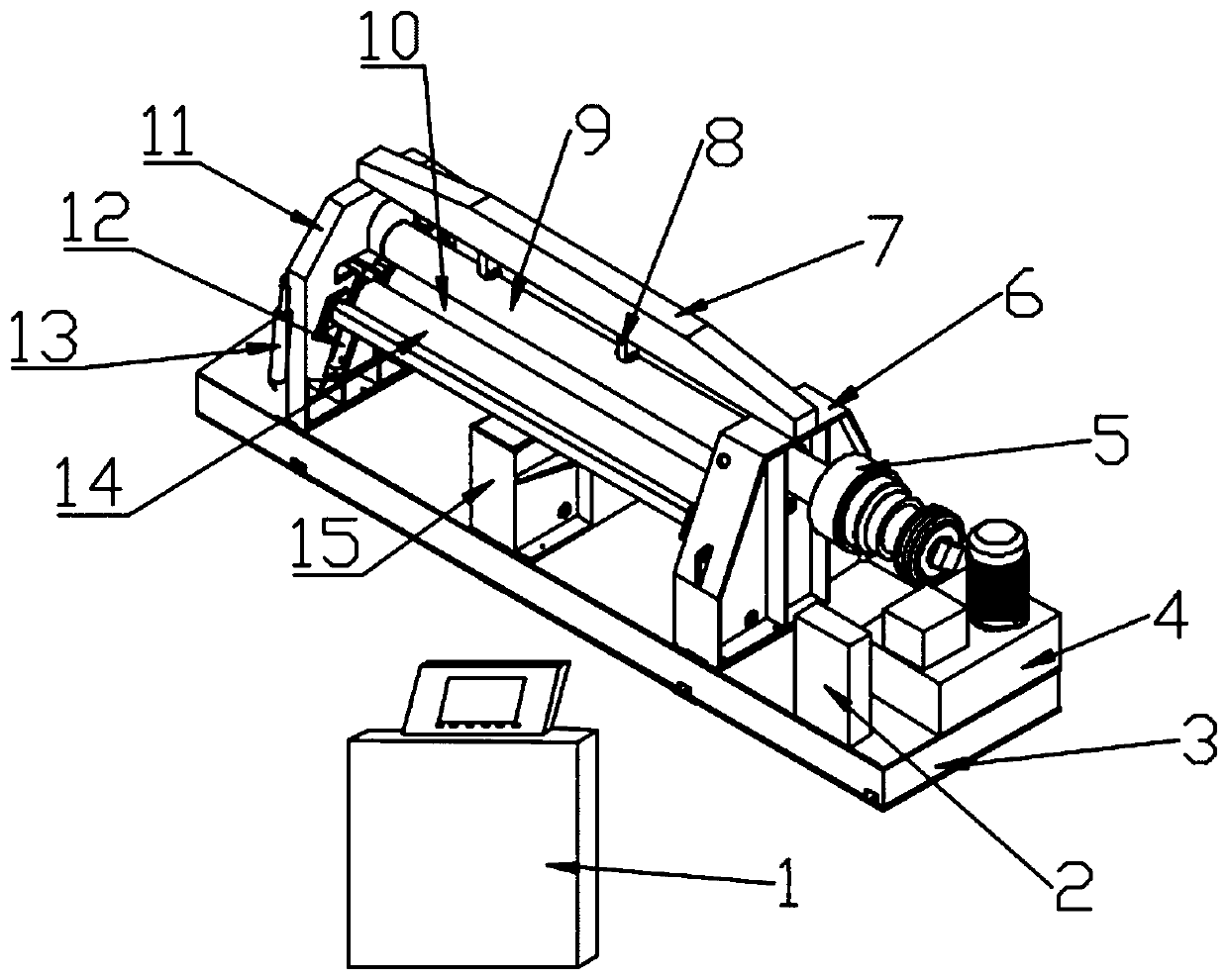

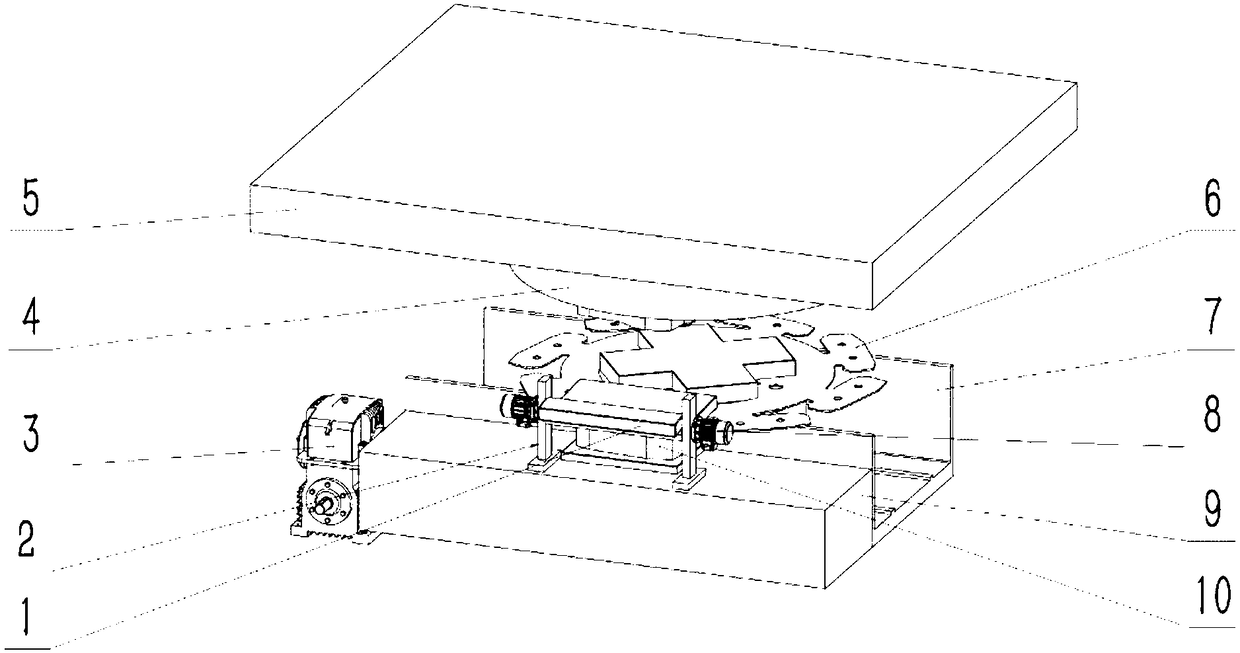

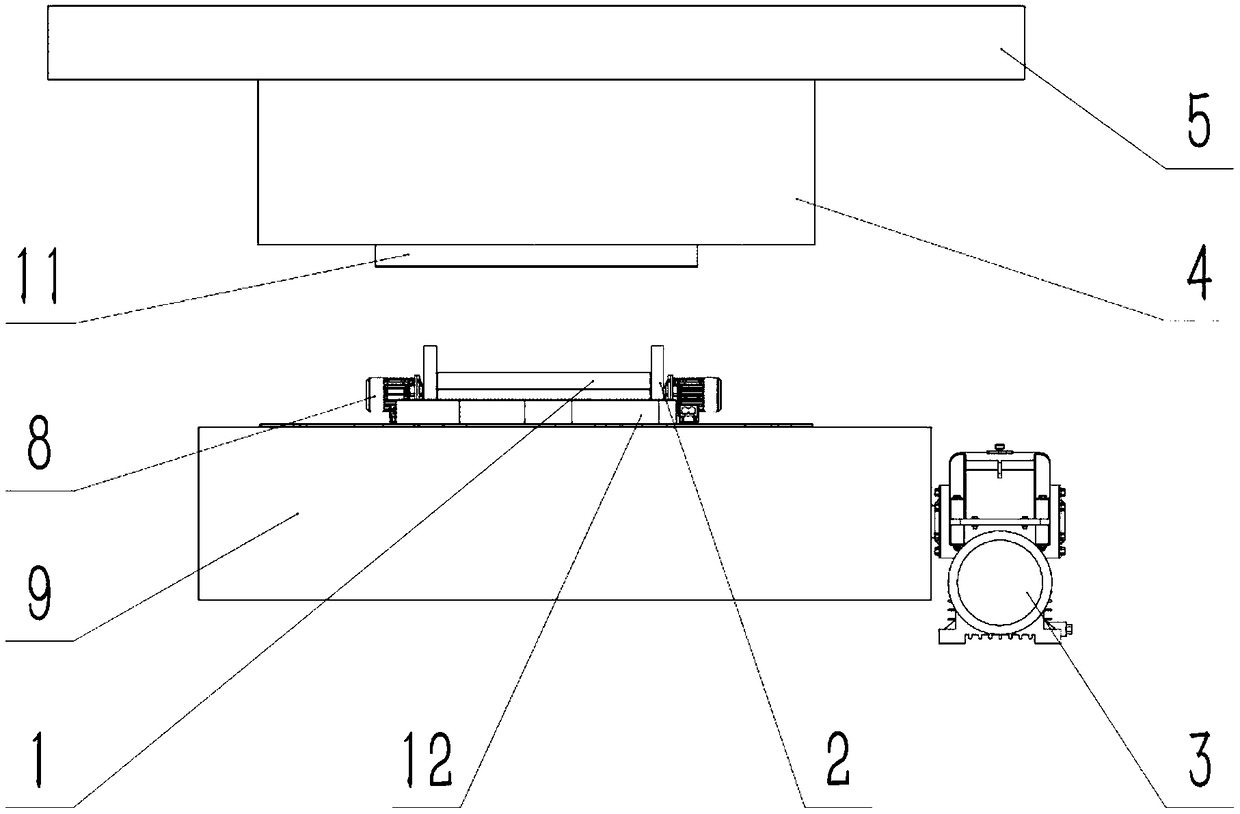

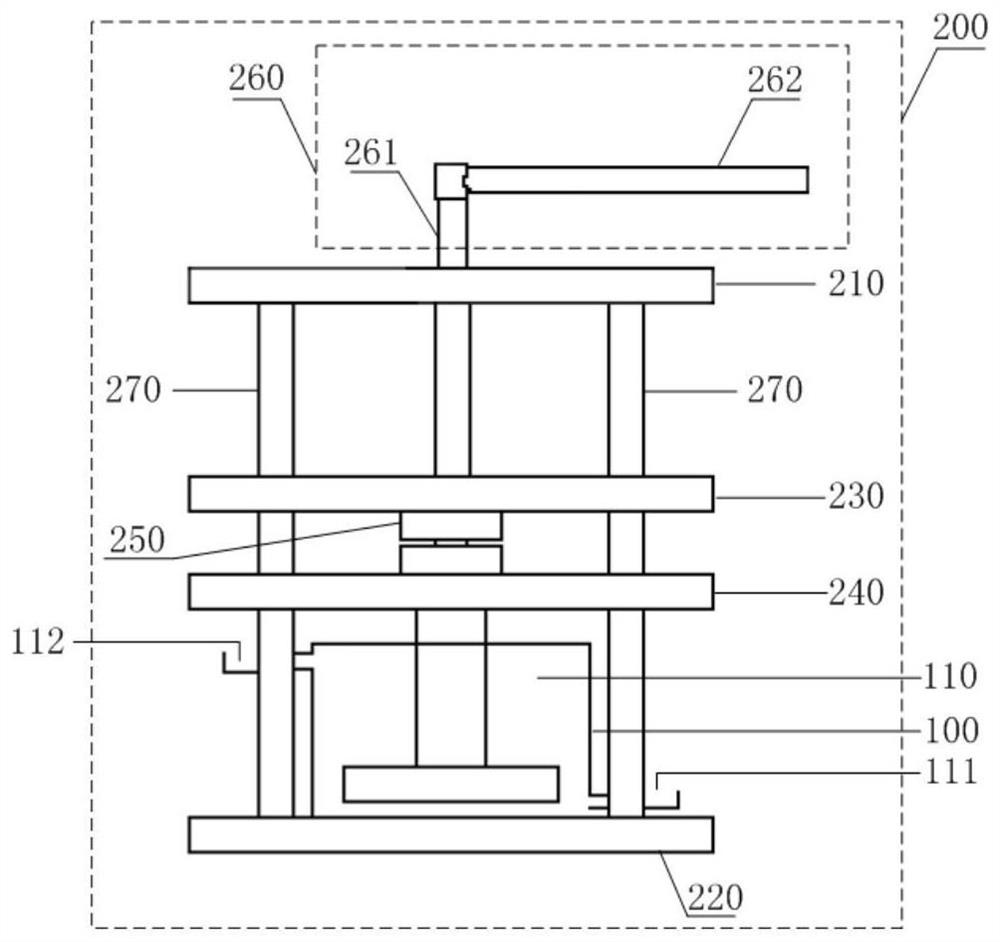

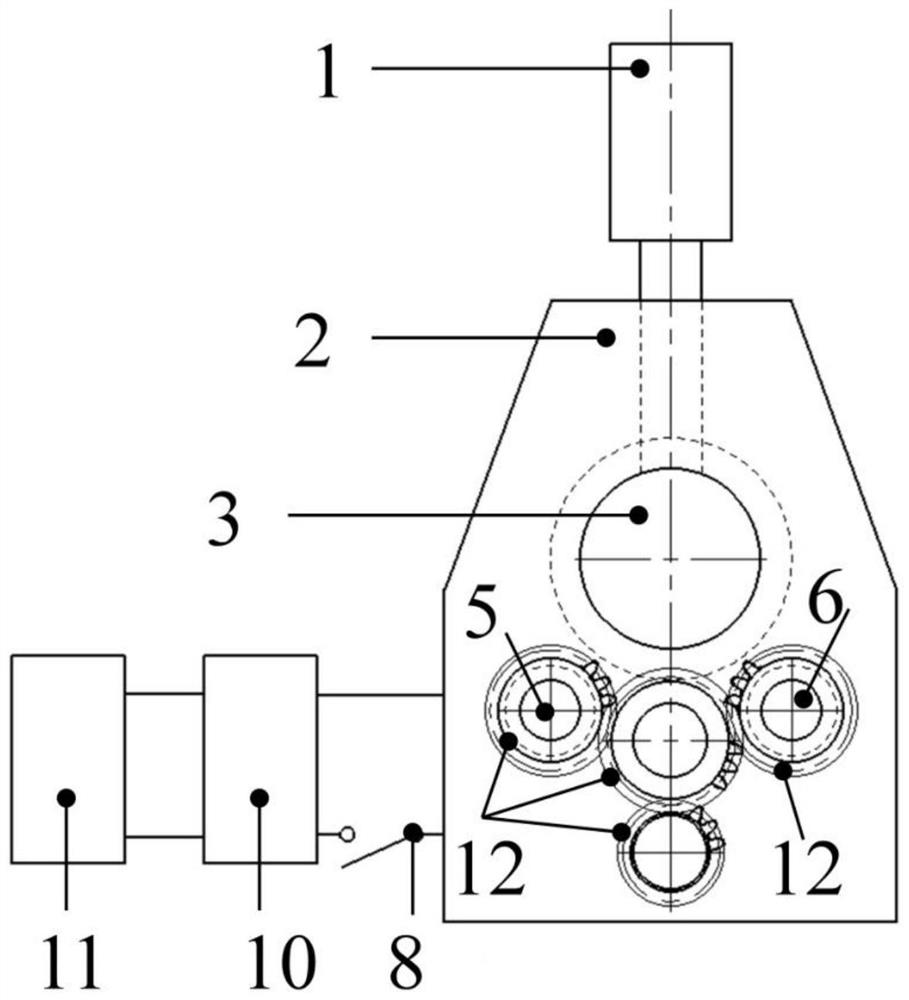

Numerical-control flexible roll bending machine for three-dimensional variable-curvature sheet metal parts

InactiveCN110802142AInhibition of reboundIncrease flexibilityShaping toolsNumerical control systemEngineering

The invention discloses a numerical-control flexible roll bending machine for three-dimensional variable-curvature sheet metal parts. The numerical-control flexible roll bending machine comprises a base, a left machine frame, a right machine frame, a turnover device, a rigid roller, a flexible roller coated with polyurethane rubber, two side rollers, an upper roller supporting device, a side roller supporting device, a driving device, a lifting device and a dedicated numerical control system. The rigid roller, the flexible roller and the two side rollers are installed on the left machine frameand the right machine frame. According to the numerical-control flexible roll bending machine, the flexible roller is located under the rigid roller and connected with the lifting device, a rigid upper roller is connected with the driving device, the lifting device drives the flexible roller to ascend and descend, the driving device drives the rigid upper roller to rotate, the upper roller supporting device and the lower roller supporting device conduct reverse supporting on the rigid upper roller and two lower rollers, and the phenomenon that in the plate rolling process, all rollers are subjected to flexural deflection due to reactive force is eliminated; and by controlling the depth, pressed into the flexible roller, of the rigid upper roller and the feeding positions of the two side rollers, the parts subjected to double variable curvature roll bending are obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A thin-wall metal bellows forming method based on shape memory polymer

ActiveCN105562493BImprove surface qualityImprove uniformityRoom temperatureUltimate tensile strength

The invention provides a method for forming a thin-wall metal bellows based on a shape memory polymer and relates to a thin-wall metal bellows forming method. The invention aims at solving the problems that wall thickness distribution of a formed part is uneven, a local region can be easily cracked, a forming device is complex and cost is relatively high when a steel die is used for carrying out stamping forming of a thin-wall metal bellows with relatively high material strength at room temperature. According to key points of the technical scheme, the method provided by the invention comprises the following steps: preparing a ripple shape memory polymer, making a forming die, making a core die to be assembled with the forming die, filling a medium bin with rubbery state shape memory polymer material, naturally cooling the shape memory polymer to room temperature, opening the die, and taking out the formed part. The method provided by the invention is applied to thin-wall metal bellows forming.

