Aluminum/nickel clad material and method for manufacture thereof, and exterior terminal for electric cell

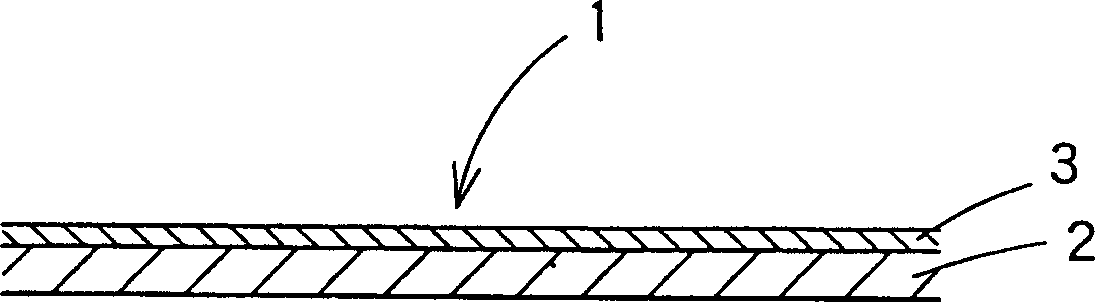

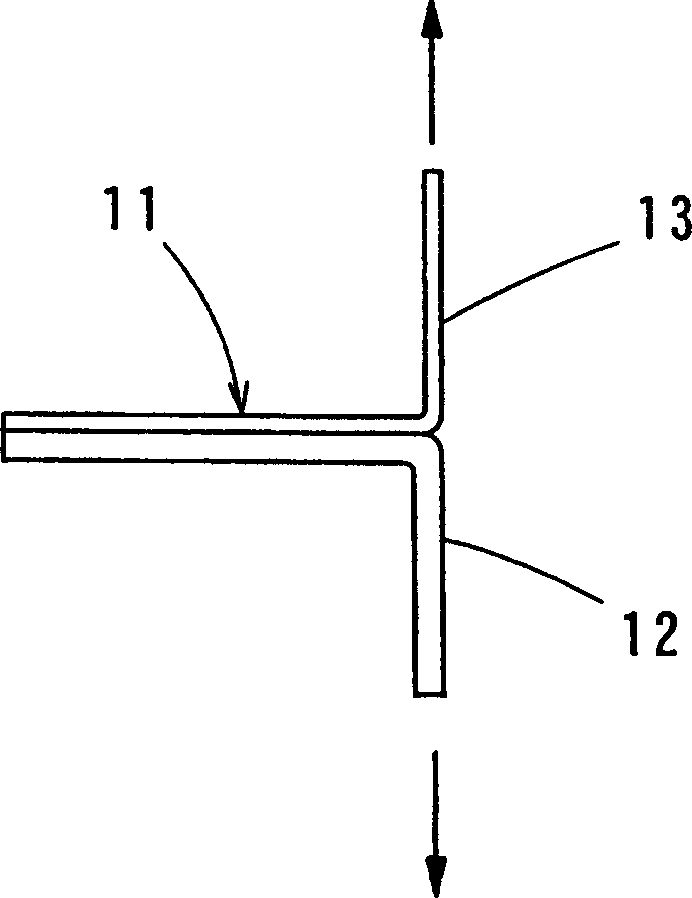

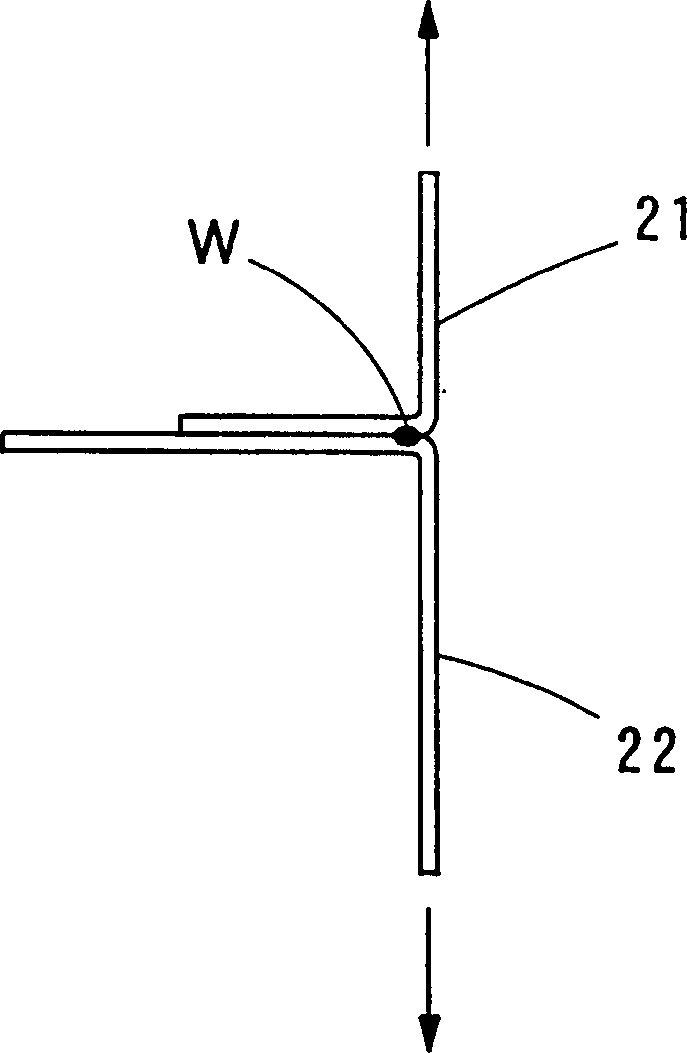

A technology for external terminals and manufacturing methods, which is applied to battery pack parts, battery boxes/coatings, manufacturing tools, etc., can solve problems such as large springback and poor shape, and achieve springback suppression, excellent bending processability, and stable welding zygosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Samples of various clad materials were produced in accordance with the following points.

[0036] Prepare a nickel sheet with a width of 60 mm and a thickness of 50 μm of pure nickel (the purity of nickel is above 99.9%) and an aluminum sheet of the same width and thickness of 50 μm of pure aluminum (the purity of aluminum is above 99.9%). After passing through the tunnel-type annealing furnace, the above-mentioned nickel sheet is heated, and then it is taken out from the tunnel-type annealing furnace, and then, within about 2 seconds, it is overlapped with the above-mentioned aluminum sheet, and they are passed through a pair of pressing rollers. For crimping, in Table 1, the heating temperature of the nickel sheet of each sample, and the reduction rate at the time of roller crimping are given.

[0037] Using a test piece having a width of 10 mm and a length of 100 mm obtained from a crimped sheet in which the aluminum layer and the nickel layer were crimped by roll bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com