Flexible compound forming device and method based on magnetic pulse synchronous discharge

A discharge device and synchronous discharge technology, applied in the field of advanced manufacturing and forming, can solve the problems of poor mold flexibility, long forming cycle, low processing efficiency, etc., and achieve the effects of reducing production costs, suppressing material rebound, and improving forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

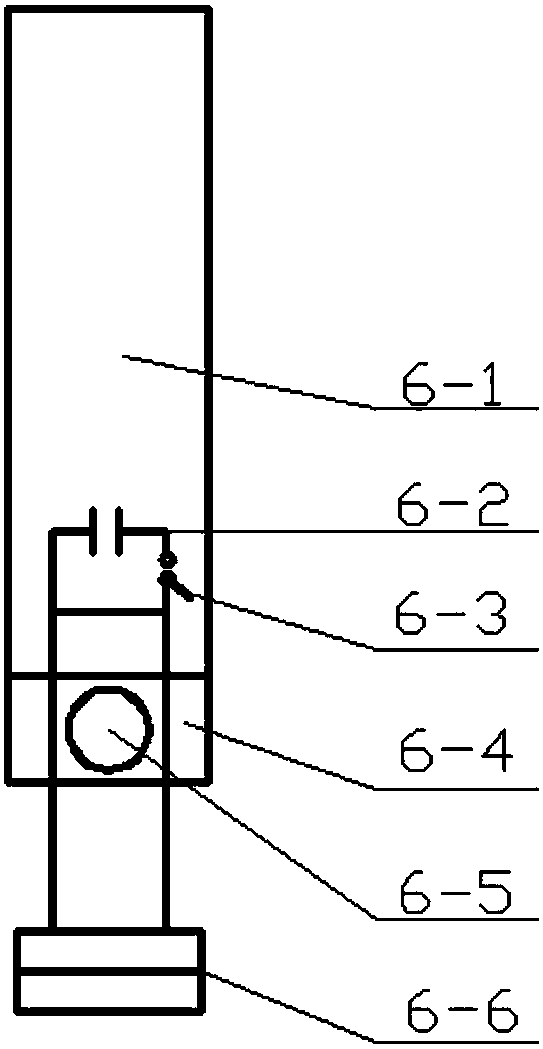

[0049] Such as figure 1 As shown, it is a magnetic pulse discharge device, which includes a coil fixing rod 6-1, a capacitor 6-2, a forming coil switch 6-3, a coil clamping plate 6-4, a bolt 6-5, and a forming coil 6-6;

[0050] The capacitor 6-2 is connected in series with the forming coil switch 6-3 and the forming coil 6-6 to form a loop; the capacitor 6-2 provides energy for the forming coil 6-6, and the forming coil switch is used to separately control the forming in the magnetic pulse discharge device 6 The coil 6-6 current switch; the coil clamping plate 6-4 is connected to the coil fixing rod 6-1; the height of the coil fixing rod 6-1 can be adjusted through the computer control system; the lines at the two ends of the forming coil 6-6 pass through the insulation It is connected with the coil clamping plate 6-4 with the bolt 6-5, and the lines at the two ends of the forming coil 6-6 are rotatable around the bolt 6-5.

[0051] The working process is to adjust the coil ...