Owner:南京柔科航空设备科技有限公司

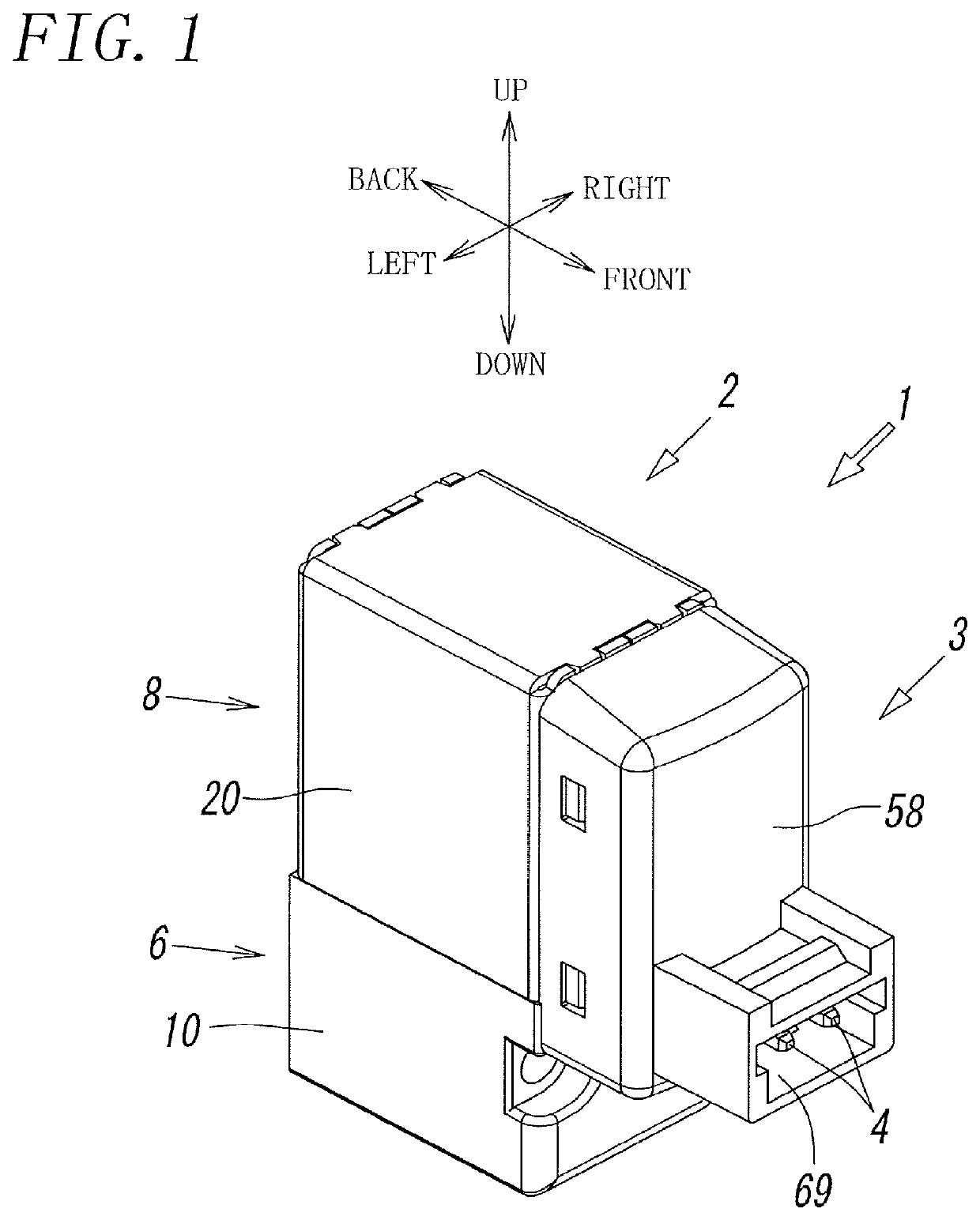

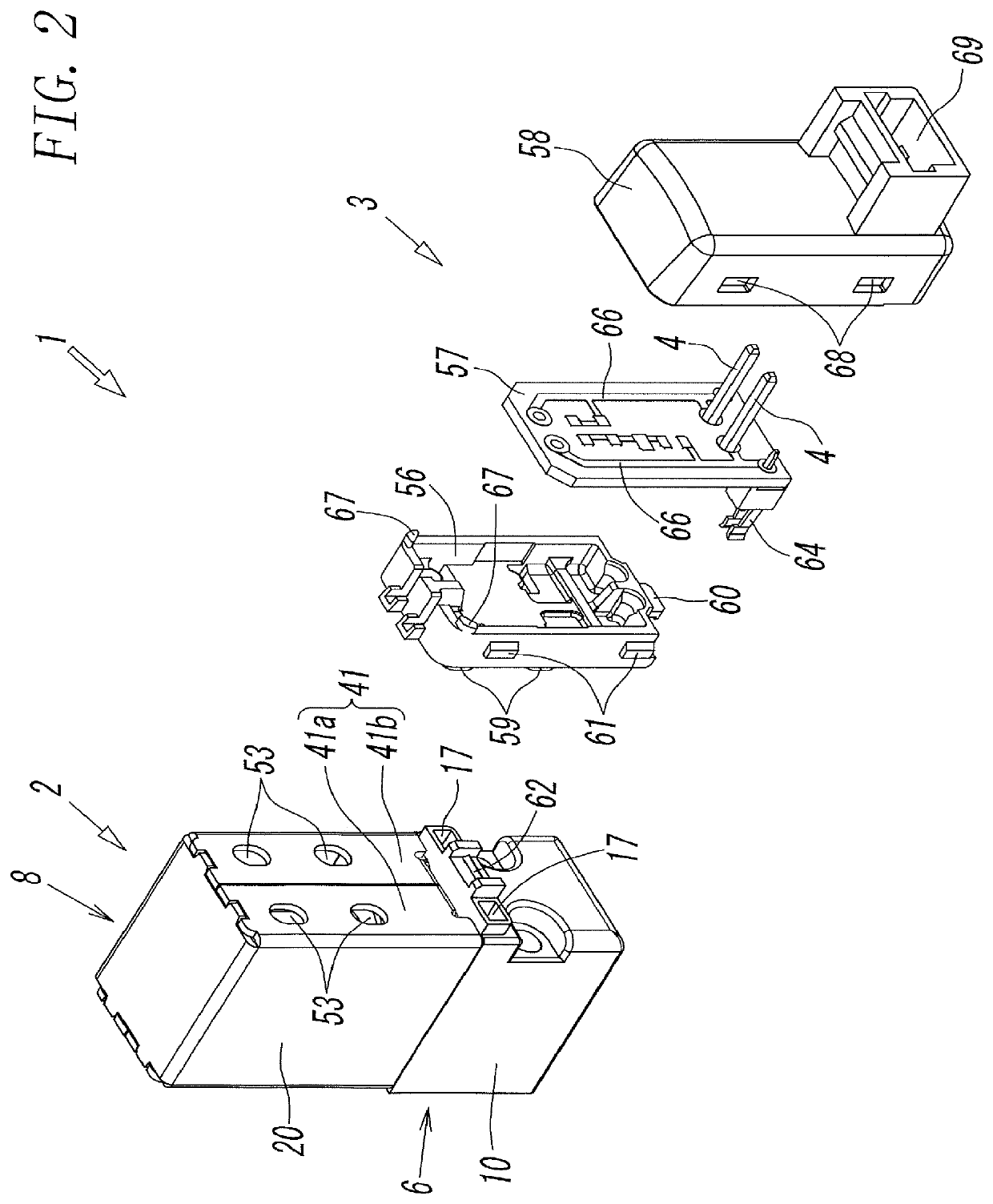

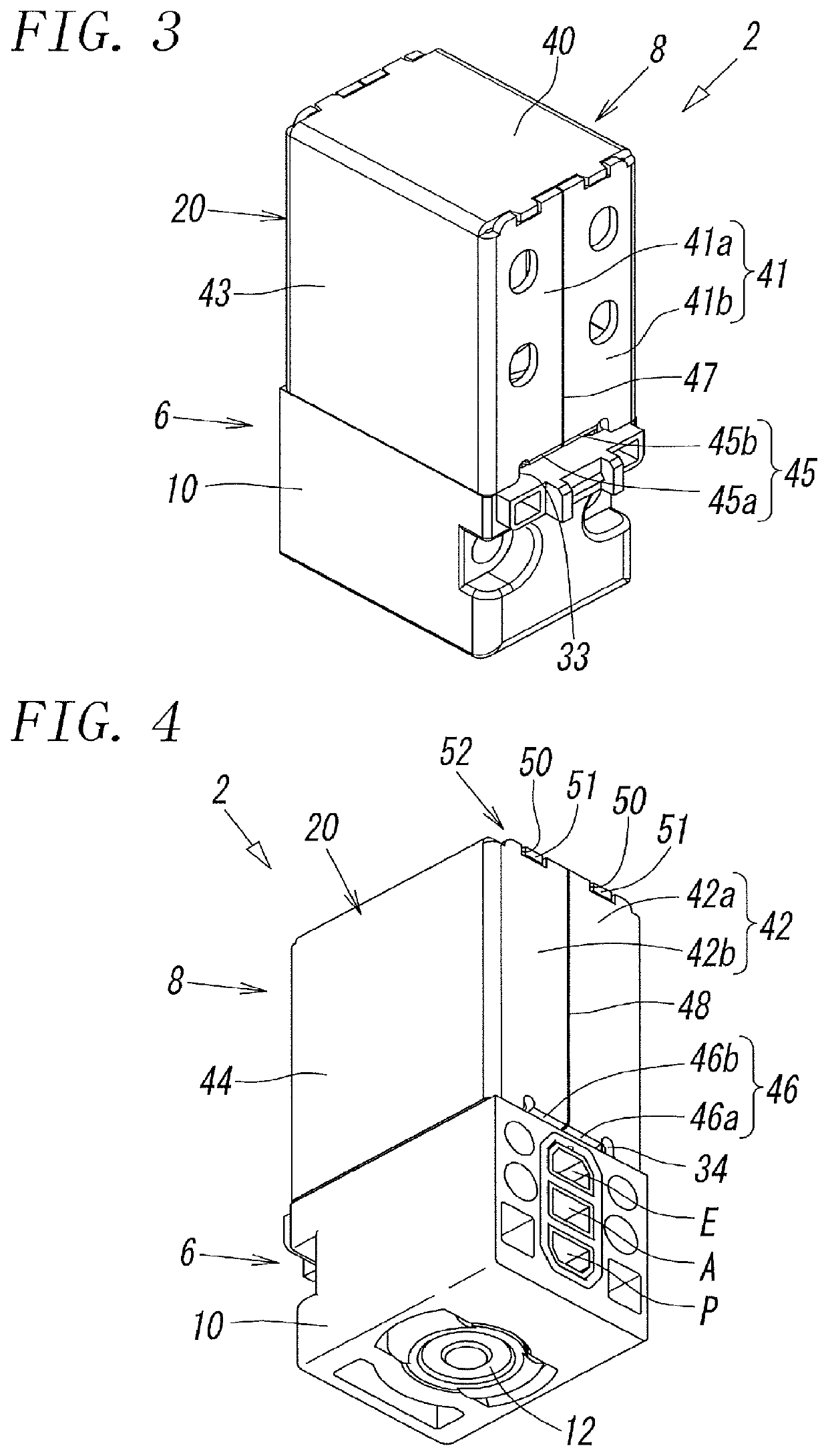

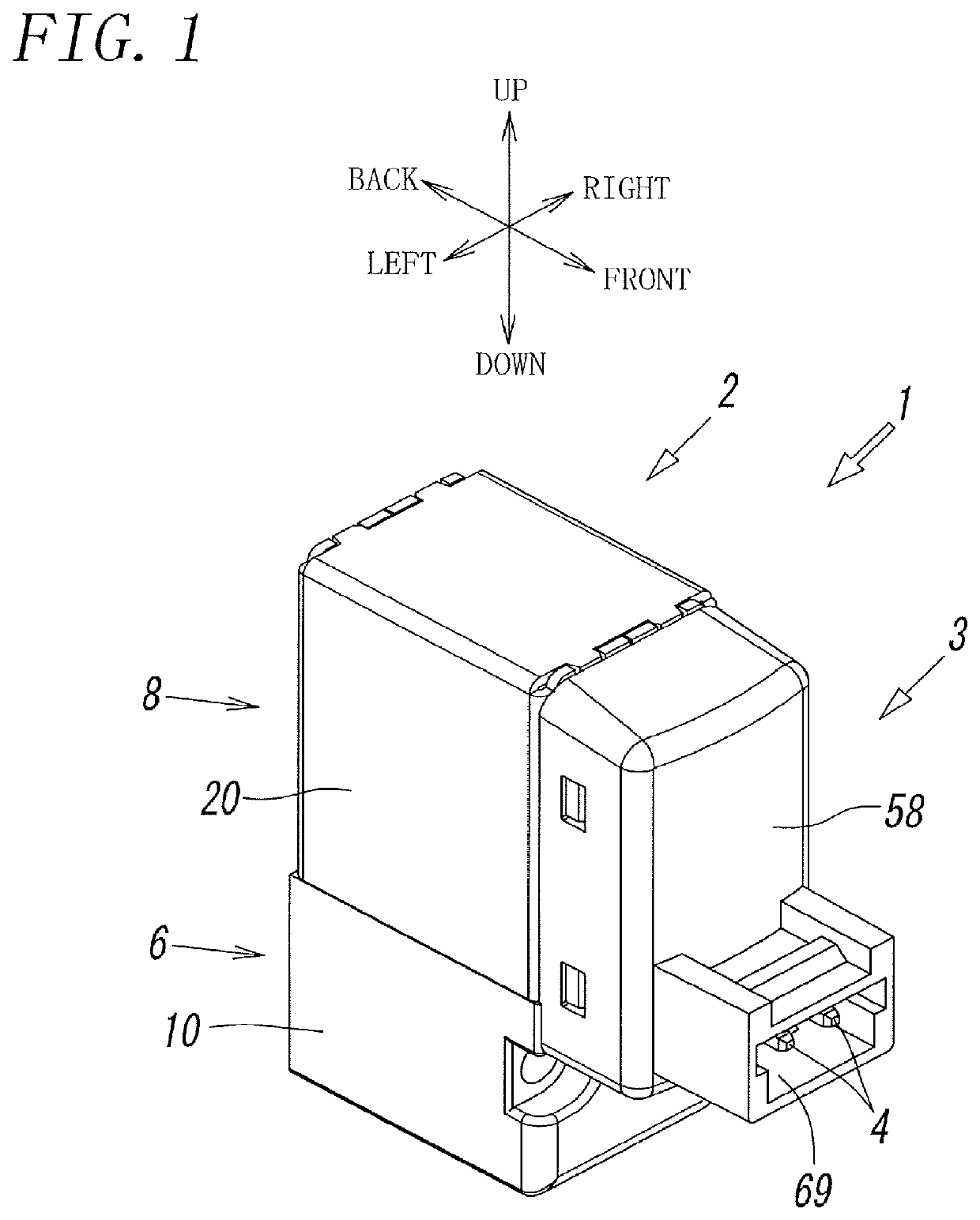

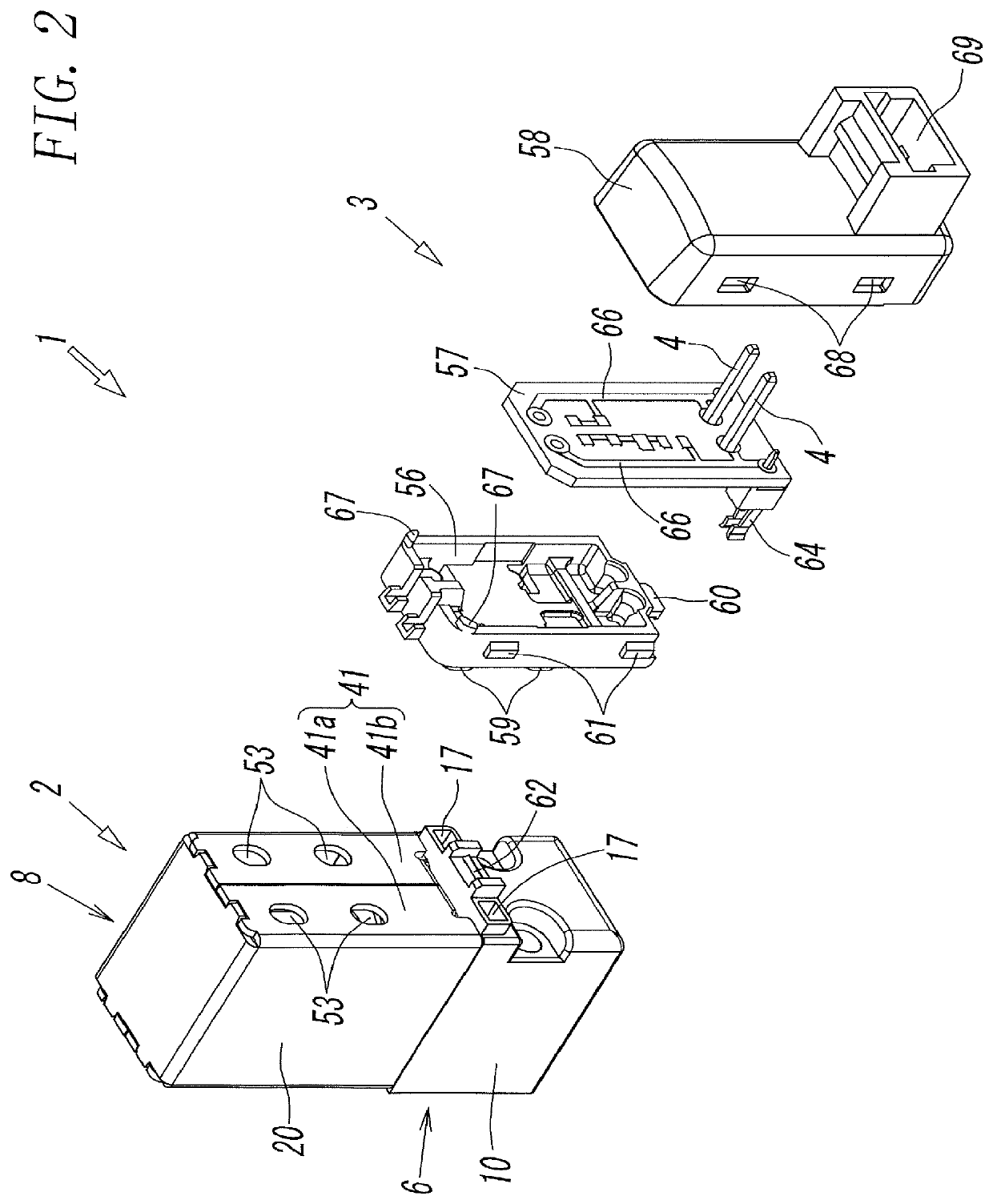

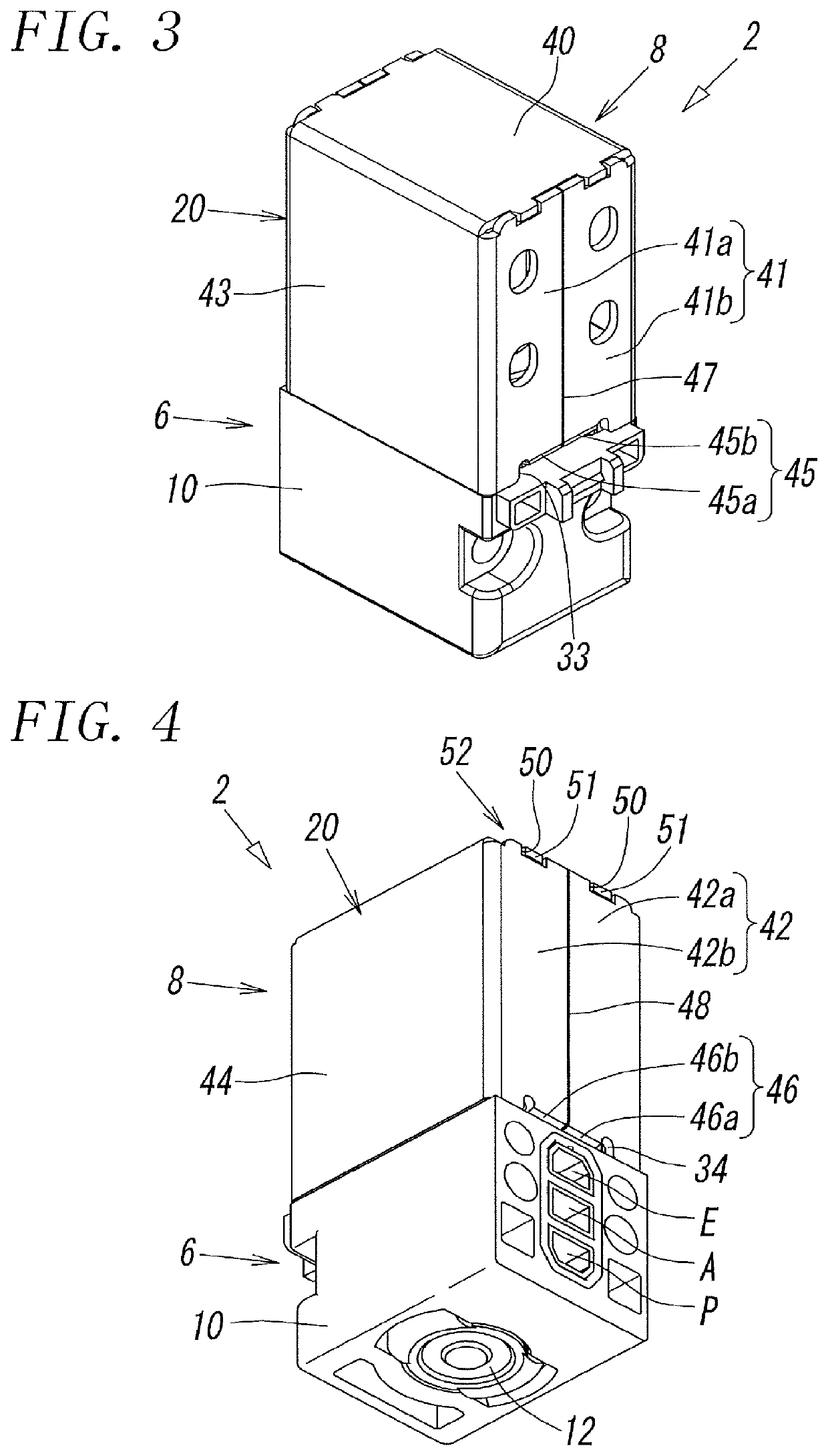

Solenoid valve

ActiveUS20210396329A1Inhibition of reboundIncrease in magnetic reluctance can be preventedOperating means/releasing devices for valvesValve housingsSolenoid valveCoupling

Latch protrusions of an upper surface wall are latched into latch recesses of a first front-surface half wall and an upper end portion of a second front-surface half wall of a magnetic cover, and latch protrusions of the upper surface wall are latched into latch recesses of a first rear-surface half wall and an upper end portion of a second rear-surface half wall of the magnetic cover. Hook portions of the first front-surface half wall and a lower end portion of the second front-surface half wall are folded into a coupling groove of the valve body, and hook portions of the first rear-surface half wall and a lower end portion of the second rear-surface half wall are folded into a coupling groove of the valve body.

