Forming method of hollow component

A hollow component and final forming technology, which is applied in the forming field of hollow components to ensure the uniformity of wall thickness, dense organization and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A method for forming a hollow member, the technical solution of which is to include the following steps:

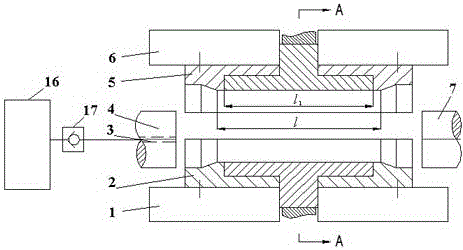

[0042] Step 1: Die preparation, first design the lower die 2, the upper die 5, the left punch 4 and the right punch 7 according to the needs of the shape of the components. The lower die 2 is connected to the lower table 1 of the press, the upper die 5 is connected to the upper slider 6 of the press, and a check valve 17 is installed between the left punch 4 and the high pressure source 16;

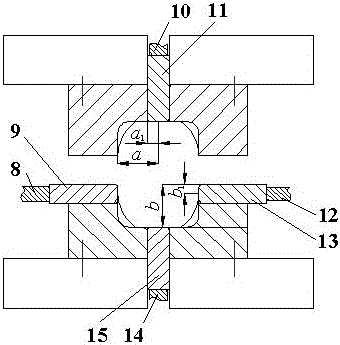

[0043] Step 2: Set up anti-deformation mechanism A (9), anti-deformation mechanism B (11), anti-deformation mechanism C (13), and anti-deformation mechanism D (15) on the mold. One end of the anti-deformation mechanism faces the mold cavity, and one end extends. Out of the mold cavity, and connected with the ejector mechanism 8, 10, 12, 14 of the press. The main point is the width of the anti-deformation mechanism a 1 about 0.1 a ~0.3 a ,high b 1 about 0.1b ~0.3 b ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com