Manufacturing method of stamped part, press forming device, and metal plate for press forming

A manufacturing method and stamping forming technology, applied in the field of stamping parts manufacturing, can solve the problems of large change in cross-section and limited application range of stamping and forming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] Next, an example of this embodiment will be described.

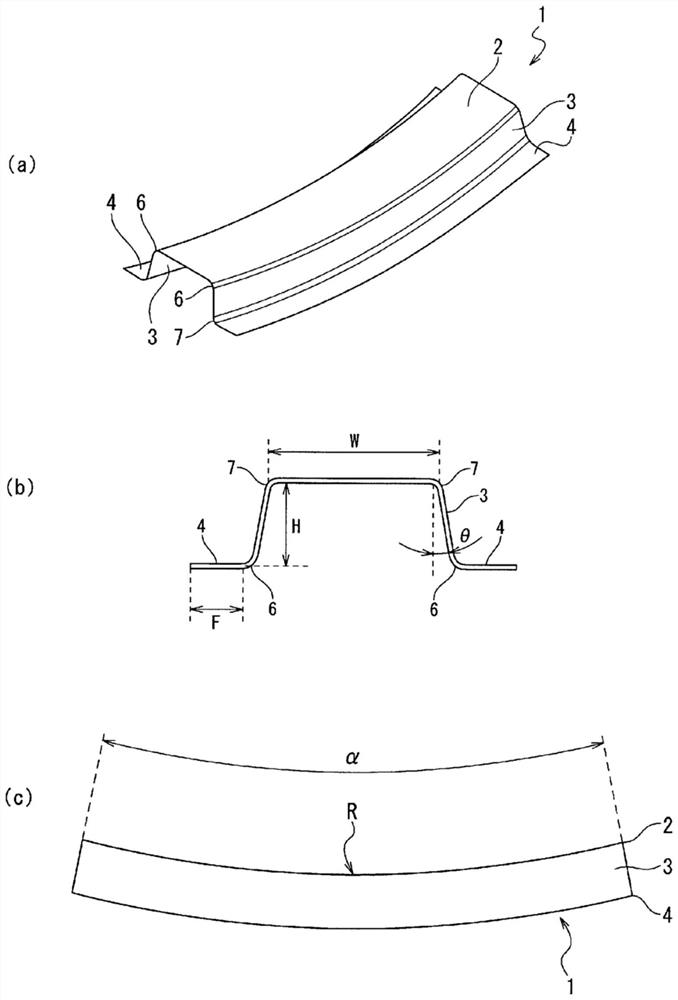

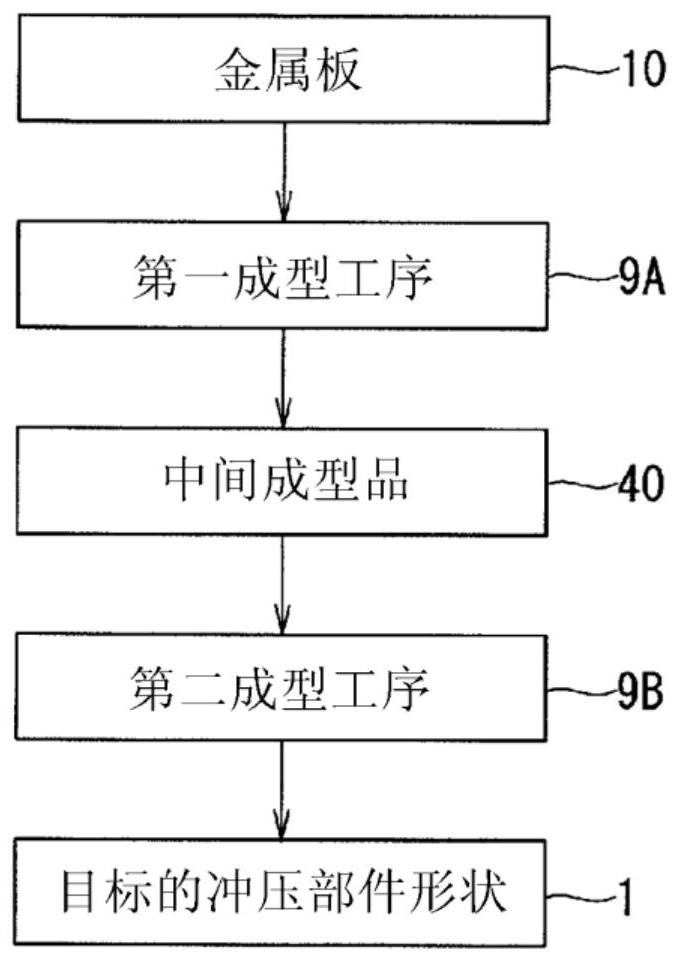

[0095] Suppose it is a 1180MPa grade cold-rolled steel sheet (thickness of 1.4mm), and it has the following characteristics Figure 1 The components with the shape shown above are analyzed by press molding.

[0096] In this embodiment, the shape parameters that define the shape 1 of the punched part are set as follows.

[0097]

[0098] Width of top plate w: 100mm

[0099] Longitudinal wall height h: 50mm

[0100] Longitudinal wall angle θ: 10 degrees

[0101] The flange length f: 30mm

[0102]

[0103] Bending angle α: 30 degrees

[0104] Roof curvature radius r: 1000mm

[0105] The length of the metal plate 10 for molding is set to be equal to the length of the top plate 2 of the target stamping part shape 1. Specifically, based on the above formula (1), the length of the metal plate 10 in the longitudinal direction is 523.6 mm.. In addition, the width was set to about 260mm.

[0106] Next, the length of the flange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com