Owner:SMC CORP

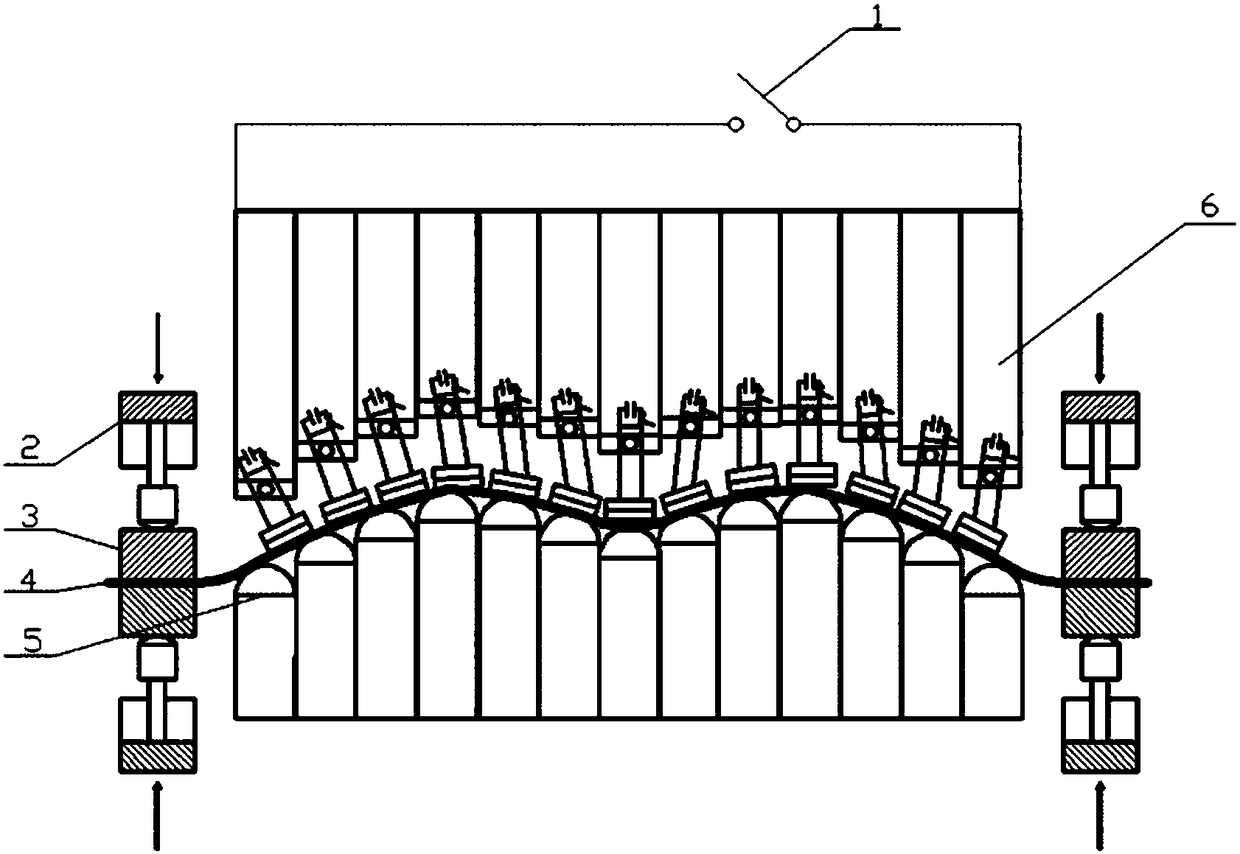

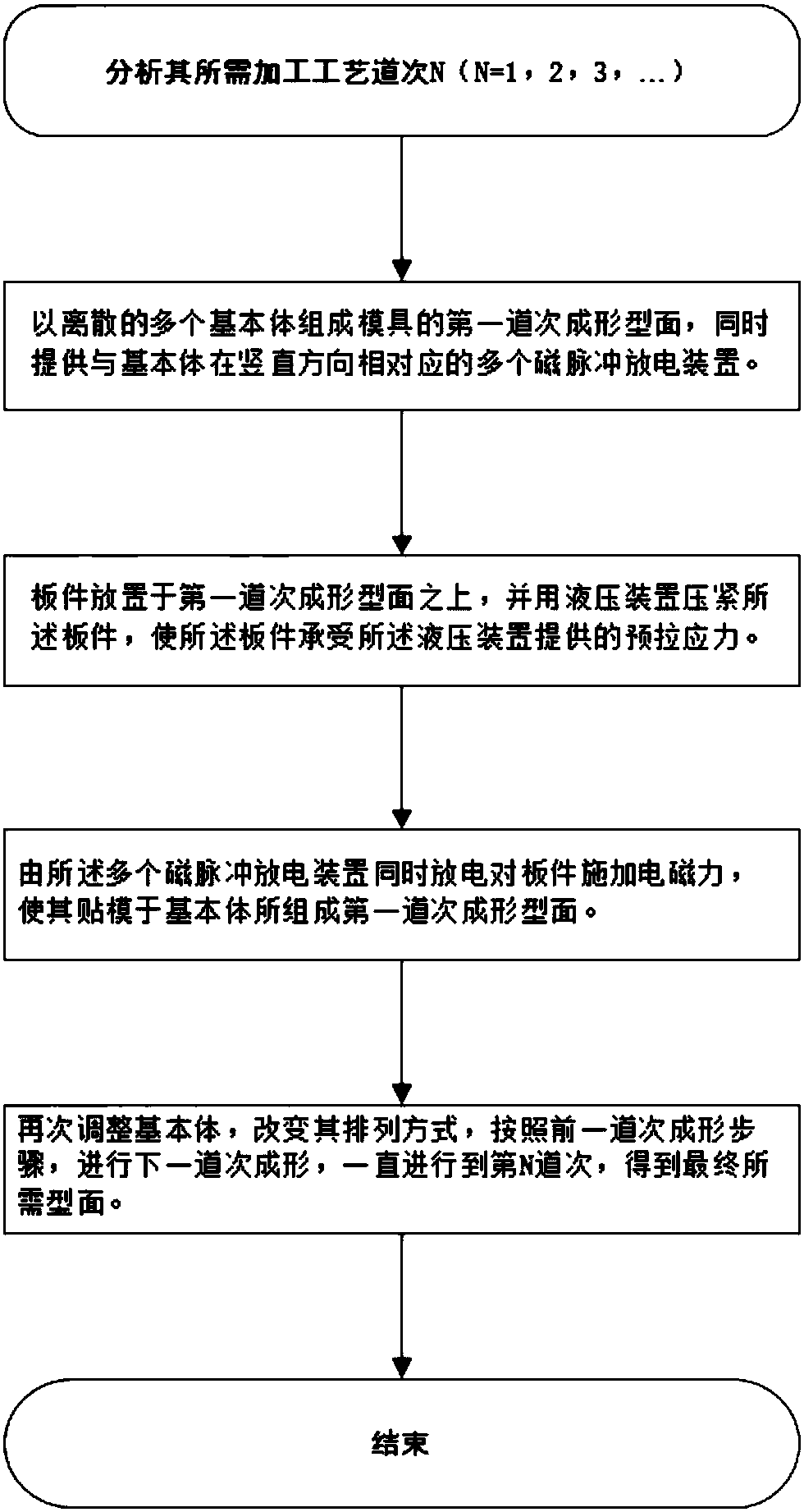

Flexible compound forming device and method based on magnetic pulse synchronous discharge

The invention discloses a flexible compound forming device and method based on magnetic pulse synchronous discharge, and belongs to the technical field of advanced manufacturing forming. The flexiblecompound forming device comprises a discharge group main switch, a plurality of magnetic pulse discharge devices, a power source and a mold. The multiple magnetic pulse discharge devices are connectedwith each other in parallel to form a parallel circuit, and the parallel circuit is connected in series with the discharge group main switch and the power source. The discharge group main switch is used for uniformly controlling a current switch of a series circuit, and the power source is used for providing electrical energy for capacitors in the magnetic pulse discharge devices. The mold is used for forming a forming profile and being matched with the magnetic pulse discharge devices to complete forming of sheet materials. According to the flexible compound forming device and method based on the magnetic pulse synchronous discharge, by flexibly arranging the multiple magnetic pulse discharge devices, a flexible multi-point mold is combined, complex profile forming can be adapted, the forming efficiency and quality are improved, and the production cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

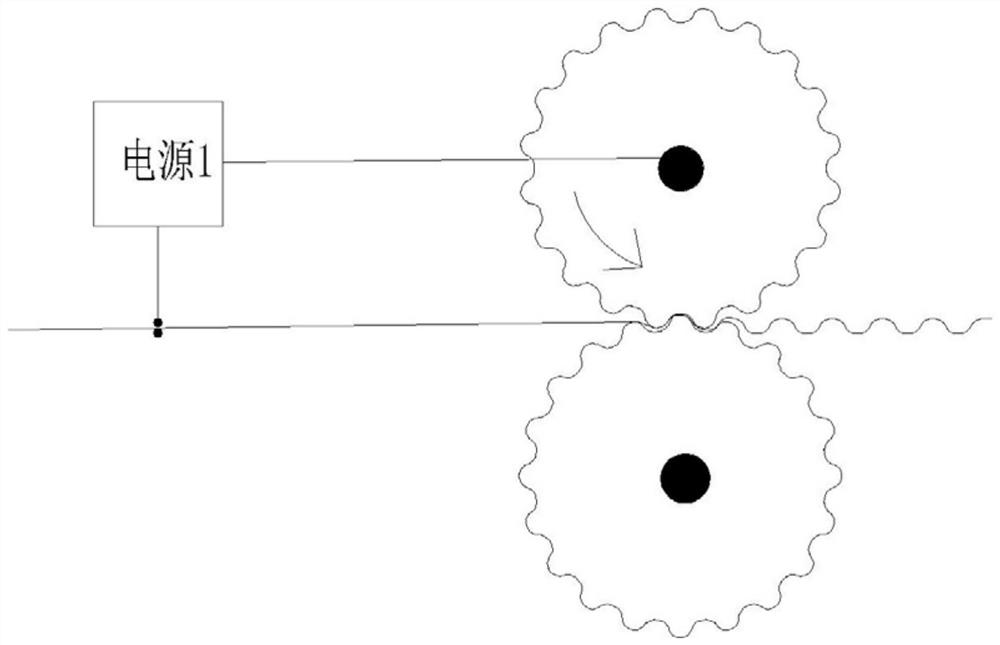

Current-assisted roll bending forming device and method for ultrathin-wall corrugated plate

PendingCN113245415ARaise the limit of plastic formingInhibit forming springbackShaping toolsWork rollClassical mechanics

The invention discloses a current-assisted roll bending forming device and method for an ultrathin-wall corrugated plate, and belongs to the field of roll bending forming machining. The current-assisted roll bending forming device is characterized by comprising a power source and a microstructure working roll set. The microstructure working roller set comprises a first roller and a second roller. Corrugated microstructures are arranged on the surfaces of the first roller and the second roller. One end of the power supply is connected with the first roller and the other end is connected with the second roller. Or one end of the power supply is connected with the first roller and the other end is connected with a thin plate. According to the current-assisted roll bending forming device and method for the ultrathin-wall corrugated plate, the plastic forming limit of the ultra-thin plate is improved, forming springback of an ultra-thin-wall microstructure is restrained, the depth-to-width ratio, the size precision and the like of the corrugated microstructures are improved, and the defects that an existing die forming technology is low in efficiency and small in area, and conventional roll bending forming is small in depth-to-width ratio and large in resilience, and secondary shape correction is needed are overcome.

