Hole-widening machining method, molding tool, molding and machining method

一种孔加工方法、用具的技术,应用在运输和包装、车辆部件等方向,能够解决花费成本及工时、生产性问题等问题,达到抑制延展凸缘破裂、提高分型性、抑制破裂及回弹的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

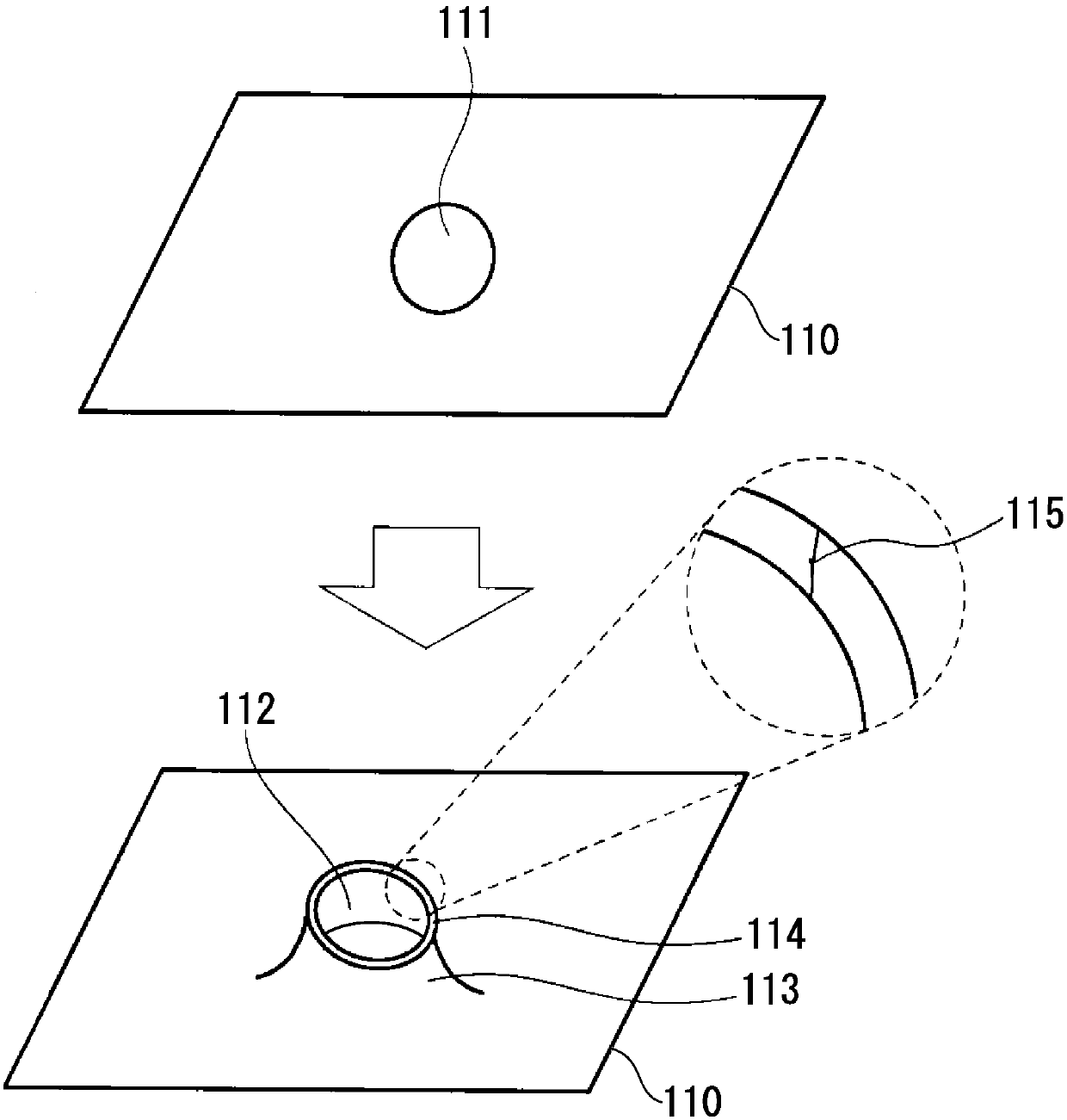

[0173] Experiments were conducted to confirm the effect of preventing cracking of the expanded flange and the effect of reducing springback during the reaming process of the present invention. As the steel sheet S (workpiece), a high-strength hot-rolled steel sheet of 780 MPa class with a thickness of 2.4 mm was prepared.