Embodiment 2

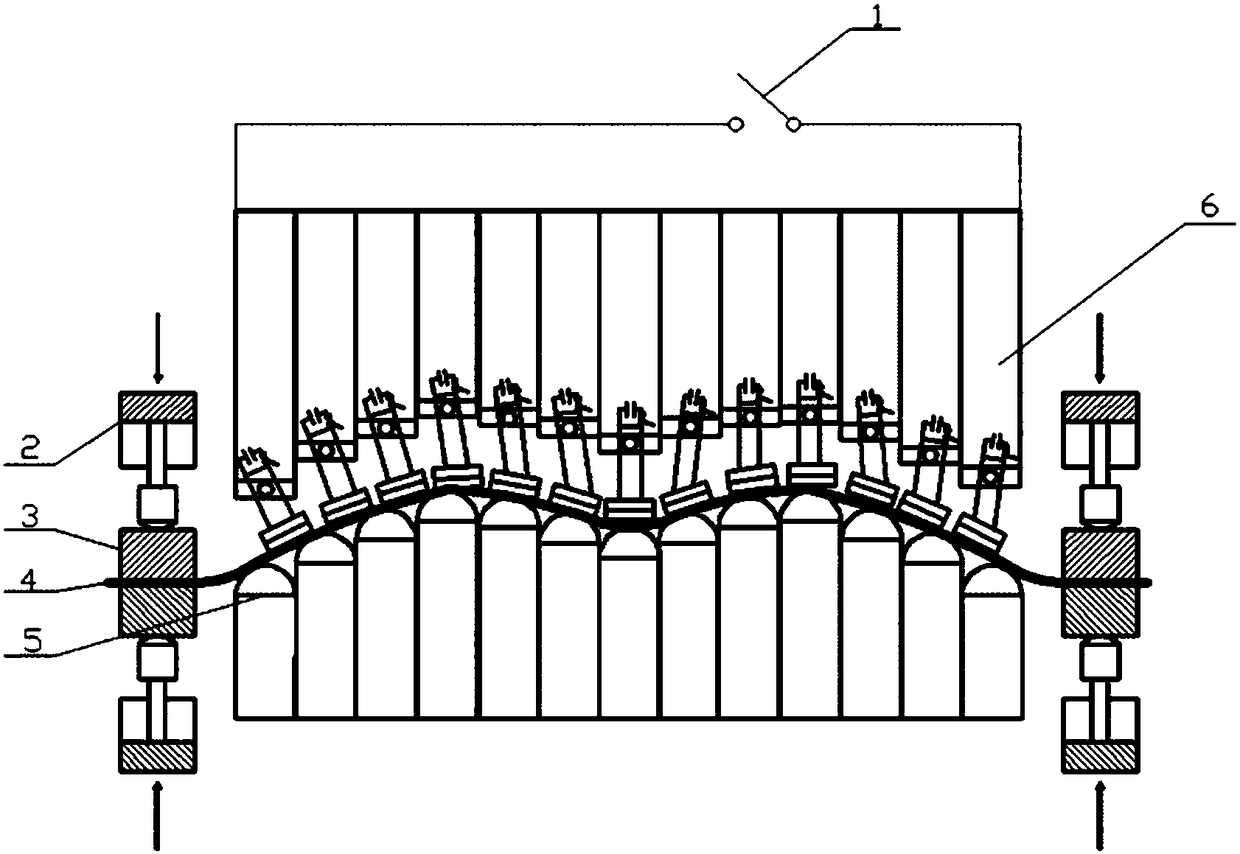

[0053] A flexible composite forming device based on magnetic pulse synchronous discharge is provided, based on the magnetic pulse discharge device in the foregoing embodiments, such as figure 2 As shown, it is a one-time molding surface forming diagram of the flexible composite forming device based on magnetic pulse synchronous discharge; the flexible composite forming device based on magnetic pulse synchronous discharge includes the main switch 1 of the discharge group, the hydraulic cylinder 2, the blank holder 3, the to-be-formed Plate 4, flexible multi-point mold 5, magnetic pulse discharge device 6;

[0054] A plurality of magnetic pulse discharge devices 6 are connected in parallel to each other to form a parallel circuit, the discharge group main switch 1 is connected in series with the parallel circuit, and the unified control circuit is switched on and off; The capacitor provides electric energy; the flexible multi-point mold 5 is composed of a plurality of discrete ...