Owner:SUZHOU UNIV

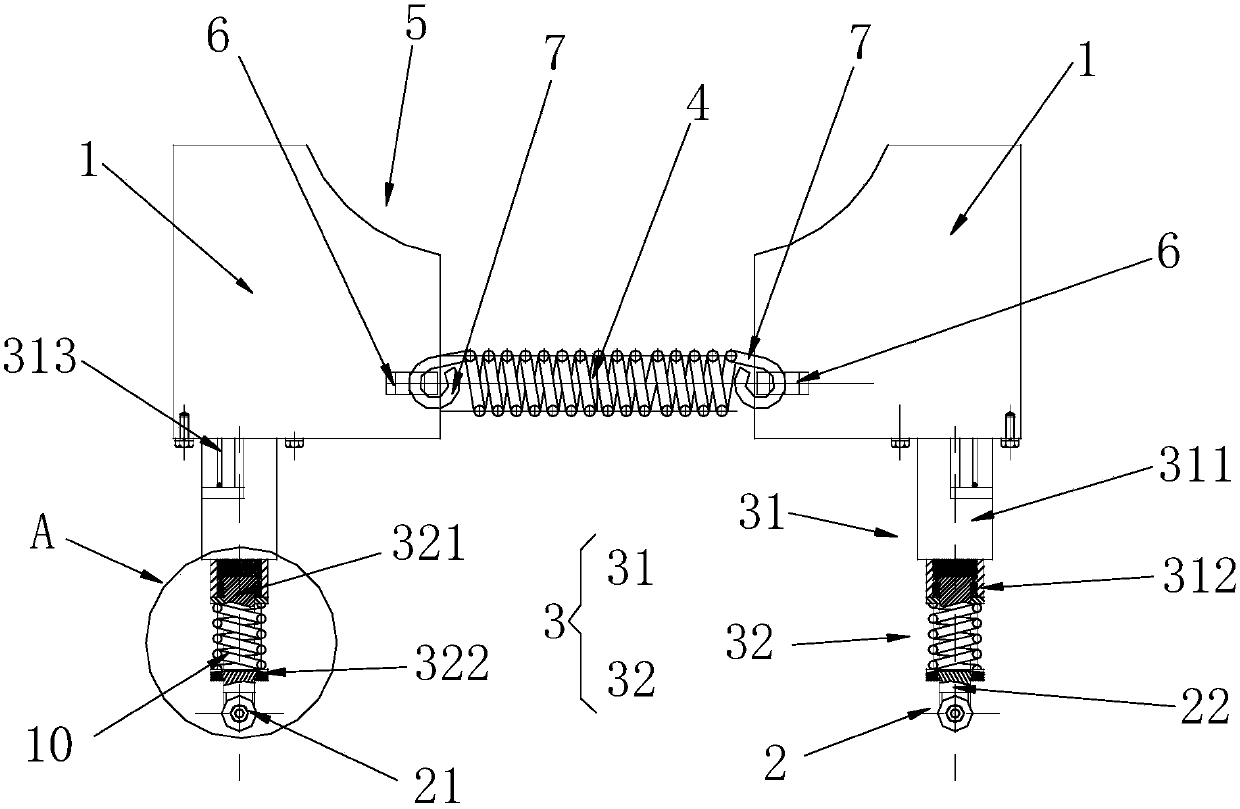

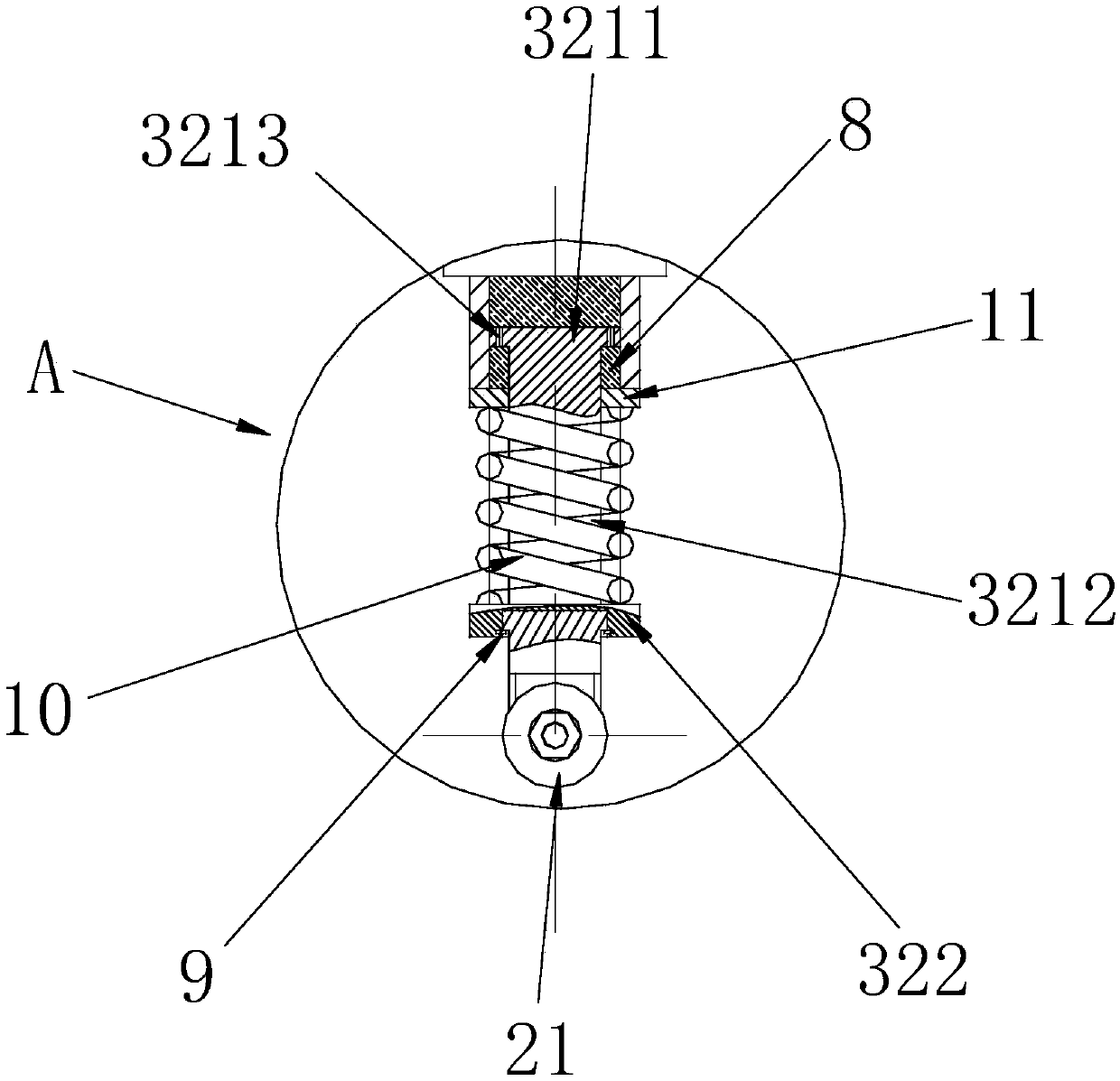

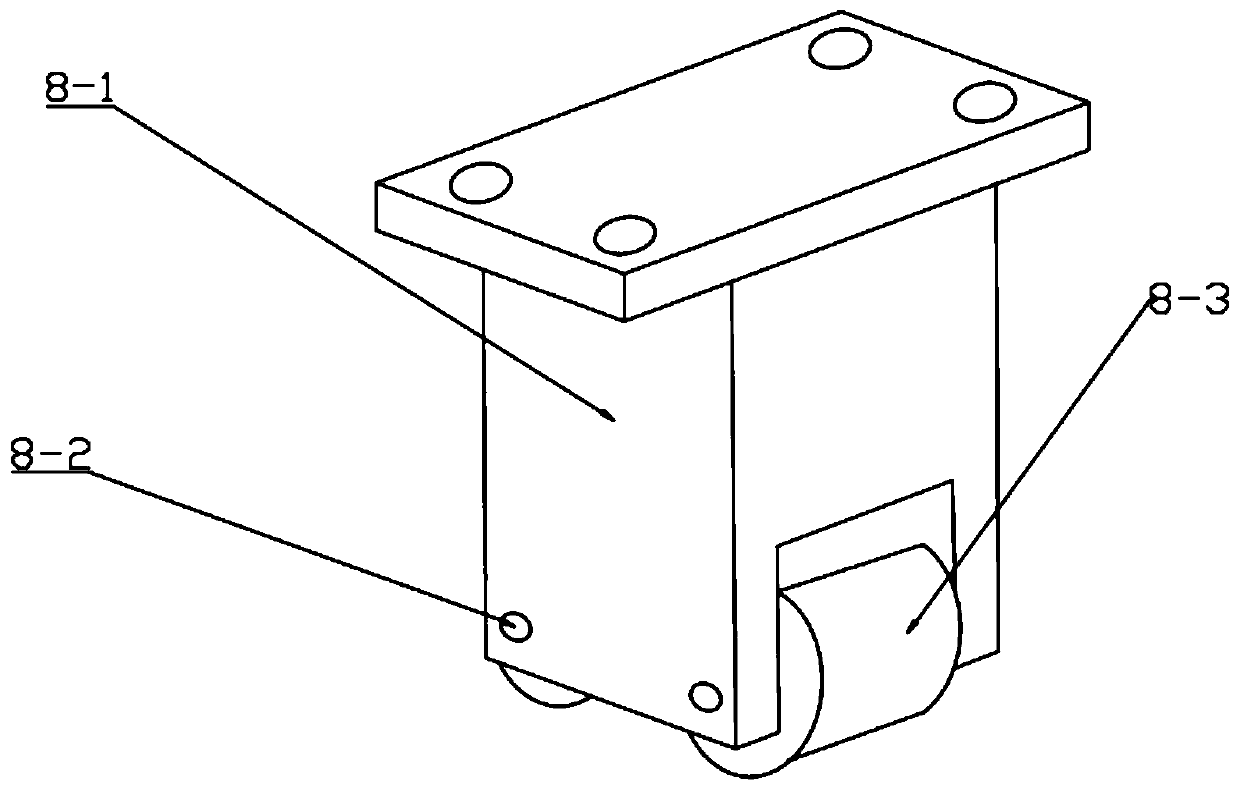

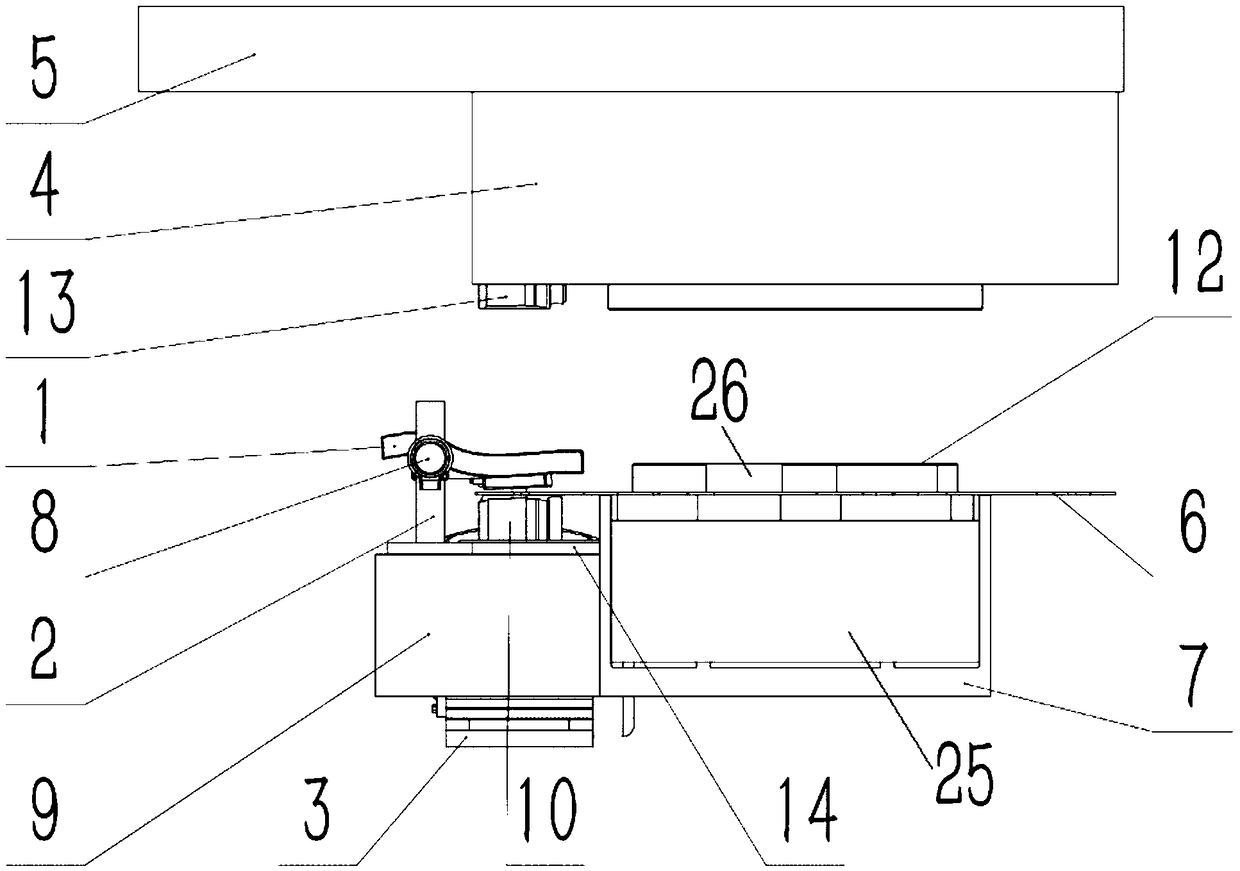

Horizontal springback inhibition device applied to waveform piece forming process

ActiveCN109013814ATo achieve the purpose of precision controlReasonable structureShaping toolsEngineeringStamping process

The invention relates to a horizontal springback inhibition device applied to the waveform piece forming process. The horizontal springback inhibition device applied to the waveform piece forming process comprises a springback inhibition auxiliary device, a rail conveying device, a core stamping device and an upper computer. After a conventional stamping process is finished, a horizontal springback inhibition step is added, a first power mechanism drives a screw rod to rotate, and the screw rod rotates to drive a sliding seat to slide, so that a first positioning pin is driven to draw close toa second positioning pin; under the control of the upper computer and a ranging module, the feeding amount is accurately controlled; the first positioning pin and the second positioning pin apply pressure on two assembling holes of a sub slice of a formed waveform piece so as to drive the two assembling holes on the waveform piece to get close; and a squeezing board module is matched for extruding the sub slice of the waveform piece for the second time, so that the aim of inhibiting the springback of the waveform piece is finally realized.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Electromagnetic auxiliary stamping incremental forming process for thin-wall curved-surface light alloy component

The invention relates to an electromagnetic auxiliary stamping incremental forming process for a thin-wall curved-surface light alloy component. The electromagnetic auxiliary stamping incremental forming process comprises the following steps that S1, solid solution aging treatment is conducted on a light alloy plate; S2, the light alloy plate is subjected to pre-stamping, and the pre-stamping deformation amount is 10%-30% of the total deformation amount; and S3, a forming coil is used for discharging to form pulse Lorentz force, the plate obtained after pre-stamping deformation is impacted, multi-pass electromagnetic incremental forming is carried out, and final forming of the thin-wall curved-surface light alloy component is completed. The sequence of the step S1 and the step S2 can be interchanged. The large thin-wall curved-surface component manufactured through the electromagnetic auxiliary stamping incremental forming process for the thin-wall curved-surface light alloy component is good in formability, high in precision and excellent in surface quality, and the comprehensive mechanical property is greatly improved.