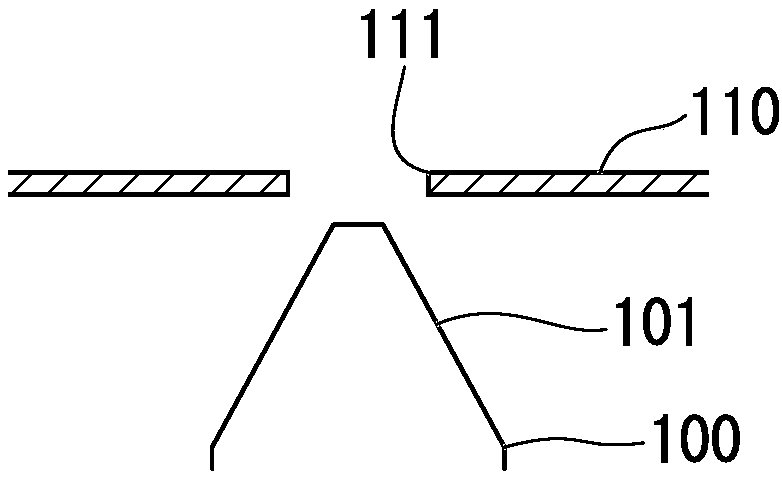

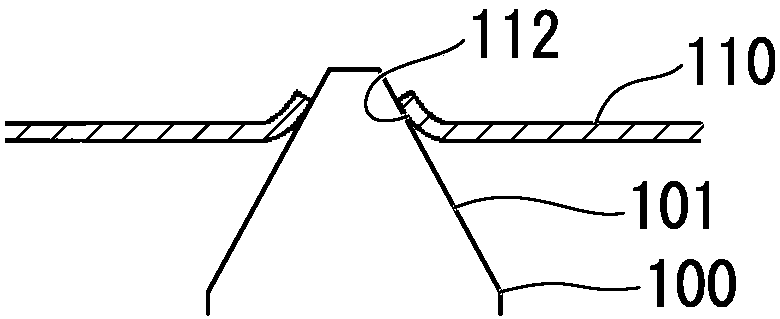

[0174] For the steel plate S, bottom holes of various sizes and shapes are provided by punching in advance. The hole expanding process was performed by pushing various forming tools into the bottom hole at a speed of 10 mm / sec.

[0175] Regarding the evaluation of the expansion flange fracture during the reaming process, for the inventive example with linear protrusions and the comparative example without linear protrusions, the size of the bottom hole was reduced by 1 mm, depending on whether the bottom hole was reduced to which It is evaluated to the extent that no extended flange fracture occurs.

[0176] Regarding springback, it is unfair if the size of the ...

Embodiment B

[0198] Experiments were conducted to confirm the influence of the number and pitch of the linear protrusions of the molding tool on the effect of preventing cracking of the extended flange and the effect of reducing springback during the reaming process.

[0199] To Figure 4A~Figure 4C Based on the molding tool of the illustrated example of the present invention, the helix angle was fixed at 45 degrees, the number of linear protrusions was changed, and the hole was expanded.

[0200] Here, the numerical index δ for appropriately performing sequential molding of linear protrusions is defined as follows. If it is assumed that the distribution of the index σn is observed at a certain time, the maximum value of the index σn is σmax and the minimum value is σmin, then it is defined as

[0201] δ=|σmax-σmin| / σmax.

[0202] The above δ can be 0.0 <δ Values in the range of <1.0. When δ=0.0, since σmax=σmin, the difference between the mountains and valleys of the index σn does not occur, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com