Embodiment 3

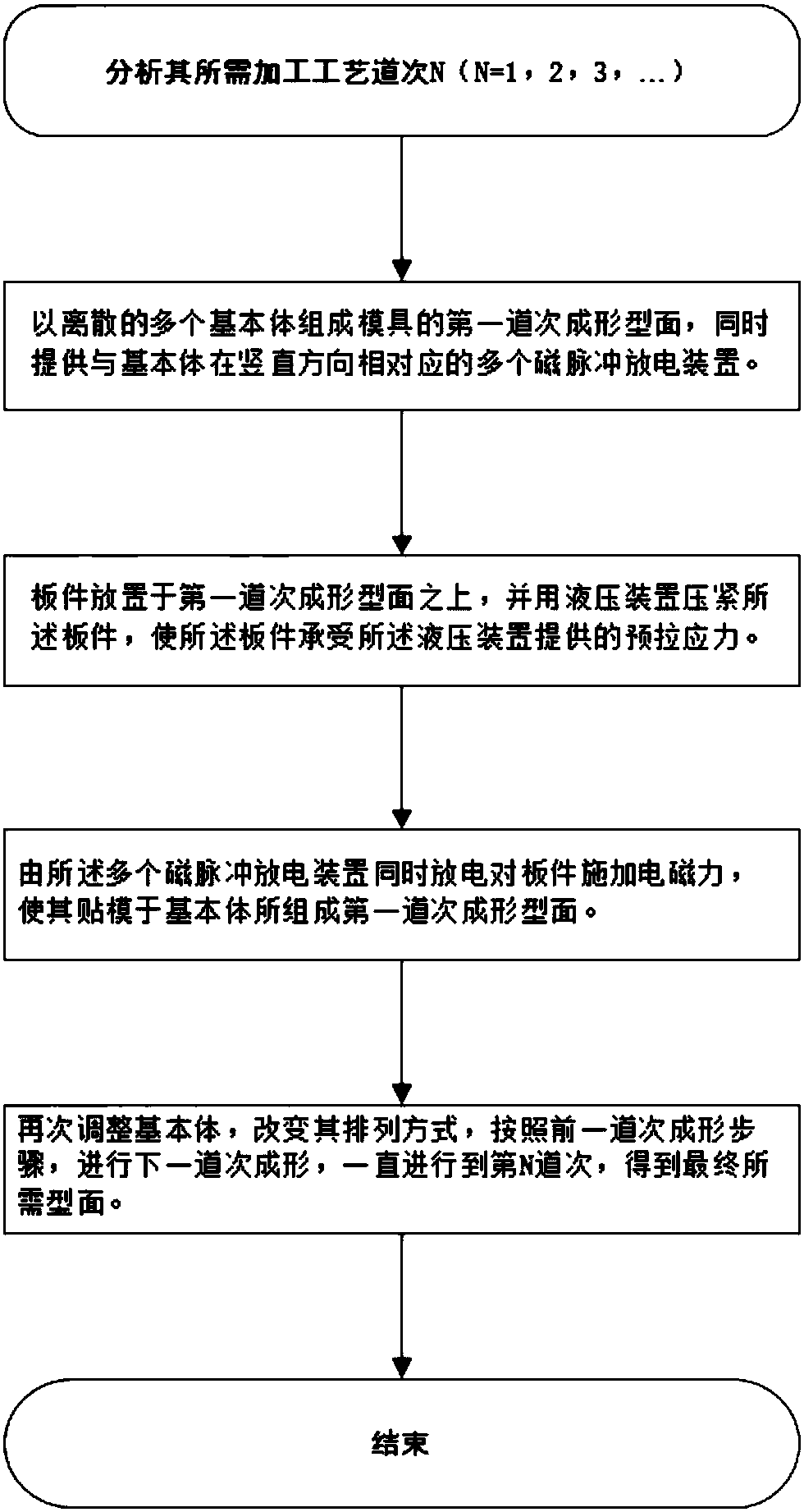

[0059] This embodiment provides a flexible composite forming method based on the flexible composite forming device of the foregoing embodiments. The main components and parameters involved in the method are set as follows:

[0060] The plate to be formed is an aluminum alloy plate, and the diameter of the area to be formed is 1000mm-1500mm; the maximum movable stroke of the coil fixing rod in the magnetic pulse discharge device is 400mm, and the diameter of the forming coil is 50mm; the flexible multi-point mold 5 The diameter of the ball head at the top of a plurality of discrete basic bodies is 60 mm; the number of hydraulic cylinders in the hydraulic device is 8-12; the flexible composite forming device based on magnetic pulse synchronous discharge in Embodiment 2 is used.

[0061] The material of the plate to be formed in the present invention is not limited to aluminum alloy, and the material can also be light-weight high-strength materials such as magnesium alloy and tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com