Owner:WUHAN UNIV OF TECH

Porosity testing tool and testing method thereof

PendingCN113945502AInhibition of reboundKeep shapePermeability/surface area analysisChemistryElectrical battery

The invention provides a porosity testing tool and a testing method thereof. The porosity testing tool comprises a liquid nitrogen cold quenching part, a pressurizing part and a porosity testing part. A cavity is formed in the liquid nitrogen cold quenching part and used for storing liquid nitrogen and storing a to-be-tested sample, and the to-be-tested sample comprises an electrode plate and / or a battery diaphragm; the pressurizing part is used for applying pressure to the to-be-tested sample; and the porosity testing part is used for testing pores in the to-be-tested sample which is subjected to liquid nitrogen cold quenching. The cold quenching treatment on the to-be-tested sample (the electrode plate and / or the battery diaphragm) can inhibit the to-be-tested sample from springback due to pressure relief after pressure is applied to the to-be-tested sample. On one hand, the real state of the to-be-tested sample can be kept, and the morphological change of the to-be-tested sample in a pressure state can be truly reflected; on the other hand, the adverse effect of springback of the to-be-tested sample after pressure relief on the porosity testing result can be inhibited, the error of the porosity testing result can be reduced, and the porosity testing accuracy is improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

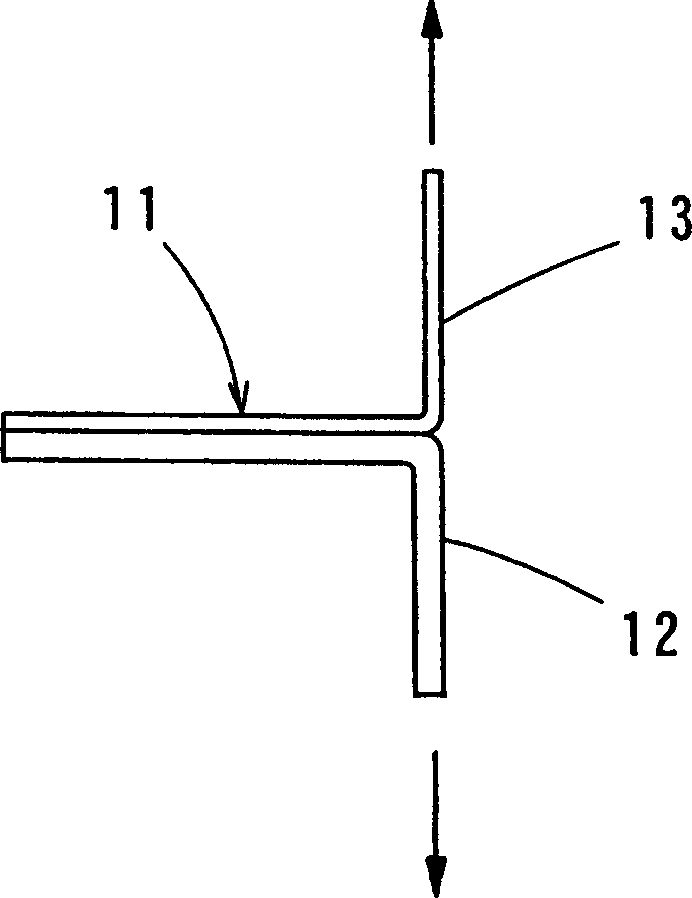

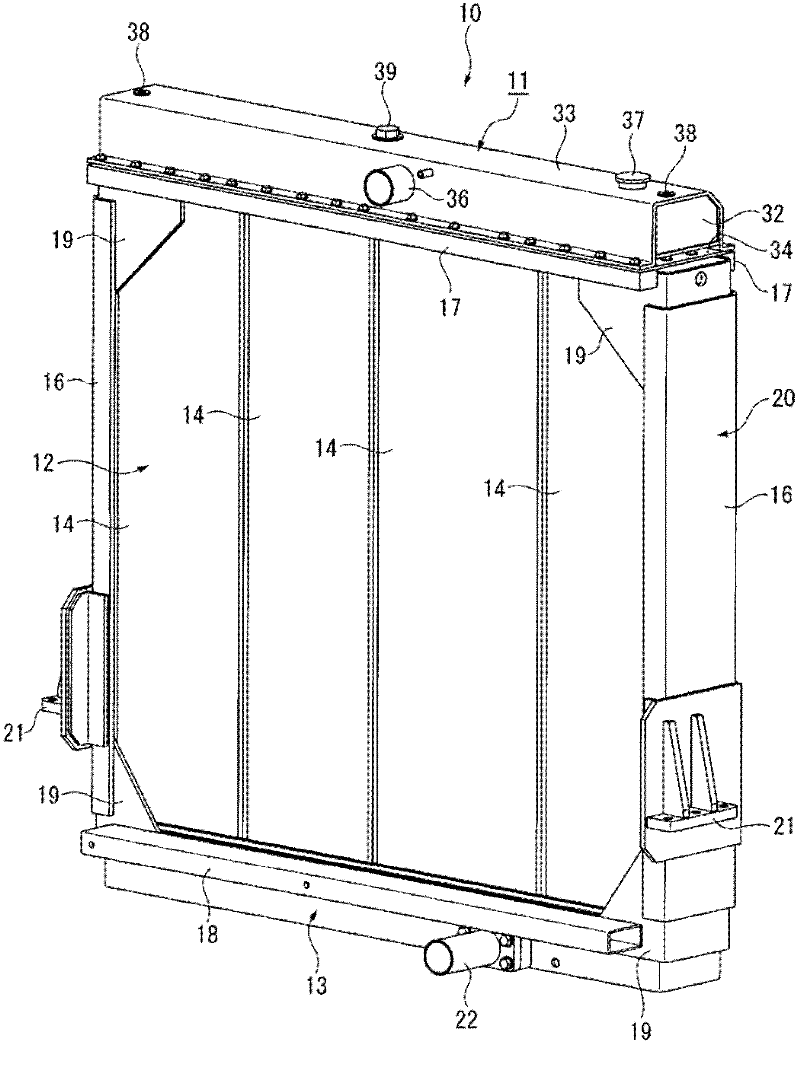

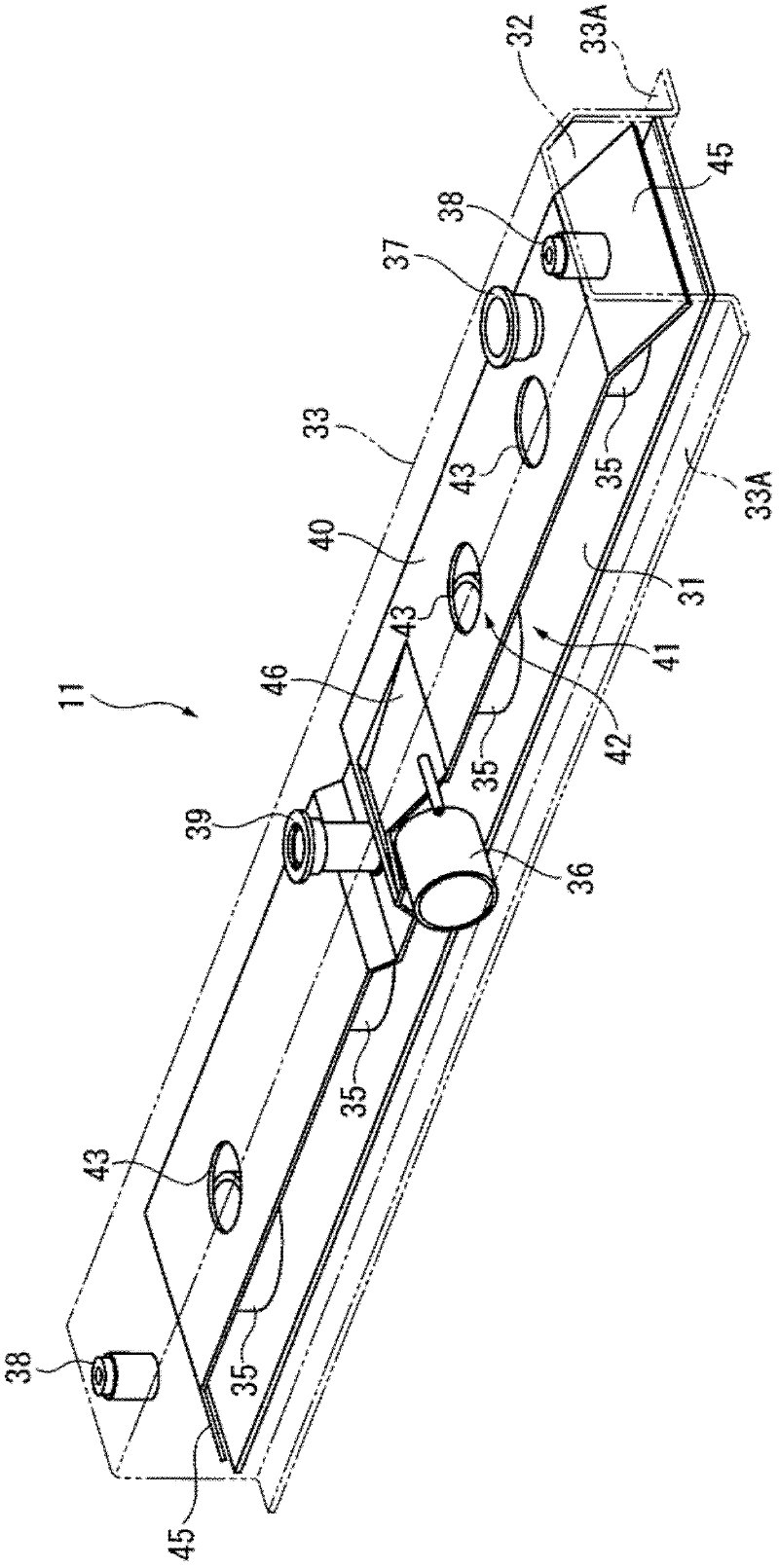

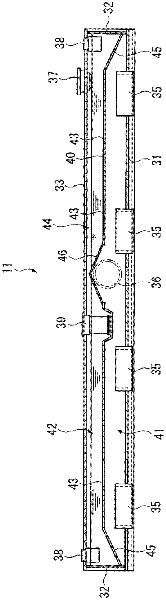

heat exchanger

ActiveCN102292612AReliable depositAvoid touchingLiquid coolingSafety devices for heat exchange apparatusNuclear engineeringHeat exchanger

The invention discloses a heat exchanger. Disclosed is a radiator (10) as the heat exchanger, comprised of an upper tank (11) to which cooling water is introduced; a core (12) in which fluid from the upper tank (11) is heat-exchanged; and a lower tank (13) in which fluid from the core (12) is concentrated, wherein a baffle plate (40) is provided within the upper tank (11); and a bent portion (45)is provided at an end of the baffle plate (40) in the longitudinal direction. The baffle plate (40) divides the inner space of the upper tank (11) into two spaces, i.e., a lower space (41) and an upper space (42), and has a communication opening (43) through which the lower space (41) is communicated with the upper space (42). The bent portion (45) is bent toward the lower space (41)at the two end parts of the length direction of the baffle plate (40).

Owner:KOMATSU LTD

Solenoid valve

ActiveUS11448337B2Inhibition of reboundIncrease in magnetic reluctance can be preventedOperating means/releasing devices for valvesValve housingsSolenoid valveCoupling

Latch protrusions of an upper surface wall are latched into latch recesses of a first front-surface half wall and an upper end portion of a second front-surface half wall of a magnetic cover, and latch protrusions of the upper surface wall are latched into latch recesses of a first rear-surface half wall and an upper end portion of a second rear-surface half wall of the magnetic cover. Hook portions of the first front-surface half wall and a lower end portion of the second front-surface half wall are folded into a coupling groove of the valve body, and hook portions of the first rear-surface half wall and a lower end portion of the second rear-surface half wall are folded into a coupling groove of the valve body.

Owner:SMC CORP

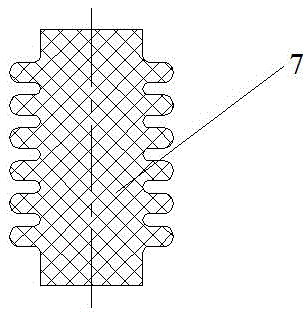

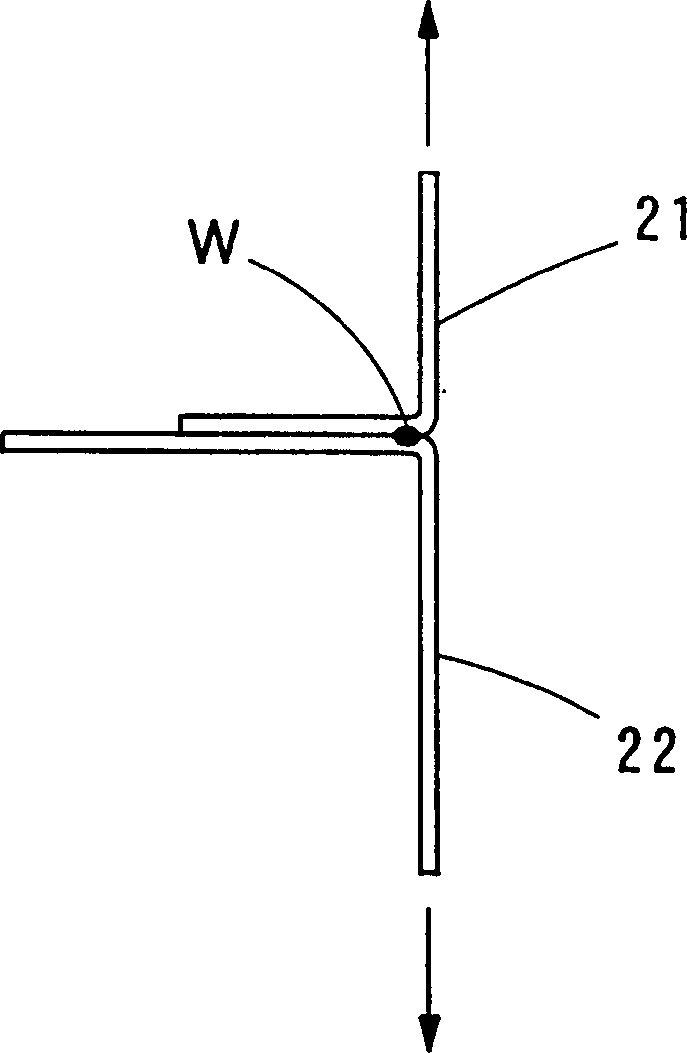

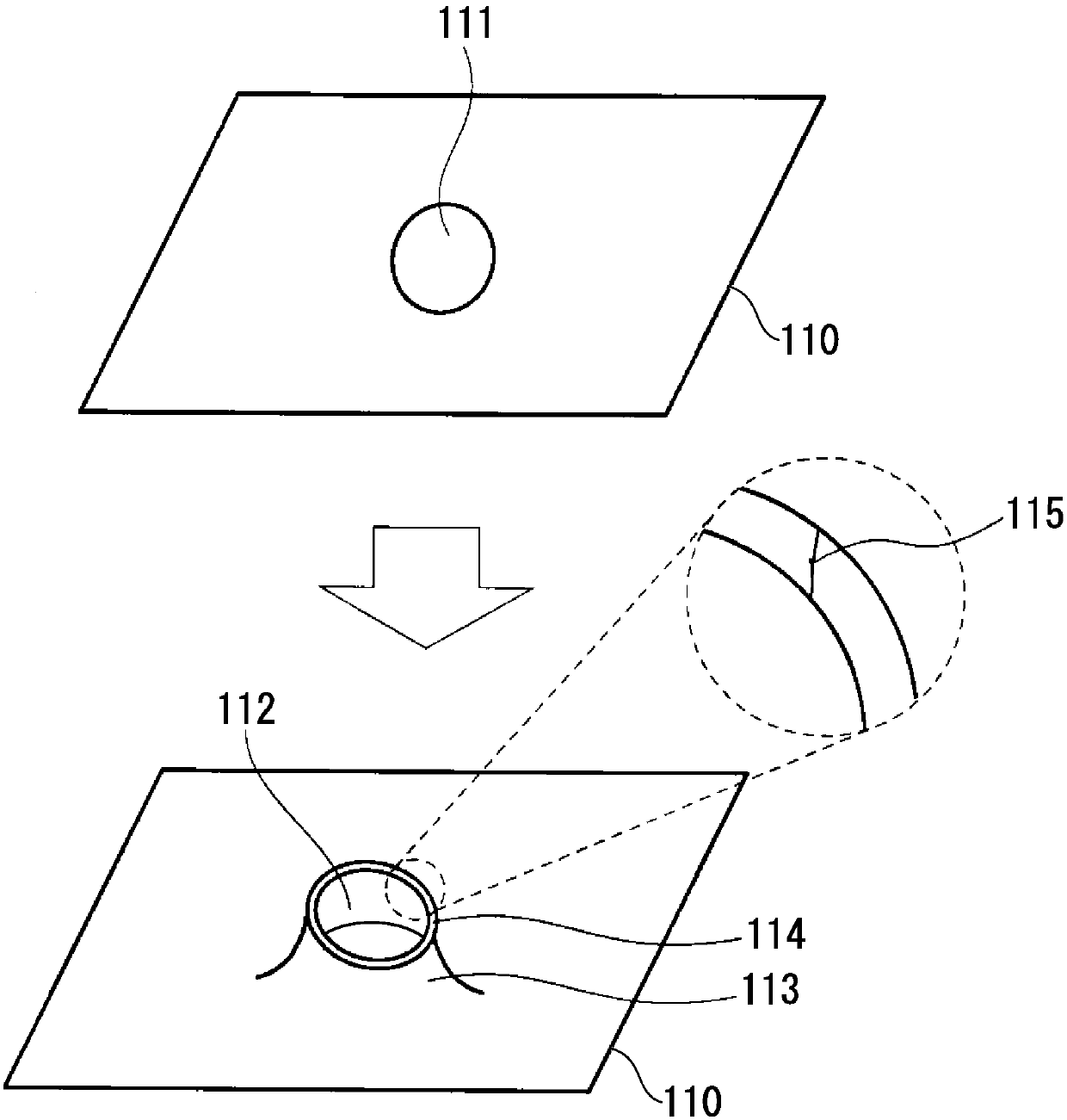

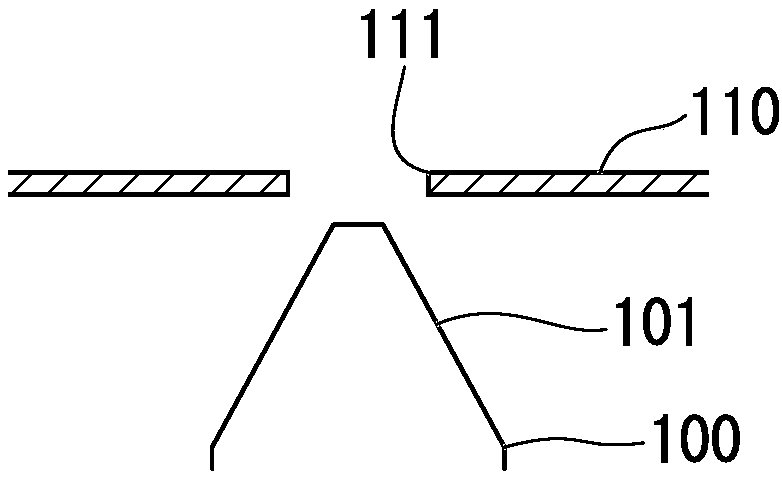

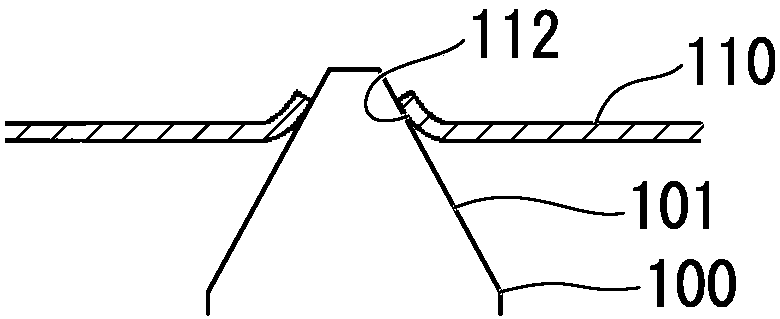

Hole-widening machining method, molding tool, molding and machining method

This hole-widening machining method has a preparation step for preparing a workpiece formed with a pilot hole and a molding tool having a widening diameter part having a wider diameter from a tip endside toward a rear end side and a linear protrusion formed to protrude from the surface of the widening diameter part to the outside, and a hole widening step for gradually widening the pilot hole inthe workpiece by pressing the molding tool into the pilot hole so that the linear protrusion of the molding tool touches a portion of the circumferential edge of the pilot hole at least twice to forma stretch flange.

Owner:NIPPON STEEL CORP

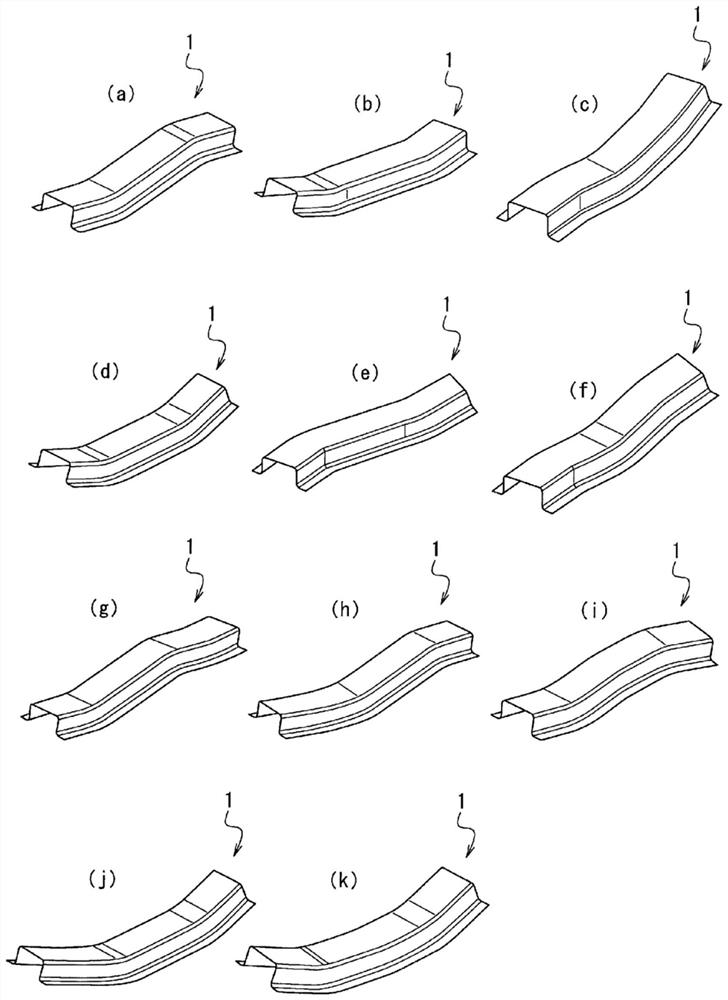

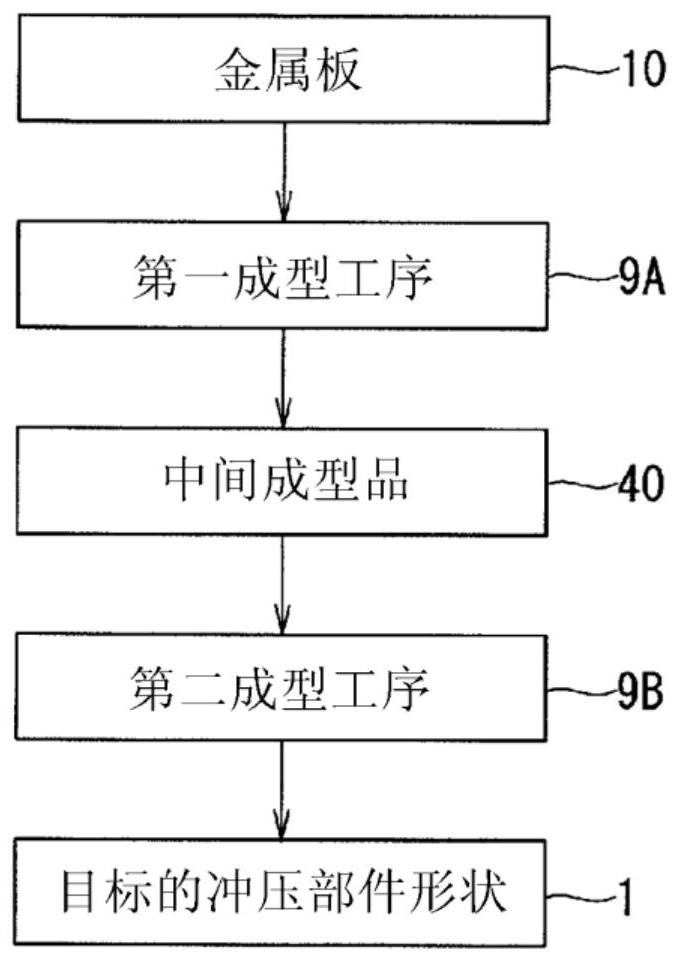

Manufacturing method of stamped part, press forming device, and metal plate for press forming

The present invention provides a press-forming technology capable of reducing molding defects of a molded part having a curved shape protruding toward a flange side when viewed from the side. This technique includes: a first forming step (9A) of press-forming a metal plate (10) into an intermediate molded product (40) having an undulating shape at a vertical wall portion forming position (13) and a flange portion forming position (14), The undulating shape has a concavo-convex shape continuous along the longitudinal direction, and the amplitude of the concavo-convex shape in the plate thickness direction gradually increases toward the position corresponding to the boundary between the vertical wall portion (3) and the flange portion (4); In the second forming step (9B), bending is performed on the intermediate formed product (40). The line length in the longitudinal direction at the position corresponding to the boundary between the vertical wall portion (3) and the flange portion (4) in the intermediate molded product (40), and the distance between the vertical wall portion (3) and the flange portion (4) in the stamped part shape (1). Line lengths in the longitudinal direction of the boundaries of the flange portion (4) are identical or close to each other.

Owner:JFE STEEL CORP

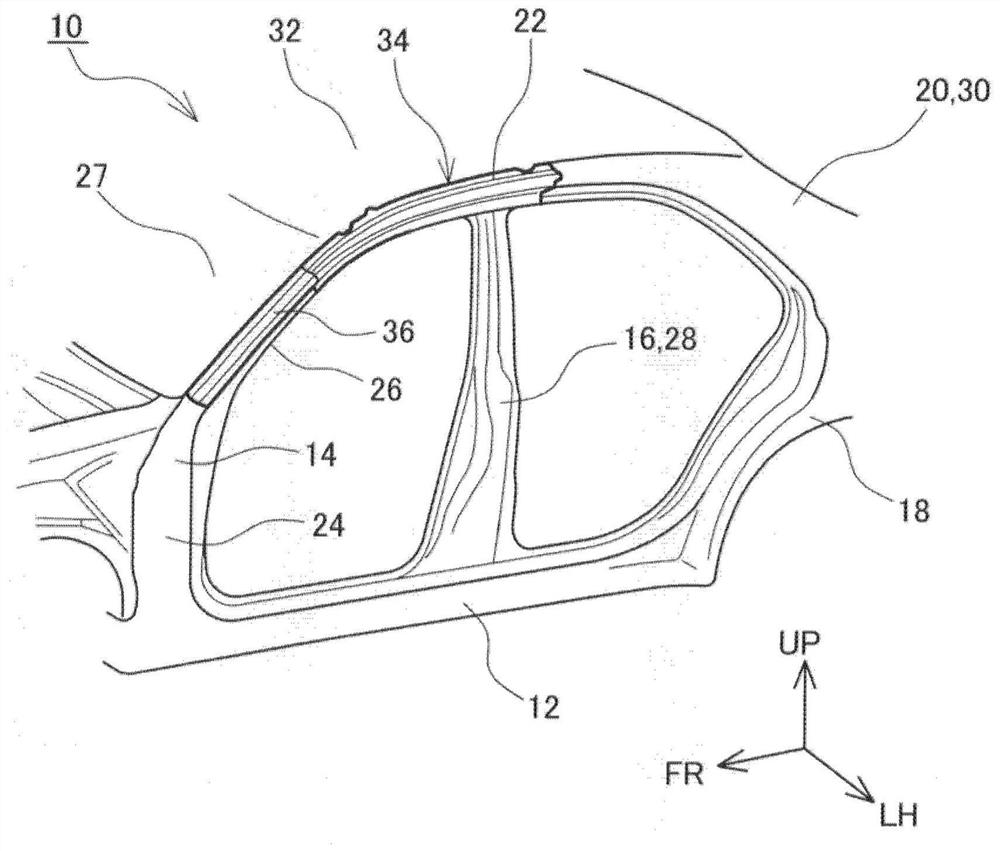

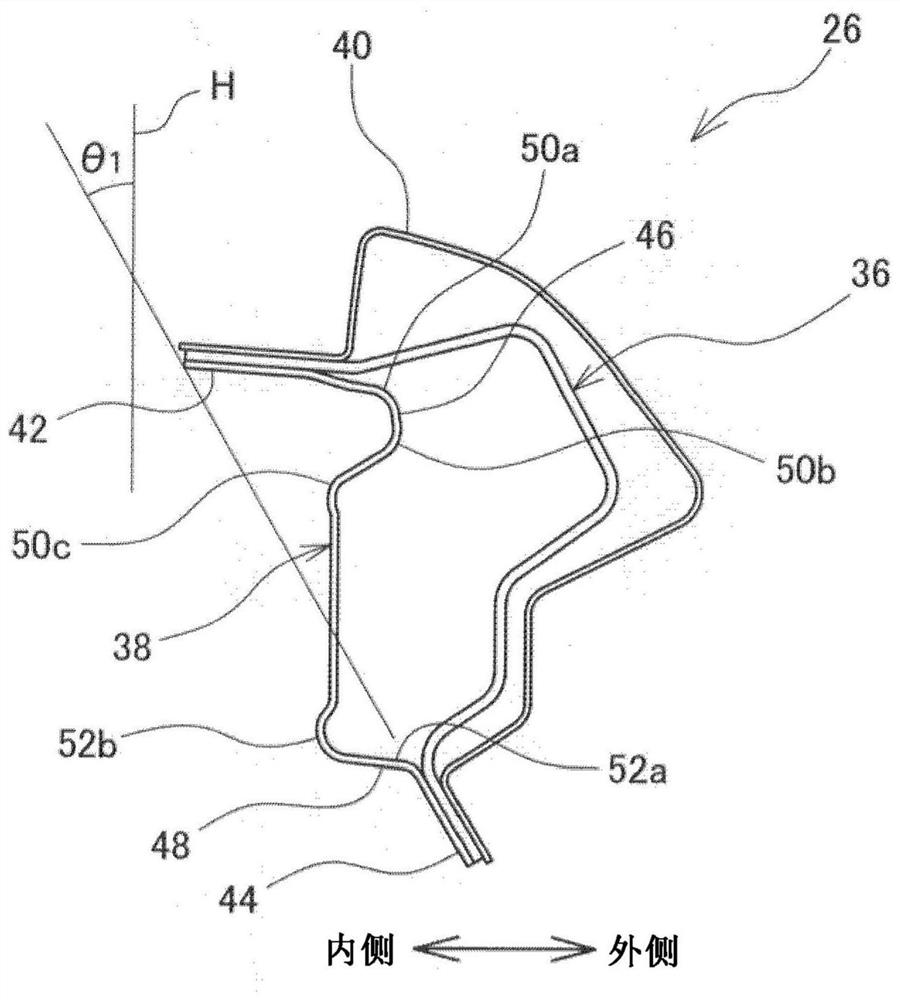

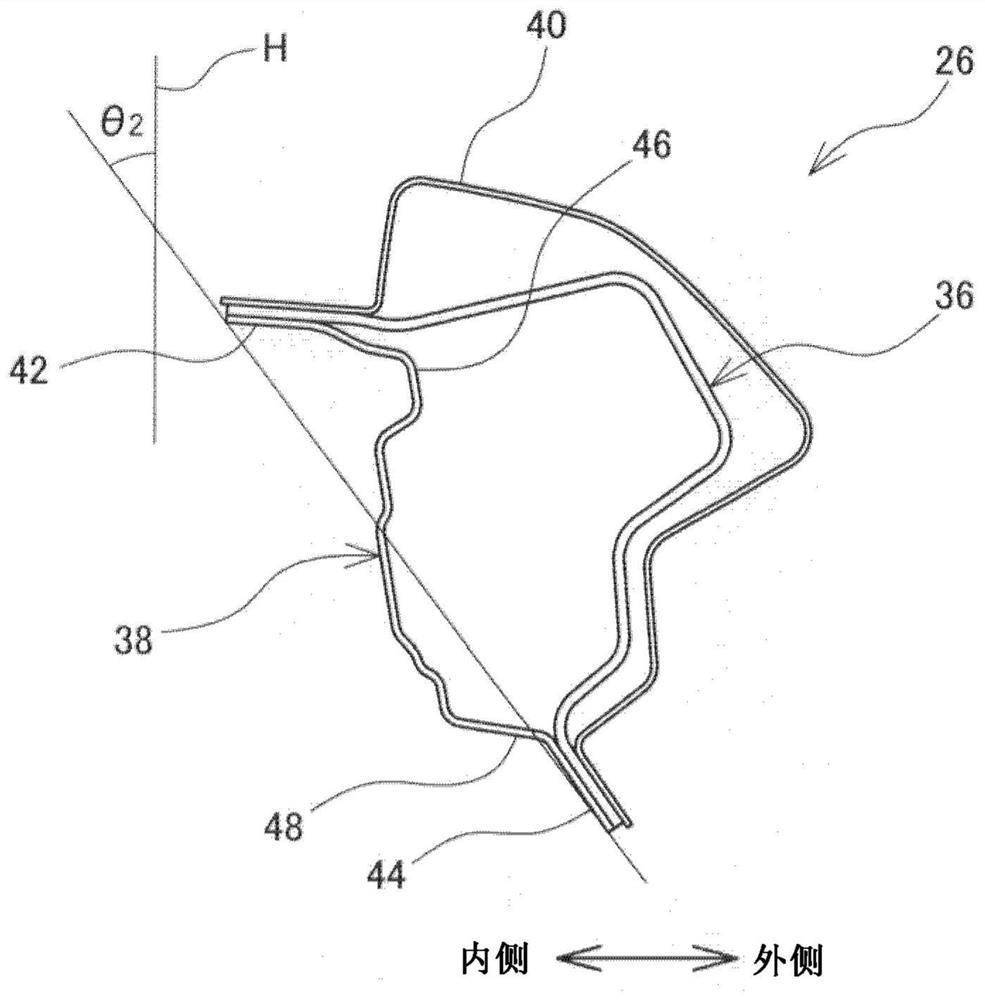

The upper arched structure of the body side part of the vehicle

InactiveCN109591892BInhibition of reboundHigh strengthSuperstructure subunitsStructural engineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

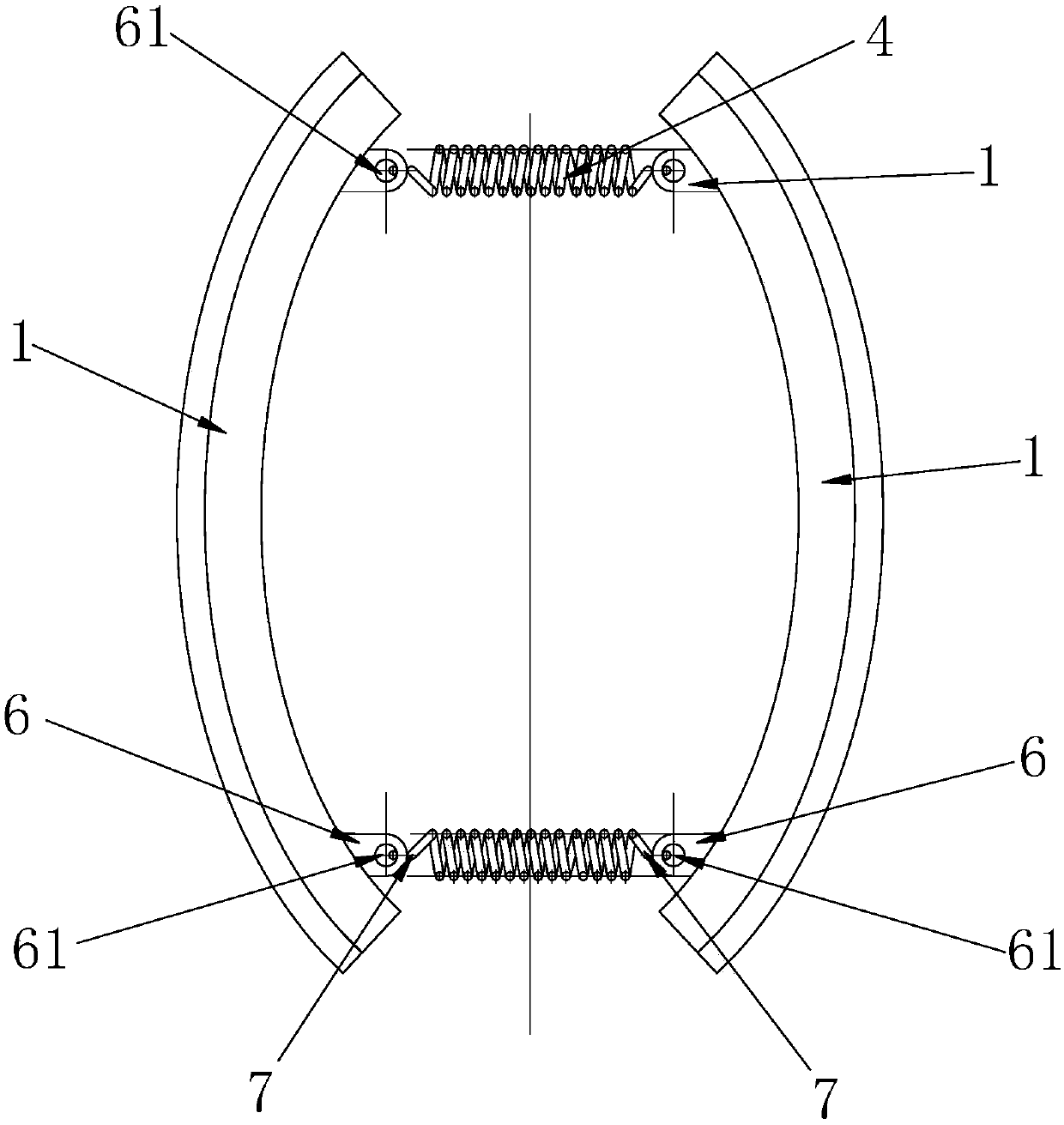

Electromagnetic auxiliary roll bending forming method and forming device thereof

The electromagnetic auxiliary roll bending forming method comprises the following steps that an elastic roller is used for pressing a plate to be bent and deformed, and the plate with an inner arc face and an outer arc face is formed; the downward pressing position of the elastic roller is kept, and periodic electromagnetic pulse discharging is conducted on the plate on the outer cambered surface of the plate; during discharge amplification, the plate is reversely bent and deformed under electromagnetic loading, and meanwhile, the elastic surface of the compression elastic roller is deformed; during discharge attenuation, the elastic surface of the elastic roller recovers deformation and forces the plate to reset; and the plate is driven to continuously move in the roll bending direction, and meanwhile periodic electromagnetic pulse discharging is continuously conducted till the continuous roll bending arc length of the plate is larger than or equal to the forming target arc length. Local reverse bending and local bending are periodically and alternately carried out on the plate, the plastic forming performance of the plate can be improved, rebound of the plate after roll bending is restrained, and the surface quality and forming precision of the formed small-curvature thin-wall bent part are improved.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com